Patents

Literature

32results about How to "Excellent water fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

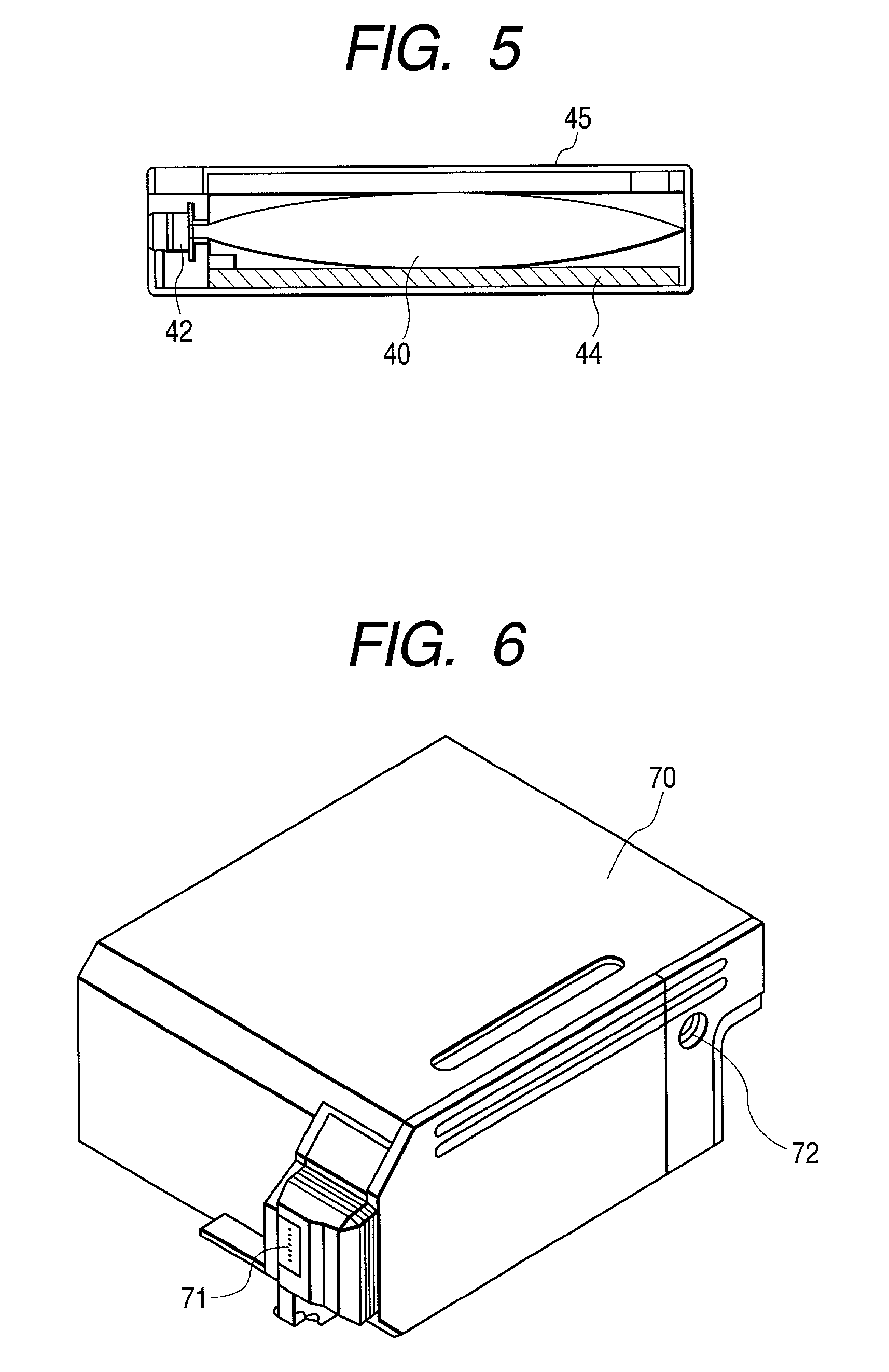

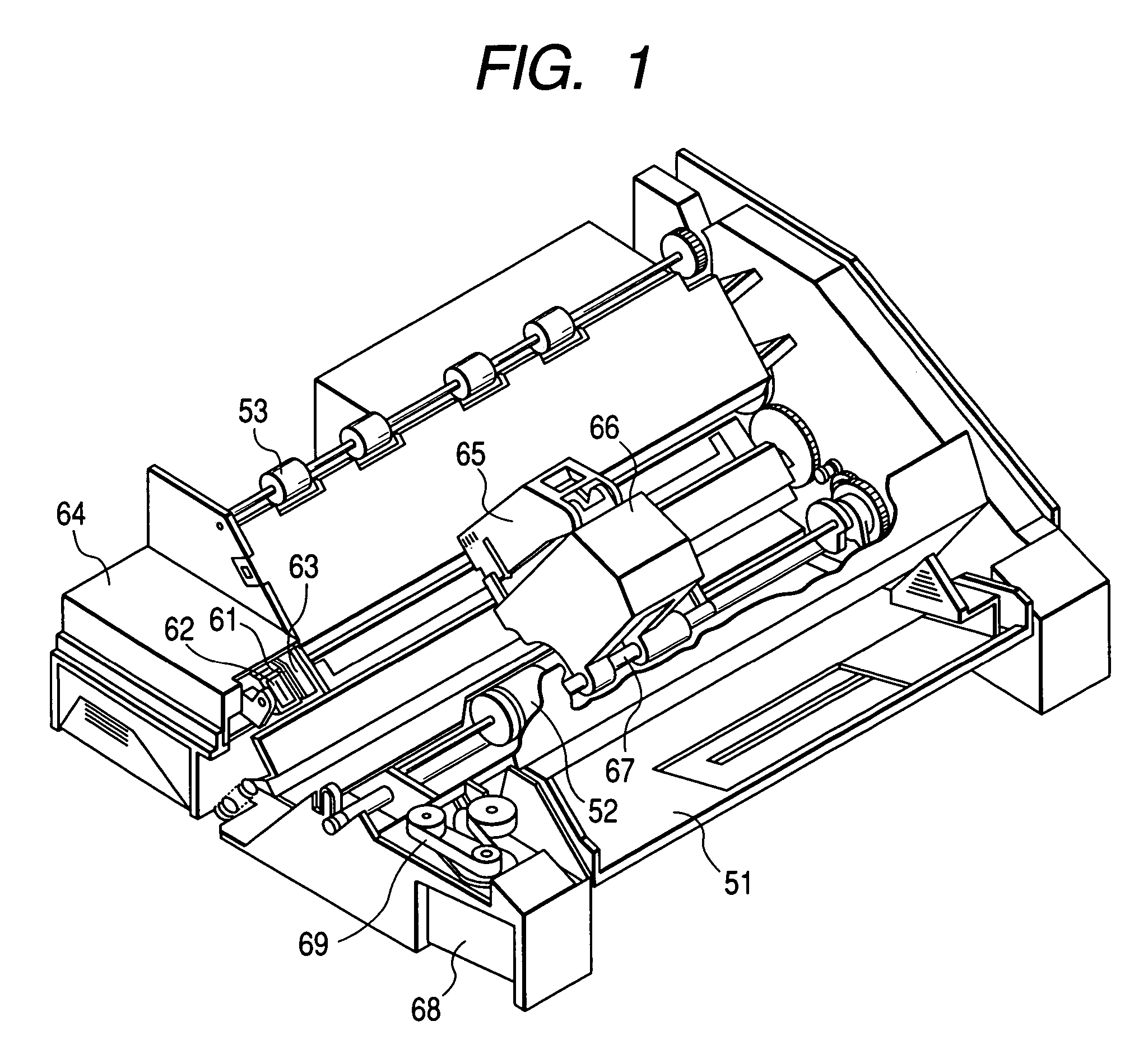

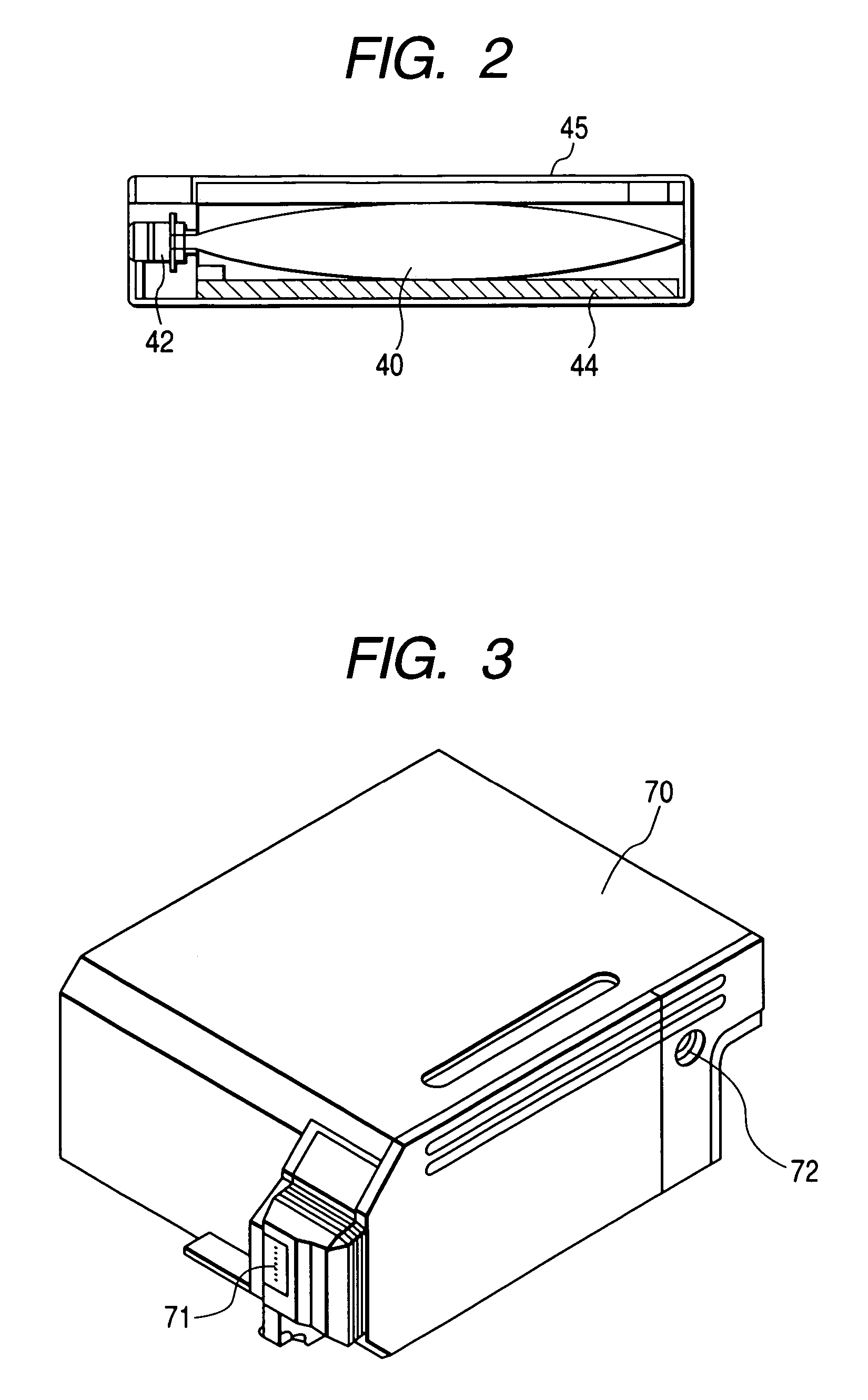

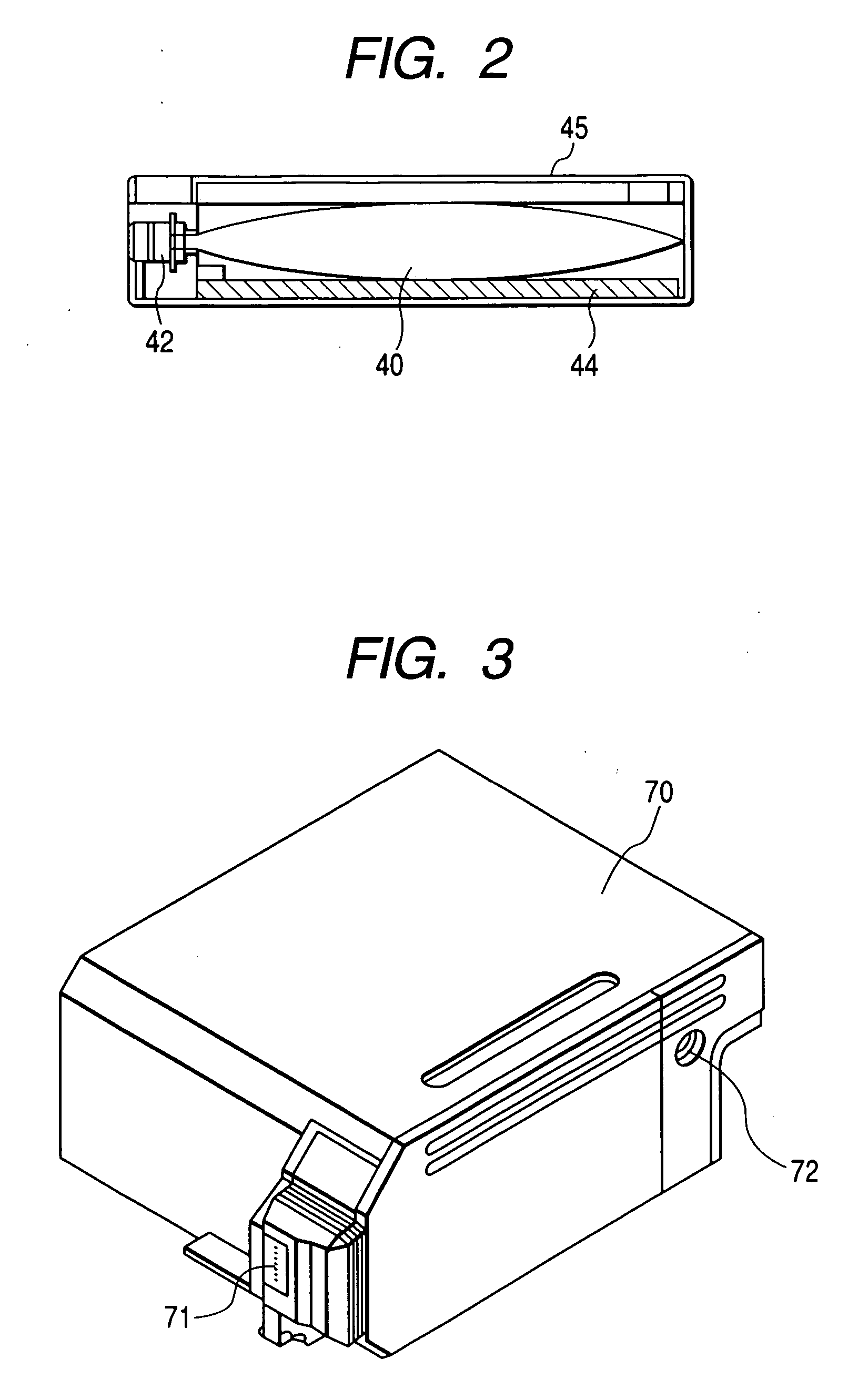

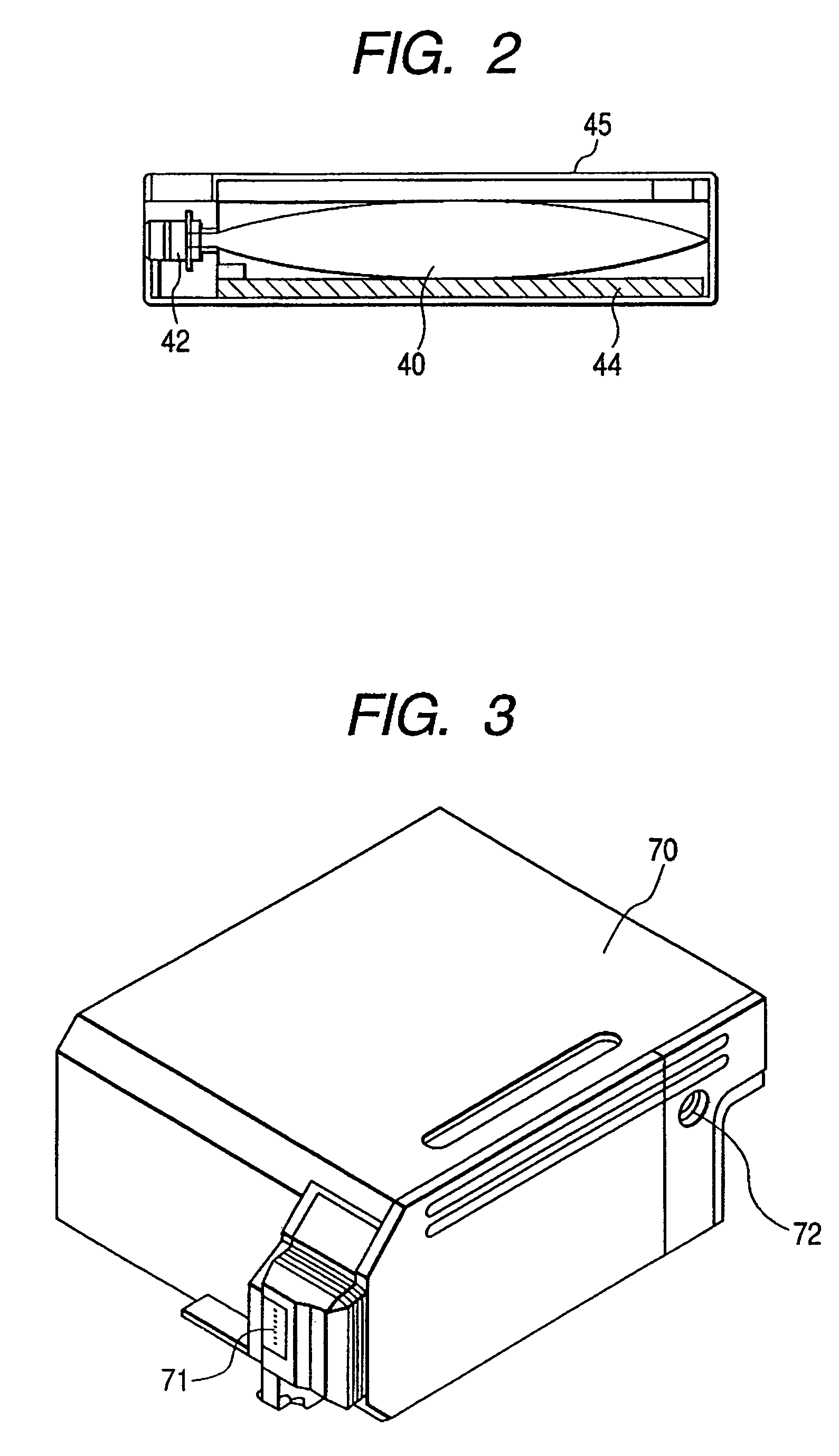

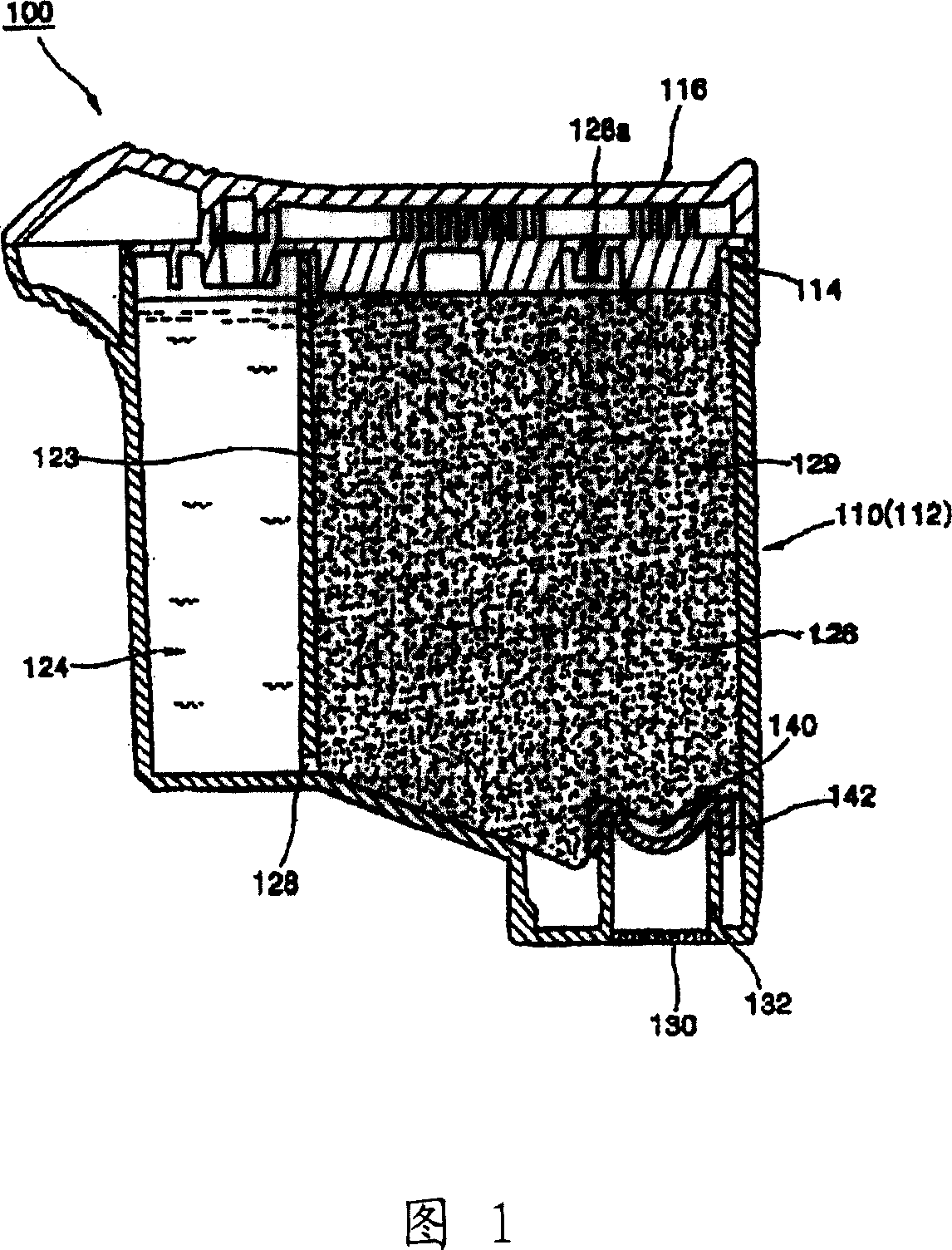

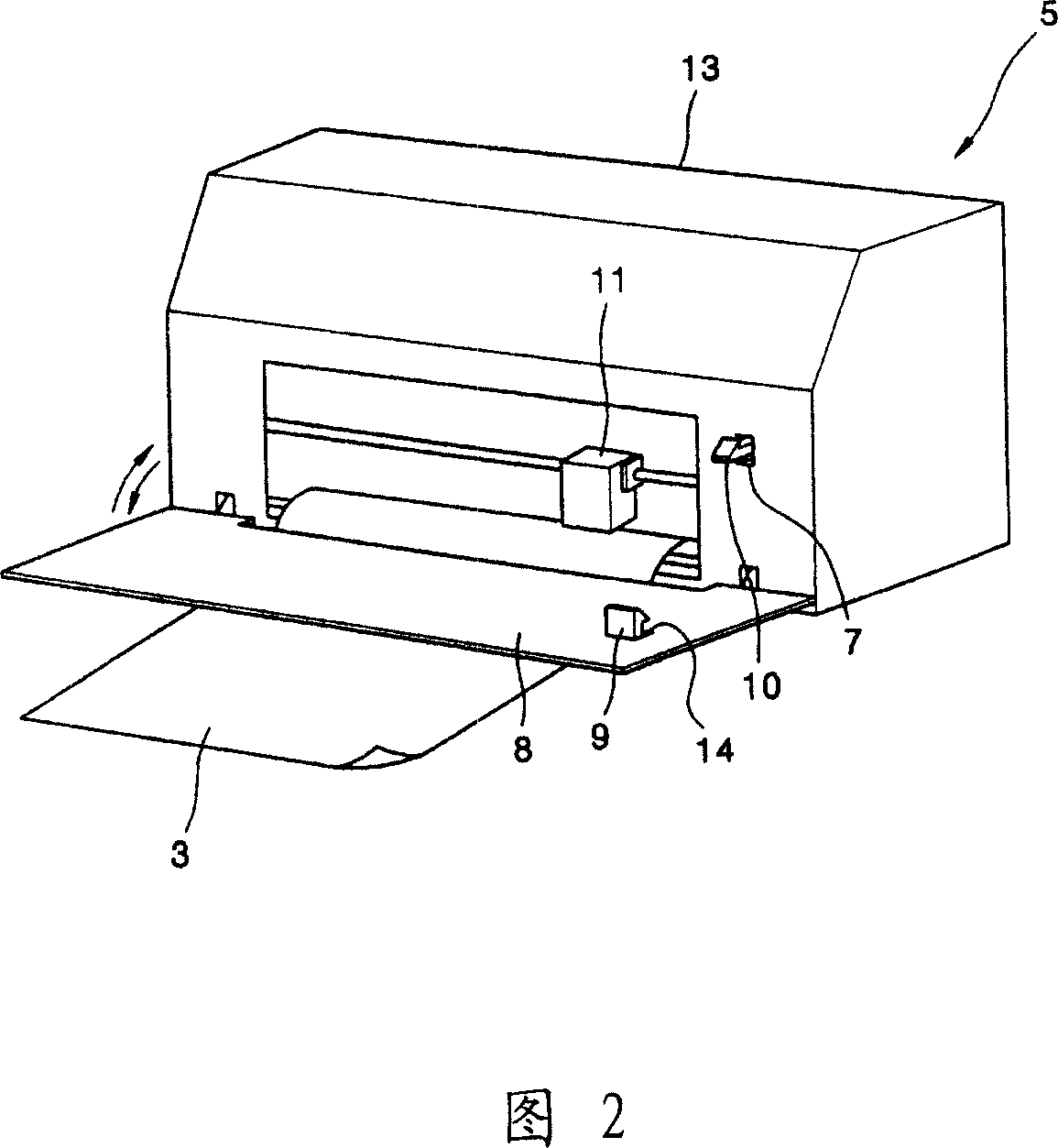

Colored fine resin particles and production process thereof, aqueous dispersion of colored fine resin particles and production process of aqueous dispersion of colored fine resin particles, ink , ink cartridge, recording unit, ink-jet recording apparatus, and ink-jet recording process

InactiveUS7008977B2Good rub-off resistanceExcellent water fastnessInksOrganic dyesDispersion stabilityWater insoluble

The invention provides colored fine resin particles useful as coloring materials for inks which can provide images having good water fastness, weather fastness and rub-off resistance and are excellent in dispersion stability, and a production process thereof. The colored fine resin particles have a structure in which a pigment coated with a water-insoluble resin is encapsulated with a copolymer composed of at least a polymerizable unsaturated monomer and a reactive emulsifier.

Owner:CANON KK

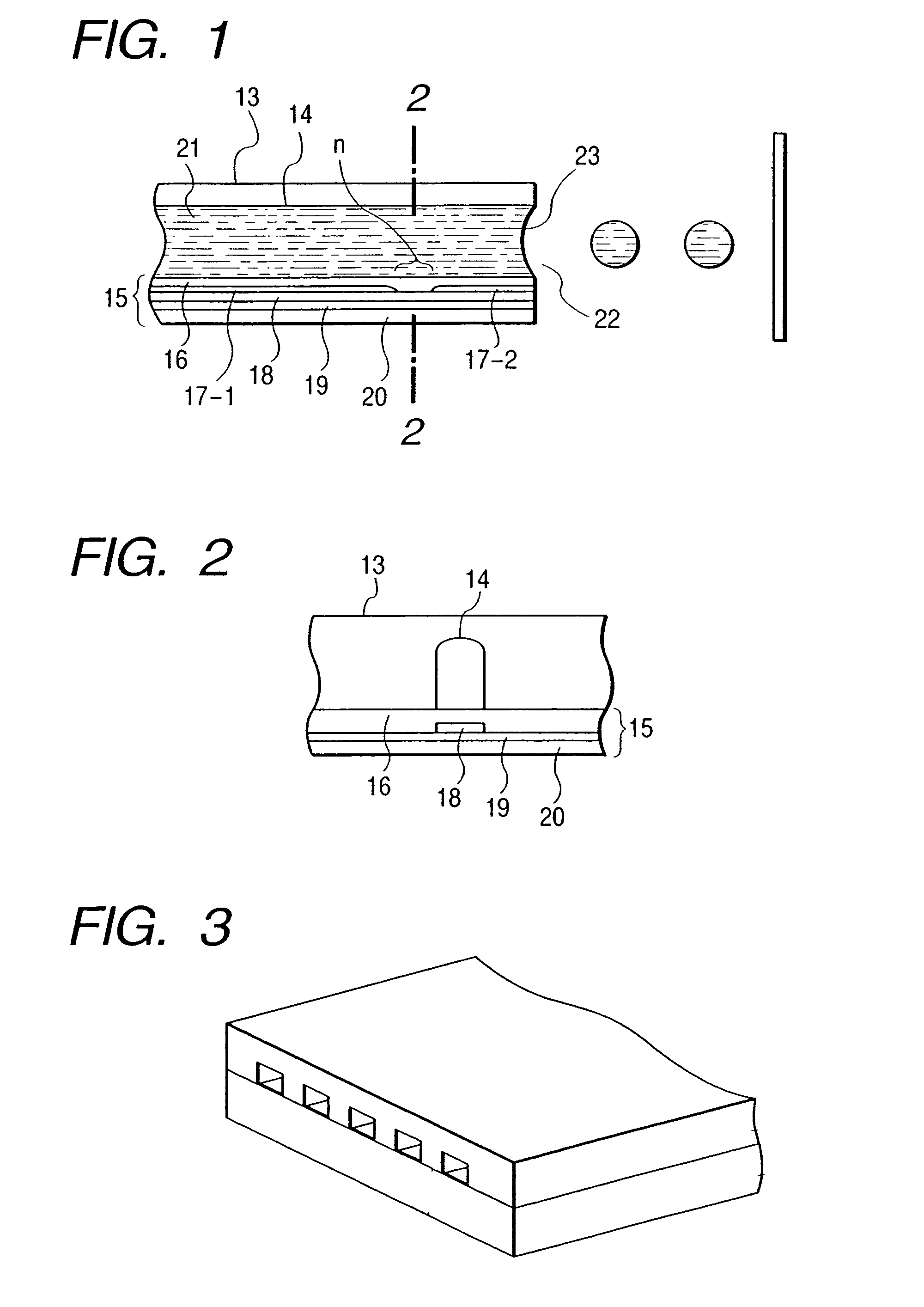

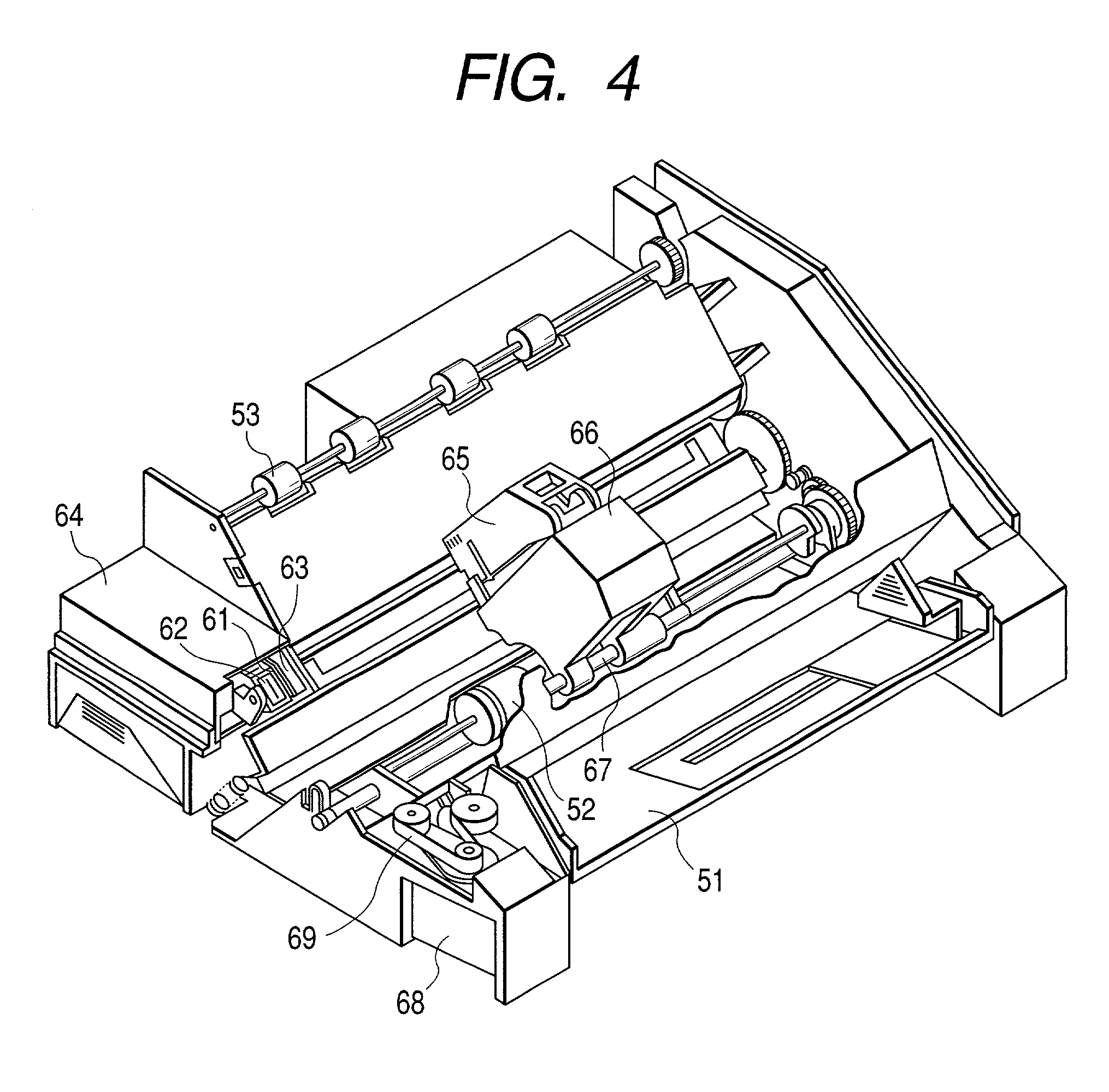

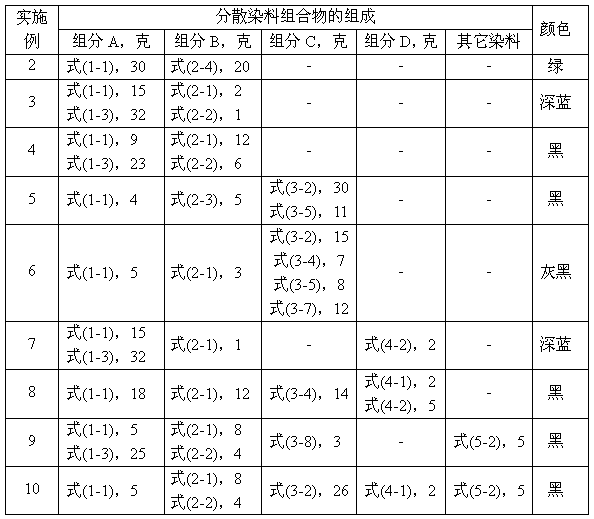

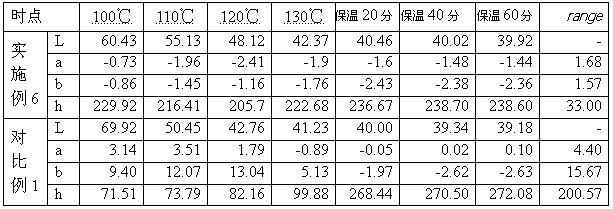

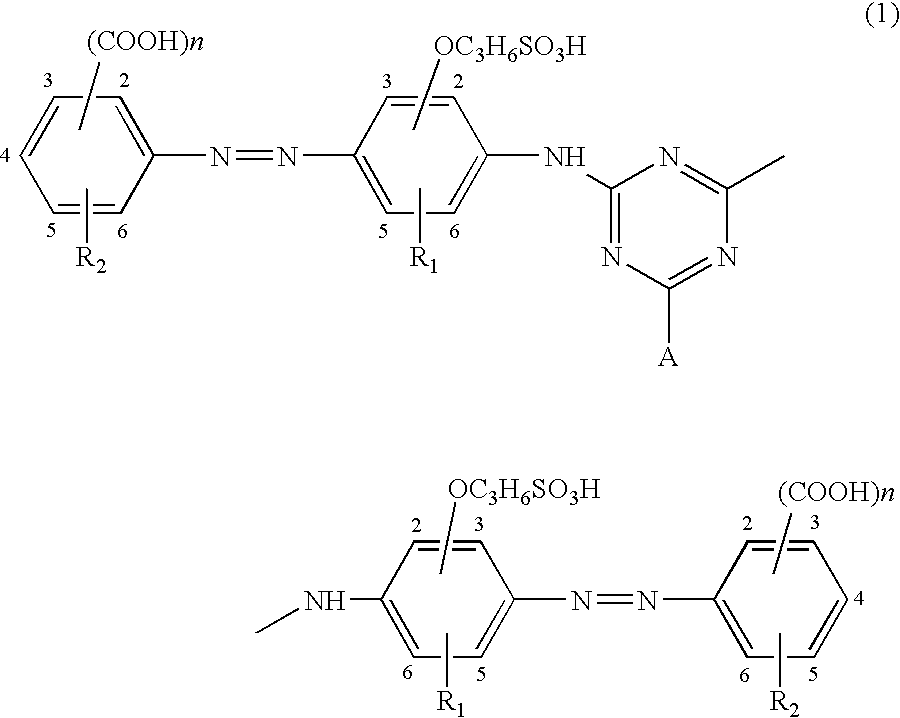

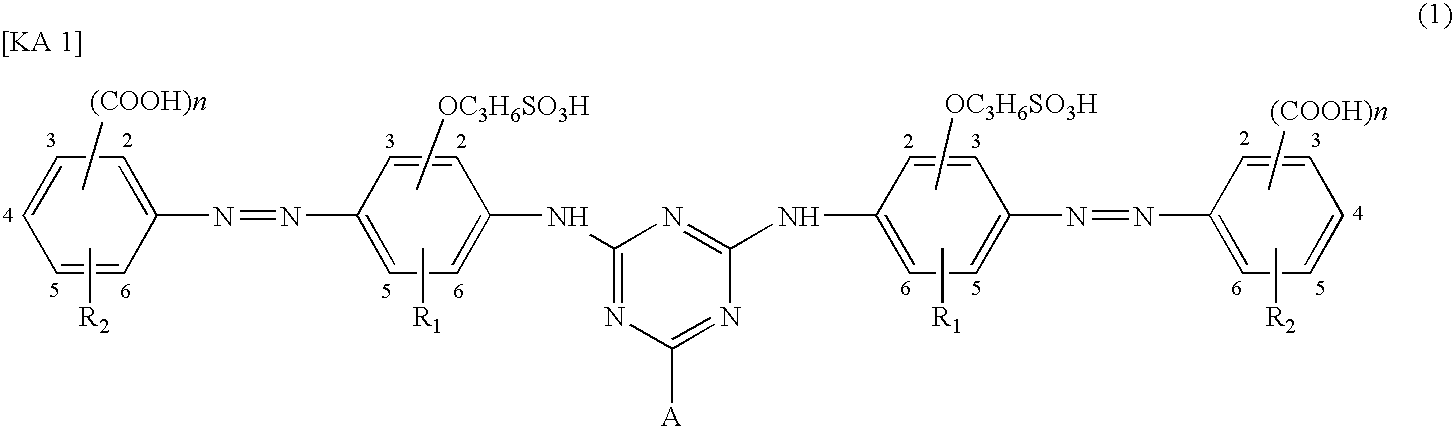

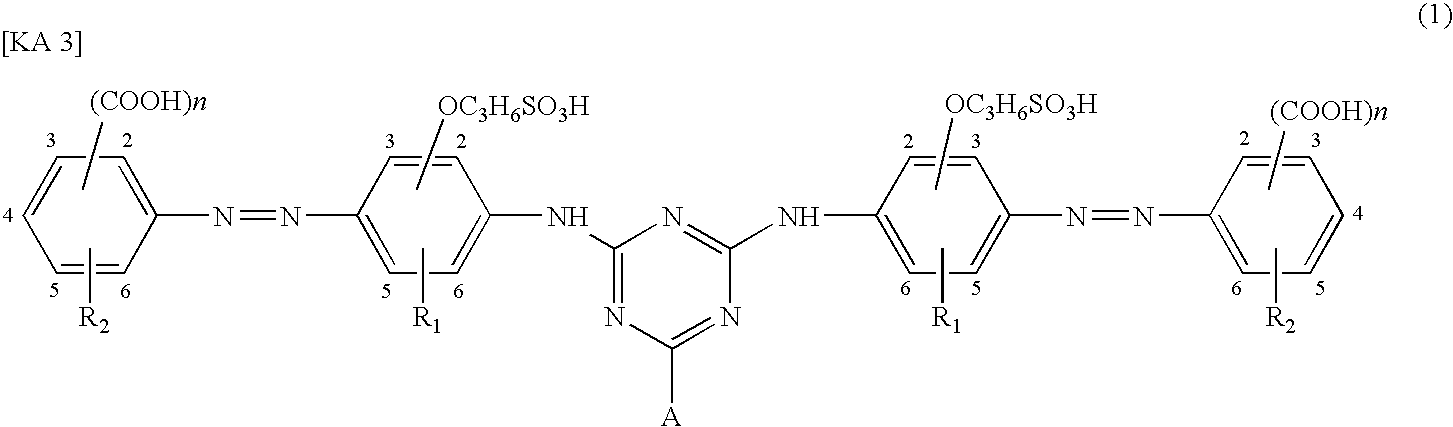

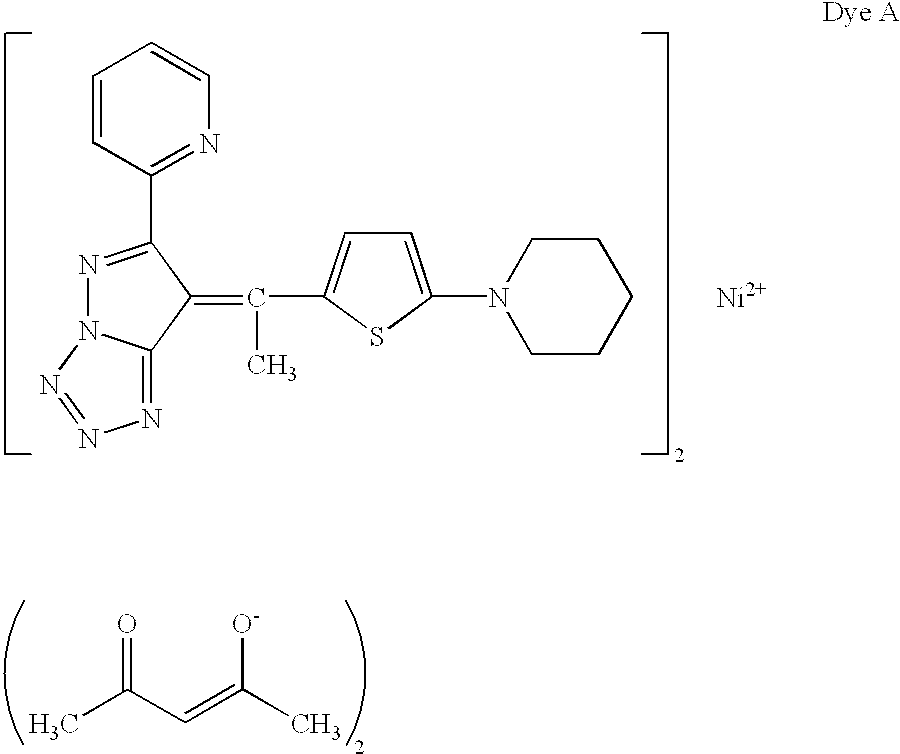

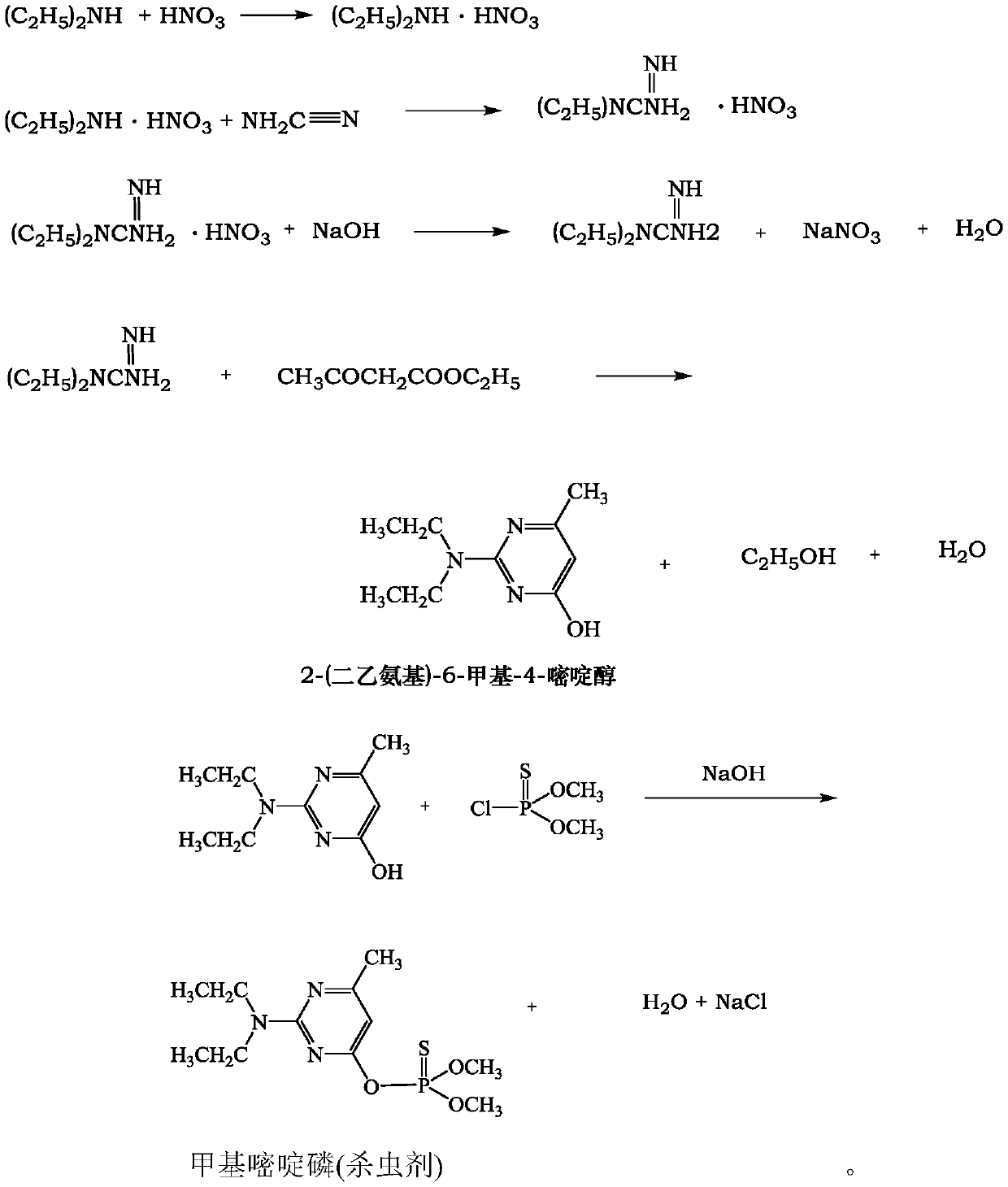

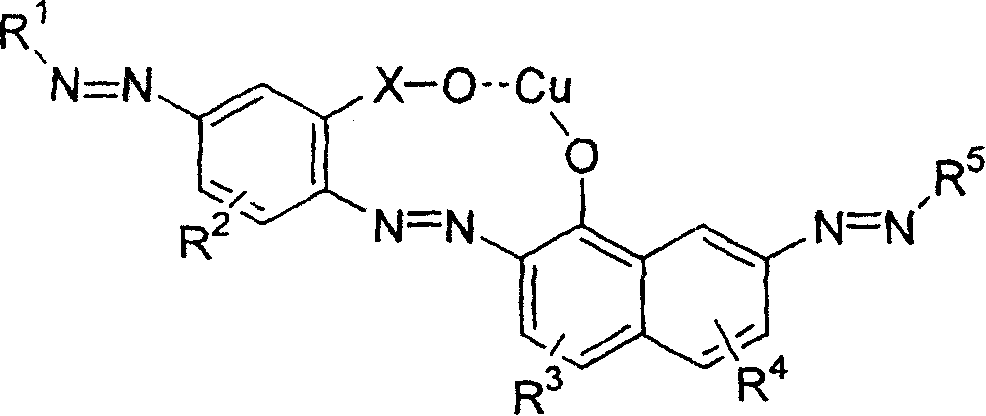

Disperse dye composition, dye product and application

InactiveCN102746712AGood washing fastness to waterImprove heat resistanceOrganic dyesDyeing processChemistryPhotochemistry

The invention discloses a disperse dye composition, a dye product and an application and belongs to the technical field of disperse dye. The disperse dye composition comprises one or multiple ingredients A shown as the formula (1) and one or multiple ingredients B shown as formula (2), wherein the formula (1) and the formula (2) are shown as the accompanying drawing. The disperse dye composition disclosed by the invention has the advantages that the deep color can be obtained through dyeing on ordinary polyester fiber, polyester ultrafine fiber and polyester fiber and polyurethane blending materials, the water washing resistance fastness is very good, and the compatibility is good.

Owner:浙江昱泰染化科技有限公司

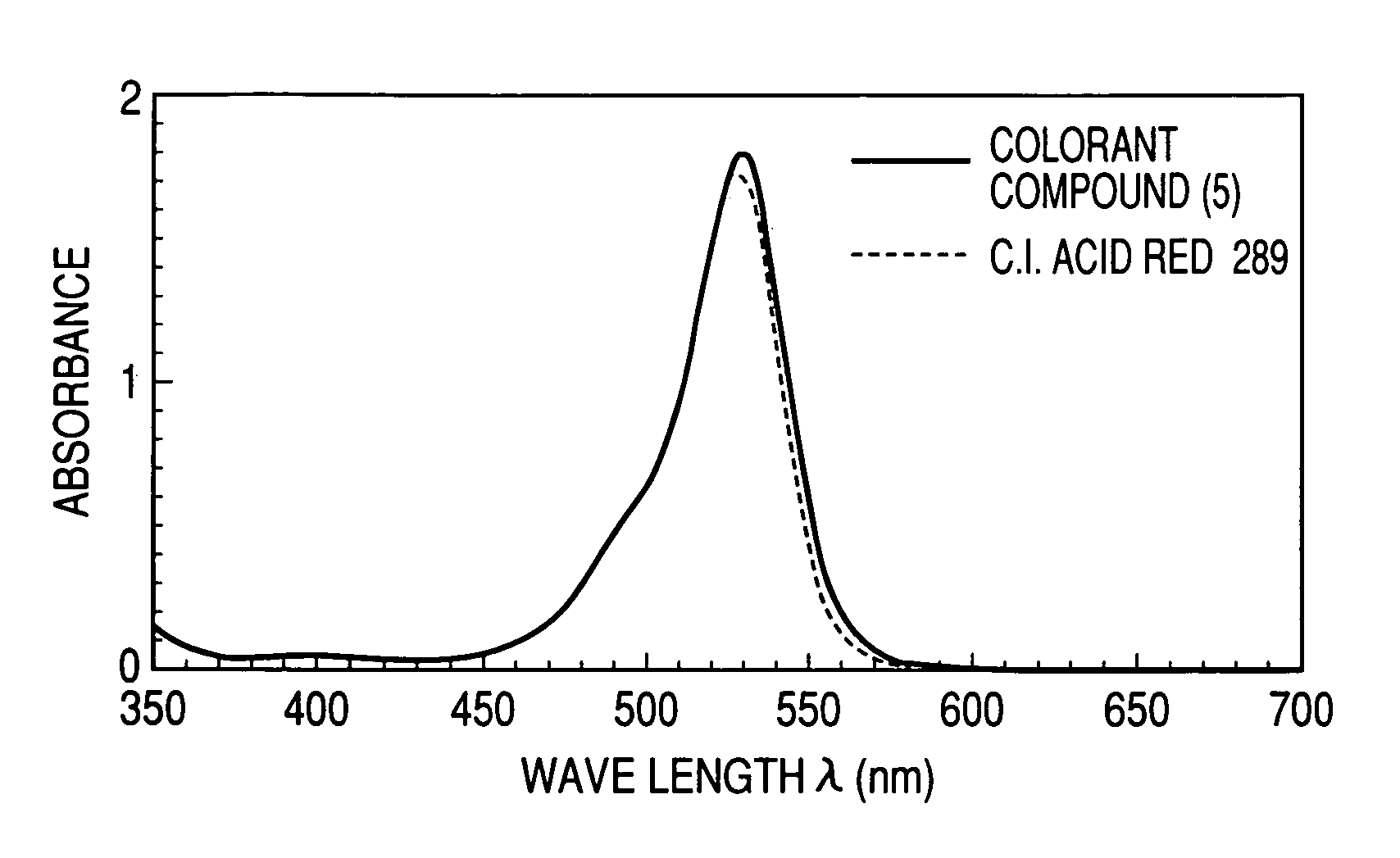

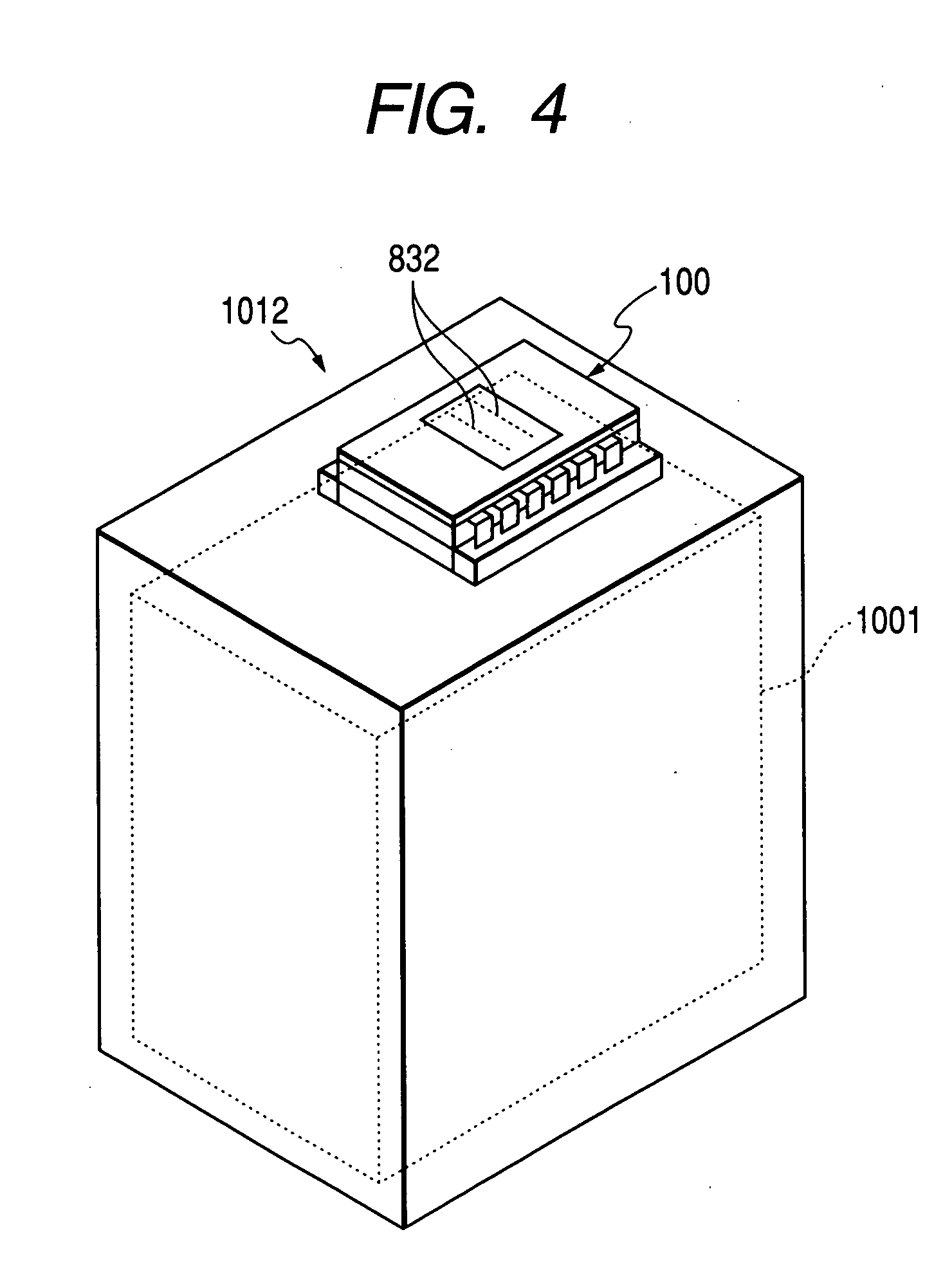

Colorant compound, ink, ink tank, recording unit, recording apparatus and recording process

InactiveUS7083667B2Improve reflective effectImprove solubilityOrganic chemistryPyronine/xanthon/thioxanthon/selenoxanthan/telluroxanthan dyesPolymer scienceEngineering

Disclosed herein is a colorant compound represented by the following general formula (1):wherein R1 and R2 are the same or different from each other and denote a linear alkyl group having 1 to 4 carbon atoms, R3 is an alkyl group having 1 to 6 carbon atoms, and An− is a counter anion, an ink comprising the colorant compound, and an ink tank, a recording unit, a recording apparatus and a recording process comprising or using the ink.

Owner:CANON KK

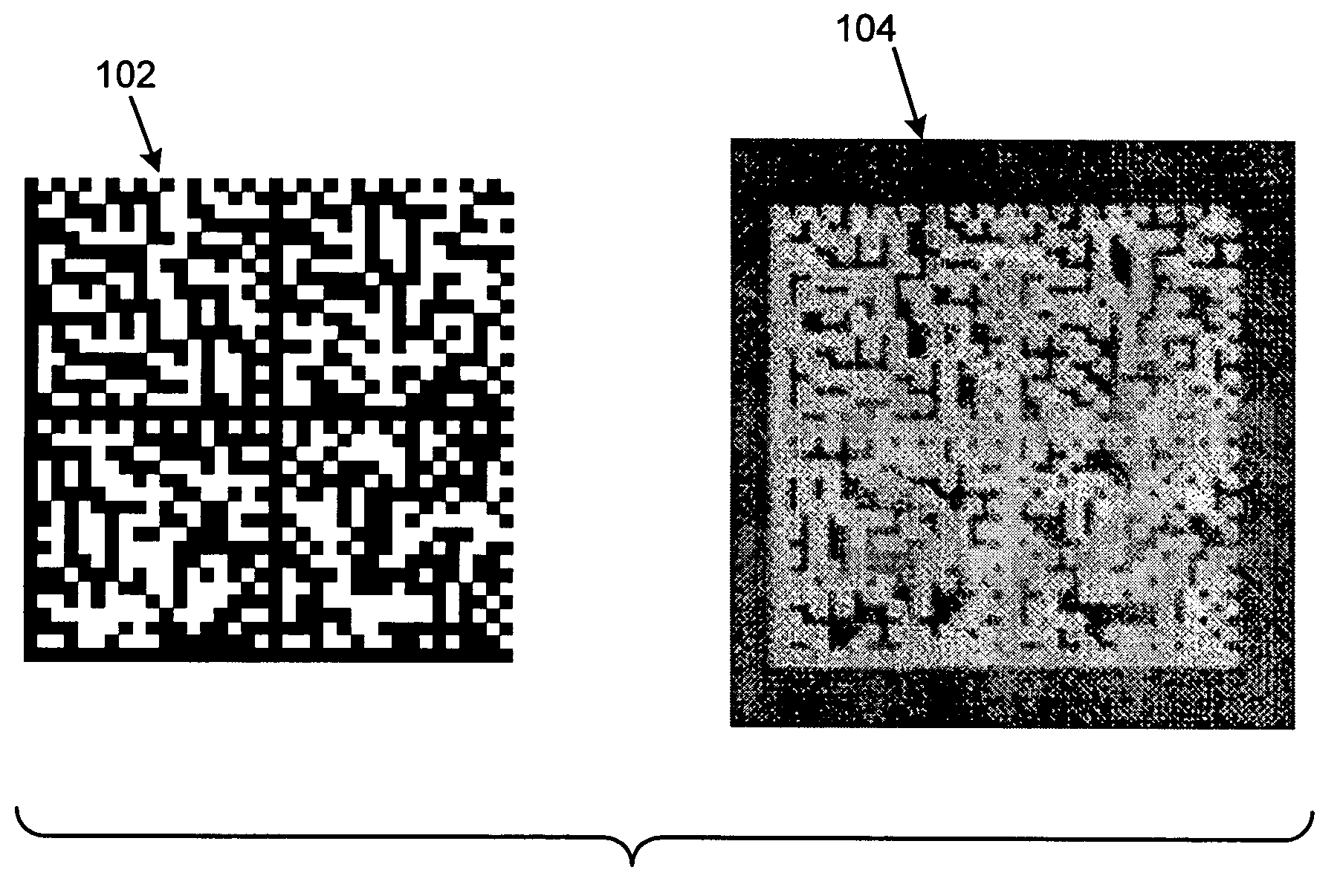

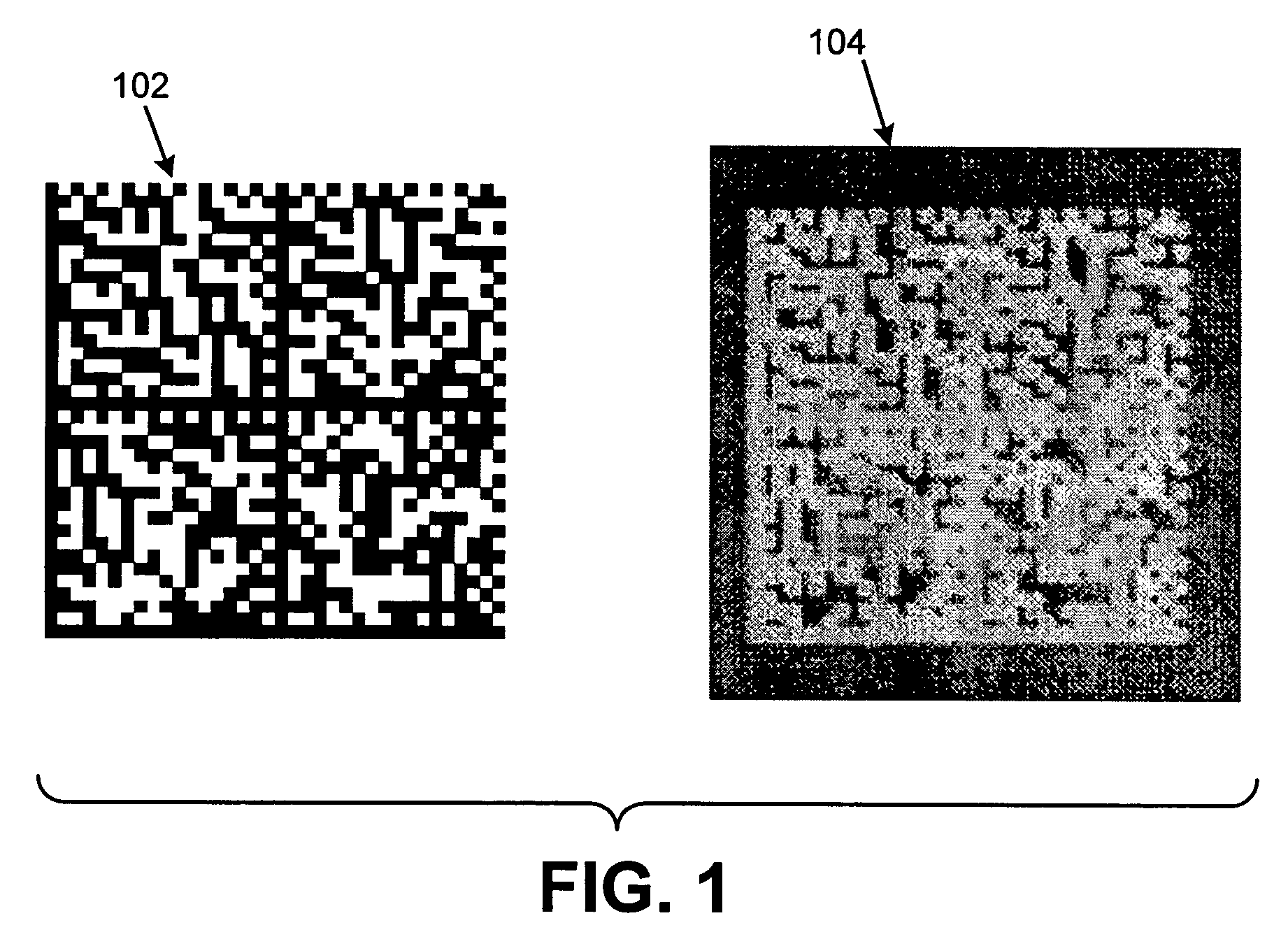

Photosensitive optically variable ink compositions useful for ink jet printing

InactiveUS20050279249A1Red fluorescenceSatisfactory solubility in waterMeasurement apparatus componentsLuminescent paintsWater solubleSurface tension

New photosensitive optically variable inks are capable of printing images having improved resistance to water. The inks produce images which can be viewed with both visible and ultraviolet light to have physically coincident positive and negative images. They contain at least two types of colorants and other suitable ingredients to enable preparation for printing. The first colorant comprises a fluorescent dye emitting light within a characteristic emission band when excited by fluorescent-exciting radiation. The second colorant, which comprises a colloidal pigment alone or with a dye, has a light absorption band at longer wavelengths than the characteristic emission band of the first colorant or overlapping the emission wavelength of the first colorant, effectively to result in a dark color. The composition also contains an aqueous liquid vehicle comprising water and a water-soluble vehicle in sufficient amounts to achieve an ink viscosity and surface tension effective for application of the ink to a substrate in a predetermined pattern by ink jet printing.

Owner:PITNEY BOWES INC

Recording material with an extrusion coated PVA layer

InactiveUS6403202B2High glossKeep dryDuplicating/marking methodsSynthetic resin layered productsPolyvinyl alcoholAqueous dispersion

A recording material for the ink-jet printing method comprises a raw base paper, an extrudable polyvinyl alcohol containing layer which is extruded on the raw base paper, and an ink-receiving layer which is applied as an aqueous dispersion or solution.

Owner:FELIX SCHOELLER TECHN PAPERS

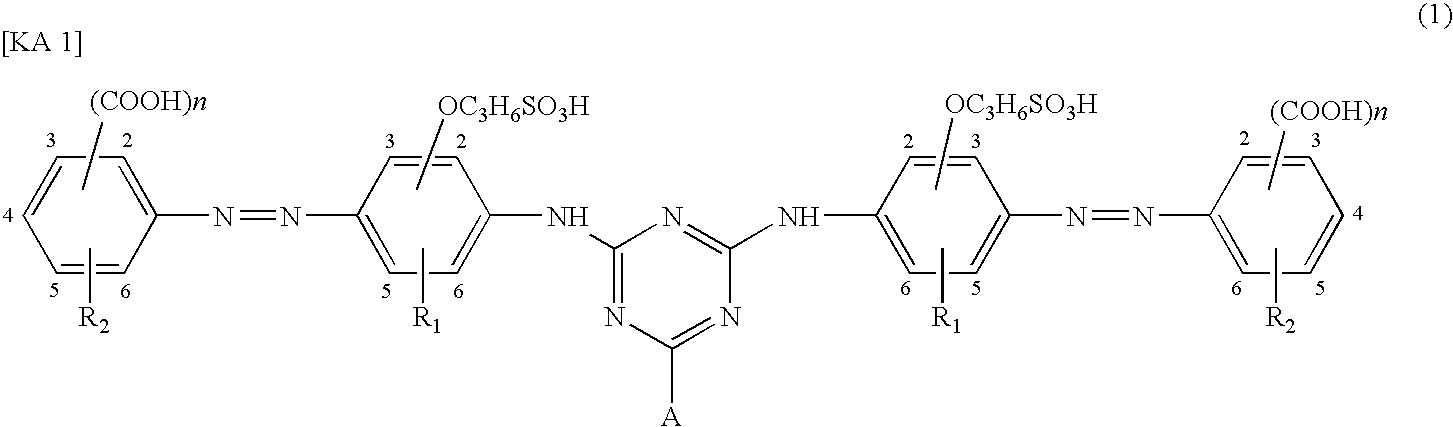

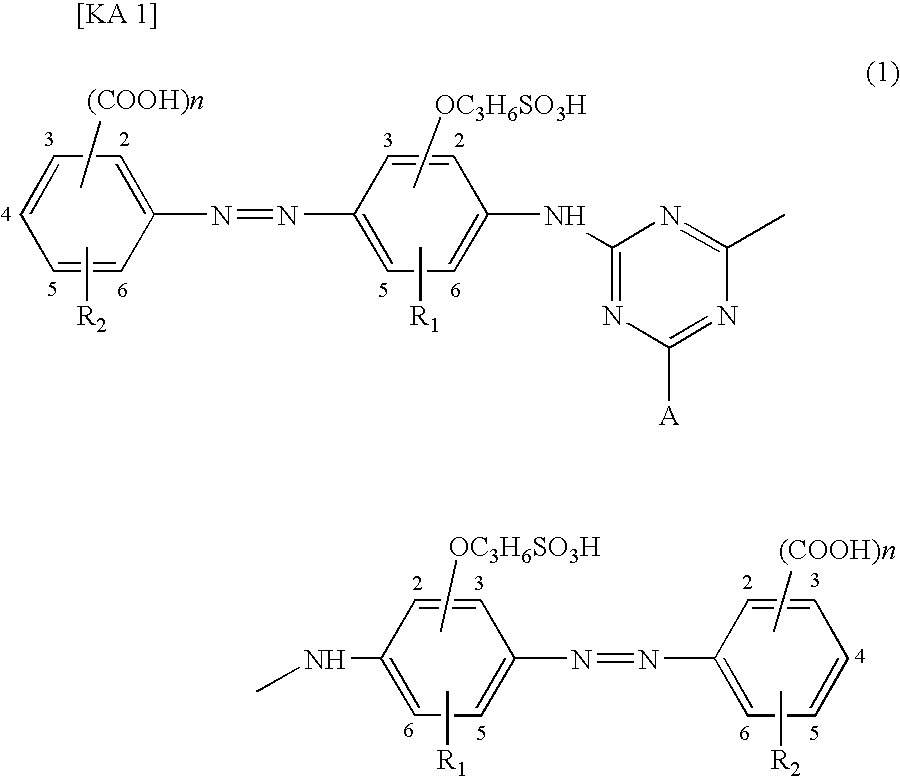

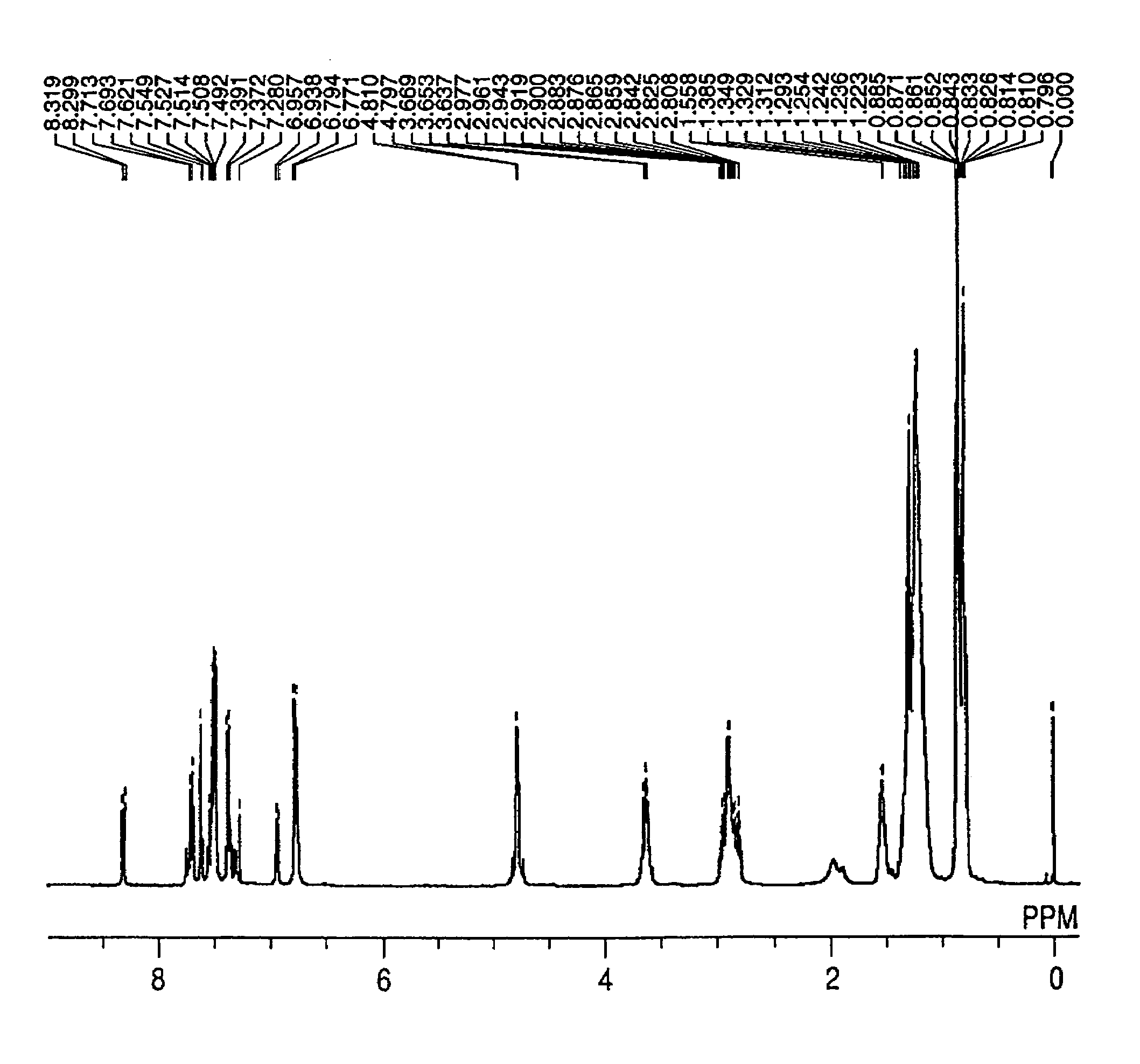

Water-soluble azo compound, ink composition, and colored article

InactiveUS7740696B2Improve solubilityFaithfully reproducedDisazo dyesOrganic chemistryMorpholineAliphatic amine

The present invention relates to a water-soluble azo compound for yellow represented by the following formula (1)wherein, A represents a hydroxy group, a morpholino group, an amino group, an aliphatic amine residue which may have a substituent, an aromatic amine residue which may have a substituent, a phenoxy group which may have a substituent, or an alkoxy group which may have a substituent, R1 represents a hydrogen atom or an alkyl group having 1 to 4 carbon atoms, R2 represents a hydrogen atom, a nitro group or a hydroxy group, and n represents an integer number of 1 to 3, respectively as a free acid, and an ink composition containing the same; said ink composition has good stability and is suitable for inkjet printing; and printed matters therewith have very high fastness such as ozone fastness and the like.

Owner:NIPPON KAYAKU CO LTD

Photosensitive optically variable ink compositions useful for ink jet printing

InactiveUS7141103B2Low viscosityExcellent water fastnessLuminescent paintsInksUltraviolet lightsPhotopigment

New photosensitive optically variable inks are capable of printing images having improved resistance to water. The inks produce images which can be viewed with both visible and ultraviolet light to have physically coincident positive and negative images. They contain at least two types of colorants and other suitable ingredients to enable preparation for printing. The first colorant comprises a fluorescent dye emitting light within a characteristic emission band when excited by fluorescent-exciting radiation. The second colorant, which comprises a colloidal pigment alone or with a dye, has a light absorption band at longer wavelengths than the characteristic emission band of the first colorant or overlapping the emission wavelength of the first colorant, effectively to result in a dark color. The composition also contains an aqueous liquid vehicle comprising water and a water-soluble vehicle in sufficient amounts to achieve an ink viscosity and surface tension effective for application of the ink to a substrate in a predetermined pattern by ink jet printing.

Owner:PITNEY BOWES INC

Water-Soluble Azo Compound, Ink Composition, and Colored Article

InactiveUS20090117341A1Excellent water solubilityStorage stability be goodOrganic chemistryDisazo dyesFree acidWater soluble

The present invention relates to a water-soluble azo compound for yellow represented by the following formula (1)(wherein, A represents a hydroxy group, a morpholino group, an amino group, an aliphatic amine residue which may have a substituent, an aromatic amine residue which may have a substituent, a phenoxy group which may have a substituent, or an alkoxy group which may have a substituent, R1 represents a hydrogen atom or an alkyl group having 1 to 4 carbon atoms, R2 represents a hydrogen atom, a nitro group or a hydroxy group, and n represents an integer number of 1 to 3, respectively)as a free acid, and an ink composition containing the same; said ink composition has good stability and is suitable for inkjet printing; and printed matters therewith have very high fastnesses such as ozone fastness and the like.

Owner:NIPPON KAYAKU CO LTD

Photocurable pigment type inkjet ink composition

ActiveUS20070015843A1Excellent propertyGood water fastnessDuplicating/marking methodsOptical articlesPigment particleSURFACTANT BLEND

A photocurable pigment type inkjet ink composition including 5 to 95 wt % of water; 0.5 to 20 wt % of a pigment; 1 to 70 wt % of a photocurable component; and 0.0001 to 30 wt % of a reactive surfactant. The reactive surfactant can serve as a pigment dispersant for dispersing pigment particles or as an emulsifier for emulsifying the photocurable component.

Owner:IND TECH RES INST

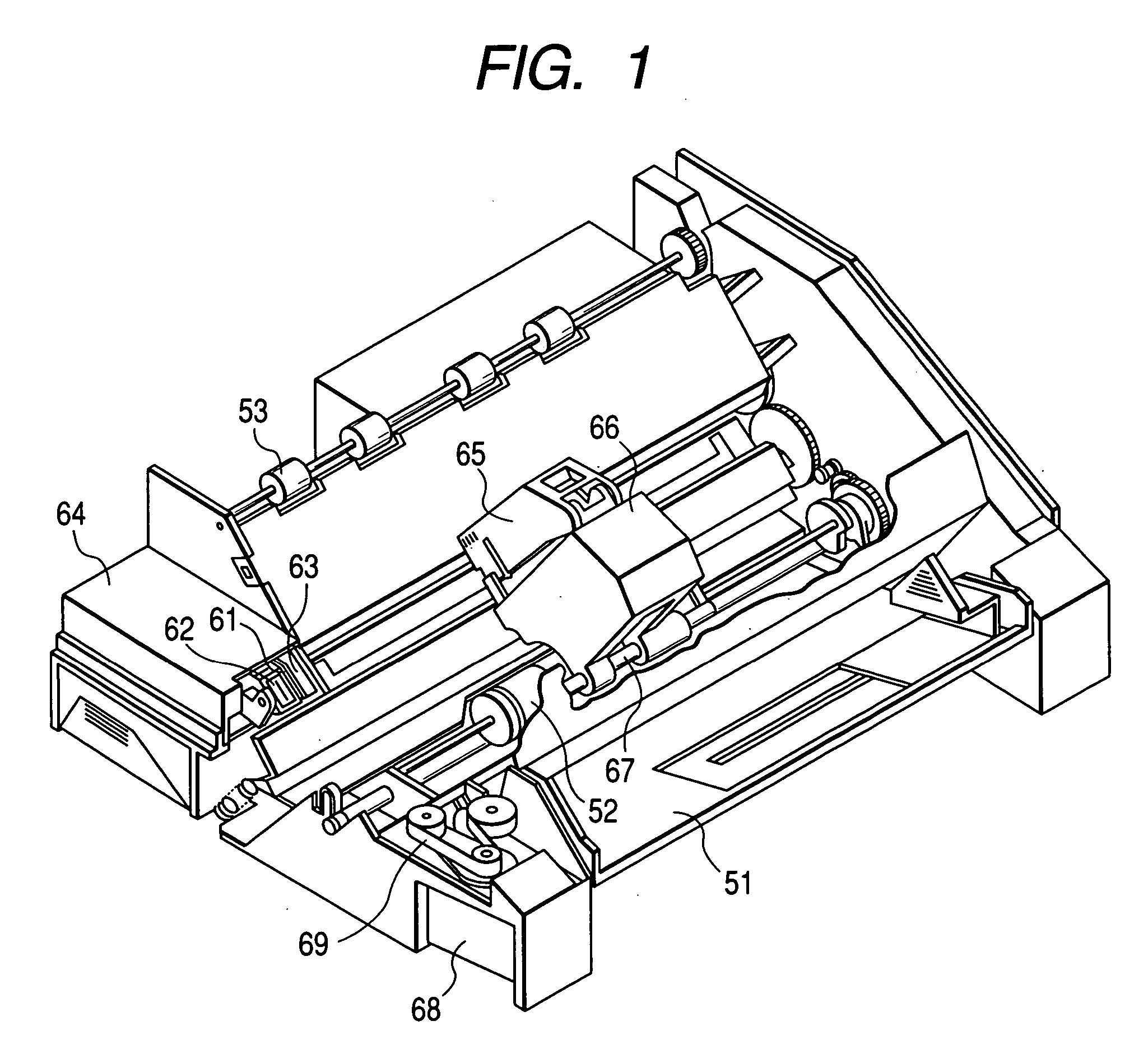

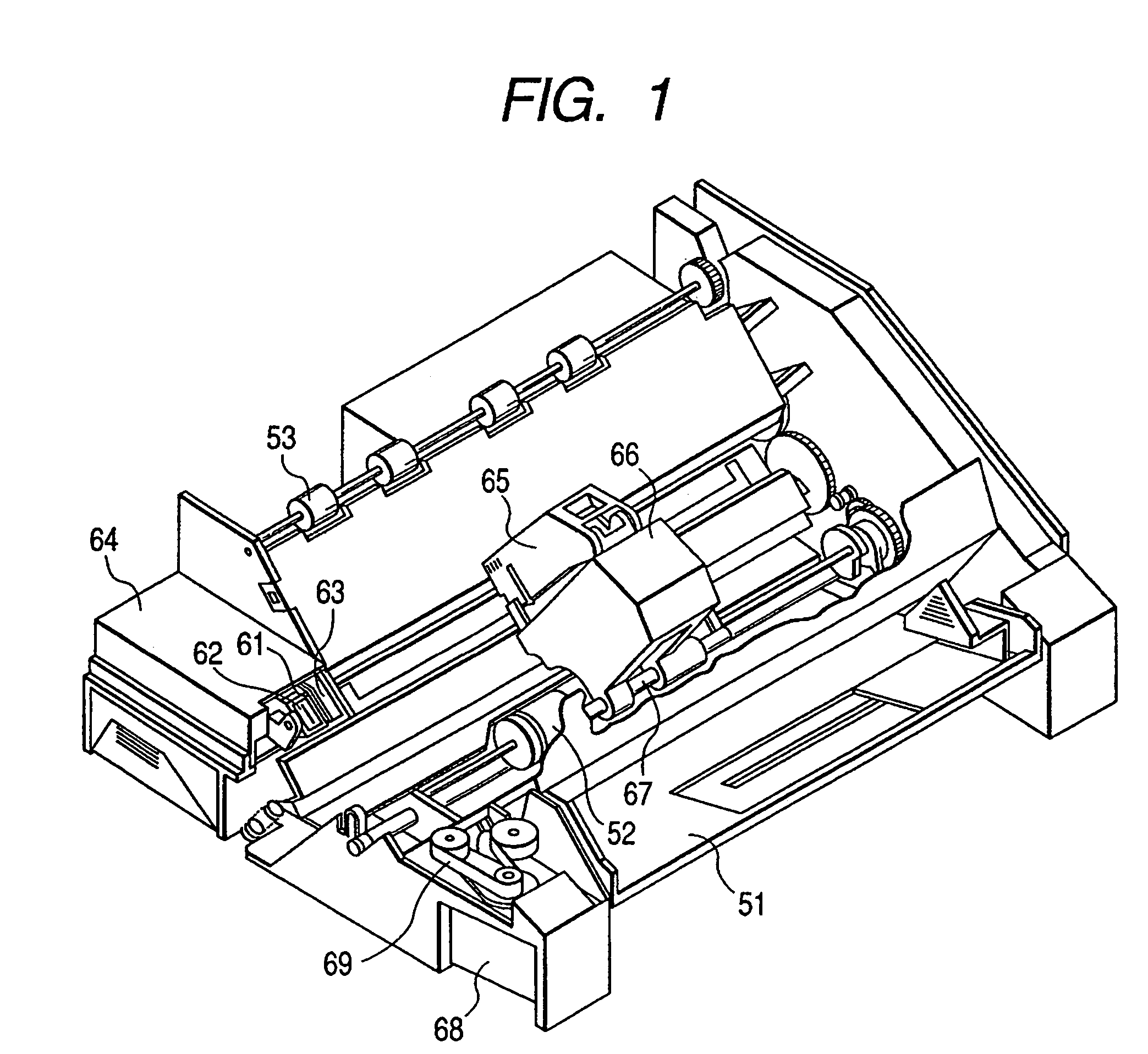

Ink jet printing method

InactiveUS6137514AExcellent water fastnessExcellent wet adhesionMeasurement apparatus componentsDuplicating/marking methodsImage recordingWater soluble

A method of ink jet printing, wherein an ink jet composition comprising water, a cationic, water soluble dye and from about 0.1% to about 10% by weight of a hardener is ejected onto an image recording element. The recording element is formed of a support and an ink receptive layer, formed on the support, wherein the ink receptive layer comprises a cross linkable polymer.

Owner:EASTMAN KODAK CO

Water-based ink comprising colored particles and image forming method using the same

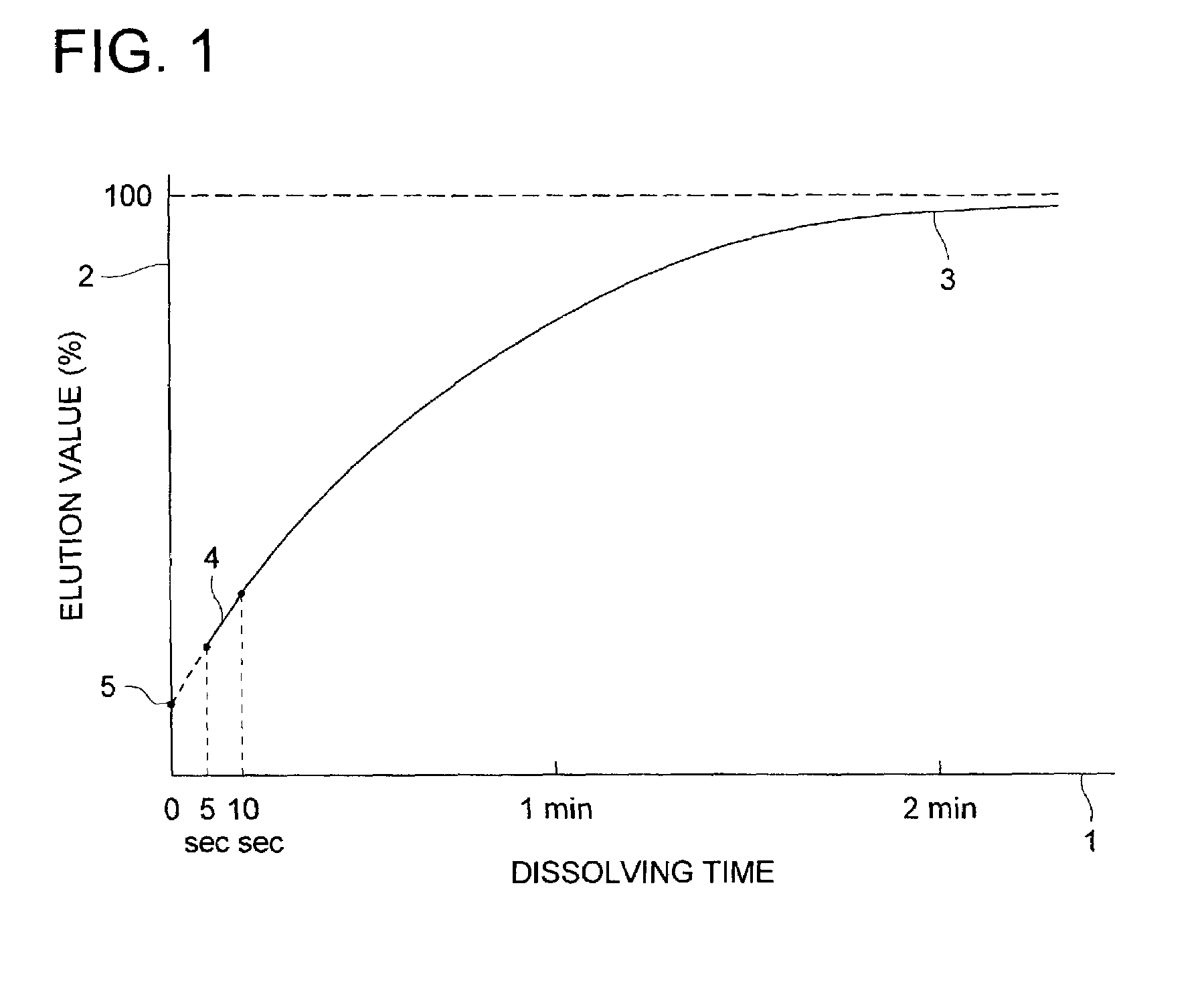

InactiveUS7037957B2Good dispersionExcellent water fastnessDuplicating/marking methodsInksWater basedElution

A water-based ink comprising water and at least one kind of colored particles selected from the group consisting of:(a) colored particles comprising a polymer containing a colorant;(b) colored particles comprising a core forming colorant and a shell forming polymer which encapsulates the core forming colorant; and(c) particles comprising a core forming polymer containing a colorant and a shell forming polymer which encapsulates the core forming polymer,wherein the initial elution value of the colorant of the colored particles being measured in a colorant dissolving solvent is at most 10% of the maximum elution value.

Owner:KONICA CORP

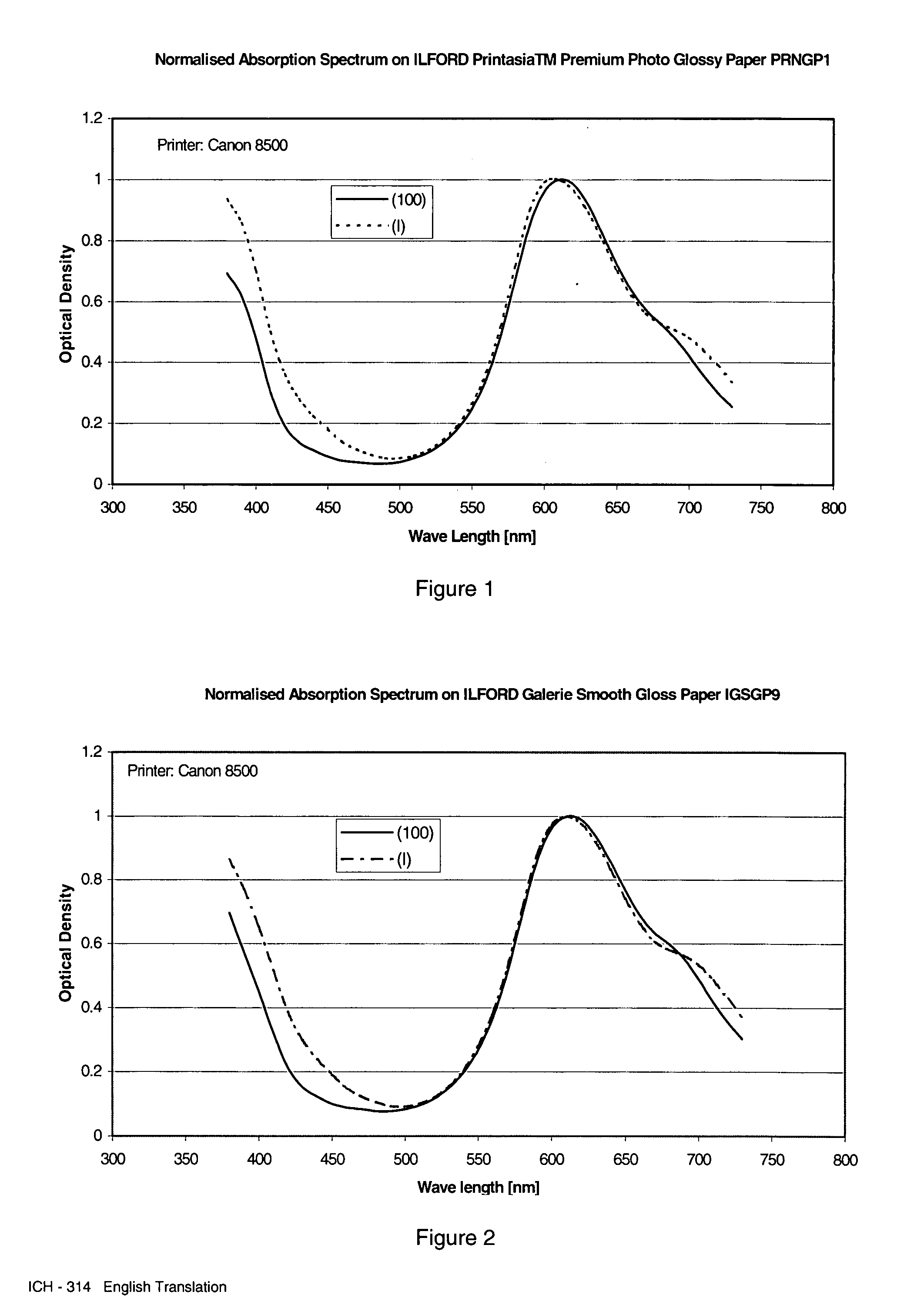

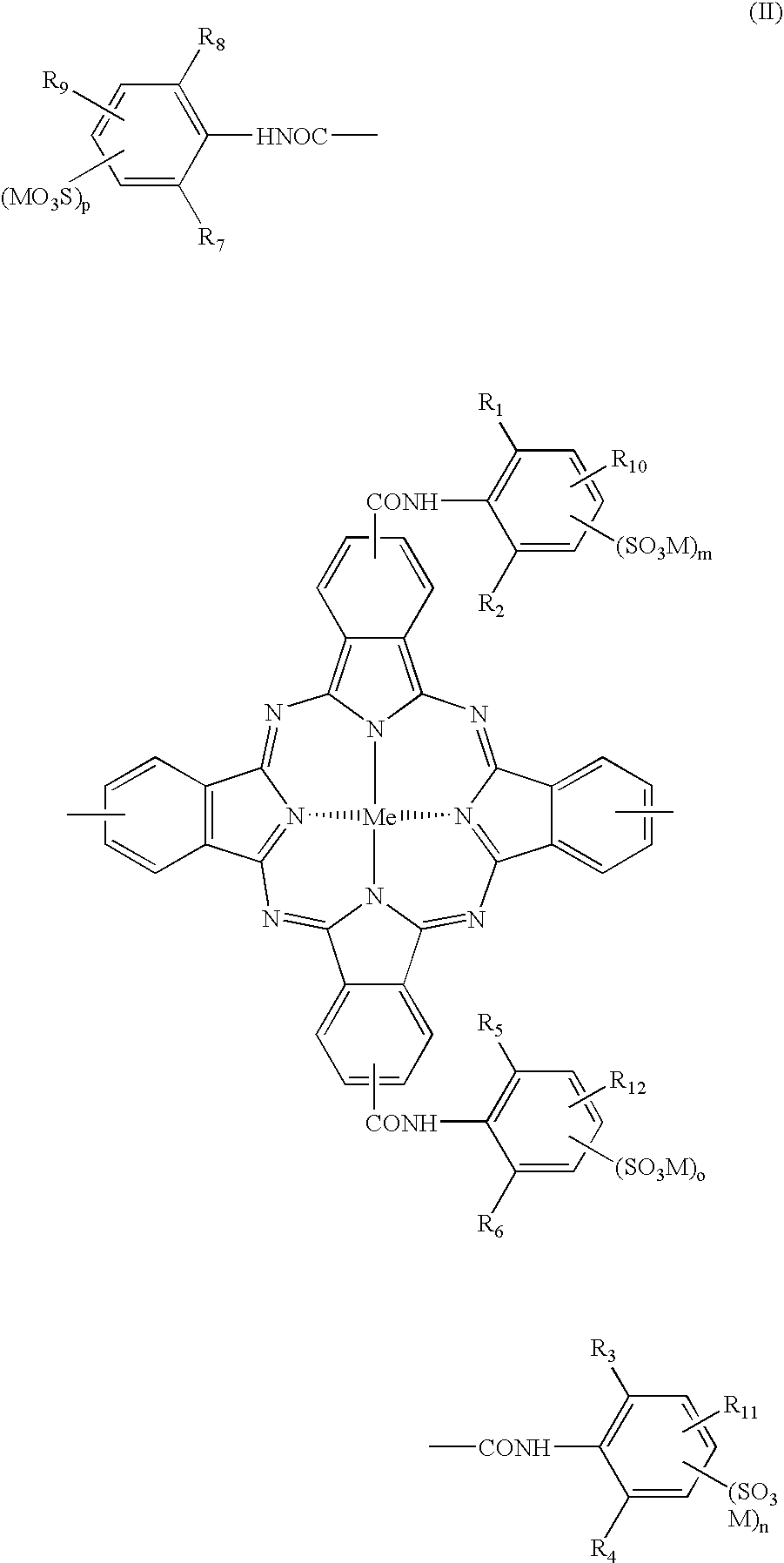

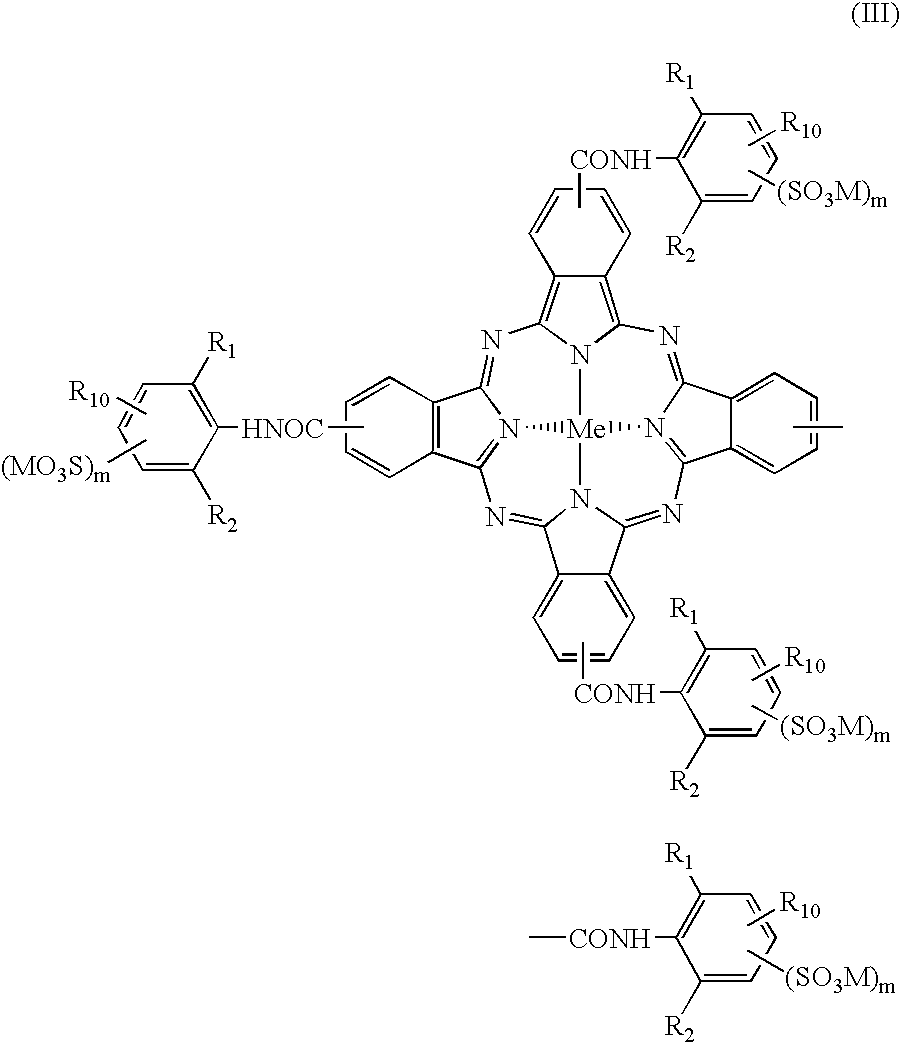

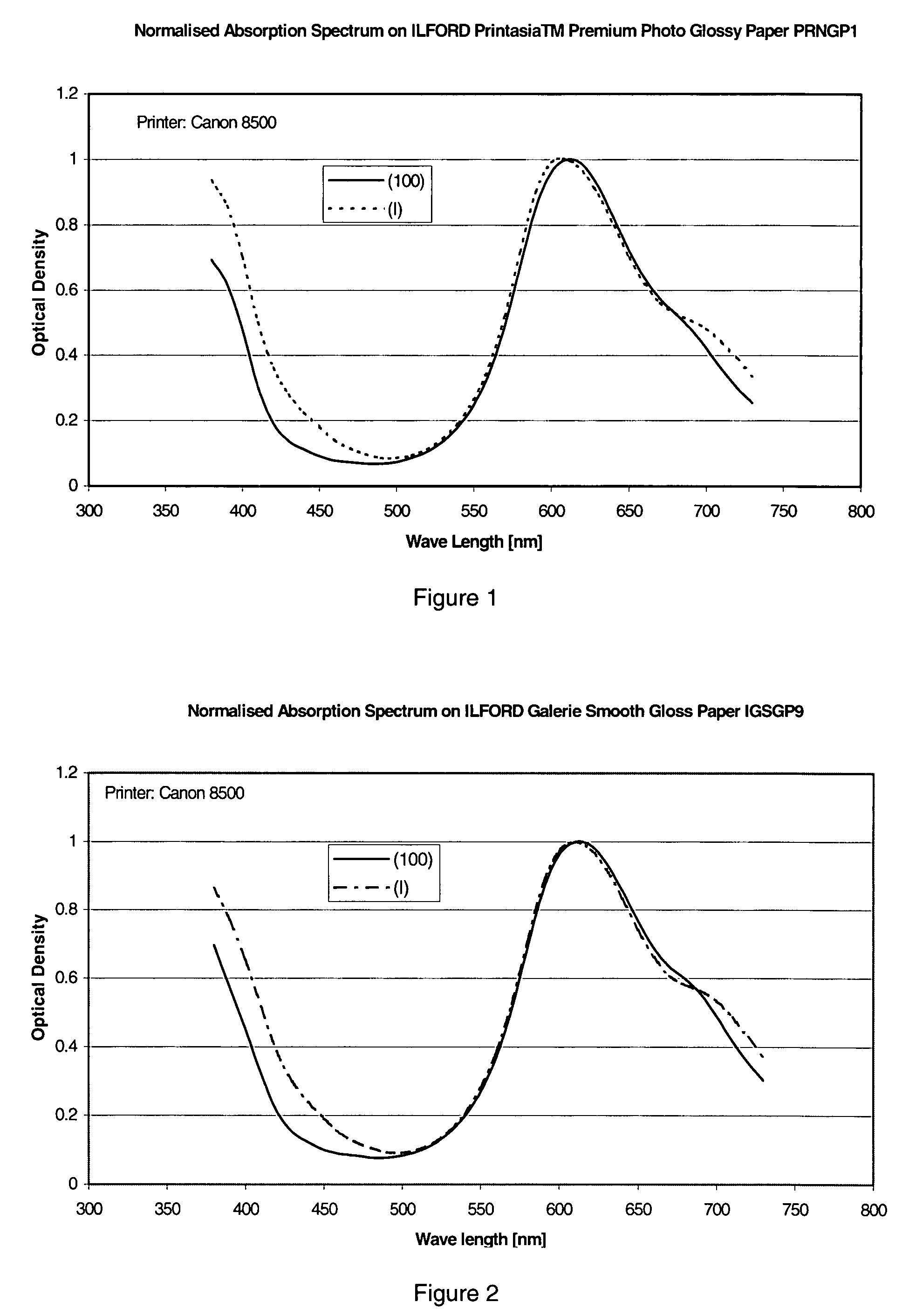

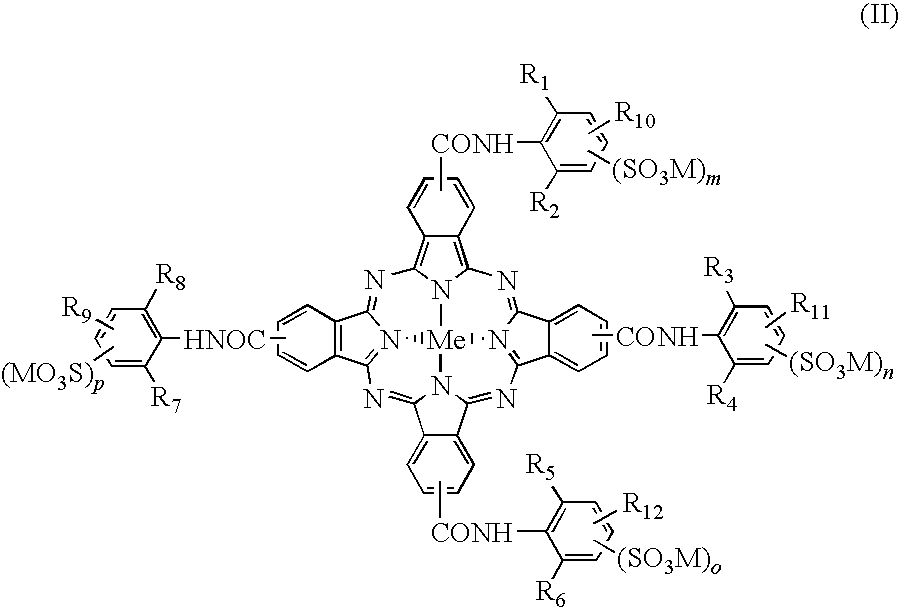

Phthalocyanine dyes and their preparation and use

InactiveUS20080257210A1Good stability against degradationSuitable hueOrganic chemistryMeasurement apparatus componentsCellulosePolymer science

Phthalocyanine dyes of general formula (II)and, in particular, of general formula (III)wherein R1-R8, R9-R12, Me, M, m, n , o and p are as defined in the specification, are excellent dyes for dying and printing cellulose containing materials and textile materials, and, especially, for the preparation of inks for ink jet printing.

Owner:ILFORD IMAGING SWITZERLAND GMBH

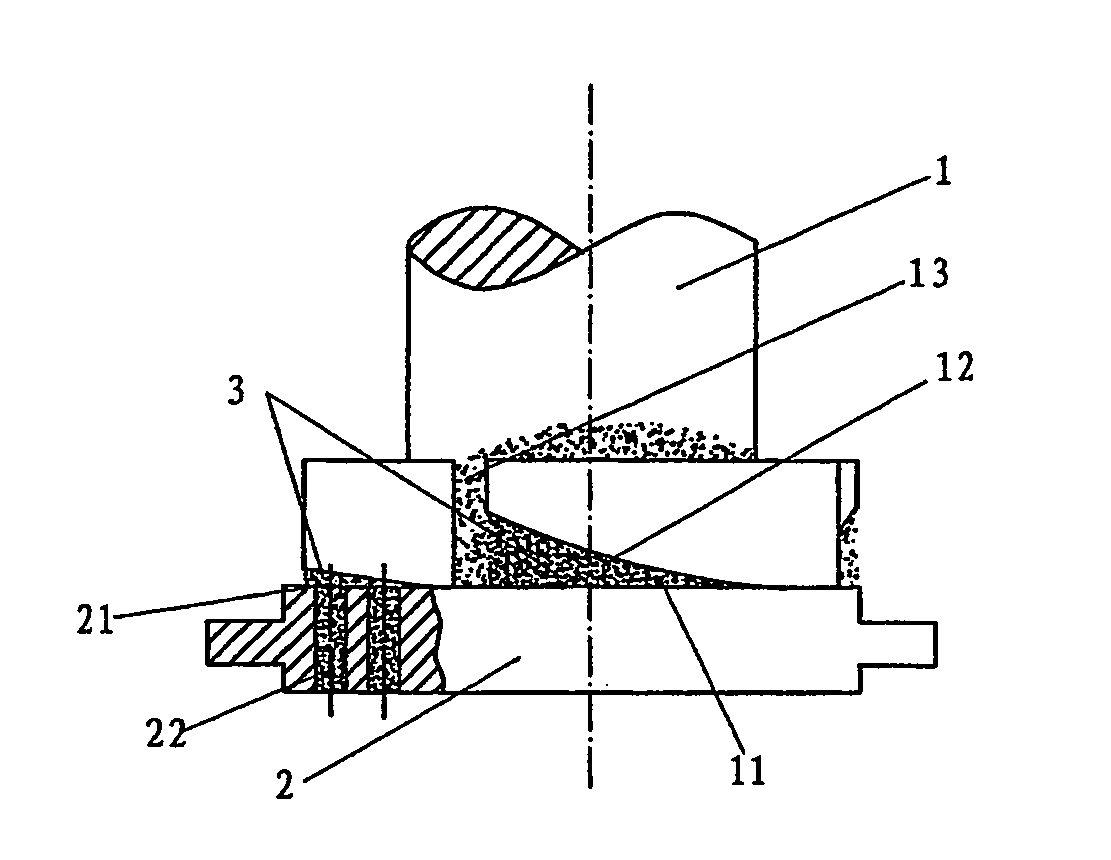

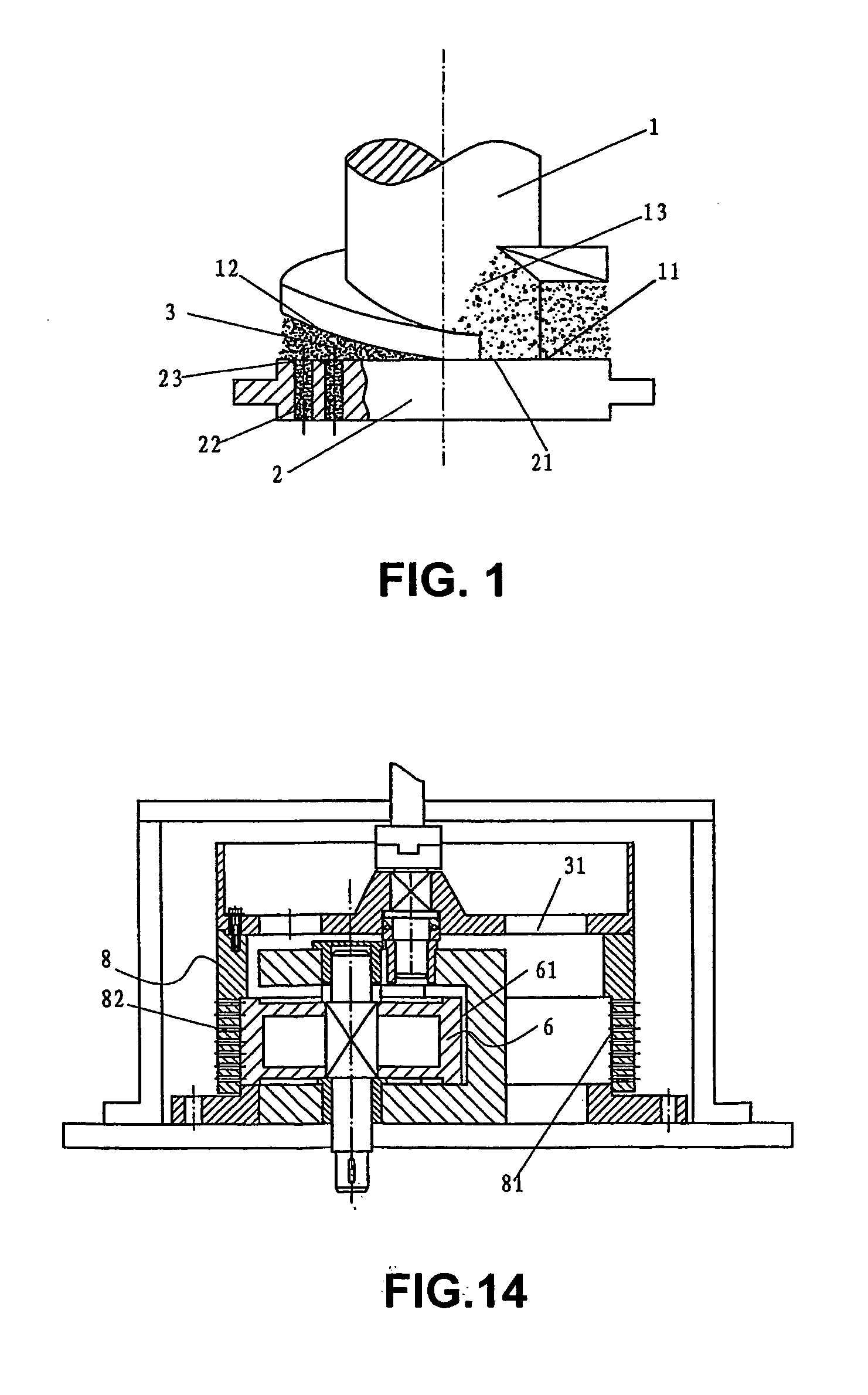

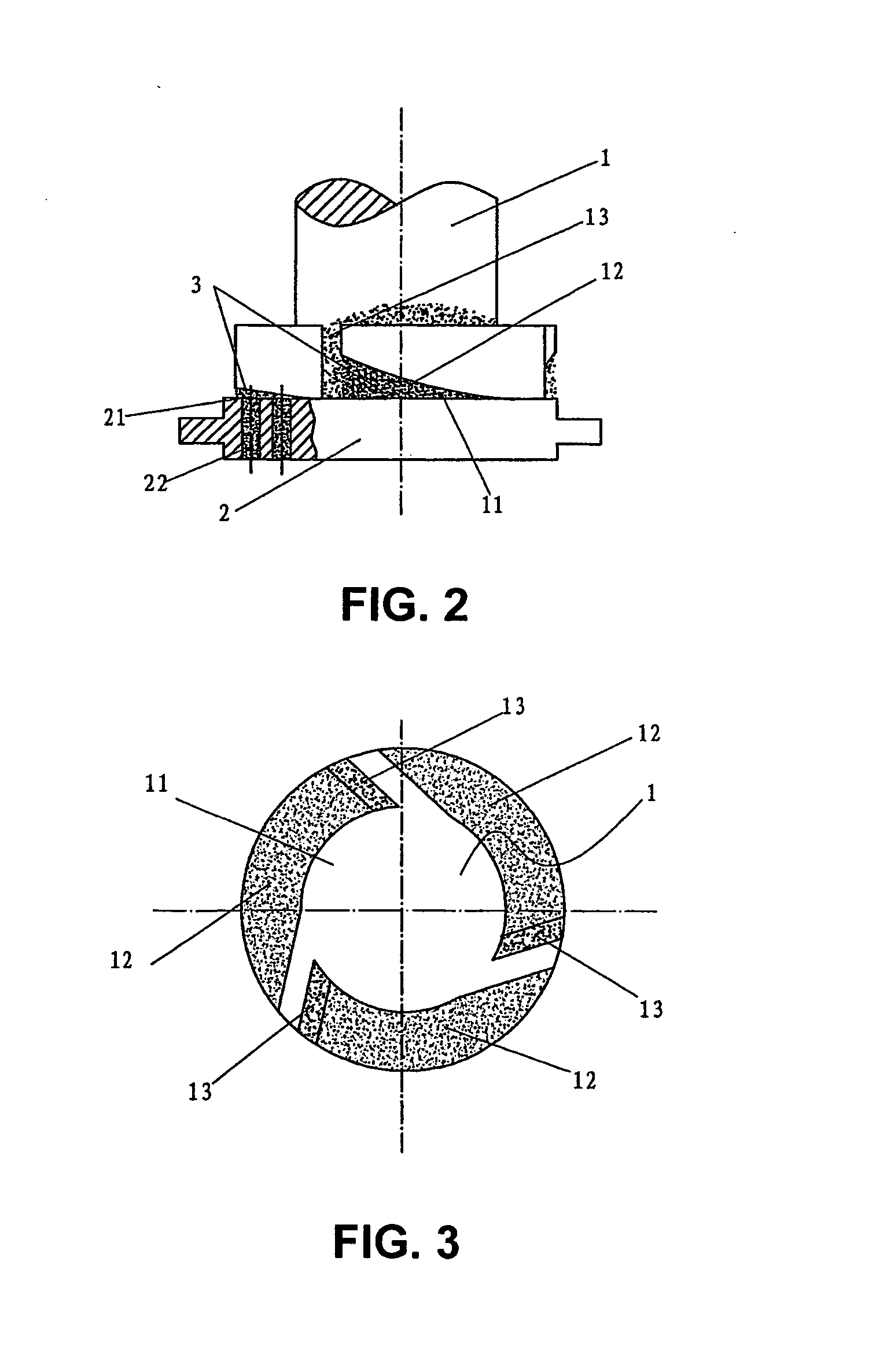

Process and a device for shaping the loosen material of raw vegetable matter

InactiveUS20060082026A1Certain linking strengthCertain water-fastnessMouldsSolid waste disposalEngineeringUltimate tensile strength

Owner:NAT HUIYUAN BIO ENERGY DEV

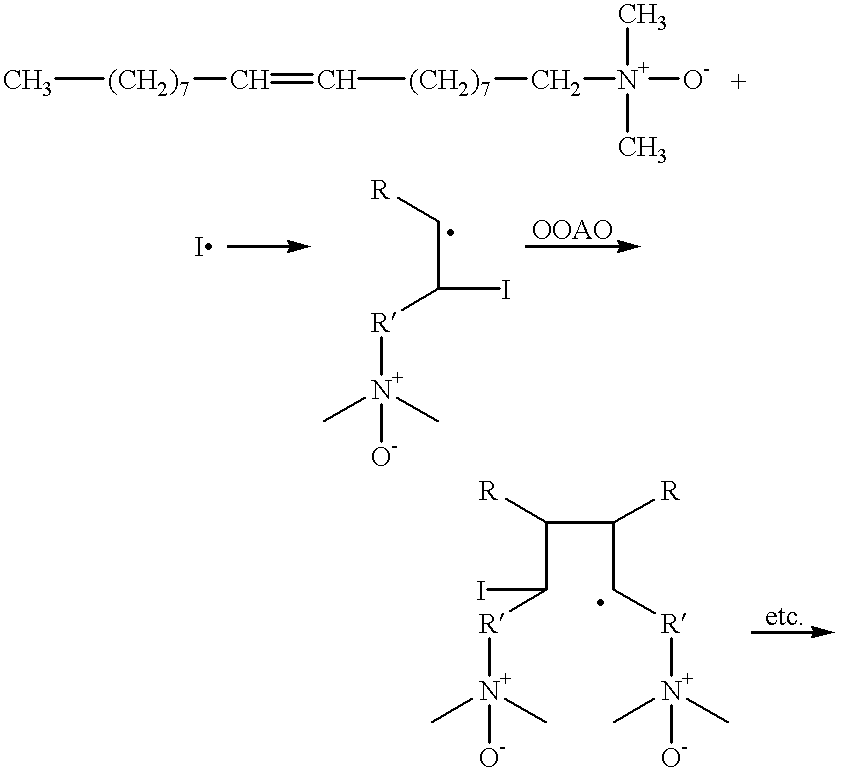

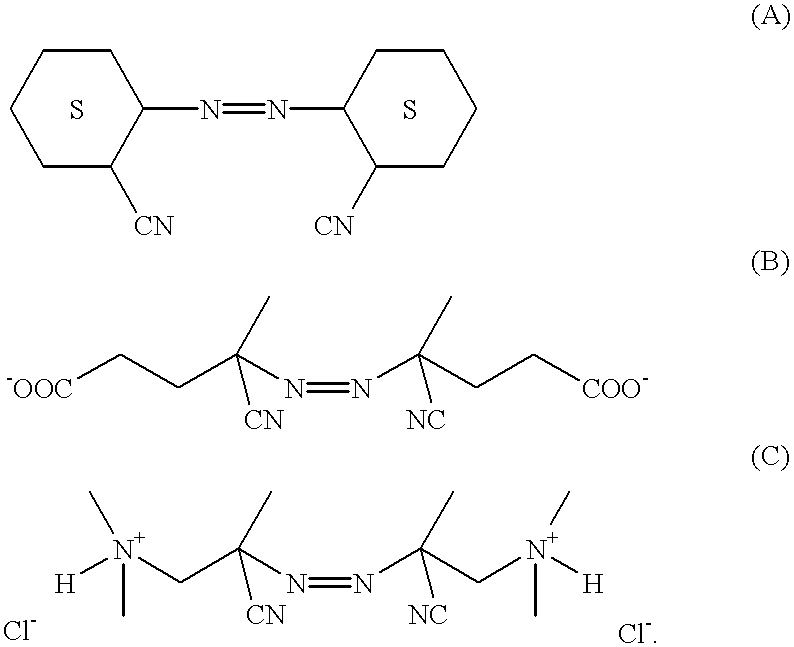

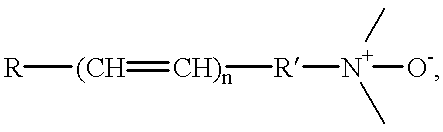

Polymers derived from unsaturated surfactants for use in ink-jet inks

InactiveUS6177485B1Improve propertyHigh molecular weightDuplicating/marking methodsInksDouble bondBleeding controls

The properties of ink-jet inks containing a colorant (pigment, macromolecular chromophore, or dye) are improved by adding thereto an additive, specifically, one or more polymers derived from unsaturated surfactants. The unsaturated surfactant(s) has at least one carbon-carbon double bond (C=C). The polymer may be simply an polymer of the unsaturated surfactant. Alternatively, the polymer may be co-polymerized with one or more vinyl monomers or one or more polymers based on the vinyl monomers may be mixed with the unsaturated surfactant polymer. The vinyl monomer(s) or polymer(s) are used to adjust or "tweak" the properties of the resultant polymer. For example, the more hydrophobic the polymer or the higher its molecular weight, then the greater the water-fastness afforded the ink-jet ink. The polymeric additive of the invention improves bleed control, water-fastness, and smear-fastness of ink-jet inks, particularly thermal ink-jet inks.

Owner:HEWLETT PACKARD DEV CO LP

Novel colorant compound, ink, ink tank, recording unit, recording apparatus and recording process

InactiveUS20050178289A1Improve reflective effectImprove solubilityOrganic chemistryMeasurement apparatus componentsPhotochemistryColoring agents

Disclosed herein are a colorant compound represented by the following general formula (1): wherein R1 and R2 are the same or different from each other and denote a linear alkyl group having 1 to 4 carbon atoms, R3 is an alkyl group having 1 to 6 carbon atoms, and An− is a counter anion, an ink comprising the colorant compound, and an ink tank, a recording unit, a recording apparatus and a recording process comprising or using the ink.

Owner:CANON KK

Ink jet ink composition

InactiveUS6139611AImproved wet abrasion resistanceExcellent water fastnessInksWater solubleOrganic chemistry

Owner:EASTMAN KODAK CO

Coloring liquid, ink tank, recording unit, recording apparatus and recording method

InactiveUS7407540B2Excellent developabilityExcellent water fastnessMeasurement apparatus componentsInksHigh colorColoring agents

A coloring liquid can form an image showing a high color developability and a high vividness as well as an excellent water fastness when used as recording material with a recording technique such as ink-jet printing. An ink tank, a recording unit, a recording apparatus and a recording method are adapted to use such a coloring liquid. Such a coloring liquid contains at least one colorant compound having a structure represented by the general formula (1) below and an ink tank, a recording unit, a recording apparatus and a recording method are adapted to use such a coloring liquid.

Owner:CANON KK

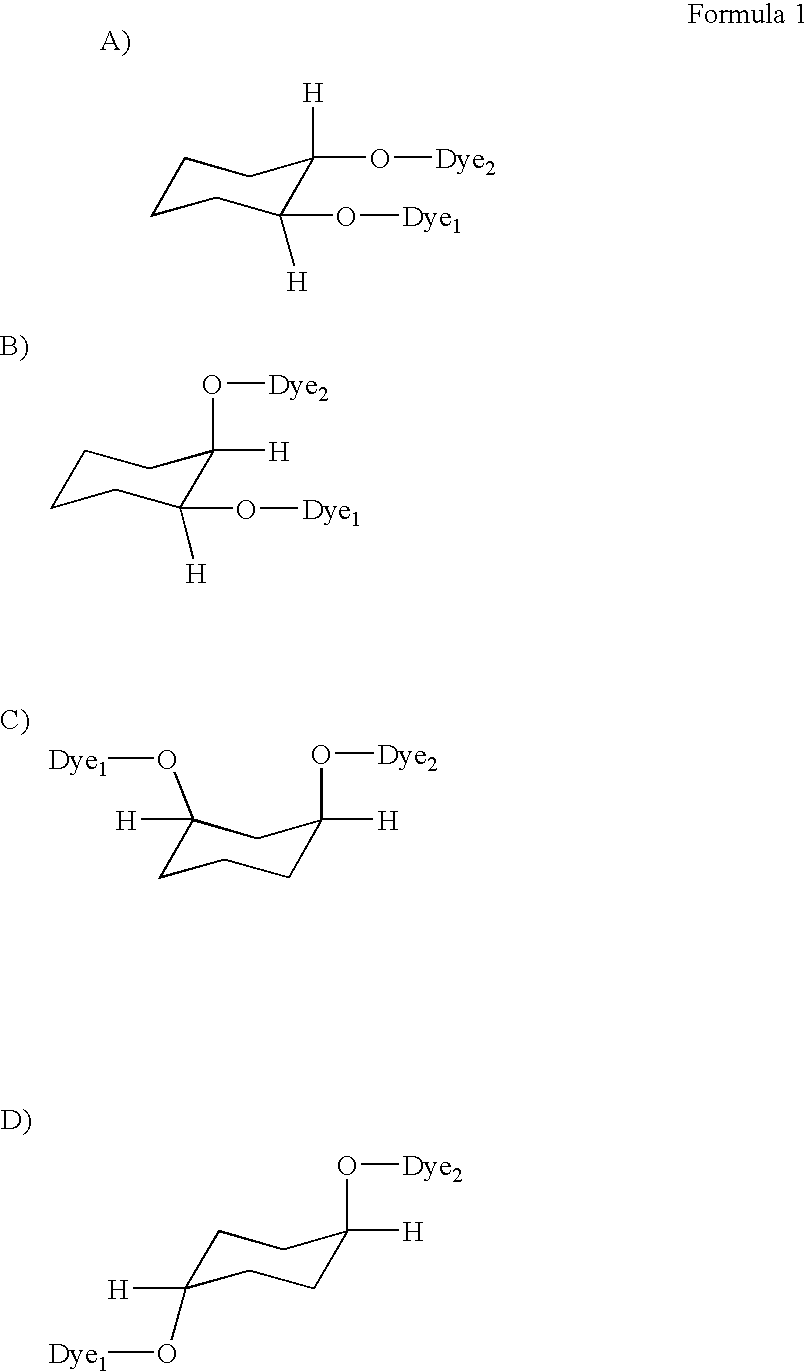

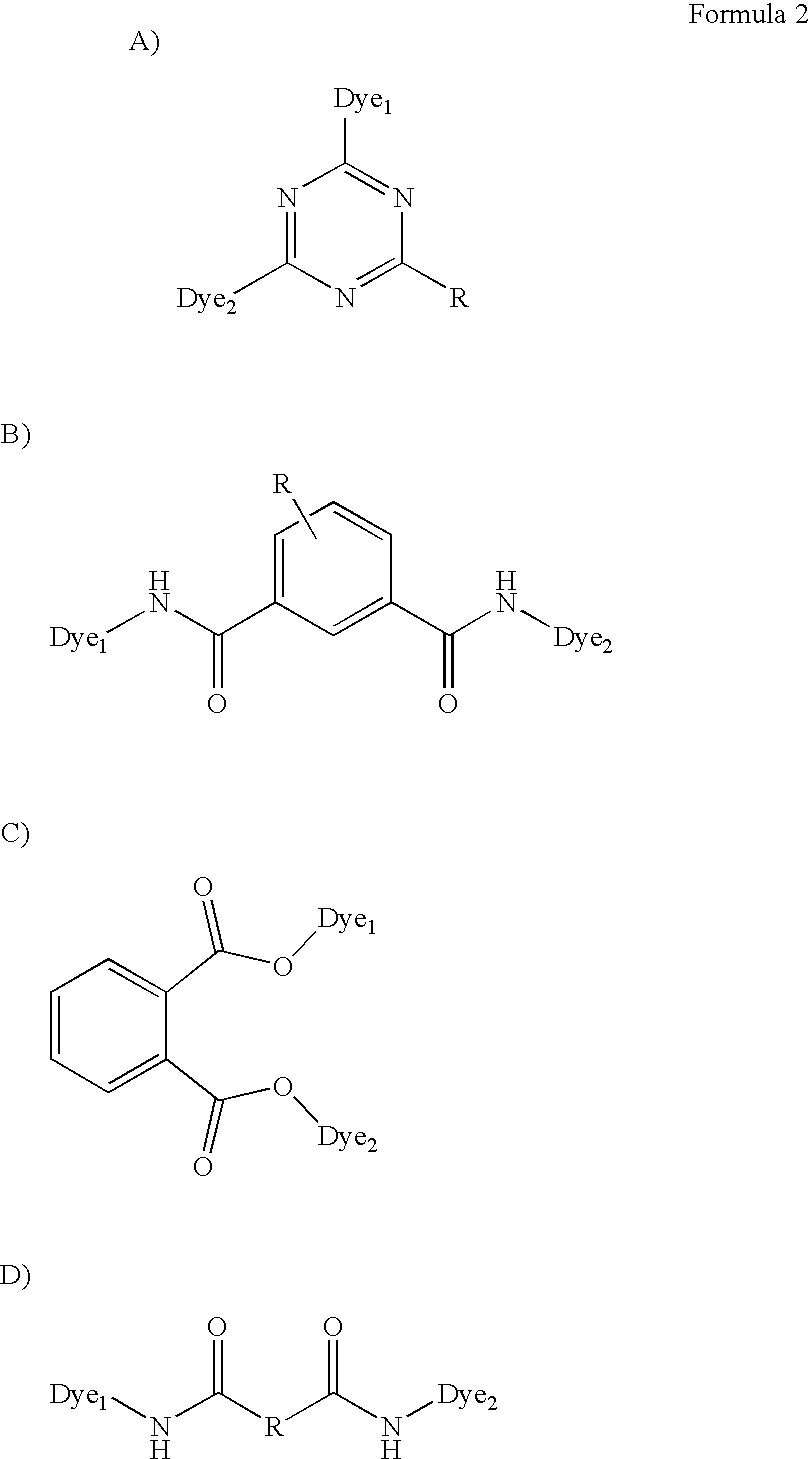

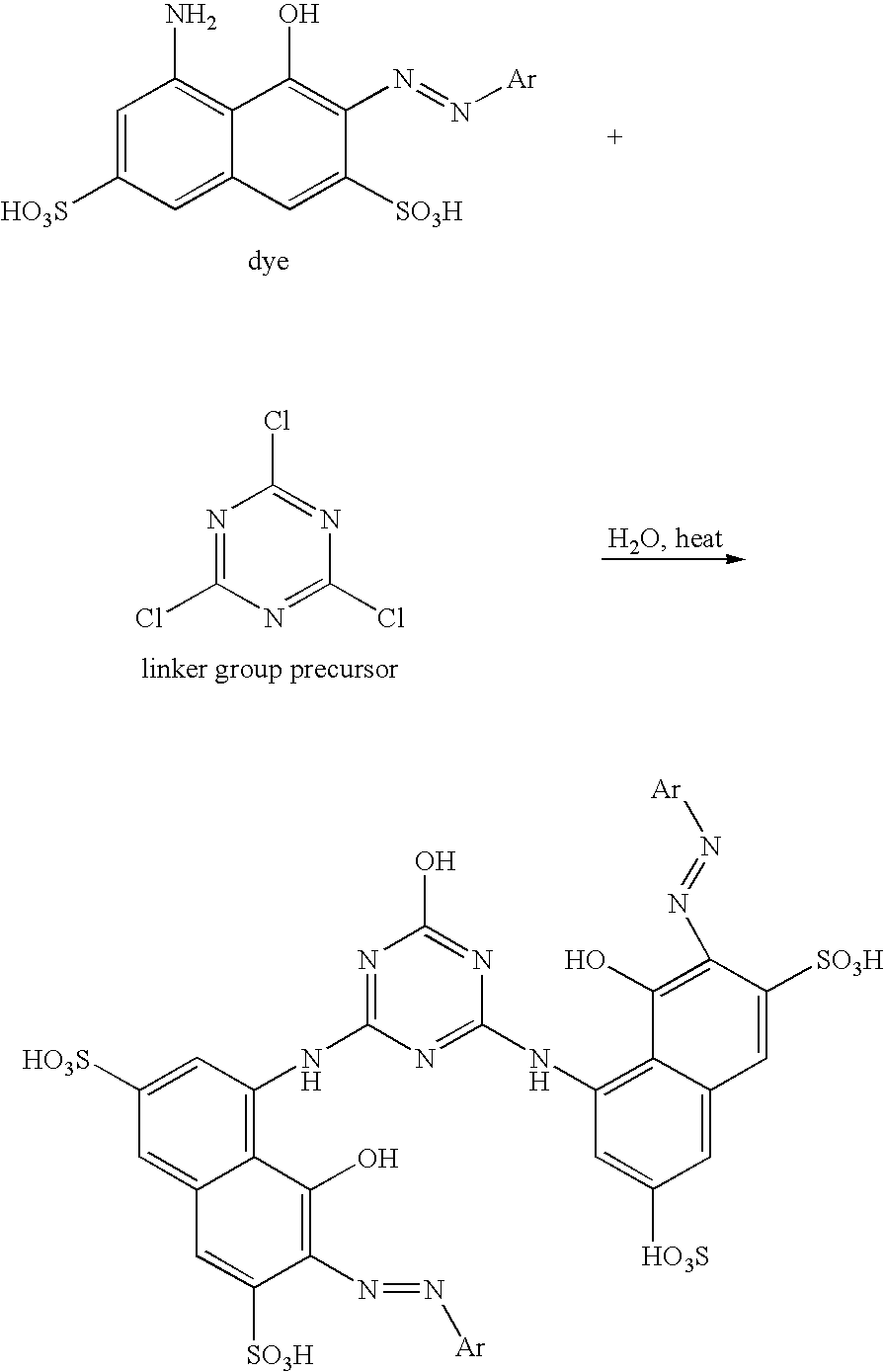

Multimeric dye structures

The present invention is drawn to multimeric dyes, ink-jet inks, and systems that can be used to print images having good water fastness and humid fastness, as well as good color characteristics. Specifically, a multimeric dye for ink-jet printing can comprise a first dye molecule chemically coupled to a second dye molecule through a linker group, wherein the multimeric dye is stable in the presence of interfering metals. These multimeric dyes can be used to form ink-jet inks and can be used in printing systems in accordance with embodiments of the present invention.

Owner:HEWLETT PACKARD DEV CO LP

Recording material with an extrusion coated PVA layer

InactiveUS20010014382A1High glossKeep dryDuplicating/marking methodsSynthetic resin layered productsPVA - Polyvinyl alcoholAqueous dispersion

A recording material for the ink-jet printing method comprises a raw base paper, an extrudable polyvinyl alcohol containing layer which is extruded on the raw base paper, and an ink-receiving layer which is applied as an aqueous dispersion or solution.

Owner:FELIX SCHOELLER TECHN PAPERS

Bright waterborne polyurethane and production method thereof

InactiveCN110305287AThe formula is scientific and rigorousThe method is simple and fastPolycarbonateChemistry

The invention relates to the technical field of production of polyurethane, and particularly discloses bright waterborne polyurethane. The bright waterborne polyurethane comprises a component A and acomponent B, wherein the component A comprises the following components in parts by weight: 70-80 parts of polycarbonate diol, 10-20 parts of polyoxypropylene triol, 30-40 parts of isophorone diisocyanate, 5-10 parts of dimethylolpropionic acid, 5-10 parts of 1,2-propanediol, 0.2-0.8 part of a catalyst, 5-10 parts of triethylamine and 200-250 parts of deionized water; and the component B comprisesthe following components in parts by weight: 70-80 parts of polycarbonate diol, 10-20 parts of polyoxypropylene triol, 20-30 parts of isophorone diisocyanate, 5-10 parts of dimethylolpropionic acid,0.2-0.8 part of a catalyst, 0.3-0.7 part of ethylenediamine, 5-10 parts of triethylamine and 180-200 parts of deionized water. According to the bright waterborne polyurethane, the defects of the priorart are overcome, use of toxic organic solvents is reduced, the situation that the toxic organic solvents volatilize to cause environmental pollution is avoided, and meanwhile, the finished product polyurethane is high in glossiness after forming a film, feels soft, and is good in color fastness to water.

Owner:安徽聚合辐化化工有限公司

Dyeing method for sofa fabrics

InactiveCN106368001AExcellent color fastness to perspirationExcellent water fastnessDyeing processPhosphateFatty alcohol

The invention discloses a dyeing method for sofa fabrics. The dyeing method includes the steps: 1) sequentially adding dimethyl formamide, N-methyl diethanol amine, sodium hexametaphosphate, magnesium sulfate and vegetable dyes into a dye vat, sequentially adding deionized water, uniformly mixing, and heating to 55 DEG C; 2) sequentially adding iminodiacetic acid, isomeric fatty alcohol polyoxyethylene ether phosphate, chitosan quaternary ammonium salt and sodium ethylene diamine tetraacetate, continuing to mix until sufficiently and uniformly blending is achieved, and heating to 65 DEG C; 3) soaking the fabrics in the dye vat for 35 minutes; 4) drying the soaked fabrics at the temperature of 80 DEG C; 5) soaking the dried fabrics in clear water to wash for 35 minutes; 6) taking out the washed fabrics to naturally dry. The fabrics dyed by the method have excellent color fastness and are good in dyeing uniformity and free from dyeing defects.

Owner:SUZHOU XIN GE HOUSEHOLD PROD CO LTD

Photocurable pigment type inkjet ink composition

ActiveUS7591890B2Maintain good propertiesExcellent water fastnessDuplicating/marking methodsOptical articlesSURFACTANT BLENDPigment particle

A photocurable pigment type inkjet ink composition including 5 to 95 wt % of water; 0.5 to 20 wt % of a pigment; 1 to 70 wt % of a photocurable component; and 0.0001 to 30 wt % of a reactive surfactant. The reactive surfactant can serve as a pigment dispersant for dispersing pigment particles or as an emulsifier for emulsifying the photocurable component.

Owner:IND TECH RES INST

Dyeing method of spandex fabric

InactiveCN106381727AExcellent color fastness to perspirationExcellent water fastnessDyeing processAcetic acidSulfonate

The invention discloses a dyeing method of spandex fabric, comprising the following steps: 1) successively adding dibutyl phthalate, diisocyanate, polypropylene glycol, butyl peroxybenzoate and vegetable dye into 1 part of deionized water in a dye vat, uniformly stirring, and heating to 55 DEG C; 2) successively pouring glycine, diisooclyl maleate sulfonate, acrylic acid ester and tetrasodium glutamate diacetate, continuously stirring until the materials are fully and uniformly mixed, and heating to 65 DEG C; 3) immersing the fabric in the dye vat for 35 min; 4) drying the immersed fabric at 80 DEG C; 5) rinsing the dried fabric in clear water for 35 DEG C; and 6) taking the rinsed fabric out of the clear water and naturally airing. The dyed fabric has excellent color fastness and good dyeing uniformity and has no dyeing defect.

Owner:SUZHOU XIN GE HOUSEHOLD PROD CO LTD

Quilt cover fabric dyeing method

InactiveCN106400532AExcellent color fastness to perspirationExcellent water fastnessDyeing processAlcoholSulfate

The invention discloses a quilt cover fabric dyeing method. The method comprises the steps of: 1) adding calcium sulfate, aspartic acid, sodium polyacrylate, titanium dioxide and vegetable dyes into deionized water in a dye vat in order, stirring the substances evenly, and performing heating to 55DEG C; 2) then adding beta-alanine, secondary alcohol ethoxylate, sodium silicate and ferrous sulfate, further conducting stirring until the substances are fully and evenly mixed, and performing heating to 65DEG C; 3) soaking the fabric in the dye vat for 35min; 4) drying the well soaked fabric at 80DEG C; 5) immersing the dried fabric in clear water and performing rinsing for 35min; and 6) taking out the rinsed fabric and conducting natural airing. According to the method provided by the invention, the dyed fabric has excellent color fastness and good dyeing uniformity, and is free of dyeing defect.

Owner:SUZHOU XIN GE HOUSEHOLD PROD CO LTD

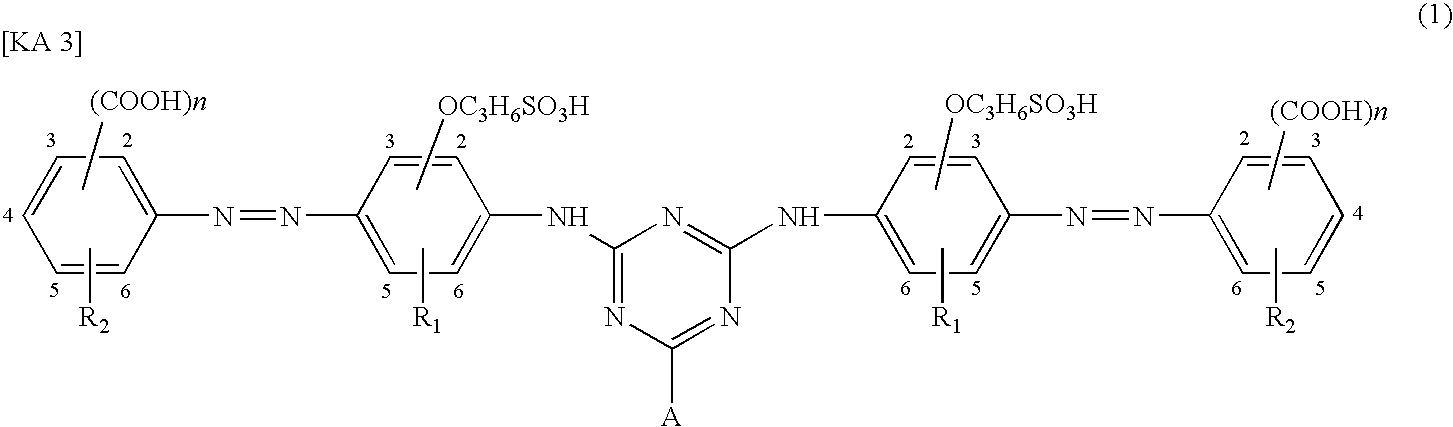

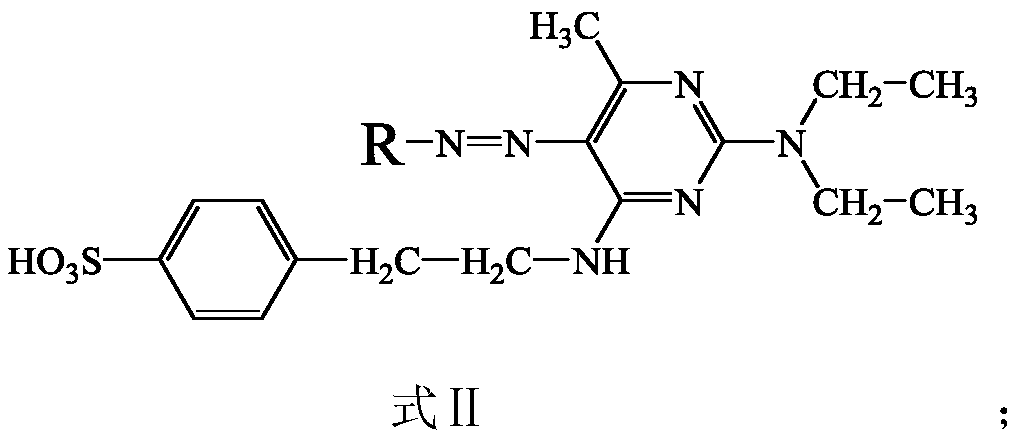

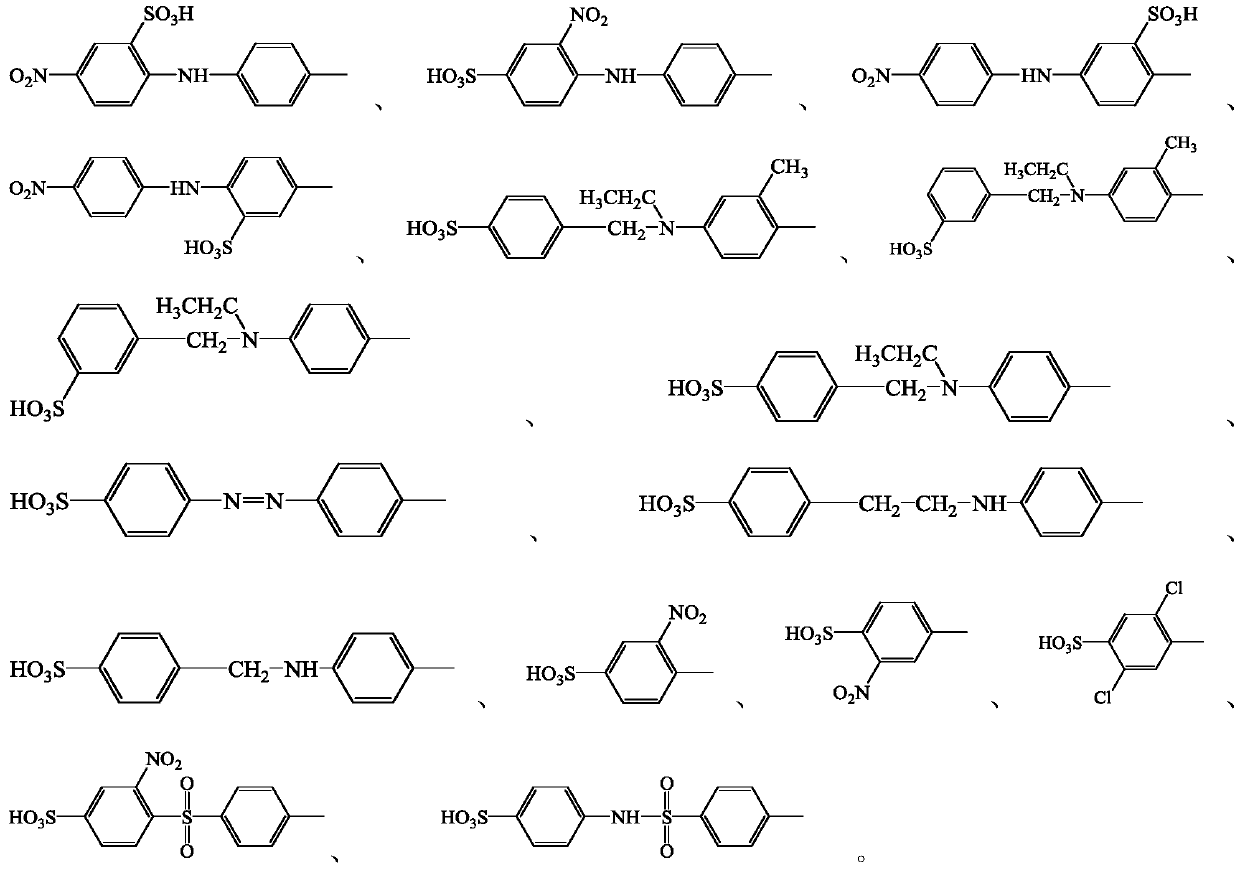

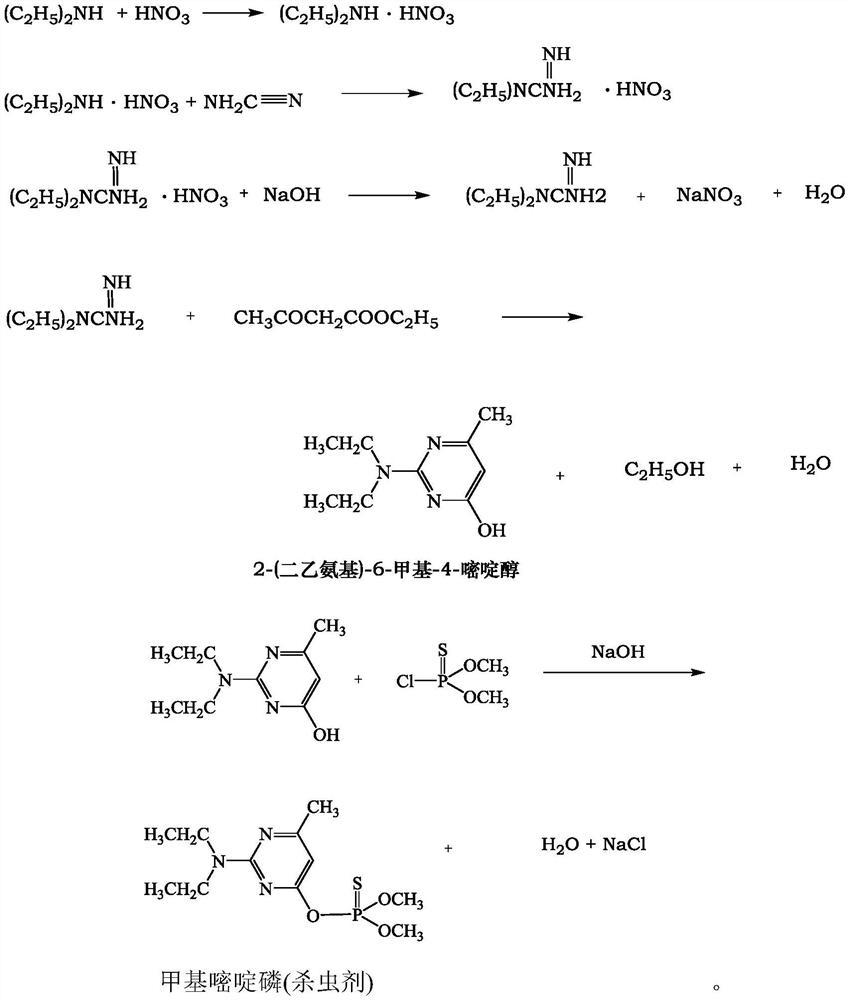

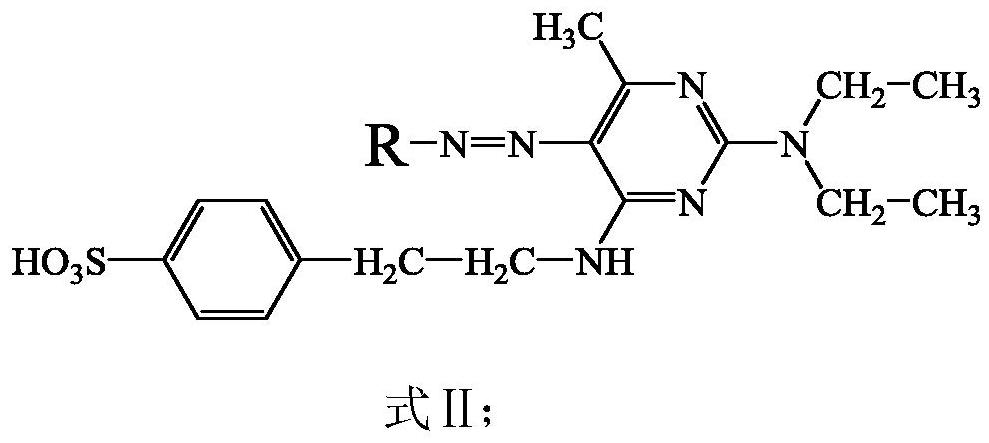

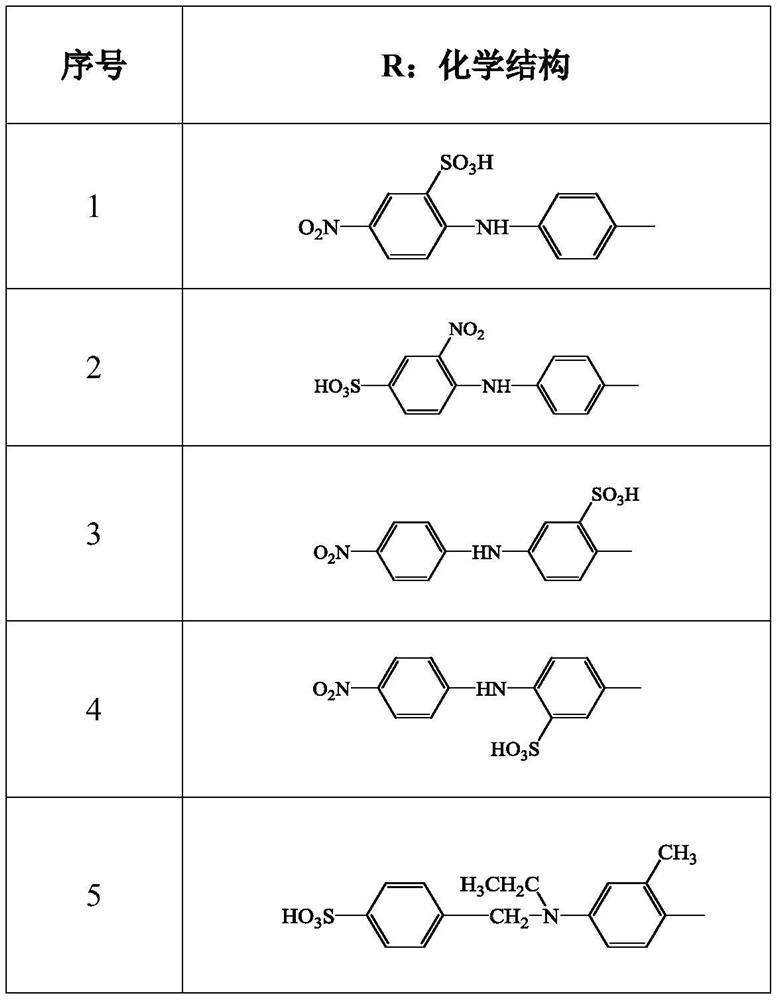

Acidic dye for polyamide fiber dyeing and preparation method thereof

The invention discloses an acidic dye for polyamide fiber dyeing. The chemical structure general formula of the acidic dye is shown in the specification, wherein R serving as a diazonium component isan aromatic sulfonic acid group. The invention also provides a preparation method of the acidic dye. The acidic dye prepared by the invention contains no heavy metal, and has excellent water treatmentfastness, excellent light fastness and bright color light when being used as a novel acidic dye for dyeing polyamide fibers.

Owner:JINHUA SHUANGHONG CHEM CO LTD

Acid dye for nylon fiber dyeing and preparation method thereof

Owner:JINHUA SHUANGHONG CHEM CO LTD

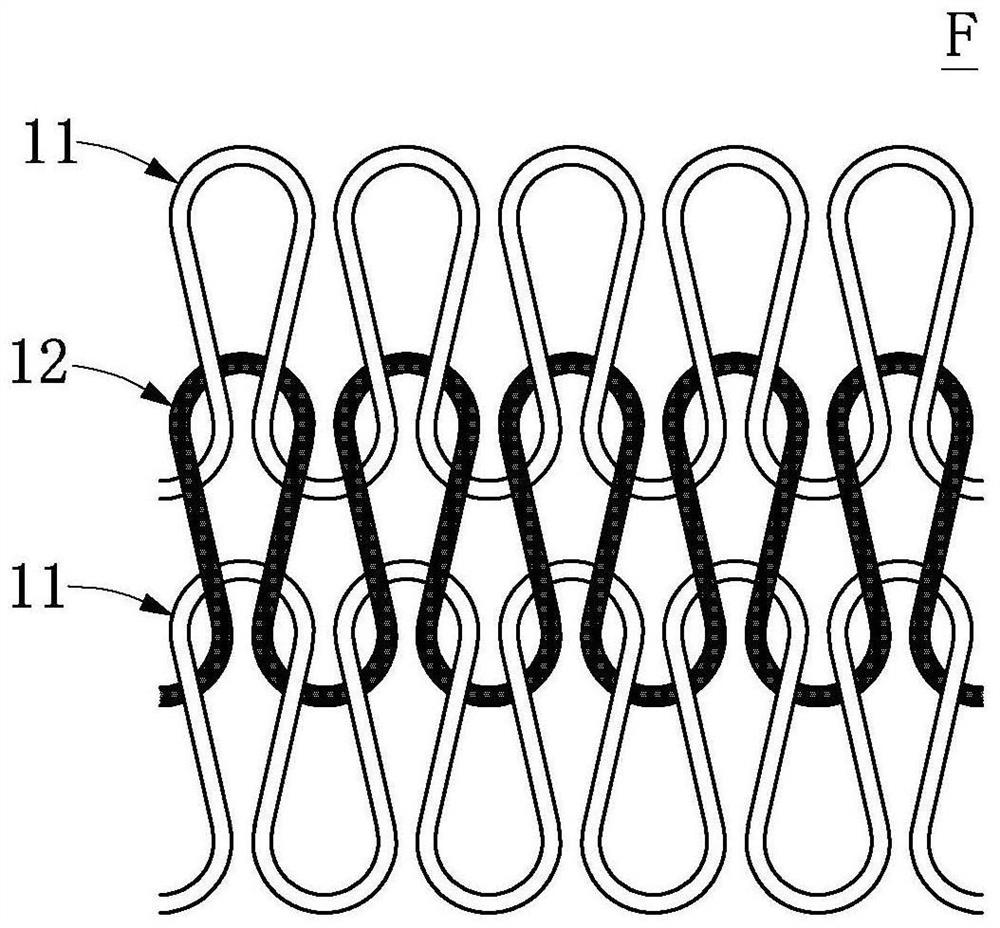

Heat storage fiber fabric and preparation method thereof

PendingCN113882077ASimple manufacturing methodImprove production efficiencyWarp knittingConjugated synthetic polymer artificial filamentsYarnFiber

The invention relates to a heat storage fiber fabric and a preparation method thereof. The heat storage fiber fabric is characterized by being formed by stranding and weaving polyester yarns and heat storage yarns; the weight percentage content of the heat storage yarns in the fabric is 30-45 wt%; and the heat storage yarns are prepared from the following components in parts by weight through a solution composite spinning method: 5-8 parts of pumice powder, 10-20 parts of far infrared ceramic powder, 15-20 parts of hyperbranched polyglycerol, 2-4 parts of a coupling agent, 1-3 parts of graphene quantum dots and 60-80 parts of hydroxyl-terminated hyperbranched polyester. The heat storage fiber fabric disclosed by the invention is good in heat storage effect, good in wearing comfort and excellent in water fastness, skin friendliness and durability.

Owner:CHANGSHU XINXIN WARP & KNITTING

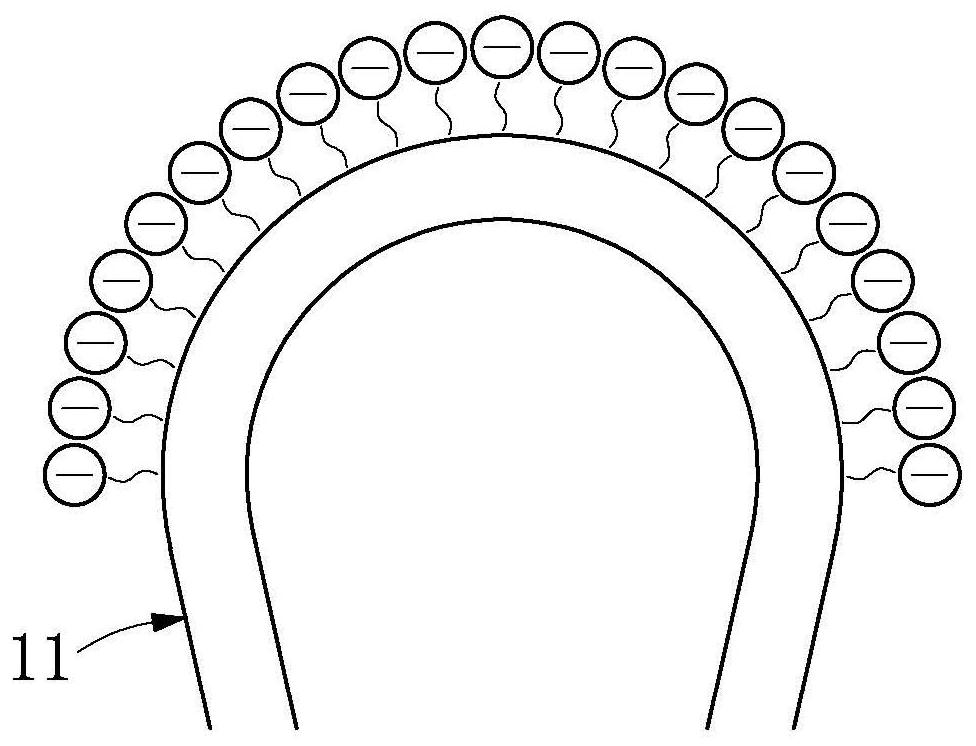

Dyeing and finishing composition and dyeing and finishing method for elastic cloth

The invention discloses a dyeing and finishing composition and a dyeing and finishing method for elastic cloth. The dyeing and finishing method for the elastic cloth comprises the following steps of (a) providing the elastic cloth which comprises elastic fibers; and (b) impregnating the elastic cloth in the dyeing and finishing composition. The dyeing and finishing composition comprises an ion modifier and a dye, wherein the elastic fibers of the elastic cloth have first ions with first charge by contacting with the ion modifier, the dye has second ions, and the second ions have second chargeopposite to the first charge. Ionic bonds are generated between the first ions of the elastic fibers and the second ions of the dye for bonding, so that the dyed and finished elastic cloth can be obtained. Therefore, a traditional coloring mode depending on pollution of the elastic fibers can be improved, and the water fastness, the washing fastness, the perspiration fastness and the rubbing fastness can be kept at the optimal level.

Owner:TEX TILE ENTERPRISE CO LTD

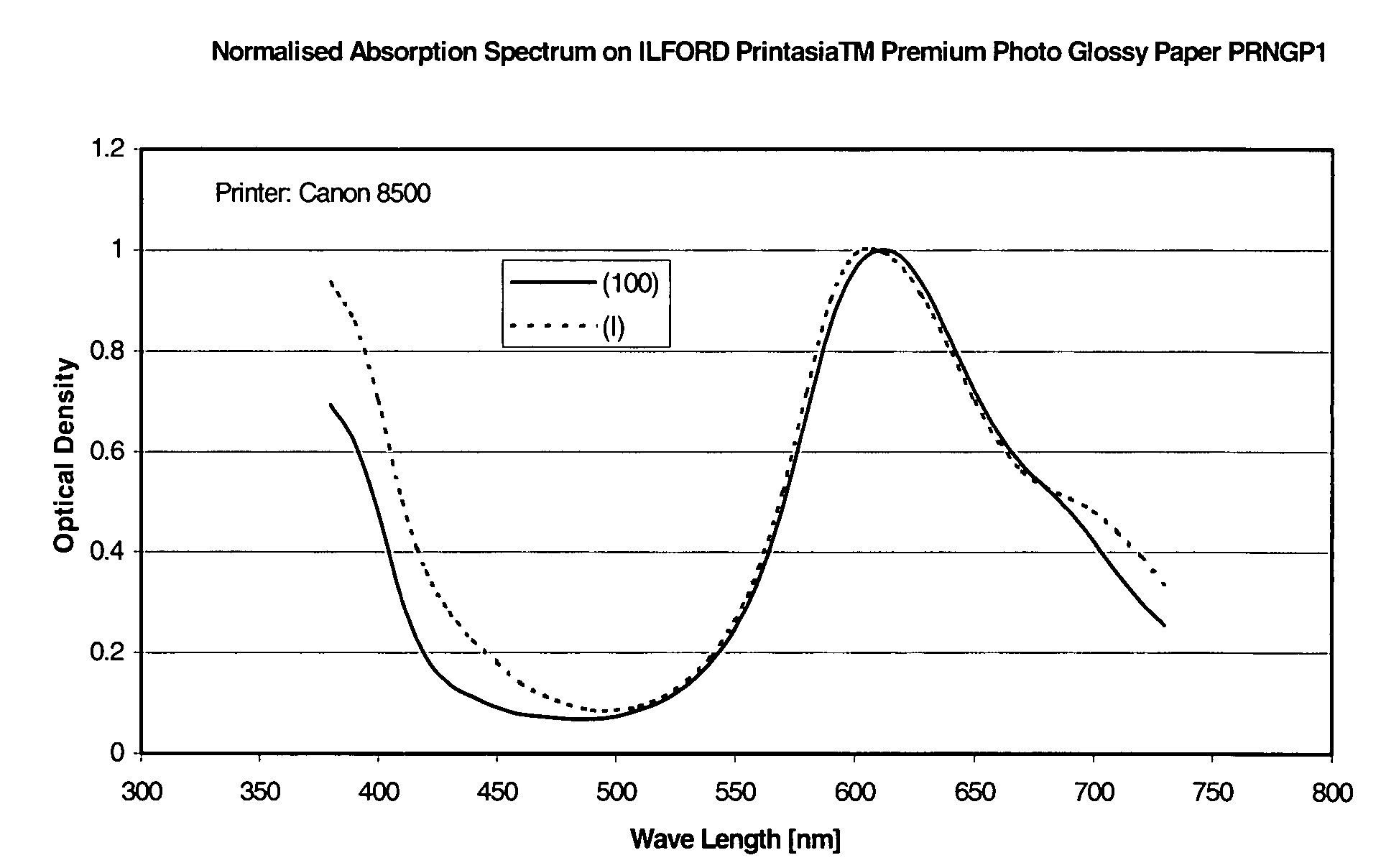

Phthalocyanine dyes and their preparation and use

InactiveUS7632345B2Good stability against degradationSuitable hueMeasurement apparatus componentsReactive dyesPolymer sciencePhthalocyanine dye

Phthalocyanine dyes of general formula (II)and, in particular, of general formula (III)wherein R1-R8, R9-R12, Me, M, m, n, o and p are as defined in the specification, are excellent dyes for dying and printing cellose containing materials and textile materials, and especially, for the preparation of inks for ink jet printing.

Owner:ILFORD IMAGING SWITZERLAND GMBH

Black ink composition, ink cartridge including the ink composition and ink jet recording apparatus including the ink cartridge

A black ink composition includes a mixture of an azo metal complex dye having a good light fastness and water fastness and an adjective dye. The ink composition has a neutral black gradation, a high optical density and a good decap performance at a print head of an inkjet printer while printing. An inkjet cartridge for inkjet printing includes the black ink composition, and a recording apparatus for inkjet printing including the ink cartridge are also provided.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com