Disperse dye composition, dye product and application

A technology of disperse dyes and compositions, applied in the direction of organic dyes, dyeing methods, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] 23 grams of the original dye shown in the formula (1-1), 24 grams of the original dye shown in the formula (1-3), 1 gram of the original dye shown in the formula (2-1), and the 2.0 grams of the original dye shown, 70 grams of dispersant MF, and 200 grams of pure water are micronized with a sand mill (for dispersion treatment), and then spray-dried to obtain the disperse dye product of the navy blue disperse dye composition of the present invention . Based on the original dyes used, the mass fraction of component A represented by formula (1-1) and formula (1-3) is 94%, and the mass of component B represented by formula (2-1) and formula (2-2) The share is 6%.

[0094]

Embodiment 2~10

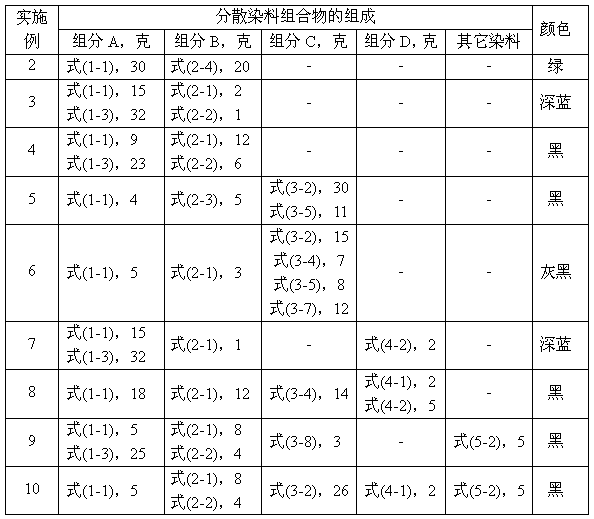

[0096] According to the data shown in Table 1, each disperse dye component, 70 grams of dispersant MF and 200 grams of water were ground and dispersed with a sand mill, and then spray-dried to make a disperse dye product.

[0097] Table 1

[0098]

Embodiment 11

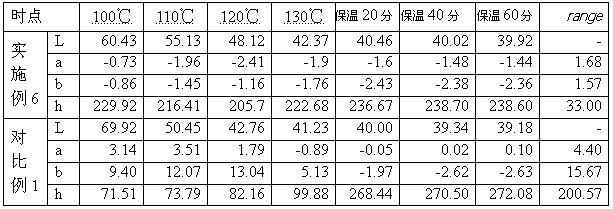

[0100] Get 0.4 gram of the disperse dye product (owf=8%) that embodiment 1~10 makes, 0.15 gram of glacial acetic acid (2g / l) and 0.15 gram of super stabilizer EL-SF (2g / l), be made into 75 milliliters dyeing Add 5.0 grams of polyester microfiber and spandex (12%) blended fabric (commonly known as T+OP fabric, which needs to be pre-shaped and scouring to remove oil before dyeing) for dyeing, and the temperature is raised from room temperature to 130°C within 30 minutes. Keep warm for 60 minutes, take out the fabric when it cools down to below 80°C, soap and reduce it with heat (60-85°C), dry it, and set it at 180°C for 30 seconds to get a deep color.

[0101] According to the 2A method stipulated in AATCC 61-2007 color fastness to home and commercial washing, GB / T5713-1997 textile color fastness test to water color fastness (equivalent to ISO 105-E01), GB / T5718-1997 textile Test method for color fastness to dry heat (sublimation) (equivalent to ISO 105-P01), literature "'Improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com