Disperse dye composition, dye product and application thereof

A technology of disperse dyes and compositions, applied in organic dyes, dyeing methods, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

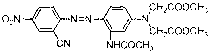

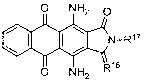

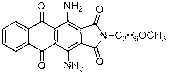

[0097] 35.0 grams of the original dye shown in the formula (1-1), 2.4 grams of the original dye shown in the formula (1-2), 1.8 grams of the original dye shown in the formula (2-5), and the 10.8 grams of the original dye shown, 70 grams of dispersant MF, and 200 grams of pure water were used for micronization (dispersion treatment) with a sand mill, and then spray-dried to obtain a yellow-brown disperse dye composition. Based on the original dyes used, the mass fraction of component A represented by formula (1-1) and formula (1-2) is 74.8%, and the mass fraction of component B represented by formula (2-5) and formula (2-7) was 25.2%.

[0098] The dispersion stability of the disperse dye of the present invention at 71°C and 130°C was tested respectively according to GB / T 5540 and GB / T 5541-2007 by double-layer filter paper filtration method. Among them, the "residue" level at 71°C is level 4, and the "filtration time" level is level A; at 130°C, the "residue" level is still le...

Embodiment 2~20

[0106] According to the data shown in Table 1, Component A, Component B, Component C, Component D, Component E, Component F, 70 grams of dispersant MF and 200 grams of water were ground and dispersed with a sand mill chemical, and then spray-dried to make disperse dyes.

[0107] Table 1 :

[0108]

Embodiment 21

[0110] Get 0.25 gram of the disperse dye (owf=5%) that embodiment 1~20 makes and 0.075 gram of glacial acetic acid (1g / l), be made into 75 milliliters of dye liquors, put into 5.0 gram of polyester superfine fibers and spandex (12% ) blended fabric (commonly known as T+OP fabric, the gray fabric has been pre-set and scoured at 180-195°C) for dyeing, heated from room temperature to 130°C within 60 minutes, kept warm for 45 minutes, and took out the fabric when cooled to below 85°C. Treat the fabric with sodium dithionite and sodium hydroxide at 85°C for 20 minutes, then treat the fabric with an acidic reducing agent (such as hydroxyalkylsulfinate) at a pH of 3.5 to 5.0 at 85°C for 20 minutes, rinse with water, After drying, dry heat setting at 160°C for 30 seconds to obtain a deep colored fabric.

[0111] According to the 2A method stipulated in AATCC 61-2007 color fastness to home and commercial washing, GB / T5713-1997 textile color fastness test to water color fastness (equiva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com