Acid dye for nylon fiber dyeing and preparation method thereof

An acid dye, nylon fiber technology, applied in azo dyes, organic dyes, monoazo dyes, etc., can solve the problems of waste water discharge, non-bright fibers, and dark color of metal complex dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

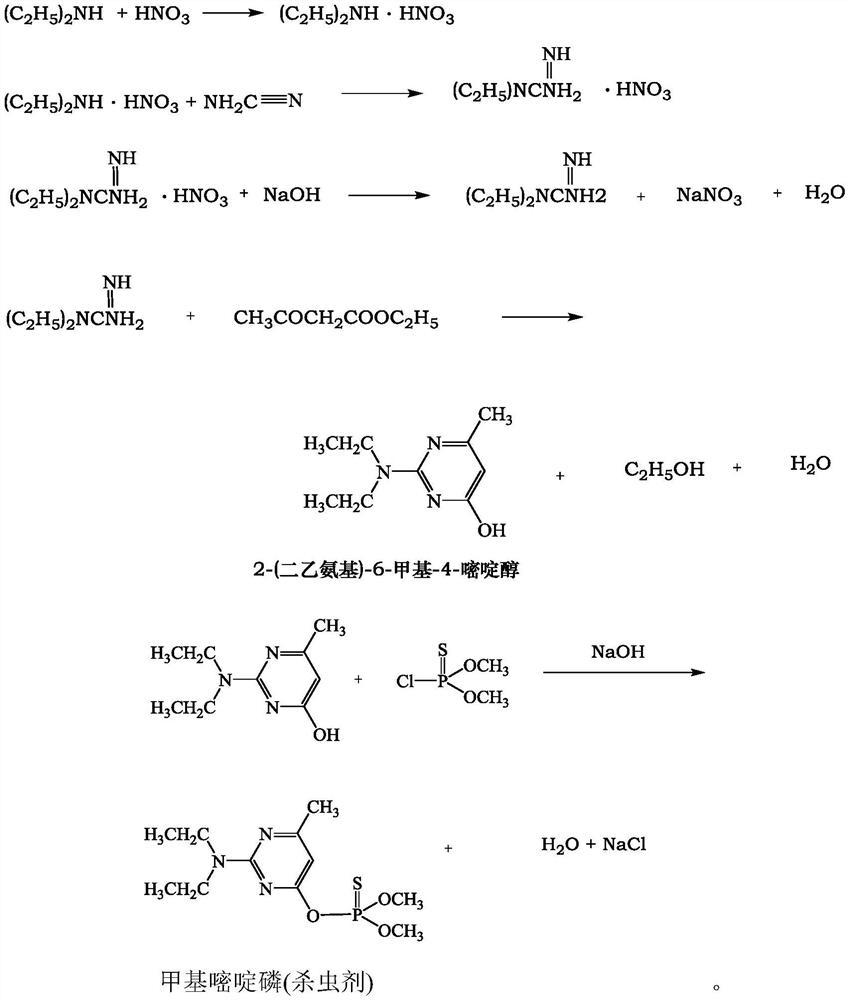

[0042] C 17 h 24 N 4 o 3 S, molecular weight: the preparation method of 364.46], carries out following steps successively:

[0043] 1), the synthesis of 2-(diethylamino)-6-methyl-4-pyrimidinol

[0044]In 250mL of water, nitric acid (9.45g, 0.15mol) was slowly added dropwise (the dropping time was about 10 minutes), then diethylamine (10.22g, 0.14mol) was added dropwise (the dropping time was about 30 minutes), and stirred for 1.5 After h, cyanamide (12.60 g, 0.3 mol) was added dropwise (the dropping time was about 30 minutes), then the temperature was raised to 75° C., and the reaction was carried out for 5 hours. Immediately after the reaction, the reactant was cooled to below 5°C with an ice-water bath, cooled and precipitated, filtered, and the filter cake was dried at 80°C to constant weight to obtain a white solid (diethylguanidine nitrate). Dissolve the white solid in a mixed solvent consisting of 100ml of toluene and 30ml of ethanol, add 6g of NaOH (0.16mol) to con...

Embodiment 1

[0053] 1), diazotization:

[0054] 2-((4-aminophenyl)amino)-5-nitrobenzenesulfonic acid [2-((4-aminophenyl)amino)-5-nitrobenzenesulfonic acid; molecular formula: C 12 h 11 N 3 o 5 S; Molecular weight: 309.30] 30.93g (0.1mol) is dissolved in 400ml water, with 10% (mass %) sodium hydroxide aqueous solution, adjust pH=7.5, add sodium nitrite 7g (0.104mol) and stir until dissolving completely, ice bath Cool down to 0°C, then add to a solution consisting of 200g of crushed ice and 26g of 30% (0.21mol) hydrochloric acid, the addition time is 30 minutes, the temperature is controlled at 0 to 5°C during the addition, and after the addition is completed, the temperature is 0 to 5 ℃ and keep stirring for 60 minutes, the diazotization is completed, and the obtained diazonium salt solution is set aside.

[0055] 2), coupling

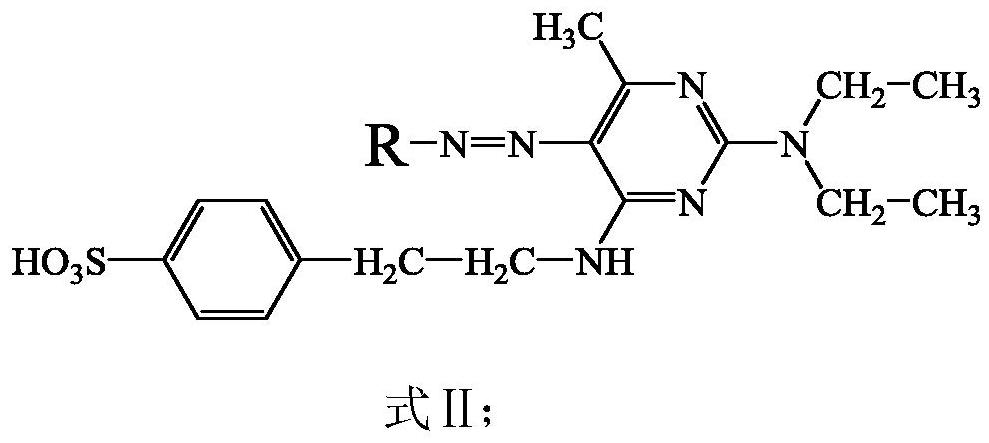

[0056] 4-(2-((2-(Diethylamino)-6-methylpyrimidin-4-yl)amino)ethyl)benzenesulfonic acid [4-(2-((2-(diethylamino)-6- methylpyrimidin-4-yl)amino)ethyl)benzenesul...

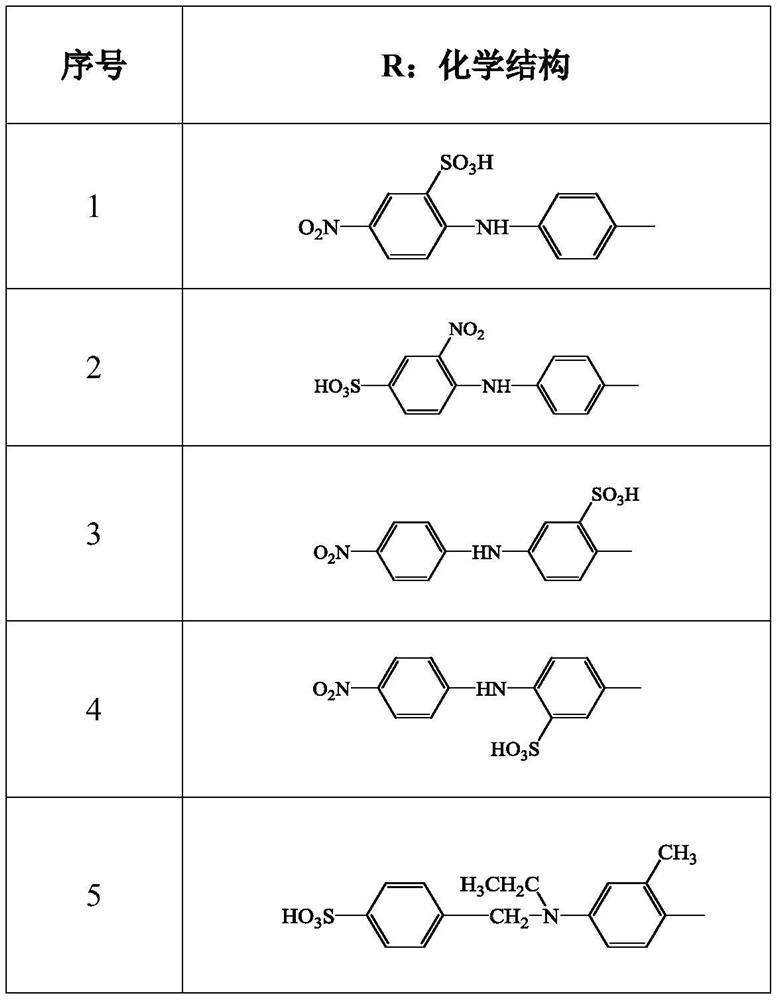

Embodiment 2~4

[0061] The 2-((4-aminophenyl)amino)-5-nitrobenzenesulfonic acid in step 1) of Example 1 was respectively replaced with 3-nitro-4-(4-aminophenylamino)benzenesulfonic acid [English name: 4-((4-aminophenyl)amino)-3-nitrobenzenesulfonic acid, molecular formula: C 12 h 11 N 3 o 5 S, molecular weight: 309.30], 30.93g (0.1mol), 2-amino-5-((4-nitrophenyl) amino) benzenesulfonic acid [English name: 2-amino-5-((4-nitrophenyl) amino)benzenesulfonic acid, molecular formula: C 12 h 11 N 3 o 5 S Molecular weight: 309.30], 30.93g (0.1mol), 5-nitro 2 ((nitrophenyl) amino) benzenesulfonic acid [English name: 5-amino-2-((4-nitrophenyl) amino) benzenesulfonic acid , molecular formula: C 12 h 11 N 3 o 5 S molecular weight: 309.30] 30.93g (0.1mol) replaces, and molar dosage remains unchanged; All the other are equal to embodiment 1; Thereby obtain the dyestuff of following chemical structure II-2, II-3, II-4 respectively:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com