Dyeing and finishing composition and dyeing and finishing method for elastic cloth

A composition and fabric technology, applied in dyeing and finishing compositions for elastic fabrics and in the field of dyeing and finishing, can solve the problems of incongruity of different colors of fabrics, achieve good water fastness, and improve the effect of dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

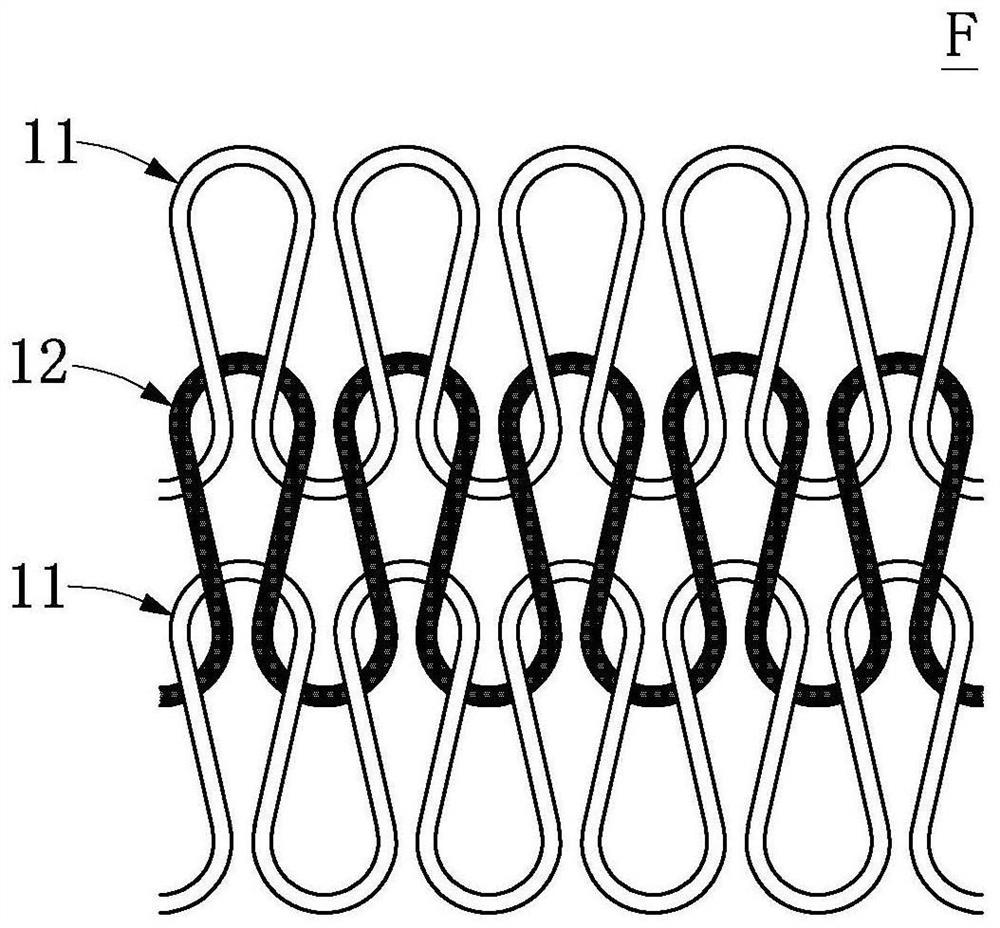

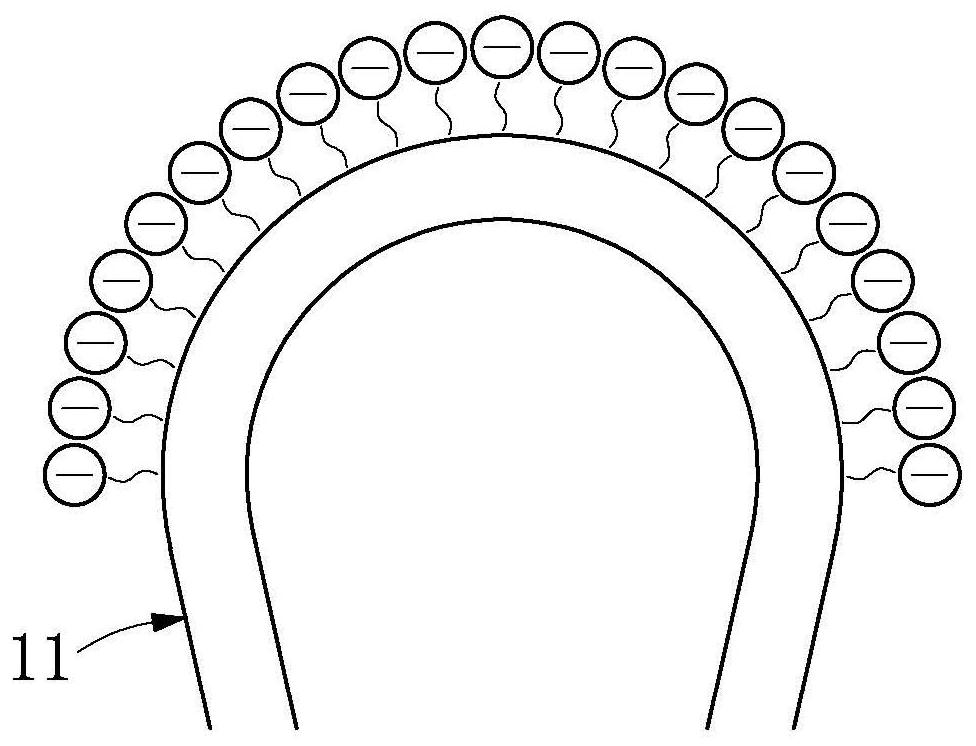

[0039] 1. Cloth: prepare elastic cloth containing 43wt.% elastic fiber, and prepare a dyeing and finishing composition.

[0040] 2. Dye composition: Dissolve the dye LANASYN Turquoise M-5G in the water of the dyeing machine, adjust to a concentration of 0.5wt.%, add 0.15wt.% ion modifier, 0.5% dye retarder, and adjust the pH value to 4.

[0041] 3. Temperature curve: The initial temperature is room temperature, and the dyeing and finishing composition is heated to a dyeing temperature between 85 and 115°C at a heating rate of 0.5 to 1.0°C / min, and the prepared elastic fabric is added to the dyeing machine , and maintain for 20 to 60 minutes. The dyeing and finishing composition is cooled to a temperature between 70 and 60°C at a cooling rate of 1 to 1.5°C / min.

[0042] 4. Washing: Wash the dyed and finished elastic fabric with water to remove excess dye. The washing time is about 3 minutes, preferably until no pigment is leached out visible to the naked eye.

[0043] 5. Col...

Embodiment 2 to 4

[0049] The detailed steps are as described in the first embodiment. In addition, in the following examples, the same elastic cloth as in Example 1 and different concentrations of ion modifiers were also used for experiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com