Patents

Literature

157 results about "Disperse yellow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

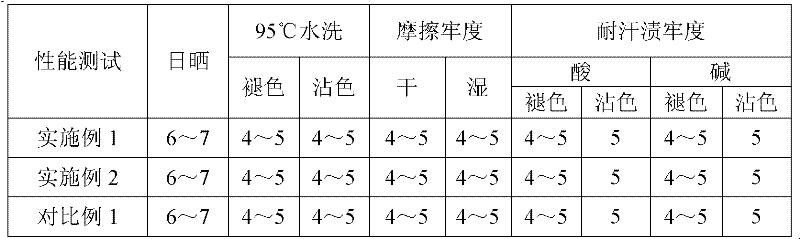

The dyes producing the most reactions were Disperse Blue 124, Disperse Red 1, Disperse Orange 3, and Disperse Yellow 3. Patch testing of the eczematous patients with these four dyes and a standard series elicited reactions in 19 with eight patients reacting to dyes only.

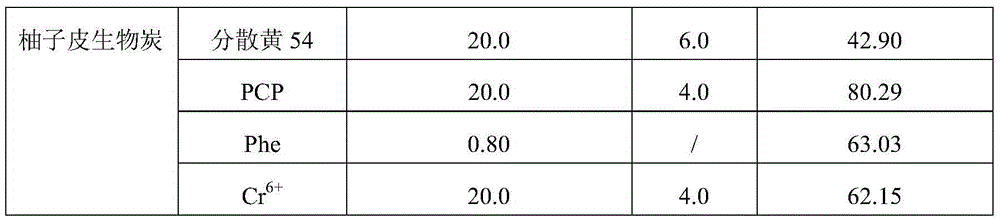

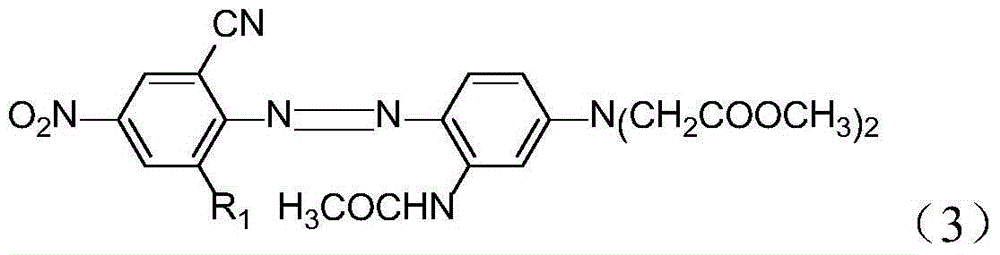

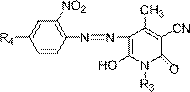

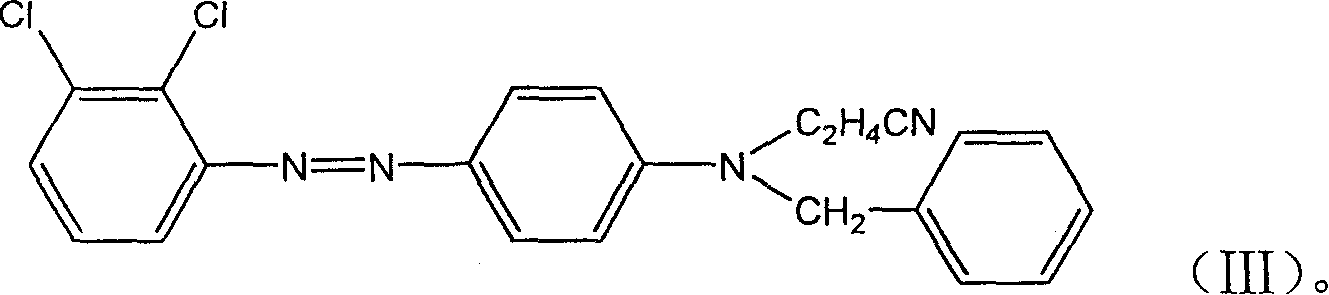

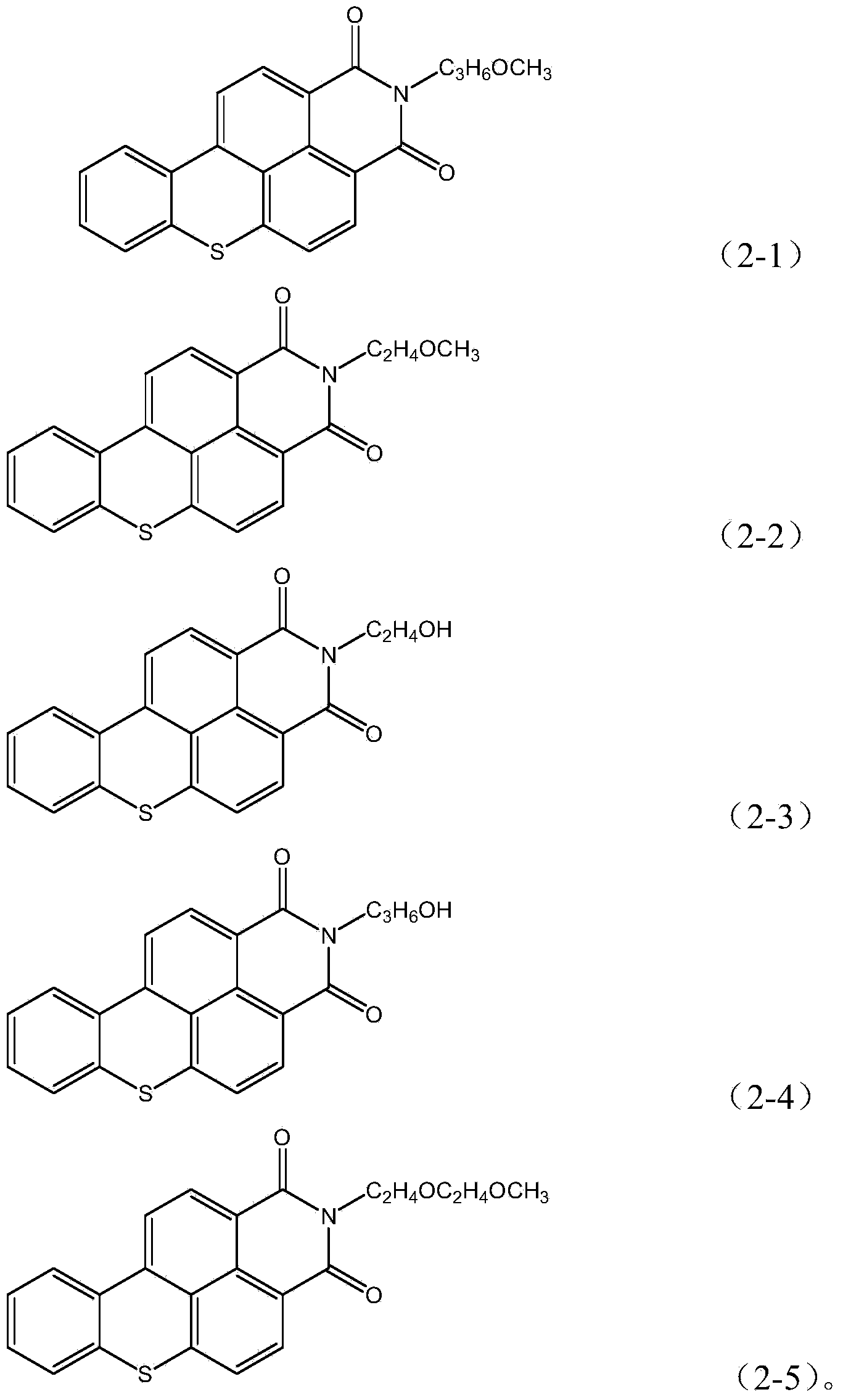

Disperse yellow-brown dye composition and disperse dye

The disperse yellow-brown dye composition and corresponding disperse dye are provided. The disperse yellow-brown dye composition consists of component A in 1-99 wt% and component B in 1-99 wt% basically, with the structures of component A and component B being shown. The disperse yellow-brown dye composition may be treated into liquid state with particle, emulsion, powder or granule. The disperse yellow-brown dye based on the disperse blue dye composition is used in dyeing polyester fiber material, and through regulating the ratio of different components, excellent yellow to orange dyed fabric with bright color, excellent dispersivity, sunfast property, water resistance, sweat resistance and other advantages may be obtained.

Owner:ZHEJIANG LONGSHENG GROUP

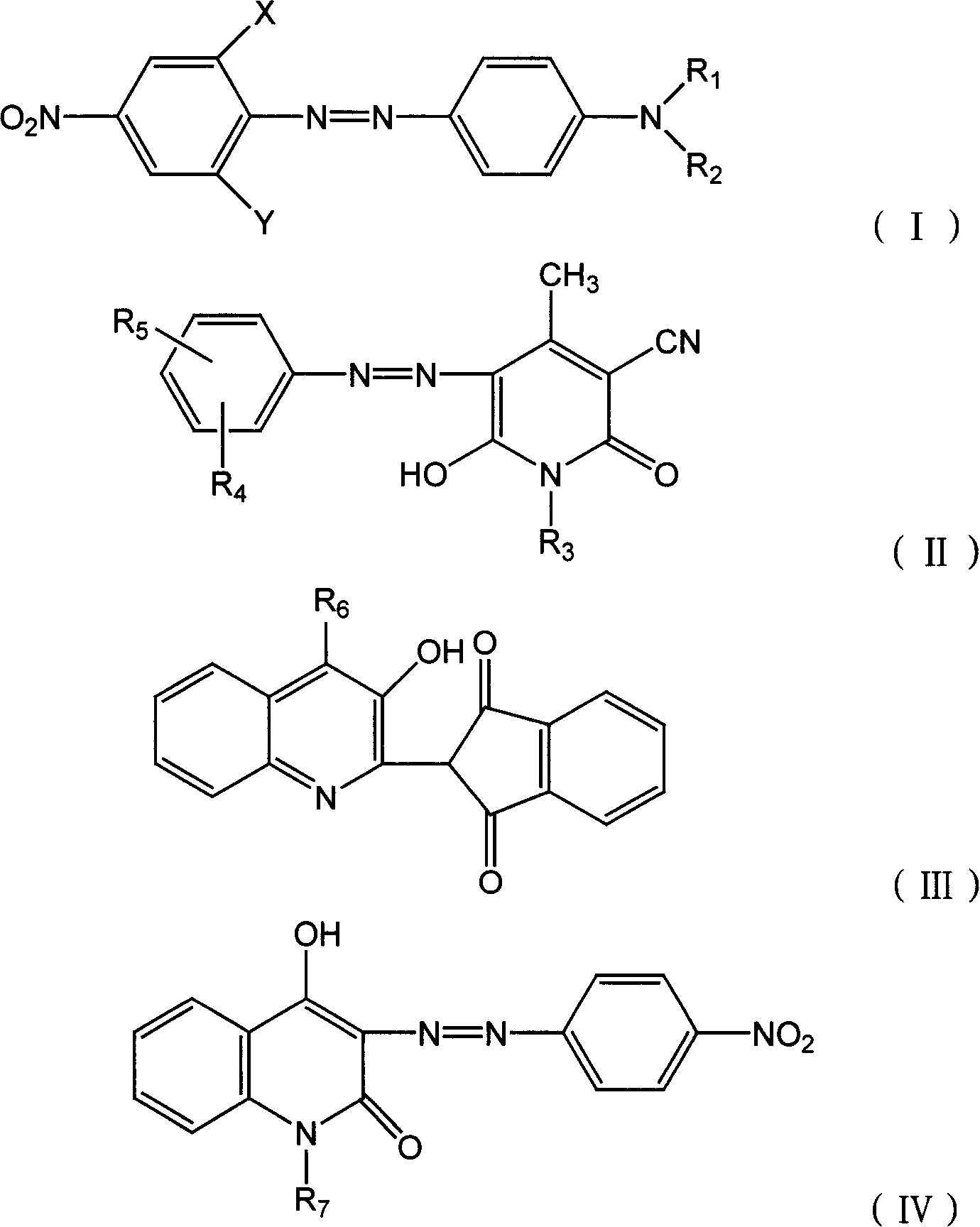

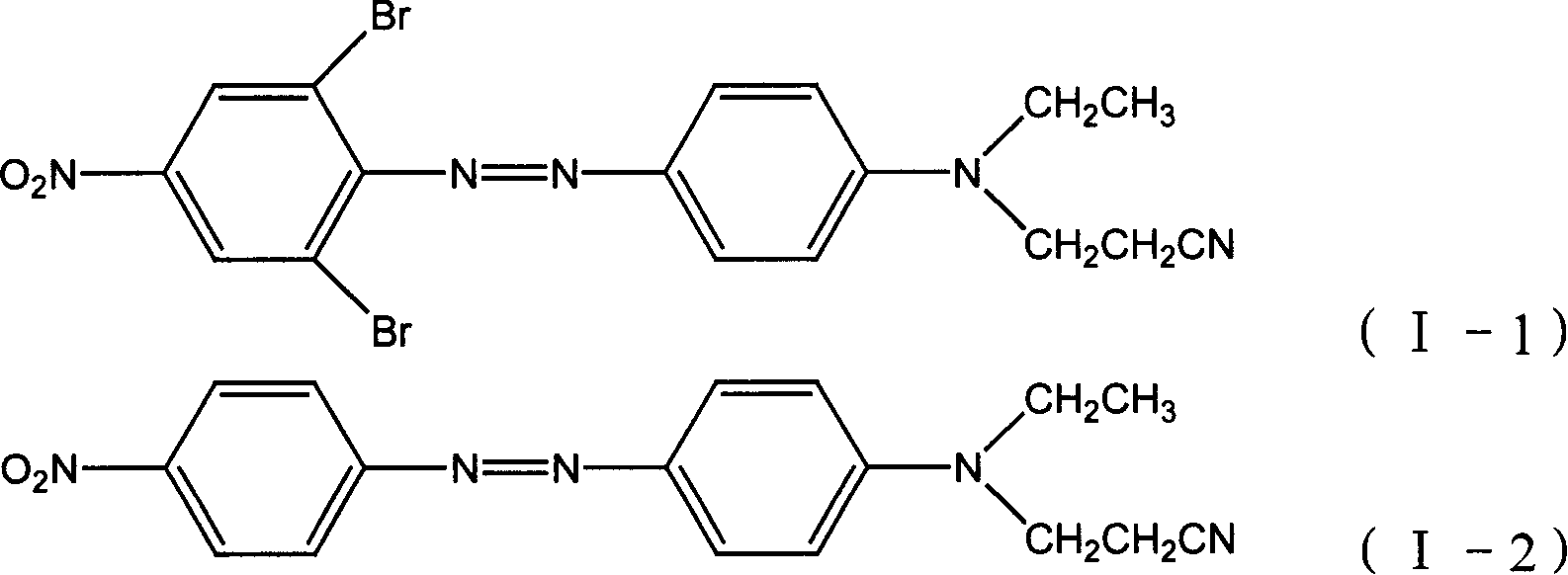

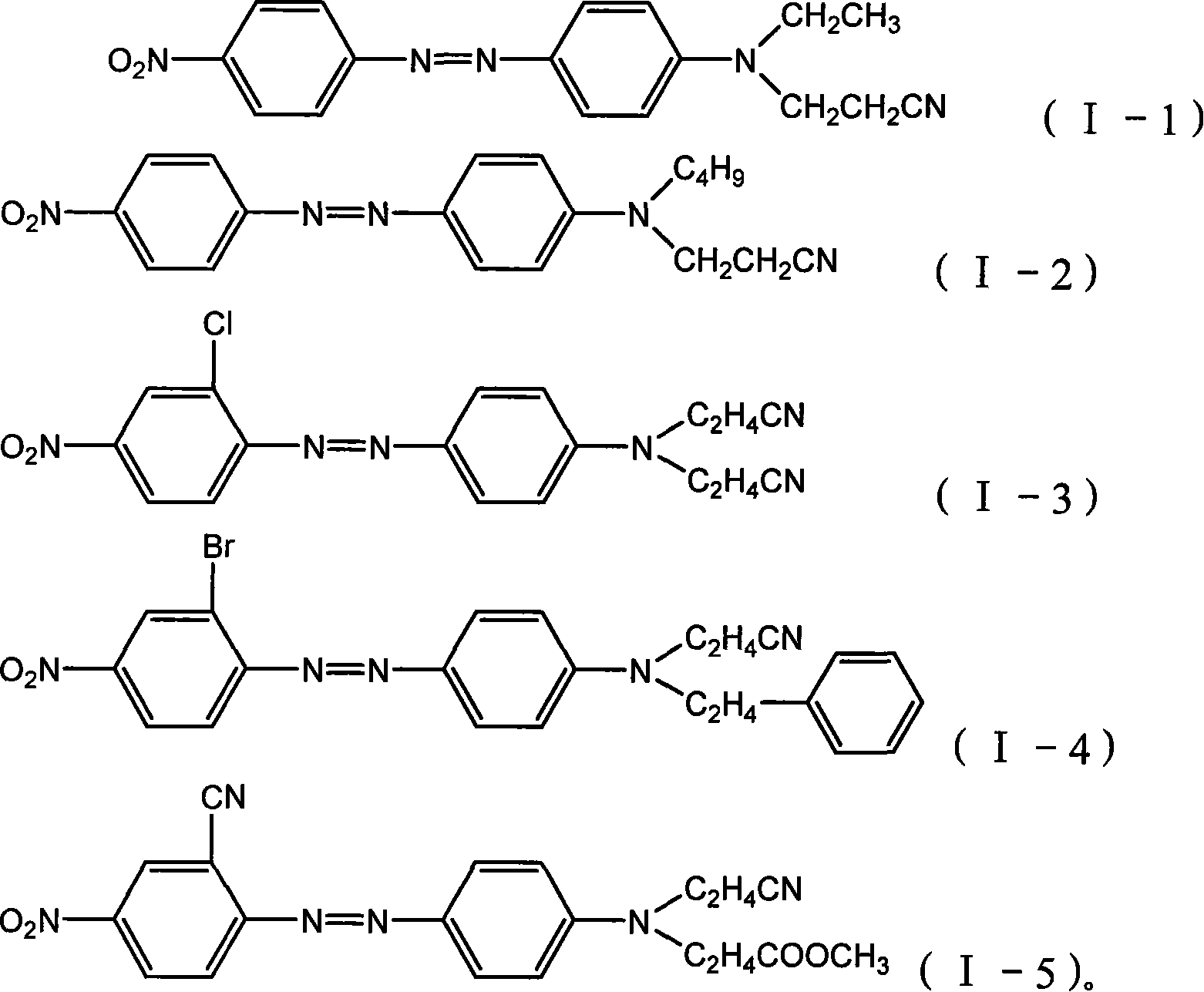

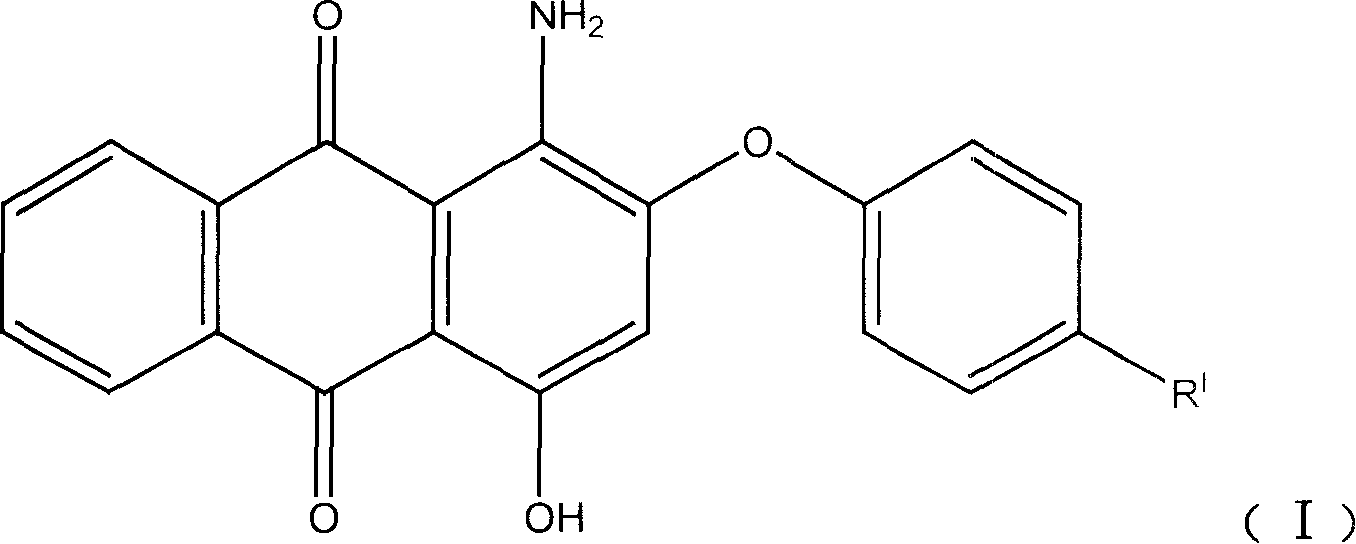

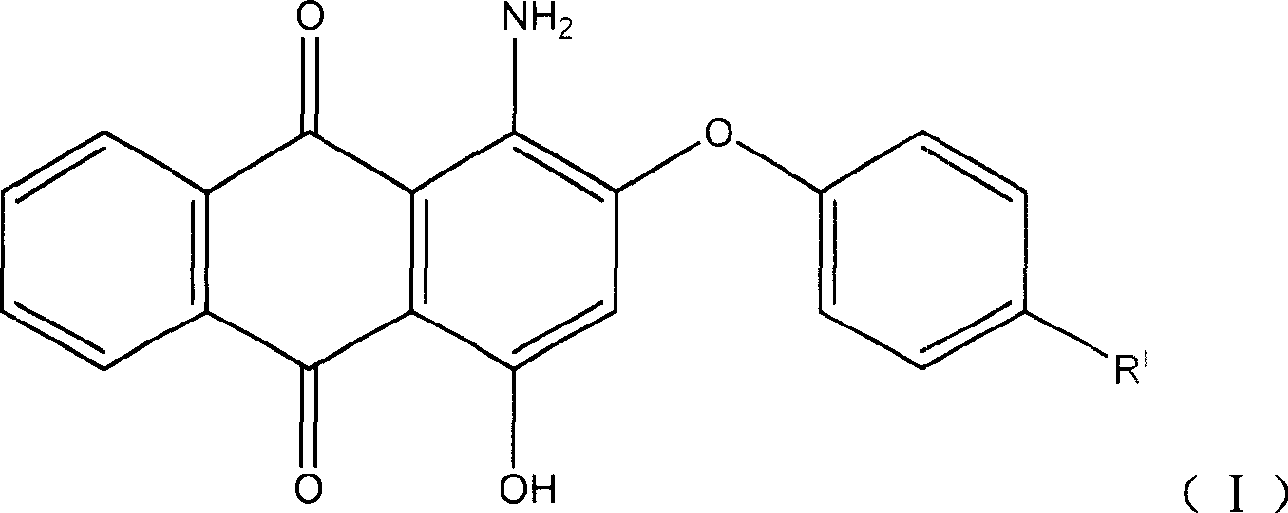

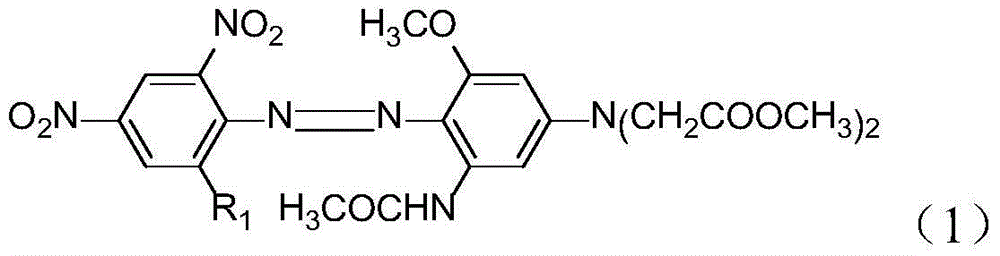

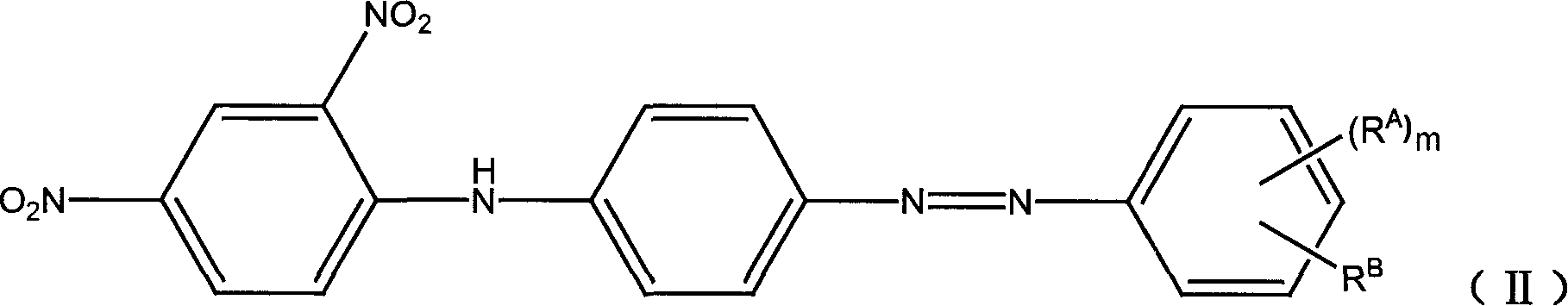

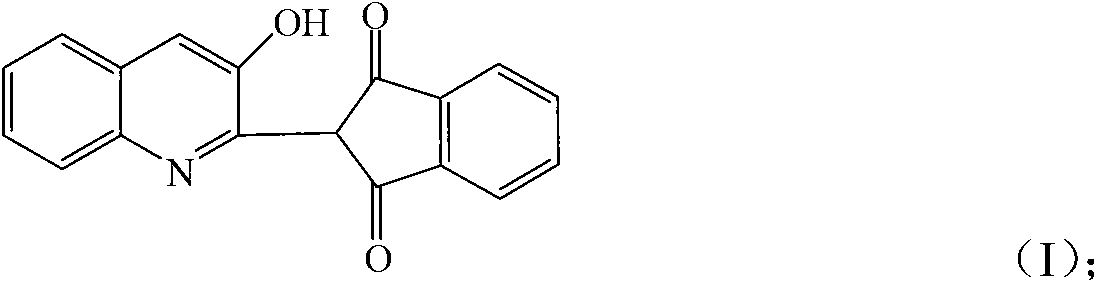

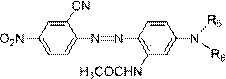

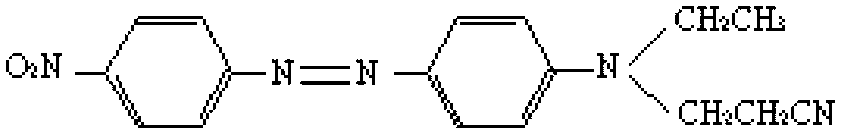

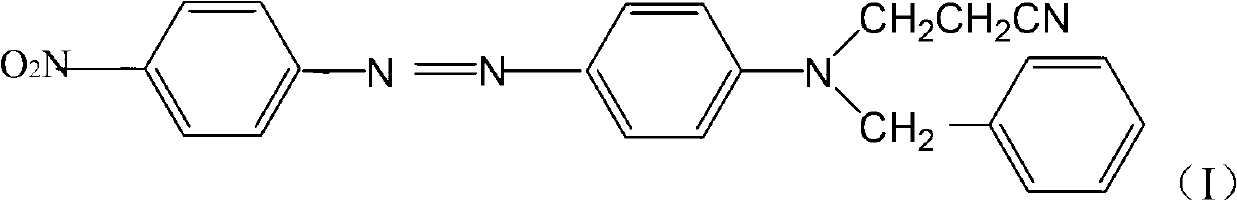

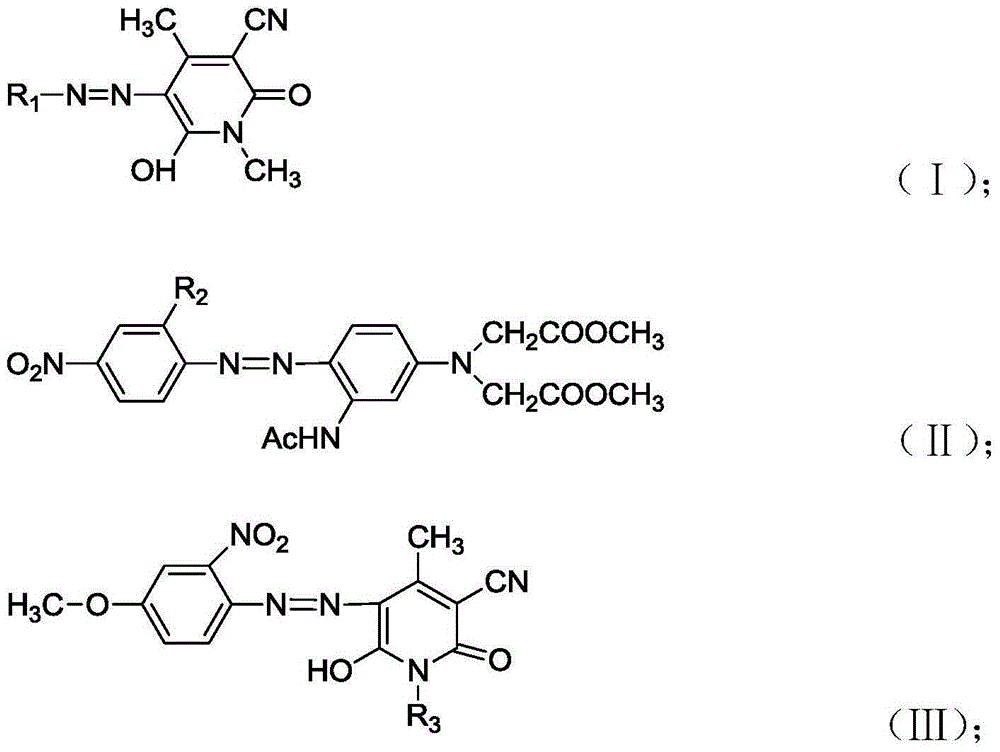

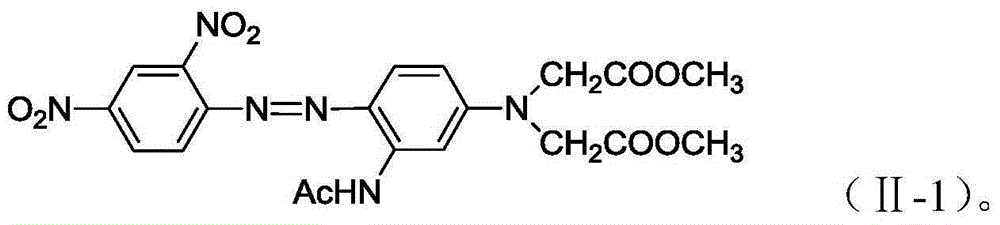

Ccomposition of dispersed yellow dye

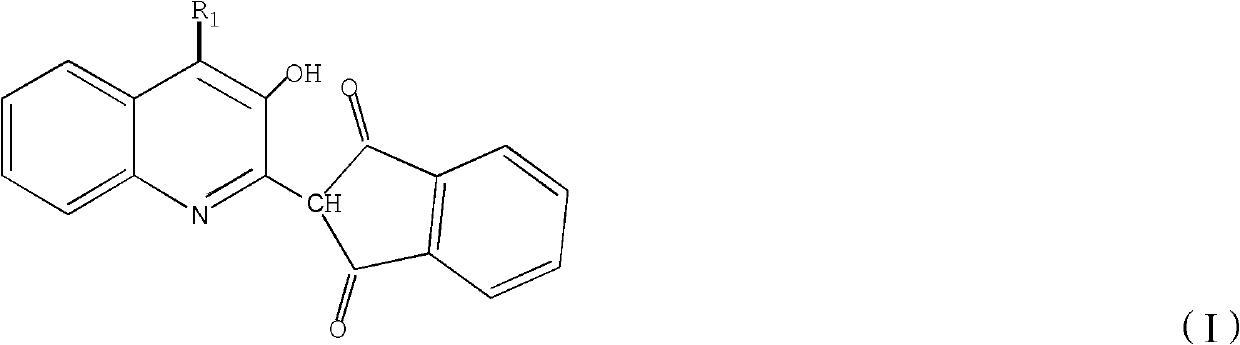

This invention provides disperse yellow dye composition, which comprises component A (one or more compound as shown in chemical formula I) 5-40 wt.% and component B (one or more compound as shown in chemical formula II) 60-95 wt.%. Polyester fiber material dyed with the dye prepared from the disperse yellow dye composition is a yellow fabric, and has such advantages of fresh color, high dispersibility, high washing resistance and high sweat resistance.

Owner:浙江龙盛染料化工有限公司 +2

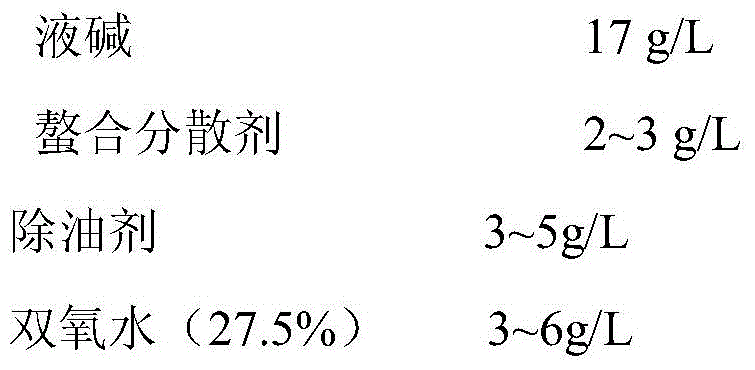

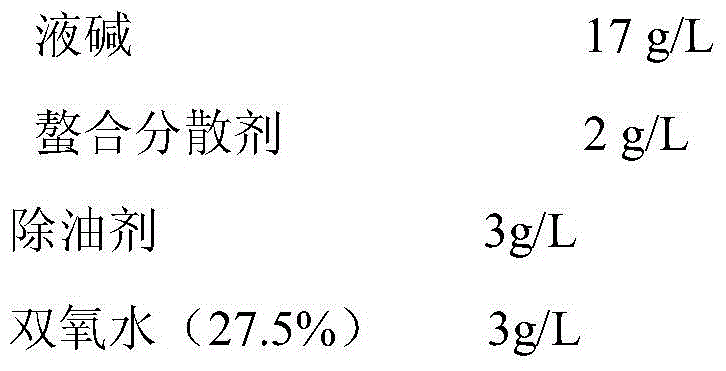

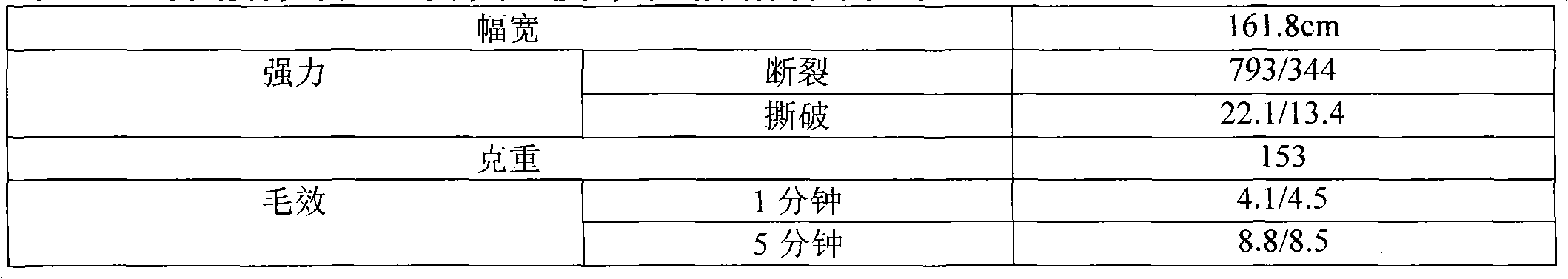

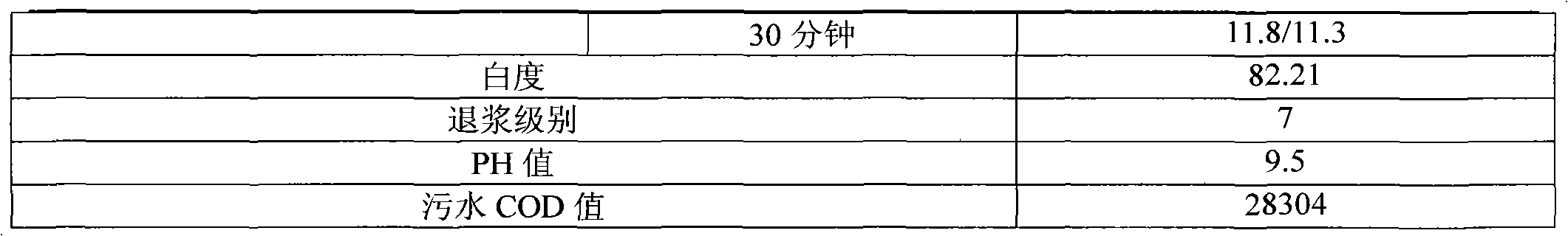

Dyeing and finishing process for improving color fastness to light of light-colored fabric of FDY (Fully Drawn Yarn) polyester filament yarn warp and weft four-way elastic textile

ActiveCN105696385AShrink evenlyNot prone to wrinklesGrip property fibresDyeing processAcetic acidDisperse dye

The invention discloses a dyeing and finishing process for improving the color fastness to light of a light-colored fabric of an FDY (Fully Drawn Yarn) polyester filament yarn warp and weft four-way elastic textile. The dyeing and finishing process comprises a dyeing process; a formula of a dyeing auxiliary adopted in the dyeing process comprises the following components: 0.5g / L to 1g / L of high-efficiency dispersant, 2g / L to 3g / L of chelating dispersant, 0.3g / L to 0.5g / L of 99 percent glacial acetic acid, X percent (o.w.f.) (on Weight the Fabric) of disperse yellow AM-2R, Y percent (o.w.f.) of disperse red AM-SLR and Z percent (o.w.f.) of disperse blue AM-SLR, wherein the sum of X, Y and Z is not more than 0.5, and a bath ratio is 1: (3 to 4). According to the dyeing and finishing process, the light-colored fabric of the FDY polyester filament yarn warp and weft four-way elastic textile which does not contain a fluorescent whitening agent and is obtained by being dyed by a disperse dye with color fastness to high sunlight is used as greige cloth; the color fastness to light which is up to a rating of 5 to 6 is realized through the specific dyeing and finishing process.

Owner:杭州天宇印染有限公司

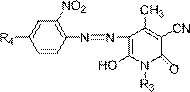

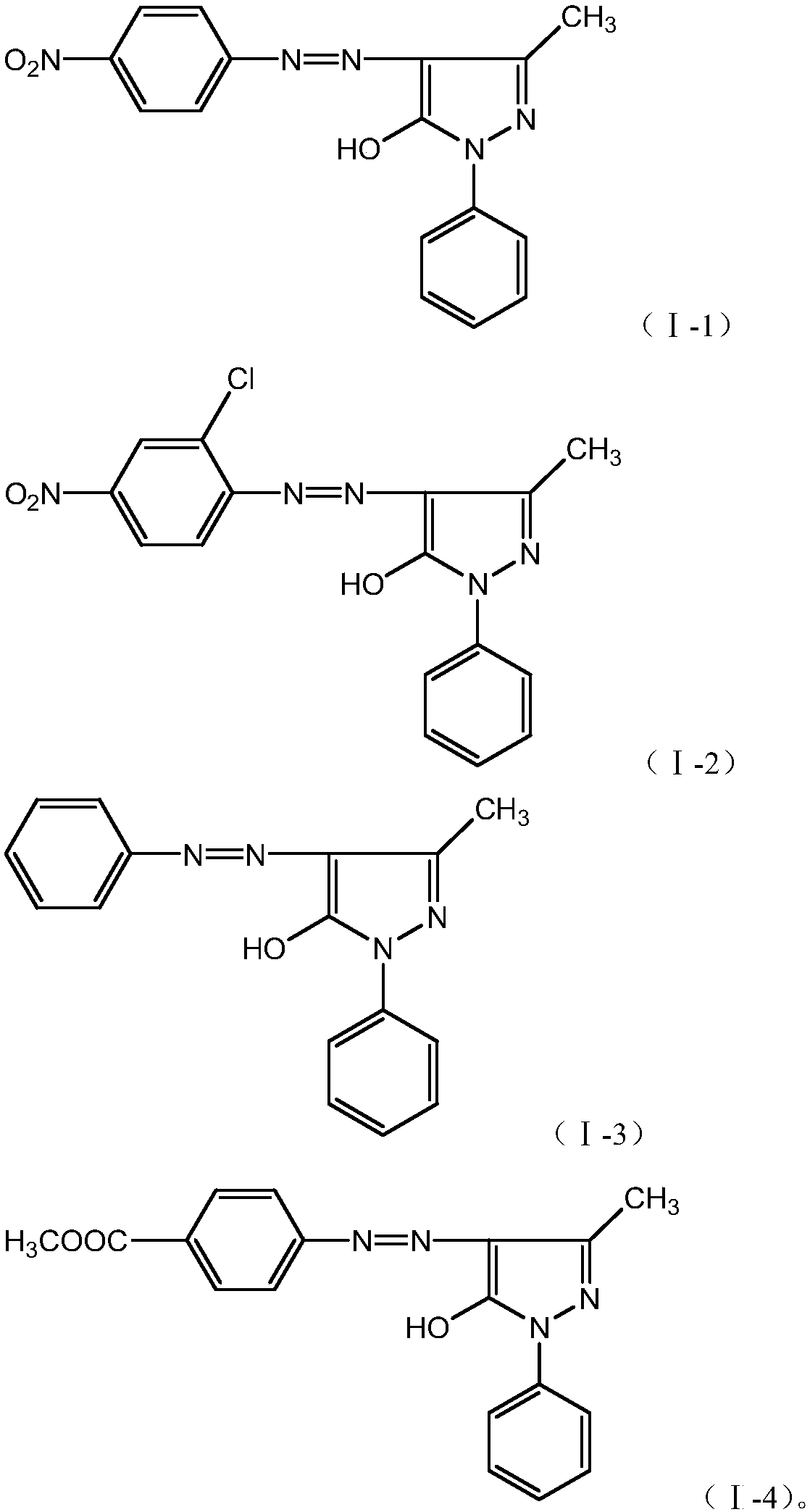

Environment-friendly type yellow disperse dyestuff composition

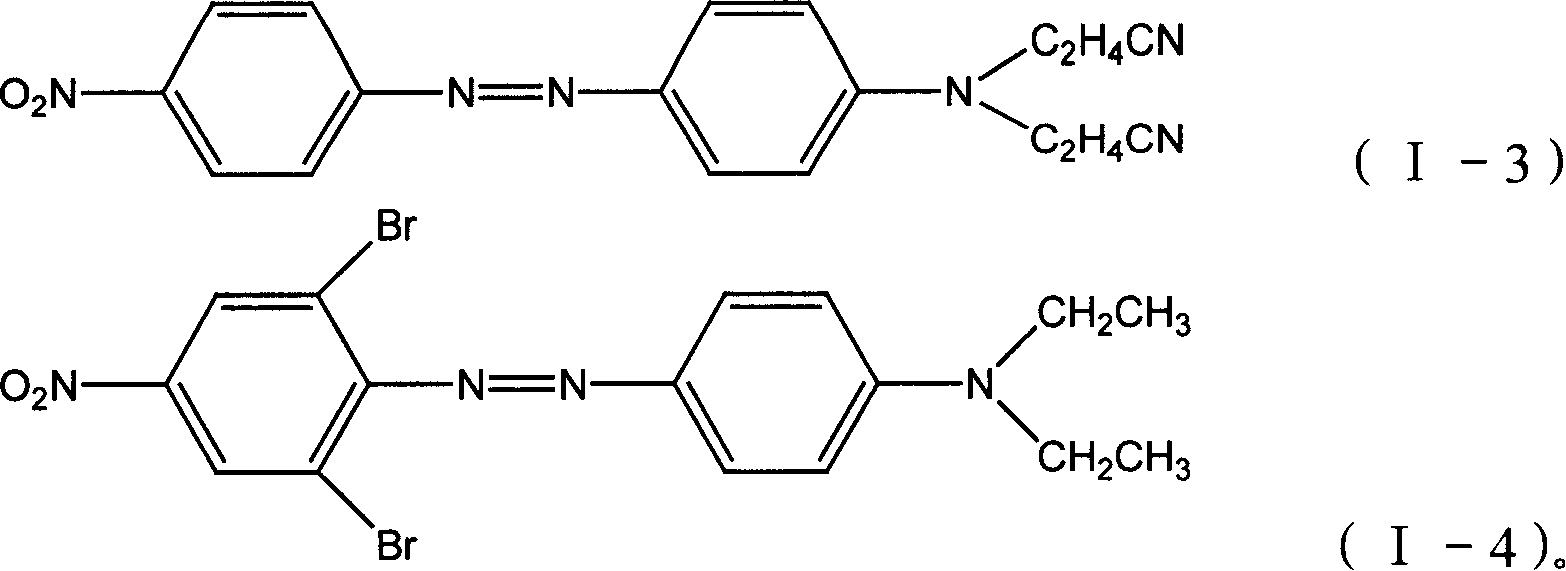

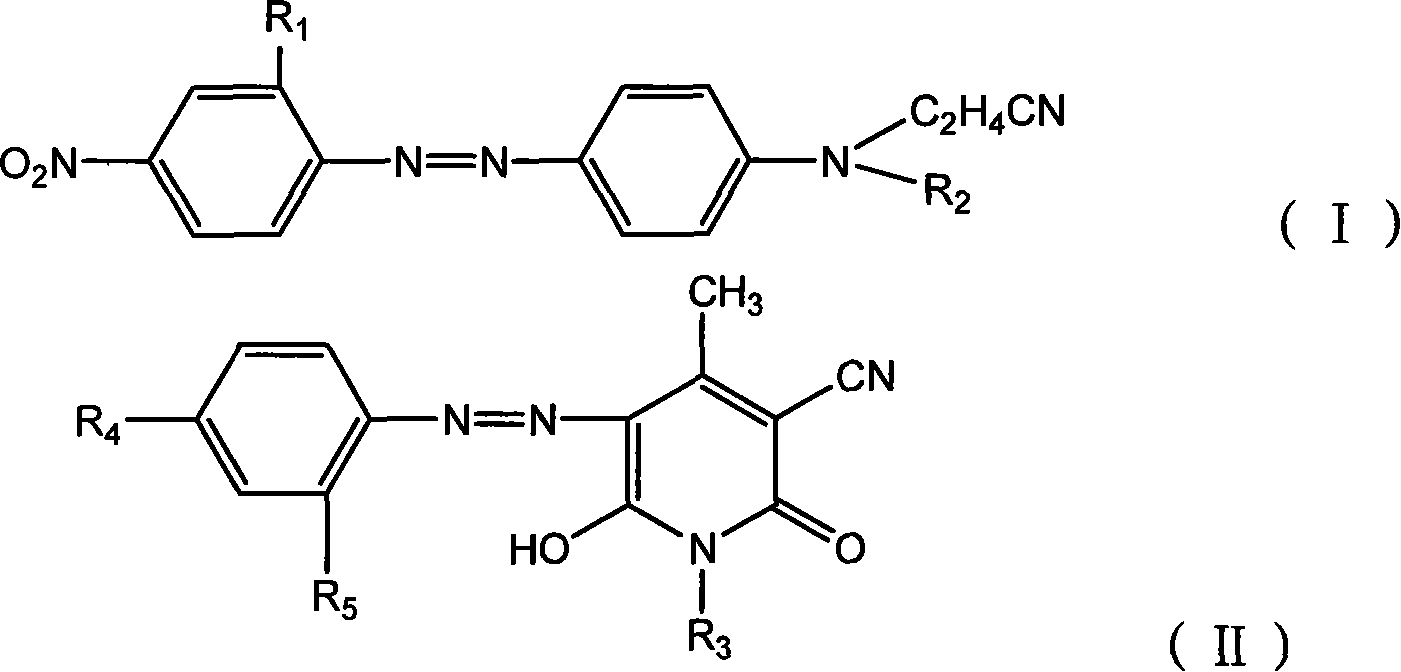

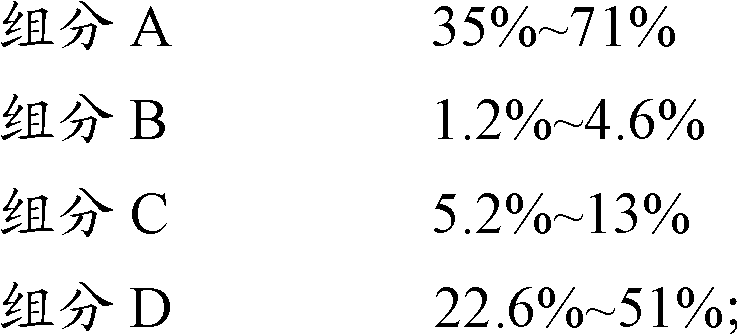

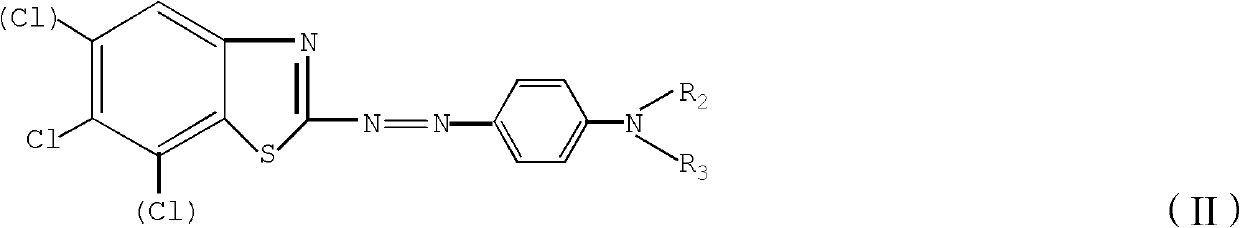

The invention discloses an environment-friendly type yellow disperse dyestuff composition, comprising 35-71 wt% of ingredient A, 1.2-4.6 wt% of ingredient B, 5.2-13 wt% of ingredient C and 22.6-51 wt% of ingredient D, wherein the ingredient A contains one or more compounds as shown in formula (I), the ingredient B contains one or more compounds as shown in formula (II), the ingredient C is the compound as shown in formula (III) and the ingredient D contains one or more compounds as shown in formula (IV). The environment-friendly type yellow disperse dyestuff composition provided by the invention has gorgeous colors during the dyeing process, good lifting force, excellent fastness in all aspects, especially has good compatibility when blending with Disperse-Blue 2BLN and Disperse-Red 3B as well as basically consistent dyeing rate; and under the same dyeing depth, less dosage of the dye is used, dye cost is low, the pH value has a wide application range; and the environment-friendly type disperse yellow dyestuff composition is valuable and has good reproducibility.

Owner:ZHEJIANG RUNTU

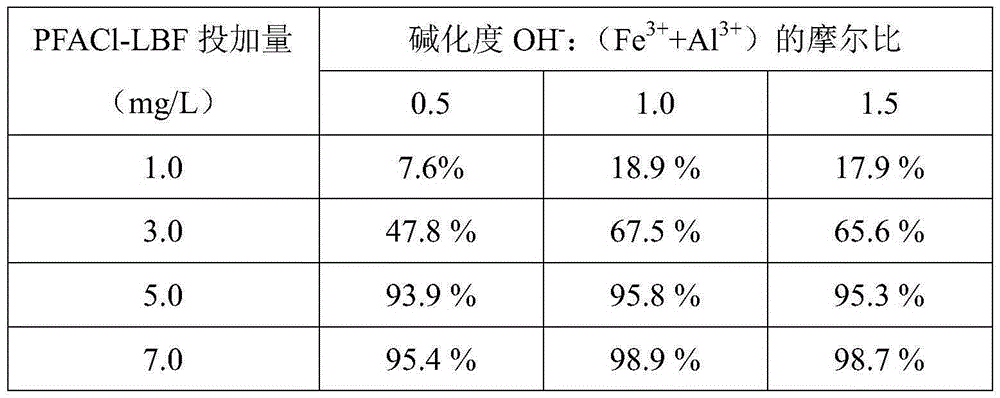

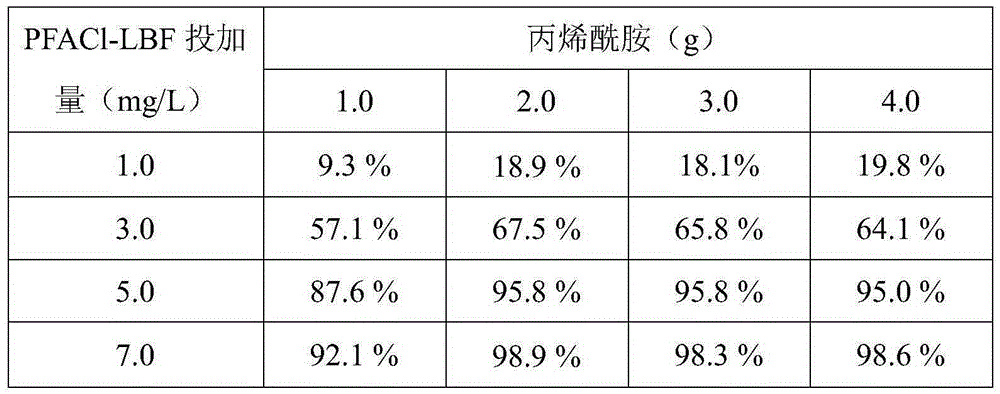

Polyaluminum ferric chloride-paper mill sludge based polymer composite flocculant and preparation method thereof

ActiveCN105384231AImprove performanceStable decolorization rateSludge treatmentWaste water treatment from plant processingTreatment effectDissolution

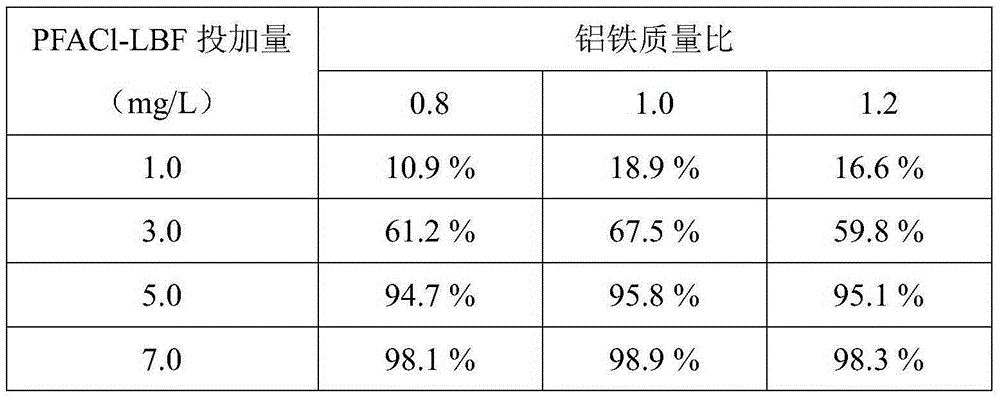

The invention relates to polyaluminum ferric chloride-paper mill sludge based polymer composite flocculant and a preparation method thereof. The preparation method includes the steps that a paper mill sludge raw material is directly subjected to dissolution and crude extraction through alkali liquor so that lignin can be obtained, a cation-type paper mill sludge based polymer is prepared through graft modification to be reacted with polyaluminum ferric chloride in a mixed mode, and accordingly the novel efficient composite flocculant is prepared. When the obtained flocculant is used for treating a simulated dye water sample and the dosing quantity is 5 mg / L, the chroma removing rate of disperse yellow water samples is stabilized to be above 95%, and meanwhile a good coagulation effect is achieved on both the water samples under the different acidity-alkalinity conditions and other various water samples. The process is simple, the number of needed devices is small, industrialized production and application can be facilitated, and waste recycling is achieved; moreover, the prepared flocculant is high in flocculation efficiency and wide in application range, and a good treatment effect can be achieved on common water body pollutants.

Owner:SHANDONG UNIV

Sublimation fastness improved dispersion red dyes mixture

ActiveCN1927948ASolve the problem of serious shade changeImprove discolorationOrganic dyesFiberTints and shades

The disperse red dye mixture with raised sublimation fastness consists of dye in the chemical general expression as shown in 5-95 wt%, and C.I. disperse red 343, C.I. disperse red 92 or C.I. disperse red 146 in 5-95 wt%. The disperse red dye mixture has sublimation fastness raised to Level 3, and may be compounded with disperse blue 2BLN and disperse yellow in the same sublimation fastness to form various kinds of marketable dyes with balanced sublimation fastness. It may be also used directly in dyeing.

Owner:WUJIANG LVZHOU DYESTUFF CHEM

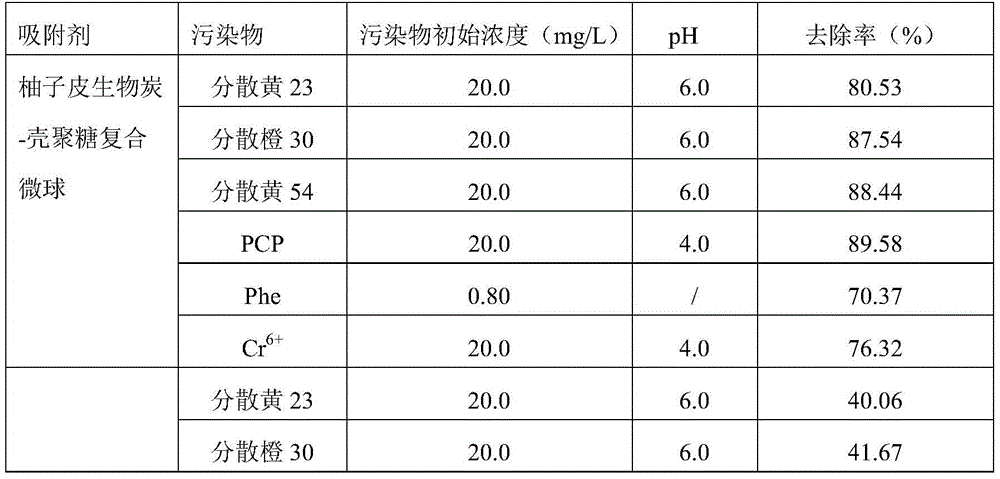

Preparation method and application of composite microspheres

InactiveCN105597691AImprove adsorption capacityImprove recycling efficiencyOther chemical processesWater contaminantsMicrosphereWastewater

The invention provides a preparation method and an application of composite microspheres. Chitosan powder is added to an acetic acid solution to be dissolved, shaddock peel charcoal and a chitosan solution are added and mixed uniformly, the mixed solution is added to a NaOH solution, shaddock peel charcoal-chitosan composite microspheres are prepared, allowed to stand for 12 h and washed with deionized water until the shaddock peel charcoal-chitosan composite microspheres are neutral, and the composite microsphere are prepared. The prepared shaddock peel charcoal-chitosan composite microspheres are used for adsorbing pollutants in water. The invention provides the preparation method of the shaddock peel charcoal-chitosan composite microspheres and the application of the shaddock peel charcoal-chitosan composite microspheres in removal of disperse yellow dye, PCP, Phe and Cr<6+> in wastewater. By means of the prepared microspheres, the adsorption capacity and the recovery efficiency of shaddock peel charcoal are improved, the recovery cost is reduced, secondary pollution is avoided, and the composite microspheres are an environment-friendly adsorptive material capable of being repeatedly used.

Owner:OCEAN UNIV OF CHINA

High washing fastness dispersed dark blue dye composition

ActiveCN103421347BSolve the problem of poor color fastnessHigh color fastnessOrganic dyesDyeing processDisperse yellowMaterials science

The invention relates to a dye composition, in particular to a high washing fastness dispersed dark blue dye composition. The high washing fastness dispersed dark blue dye composition is composed of 35 % to 50 % of dispersed red, 20 % to 40 % of dispersed golden yellow, 10 % to 30 % of dispersed purple and 10 % to 30 % of dispersed yellow in a mixing mode, and the balance auxiliaries. The dispersed red is the combination of one or more kinds of compounds shown in a formula (1); the dispersed golden yellow is the combination of one or more kinds of compounds shown in a formula (2); the dispersed purple is the combination of one or more kinds of compounds shown in a formula (3), and the dispersed yellow is the combination of one or more kinds of compounds shown in a formula (4); when the high washing fastness dispersed dark blue dye composition is used for dyeing of spandex fabrics, the dyeing effect is good, the color fastness is good, and the quality of the spandex fabrics can be greatly improved.

Owner:HANGZHOU FLARIANT SPECIALTY

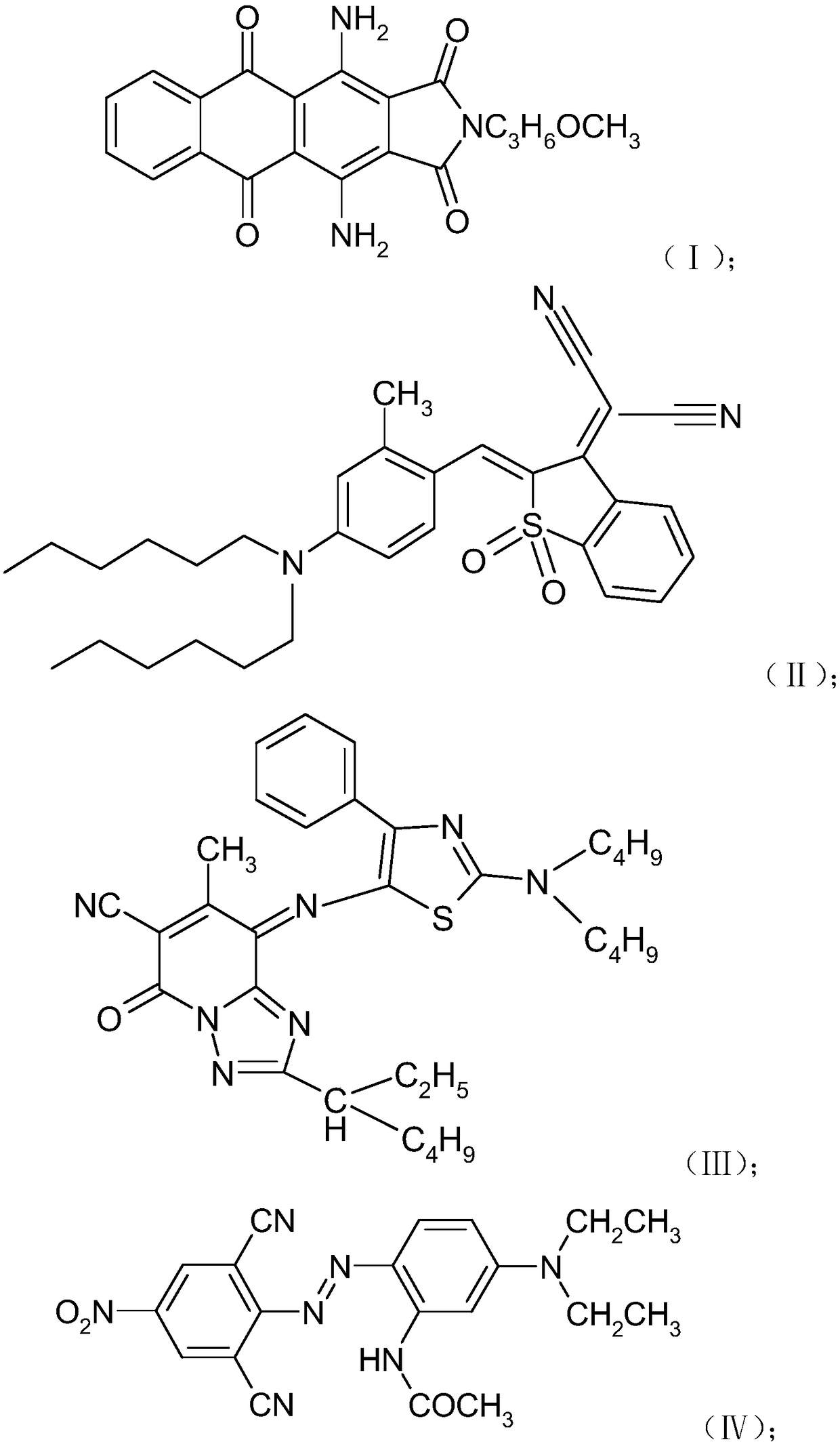

Disperse yellow dye mixture with promoted fastness to sublimation

ActiveCN1884392ASolve the problem of serious shade changeBalanced sublimation fastnessOrganic dyesDyeing processFiberDisperse yellow

Owner:WUJIANG LVZHOU DYESTUFF CHEM

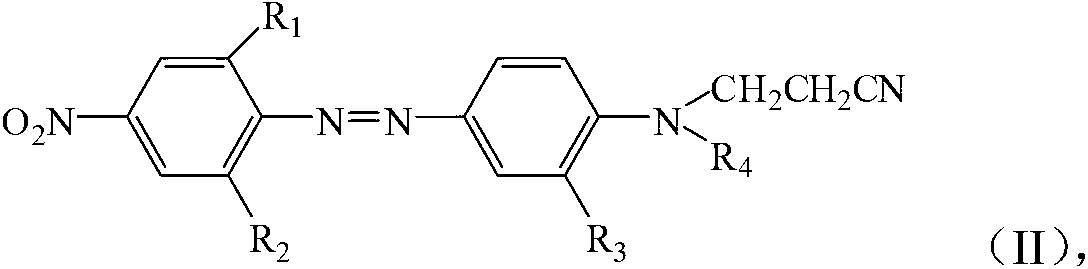

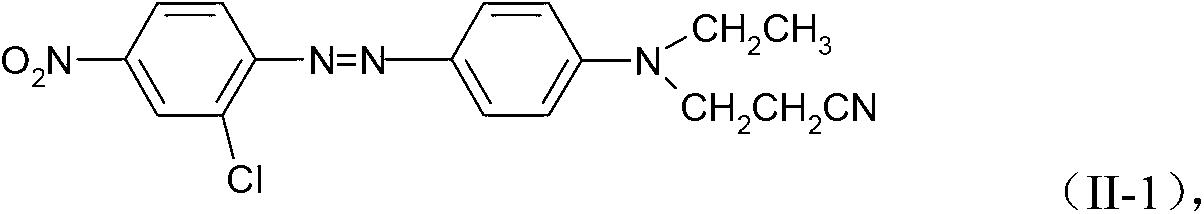

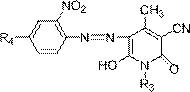

Monoazo type composition dye

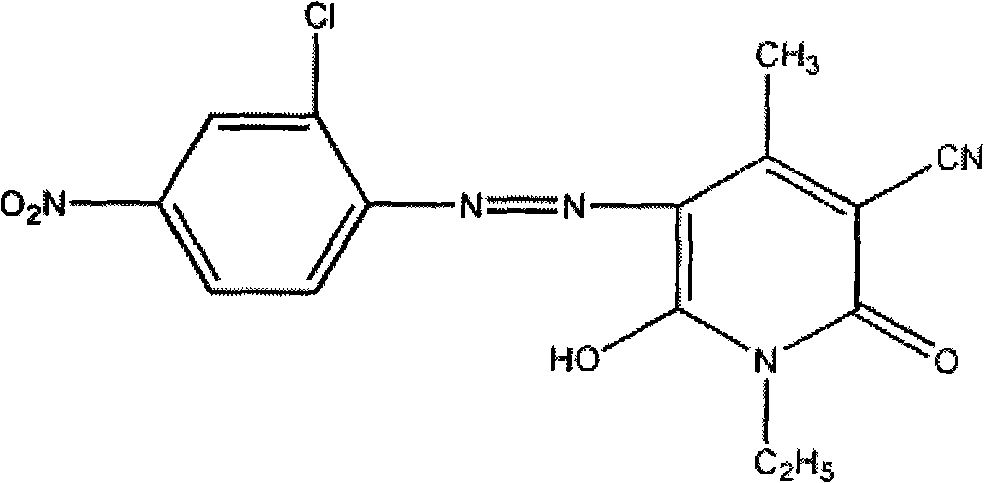

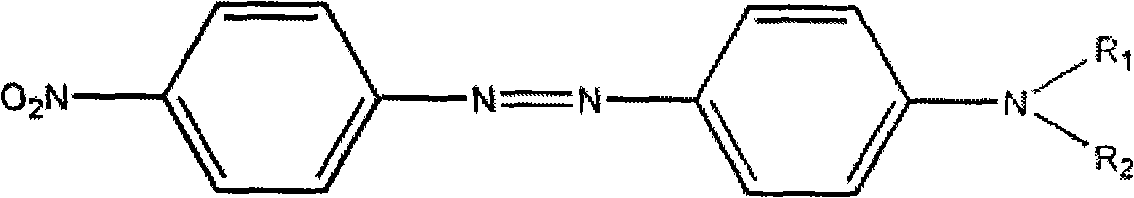

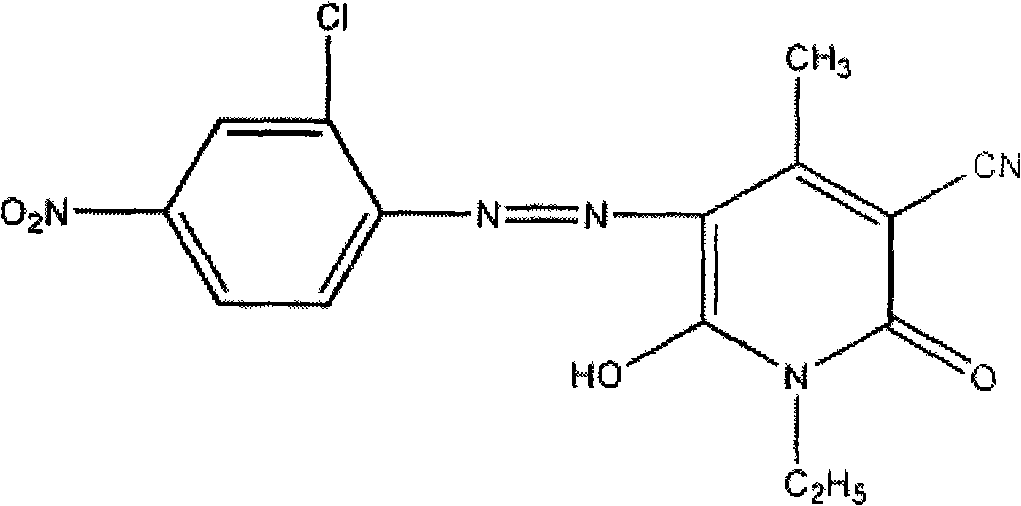

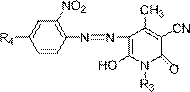

The invention relates to a disperse yellow dye, in particular to a monoazo type composition dye which is suitable for dyeing and printing polyester fabrics and blended fabrics thereof. The dye comprises a component I which is 2-chloro-4-nitrophenylazo-N'-ethyl-3'-cyano -4'-methyl-6'-hydroxy-2'-pyridone and a component II, wherein the component II can be a component II-1 which is 4-nitrophenylazo-N'-ethyl-N'-cyanoethylaniline or a component II-2 which is 4-nitrophenylazo-N'-cyanoethyl-N'-ethyoxyl formylaniline; the ratio of the component I and the component II in percentages by weight is preferably 60-95% : 40-5% and 30-95% : 70-5%, thus a wider yellow spectrum space can be provided. In addition, the invention also contains a diffusant which is preferably MF or sodium lignin sulfonate. Theinvention has the advantages of high migration ability, high intensity, and the like and can better substitute for disperse golden yellow E-3RL (disperse yellow 23) which is forbidden at present.

Owner:董源

High washing fastness dispersed dark blue dye composition

ActiveCN103421347AImprove washing fastnessHigh coloring rateOrganic dyesDyeing processDisperse yellowMaterials science

The invention relates to a dye composition, in particular to a high washing fastness dispersed dark blue dye composition. The high washing fastness dispersed dark blue dye composition is composed of 35 % to 50 % of dispersed red, 20 % to 40 % of dispersed golden yellow, 10 % to 30 % of dispersed purple and 10 % to 30 % of dispersed yellow in a mixing mode, and the balance auxiliaries. The dispersed red is the combination of one or more kinds of compounds shown in a formula (1); the dispersed golden yellow is the combination of one or more kinds of compounds shown in a formula (2); the dispersed purple is the combination of one or more kinds of compounds shown in a formula (3), and the dispersed yellow is the combination of one or more kinds of compounds shown in a formula (4); when the high washing fastness dispersed dark blue dye composition is used for dyeing of spandex fabrics, the dyeing effect is good, the color fastness is good, and the quality of the spandex fabrics can be greatly improved.

Owner:HANGZHOU FLARIANT SPECIALTY

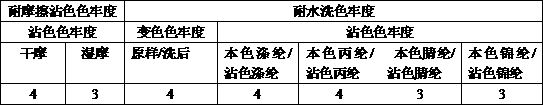

Economical dispersion dye mixture

InactiveCN108727866AGood color fastness to washingGood color fastness to rubbingOrganic dyesDisperse dyeDisperse yellow

The invention discloses an economical dispersion dye mixture. 1000 parts of dispersion dye mixtures are prepared from the following ingredients in parts by weight: 0.1 to 800 parts of C.I. disperse blue 60, 20 to 200 parts of C.I. disperse blue 354 and / or disperse color blue B, 0.1 to 20 parts of C.I. disperse blue 165, 0.1 to 70 parts of C.I. disperse green 9, 0.1 to 5 parts of C.I. disperse yellow 64 and / or C.I. disperse yellow 114, 175 to 800 parts of dispersing agents MF and / or dispersing agents NNO and 0.1 to 5 parts of EDTA-2Na or EDTA-4Na. The economical dispersion dye mixture has thecharacteristics of high washing resistant color fastness, rubbing resistant color fastness, light resistant color fastness and sublimation color fastness, and is applicable to the dyeing effect requirement of various fiber fabrics; the production cost is low; the economical dispersion dye mixture is applicable to large-scale production.

Owner:绍兴金绿洲新材料科技有限公司

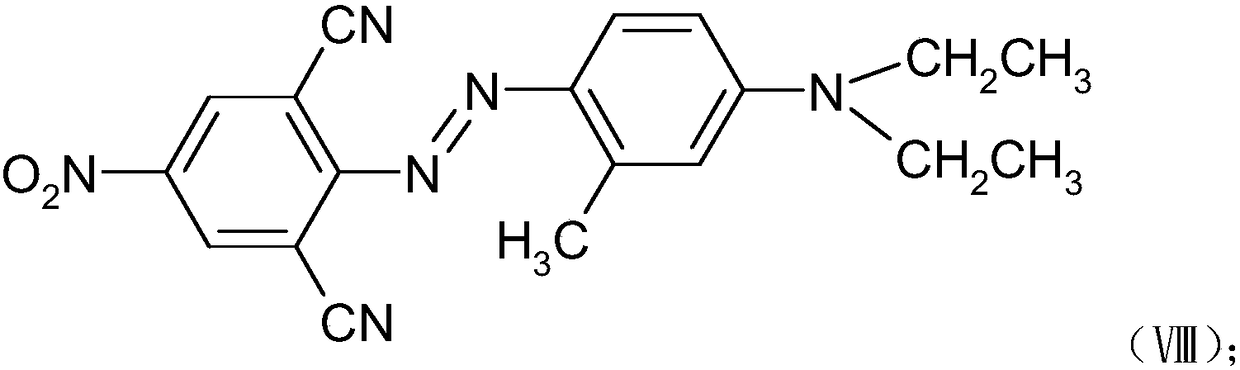

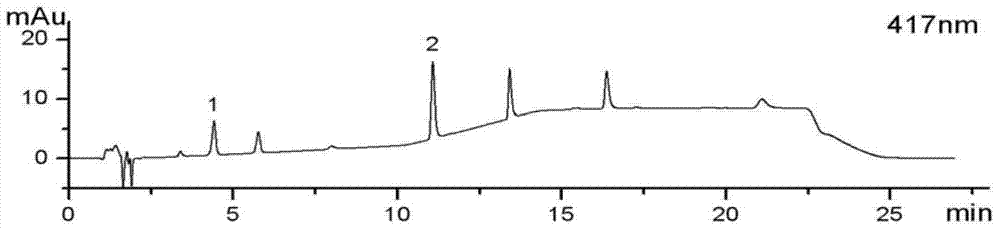

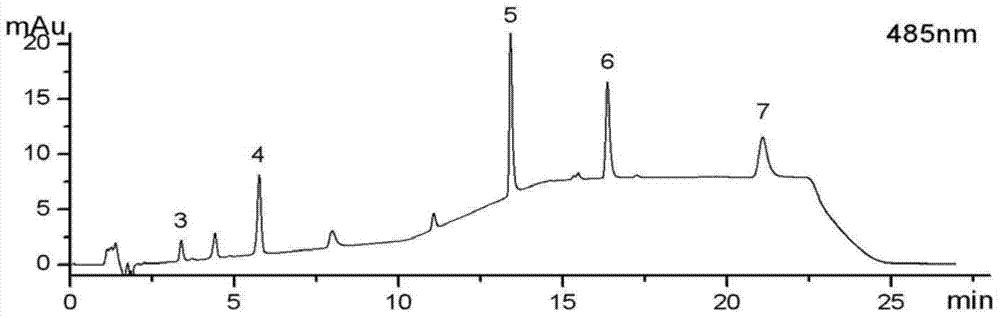

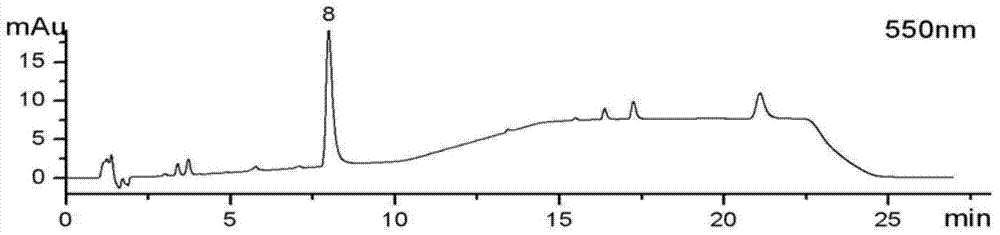

HPLC (high performance liquid chromatography) method for determining ten synthetic colorants in cosmetic

The invention discloses an HPLC method for determining ten synthetic colorants in a cosmetic simultaneously. According to the method, tetrahydrofuran, dimethyl sulfoxide and methyl alcohol are used for extracting the colorants in a sample under the auxiliary condition of ultrasonic wave, the colorants are separated on a chromatographic column of EclipseXDB-C18 (3.5 mu m, 4.6*150mm) through high-speed centrifugal clarification, acetonitrile and 0.02 mol / L of an ammonium acetate solution with the pH of 4.6 are taken as mobile phases for gradient elution, a diode array detector is used for performing determination, and quantification is performed with an external standard method. The method can simultaneously determine ten synthetic colorants of pigment red 57, pigment orange 5, acid yellow 36, pigment red 53, acid purple 49, rhodamine B, solvent blue 35, Sudan red II, Sudan red IV and disperse yellow 3, and the determination minimum is 20 mg / Kg. The method is simple, fast, sensitive and suitable for quantitative determination of colorants in oily, powdery and paste cosmetics.

Owner:THE INSPECTION & QUARANTINE TECH CENT ZHEJIANG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

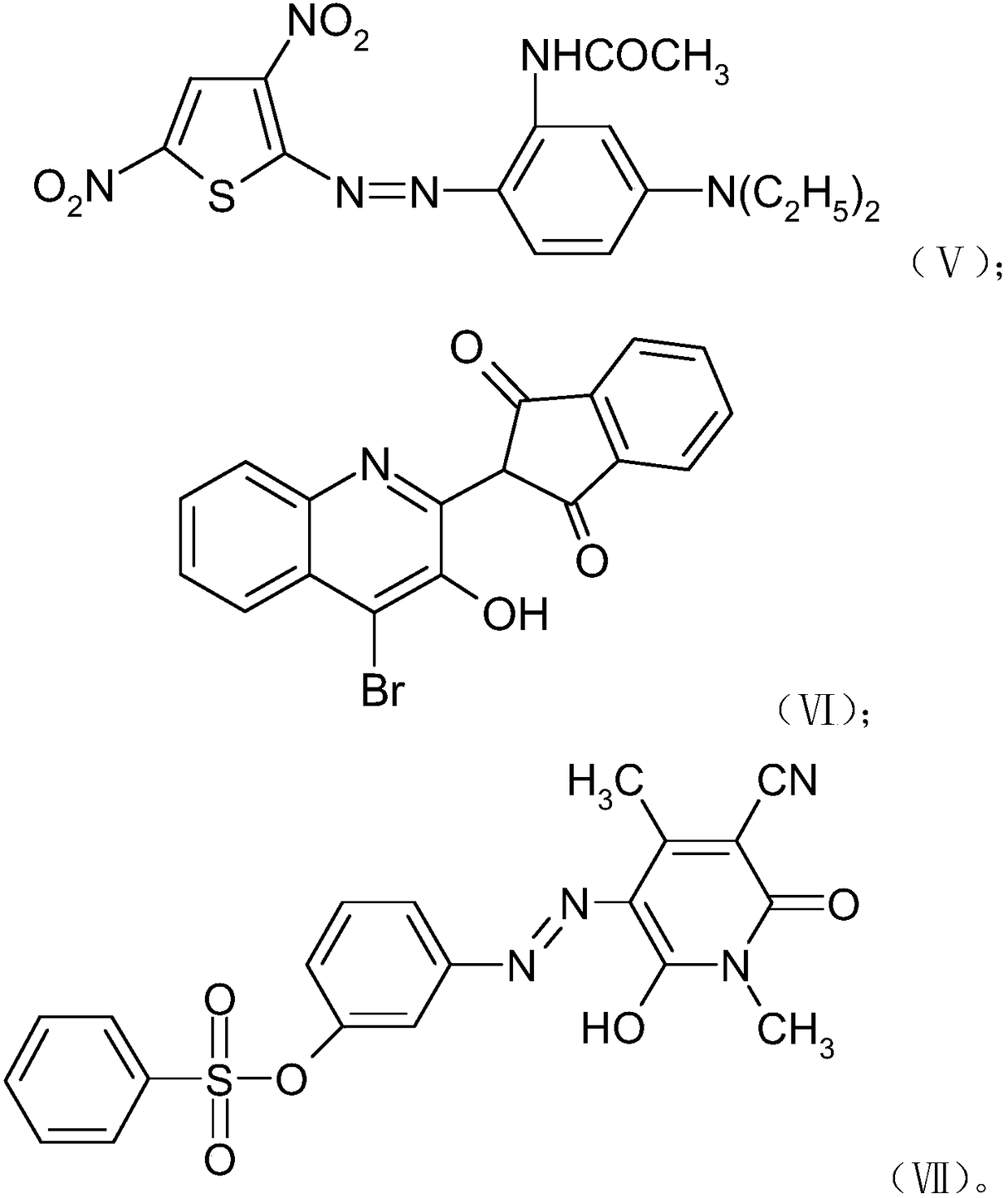

Environmentally-friendly composite disperse yellow dye

The invention relates to the technical field of disperse dyes and provides an environmentally-friendly composite disperse dye to solve a problem that a substance capable of effectively substituting C.I. disperse yellow 23 which is prohibited because of an Oeko-TexStandard100 standard and a European Eco-Label rule has not been found yet. The environmentally-friendly composite disperse dye is prepared through mixing 10-50% of a dye A, 0.05-35% of a dye B, 0-10% of a dye C, and the balance assistant, and the sum of the weight percentages of all above components is 100%. The yellow dye is basically close to the C.I. disperse yellow 23 and has more superior performances than C.I. disperse yellow 23. The composite disperse yellow dye has the advantages of gorgeous color and light, high color yield, good lifting capability, high synchronism, excellent color fastness, good compatibility with other low temperature type dyes (such as C.I. disperse red 60 or C.I. disperse blue 56), wide dyeing pH range (4-8), and satisfying of the environmental protection requirement when the composite disperse yellow dye is used in dyeing.

Owner:ZHEJIANG JIHUA GROUP +1

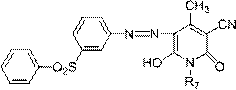

High washing fastness dispersed yellow and brown dye composition

The invention relates to a high washing fastness dispersed yellow and brown dye composition. The high washing fastness dispersed yellow and brown dye composition aims at overcoming the defects that a dye composition is poor in color fastness in the prior art. The high washing fastness dispersed yellow and brown dye composition is composed of, by weight, 20 % to 40 % of dispersed orange, 25 % to 50 % of dispersed golden yellow, 10 % to 20 % of dispersed red dye and 10 % to 20 % of dispersed yellow in a mixing mode, and the balances auxiliaries. The dispersed orange is the combination of one or more compounds shown in a formula (1); the dispersed golden yellow is the combination of one or more compounds shown in a formula (2); the dispersed red dye is the combination of one or more compounds shown in a formula (3); the dispersed yellow is the combination of one or more compounds shown in a formula (4); R7 in the formula (4) is -CH3 or -CH2CH3. When the high washing fastness dispersed yellow and brown dye composition is used for dyeing of spandex fabrics, the dyeing effect is good, the color fastness is good, and the quality of the spandex fabrics can be greatly improved.

Owner:HANGZHOU FLARIANT SPECIALTY

Black ink for ink jet textile printing and textile printing method

ActiveUS9109327B2Good light fastnessImprove light resistanceInksTypewritersTextile printerDisperse dye

There is provided a black ink for ink jet textile printing which includes a disperse dye (A), a disperse dye (B), a disperse dye (C), water, and an organic solvent. The disperse dye (A) is at least one of C.I. Disperse Blue 60 and C.I. Disperse Blue 165, the disperse dye (B) is at least one of C.I. Disperse Red 92, and C.I. Disperse Red 154, and the disperse dye (C) is C.I. Disperse Yellow 163.

Owner:SEIKO EPSON CORP

Disperse yellow dye formula

The invention relates to a disperse dye formula, particularly a disperse yellow dye formula. The disperse yellow dye is prepared by mixing the following components in percentage by mass: 60-70% of dyeing monomer A with the chemical formula disclosed in the specification, 10-15% of dyeing monomer B with the chemical formula disclosed in the specification, and 20-25% of dyeing monomer C with the chemical formula disclosed in the specification. The dye mixed according to the formula can substitute disperse yellow RGFL, has the same dyeing effect as the disperse yellow RGFL, and keeps the ratio of the dyeing monomer B-dyeing monomer C mixture to the dyeing monomer A at 3:7-4:6. The method for preparing the finished product dye comprises the following steps: adding assistants and water or any other lubricant, milling with a sand mill, and drying the finished product to synthesize the color of the disperse yellow RGFL. The finished product can be used directly to completely substitute the disperse yellow dye RGFL.

Owner:JIANGSU D I A N CHEM CO LTD

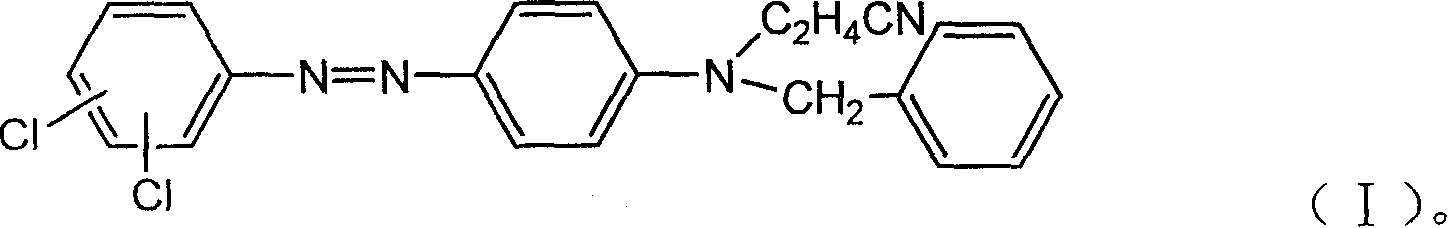

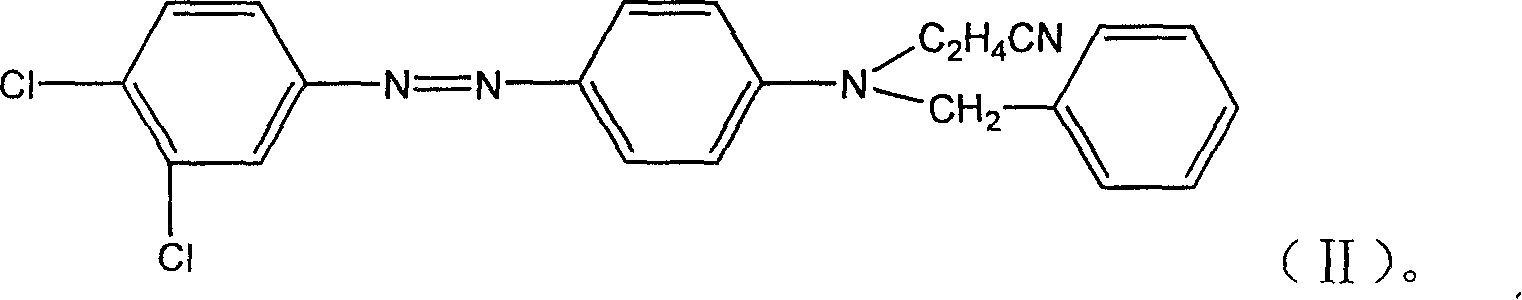

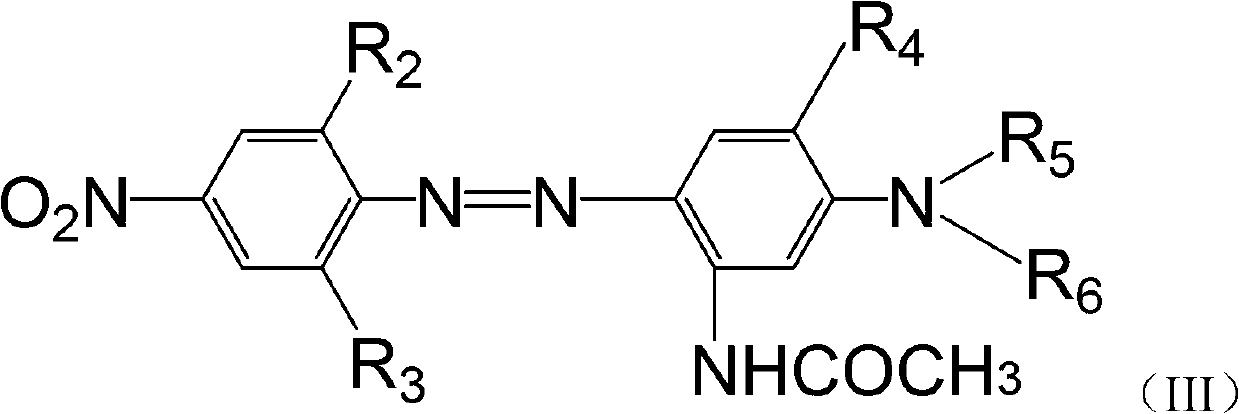

Single diazo compound, its preparation method and use

InactiveCN1869004AHigh color fastnessEffective dispersionMonoazo dyesOrganic chemistryNitrosylsulfuric acidColour fastness

A monoazo compound used for the disperse yellow dye with high dye fastness is prepared through diazotizing reaction between dichlorophenylamine and nitrosylsulfuric acid in sulfuric acid to obtain diazonium salt, coupling reaction on N-cyanoethyl-N- benzylphenylamine and post-treating.

Owner:闰土控股集团有限公司

Disperse yellow dye

The invention relates to a disperse dye, and particularly relates to disperse yellow dye. The disperse yellow dye is obtained by mixing the following raw materials in percentage by mass: 55-70% of a chromatid A with a chemical formula of or a chromatid B with a chemical formula of, and 30-45% of a chromatid C with a chemical formula of. A dye mixed according to the scheme and the prescription can replace a disperse yellow RGFL, and has a dyeing effect same as that of the disperse yellow RGFL; and when a finished dye product is prepared, auxiliaries, water or other lubricants are added in the chromatids, and the obtained mixture is ground by using a sand mill, the obtained product is dried, then the obtained finished product can be directly used, and can replace the disperse yellow RGFL.

Owner:ZHEJIANG SHANYU TECH CO LTD

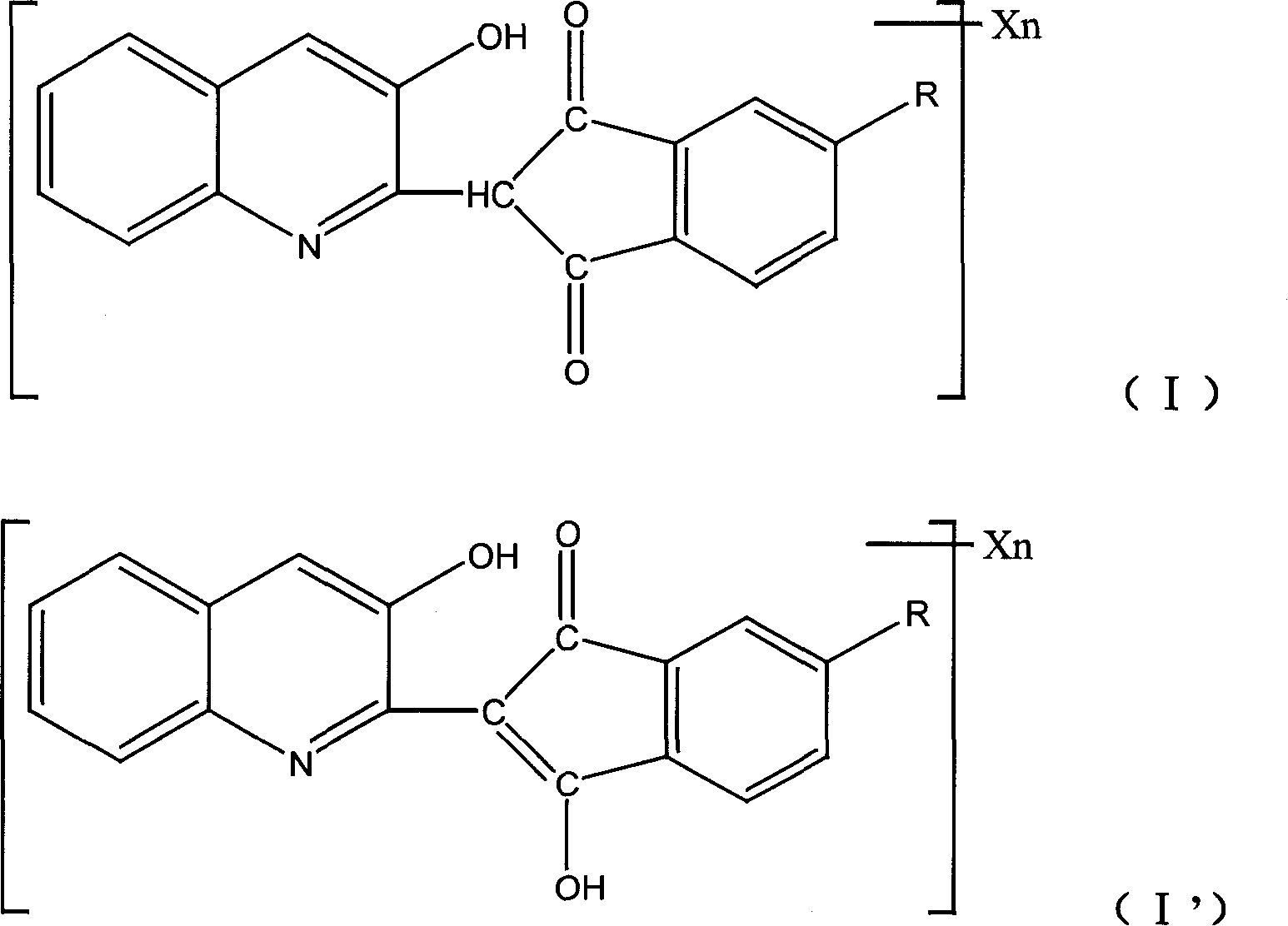

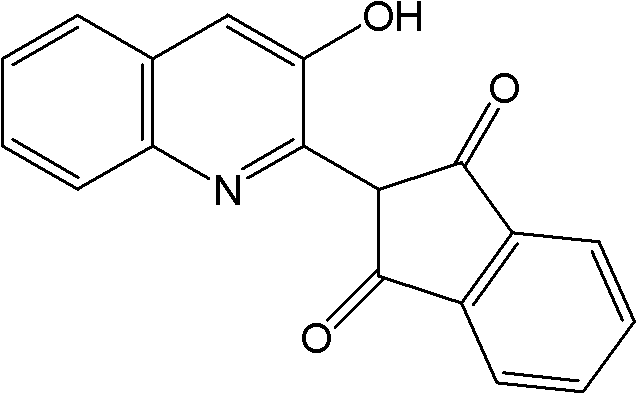

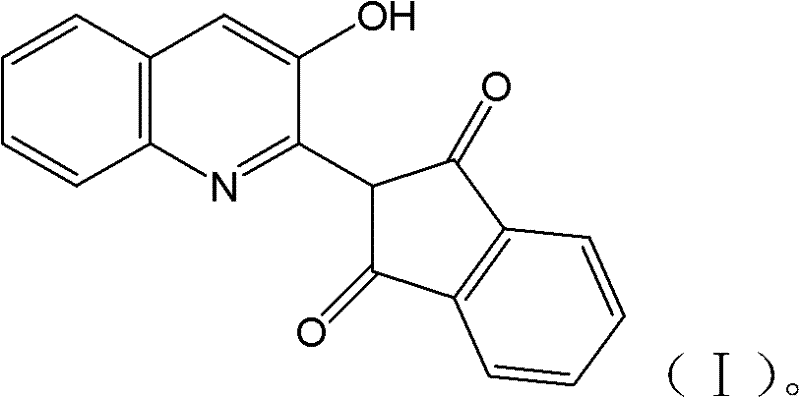

Preparation technology of dye disperse yellow 54#

InactiveCN105669545ASimple post-processingProcess environmental protectionOrganic chemistryAzo dyesThermal insulationCarboxylic acid

The invention discloses a preparation technology of dye disperse yellow 54#. The preparation technology comprises the steps that a thermal reaction is conducted on 2-methyl-3-hydroxyquinoline or 2-methyl-3-hydroxyquinoline-4-carboxylic acid and phthalic anhydride at the temperature of 200+ / -20 DEG C, after the reaction is completed, materials are put into hot water for dilution while the materials are hot, after dilution is completed, stirring and cooling are conducted to reach the temperature of 80+ / -10 DEG C, the materials are subjected to grinding through a colloid grinder, the pH value of the materials is adjusted to be between 7.5 and 9.0, thermal insulation is conducted at the temperature of 50-100 DEG C for 30 min or above, filtering and washing are conducted, and a target product is obtained. According to the preparation technology of the dye disperse yellow 54#, high-boiling-point solvent trichlorobenzene is not adopted in the reaction system, the phenomena of caking and balling of the product are greatly relieved, the aftertreatment process is easier, the whole technology is greener and more environmentally friendly, the grinding process of the colloid grinder is added for the diluted materials, the phenomena of caking and balling of the product are further significantly relieved, and the purity of the prepared target product reaches up to 98%-99.5%.

Owner:JIANGSU HUAER CHEM

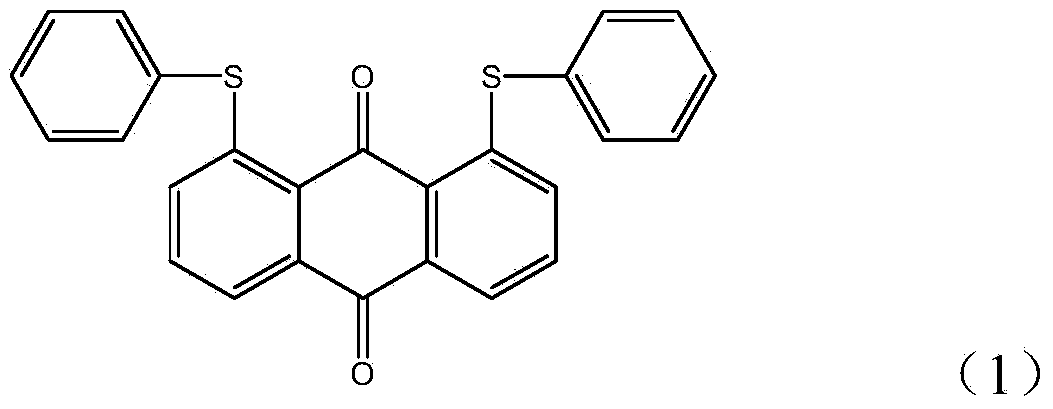

High-light fastness yellow disperse dye mixture and application thereof

ActiveCN103665932AGood light fastnessImprove light fastnessOrganic dyesDyeing processDisperse dyeColor changes

The present invention discloses a high-light fastness yellow disperse dye mixture and an application thereof, wherein the disperse dye mixture mainly comprises 75-25% by weight of a dye monomer A and 25-75% by weight of a dye monomer B, and the disperse dye mixture is provided for polyester fiber dyeing. According to the dye mixture, C.I.disperse yellow 163 (represented by a formula 1) is adopted as the one component of the dye mixture, and one or two dyes represented by a formula II are adopted as the other component, and the principle of blending synergy of the disperse dye is completely utilized, such that characteristics of excellent light fastness, excellent dyeing tolerance, excellent color change according to different light sources (used for blending gray, brown and other sensitive colors with no color change according to different light sources), and good application effect are provided when the obtained dye mixture is used for polyester fiber dyeing.

Owner:约克夏染料(中山)有限公司

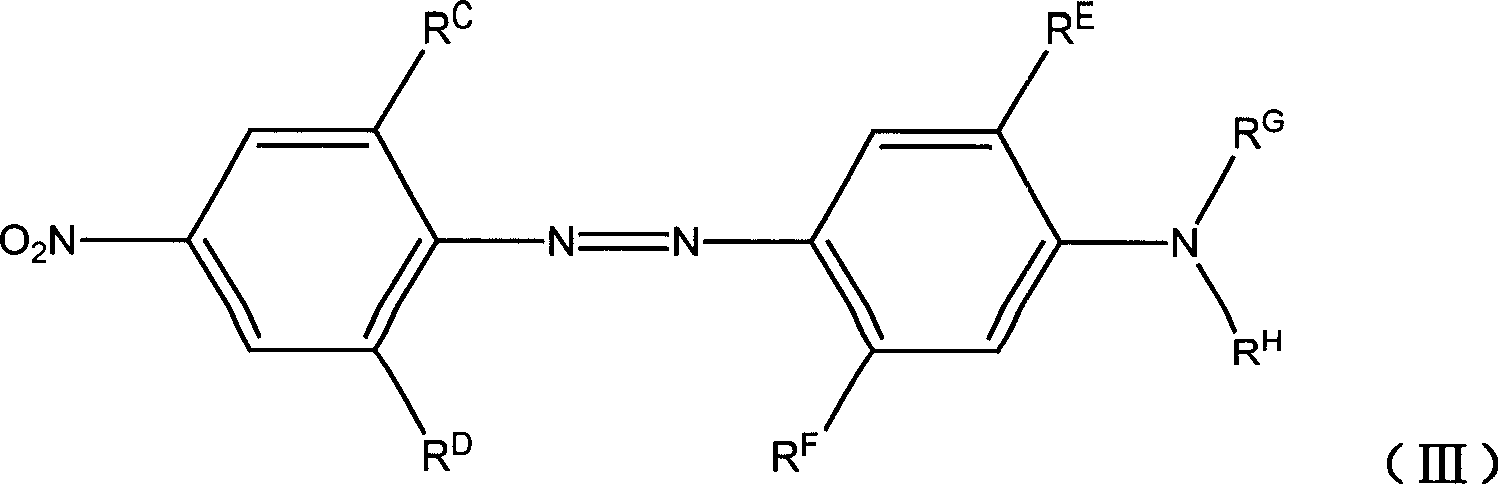

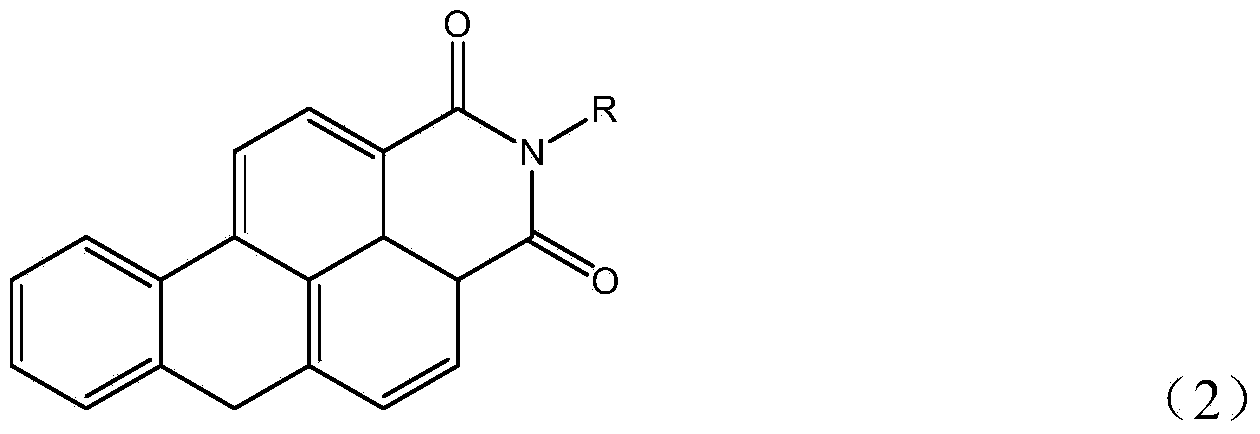

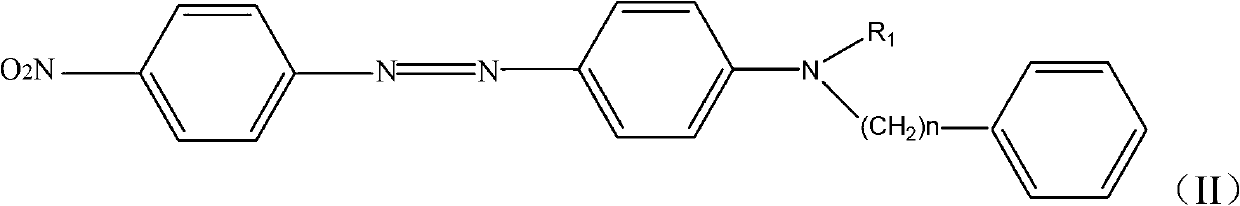

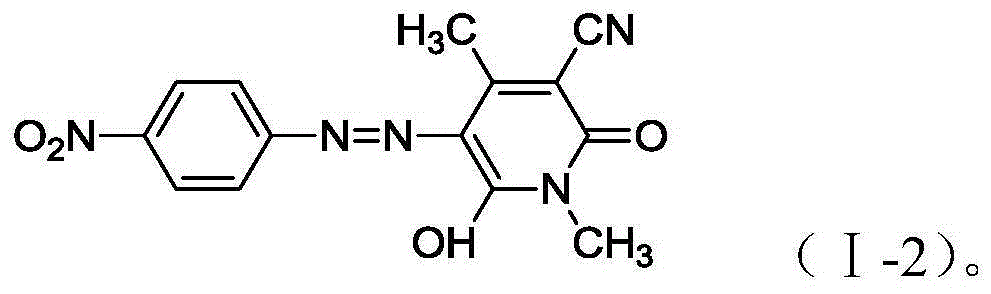

Complex dye composition, complex disperse dyes and preparation methods of composition and dyes

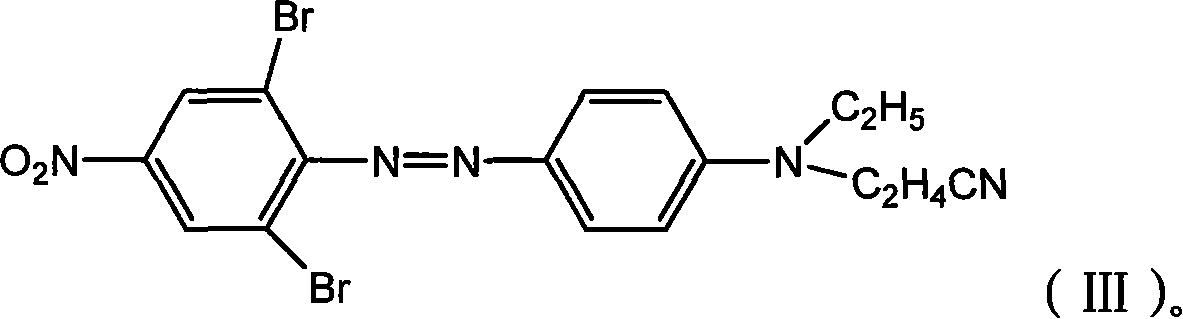

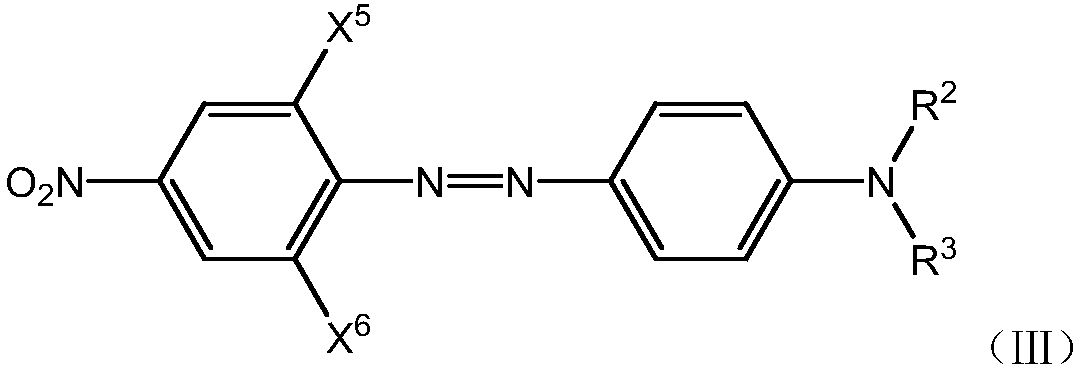

The invention relates to a complex dye composition, complex disperse dyes and preparation methods of the composition and the dyes. The complex dye composition comprises the following constituents shown in the following formulas (I), (II) and (III). According to the invention, the complex disperse dyes are environmental-friendly disperse yellow to orange dyes which are good in lifting power, good in washing fastness, and wide PH applicable range, and good in compatibility.

Owner:ZHEJIANG RUNTU

Production process for damp-proof chemical-fiber insulation rope for hot-line work

InactiveCN1438383ASolve problems that cannot be solved for a long timeExcellent moisture-proof insulation performancePlastic/resin/waxes insulatorsTextile cablesAcetic acidFiber

The invention uses chemical fiber materials, the manufacturing method is: the materials are combined and twisted into cord, uses azo disperse yellow and antraquinone disperse red to dye them, then carries on water-protection trimming craft, the trimming liquid is oleophobic water resisting agent, such as organic silicon or fluorin polymer, adds in glacial acetic acid to regulate the pH value, controls the time and temperature, then they are dried and formed into cord.

Owner:NINGBO TIANHONG POWER APPLIANCE

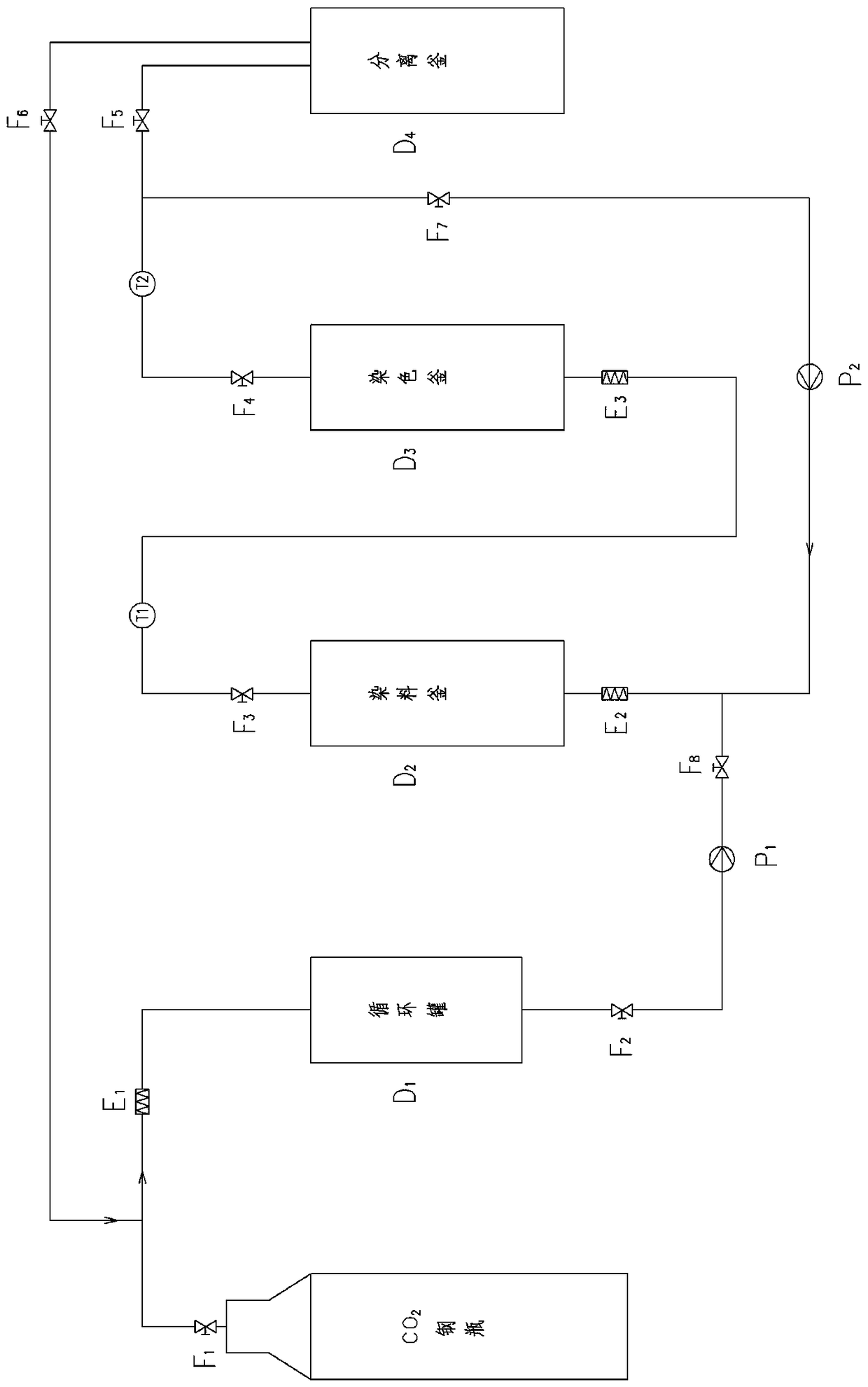

Supercritical CO2 fluid dye composition for textile, dyeing system and method

ActiveCN108086022AGood compatibilityReal-time detection of scale changesDyeing processCarbon dioxide cylinderDisperse dye

The invention belongs to the technical field of anhydrous dyeing of textile and particularly relates to a dyeing technology of textile in a supercritical CO2 fluid with three-primary color disperse dye. At least two of the three-primary color dye including C.I. disperse red 140, C.I. disperse yellow and C.I. disperse blue 56 are mixed in any ratio. All the disperse dyes are well compatible, are suitable to be used for supercritical CO2 fluid dying and can be combined to dye textile in various colors. The dyeing system of the composition comprises a CO2 steel cylinder, a booster pump, a dye kettle, a dyeing kettle and a separation kettle which are sequentially connected. A circulating pump is also arranged between a fluid outlet of the dyeing kettle and a fluid inlet of the dye kettle. Online detection is adopted in the dyeing process of the supercritical CO2 fluid, the proportion change of the three-primary color dye can be detected in real time, and competitive dyeing phenomenon can be avoided.

Owner:亚临界(上海)技术有限公司

Disperse yellow dye prescription

The invention relates to a disperse dye compound, and particularly relates to a disperse yellow dye compound. The disperse yellow dye prescription is obtained by mixing the following raw materials in percentage by mass: 65% of a chromatid A with a chemical formula shown in the description, 10% of a chromatid B with a chemical formula shown in the description, and 25% of a chromatid C with a chemical formula shown in the description. A dye mixed according to the scheme compound can replace a disperse yellow RGFL, and has a dyeing effect the same as that of the disperse yellow RGFL; the ratio of a mixture of the chromatid B and the chromatid C to the chromatid A is kept at (3:7)-(4:6); and when a finished dye product is prepared, auxiliaries and water are added in the chromatids, the obtained mixture is ground by using a sand mill, and then the obtained product is dried, so that the color of the disperse yellow RGFL can be synthesized, and then the obtained finished product can be directly used and can replace the disperse yellow RGFL.

Owner:ZHEJIANG SHANYU TECH CO LTD

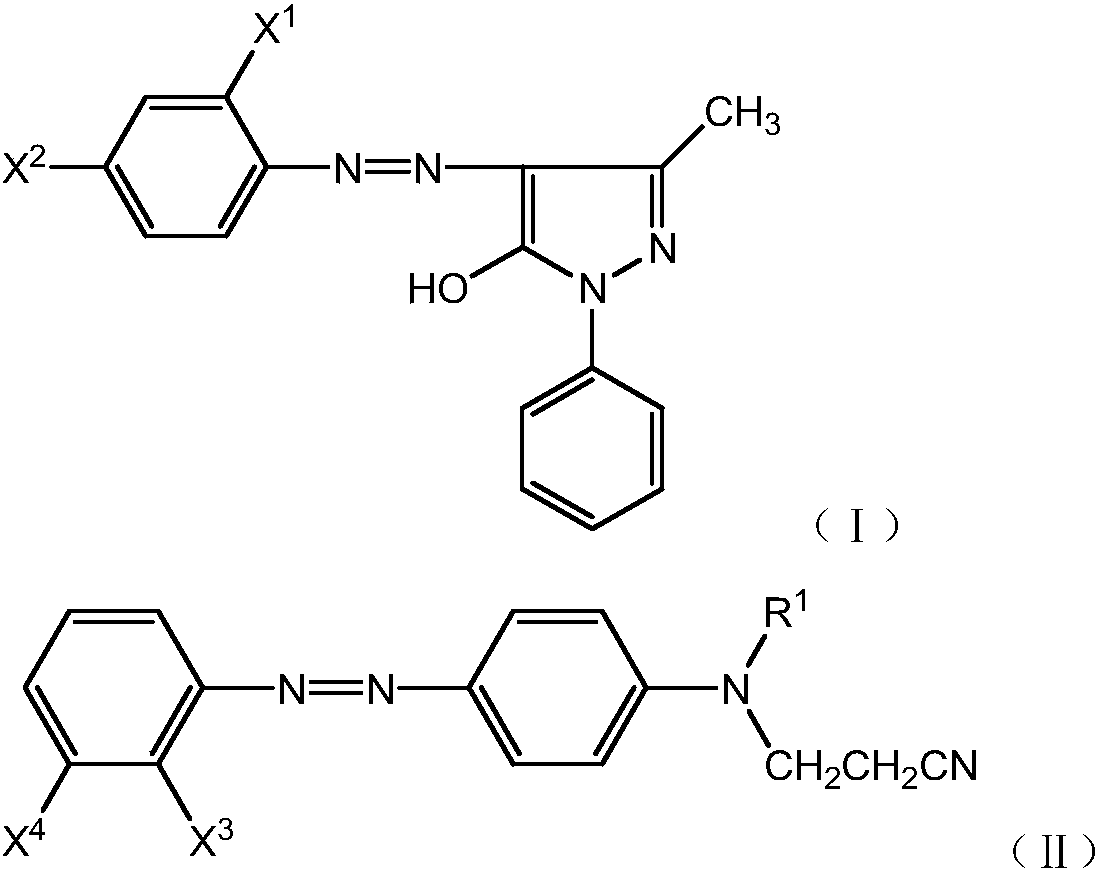

Disperse yellow dye composition and product thereof

A disperse yellow dye composition, comprising component A and component B, the component A is selected from at least one of the following formula (I), and the component B is selected from the following formula (II) At least one of the components, based on the component A and component B, the mass percentage of component A is 5 to 95%, and the mass percentage of component B is 5 to 95%; in formula (I) : X1, X2 are each independently: hydrogen, halogen, nitro or -COOCH3; in formula (II): X3, X4 one of which is hydrogen and the other is nitro; R1 is C1~C4 alkyl; the present invention provides The disperse yellow dye composition and dye products of this product have the characteristics of good compatibility, good levelness, good pH dependence, excellent sublimation resistance and washing fastness when used in the dyeing of hydrophobic fiber materials;

Owner:ZHEJIANG LONGSHENG GROUP +1

A kind of preparation method of disperse yellow dye

InactiveCN102295837AReduce consumptionReduce the feed ratioQuinoline dyesCarboxylic acidPhotochemistry

The invention provides a preparation method for a disperse yellow E-3G. The method comprises: adding 4-carboxylic acid and phthalic anhydride to a kneading device, starting the stirring, heating to a temperature of 170-200 DEG C, holding the temperature and carrying out condensation reaction until no gas is released; cooling to the temperature less than 60 DEG C after completing the reaction, then transferring the condensation compound in the kneading devices into water, then heating to the temperature of 90-100 DEG C, then holding for 1-3 h; carrying out filtering, and washing the filter cake through the water to obtain the filter cake of the disperse yellow dye. With the present invention, during the preparation process for the disperse yellow E-3G, the raw materials such as the 4-carboxylic acid and the phthalic anhydride are directly subjected to the condensation reaction in the kneading device, such that the disadvantage of the requirement of adding a plurality of an organic solvent DMF in the existing condensation process is overcome, the feeding ratio of the 4-carboxylic acid to the phthalic anhydride is reduced, such that the raw material consuming is substantially reduced, the production cost is saved, the waste water discharging is reduced; the method has characteristics of simple process, convenient operation and suitability to popularization and application; significant economic benefits and social benefits are provided.

Owner:ZHEJIANG LONGSHENG GROUP

Formula of foam disperse dyeing system and preparation method thereof

InactiveCN102115616AEasy to operateIncrease productivityOrganic dyesDyeing processTextile printerFoaming agent

The invention discloses a formula of a foam disperse dyeing system and a preparation method thereof. The formula contains 4-6g / L of foaming agent, 4-8g / L of thickening agent, 1-5ml / L of dispersing agent and high temperature disperse dark blue, high temperature disperse yellow brown or high temperature disperse red, wherein the total quantity of the three dyes is 20-60g / L. The formula and the method have the following beneficial effects: the foam dyeing technology is applied to the textile printing and dyeing process and the method is simple to operate, energy-saving and environment-friendly and is beneficial to greatly improving the production efficiency; in the dyeing process, water consumption is greatly reduced and wastewater discharge is reduced, thus being beneficial to environmental protection; and the products have the advantages of high fastness, high dye color yield, uniform dyed cloth cover and the like.

Owner:HUAFANG

Disperse yellow dye mixture resistant to light and acid-base and improved in sublimation fastness

InactiveCN102408749AGood light fastnessGood acid and alkali resistanceOrganic dyesDyeing processHydrogenStructural formula

A disperse yellow dye mixture resistant to light and acid-base and improved in sublimation fastness is formed by mixing a dye part and an auxiliary part, wherein the dye part is composed of two dyes in the following mass percentage contents: (1) 50-85% dye in accordance with a chemical general formula (I), wherein R in the formula (I) represents hydrogen or an alkyl having less than or equal to 4 carbon atoms; and (2) 15-50% dye in accordance with a chemical structural formula (II).

Owner:WUJIANG LVZHOU DYESTUFF CHEM

Disperse yellow brown dye composition with high dyeing degree

InactiveCN105062137APromote environmental protectionReduce manufacturing costOrganic dyesColor effectPerspiration

The invention discloses a disperse yellow brown dye composition with a high dyeing degree. The composition comprises, by mass, 5-10% of a component A represented by structural formula (I), 5-25% of a component B represented by structural formula (II), 5-25% of a component C represented by structural formula (III), and the balance of an assistant. The dye composition only contains two components, so the preparation steps are greatly simplified; the composition contains no chlorine-containing components, so the environmental protection performance of the composition is greatly improved, preparation of the chlorine-containing components is avoided, and the production cost and the environmental protection cost are greatly reduced; and the use amounts of the component A and the component B are reduced, and a strong deep color effect exists, so the production cost of the dye composition is further reduced on the premise of guaranteeing the brilliant color, the washing fastness, the scrubbing fastness, the perspiration fastness, the light fastness and the dyeing degree of a dyed sample cloth dyed by using the dye composition.

Owner:HANGZHOU FLARIANT SPECIALTY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com