Production process for damp-proof chemical-fiber insulation rope for hot-line work

A production process and live working technology, applied in the direction of organic insulators, plastic/resin/wax insulators, textile cables, etc., can solve the problems of non-moisture-proof performance, loss, personal and electrical equipment hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

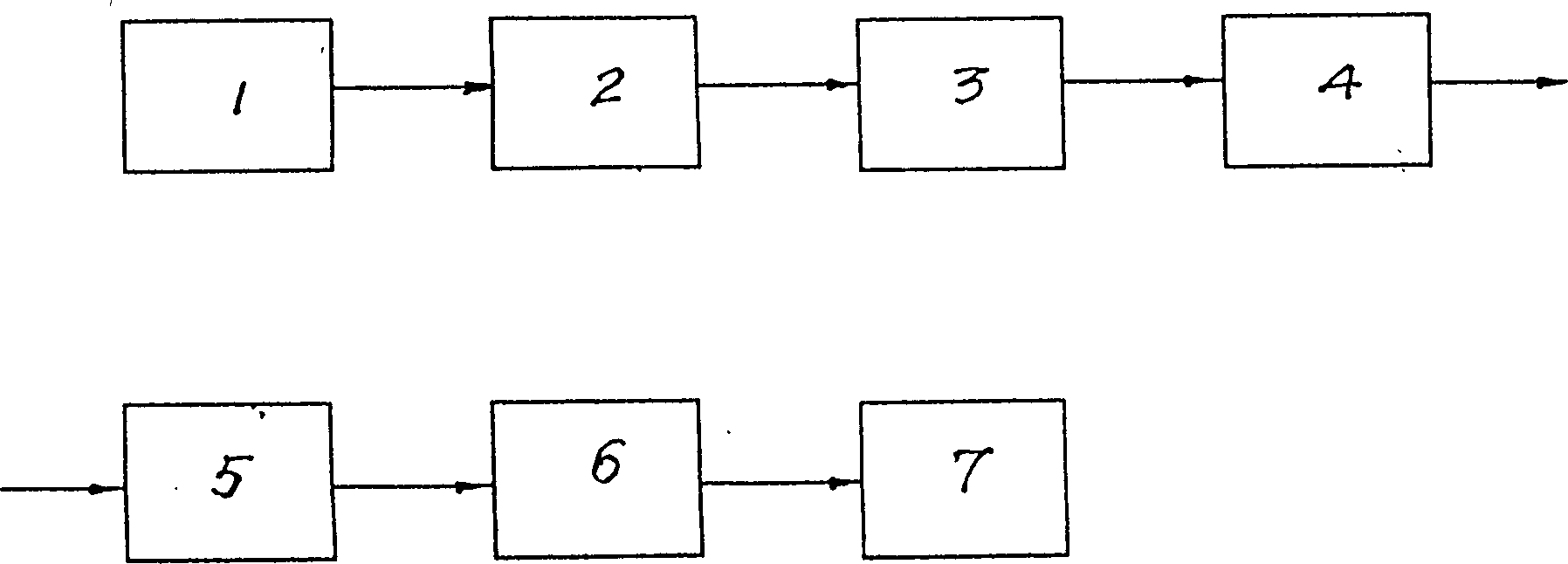

[0015] Example 1: Comparing the drawings, (1) chemically synthetic fibers such as nylon and polyester fiber materials are combined and twisted into fine threads; (2) for dyeing treatment, the dyes are azo-based disperse yellow and Anthraquinone disperse red, dye to material ratio is 1:100, bath ratio is 1:20-30, add glacial acetic acid to adjust PH to 4-5, control temperature is about 130℃, control time is about 30min, (3 ) After dyeing into orange, cool to 70-80℃, drain the water, and then enter the waterproof finishing process (4). The finishing liquid is oleophobol-SL, which is compared with the material 1:10, bath ratio 1:20-30, add glacial acetic acid to adjust PH to 5-6, control temperature at about 130℃, control time for about 30min, (5) After draining and drying, enter into finishing Set the shape (6), control the temperature at about 180℃, and the time is 20-40min, and (7) make the rope finished product.

Embodiment 2

[0016] Example 2: Comparing the drawings, (1) the chemically synthetic fiber material is combined and twisted into fine threads, (2) is dyed, and the dyes are azo-based disperse yellow and anthraquinone-based dispersion Red, dye to material ratio 1:100, bath ratio 1:20-30, add glacial acetic acid to adjust PH to 4-5, control temperature at about 130℃, control time for about 30min, (3) After dyeing orange red After cooling to 70-80℃, drain the water, and then enter the waterproof finishing process (4). The finishing liquid is made of silicone water repellent H, a methyl hydrogen-containing silicone oil emulsion, with a concentration of 100g / l Adjust the PH to 5-6, the temperature is 130°, and the control time is about 30min. (5) After draining and then enter the drying process, the drying temperature is about 80-90℃, (6) After finishing and shaping, The temperature is controlled at about 180°C, and the time is 30-40min. (7) The rope is then made into a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com