Method for producing dam-proof mulberry insulation rope for hot-line work

A production method and technology of live working, applied in the field of ropes made of silkworm filament materials, can solve the problems of high risk, loss, personal injury and electrical equipment hazards of live working

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

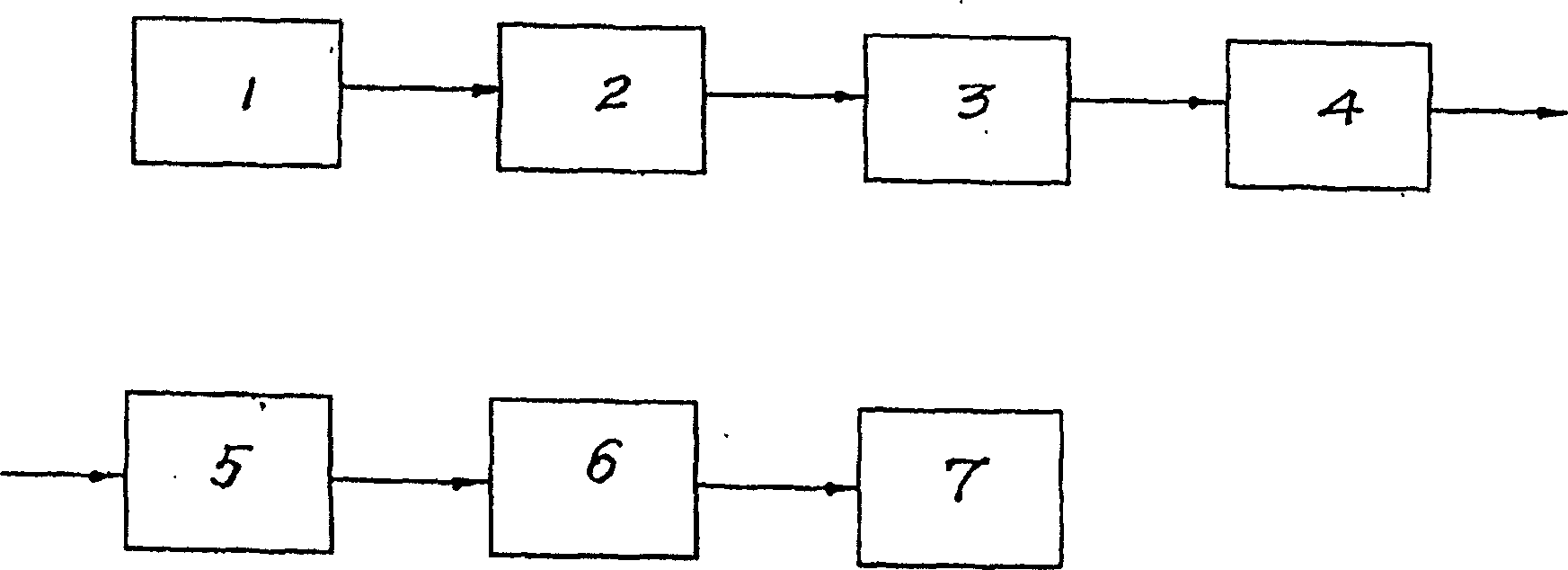

Image

Examples

Embodiment 1

[0015] Embodiment 1: with reference to the accompanying drawings, (1) the silkworm long fiber material is made into a thread through doubling and twisting, (2) dyeing treatment, the dyed dyes are polar Pula yellow GN and Pula red B , dyed orange, the ratio of dyeing solution to material is 1:100, the bath ratio is 1:20-30, add glacial acetic acid to adjust the pH to 4-5, control the temperature at 100°C, and control the time for about 30 minutes, (3) After dyeing, cool to 70-80°C, drain the water, and then enter the waterproof treatment process (4). The waterproof agent is made of organic fluoropolymer, Oleophobol-C, oil-repellent and water-repellent agent and materials The ratio is 8-10:100, the bath ratio is 1:20-30, add glacial acetic acid to adjust the pH to 4-5, control the temperature at 100°C, and control the time for about 30 minutes. (5) Drain and then enter the drying process , the drying temperature is 80-90°C, (6) finishing and finalizing the shape, controlling the...

Embodiment 2

[0016] Embodiment 2: With reference to the accompanying drawings, (1) the silkworm long fiber material is made into a thread through doubling and twisting, (2) dyeing treatment, the dyed dyes are polar Pula yellow GN and Pula red B , dyed orange, the ratio of dyeing solution to material is 1:100, the bath ratio is 1:20-30, add glacial acetic acid to adjust the pH to 4-5, control the temperature at about 100°C, and control time for about 30min, (3 ) after dyeing, cool to 70-80°C, drain the water, and then enter the waterproof treatment process (4). Make a bath solution with a concentration of 150g / l, adjust the pH to 6-6.5, control the temperature at 100°C, and control the time for 30 minutes. (5) Drain and then enter the drying process, and the drying temperature is at 80-90°C. 6) Finishing and finalizing the shape, controlling the temperature at about 110°C for about 30 minutes, and (7) making the rope into a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com