Moisture-proof polyester insulating rope for live work and preparation method thereof

A technology for live operation and insulating ropes, which is applied in textile cables, auxiliary equipment for rope making, textiles and papermaking, etc., can solve the problems of poor waterproof effect, and the performance of moisture-proof insulating ropes cannot meet national standards, and can simplify the preparation process. The effect of shortening the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

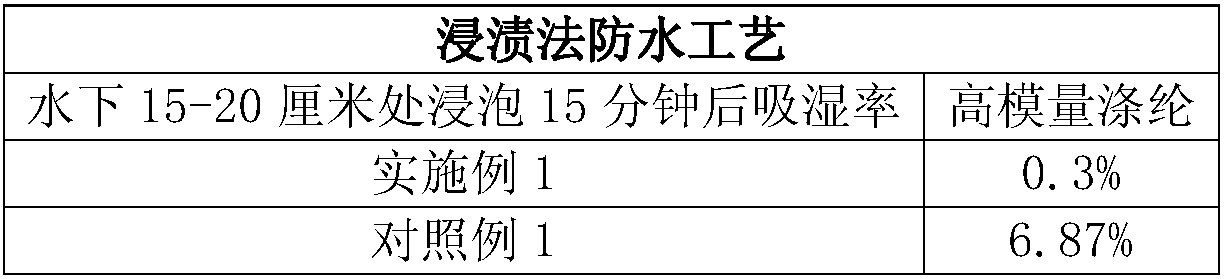

Embodiment 1

[0038] step one

[0039] Polyester filaments are made into threads by doubling and twisting, dyed by dipping acid dyes, and then processed into orange-yellow, then taken out, washed, and dried to obtain dyed core materials; the dyes used are disperse dyes with anthraquinone structure; the dosage is 1.5% of silk mass. In this embodiment, a skein dyeing machine is used for dyeing; when a skein dyeing machine is used for dyeing, the liquor ratio is controlled to be 1:10.

[0040] step two

[0041] According to the mass ratio, after water-based polyurethane and / or polyacrylate:coupling agent=1:1 are mixed evenly, liquid B is obtained;

[0042] The dyed core material obtained in step 1 is placed in liquid B, and after immersion at 100°C for 1 hour, a dyed core material with a transition layer is obtained; the liquid B is composed of a coupling agent, water-based polyurethane and polyacrylate in a mass ratio of 1 : 1 composition; the general formula of the coupling agent is YSiX3...

Embodiment 2

[0050] step one

[0051] Polyester filaments are made into threads by doubling and twisting, dyed by dipping acid dyes, and then processed into orange-yellow, then taken out, washed, and dried to obtain dyed core materials; the dyes used are disperse dyes with anthraquinone structure; the dosage is 1% of silk mass. Adopt hank yarn dyeing machine to carry out dyeing in the present embodiment; When adopting hank yarn dyeing machine to carry out dyeing, control bath ratio is 1:20;

[0052] step two

[0053] According to the mass ratio, polyacrylate: coupling agent = 1:10, after mixing evenly, liquid B is obtained;

[0054] Place the dyed core material obtained in step 1 in liquid B, and soak it at 130°C for 0.5 hours to obtain a dyed core material with a transition layer; the general formula of the coupling agent is YSiX3, where Y is -CH3 and X is -OCH3; The general formula of the polyacrylate is Wherein the number of carbon atoms on the R group is 8; the particle size of th...

Embodiment 3

[0059] step one

[0060] Polyester filaments are made into threads by doubling and twisting, dyed by dipping acid dyes, and then processed into orange-yellow, then taken out, washed, and dried to obtain dyed core materials; the dyes used are disperse dyes with anthraquinone structure; the dosage is 3% of silk mass. In this embodiment, a skein dyeing machine is used for dyeing; when a skein dyeing machine is used for dyeing, the liquor ratio is controlled to be 1:10.

[0061] step two

[0062] According to the mass ratio, water-based polyurethane: coupling agent = 1:20, after mixing evenly, liquid B is obtained;

[0063] The dyed core material obtained in step 1 is placed in liquid B, and after immersion at 120° C. for 40 minutes, a dyed core material with a transition layer is obtained; the liquid B is composed of a coupling agent and water-based polyurethane in a mass ratio of 1:1; the The general formula of the coupling agent is YSiX3, wherein Y is-CH3, X is-OCH3; the gen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com