Patents

Literature

388results about How to "Short manufacturing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrocarbon cracking catalyst containing modcfied faujasite

InactiveCN1624079AGood hydrothermal stabilityHigh reaction conversion rateCatalytic crackingHigh resistanceRare earth

A hydrocarbon cracking catalyst containing modified octahedra zeolite is prepared from modified octahedra zeolite, one or moke kinds of other modified zeolite, clay and refractory inorganic oxide through proportional mixing, spray shaping, and washing. Its advantages are high activity and stability, high gasoline output rate, low coke output rate, and high resistance to heavy metal pollution.

Owner:PETROCHINA CO LTD

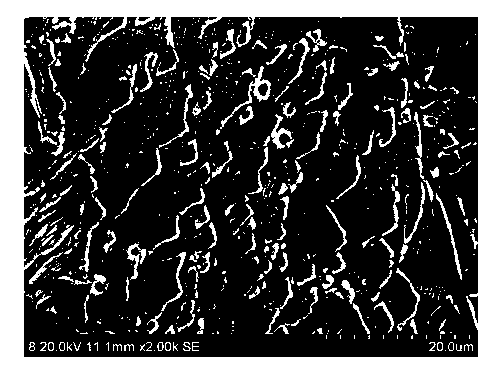

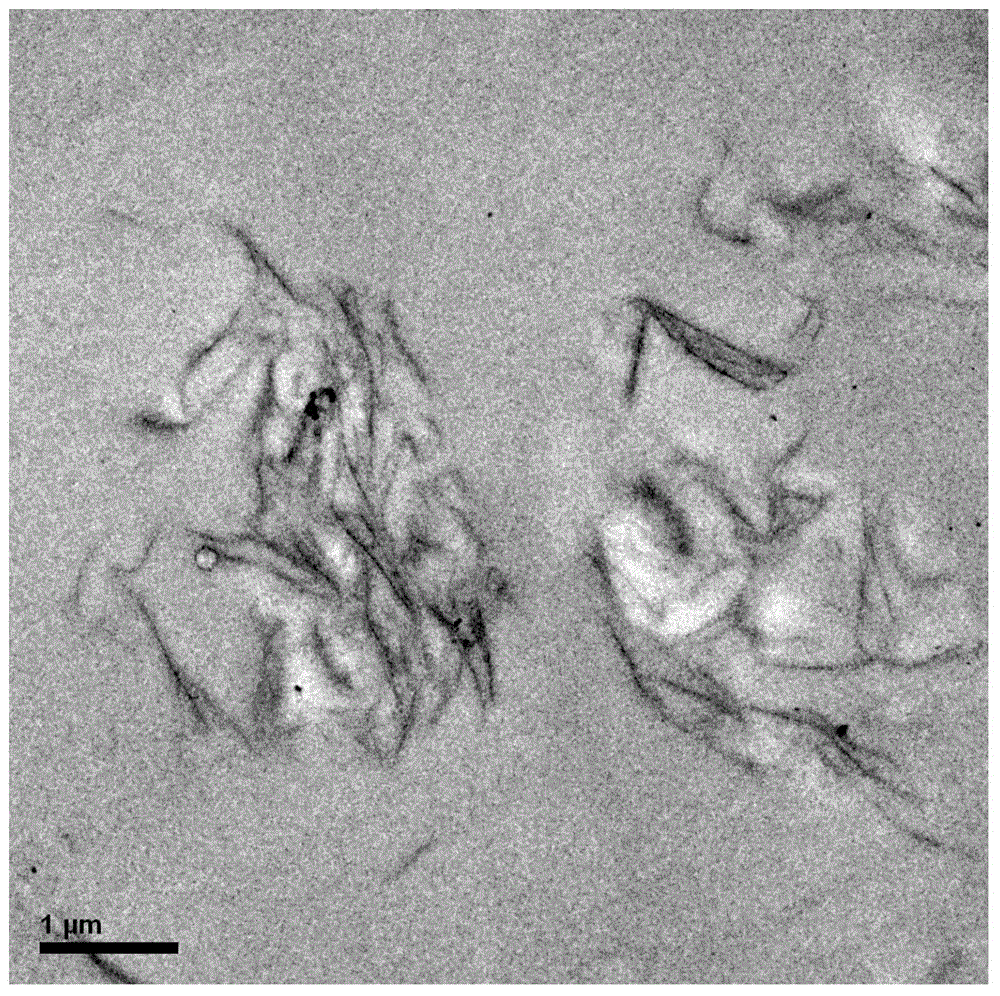

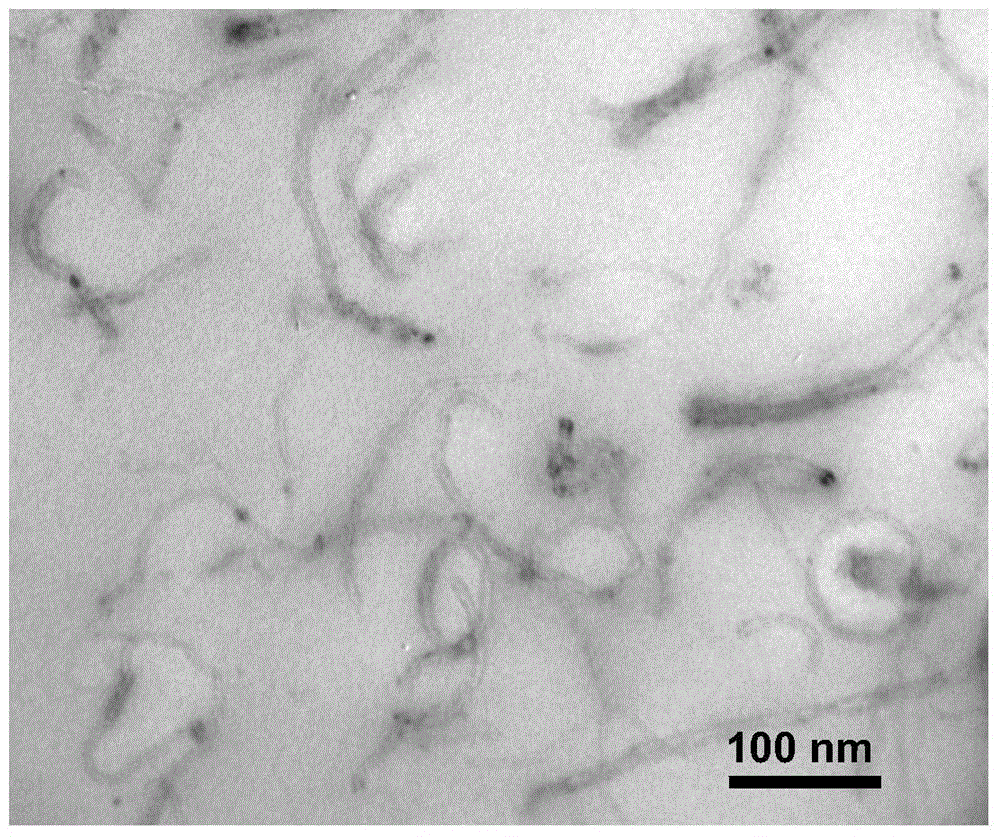

Graphene micro-sheet used for waterborne anticorrosive coating and preparation method thereof

InactiveCN106566303ADefects that reduce corrosion resistanceEasy to peelAnti-corrosive paintsSolubilityGraphite

The invention discloses a graphene micro-sheet used for a waterborne anticorrosive coating and a preparation method thereof. According to the invention, graphite is stripped to prepare the graphene micro-sheet by utilizing mechanical shearing force, so the lamellar structure of graphene is protected, and the corrosion resistance of graphene lamella is avoided from decrease due to damage of the graphene lamella; meanwhile, in the process of preparing the graphene micro-sheet, a surfactant is utilized for surface modification of the prepared graphene micro-sheet, so the water solubility of the graphene micro-sheet is increased; the modified graphene is coated with a shell material, so a modified graphene microcapsule with a shell is formed, and the modified graphene is prevented from agglomeration during storage and formulation; and the shell is a macromoleclar polymer, so the compatibility of graphene with materials in the anticorrosive coating can be improved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Composite coating with friction-decreasing function and biological-foul and seawater resistances and its production

InactiveCN101074331AImprove the protective effectResistant to microbial foulingAntifouling/underwater paintsPaints with biocidesComposite ceramicAlloy

A composite coating against biological fouling and seawater corrosion and its production are disclosed. The composition consists of oxide based-phase ceramic powder 80-95 wt% and powder against biological fouling 5-20 wt% with Cu, CuO or Cu2O powders. The composite coating comprises binding bottom layer, composite ceramic coating and surface sealing layer; ZnNi alloy powder is sprayed on metal substrate of binding bottom layer by supersonic flame; Composite ceramic power against biological fouling and sea-water corrosion is sprayed on bottom of composite ceramic coating by plasma; Inorganic or organic sealer with low surface energy is sprayed on surface sealing layer. An insulating ceramic transient layer is added between binding bottom layer and composite ceramic coating when Cu powder is adopted. It's simple and cheap and can be used for industrial production.

Owner:WUHAN UNIV OF TECH

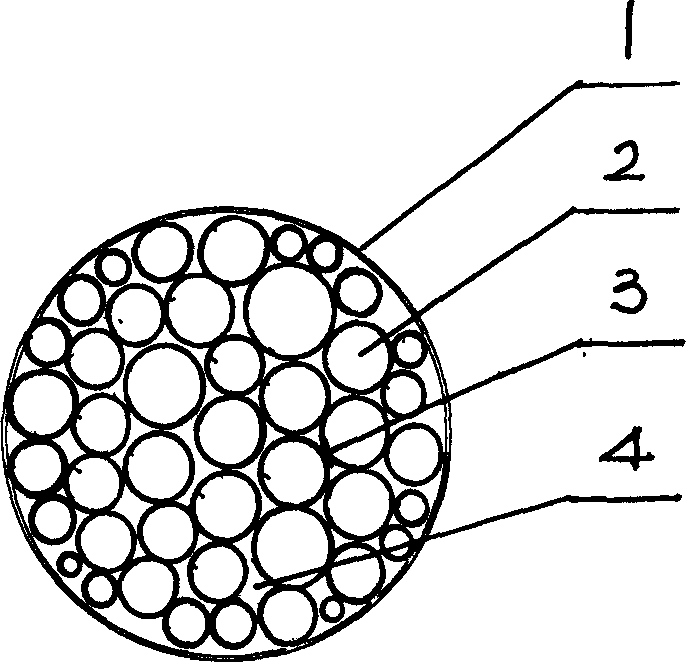

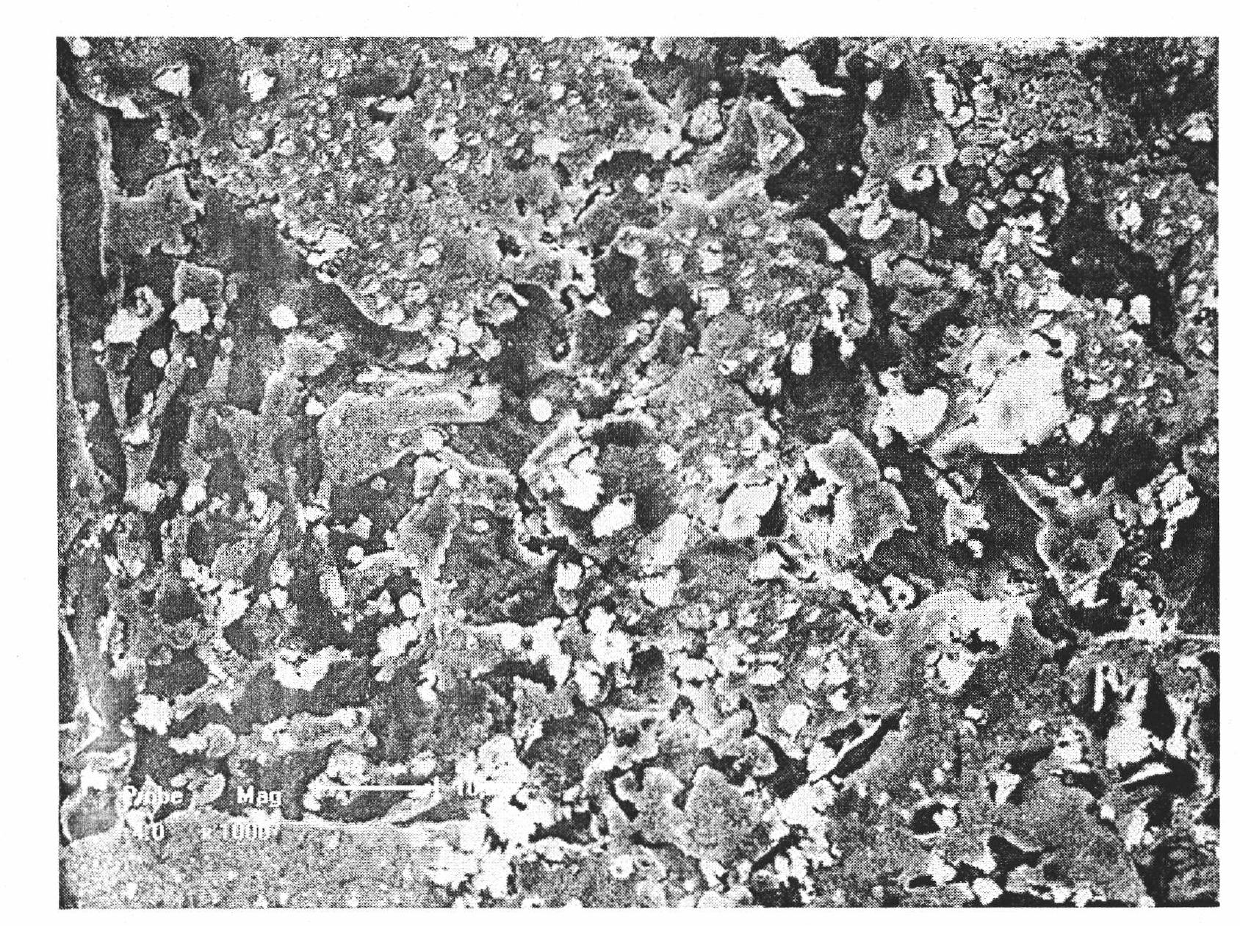

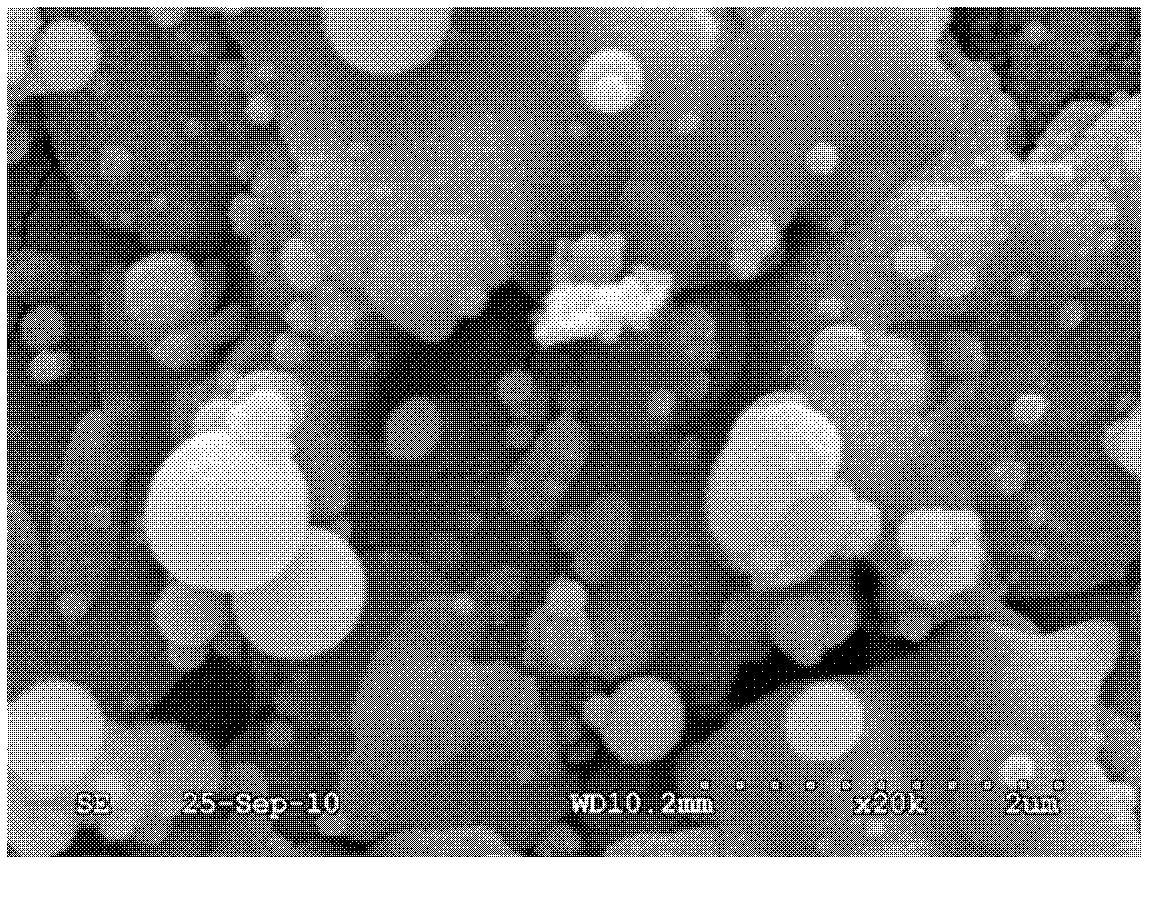

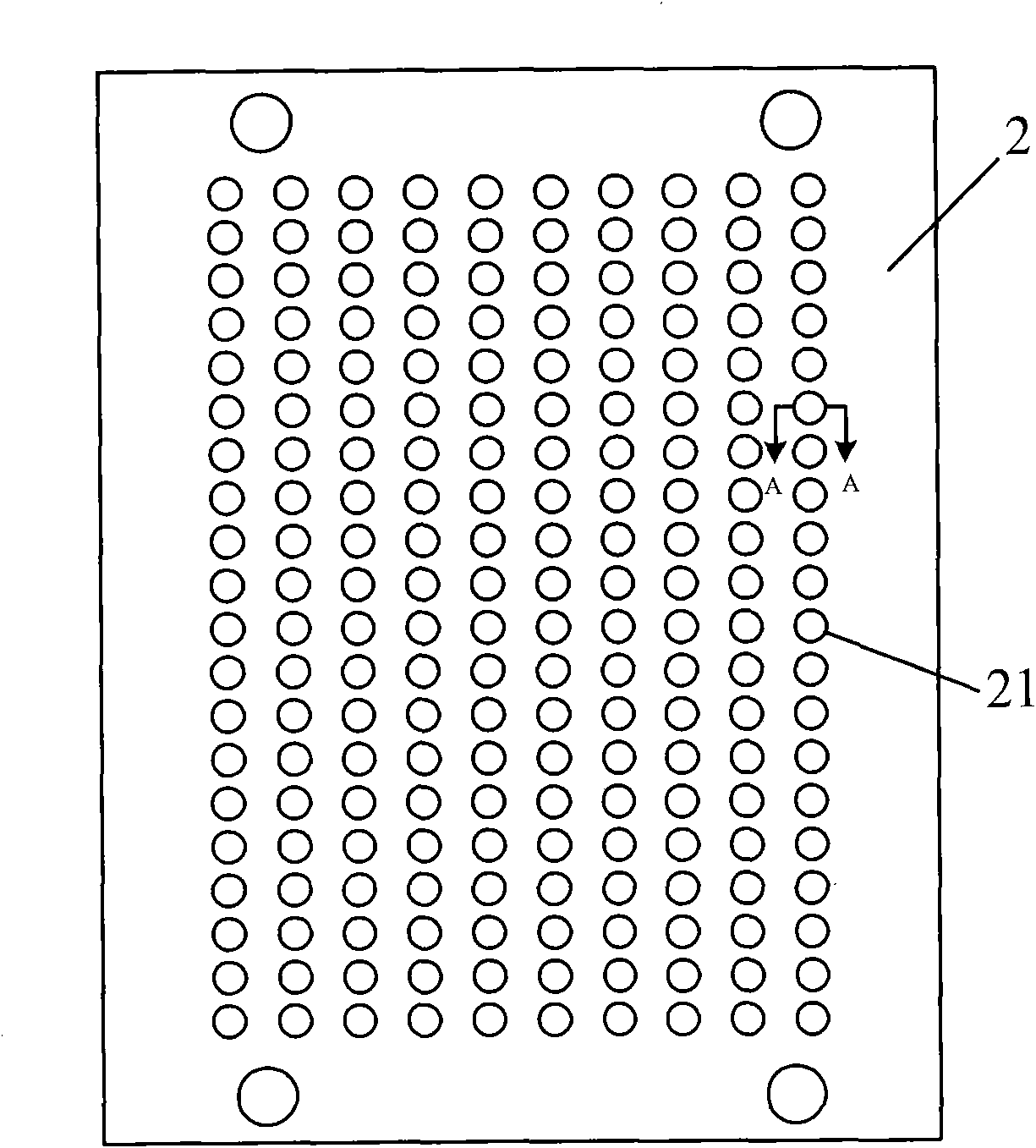

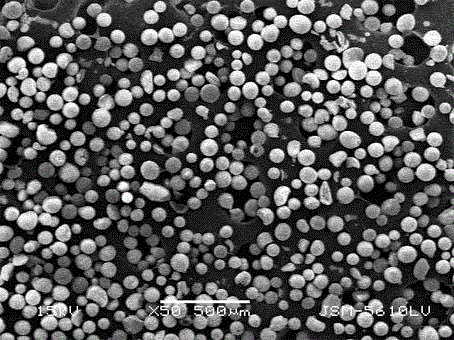

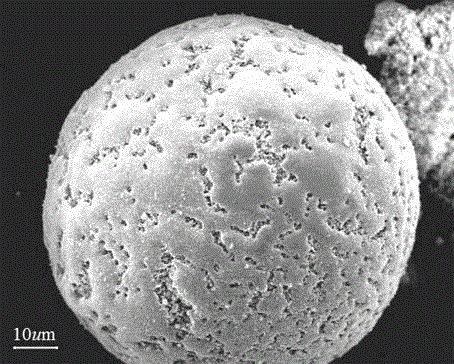

Prepn of nanometer aggregated zirconia powder for hot spraying

InactiveCN1637080AControl growthStructure does not growLiquid surface applicatorsCoatingsThermal sprayingMass ratio

The preparation process of nanometer aggregated zirconia powder for spraying includes: mixing nanometer zirconia powder stabilized with 20-60 nm granularity yttrium oxide and adhesive in the mass ratio of 95:5 to 98:2 and adding pure water of 1-1.3 times the mixture weight to compound slurry; spraying at 110-300 deg.c to form micron level aggregated powder; and final plasma nodulizing or sintering to form compact powder of 40-90 micron granularity and with the nanometer crystal structure maintained. The obtained powder may meet the technological requirement of plasma spraying or flame spraying. The technological process is simple, great in output, safe, reliable, low in cost and suitable for continuous industrial production.

Owner:WUHAN UNIV OF TECH

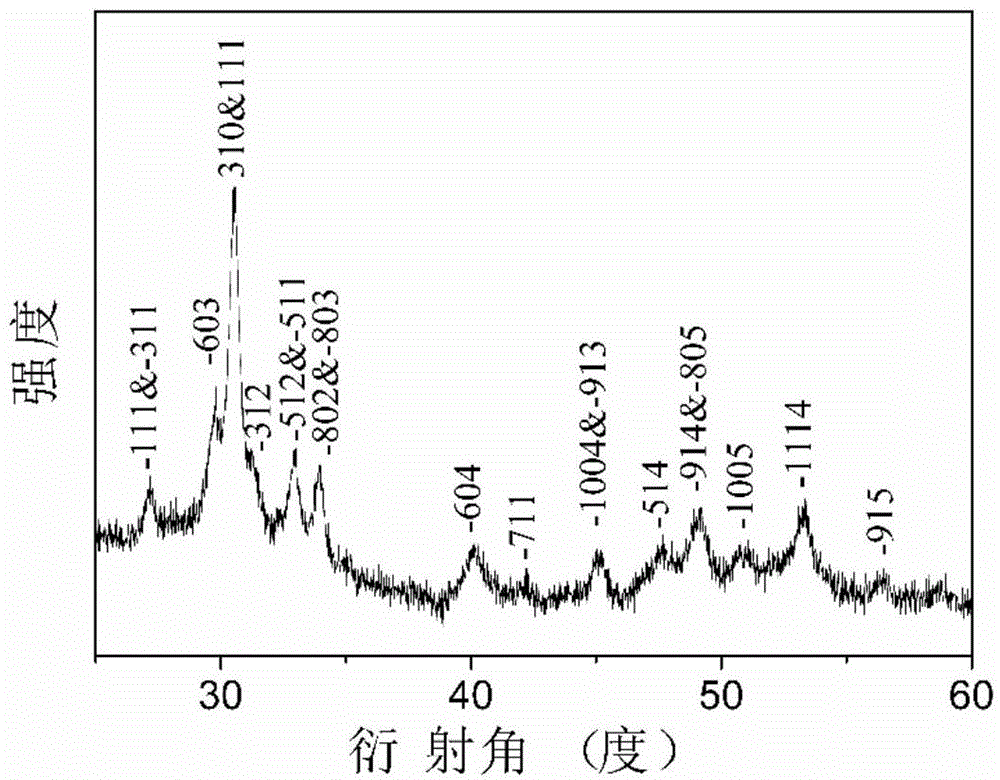

Modified octahedral zeolite

InactiveCN1209288CGood hydrothermal stabilityHigh reaction conversion rateCatalytic crackingFaujasite aluminosilicate zeoliteAmmonium compoundsFiltration

A modified faujasite is obtained by exchanging the faujasite with a phosphorus compound and an ammonium compound, and then introducing a rare earth solution into the exchange slurry for further reaction, filtering, washing, and roasting with water vapor. Mix the zeolite component, clay and the precursor of the high-temperature-resistant inorganic oxide uniformly in a certain proportion, spray molding, and washing. The prepared catalyst has good activity and stability, high gasoline yield, low coke yield, and heavy oil Strong cracking ability and heavy metal pollution resistance.

Owner:PETROCHINA CO LTD

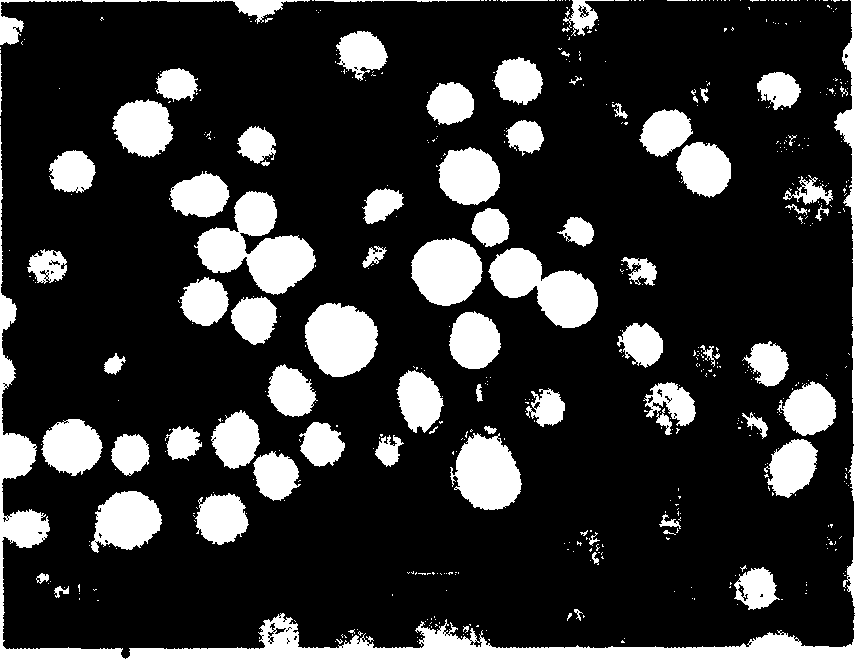

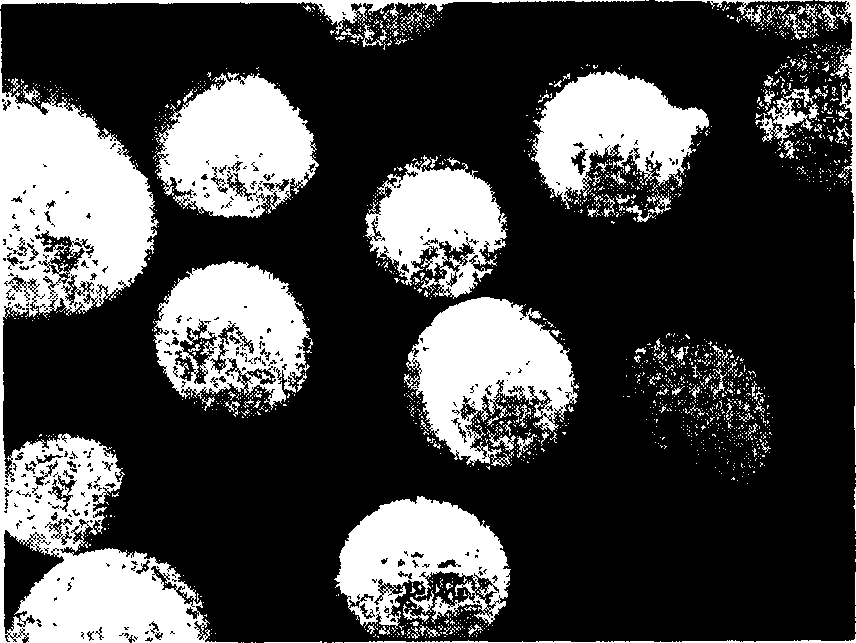

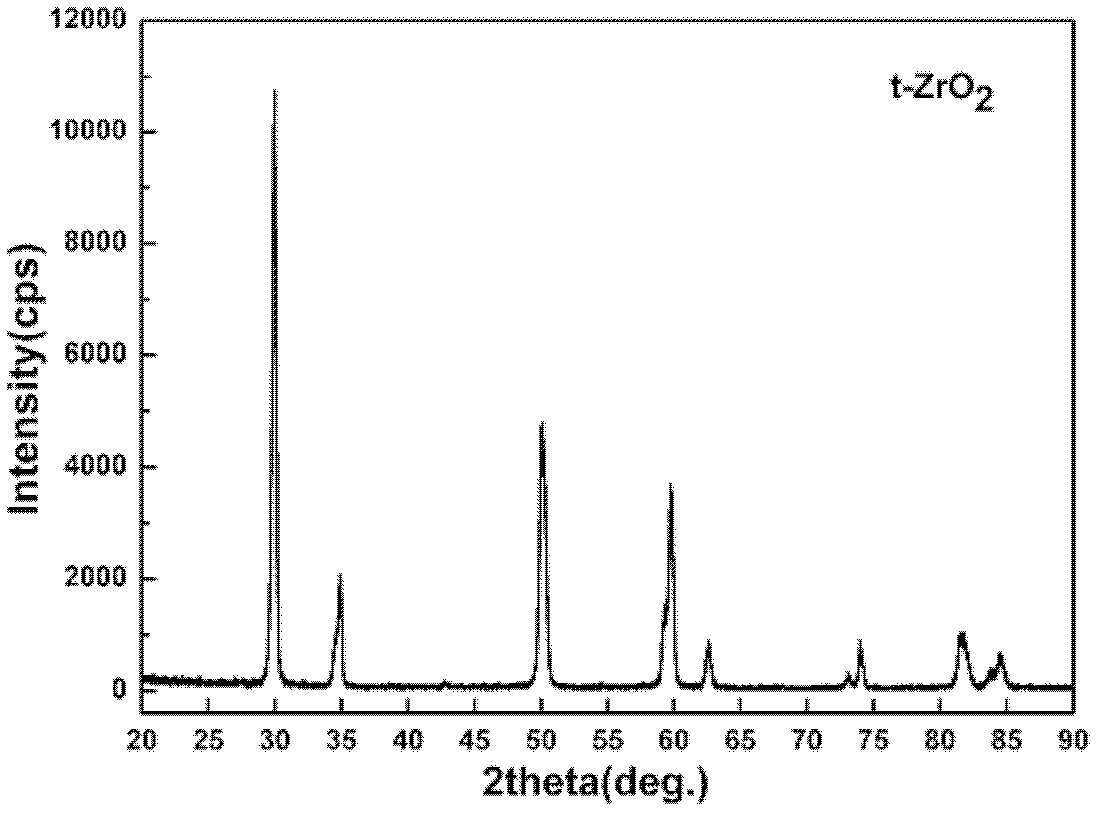

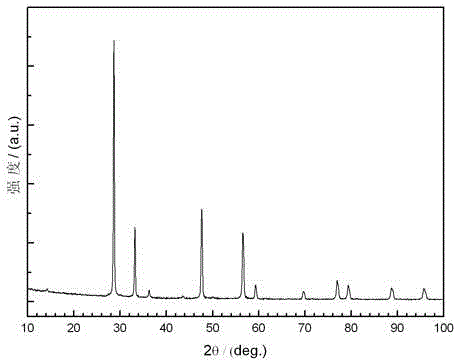

Nano structure yttrium stabilized zirconium oxide aggregated powder and its producing method

InactiveCN1587062AShort manufacturing processSuitable for continuous mass productionTitanium dioxideNano structuringGranularity

The nanometer structure yttrium stabilized aggregated zirconium oxide powder consists of nanometer crystal particle of size smaller than 100 nm and is in aggregated powder structure in granularity of 40-90 microns. Inside the aggregated structure, the nanometer zirconium oxide particles are contacted partially with pure cavity inside. The production process includes adding water into nanometer zirconium oxide particle containing yttrium oxide to obtain aquatic suspended colloid, and subsequent spray drying, sieving, heat treatment and plasma densifying. The production process is simple, low in cost, continuous and suitable for industrial production, and the product is suitable for plasma spraying, flame spraying, etc. and may be used in preparing various kinds of heat resisting coating, wear resisting coating and anticorrosive coating in various industry.

Owner:湖北葛店开发区地大纳米材料制造有限公司

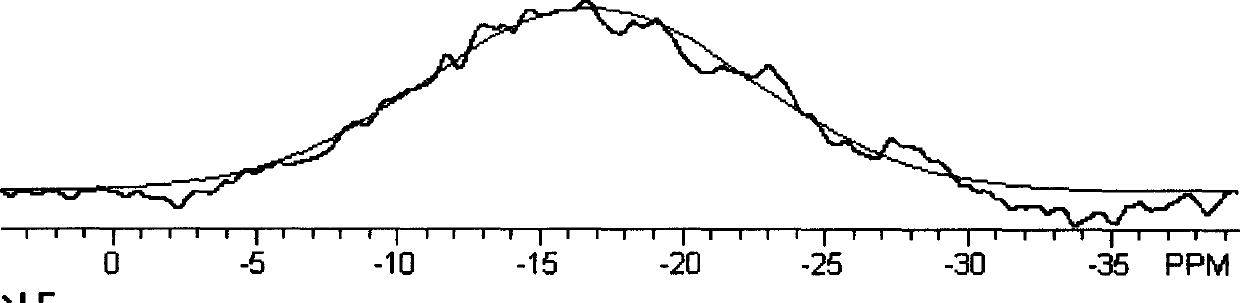

REY molecular sieve containing phosphor and amorphous silica, preparation method and application

ActiveCN1660496ADelay the speed of dealuminationImprove unit cell integrityMolecular sieve catalystsRefining by aromatic hydrocarbon hydrogenationMolecular sievePhosphor

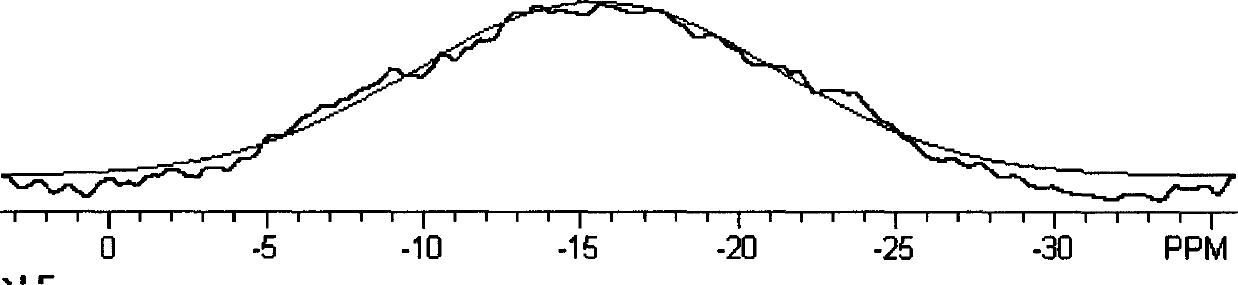

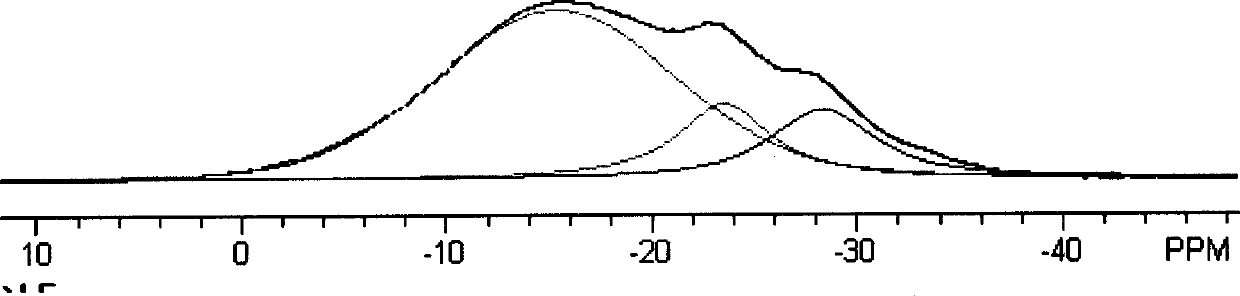

A molecular sieve REY containing P and amorphous silicon oxide for decreasing the content of olefin in gasoline and improving the selectivity of coke features that in its P MAS NMR spectrum the summary area of its -15+ / -2 ppm peak and -23+ / -2 ppm peak is 85% greater than the total peak area. Its preparing process is also disclosed.

Owner:CHINA PETROLEUM & CHEM CORP +1

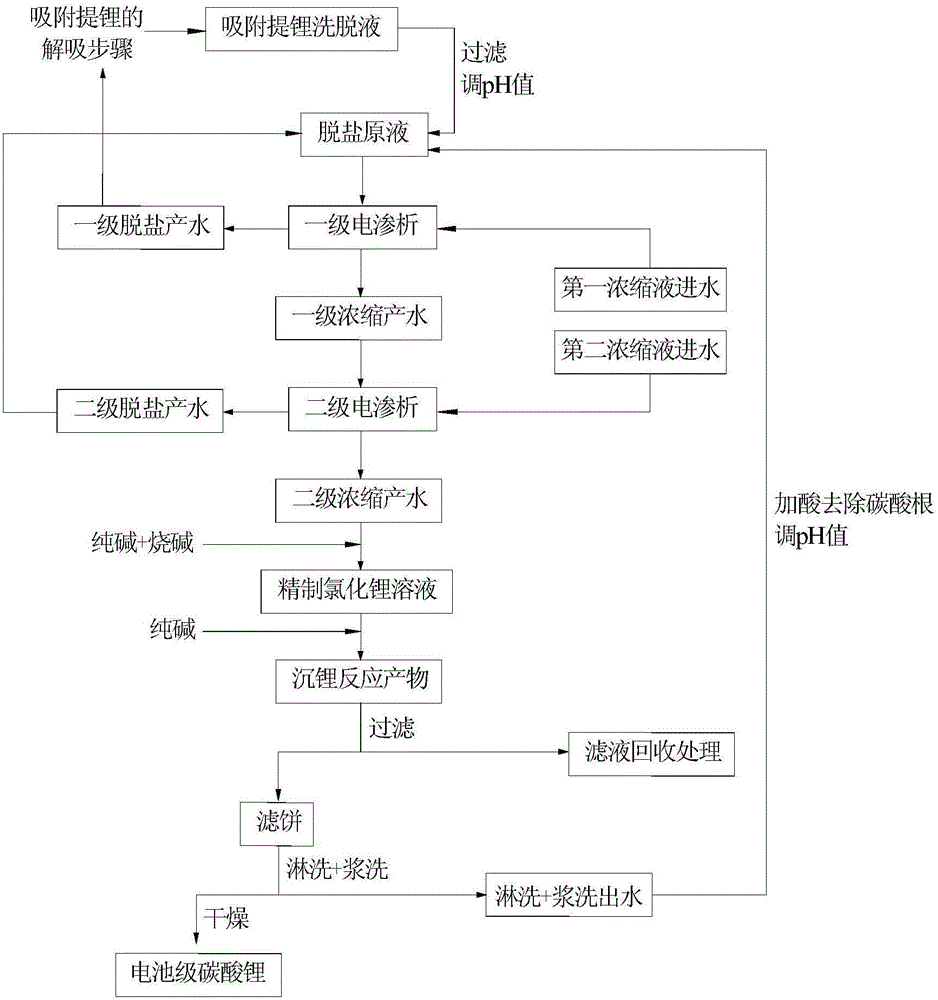

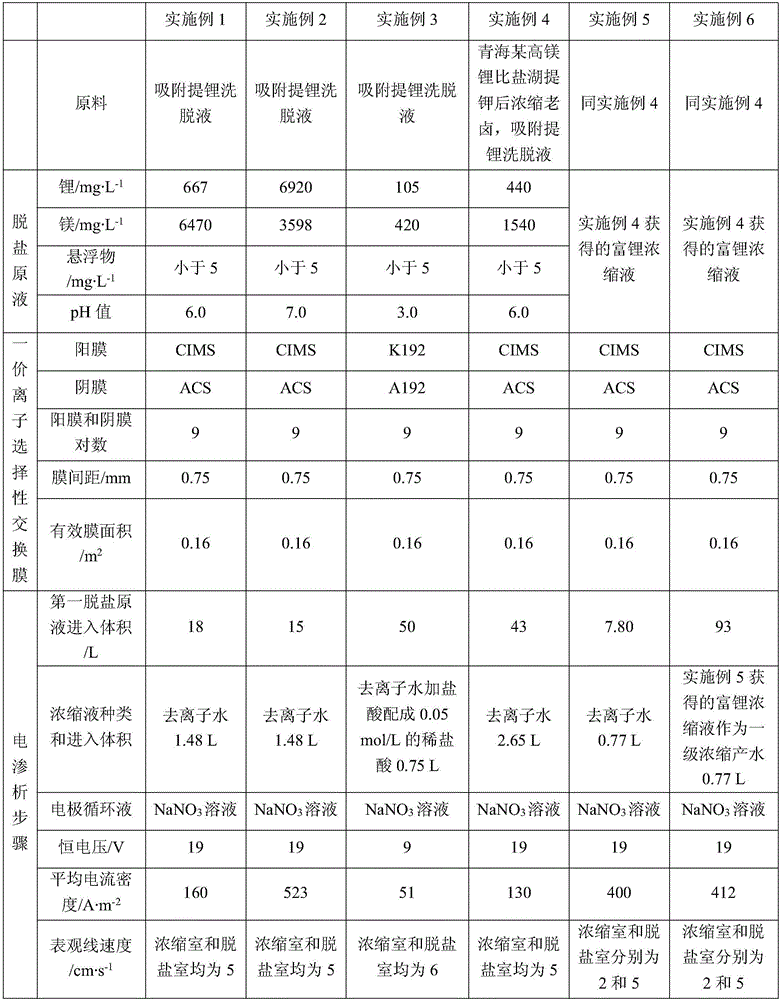

Preparation method of battery-grade lithium carbonate

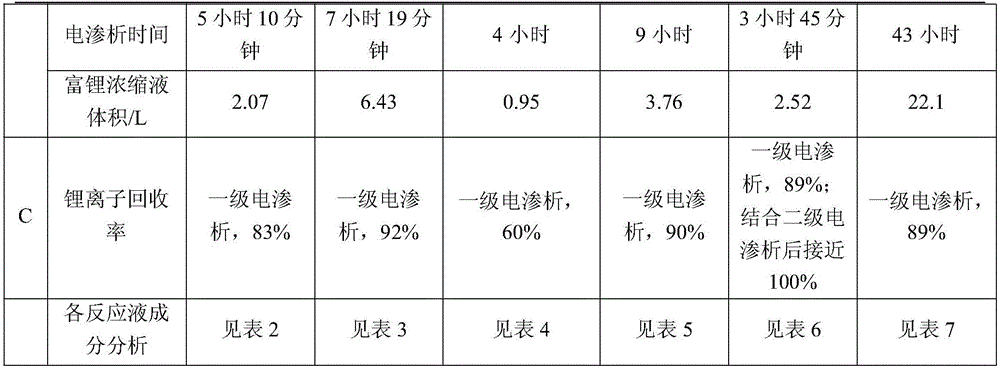

ActiveCN106186002AEfficient separationShort processGeneral water supply conservationElectrodialysisLithium carbonateMonovalent ions

The invention discloses a preparation method of battery-grade lithium carbonate. The preparation method comprises the following steps: taking a lithium adsorption and desorption eluent as a raw material, performing primary and secondary monovalent ion selective electrodialysis treatment, concentrating and enriching a lithium ion by utilizing the monovalent ion selectivity of a monovalent ion selective cation membrane and a monovalent ion selective anion membrane, and intercepting magnesium ions, sulfate ions and borate ions, thereby realizing efficient separation of lithium and magnesium as well as sulfate and borate ions and other impurity ions and lithium concentration and obtaining a lithium-rich concentrated solution with a lithium content of 10-20 g / L and a ratio of magnesium to lithium of 0.1-1; obtaining the battery-grade lithium carbonate through the steps of deep calcium and magnesium removal, heavy lithium conversion, filtering and washing, drying, cooling and the like. According to the preparation method disclosed by the invention, the preparation process of the battery-grade lithium carbonate is greatly shortened, the process continuity is obviously improved, the cost is reduced, and the bottleneck problem of magnesium removal and concentration by using the salt lake lithium adsorption and desorption eluent with high magnesium-lithium ratio is solved.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

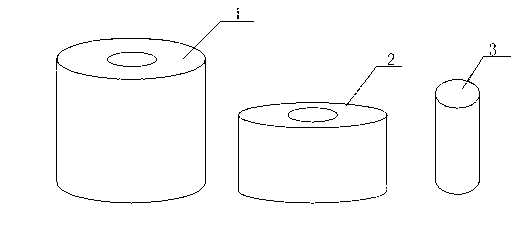

Method for preparing Mg-Li alloy by vacuum synchronous thermal reduction

The invention relates to a method for preparing an Mg-Li alloy by vacuum synchronous thermal reduction, belonging to the novel technical field of preparing magnesium alloy materials. The process course comprises the following steps of: preparing reactants according to stoichiometry of reduction reaction; pulverizing solid reactants and uniformly mixing; pressing the reactant powder into blocks and placing the blocks into a reduction tank, and carrying out thermal reduction reaction at the vacuum degree of 1-20Pa and the temperature of 950-1,500 DEG C; collecting alloy steam generated by reaction; and condensing the alloy steam to obtain an Mg-Li alloy in a condensed state. In the invention, the oxides of metals Mg and Li or a precursor of the oxides are utilized as raw materials, the synchronous reduction of the metals Mg and Li is realized through vacuum thermal reduction to prepare the Mg-Li alloy directly. The alloy preparation process has short route, wide sources of the raw materials, high material utilization rate, favorable economy and manufacturability, high efficiency and energy saving.

Owner:CHONGQING UNIV

Preparation method of powder metallurgy tool and mould steel

The invention discloses a preparation method of powder metallurgy tool and mould steel. The preparation method combines the advantages of vacuum induction melting, inert gas atomized powdering process and powder metallurgy technology, and comprises the steps of utilizing gas atomized powdering equipment to melt tool and mould steel, preparing high-quality tool and mould steel powder with little porosity powder, little nonmetal inclusion and a small size through an optimally designed negative pressure powdering process, and preparing high-quality powder metallurgy tool and mould steel ingot through further thermal dynamic degassing, sheathing and hot isostatic pressing.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

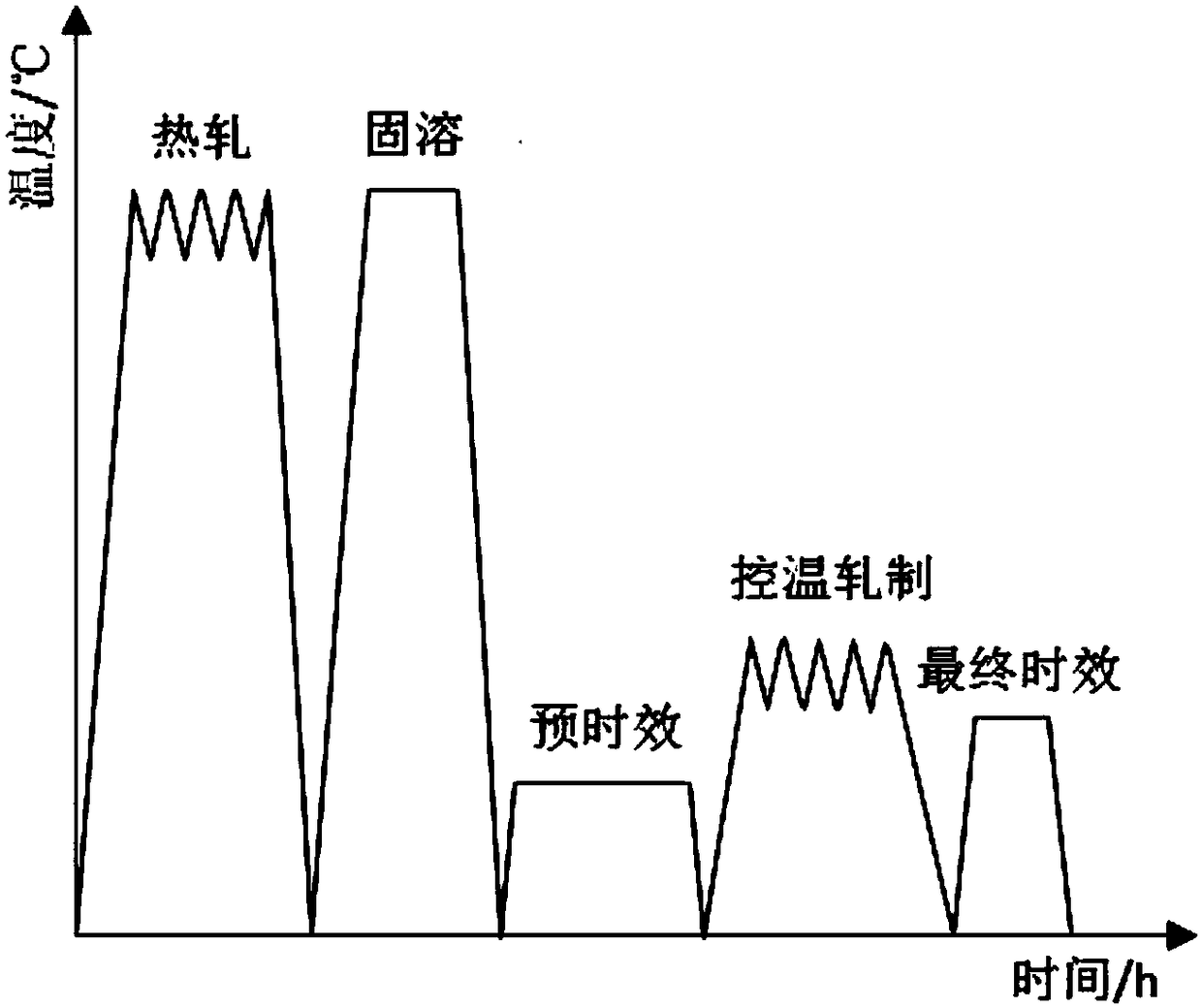

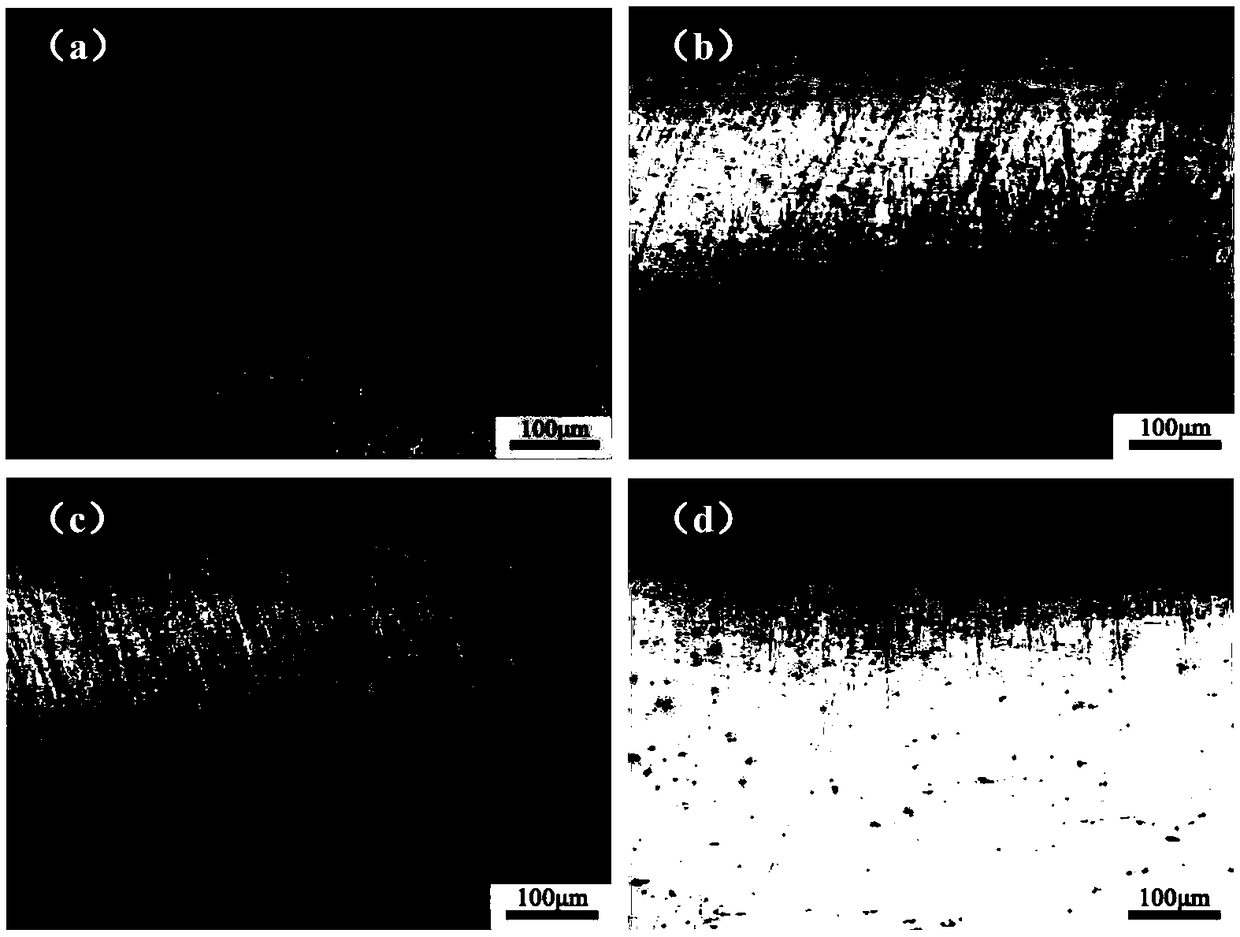

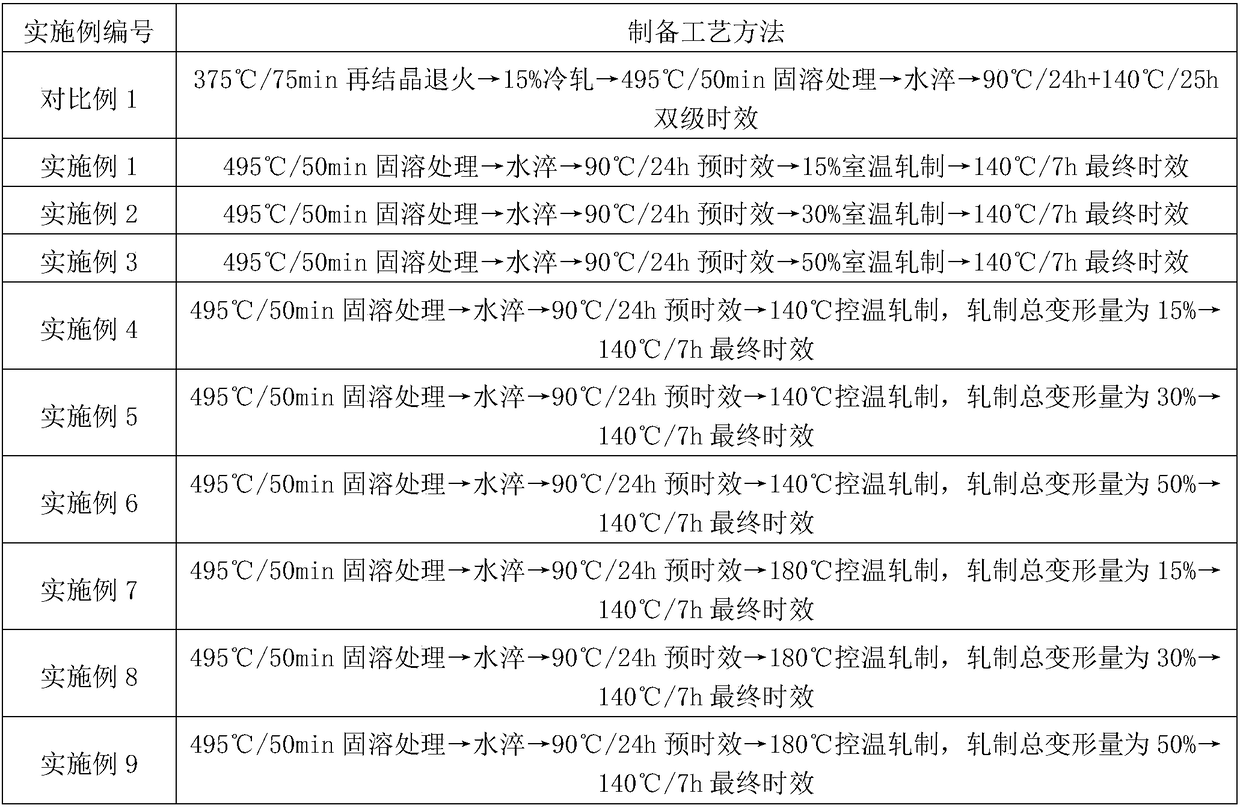

Thermomechanical treatment method for preparing high strength high corrosion-resistant Al-Mg-Zn aluminum alloy in short process

The invention relates to a thermomechanical treatment method for preparing a high strength high corrosion-resistant Al-Mg-Zn aluminum alloy in a short process and belongs to the field of aluminum alloys and preparation processes thereof. The method comprises the following steps: carrying out solution quenching on a panel after hot rolling an aging precipitation strengthened Al-Mg-Zn serial aluminum alloy; carrying out pre-aging treatment for 15-30 hours at 60-120 DEG C after quenching; then carrying out 10-60% of temperature controlled rolling deformation within a range from the room temperature to 200 DEG C; and carrying out final aging treatment for 3-15 hours at 120-160 DEG C after rolling. By introducing the thermomechanical treatment method, compared with a conventional process, a recrystallization annealing process is cancelled, and the final aging treatment insulating time is shortened, so that the panel preparation process flow is shortened, and meanwhile, the strength (comparable to 7050-T7651) and the intercrystalline corrosion resistance of the panel are improved greatly. The thermomechanical treatment method has important reference value in developing high strength corrosion-resistant aging precipitation strengthened Al-Mg-Zn aluminum alloy of ships and special vehicles.

Owner:UNIV OF SCI & TECH BEIJING

Fiber reinforced high temperature thermal barrier composite ceramic thick coating material as well as preparation and application thereof

InactiveCN101518968AGood heat insulationIncreasing the thicknessLaminationLamination apparatusAtmospheric layerComposite ceramic

The invention relates to a fiber reinforced high temperature thermal barrier composite ceramic thick coating material. The fiber reinforced high temperature thermal barrier composite ceramic thick coating material has the following structure: spray coating layers having the 'concrete' action and reinforced layers which are arranged between the spray coating layers and have the 'steel bar' action are arranged in turn on the surface of a metallic matrix workpiece of a spray coating and cementing bottom layer; the spray coating layers at least have 3 layers and are prepared from a powdery composite coating material with double effects of high temperature thermal barrier and ablative heat protection by a plasma spraying process; and the reinforced layers are formed by high temperature fibers which wrap the spray coating layers in a paralleled or staggered mode for one or two times, and the use temperature of high temperature fibers is more than or equal to 700 DEG C. The material is prepared by the following steps: preparation of a matrix, spray coating, wrapping and the like. The material can be coated on the surfaces of various aircrafts moving at a high speed in the atmospheric layer through the plasma spraying process so as to have the actions of the high temperature thermal barrier and the ablative composite protective layer. The material can improve the upper limit of the working temperature of a metallic matrix in a high temperature environment and simultaneously prolong the service time of the metallic matrix in a high temperature extreme environment. The material has high practicability and is suitable for the industrialized production.

Owner:WUHAN UNIV OF TECH

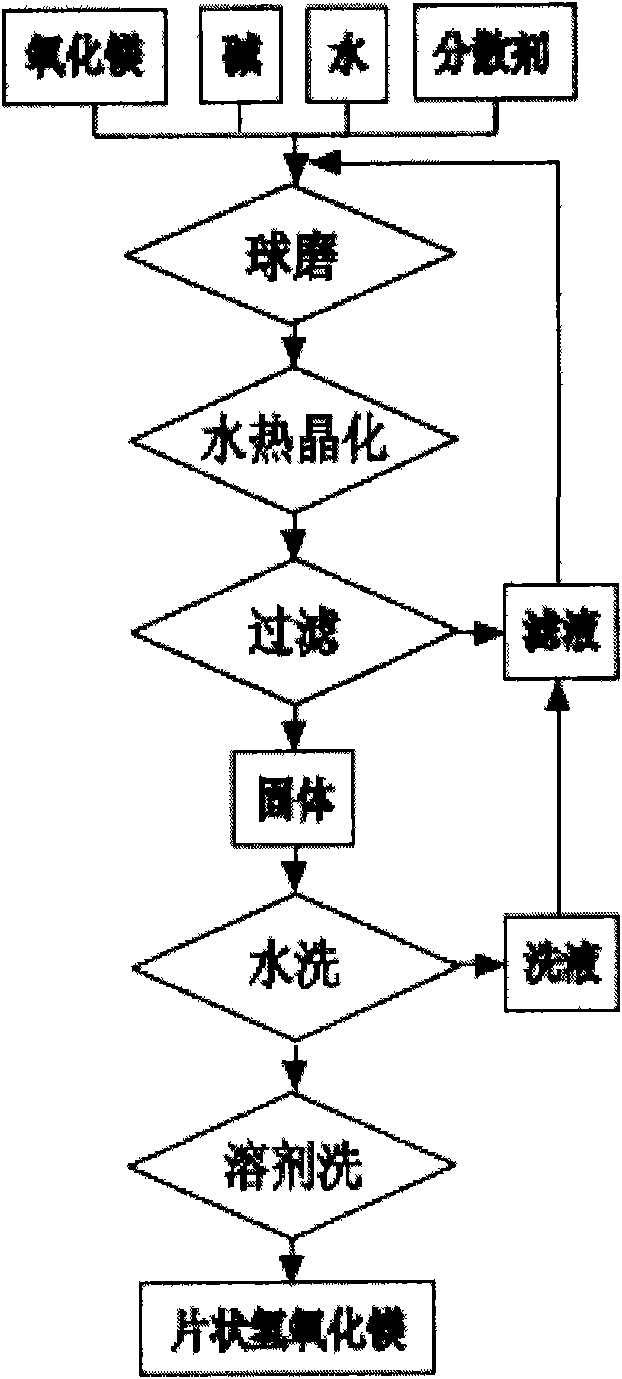

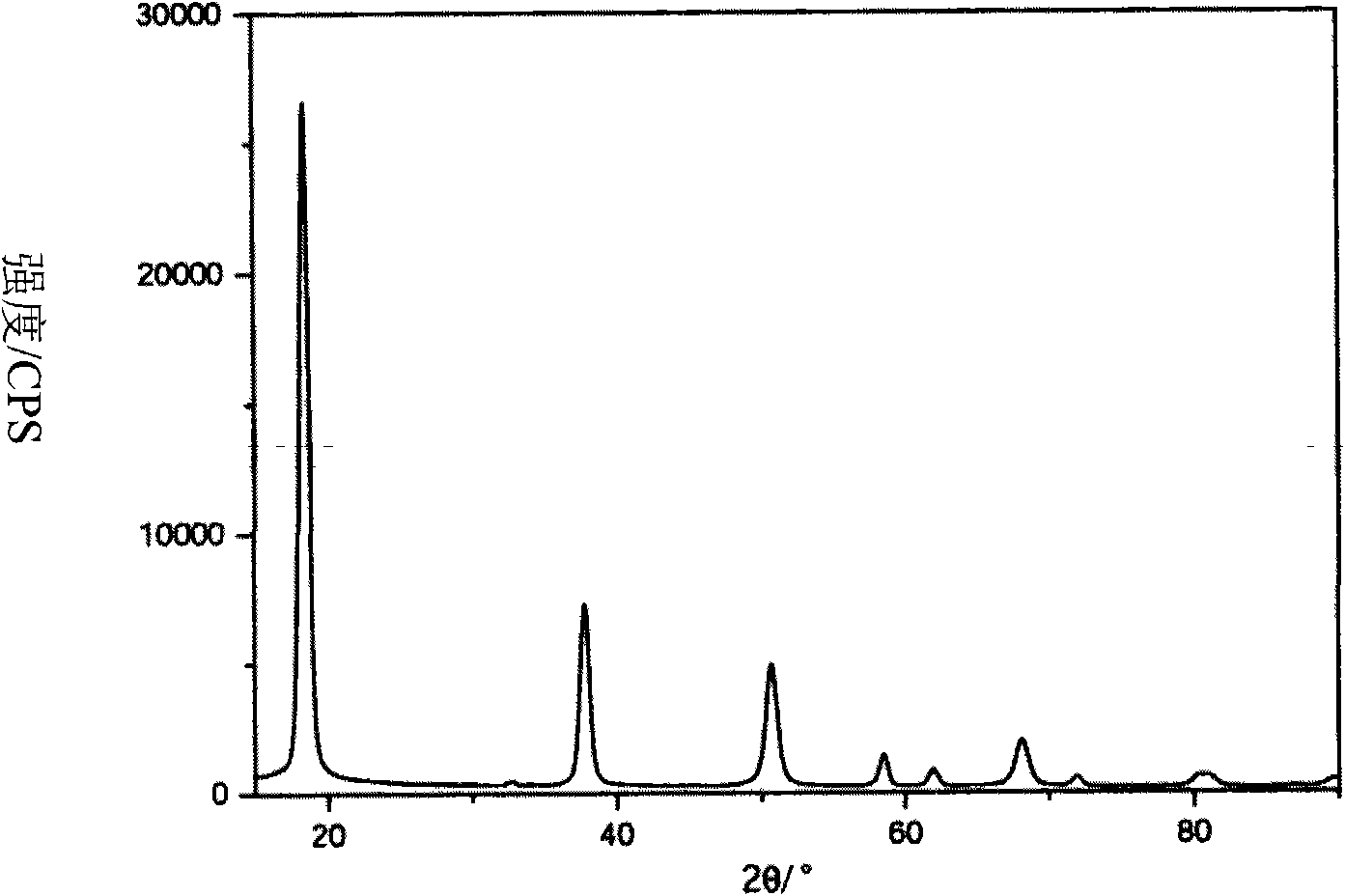

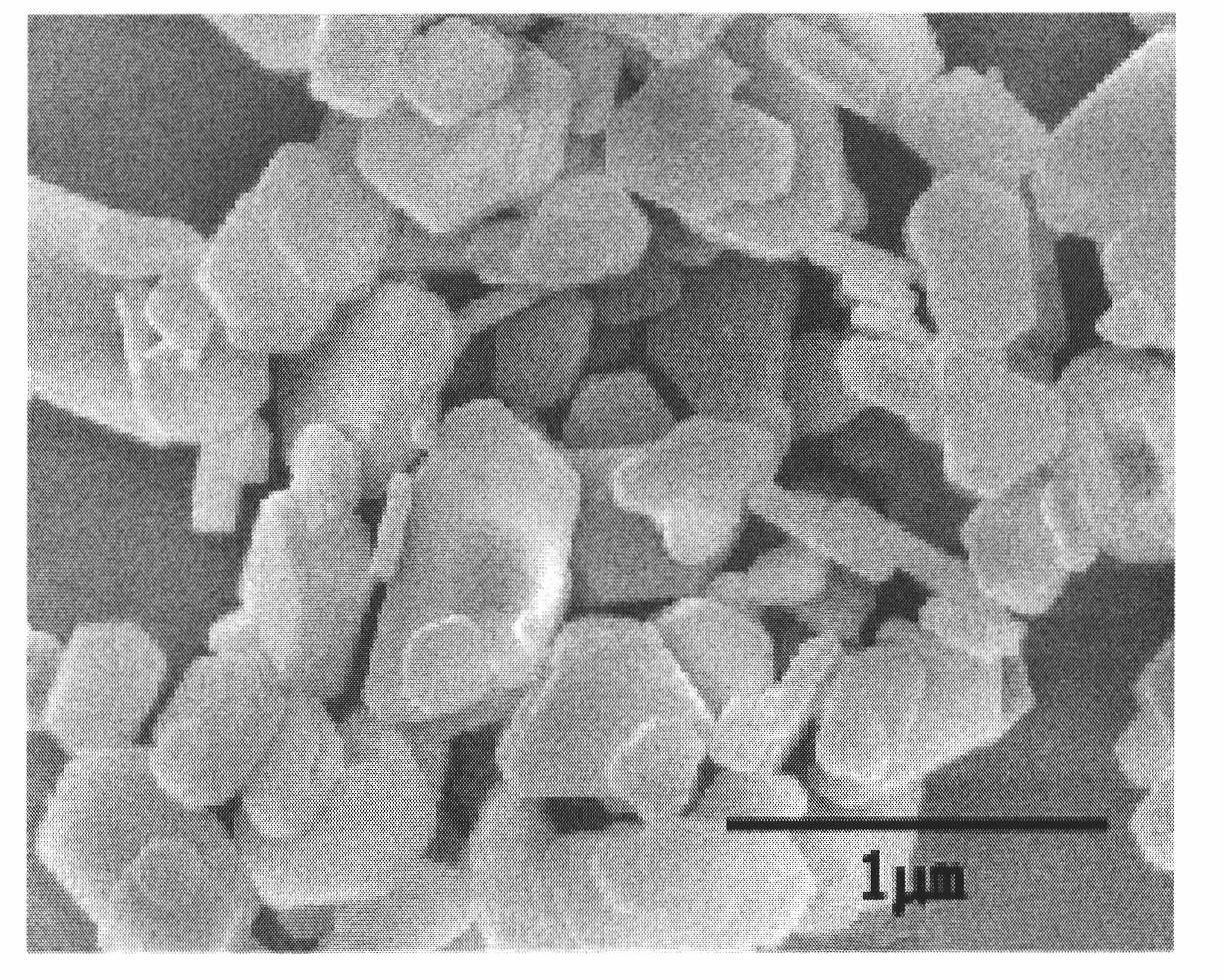

Method for preparing submicron lamellar magnesium hydroxide by intensifying alkali

ActiveCN102101684AReduce the activation energy of the hydrolysis reactionImprove surface activityMagnesium hydroxideSide productL&D process

The invention relates to a method for preparing submicron lamellar magnesium hydroxide by intensifying alkali, comprising the following steps of: mixing magnesium oxide, the alkali, a dispersing agent and water into slurry according to a certain proportion; carrying out mechanical and chemical treatment to prepare the slurry used for crystallization; carrying out hydrothermal crystallization; carrying out solid-liquid separation on a product, and washing and drying a solid to obtain submicron lamellar magnesium hydroxide powder. In the invention, filter liquor can be recycled; the hydrolysis of the magnesium oxide and the nucleation of the magnesium hydroxide are promoted by utilizing mechanical and chemical action and alkali intensifying action, the shape and the growth of a magnesium hydroxide crystal is regulated and controlled through the hydrothermal crystallization, and no alkali is consumed in the process; as the magnesium oxide is used as a raw material and an alkalizing mechanical and chemical treatment-hydrothermal crystallization process is adopted, the preparation process flow of the submicron high-dispersion lamellar magnesium hydroxide is shortened, the consumption of the alkali used for a process for preparing the magnesium hydroxide by precipitating soluble magnesium salt and the cost input are decreased, and the hydrothermal crystallization process does not generate any side product like chemical salt and is a clean production process; and in addition, the obtained submicron lamellar magnesium hydroxide is widely used in the fields of flame-retardant and catalytic carriers and other functional materials.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing skin-core type composite polylactic acid tows for cigarettes by one-step method

InactiveCN105887224AShort manufacturing processSimple configurationFilament/thread formingConjugated synthetic polymer artificial filamentsPreparing skinSlow cooling

The invention provides a method for preparing skin-core type composite polylactic acid tows for cigarettes by a one-step method, and belongs to the technical field of preparation of cigarette filter tip materials. The method comprises the following steps: slicing polylactic acid skin layer resin and polylactic acid core layer resin and respectively feeding the slices into a pre-crystallization drying device for pre-crystallization drying at first; respectively feeding the polylactic acid skin layer resin slices and the polylactic acid core layer resin slices which are subjected to pre-crystallization drying into two screw extruders, melting into polylactic acid skin layer resin melt and polylactic acid core layer resin melt, and simultaneously extruding the polylactic acid skin layer resin melt and the polylactic acid core layer resin melt into a composite spinning box for spinning; spraying out in the form of filaments by using a spinneret; successively performing slow cooling, annular air blast cooling and curing, tow oiling, hot roller drafting, curling, loosing and shaping, filament swaying and packaging on the filaments to obtain the finished product, wherein the weight ratio of the polylactic acid skin layer resin slices to the polylactic acid core layer resin slices is 30-50:70-50, and a composite spinning assembly is provided with isolated flow paths. The method has the advantages that the preparation process is shortened, equipment layout is simplified, preparation efficiency is improved, preparation cost is reduced, and energy consumption is reduced.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

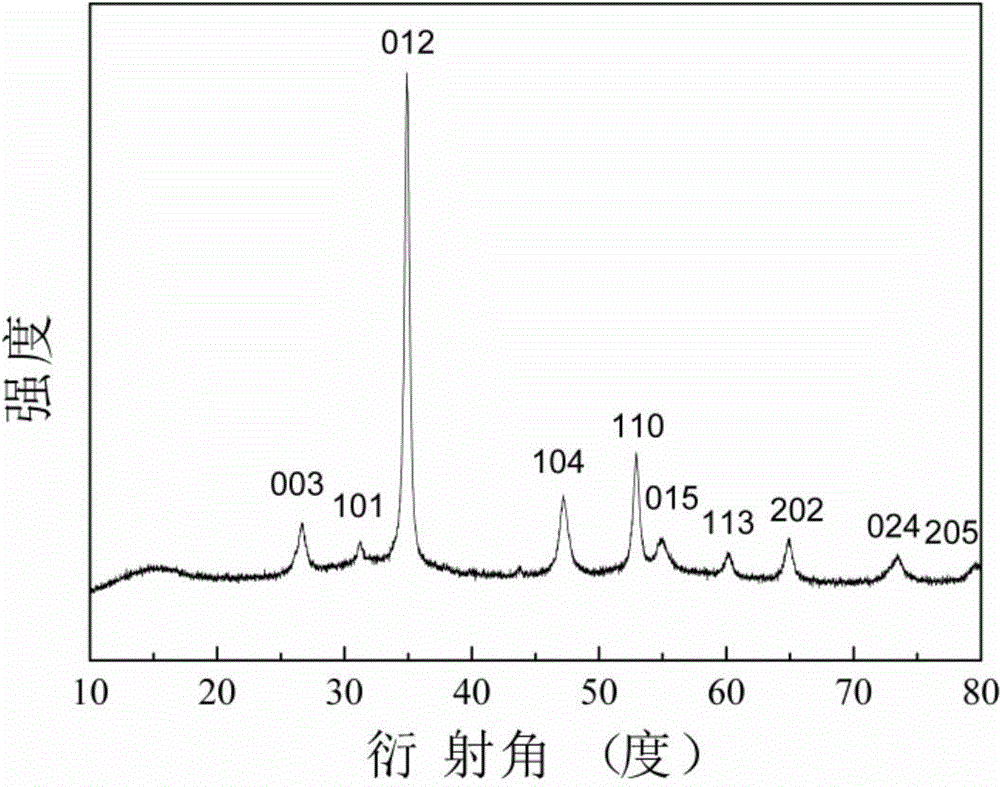

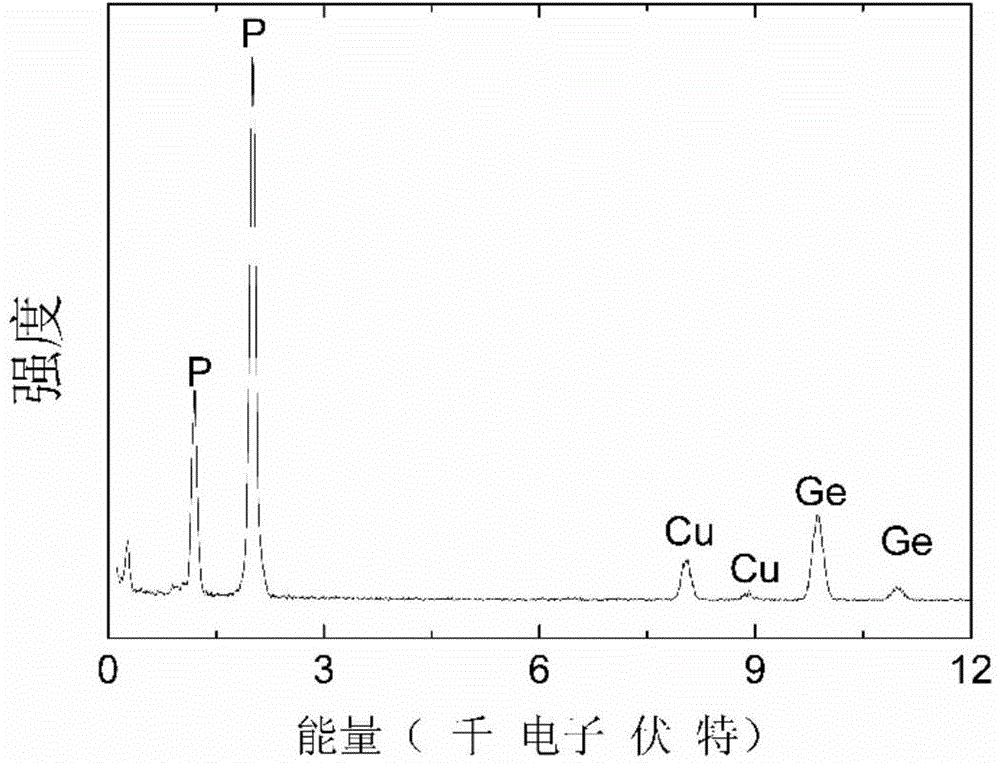

Negative electrode active material for lithium-ion/sodium-ion battery, negative electrode and battery

ActiveCN104600299AHigh lithium/sodium storage capacityHigh lithium/sodium storage activityCell electrodesSecondary cellsLithiumCharge discharge

The invention provides a negative electrode active material for a lithium-ion / sodium-ion secondary battery, a negative electrode and a battery, belonging to the technical field of electrochemistry and batteries. The negative electrode active material comprises a phosphorus-germanium compound, or / and a first complex formed by the phosphorus-germanium compound and elementary P or / and elementary Ge, or / and a second complex formed by the phosphorus-germanium compound and conductive components, or / and a third complex formed by the first complex and conductive components. The negative electrode provided by the invention comprises the negative electrode active material. The negative electrode has the advantages of high specific capacity, high initial Coulomb efficiency, small charge-discharge voltage platform difference and good high-current charge-discharge performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of oxide surface layer shell for titanium alloy precision casting

The invention discloses a preparation method of an oxide surface layer shell for titanium alloy precision casting. The preparation method comprises the steps of preparation of binders, preparation of surface layer powdery material, preparation of surface layer coating, preparation of a surface layer shell, shell dewaxing, shell roasting and the like; the preparation method has the beneficial effects that: the used raw material has low price and is easily available, the traditional process is improved, the using amounts of zirconium oxide and yttrium oxide are greatly reduced, the process is simplified, the preparation flow is shortened, and the labor and raw material costs are reduced; adhesive adopts silicon sol and zirconium acetate as main raw materials and is added with n-caprylic alcohol and polyvinyl alcohol, so that the surface layer coating has good coating property, can be uniformly coated on a wax mold and has good compactness; the adhesive is added with zirconium oxide fireproofing ingredient, therefore, the surface layer shell is capable of resisting high temperature; steam dewaxing is adopted to achieve the effect of no environment pollution; the prepared surface layer shell has no influence on human health, has wide application range, small interface reaction layer with thickness 0.018-0.02mm, high precision and excellent performance and is easy to realize post-finishing.

Owner:QINGDAO RUNQIAN HI TECH CO LTD

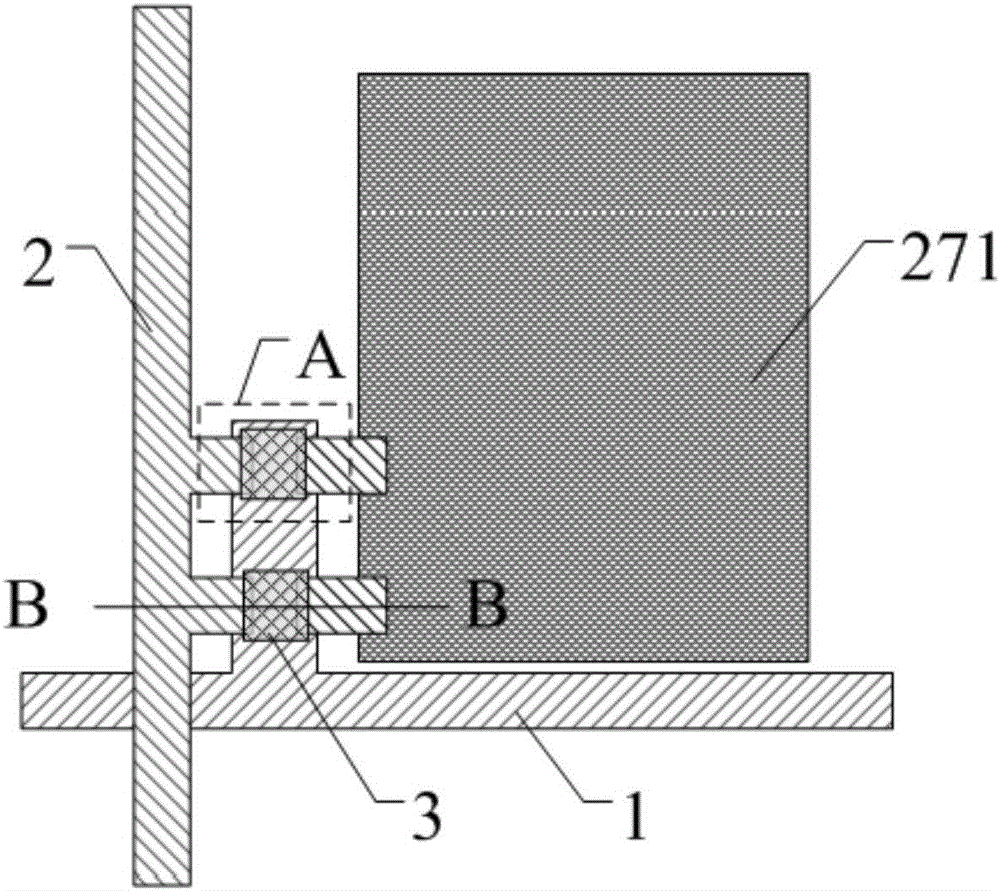

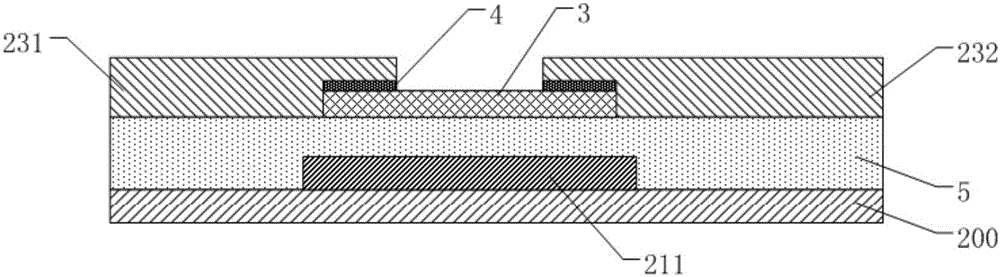

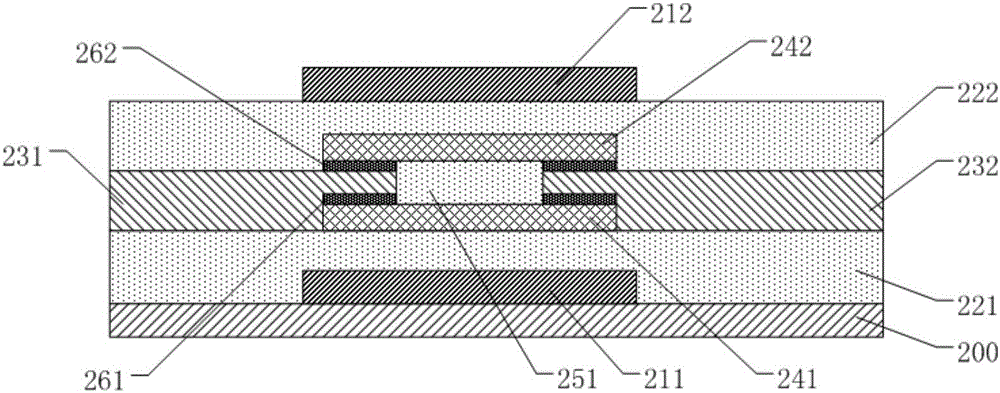

Switch element, the preparation method of the switch element, array substrate and display apparatus

PendingCN106409845ASmall footprintShort manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingPower flowTransistor

The invention discloses a switch element, the preparation method of the switch element, array substrate and display apparatus. The switch element comprises a substrate; a first film transistor arranged on the substrate; and a second film transistor arranged on the first film transistor. The first film transistor consists of a first electrode and a second electrode. The first film transistor and the second film transistor share the first electrode and the second electrode. According to the switch element of the invention, two film transistors are in parallel arrangement with one above the other. This design increases the open-state current of the switch element while reducing the size of the switch element. In addition, as the two film transistors share the same source electrode layer and the drain electrode layer, the preparation technology for the switch element is simplified and the cost is reduced.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

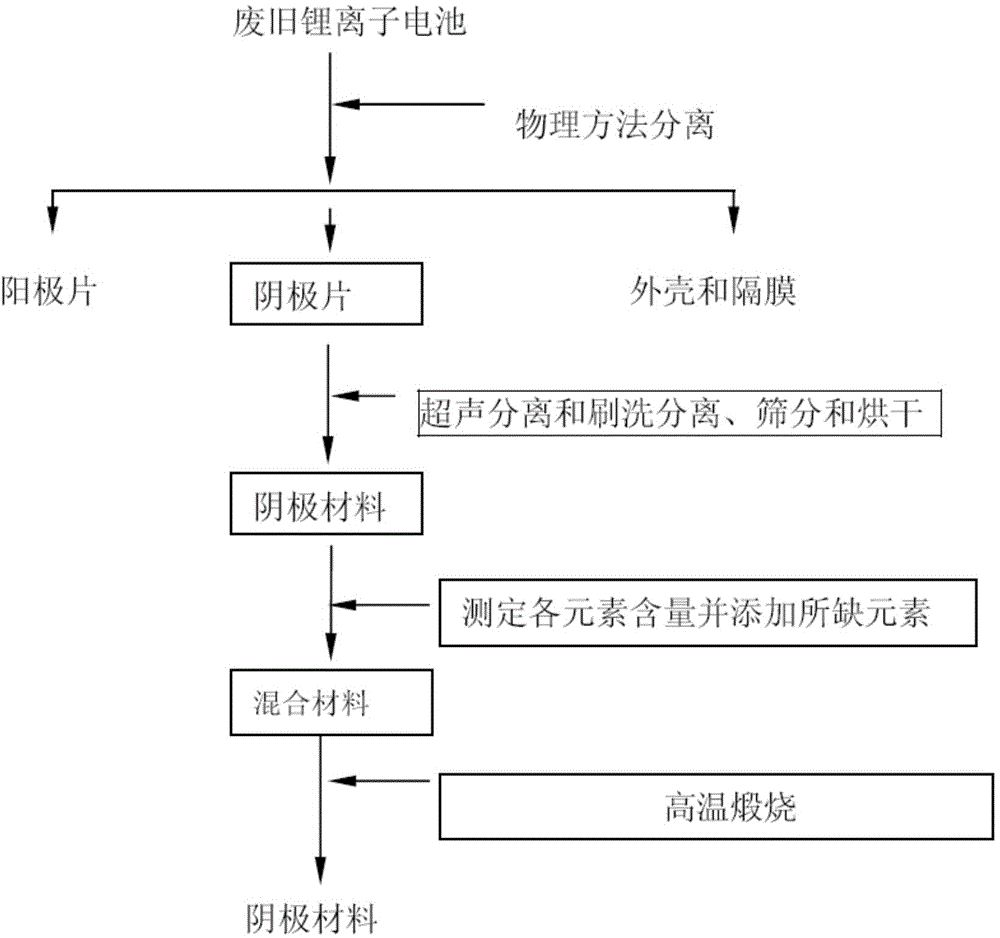

Method for preparing cathode material of lithium ion battery

InactiveCN103956533AImprove performanceReduce pollutionCell electrodesWaste accumulators reclaimingLithium-ion batteryCobalt

The invention discloses a method for preparing a cathode material of a lithium ion battery. The method comprises the following steps: 1, separating a cathode material on a cathode sheet of a waste and old lithium ion battery or a cathode material in lithium ion battery production scraps; and 2, determining the mass ratio of useful elements in the separated cathode material, calculating deficient elements of the separated cathode material according to the mass ratio of the elements of raw materials for preparing the cathode material of the lithium ion battery, adding compounds of the deficient elements in order to reach the stoichiometric ratio of a target product, and preparing the cathode material of the lithium ion battery. The method can recycle cathode materials comprising lithium cobaltate, nickel cobalt lithium manganate and lithium manganate used in waste and old lithium ions and cathode material scraps comprising lithium cobaltate, nickel cobalt lithium manganate and lithium manganate generated in the production of the lithium ion battery according to the waste recycling situation.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Method for preparing short-flowpath fine crystal super-plastic material

ActiveCN101333583AShort manufacturing processIncreased superplasticityPlastic materialsFriction stir processing

Disclosed is a process for preparing short process fine crystalline superplasticity materials, which is characterized in that: cast alloy is used as a starting material for carrying out the agitation and friction processing after the homogenization heat treatment, and a bulky, loose and uneven cast structure is changed into an even and compact fine crystalline superplasticity structure.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Laser sintering synthesis method of ceramic-particle-reinforced nickel-aluminum-based composite

InactiveCN102876926AEasy to control speedPlay a role in strengthening the matrixNumerical controlPhase formation

The invention belongs to the technical field of material processing and particularly relates to a laser sintering synthesis method of a ceramic-particle-reinforced nickel-aluminum-based composite. The technical scheme includes that the laser sintering synthesis method includes the steps: mixing nickel powder with aluminum powder according to the atomic ratio of Ni to Al of 3:1, adding tungsten concentrate powder accounting for 0.5-2wt% of the total weight of nickel-aluminum mixed powder, performing ball milling to obtain uniformly-mixed mixed powder, compacting the mixed powder to a cylindrical compact, placing the compact on a numerically-controlled machine tool, starting a CO2 laser machine with the laser powder of 900-1200W for laser radiation for 10-20s, and lighting the surface of the compact to enable the compact to generate self-propagating reaction, so that the ceramic-particle-reinforced nickel-aluminum-based composite by laser sintering synthesis is obtained. According to the laser sintering synthesis method, matrix reaction, reinforced phase formation and metal-based composite preparation are combined together, and the reinforced ceramic phase subjected to in-situ synthesis enables high-temperature mechanical properties of a nickel-aluminum intermetallic compound to be obviously improved and enhanced.

Owner:LIAONING TECHNICAL UNIVERSITY

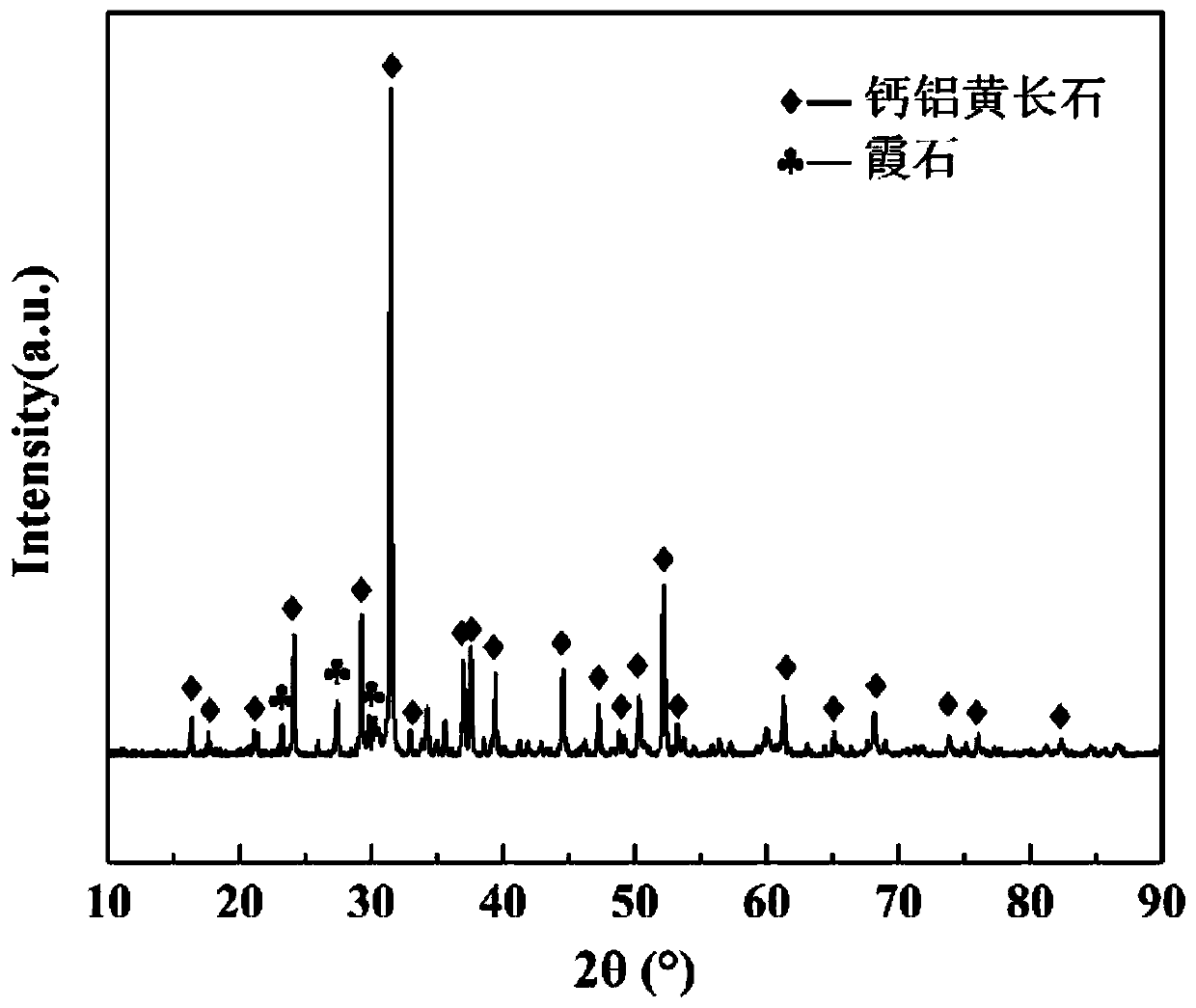

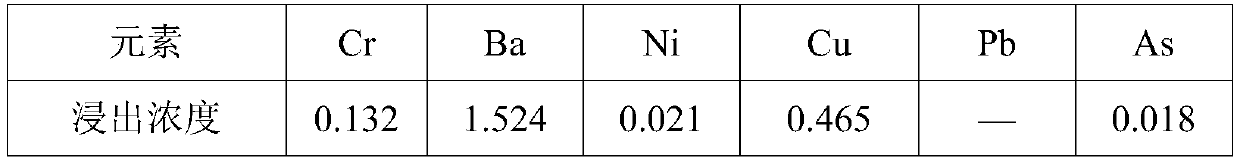

Harmless and resourceful treatment method for smelting slag generated during iron capture of waste catalysts

The invention relates to the technical field of harmless and resourceful treatment of solid waste and provides a harmless and resourceful treatment method for smelting slag generated during iron capture of waste catalysts. The method comprises the following steps: directly carrying out casting and calendering to obtain base glass by using glassy-state smelting slag generated by capturing a waste catalyst with iron as a raw material and heavy metals such as Fe2O3, Cr2O3, TiO2, NiO and PbO in the smelting slag as nucleating agents without adding any other reagent; subjecting the base glass to synchronous nucleation and crystallization at a certain temperature; and performing annealing to eliminate stress so as to obtain a microcrystalline glass product. The method has the advantages that heavy metal in the smelting slag generated smelting slag generated during iron capture of waste catalysts is solidified, so pollution is avoided; nucleation and crystallization heat treatment are synchronously carried out, so the method has the advantages of short flow, low energy consumption and easiness in industrial production; the harmless and resourceful utilization of the smelting slag is realized; the added value of the obtained microcrystalline glass is high; obvious environmental protection and economic benefits are obtained; and the method has good market prospects.

Owner:UNIV OF SCI & TECH BEIJING

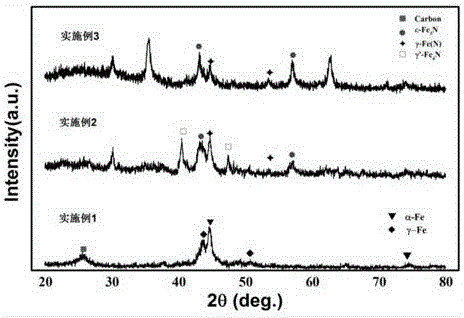

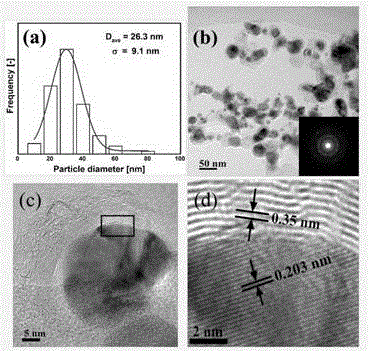

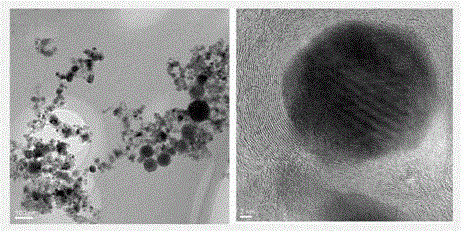

Graphene-coated variable phase nano magnetic composite material and preparation method thereof

ActiveCN106683813AReduce pollutionLow toxicityInorganic material magnetismInductances/transformers/magnets manufactureMagnetite NanoparticlesPhase variable

The invention provides a graphene-coated variable phase nano magnetic composite material with a core-shell structure. The shell is a graphene shell which is formed by multiple layers of graphene sheets, and the thickness of the shell layer is 5-50nm; and the core is a magnetic core and is a phase-variable nano magnetic particle with a particle diameter of 10-90nm. The invention also provides a preparation method of the graphene-coated variable phase nano magnetic composite material. According to the method provided by the invention, the ferrocene powder is taken as an iron source and a carbon source, and the plasma is taken as a synthetic environment so as to ensure that the toxicity and environmental pollution caused by reactants can be reduced and the mass production can be facilitated; the phase of the obtained magnetic nano particles can be controlled by controlling the nitrogen ratio of the plasma in the preparation process; and the graphene-coated nano magnetic powder prepared by adopting the method provided by the invention is fine in particle size, uniform in distribution, good in degree of sphericity and short in preparation process.

Owner:BEIJING UNIV OF TECH

High-bending strength oxidized carbon nanomaterial/carbon fiber/epoxy resin composite material and preparation method thereof

The invention provides a high-bending strength fiber-reinforced epoxy resin composite material. The preparation method comprises the following steps: simply stirring for rapidly transferring an oxidized carbon nanomaterial from an aqueous phase to an epoxy resin mixture containing N,N-diglycidyl p-hydroxylaniline glycidyl ether; performing water removal and high-temperature treatment, adding a curing agent, compounding with carbon fibers, curing and forming. The composite material is simple and high-efficiency, the oxidized carbon nanomaterial does not need to be subjected to acylating chlorination and other chemical modifications, any organic solvent is not used, the processing time is short, the energy consumption is low, and industrialization is easily realized; and meanwhile, the carbon nanomaterial is high in content and uniform in dispersion, the mechanical property of the composite material is outstanding, the bending strength can be 2.5GPa or over, and the increase amplitude is over 1-fold (the highest amplitude can reach 160 percent). The composite material disclosed by the invention can be used for preparing high-strength and high-modulus carbon fiber reinforced composite materials and can be widely applied to the fields such as aerospace, automobiles, building or bridge reinforcement, power electronics and sport equipment.

Owner:ZHEJIANG UNIV

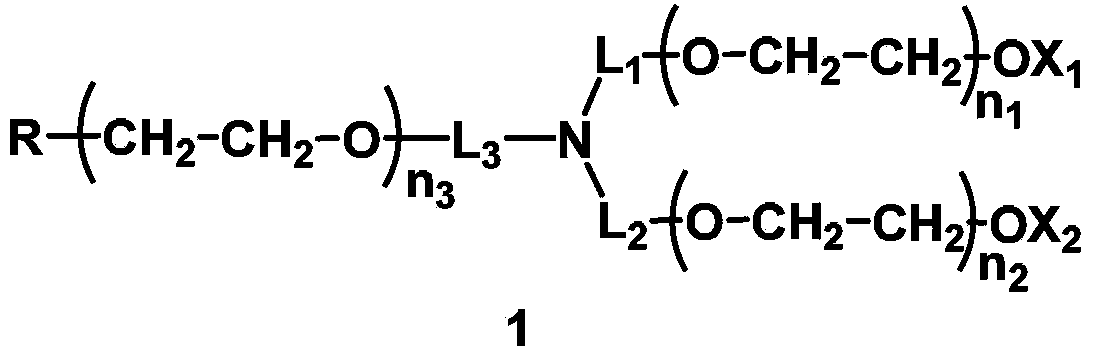

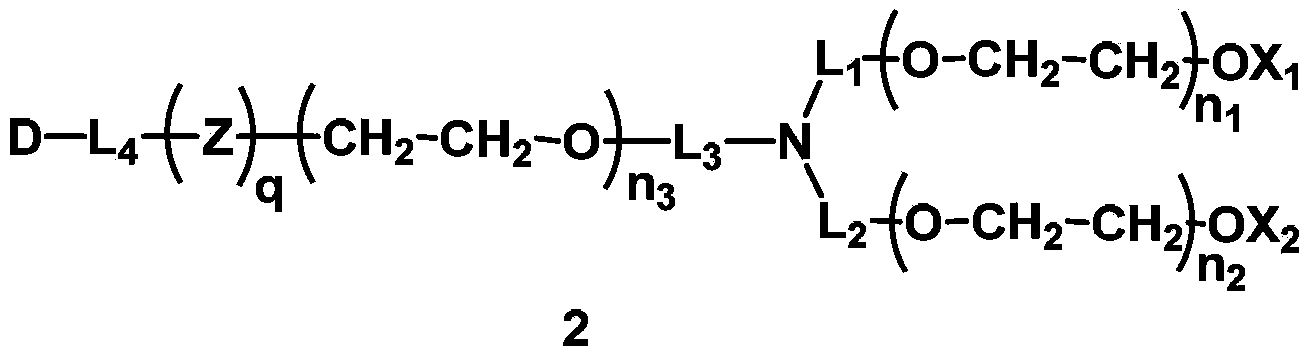

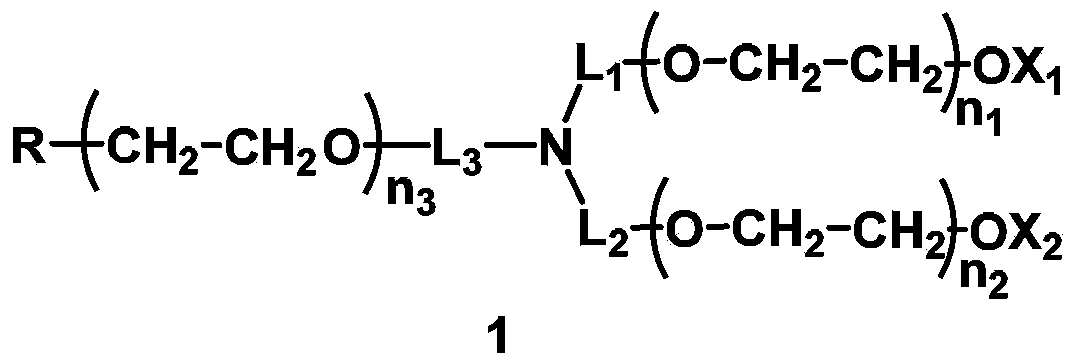

Single functionalized polyethylene glycol with nitrogen-atom branching center, preparation method and biologically-relevant substance thereof

ActiveCN104387577ARich varietyBroad room for developmentPeptide preparation methodsEnzyme stabilisationEnzymeNitrogen atom

The invention discloses single functionalized polyethylene glycol with a nitrogen-atom branching center, a preparation method and a biologically-relevant substance thereof. General formula of the single functionalized polyethylene glycol with the nitrogen-atom branching center is as shown in the formula (1), and general formula of the polyethylene glycol-modified biologically-relevant substance is as shown in the formula (2), wherein X1 and X2 are an alkyl group having 1-20 carbon atoms; n1, n2 and n3 are an integer of 1-1000; L1, L2 and L3 are a linking group which stably exists under the illumination, enzyme, acidic or alkaline condition; R is a functional group; D is the biologically-relevant substance; Z is a linking group; and L4 is residue obtained after a reaction between a functional group and the biologically-relevant substance. The branched polyethylene glycol with the nitrogen-atom center enriches varieties of branched polyethylene glycol, is easy to interact with a substrate, is more beneficial to protection of the substrate by polyethylene glycol, improves in vivo status of the substrate more effectively, and has a wider prospect.

Owner:XIAMEN SINOPEG BIOTECH

Method for synthesizing in-situ formed ceramic particle reinforced iron-aluminum-based composites by laser combustion

InactiveCN101906572AIncrease profitImprove performanceSelf-propagating high-temperature synthesisIron powder

The invention discloses a method for synthesizing in-situ formed ceramic particle reinforced iron-aluminum-based composites by laser combustion, belonging to the technical field of materials. The in-situ formed ceramic particle reinforced iron-aluminum-based composites are prepared by the following steps of: putting tungsten ore powder, iron powder, aluminum powder and carbon powder in a ball mill for milling to obtain a mixed powder material; and compressing the mixed powder material into a pressed compact, transmitting a high-energy laser beam by employing a CO2 laser processing machine to ignite the surface of the pressed compact and trigger self-propagating high temperature synthesis of the pressed compact. By the invention, two ceramic particle reinforced phases are simultaneously formed on one substrate, which shortens the preparation process of the composites, lowers material manufacture cost and facilitates large-scale production and application.

Owner:LIAONING TECHNICAL UNIVERSITY

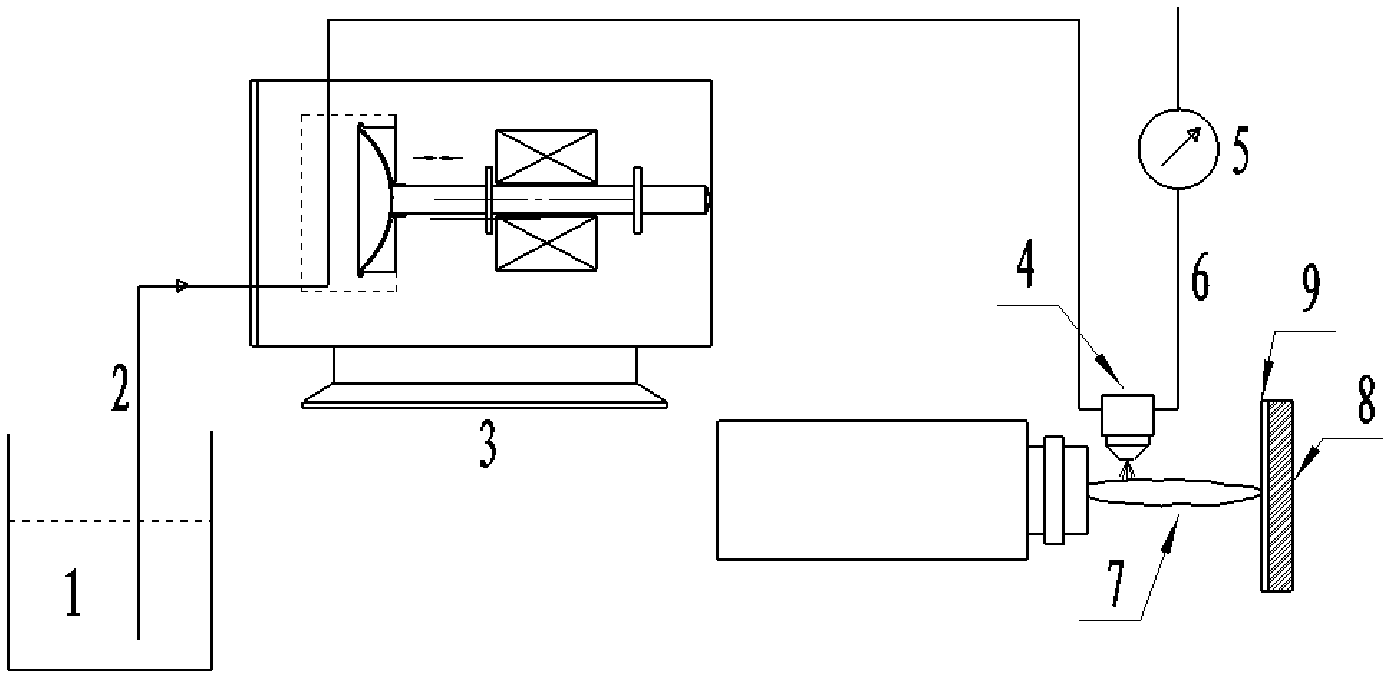

Preparation method of thermal barrier coating and thermal barrier coating prepared by preparation method

ActiveCN102851631AShort manufacturing processOptimal Control StructureMolten spray coatingLiquid/solution decomposition chemical coatingPlasma jetProduction rate

The invention discloses a preparation method of a thermal barrier coating and the thermal barrier coating prepared by the preparation method. According to the method, a solution precursor composed of zirconates and yttrium salts is used as a spraying raw material. The solution precursor is atomized into liquid drops through a two-phase flow atomizing nozzle; and the liquid drops are sent for plasma jet, undergo plasma jet heating and acceleration and are deposited on a matrix to form the thermal barrier coating. The thermal barrier coating is nanostructured and has a vertical crack structure. The solution precursor liquid material replaces an agglomerated powder to be used as a spraying raw material, thus greatly simplifying tedious processes of traditional air plasma spraying for coating preparation. There are few technological processes for coating preparation in the invention, thus raising productivity and reducing cost. in addition, the coating structure is controllable and technical production can be realized. By the adoption of the prepared coating, defects of a coating prepared by traditional plasma spraying are eliminated, and a high-performance coating which satisfies special requirements can be prepared.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

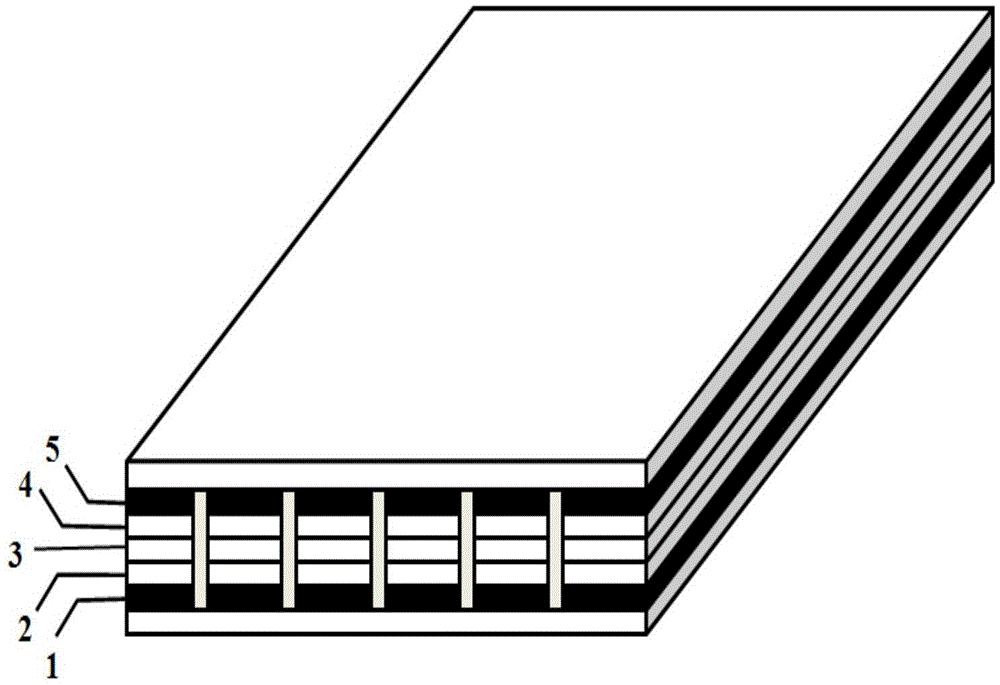

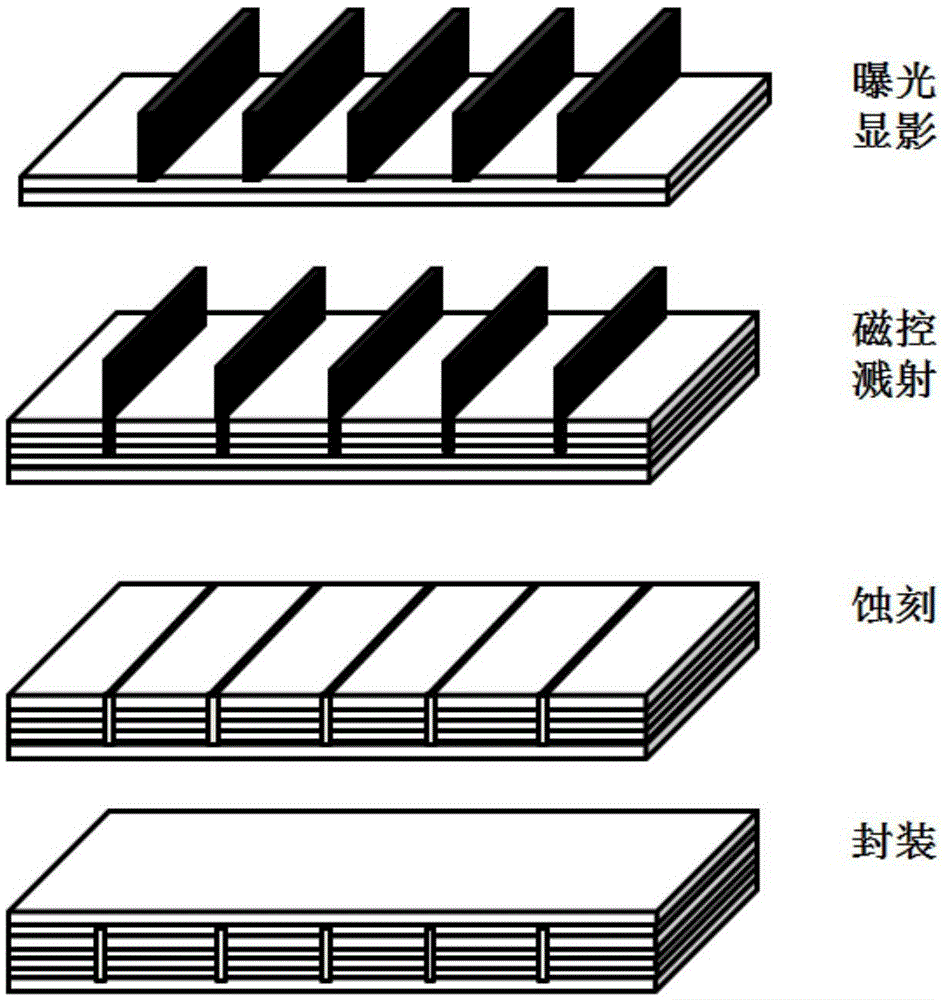

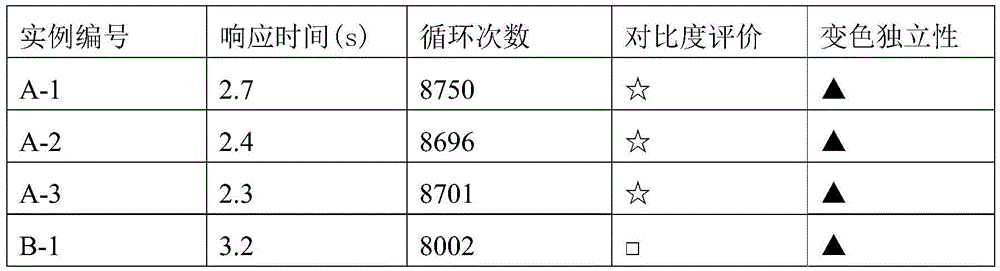

All-solid-state electrochromic device having controllable color-changing area and method for preparing same

The invention discloses an all-solid-state electrochromic device having a controllable color-changing area and a method for preparing the same. The method is characterized in that: patterns are transferred on a conductive glass pane by means of films and dry films with the thickness being 30-50 [mu]m; thin-strip-shaped dry films with the width being 1-2 mm and with the height identical to the film thickness are formed on the conductive surface after exposure and development; an electrochromism layer (EC), an ion conductive layer (IC) and an ion storage (counter electrode) layer (CE) are sequentially plated on the substrate through a magnetron sputtering manner; the left dry film and a transparent conductive layer are etched by two etching solutions respectively; another glass pane of which a transparent conductive layer at the corresponding position of the other surface is etched is completely packaged through packaging technology, and therefore the all-solid-state electrochromic device having a controllable color-changing area is obtained. The all-solid-state electrochromic device prepared through the method provided by the invention can control the transmittance of color-changing glass, can control the color-changing area, is easy to package, and has a long service lifetime.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Method for preparing smelting cast-in-site synthetic alpha-Al2O3 granule reinforced copper base composite material

The present invention relates to fusion casting-in-site synthesis process of preparing alpha-Al2O3 grain reinforced copper base composite material, and belongs to the field of metal base composite material. The technological process includes: compounding materials based on reaction formula 2Al+3CuO-->3Cu+Al2O3; mixing materials Al and CuO in a material mixing machine and forming; heating matrix material Cu of over 99.0 % purity in MF inducing furnace to the temperature of 50-150 deg.c over the smelting point of Cu; pressing the fabricated blocks on 1-10 wt% of the melt into the melt and maintaining; casting to obtain in-site reacted alpha-Al2O3 grain reinforced copper base composite material. The advantages include shortened technological process, low manufacture cost and wide application as high strength and high conductivity electronic and electric material.

Owner:UNIV OF SCI & TECH BEIJING

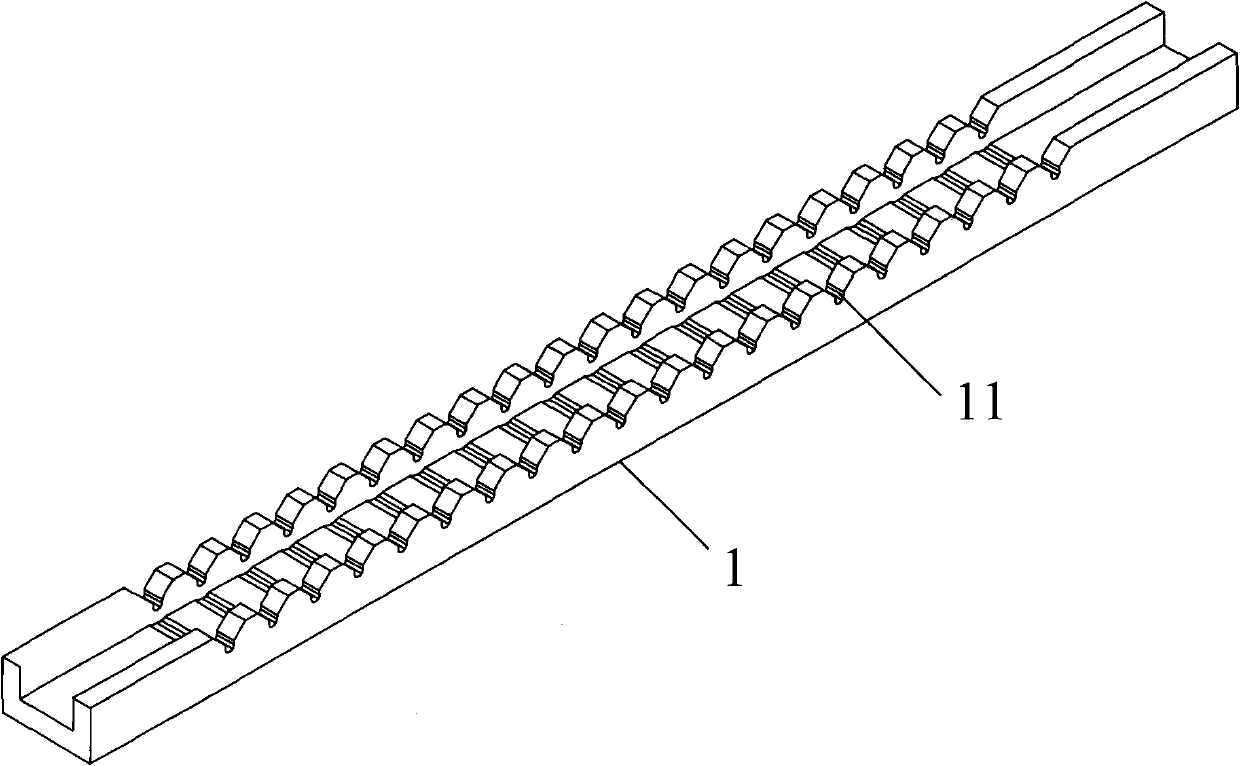

Method for preparing heat dipping tin of plastic sealed axial diode

ActiveCN101768710ASimple structureEasy to assemble and disassembleHot-dipping/immersion processesSemiconductor/solid-state device manufacturingProduction lineDip soldering

The invention discloses a method for preparing heat dipping tin of a plastic sealed axial diode, which comprises the following steps: placing the plastic sealed axial diode in an adapter plate; placing a first heat dipping tin positioning fixture below the adapter plate, ensuring that a lower substrate of the first heat dipping tin positioning fixture is tightly attached to a bottom plate of the adapter plate, and tightly clamping a first electrode of the diode by using the first heat dipping tin positioning fixture; removing the adapter plate, placing the first heat dipping tin positioning fixture in a guide rail of a tin dipping machine, and starting the tin dipping machine to perform dip soldering on a second electrode of the diode; tightly clamping the second electrode of the plastic sealed axial diode by a second heat dipping tin positioning fixture through the adapter plate; placing the second heat dipping tin positioning fixture in the guide rail of the tin dipping machine, and performing dip soldering on the first electrode of the diode; and finally, cleaning and drying the plastic sealed axial diode. The plastic sealed diode heat dipping tin positioning fixture with simple structure, convenient assembly and disassembly and reliable positioning is adopted, so that the processing speed of the heat dipping tin is improved, the material backlog of the procedure is reduced, and the production line is facilitated.

Owner:SIYANG GRANDE ELECTRONICS CO LTD

Nanostructured cerium-doped lanthanum zirconate spherical powder for thermal spraying and preparation method thereof

InactiveCN102719778AGood liquidityLow thermal conductivityMolten spray coatingEfficient propulsion technologiesCorrosion resistantThermal conductivity

The invention relates to a nanostructured cerium-doped lanthanum zirconate spherical powder for thermal spraying and a preparation method thereof. The nanostructured cerium-doped lanthanum zirconate spherical powder for thermal spraying is characterized in that the nanostructured cerium-doped lanthanum zirconate spherical powder for thermal spraying is uniform spherical powder, the grain size of the spherical powder is 20Mu m to 90Mu m, nanostructured cerium-doped lanthanum zirconate grains are agglomerated to form the nanostructured cerium-doped lanthanum zirconate spherical powder for thermal spraying, wherein the nanostructured cerium-doped lanthanum zirconate grains are of a single-phase pyrochlore structure, the grain size is 30nm to 250nm, grain size distribution is uniform and controllable, the nanostructured cerium-doped lanthanum zirconate grains are spherical, and are obtained by doping the Zr site with Ce, the chemical formula is La2Zr2-xCexO7, wherein x is greater than or equal to 0.1 and less than or equal to 0.5. Since the nanostructured cerium-doped lanthanum zirconate spherical powder for thermal spraying is uniform spherical powder, the flowability is good, the thermal conductivity is low, the linear thermal expansion coefficient is great, the high-temperature stability is good, and the nanostructured cerium-doped lanthanum zirconate spherical powder for thermal spraying is particularly suitable for the preparation of various high temperature-resistant thermal barrier coatings or high temperature-resistant wear-resistant, corrosion-resistant coatings by plasma spraying, flame spraying, electric arc spraying and other thermal spraying processes.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com