Harmless and resourceful treatment method for smelting slag generated during iron capture of waste catalysts

A disposal method and technology for smelting slag, which is applied in the field of harmless and resourceful disposal of smelting slag from iron-captured waste catalysts, can solve the problems of non-resource utilization, waste of land, and increased cost, and achieve low leaching concentration and avoid pollution , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

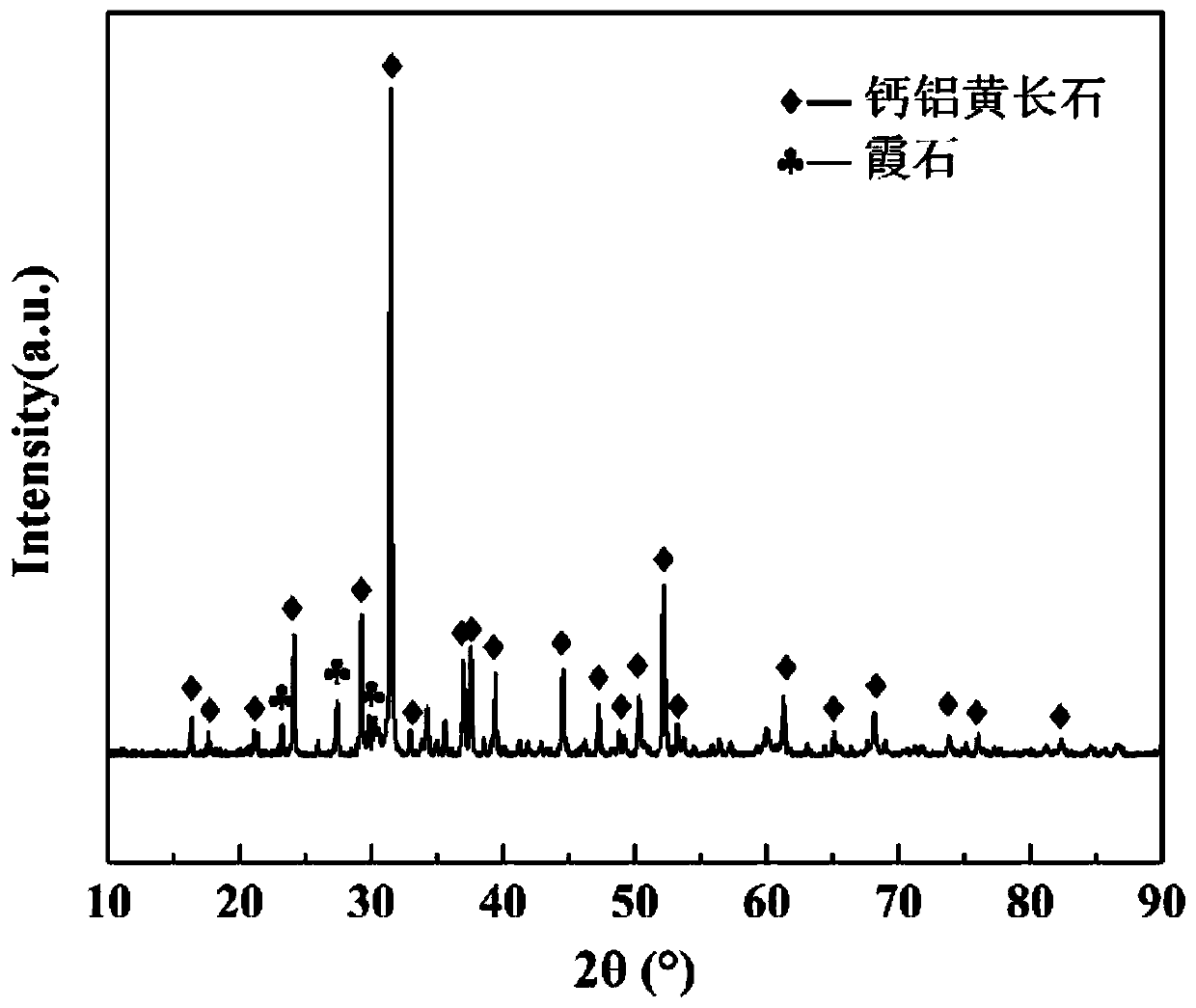

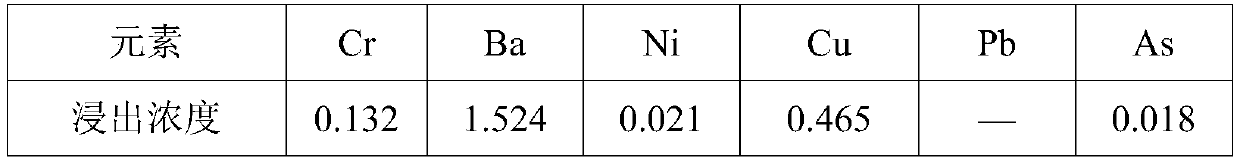

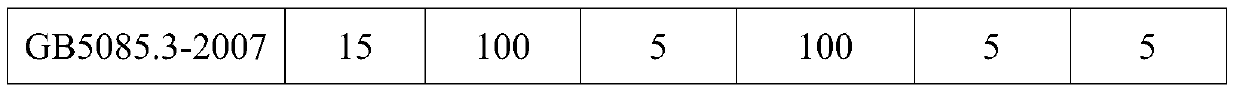

[0032]The smelting slag of PGMs, an iron-captured waste vehicle exhaust catalyst, is directly cast and rolled to obtain the basic glass. The chemical composition of the basic glass is: SiO 2 :22%, CaO:20%, Al 2 o 3 25%, Na 2 O:10%, MgO:5%, ZrO 2 :5%, CeO 2 :4%, Fe 2 o 3 :2%, CaF 2 :3%, MnO:1.5%, TiO 2 :0.5%, BaO:0.4%, Cr 2 o 3 :0.3%, NiO:0.2%, CuO:0.2%, PbO:0.3%, V 2 o 5 : 0.2%, As: 0.1%, Others: 0.3%. The basic glass is heat-treated at 700°C for 120 minutes. Under this condition, nucleation and crystallization proceed simultaneously to form a crystallized glass with uniform distribution of crystallites, and finally anneal to eliminate stress to obtain a glass-ceramic product. Such as figure 1 As shown, the main crystal phase of glass-ceramic is calcium aluminate feldspar and a small amount of nepheline, which solidifies heavy metals in the crystal phase; the leaching concentration of heavy metals in the product is much lower than that in the "Leaking Toxicity Id...

Embodiment 2

[0039] The smelting slag of PGMs, an iron-captured waste vehicle exhaust catalyst, is directly cast and rolled to obtain the basic glass. The chemical composition of the basic glass is: SiO 2 : 23%, CaO: 21%, Al 2 o 3 24%, Na 2 O: 12%, MgO: 5.5%, ZrO 2 :4%, CeO 2 :3%, Fe 2 o 3 :3%, CaF 2 :2%, MnO:0.5%, TiO 2 :1.0%, Cr 2 o 3 : 0.1%, NiO: 0.05%, CuO: 0.1%, PbO: 0.2%, As: 0.05%, others: 0.4%. The basic glass is heat treated at 730°C for 100 minutes. Under this condition, nucleation and crystallization proceed simultaneously to form a crystallized glass with uniform distribution of crystallites, and finally anneal to eliminate stress to obtain a glass-ceramic product. The main crystal phase of the glass-ceramics is calcium aluminum feldspar, which solidifies heavy metals in the crystal phase, and the leaching concentration of heavy metals in the product is much lower than the "Leaking Toxicity Identification of Hazardous Waste Identification Standards" (GB5085.3-2007), ...

Embodiment 3

[0041] The smelting slag of PGMs, an iron-captured waste vehicle exhaust catalyst, is directly cast and rolled to obtain the basic glass. The chemical composition of the basic glass is: SiO 2 : 24%, CaO: 21%, Al 2 o 3 25%, Na 2 O: 6%, MgO: 7%, ZrO 2 :5%, CeO 2 :4%, Fe 2 o 3 :2%, CaF 2 :2.2%, MnO:1.0%, TiO 2 :0.7%, BaO:0.5%, Cr 2 o 3 : 0.2%, NiO: 0.15%, CuO: 0.12%, CdO: 0.1%, PbO: 0.3%, V 2 o 5 : 0.1%, As: 0.05%, Others: 0.6%. The basic glass is heat-treated at 750°C for 90 minutes. Under this condition, nucleation and crystallization proceed simultaneously to form a crystallized glass with uniform distribution of crystallites, and finally anneal to eliminate stress to obtain a glass-ceramic product. The main crystal phase of the glass-ceramics is calcium aluminum feldspar, which solidifies heavy metals in the crystal phase, and the leaching concentration of heavy metals in the product is much lower than the "Leaking Toxicity Identification of Hazardous Waste Ident...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com