Nano structure yttrium stabilized zirconium oxide aggregated powder and its producing method

A technology of yttrium-stabilized zirconia and nano-zirconia, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems that the actual application of production is too far from the scale, the production cost is increased, and it is difficult to achieve scale. Effects of eliminating relaxation and internal stress, low cost, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

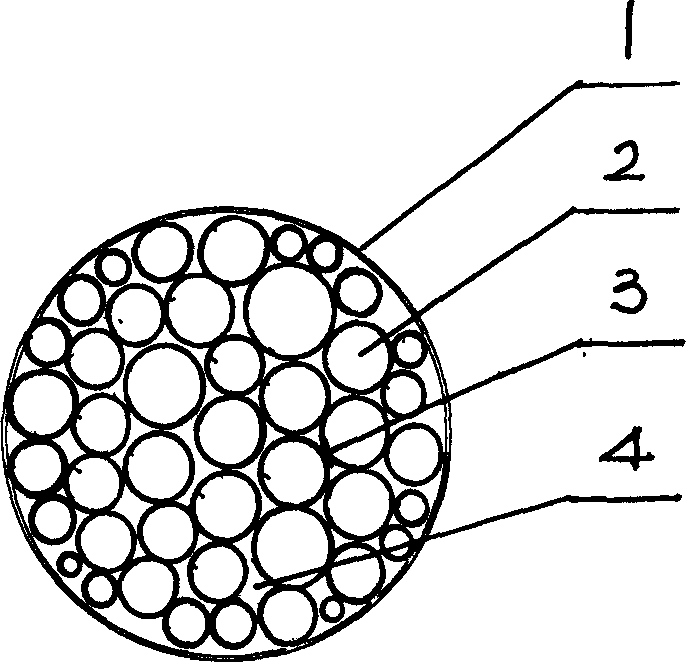

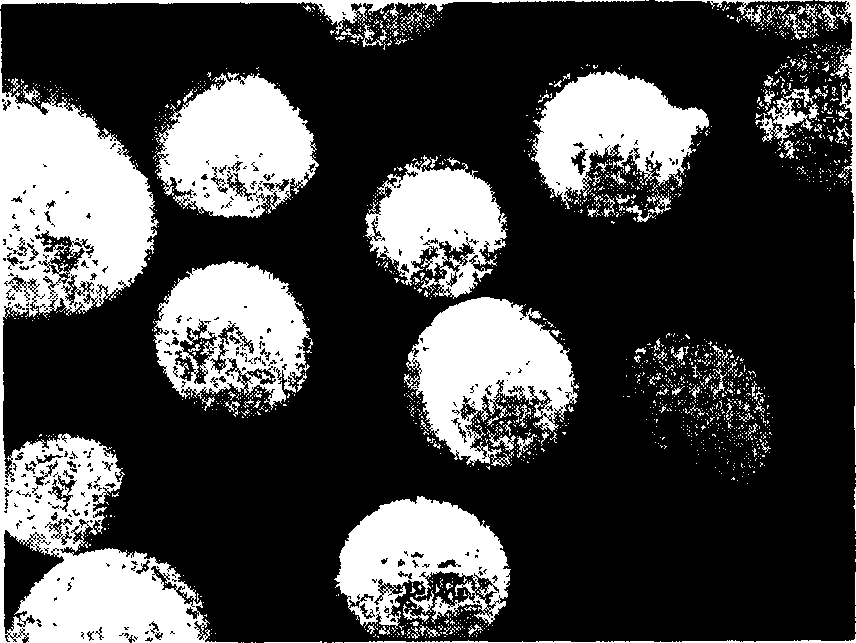

[0040] Take 10 kg containing 6wt% Y 2 o 3 Nano ZrO 2 (Partially stabilized yttrium oxide) powder, with an average crystal particle size of 20nm, was added with 15 kg of ultra-pure water, stirred evenly, uniformly dispersed with a colloid mill for 10 minutes, and prepared into a stable suspension slurry for use.

[0041] Purified compressed air is used as the carrying gas, the gas pressure is controlled at 0.3-0.8MPa, and the slurry is sprayed into the drying tower by a two-fluid nozzle, and the atomized slurry shrinks into an agglomerated spherical shape depending on its own surface tension, and is dried The air inlet temperature of the tower is controlled at 200°C, and the air outlet temperature is controlled at 120°C, so that the aerosol droplets are fully dried in the hot air. The dry agglomerated powder is then drawn into a cyclone separator by suction for collection.

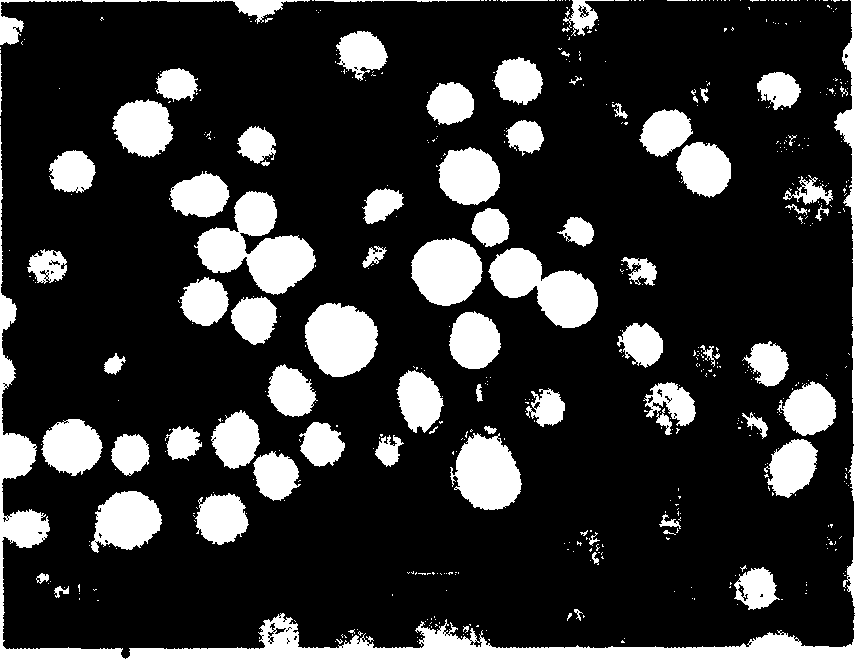

[0042] Sieve the collected powder with a mechanical sampling sieve. The particle size range of the fi...

Embodiment 2

[0054] Take 10 kg containing 6wt% Y 2 o 3 Nano ZrO 2 (Partially stabilized yttrium oxide) powder, with an average crystal particle size of 20nm, was added with 15 kg of ultra-pure water, stirred evenly, uniformly dispersed with a colloid mill for 10 minutes, and prepared into a stable suspension slurry for use.

[0055] The slurry is sprayed into the drying tower with a centrifugal atomizing disc. The rotational speed of the centrifugal atomizer is 10000r / min. The atomized slurry particles shrink into agglomerated spherical shape by virtue of their own surface tension, and are dried in the hot air. The drying tower The heating temperature of the heater is controlled at 200°C to quickly evaporate the water in the mist droplets, and the dry agglomerated powder is collected by a cyclone separator. Sieve the collected powder with a mechanical sampling sieve. The particle size ranges from 40 to 100 μm (ie, 150 to 350 mesh). The powder with a particle size greater than 100 μm and ...

Embodiment 3

[0067] Take 10 kg containing 8wt% Y 2 o 3 Nano ZrO 2 (Partially stabilized yttrium oxide) powder, with an average crystal particle size of 10nm, was added with 20 kg of ultra-pure water, stirred evenly, uniformly dispersed with a colloid mill for 10 minutes, and prepared into a stable suspension slurry for use.

[0068] Purified compressed air is used as the carrying gas, the gas pressure is controlled at 0.3-0.8MPa, and the slurry is sprayed into the drying tower by a two-fluid nozzle, and the atomized slurry shrinks into an agglomerated spherical shape depending on its own surface tension, and is dried The air inlet temperature of the tower is controlled at 240°C, and the air outlet temperature is controlled at 150°C, so that the aerosol droplets are fully dried in the hot air. The dry agglomerated powder is then drawn into a cyclone separator by suction for collection.

[0069] Sieve the collected powder with a mechanical sampling sieve. The particle size range of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com