Preparation method of thermal barrier coating and thermal barrier coating prepared by preparation method

A technology of thermal barrier coating and solution, which is applied in the direction of coating, metal material coating process, liquid chemical plating, etc., and can solve the problem of lower thermal shock resistance of coating, lower thermal insulation performance of coating, and weak lamellar bonding and other issues to achieve the effects of improving productivity, simplifying cumbersome processes, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

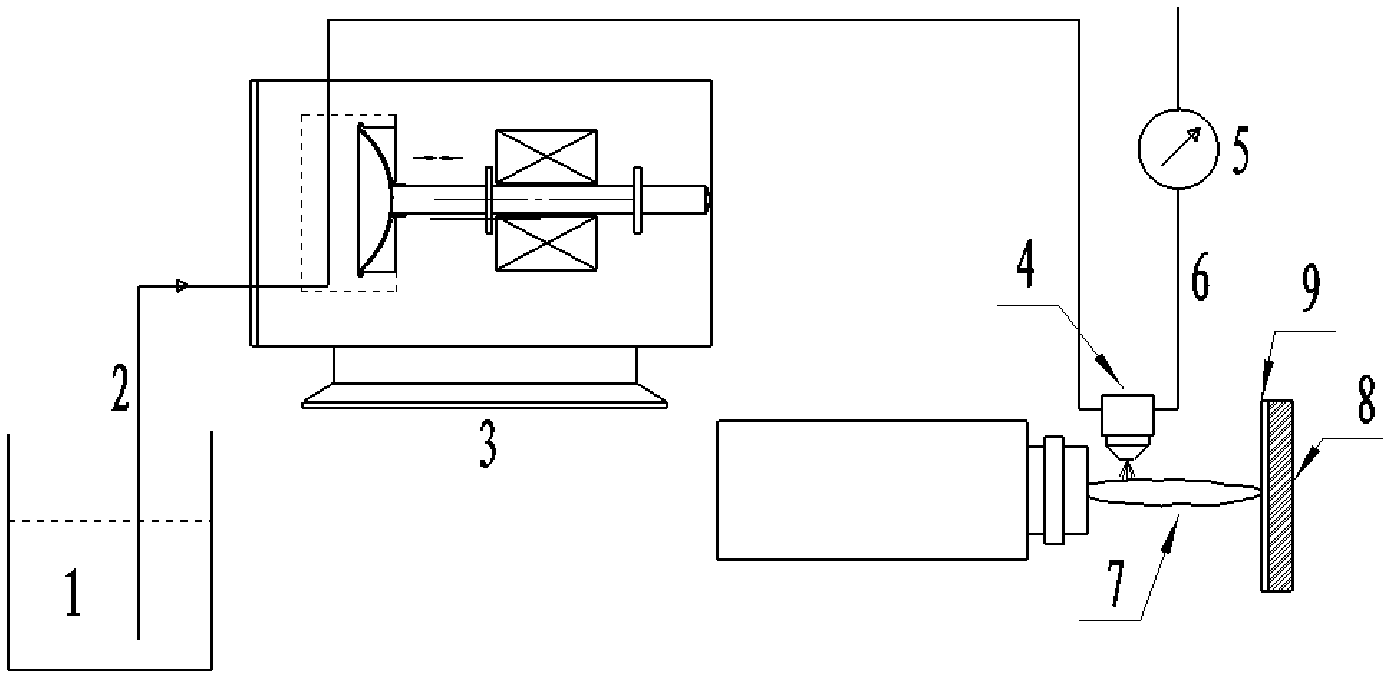

Method used

Image

Examples

Embodiment 1

[0049] Take yttrium nitrate solid and join in the zirconium acetate solution, make metal Zr ion concentration be 1mol / L in the solution, control the concentration of yttrium oxide in zirconia to be 7~8wt%, electromagnetic stirring at room temperature makes yttrium nitrate fully dissolve and Mix to obtain a YSZ solution precursor with a solute concentration of 9%.

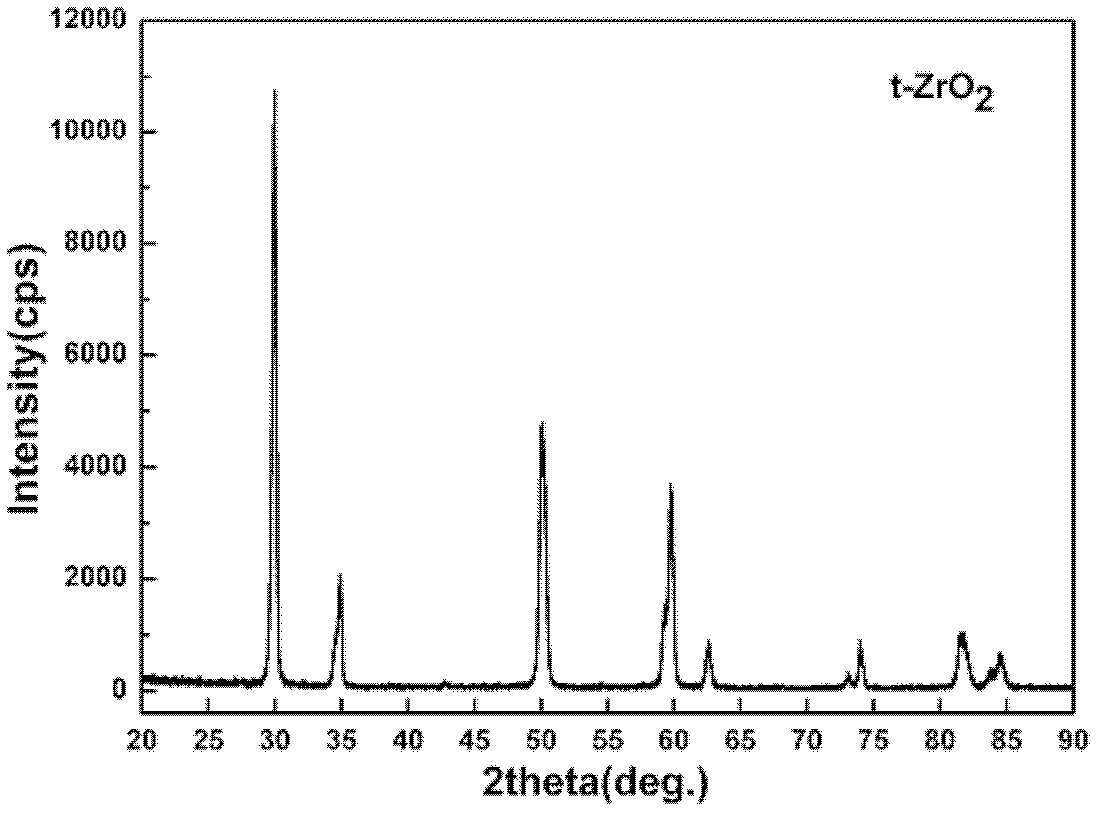

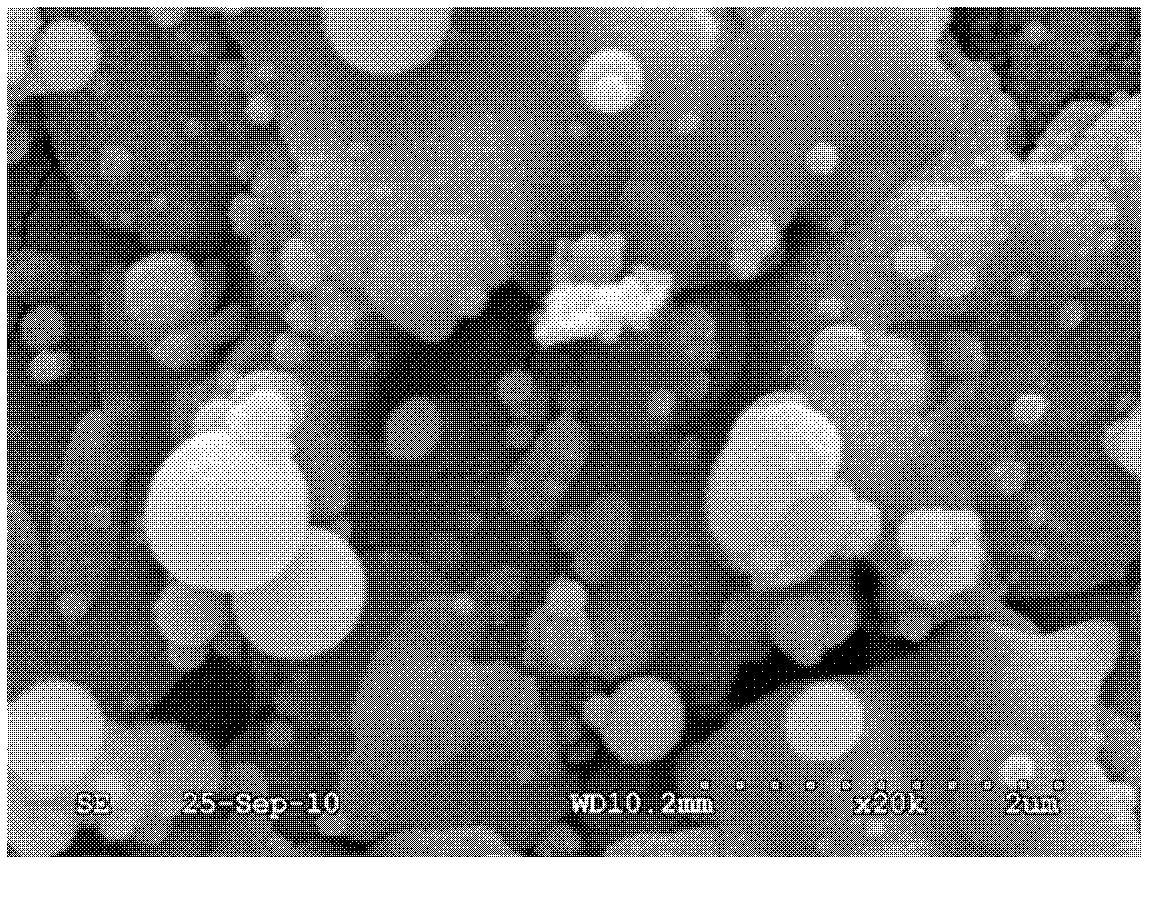

[0050] The prepared solution precursor was atomized through a two-flow atomization nozzle at a flow rate of 25ml / min and then sent into the plasma jet. A thermal barrier coating is formed on the substrate. The crystal structure and surface morphology of the coating were tested by X-ray diffraction (XRD) and scanning electron microscope, respectively. Such as Figure 2a As shown, the results show that: the coating is a single tetragonal phase structure, no monoclinic phase exists. Such as Figure 2b As shown, the results show that the coating is nanostructured and the grain size is less than 100nm.

Embodiment 2

[0052] Weigh the solid yttrium nitrate and add it to the zirconium acetate solution, so that the metal Zr ion concentration in the solution is 2.4mol / L, control the concentration of yttrium oxide in the zirconia to 7-8wt%, and stir electromagnetically at room temperature to fully dissolve the yttrium nitrate and mixed to obtain a YSZ solution precursor with a solute concentration of 23%. The prepared solution precursor is sent into the plasma jet through the two-flow atomization nozzle at a flow rate of 50ml / min under the atomization gas pressure of 0.2MPa. A series of processes such as decomposition and melting, and finally deposited on the superalloy substrate to form a thermal barrier coating. The coating microstructure was tested by scanning electron microscope (SEM), and the coating porosity was analyzed by image method. The result is as Figure 3a As shown, the results show that a vertical crack structure is formed in the coating, the pores are evenly distributed in th...

Embodiment 3

[0054] The solution precursor was prepared according to Example 2. The solution precursor is fed into the plasma jet at a flow rate of 25ml / min through a two-flow atomizing nozzle at an atomizing gas pressure of 0.1MPa, and deposited on the superalloy substrate to form a thermal barrier coating. The coating microstructure was examined by scanning electron microscopy (SEM). The result is as Figure 4a As shown, the results show that a vertical crack structure is formed in the coating, without transverse interlayer cracks, and the pores are evenly distributed in an island shape, and a large number of pores are smaller than 2 μm ( Figure 4b ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com