Patents

Literature

31results about How to "Simplify cumbersome process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

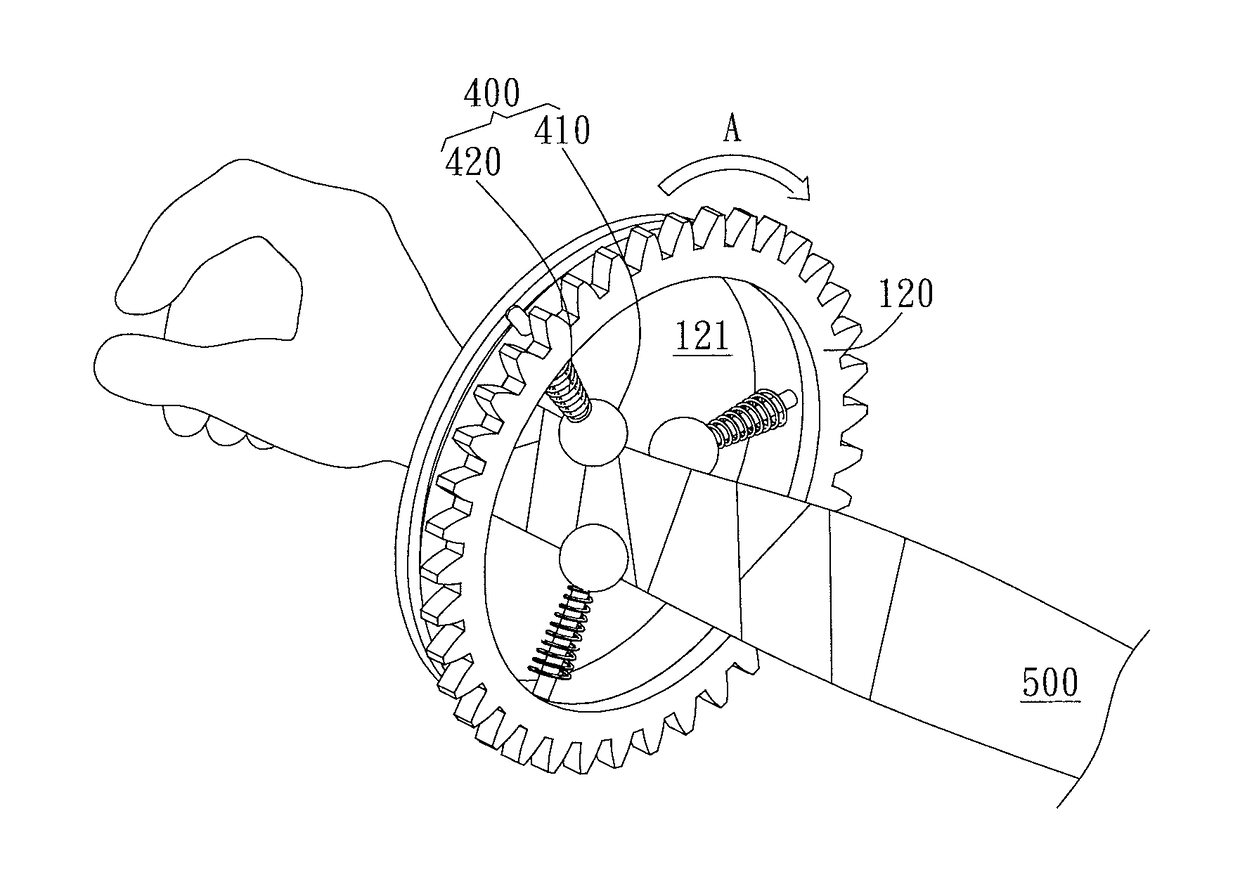

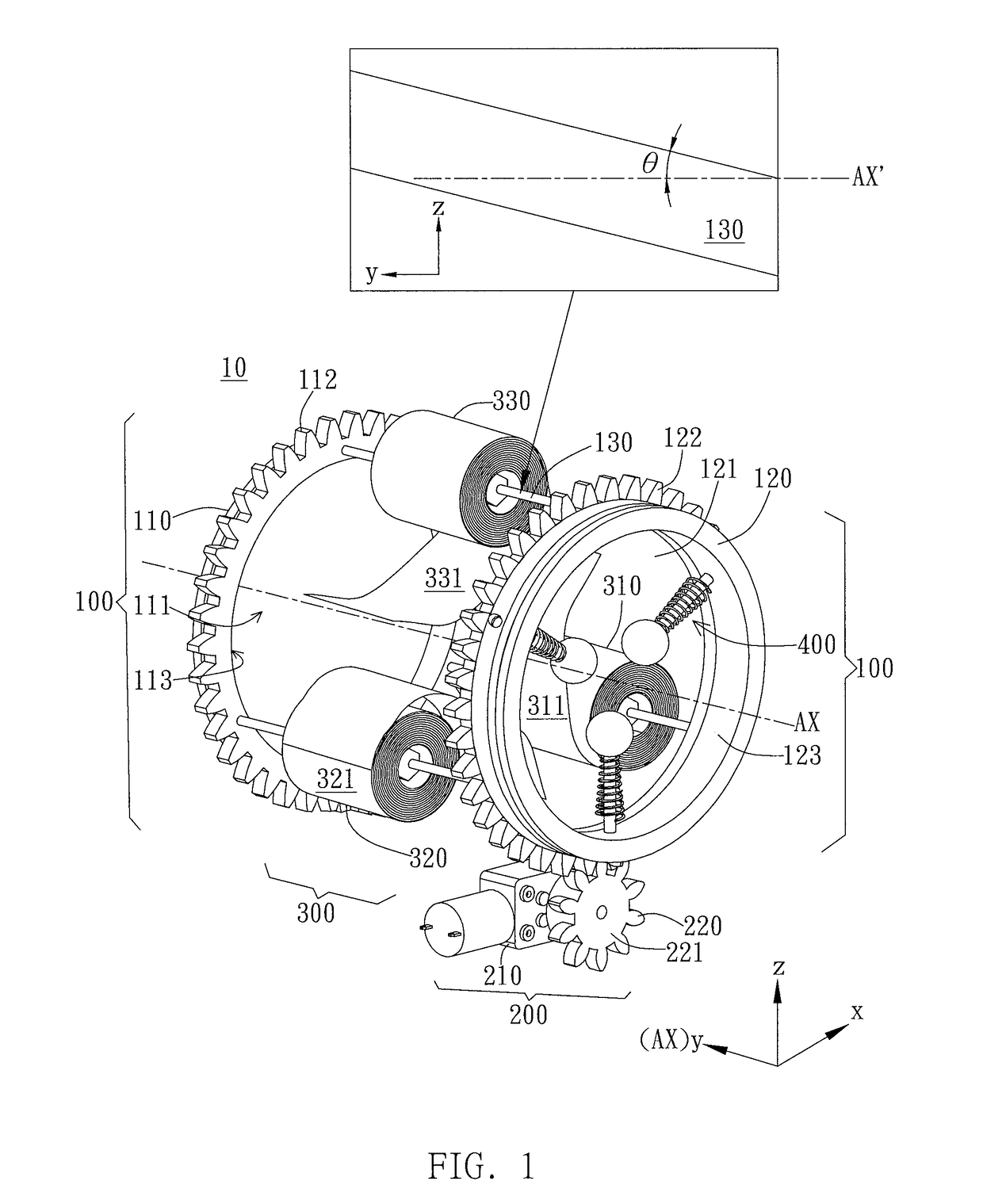

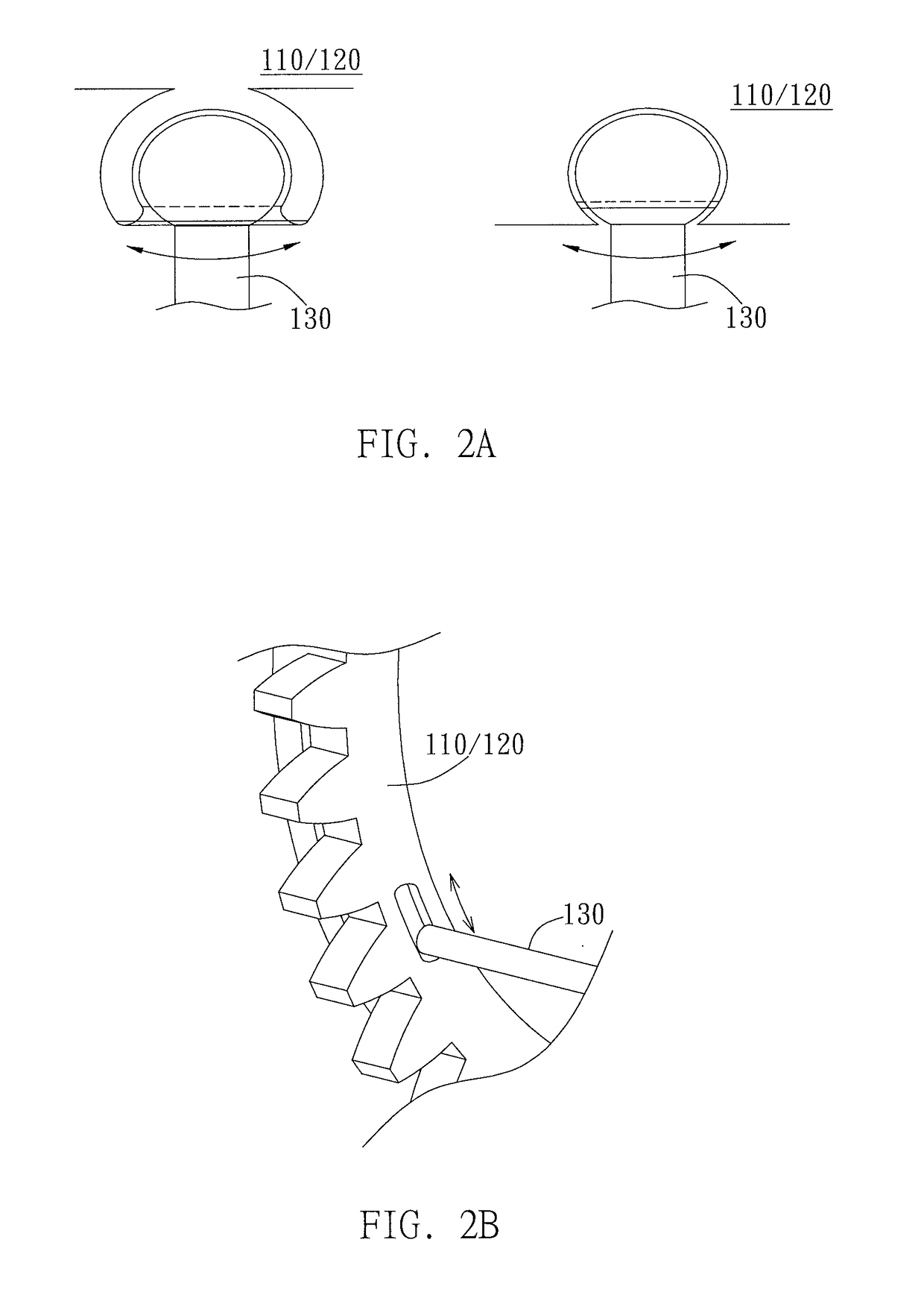

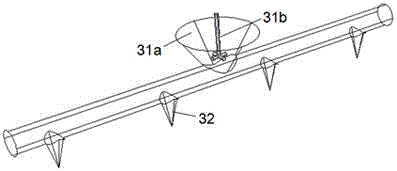

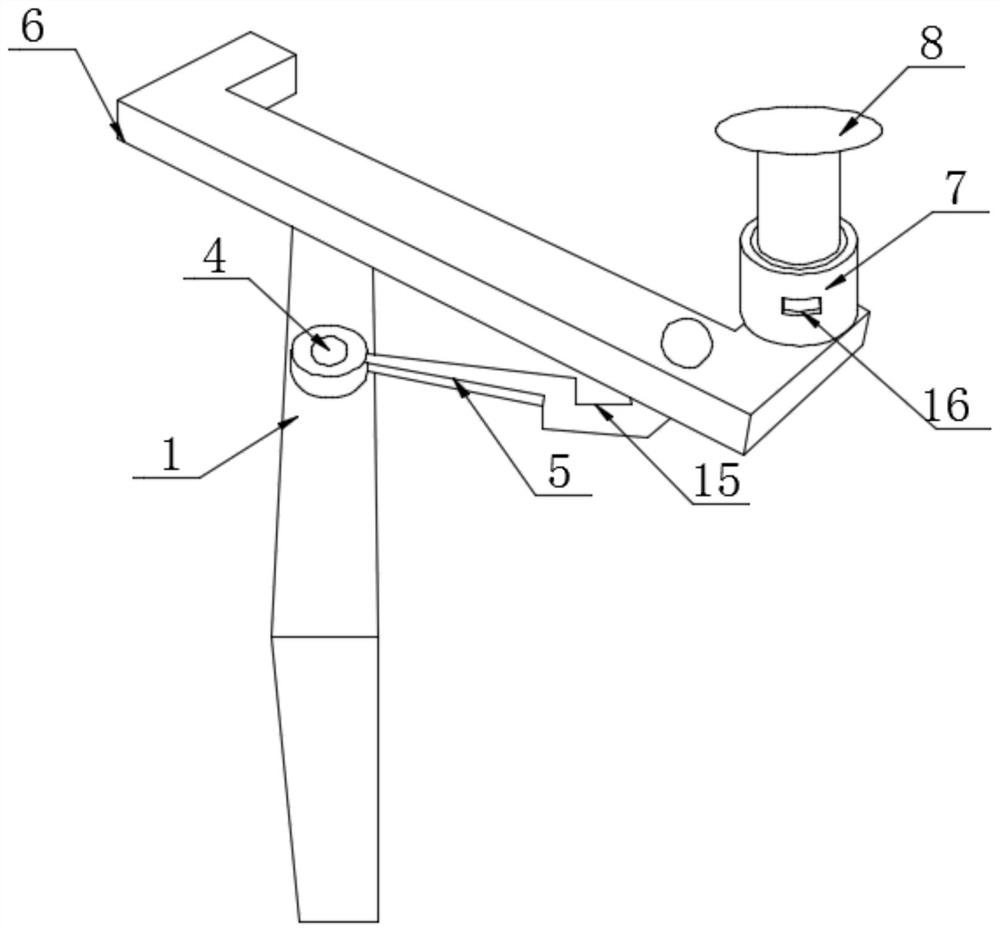

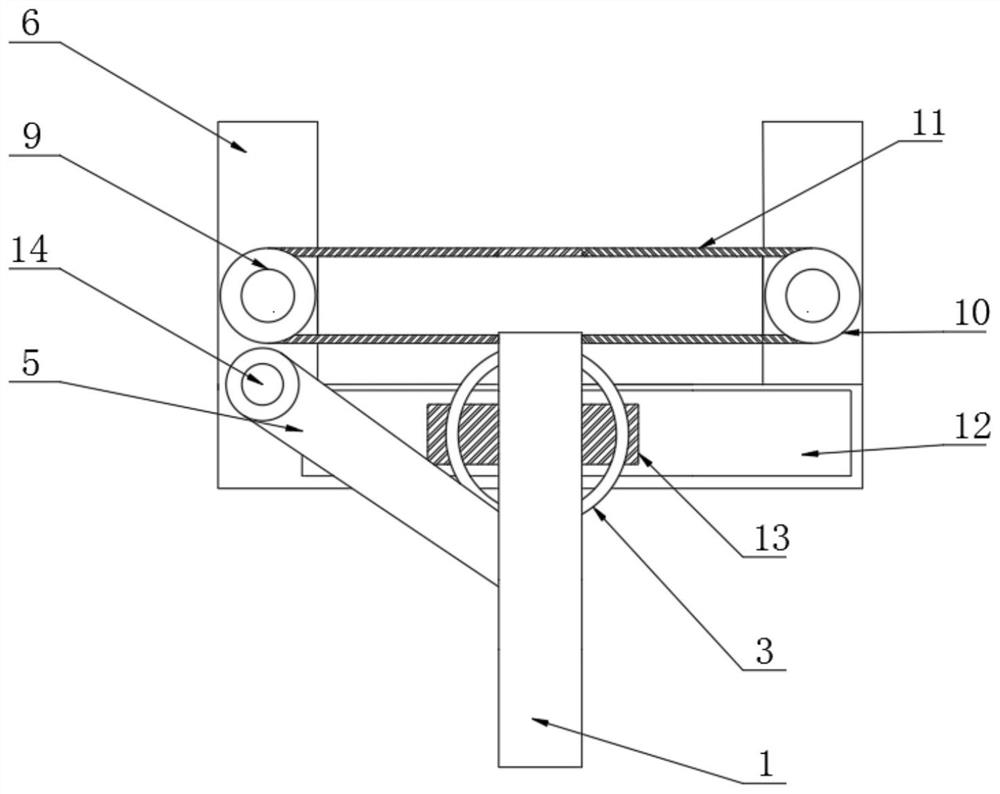

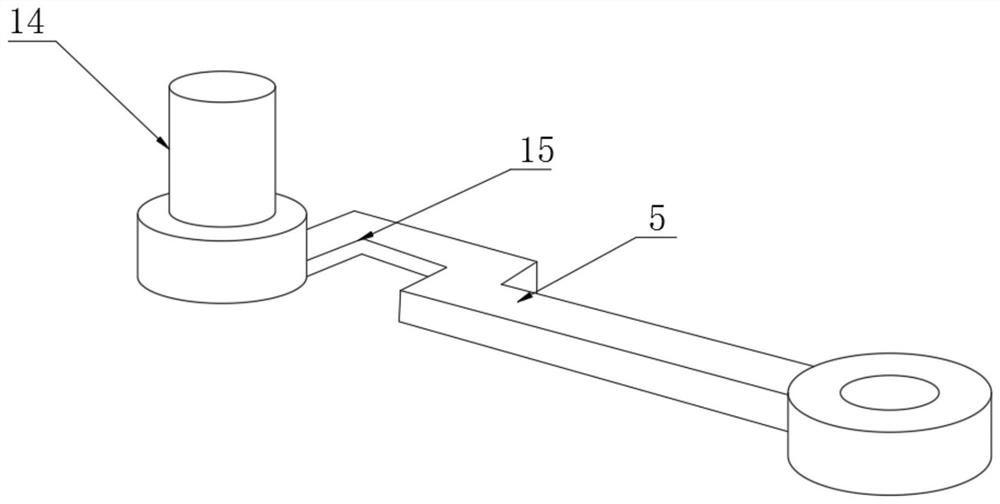

Wrapping device for wrapping body parts

ActiveUS20180280211A1Reduce implementation timeSimplify cumbersome processPlaster of paris bandagesEngineeringMechanical engineering

Owner:NATIONAL CHIAO TUNG UNIVERSITY

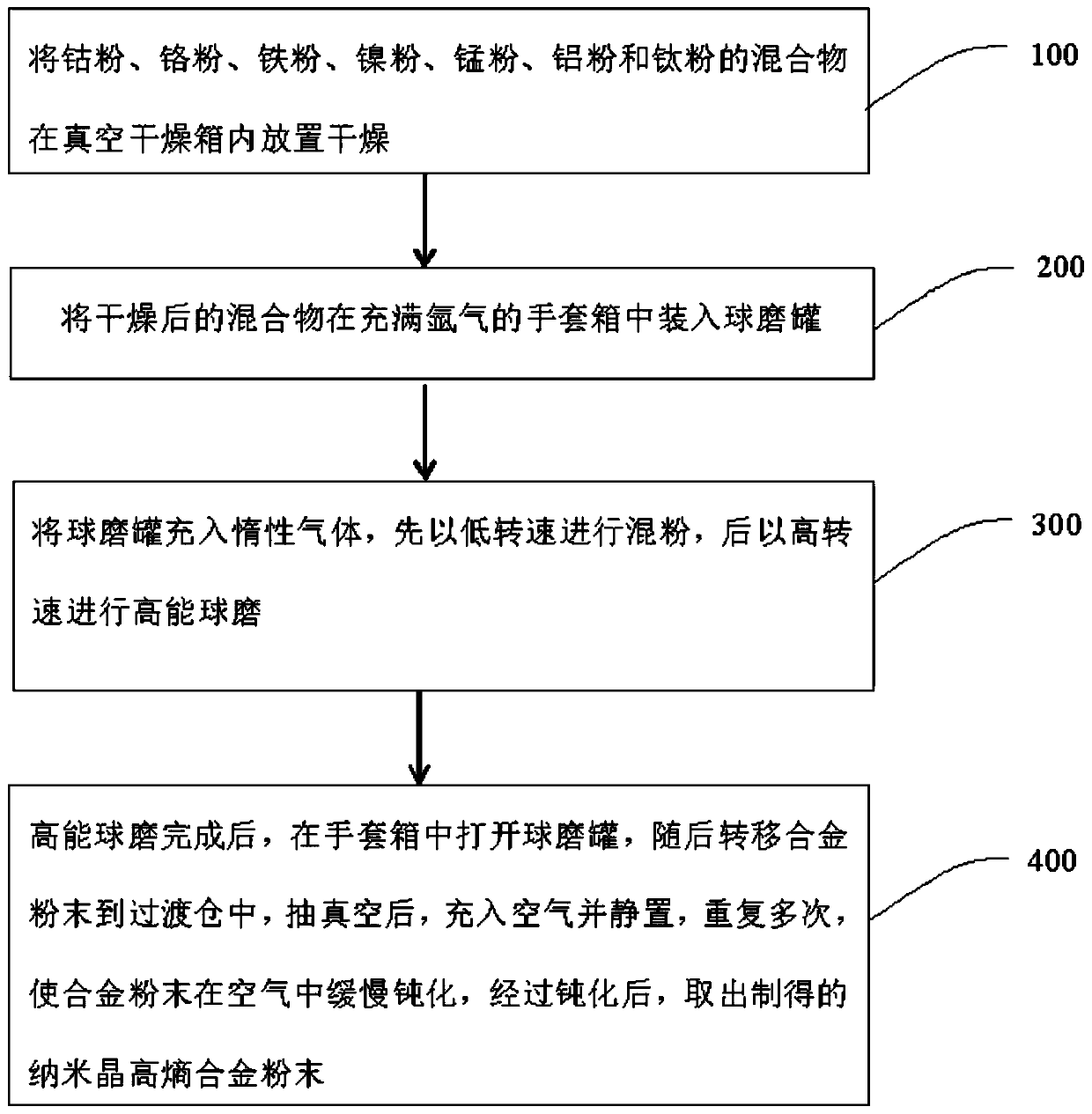

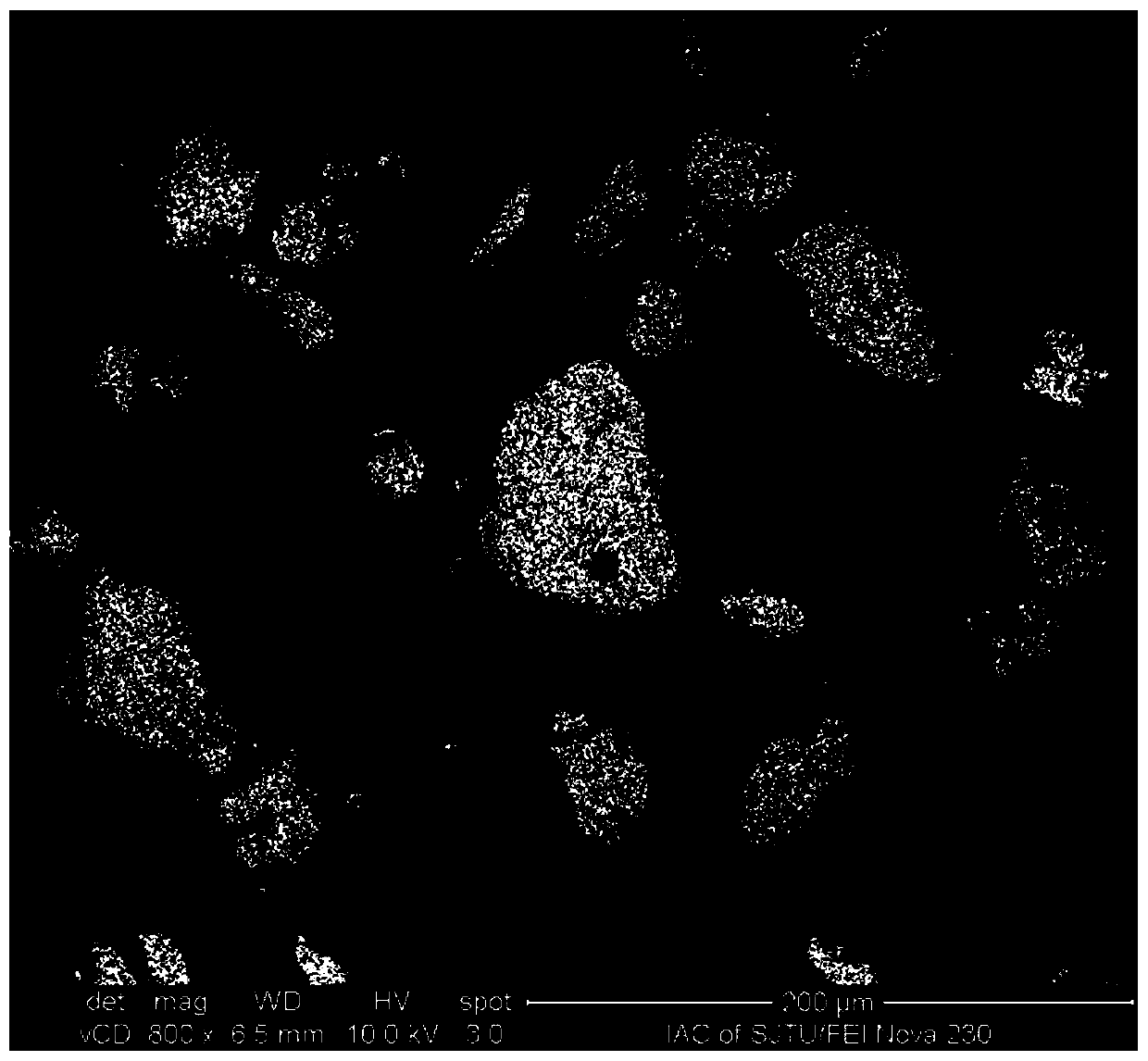

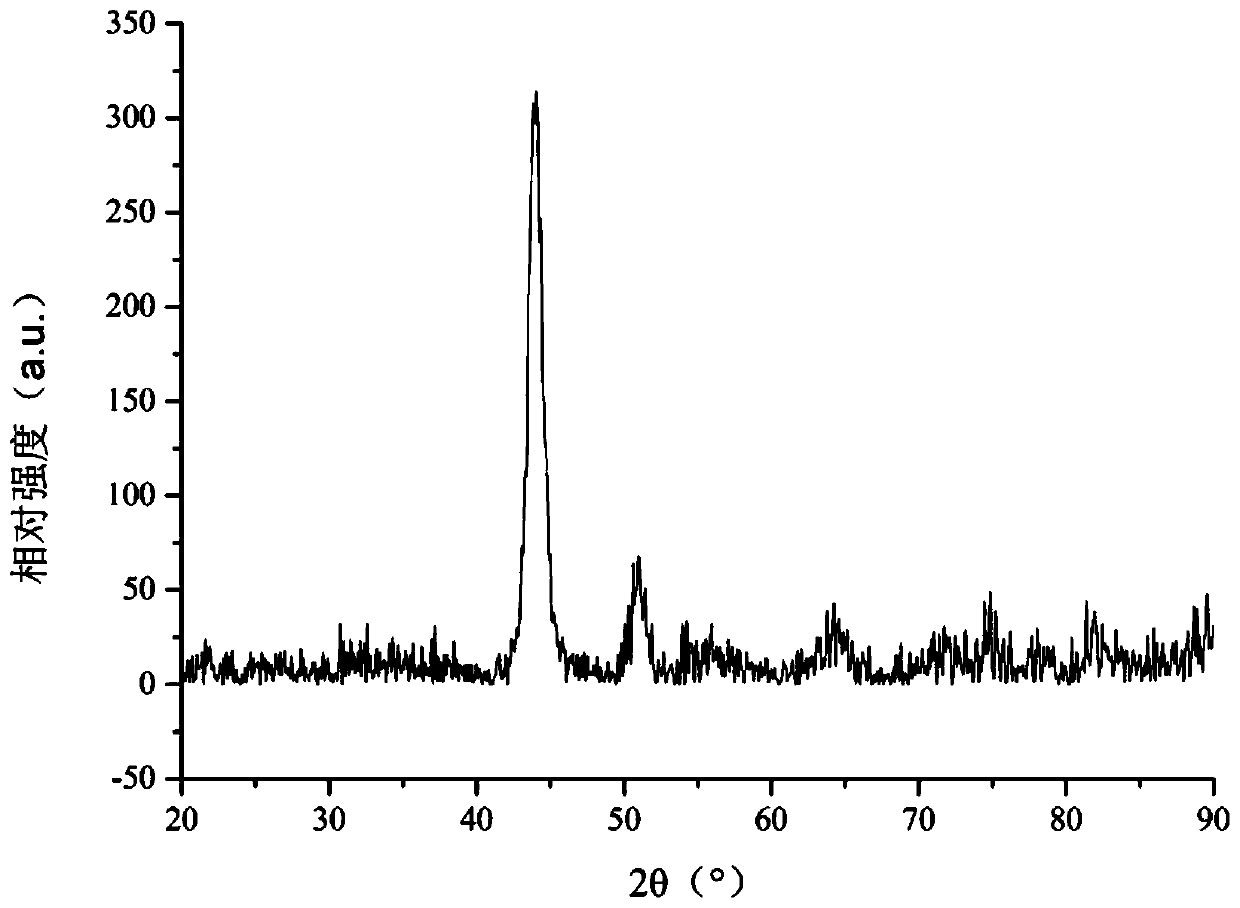

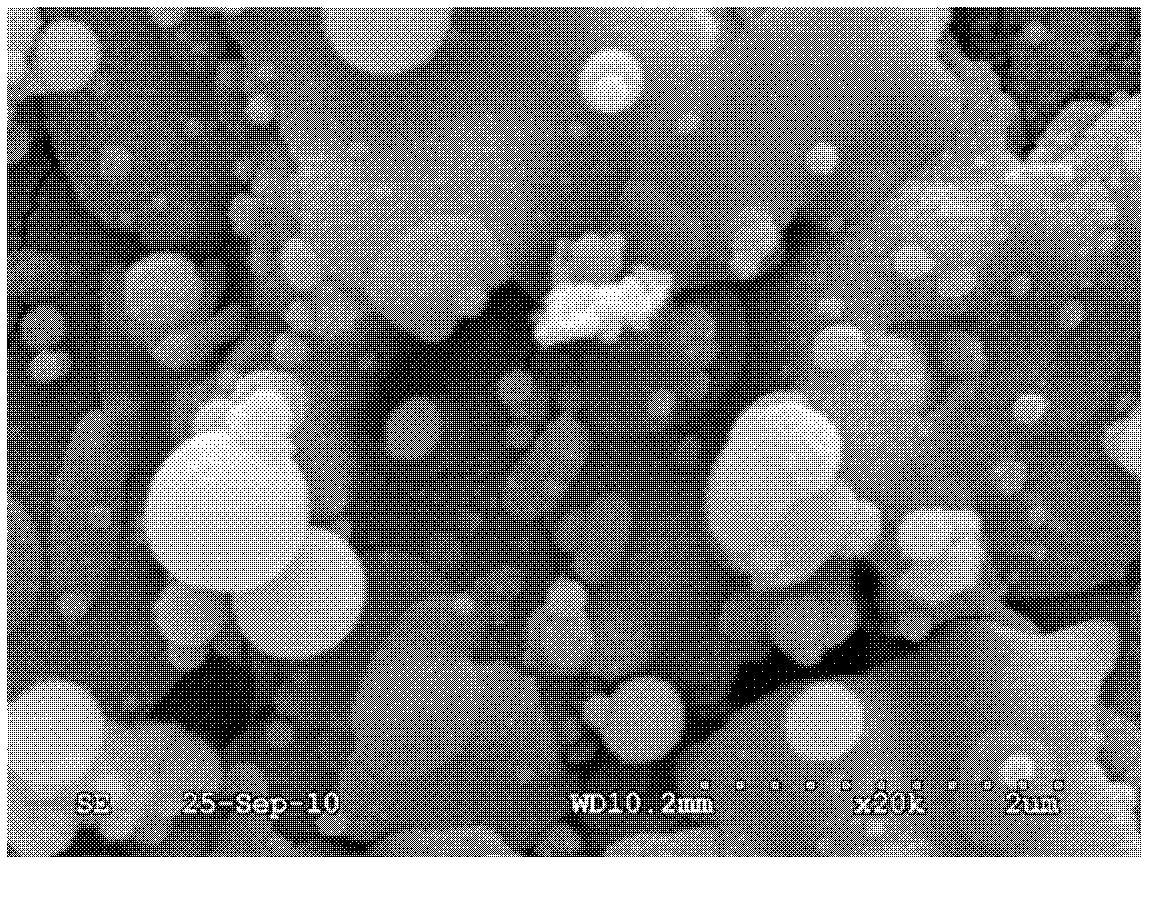

Nanocrystalline high-entropy alloy powder and preparation method thereof

InactiveCN110576185AOvercome high energy consumptionLower the activation energy of the reactionHigh entropy alloysPowder metallurgy

The invention discloses nanocrystalline high-entropy alloy powder and a preparation method thereof, and relates to the technical field of powder metallurgy. The invention involves the nanocrystallinehigh-entropy alloy powder and the preparation method of the nanocrystalline high-entropy alloy powder, wherein the nanocrystalline high-entropy alloy powder comprises cobalt powder, chromium powder, iron powder, nickel powder, manganese powder, aluminum powder and titanium powder; and the metal element powder is directly mixed through a high-energy mechanical ball milling method by the preparationmethod of the nanocrystalline high-entropy alloy powder, and the nanocrystalline high-entropy alloy powder is prepared according to the specific steps. According to the nanocrystalline high-entropy alloy powder and the preparation method, through high-speed impact and grinding of grinding medium, reaction activation energy is reduced, powder activity is improved, solid diffusion among element powder is promoted, low-temperature chemical reaction is induced, and finally, the alloy powder with uniform composition and structure distribution is obtained, so that the problems of element volatilization and non-uniform components of the powdering after smelting is conducted are solved. The technical is simple in equipment, the procedure is simplified compared with a traditional method, the manufacturing cost is reduced, and the nanocrystalline high-entropy alloy powder powder the preparation method thereof are suitable for industrial large-scale preparation.

Owner:SHANGHAI JIAO TONG UNIV

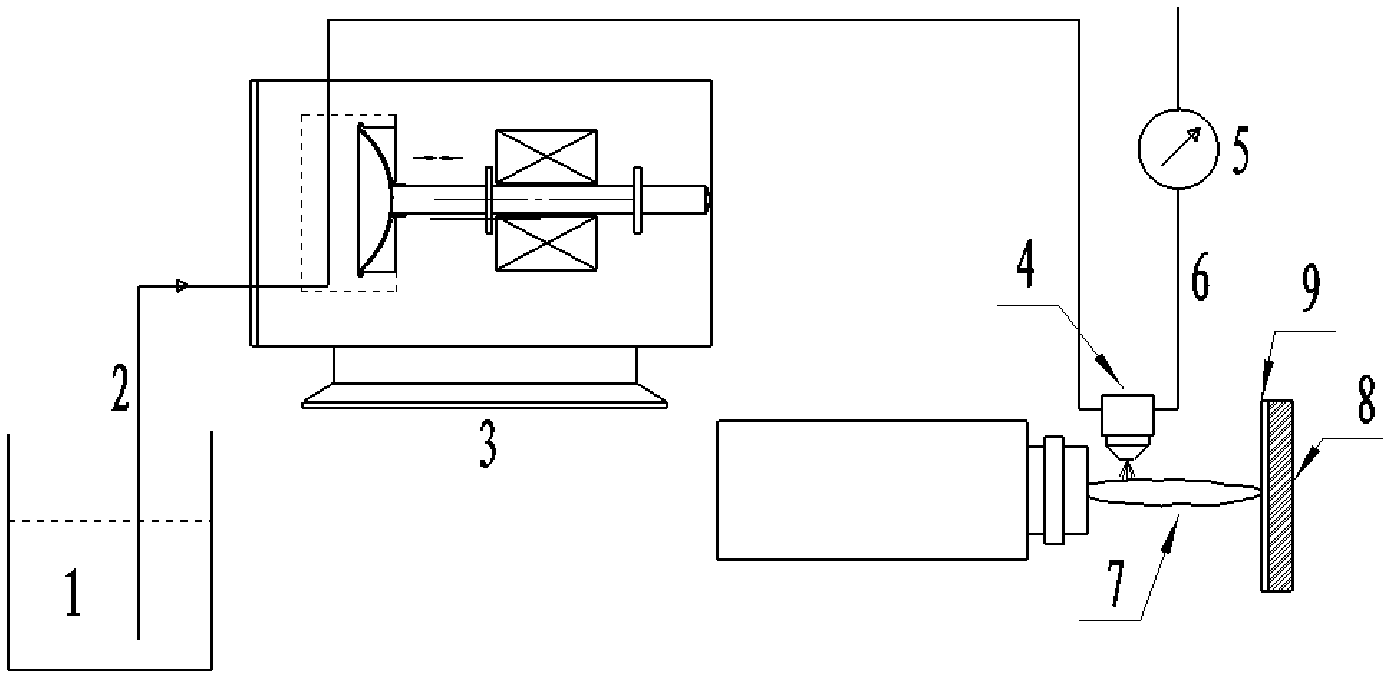

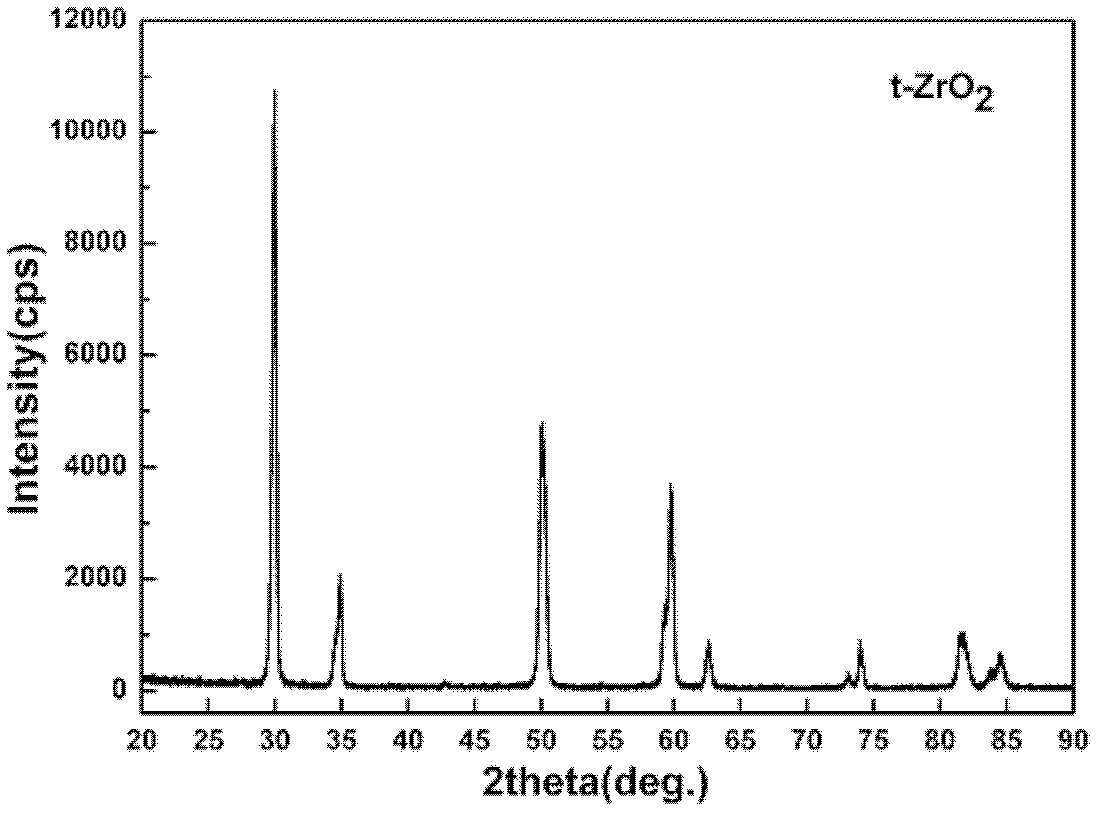

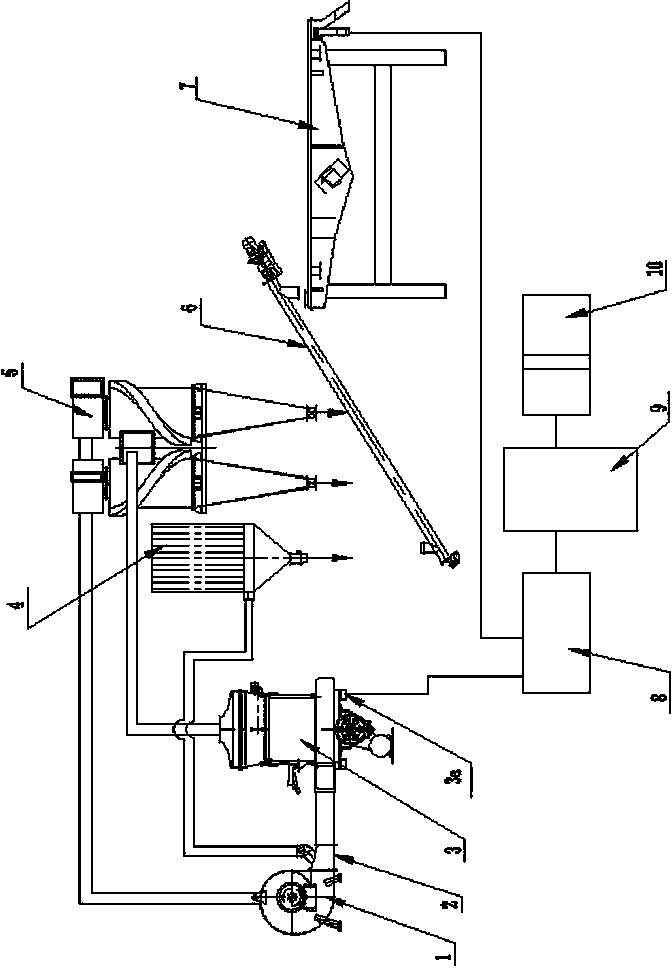

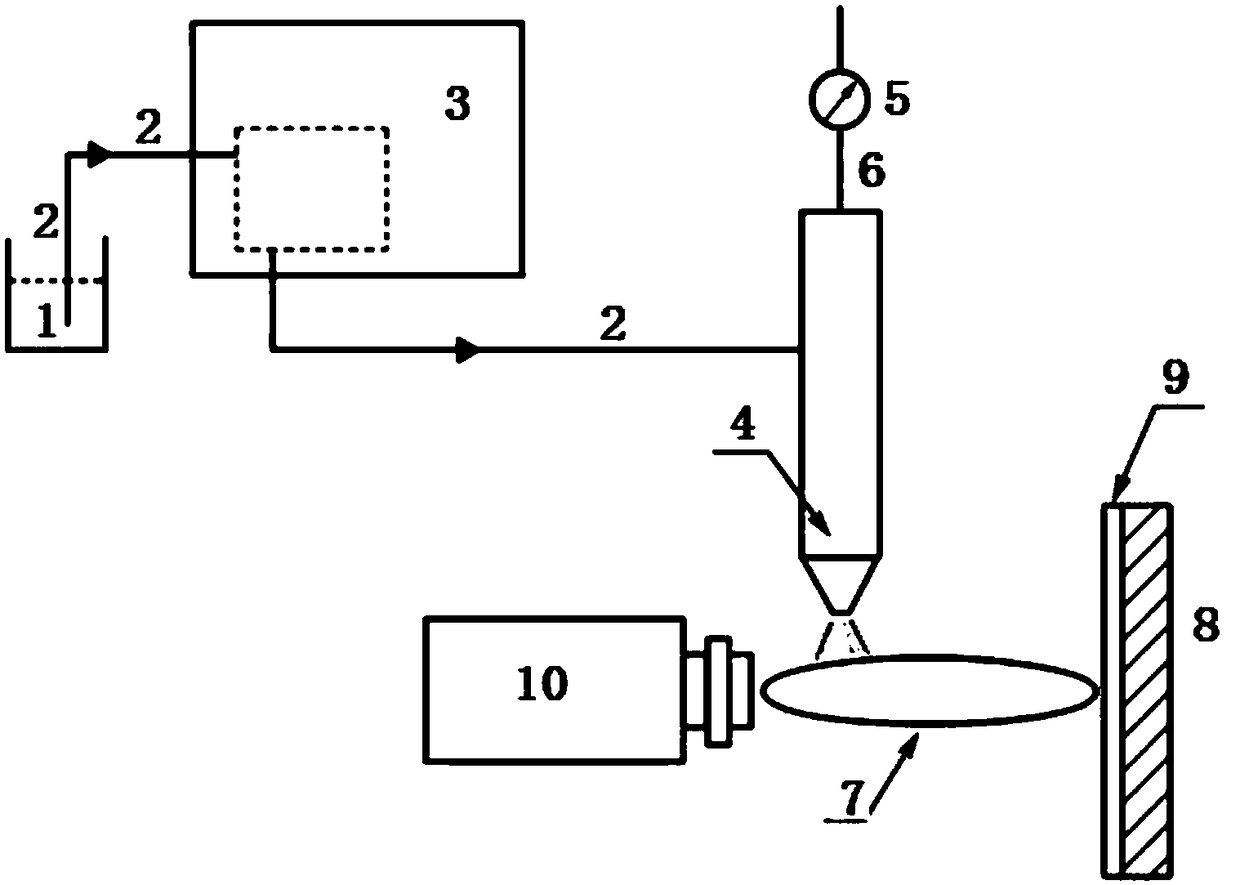

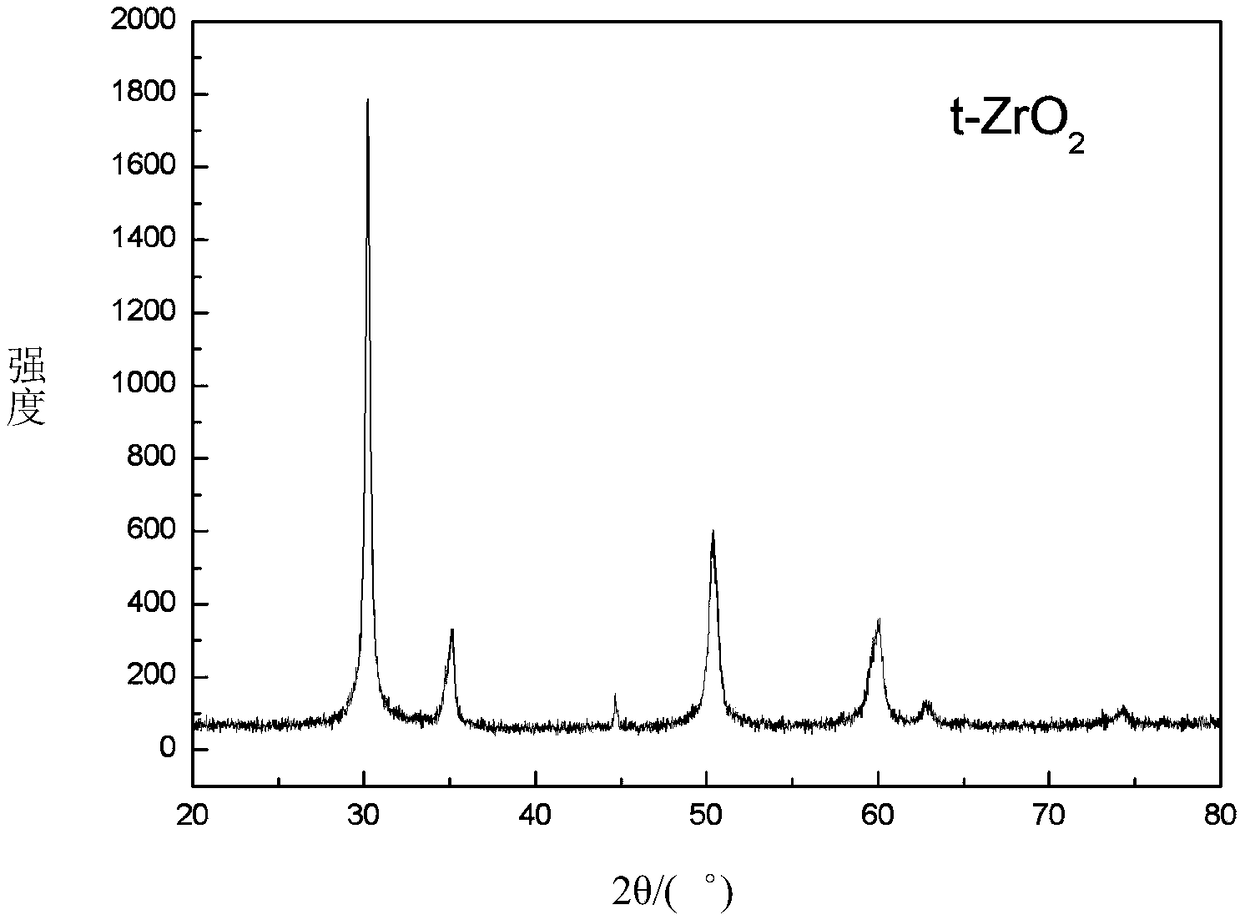

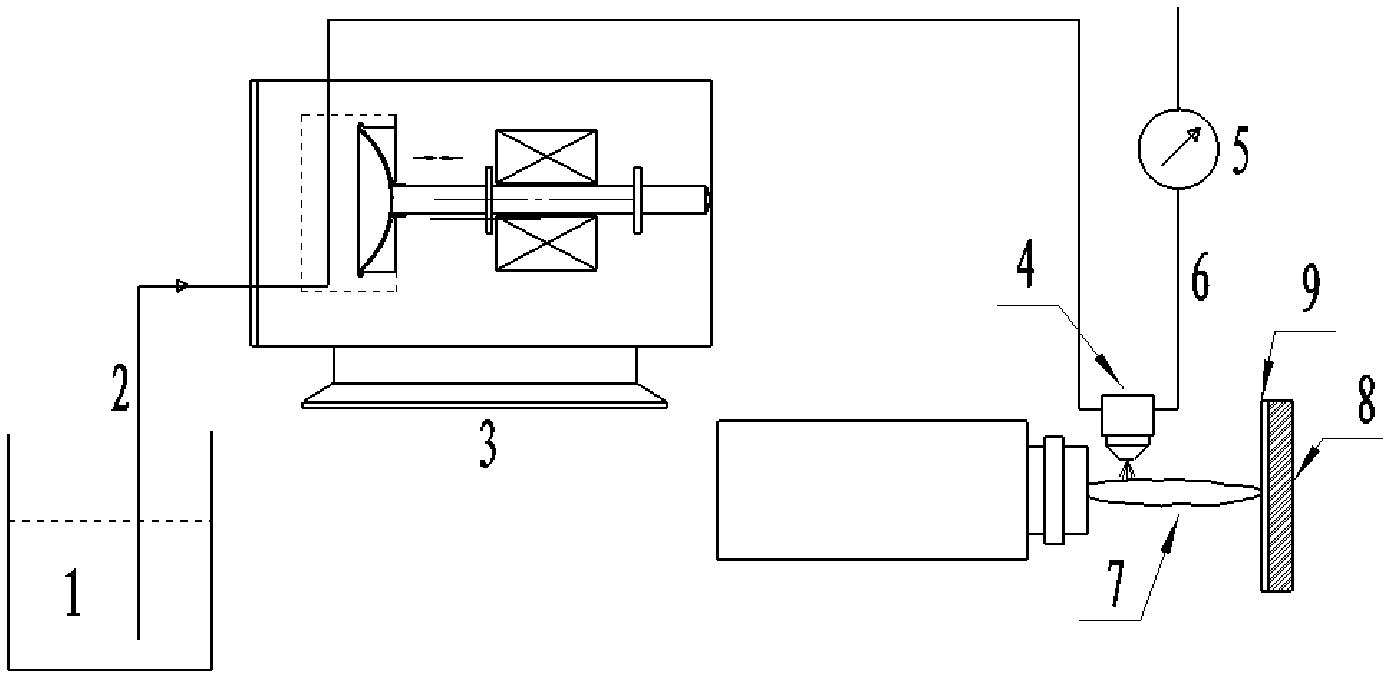

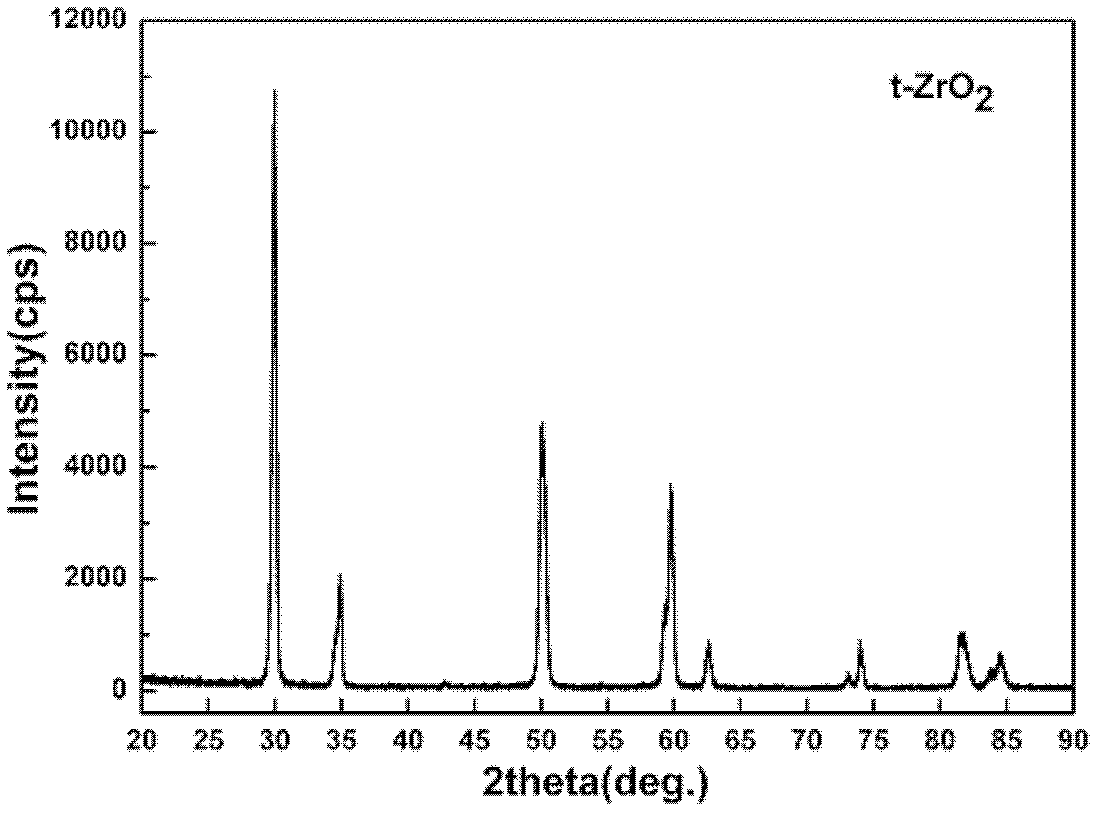

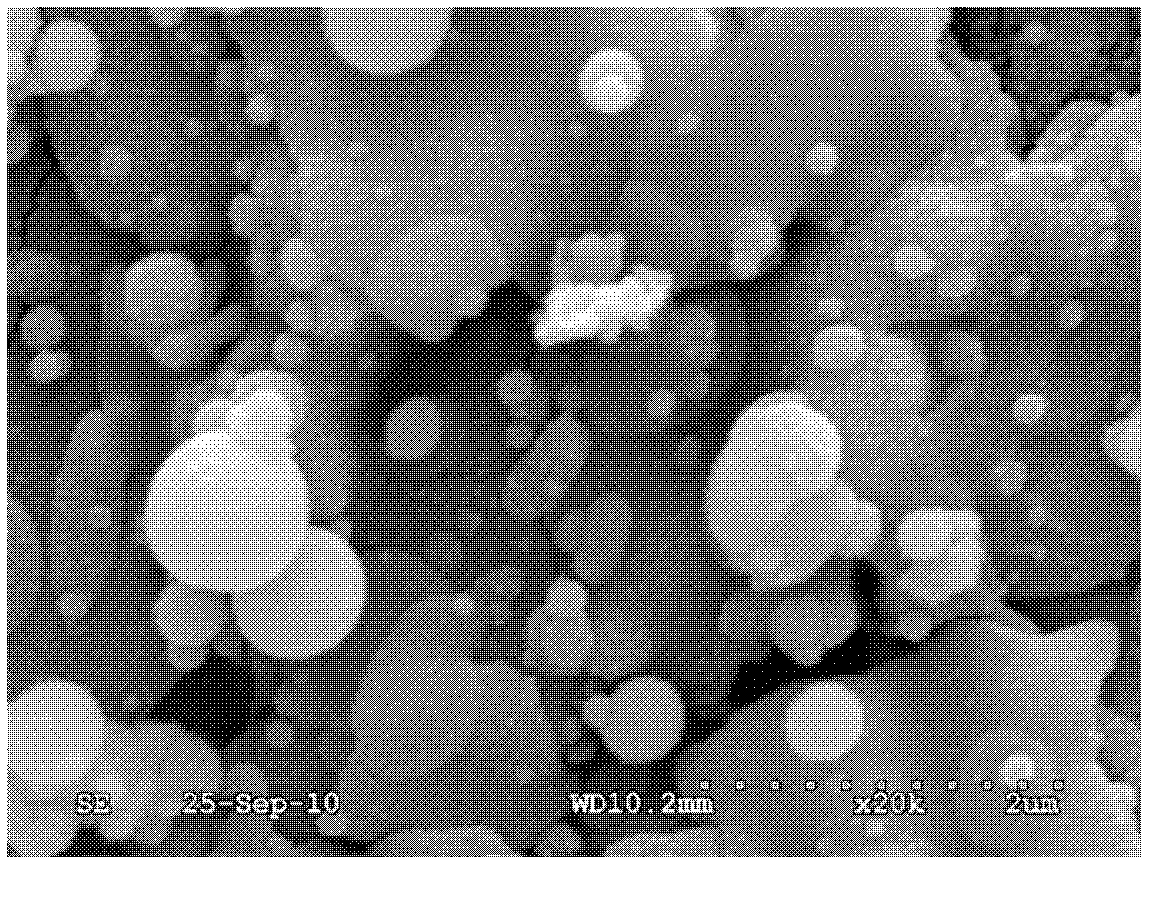

Preparation method of thermal barrier coating and thermal barrier coating prepared by preparation method

ActiveCN102851631AShort manufacturing processOptimal Control StructureMolten spray coatingLiquid/solution decomposition chemical coatingPlasma jetProduction rate

The invention discloses a preparation method of a thermal barrier coating and the thermal barrier coating prepared by the preparation method. According to the method, a solution precursor composed of zirconates and yttrium salts is used as a spraying raw material. The solution precursor is atomized into liquid drops through a two-phase flow atomizing nozzle; and the liquid drops are sent for plasma jet, undergo plasma jet heating and acceleration and are deposited on a matrix to form the thermal barrier coating. The thermal barrier coating is nanostructured and has a vertical crack structure. The solution precursor liquid material replaces an agglomerated powder to be used as a spraying raw material, thus greatly simplifying tedious processes of traditional air plasma spraying for coating preparation. There are few technological processes for coating preparation in the invention, thus raising productivity and reducing cost. in addition, the coating structure is controllable and technical production can be realized. By the adoption of the prepared coating, defects of a coating prepared by traditional plasma spraying are eliminated, and a high-performance coating which satisfies special requirements can be prepared.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

Al-Mg-Si-Cu-Ti-Sr alloy and method for making same

The invention provides a Al-Mg-Si-Cu-Ti-Sr alloy for preparing car body plate. The alloy consists of Al, Mg, Si, Cu, Mn, Ti, and Sr, and the contents of the components (by weight) are as follows: Mg: 1.0-1.5%, S: 1.0-1.5%, Cu: 0.5-1.0%, Mn: 0.1-0.6%, Ti: 0.1-0.3%, Sr: 0.01-0.1%, Al: the rest. The invention also provides the preparing method, characterized by preparing Al-Si-Ti alloy and other required elements by direct electrolytic method. The alloy plate provided by the invention has improved mechanical property and shaping property.

Owner:ZHENGZHOU UNIV

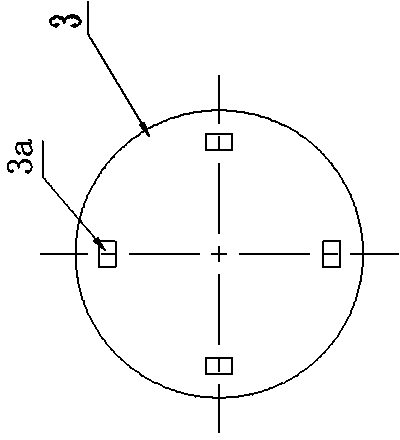

Breaking and separation integrated comprehensive recovery method of chrysotile tailings

InactiveCN103433137AReduce the delivery linkReduce lossesMagnetic separationGrain treatmentsRecovery methodMagnetic separator

The invention provides a breaking and separation integrated comprehensive recovery method of chrysotile tailings, which is characterized by comprising the steps of putting the dried chrysotile tailings in breaking and separation integrated equipment consisting of a pulverizer and a cyclone powder collector, achieving pulverizing and separation by adding 4-8 sand discharge ports on a pulverizing disc of the pulverizer, separating a chrysotile mixed material containing dust and tailing waste, conveying the chrysotile mixed material to a plane revolving screen or a plane shaking screen for classification and dedusting, removing fine sand and the dust, obtaining chrysotile products of different levels, roughing the tailing waste, the fine sand and the dust with a weak magnetic separator, obtaining magnetic middlings and tailings, and conveying the magnetic middlings into a ball mill for milling, and a wet weak magnetic separator for concentrating to obtain magnetite concentrates and tailings. According to the method, two production processes, grinding & asbestos fiber opening, and separation, of the chrysotile tailings are organically combined into a whole, effects of energy conservation and consumption reduction are achieved, and the chrysotile products of different levels and the magnetite concentrates are obtained simultaneously.

Owner:十堰源禹工贸有限公司

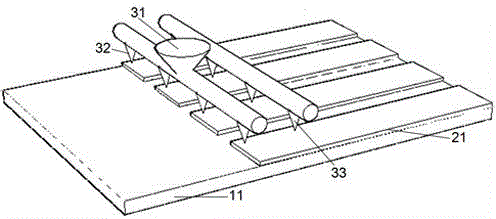

Method for preparing transparent conducting electrode based on 3D (three-dimensional) printing technique

ActiveCN104409171ASimplify cumbersome processImprove the quality rateCable/conductor manufactureState of artOrganic solvent

The invention relates to a method for preparing a transparent conducting electrode based on a 3D (three-dimensional) printing technique. The method is characterized by comprising the following steps of 1) providing a 3D printing device which comprises a collosol generation cavity, 3D printing heads and laser printing heads, 2) performing modeling: designing a model of the transparent conducting electrode by using computer modeling software and converting a software instruction of the model into a mechanical instruction of 3D printing, 3) preparing collosol: sequentially adding an inorganic metallic compound or organic metallic compound A and an organic solvent B to the collosol generation cavity to generate the collosol used for preparing the transparent conducting electrode, and 4) printing the transparent conducting electrode by using the 3D printing device, wherein the collosol generation cavity comprises a collosol generation cavity body and a stirring rod. The method effectively simplifies the complicated process of preparing the transparent conducting electrode in the prior art, increases the yield and the accuracy of the transparent conducting electrode, and lowers the preparation cost.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

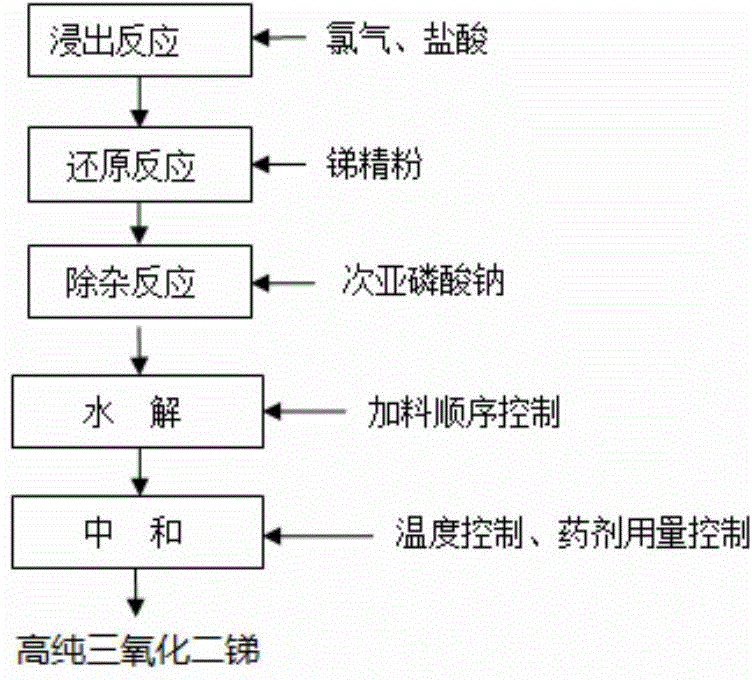

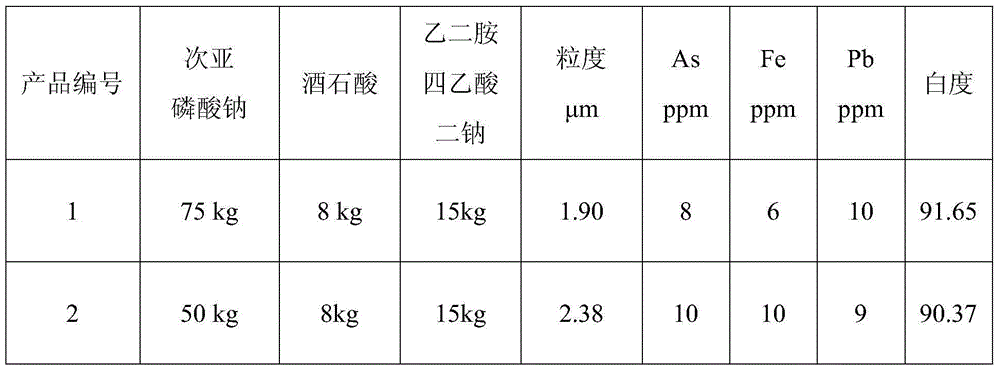

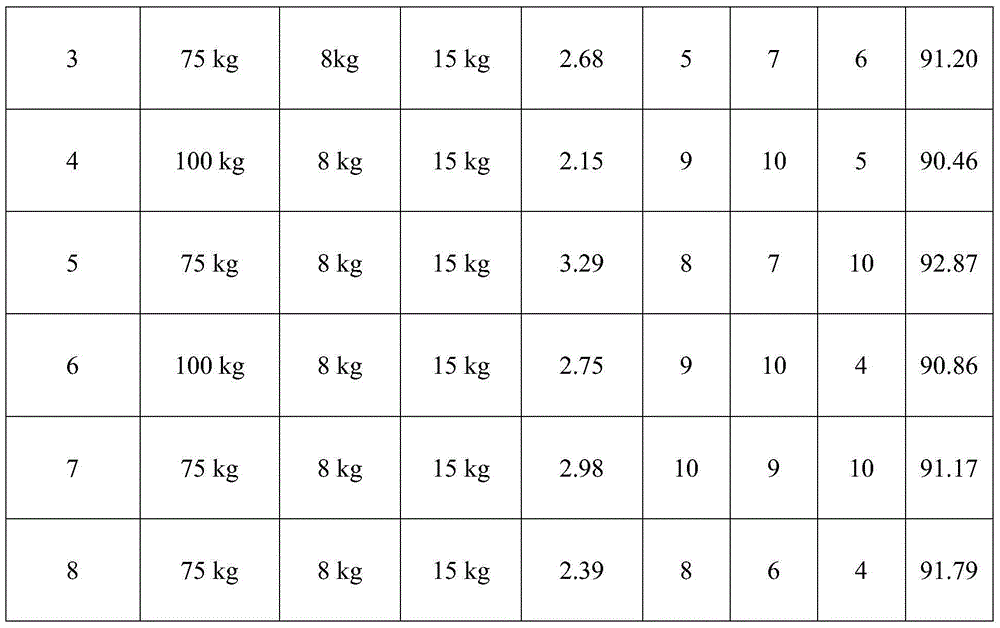

Technique for producing high-purity antimonous oxide by processing stibnite concentrate through wet method

InactiveCN104944469AHigh purityUniform particle sizeAntimony compoundsEthylene diamineAcid concentration

The invention discloses a technique for producing high-purity antimonous oxide by processing stibnite concentrate through the wet method. According to the technique, the stibnite concentrate is chloridized, a leaching agent is reduced by means of fine stibium powder, reduction liquid is selectively reduced through sodium hypophosphite under the proper temperature and proper acid concentration conditions so that arsenic is removed, iron in a solution subjected to arsenic removal is removed through hydrolysis, and lead in the solution subjected to arsenic removal is removed through ethylene diamine tetraacetic acid; meanwhile, growth of crystals is controlled by adding dihydroxysuccinic acid and controlling the neutral reaction condition, and in this way, a high-purity antimonous oxide product containing main impurities such as lead, arsenic and iron all being within 10 ppm and the average particle sizes being 2-3 microns can be produced. According to the technique, the stibium loss is small, operation is easy, production cost is low, and industrial production requirements are met.

Owner:HUNAN CHENZHOU MINING CO LTD

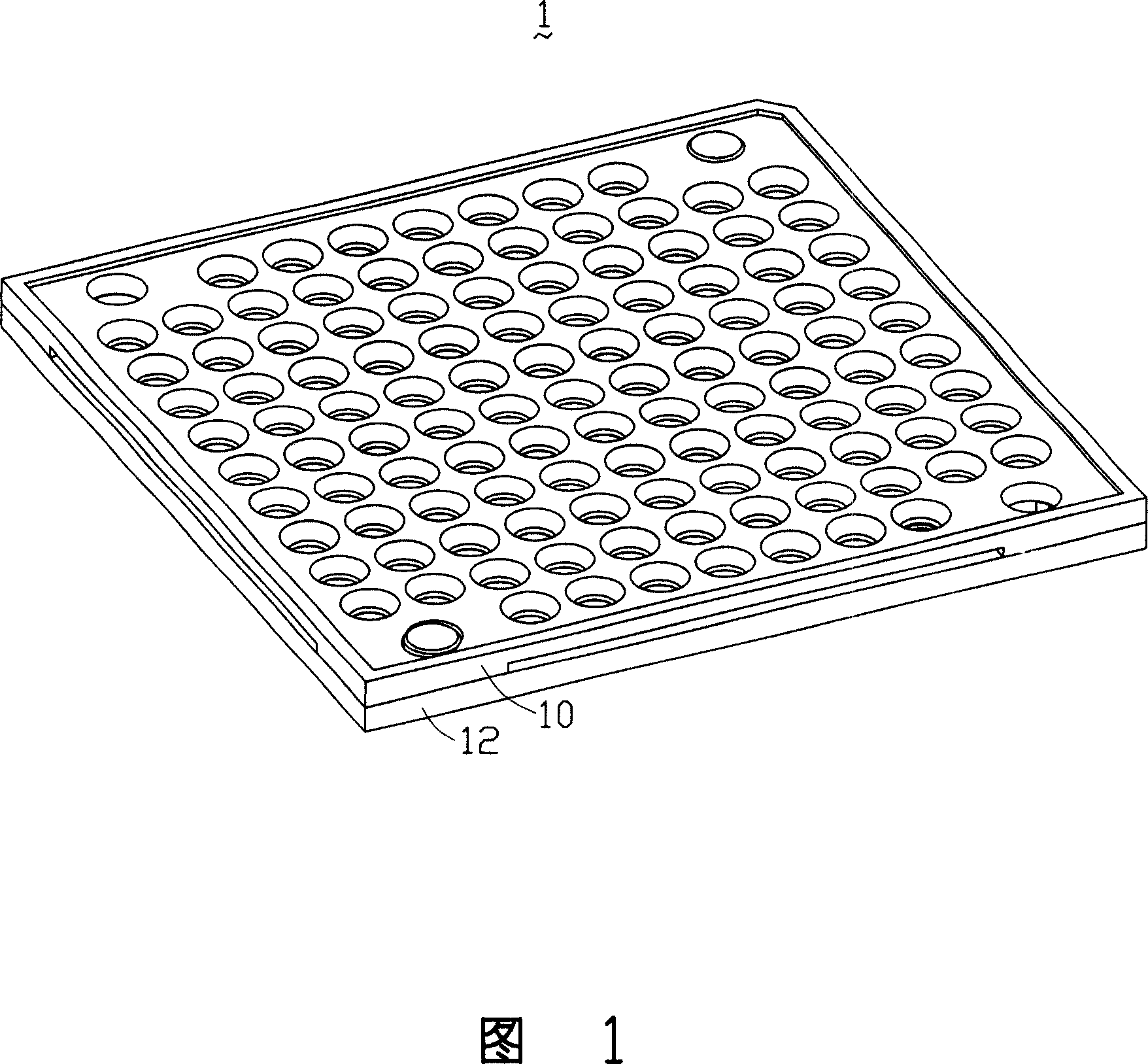

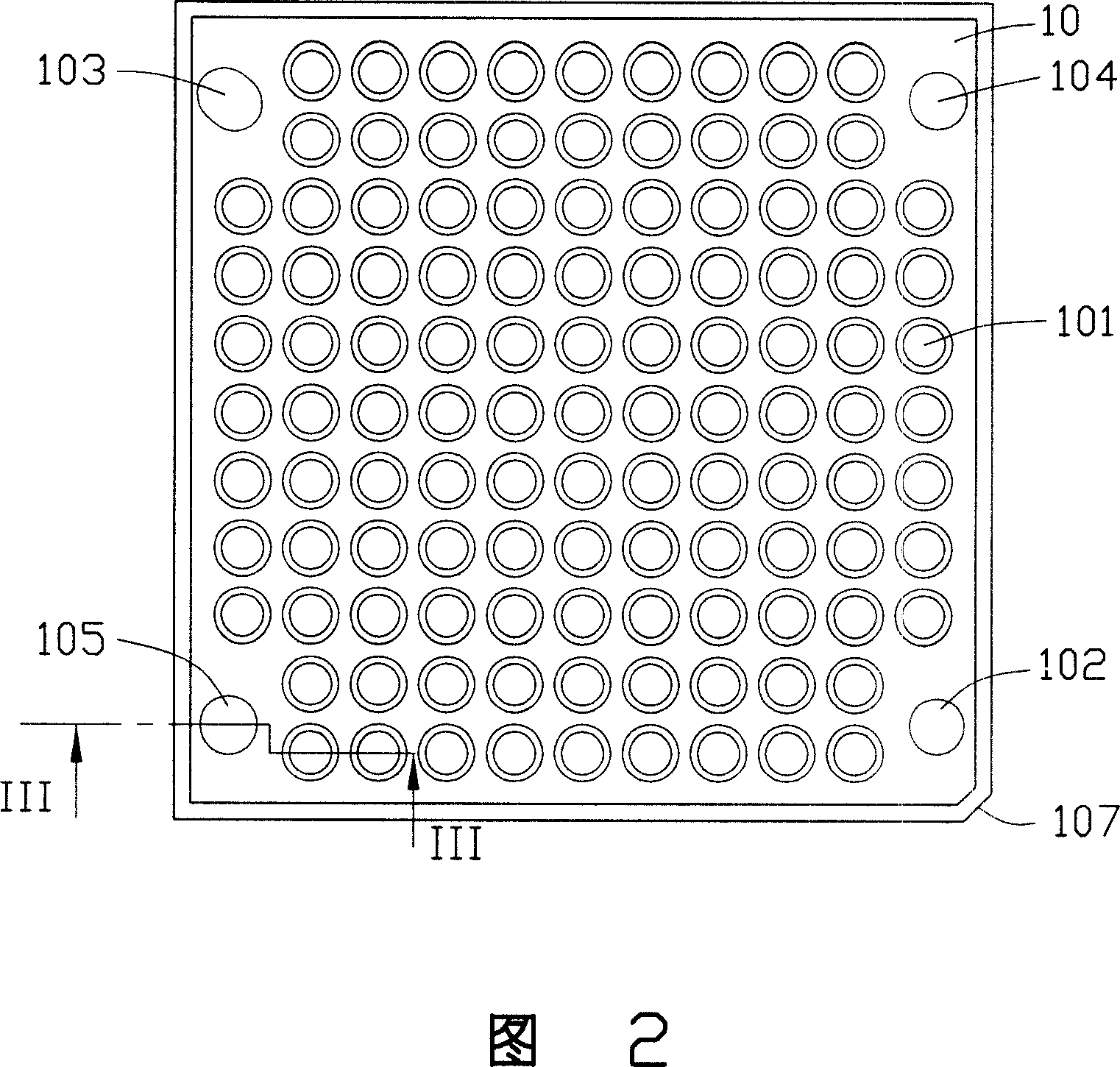

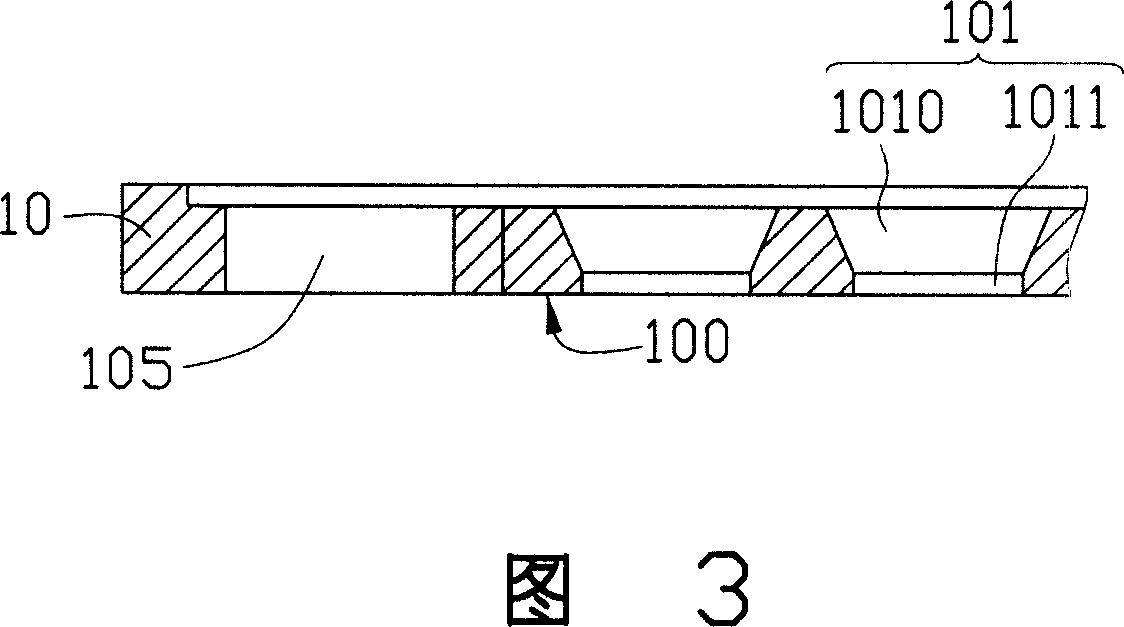

Salver for loading lens

The invention discloses a tray loading lens, including a covered body and ontology. The tray can be used to cut lens, lens coating, lens assembly or more processes. The bulk loading including a lens for the bearing hole formed in the body and covered the body linked to the surface and extends to the medial. Diameter of the carrying hole is greater than the aperture adjacent hole. Using this type of pallet can reduce costs while streamlining cumbersome process, save processing time.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Preparation method of thermal barrier coating and thermal barrier coating prepared through preparation method

InactiveCN108441806AOptimal Control StructureSimplify the tedious process of granulationMolten spray coatingPlasma jetNano structuring

The invention provides a preparation method of a thermal carrier coating and the thermal barrier coating prepared through the preparation method. According to the preparation method, a precursor solution prepared from zircon salt and ytterbium salt is used as a spraying raw material, and in a liquid-phase plasma spraying device, the precursor solution is delivered into plasma jet flow through a two-flow atomization nozzle and then deposits on a matrix to form the thermal barrier coating provided with evenly-distributed pores and vertical crack structures. The thermal barrier coating prepared through the method is a nano-structure thermal barrier coating provided with vertically-cracked columnar crystals and the evenly-distributed pores. According to the preparation method of the thermal carrier coating and the thermal barrier coating prepared through the preparation method, the precursor solution replaces agglomeration powder to serve as the raw material, so that a complex traditionalraw material pelletizing process based atmosphere plasma spraying is greatly simplified, the production efficiency is improved, and the cost is reduced. The structure of the coating is controllable, and the thermal barrier coating prepared through the preparation method is of a nano-structure and is provided with vertical crack structures. A ceramic material YbSZ has high phase stability and low thermal conductivity.

Owner:TIANJIN UNIV

Extraction process of ephedrine

InactiveCN103833559AEfficient extractionSimplify cumbersome processOrganic compound preparationAmino-hyroxy compound preparationBiotechnologyXylylene

The invention relates to an extraction process of ephedrine, and belongs to the technical field of extraction of effective components in traditional Chinese medicines. The process provided by the invention comprises the following steps: pretreatment of ephedra; alkalization; extraction with xylene; extraction; concentration; and the like. By adopting the processes such as alkalization, extraction with xylene and extraction with oxalic acid, tedious processes in the prior art can be simplified, and high purity ephedrine can be quickly and effectively extracted.

Owner:杨超

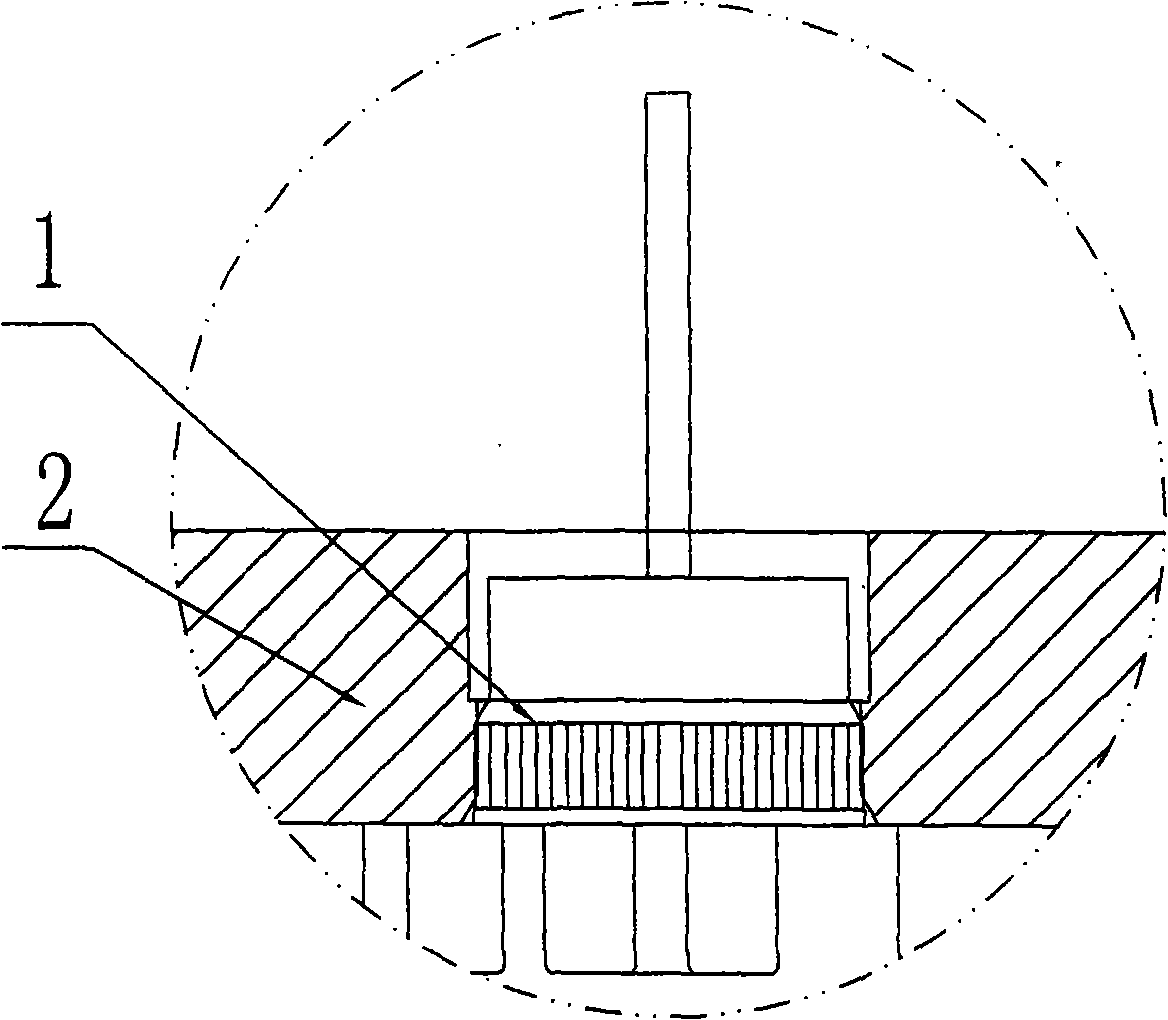

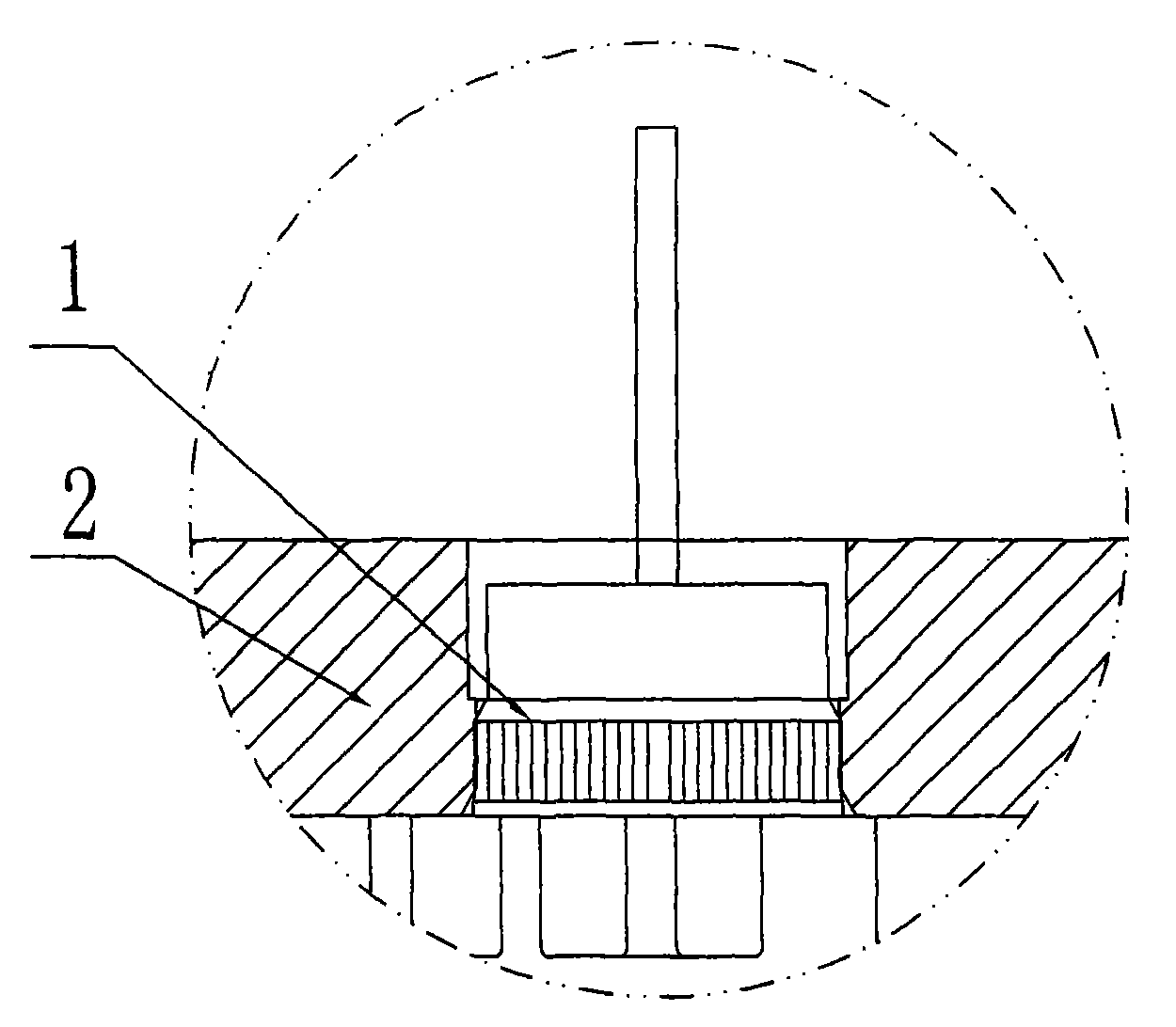

Assembling structure of diode of rectifier and heat-radiating plate for automotive

InactiveCN102064147AGuarantee working reliabilityIncrease contact areaAc-dc conversion without reversalSemiconductor/solid-state device detailsEngineeringCopper

The invention discloses an assembling structure of a diode of a rectifier and a heat-radiating plate for an automotive, comprising the diode and the heat-radiating plate. The assembling structure is characterized in that the heat-radiating plate is provided with a through hole needed by press mounting; the diode adopts a copper base structure with a circumferential surface provided with straight lines; and the diode and the heat-radiating plate are pressed and mounted together in an interference way through the through hole. The invention has the advantages of effectively simplifying the process, reducing the defective index, also enhancing the heat-radiating effect of products and enhancing the reliability of the products.

Owner:阚勇

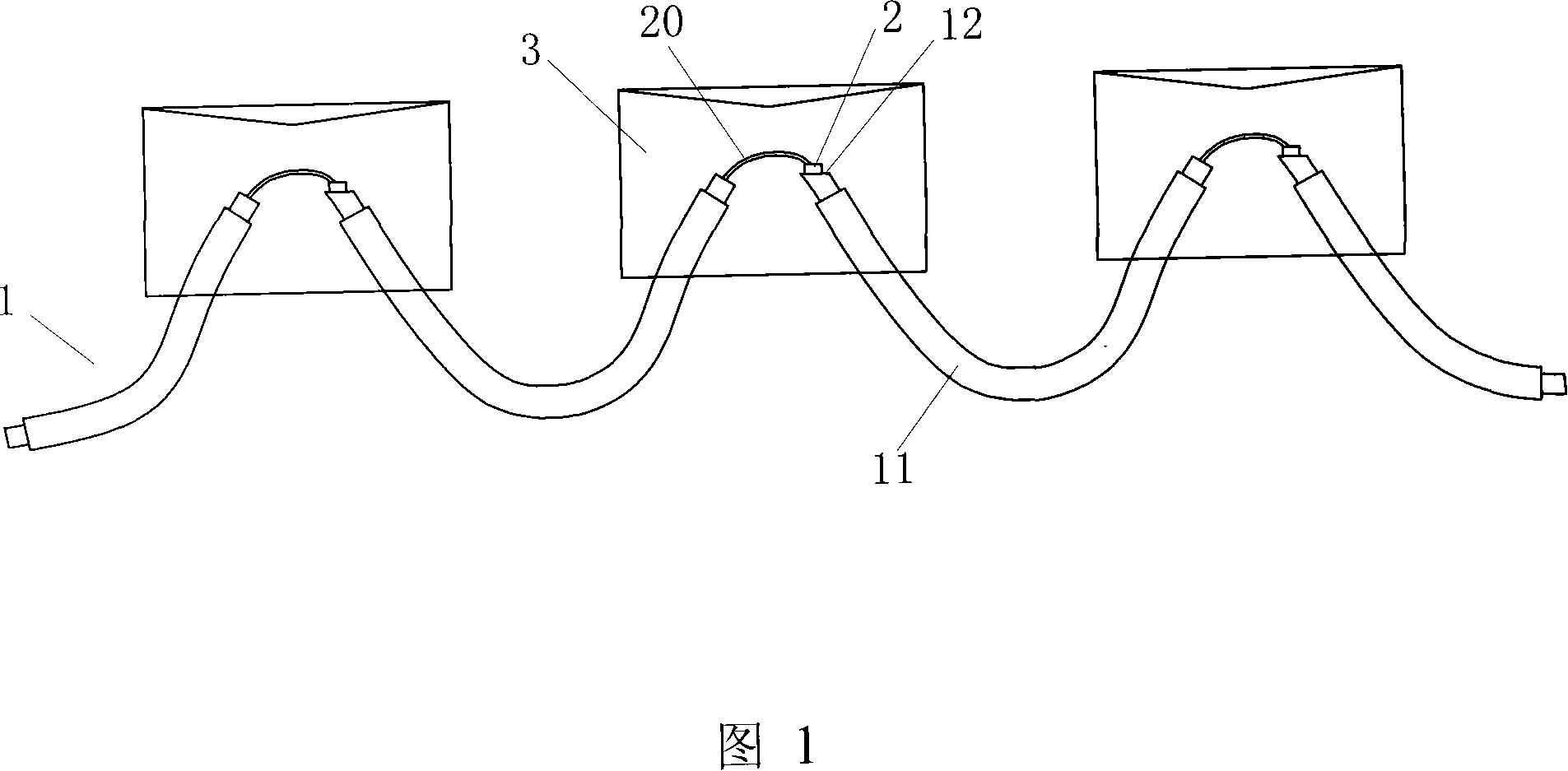

LED lamp string and manufacturing method thereof

InactiveCN101230958ASimple structureLow costPoint-like light sourceElectric circuit arrangementsElectricityEngineering

The invention discloses an LED lamp string and the making method of the lamp string, and the LED lamp string comprises a lead, a luminous wafer and a coating body. The lead is divided into multiple sections of connecting lines which connect in serials, and the luminous wafer is connected among each section of the connecting line. One end of the connecting lines is provided with an installation platform, and the luminous wafer is arranged at the installation platform and is electrically connected with the installation platform. The other pole of the luminous wafer is connected with adjacent connecting lines through a down-lead, and the luminous wafer, the down-lead and the ends of two connecting lines are sealed in the coating body. When the invention is made, the guide line of the lamp string is divided into multiple connecting lines which are connected in serials, and two adjacent connecting lines are both connected to two poles of the luminous wafer; the LED lamp string is formed after glue injection and encapsulation. Adopting the making method can save the cost of specially producing LED and simplify tedious technology of using the existing LED to manufacture the LED lamp string, which causes the LED lamp string to have the advantages of simpler structure, more convenient and quicker manufacture, lower cost, higher efficiency, better lamp string intensity and better waterproof performance.

Owner:HESHAN JIANHAO LIGHTING IND

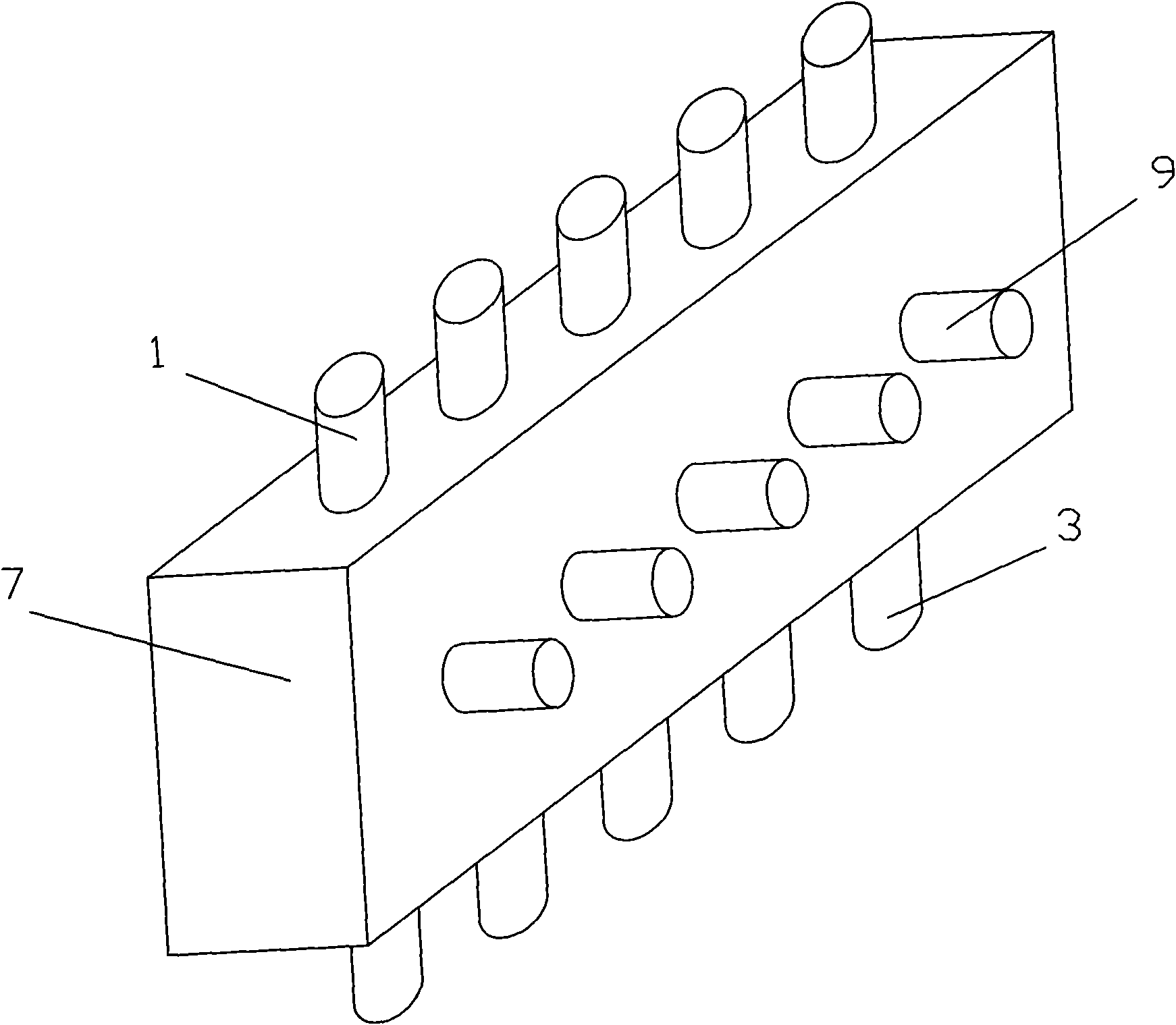

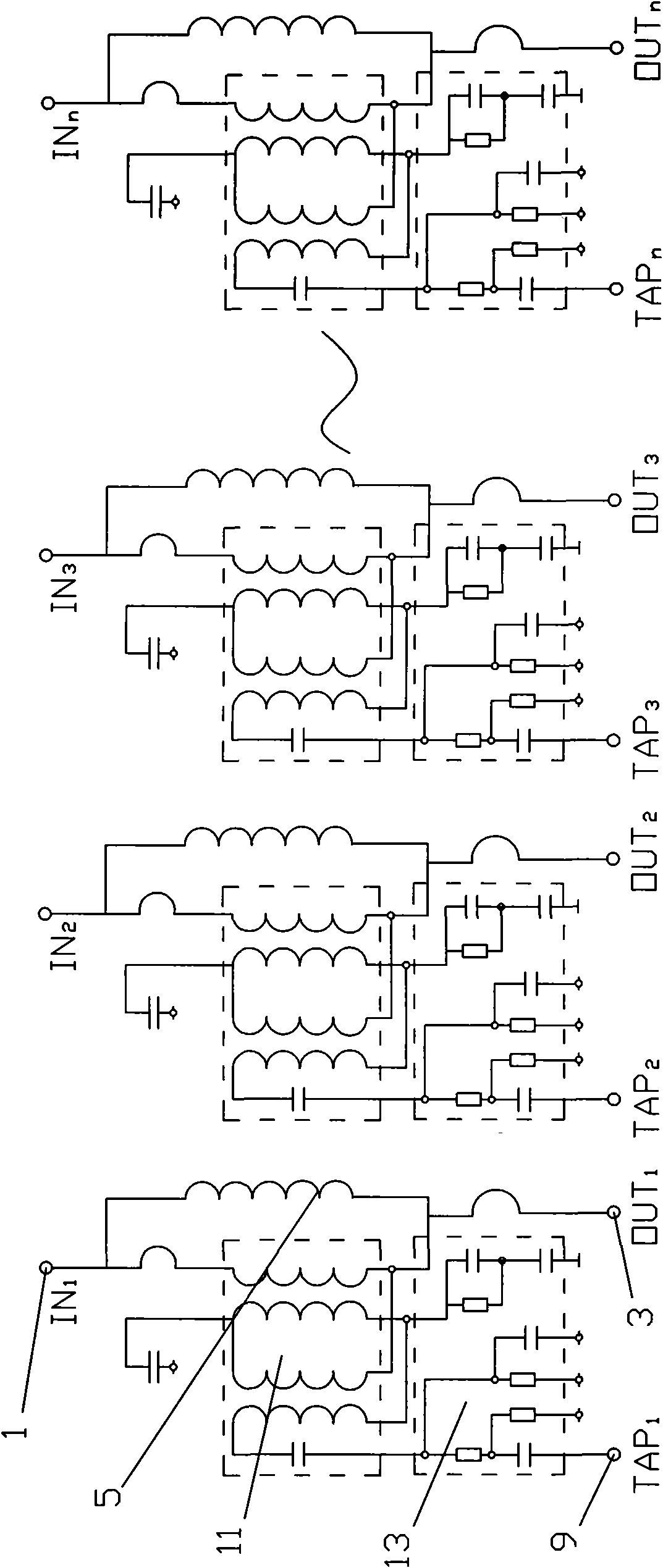

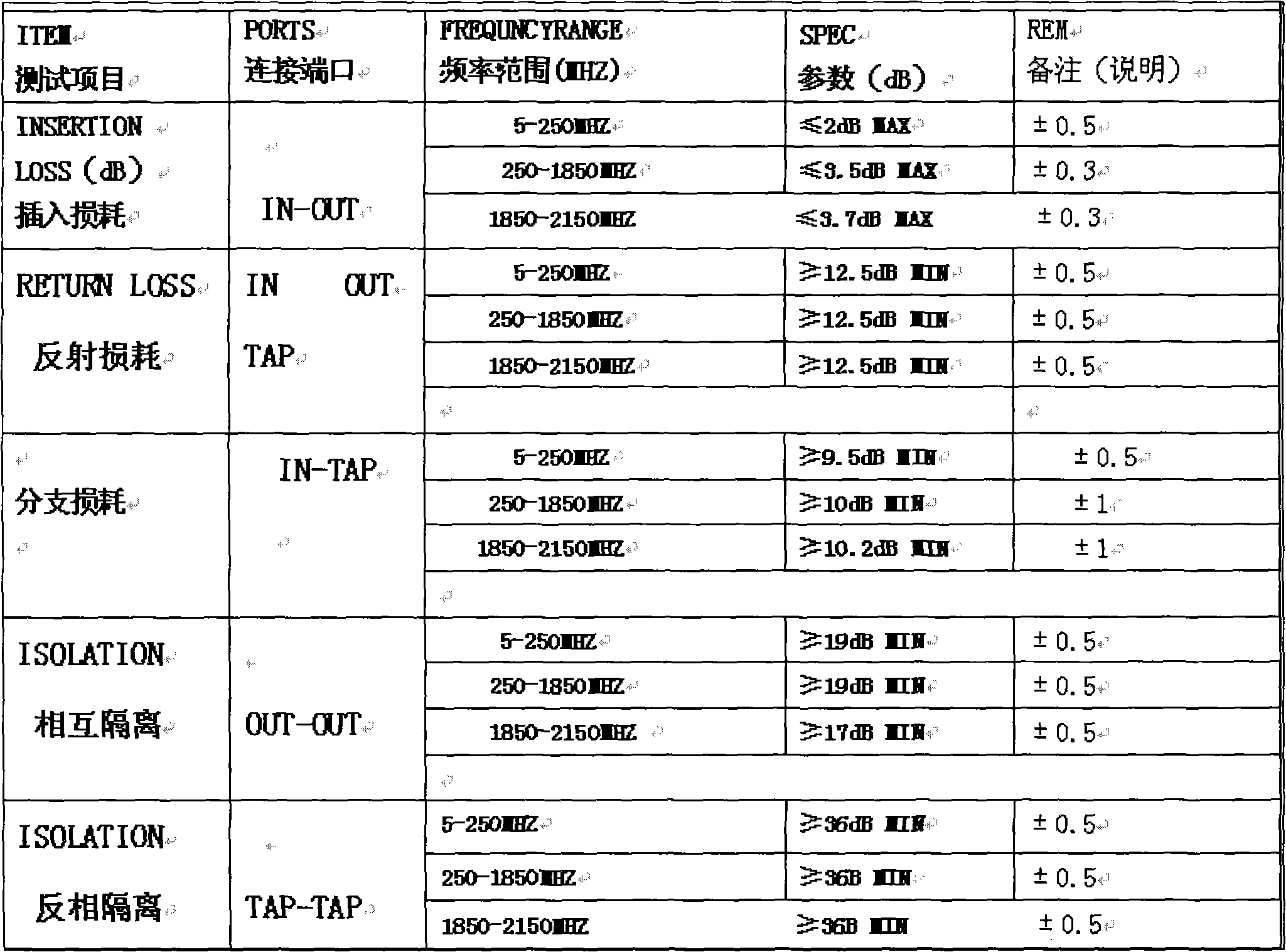

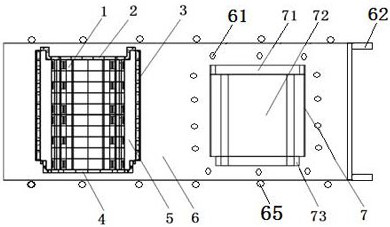

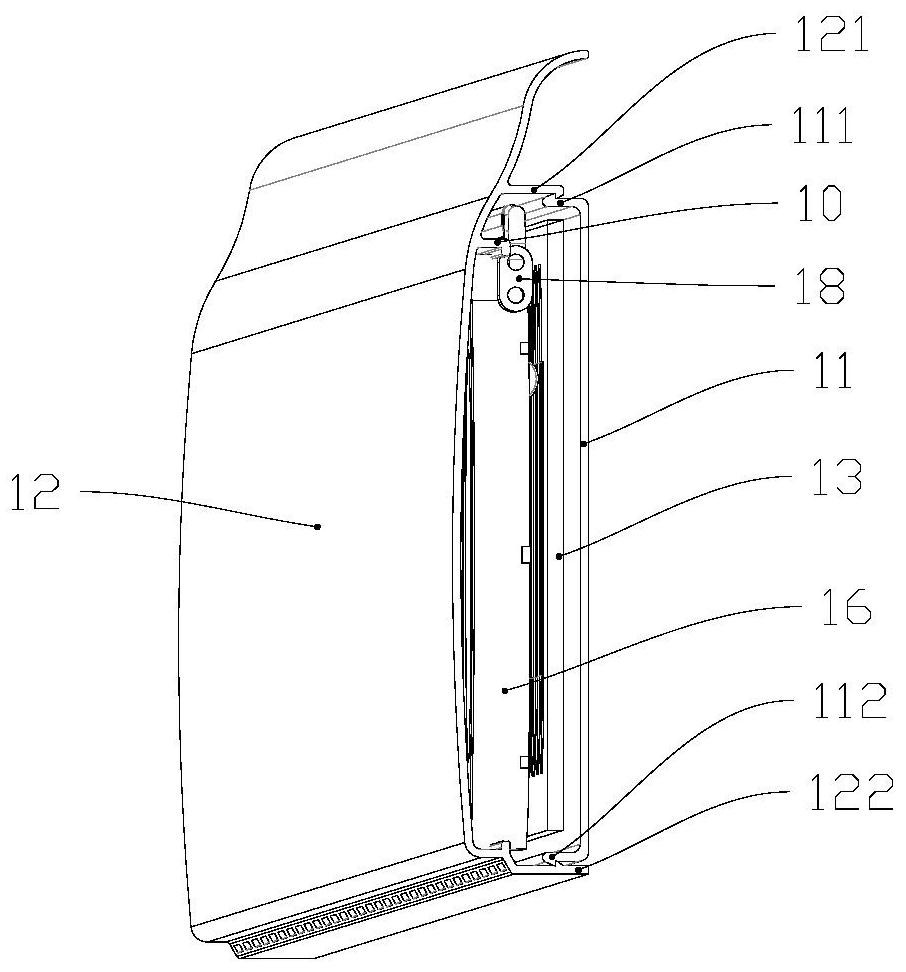

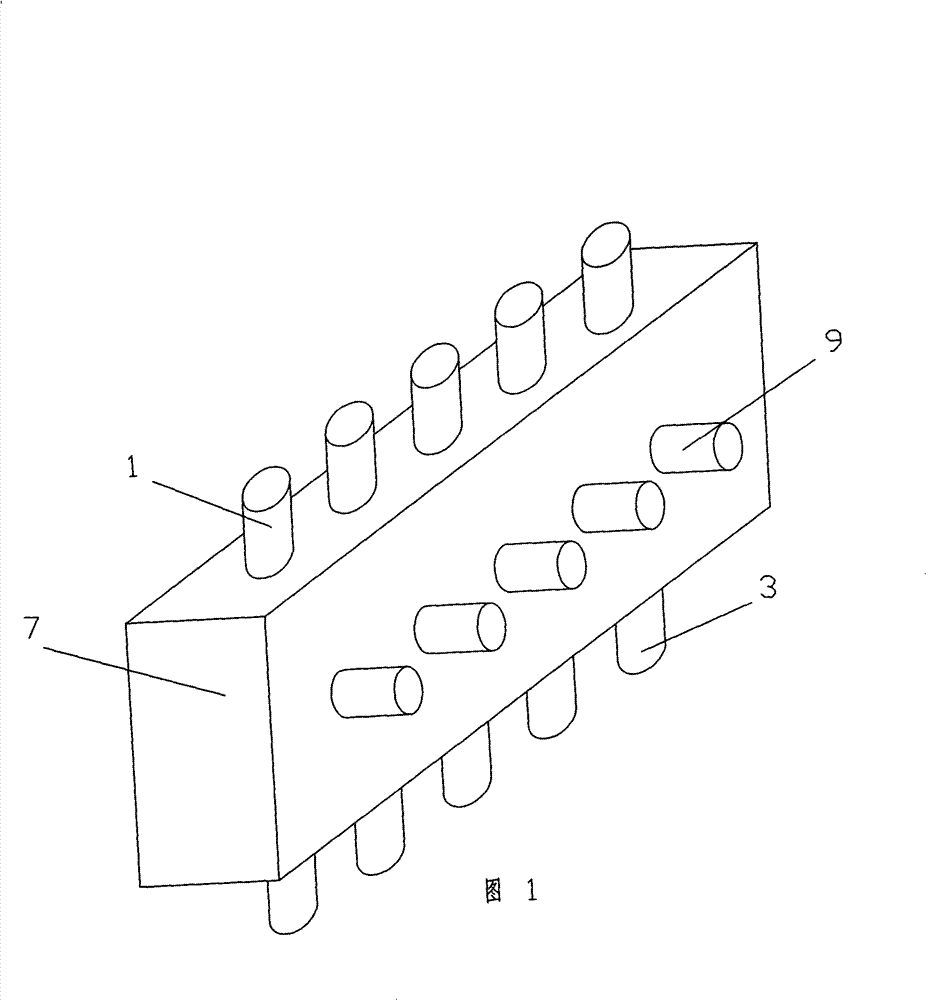

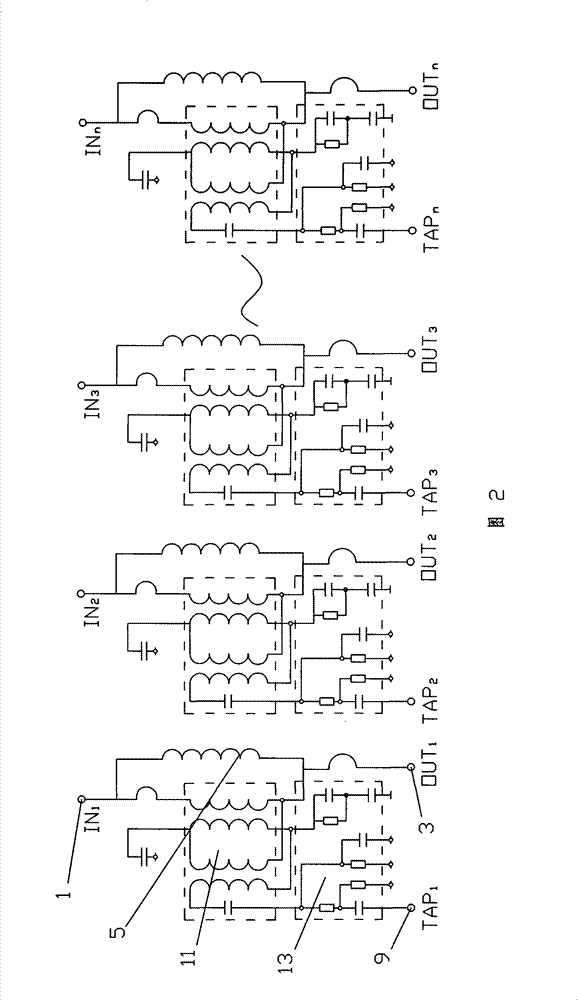

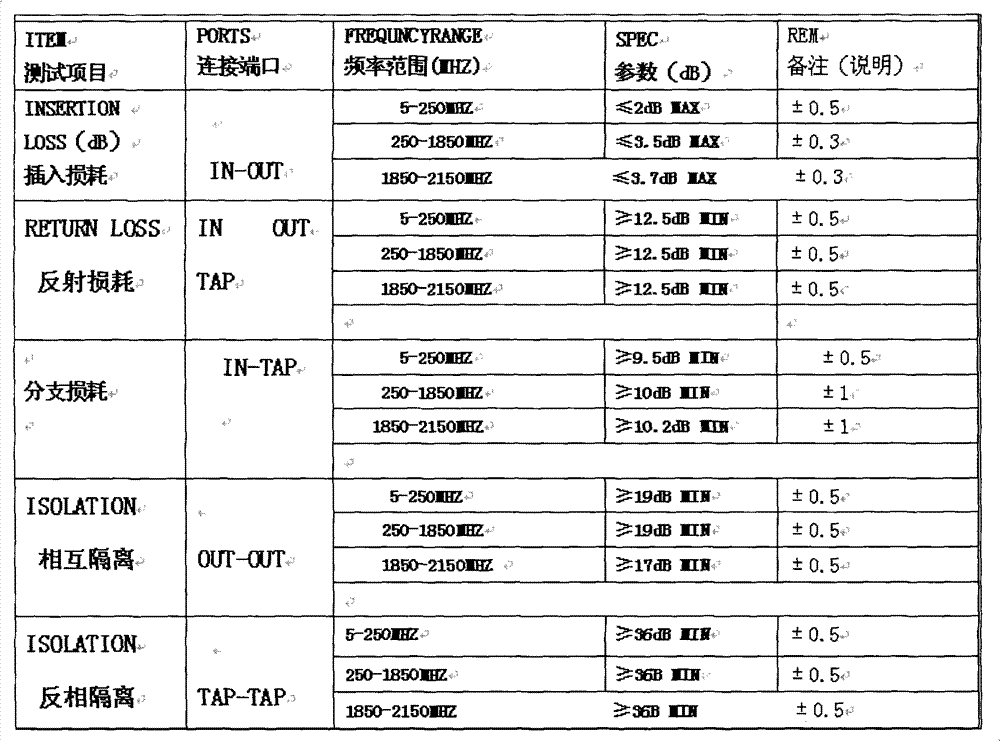

Multiway combined type satellite power divider

InactiveCN101527382AStrict moisture-proof treatmentImprove shielding effectCoupling devicesResistance capacitanceInductor

The invention relates to a multiway combined type satellite power divider comprising at least multiple ways of parallel signal transmission circuits, and each way of signal transmission circuit comprises at least one input end and two output ends; a first inductor and a shell which contains and fixes each part are connected between the input end and the first output end, a coupled circuit is connected between the input end and the second output end, and the coupled circuit is connected with a resistance-capacitance circuit which is connected with the second output end. The invention combines single dividers into an integer, thereby greatly reducing the volume, simplifying a plurality of cumbersome processes, saving the cost and further enhancing the market competitiveness.

Owner:YANGZHOU RUNWELL OPTOELECTRONICS TECH

Al-Mg-Si-Cu-Ti-Sr alloy and method for making same

The invention provides a Al-Mg-Si-Cu-Ti-Sr alloy for preparing car body plate. The alloy consists of Al, Mg, Si, Cu, Mn, Ti, and Sr, and the contents of the components (by weight) are as follows: Mg: 1.0-1.5%, S: 1.0-1.5%, Cu: 0.5-1.0%, Mn: 0.1-0.6%, Ti: 0.1-0.3%, Sr: 0.01-0.1%, Al: the rest. The invention also provides the preparing method, characterized by preparing Al-Si-Ti alloy and other required elements by direct electrolytic method. The alloy plate provided by the invention has improved mechanical property and shaping property.

Owner:ZHENGZHOU UNIV

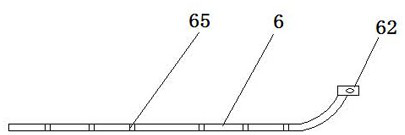

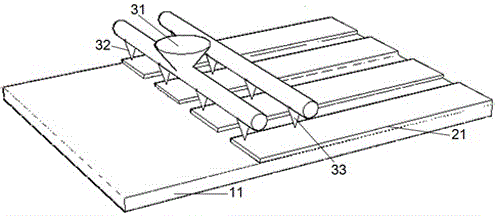

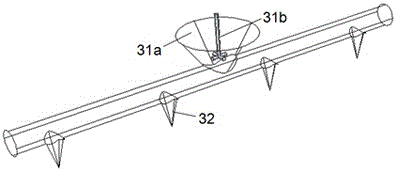

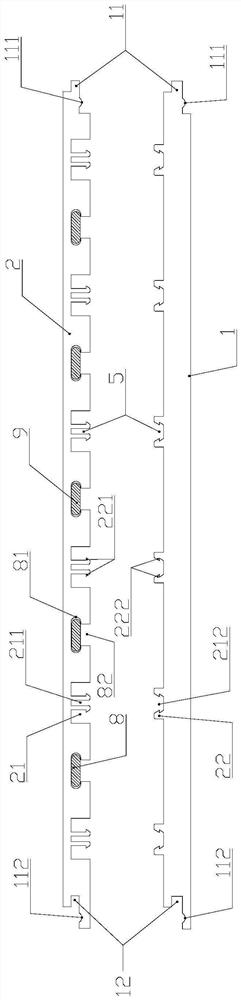

Movable improved fabricated box culvert formwork and construction method thereof

PendingCN114855658AReduce shipping costsSimplify cumbersome processGround-workUnderground chambersArchitectural engineeringPrefabrication

The invention relates to a movable improved assembly type box culvert template and a construction method thereof, the movable improved assembly type box culvert template comprises a threaded pull rod, a bolt and a nut, and the movable improved assembly type box culvert template further comprises a movable base table, an outer template, an inner template, a concave end template and a convex end template, according to the cast box culvert, construction of a transportation road and prefabrication factory construction do not need to be carried out, casting, maintenance and installation of the box culvert can be completed beside a foundation pit where a box culvert line is arranged, and synchronous propelling can be kept along with propelling of a construction line; the transportation cost can be reduced, the tedious process is simplified, and the construction speed is increased.

Owner:NO 1 ENG CO LTD OF FHEC OF CCCC

A kind of nanometer copper powder and preparation method thereof

ActiveCN107790733BSimplify cumbersome processSolve bottlenecksTransportation and packagingMetal-working apparatusArgon atmosphereTube furnace

Owner:SHANGHAI JIAOTONG UNIV

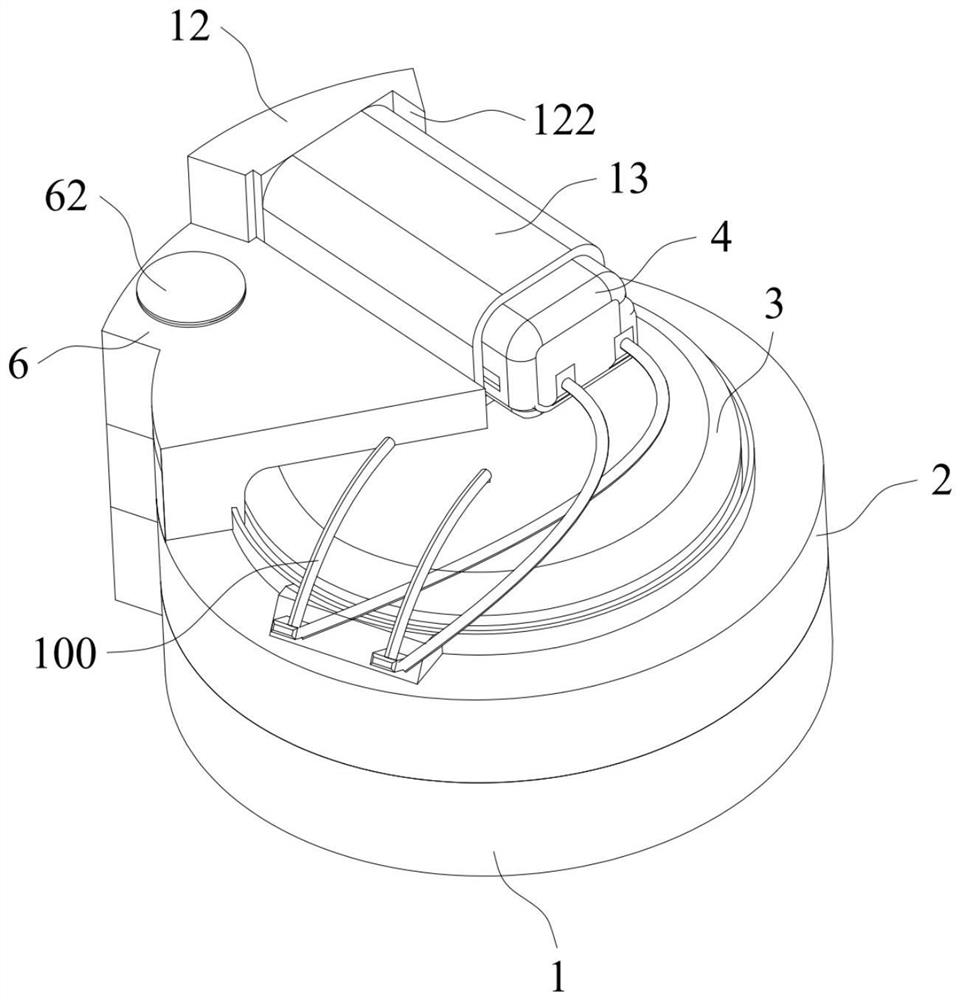

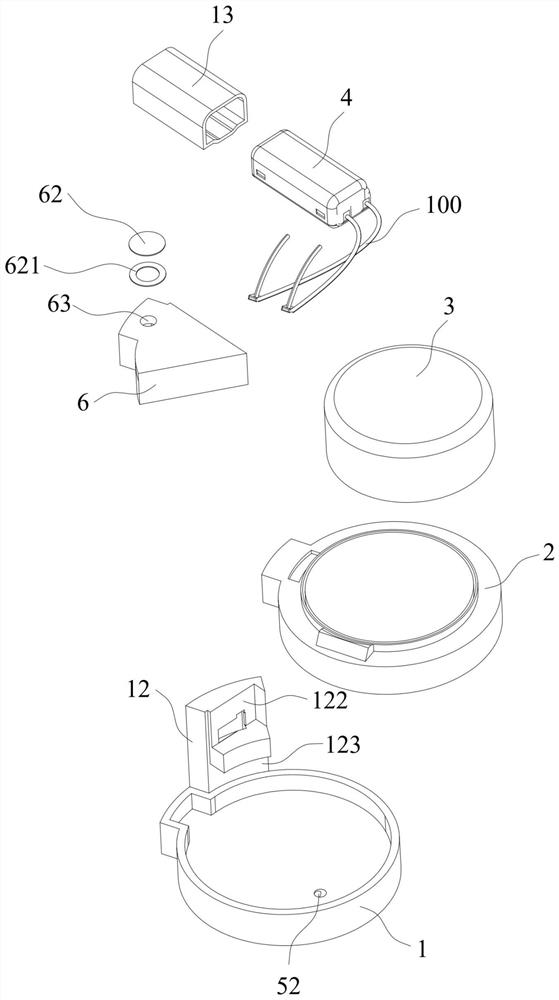

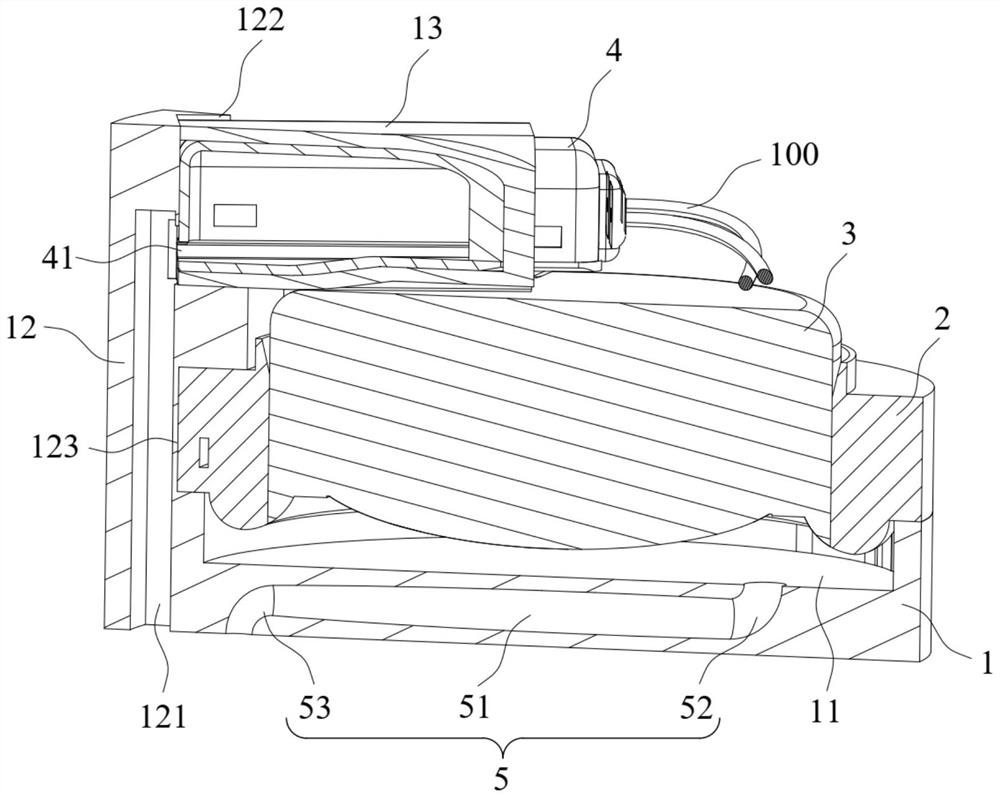

Loudspeaker module

PendingCN114125651AAvoid failureSimplify cumbersome processFrequency/directions obtaining arrangementsTransducer casings/cabinets/supportsLoudspeakerMechanical engineering

The invention relates to the technical field of electronics, in particular to a loudspeaker module which comprises a module shell, a first damping part, a first loudspeaker, a second loudspeaker and a first sound outlet pipeline, and a front cavity is formed in the surface of the module shell; the first damping piece is arranged on the end face, facing the front cavity, of the module shell. The first loudspeaker is arranged on the first damping piece, and the first loudspeaker corresponds to the interior of the front cavity; the second loudspeaker is arranged on the module shell, and a sound outlet of the second loudspeaker is communicated with the outer surface of the module shell; the first sound outlet pipeline is arranged in the module shell, one end of the first sound outlet pipeline communicates with the front cavity, and the other end of the first sound outlet pipeline communicates with the surface, away from the front cavity, of the module shell. According to the loudspeaker module, the front cavity, the first loudspeaker, the second loudspeaker, the first damping part and the first sound outlet pipeline are integrated on the module shell, the damping effect is achieved, the process of assembling loudspeaker parts in electronic equipment is simplified, the product yield and the machining efficiency are improved, and the production cost is reduced.

Owner:LUXSHARE ELECTRONICS TECH (KUNSHAN) LTD

Preparation method of thermal barrier coating and thermal barrier coating prepared by preparation method

ActiveCN102851631BShort manufacturing processOptimal Control StructureMolten spray coatingLiquid/solution decomposition chemical coatingPlasma jetProduction rate

The invention discloses a preparation method of a thermal barrier coating and the thermal barrier coating prepared by the preparation method. According to the method, a solution precursor composed of zirconates and yttrium salts is used as a spraying raw material. The solution precursor is atomized into liquid drops through a two-phase flow atomizing nozzle; and the liquid drops are sent for plasma jet, undergo plasma jet heating and acceleration and are deposited on a matrix to form the thermal barrier coating. The thermal barrier coating is nanostructured and has a vertical crack structure. The solution precursor liquid material replaces an agglomerated powder to be used as a spraying raw material, thus greatly simplifying tedious processes of traditional air plasma spraying for coating preparation. There are few technological processes for coating preparation in the invention, thus raising productivity and reducing cost. in addition, the coating structure is controllable and technical production can be realized. By the adoption of the prepared coating, defects of a coating prepared by traditional plasma spraying are eliminated, and a high-performance coating which satisfies special requirements can be prepared.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

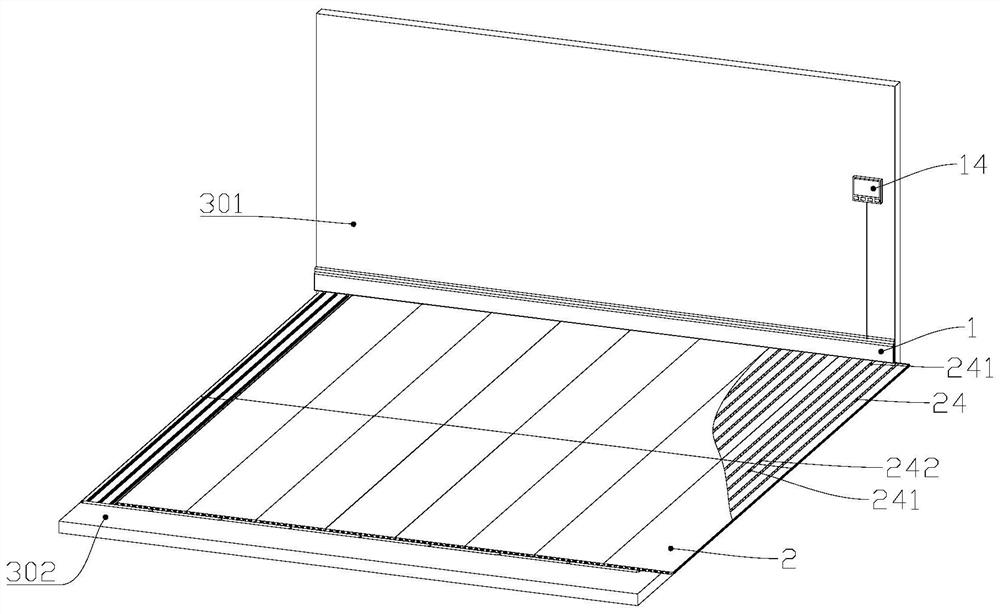

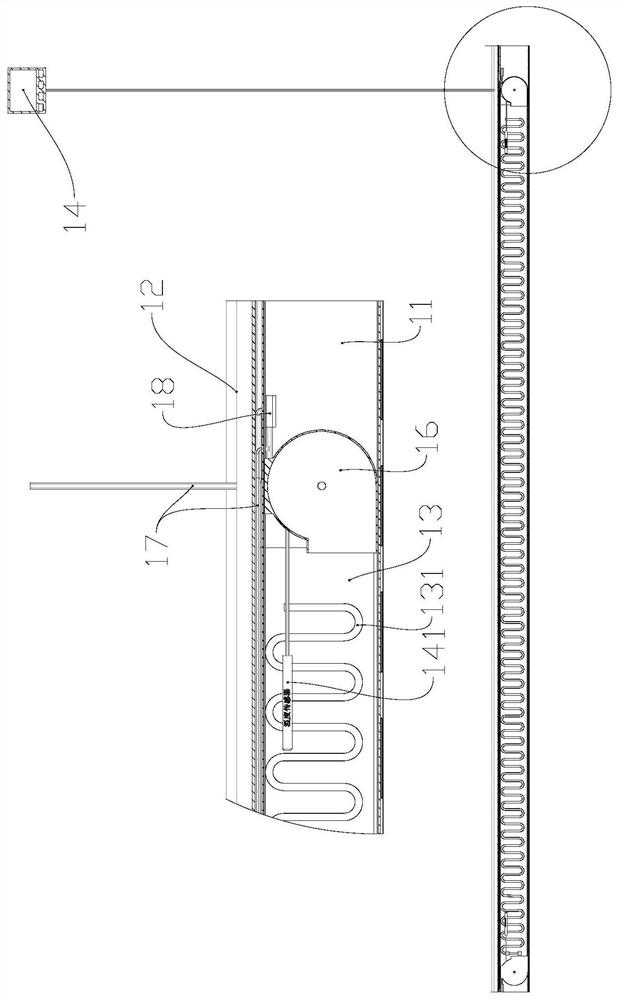

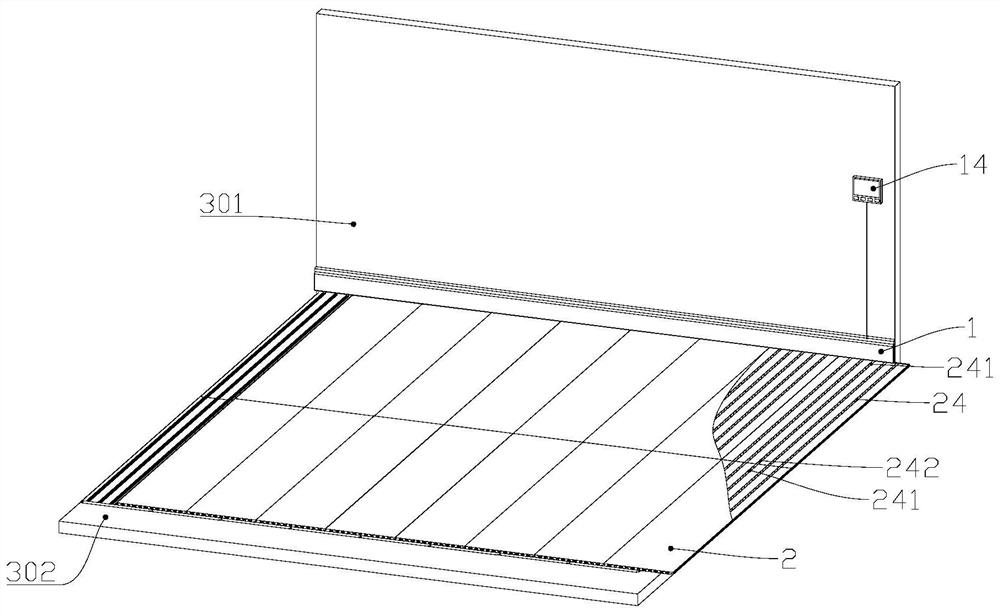

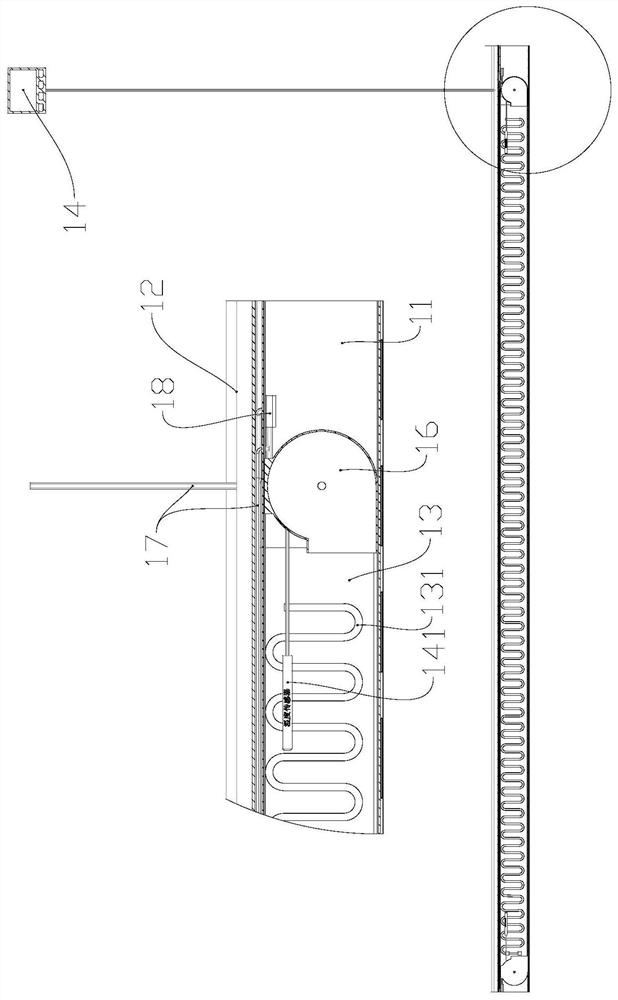

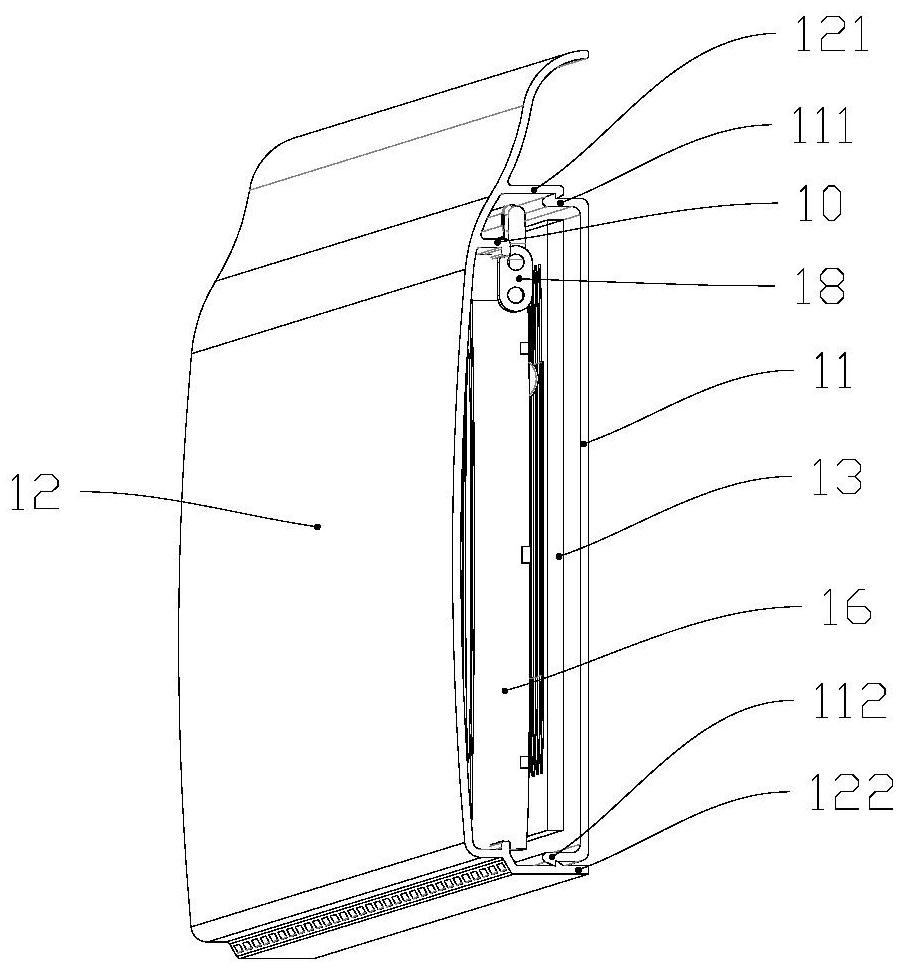

An indoor heating system

ActiveCN112212388BImprove heating effectDistribute quicklyLighting and heating apparatusElectric heating systemBaseboardUnderfloor heating

The invention relates to an indoor heating system, comprising an electric heating skirting board installed on the wall, a heat-conducting profile floor for laying the ground, an electric heating skirting board, a bottom board close to the wall, and a cover board covering the bottom board , heat-conducting profile floor, including the base plate for laying the ground, the panel covering the base plate, and the blower is set in the channel through the base plate and the cover plate, and the blower can move the hot air formed by heating the air with the electric heating element in the channel along the length direction of the channel , from the air port at the bottom of the skirting board to accelerate the discharge, so that the heat in the channel can be quickly circulated to the floor. The heat pipe in the floor is used as a passive heat transfer element. The heat pipe has high thermal conductivity and temperature uniformity, and can quickly turn the electric heating The heat of the baseboard baseboard is transmitted step by step to the next floor, so that it can be quickly transmitted to every part of the room, which accelerates the heating effect of the indoor environment, overcomes the disadvantages of the traditional floor heating method that heats up very slowly, and saves a lot energy consumption.

Owner:王旭

Multiway combined type satellite power divider

InactiveCN101527382BStrict moisture-proof treatmentImprove shielding effectCoupling devicesResistance capacitanceInductor

The invention relates to a multiway combined type satellite power divider comprising at least multiple ways of parallel signal transmission circuits, and each way of signal transmission circuit comprises at least one input end and two output ends; a first inductor and a shell which contains and fixes each part are connected between the input end and the first output end, a coupled circuit is connected between the input end and the second output end, and the coupled circuit is connected with a resistance-capacitance circuit which is connected with the second output end. The invention combines single dividers into an integer, thereby greatly reducing the volume, simplifying a plurality of cumbersome processes, saving the cost and further enhancing the market competitiveness.

Owner:YANGZHOU RUNWELL OPTOELECTRONICS TECH

Preparation method of few-layer hexagonal boron nitride

InactiveCN107416780ASimplify cumbersome processImprove production efficiencyNitrogen compoundsHexagonal boron nitrideBoron nitride

The invention provides a preparation method of few-layer hexagonal boron nitride, belongs to the technical field of nano-materials, and solves the technical problems that an existing process for preparing the few-layer hexagonal boron nitride is complicated, low in productivity and the like. The preparation method includes the steps: placing a high-temperature stainless steel container with boron nitride powder into a muffle furnace at normal temperature; beginning to heat the boron nitride powder, performing high-temperature baking on the boron nitride powder, and keeping the temperature for 5min-300min; taking out the container after temperature keeping, rapidly adding normal-temperature cooling solvents into the stainless steel container with the boron nitride powder, and performing quenching on the boron nitride to reach normal temperature; performing centrifuging on mixture after cooling, and taking liquid supernatant to obtain a few-layer hexagonal boron nitride sample. The preparation method has the advantages that the method is high in efficiency and productivity, green, environmentally friendly and the like.

Owner:HUBEI UNIV OF SCI & TECH

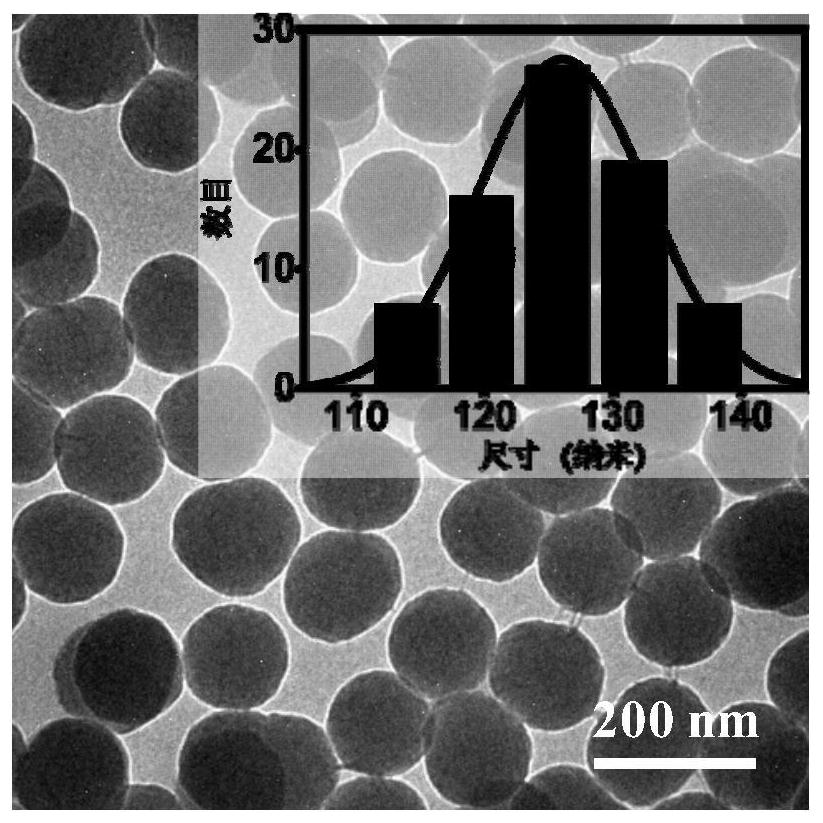

A preparation method of highly stable carbon dots-silica composite particles

InactiveCN109679646BGood chemical stabilityUniform sizeFluorescence/phosphorescenceLuminescent compositionsFluoProbesPtru catalyst

A method for preparing highly stable carbon dot-silicon dioxide composite particles of the present invention belongs to the technical field of carbon materials and fluorescent composite nanomaterials. Firstly, quaternary ammonium base is used as catalyst and doped carbon source, and TEOS is used as silicon source to synthesize spherical silica nanoparticles doped with quaternary ammonium base; Fluorescent carbon dots are formed by in-situ dehydration condensation in the silicon oxide matrix, and carbon dot-silica fluorescent composite nanoparticles are obtained. The preparation process of the invention is simple, and the prepared composite particles have the advantages of uniform size, photobleaching resistance, high chemical stability, good biocompatibility and easy surface modification, etc., and can be used as a universal fluorescent reference material and other fluorescent materials Composite construction of dual-emission ratiometric fluorescent probes.

Owner:JILIN UNIV

Special film product-based external Logo treating process

InactiveCN103341947AAchieve seamless integrationAvoid affecting the Logo effectCoatingsEngineeringProduct base

The invention discloses a special film product-based external Logo treating process which comprises the following steps of: 1, processing a Logo paster; 2, locating the Logo paster on a special film by using a special fixture, then locating the film in a mould cavity of an injection mould; 3, injecting high-temperature plastic fluid in the mould cavity; and 4, carrying out mould stripping after forming, and cooling to obtain a finished product. According to the special film product-based external Logo treating process, the complicated process of plating and then deplating is simplified, the realization of a Logo effect is prevented from being influenced by specialty of appearance effect of the special film, a Logo is seamlessly fused with a main body structure, the effect of simultaneously showing the external Logo and the special film on the same product is realized, and the appearance effect richness is improved.

Owner:ZHEJIANG TRILLION GAME TECH

Indoor heating system

ActiveCN112212388AImprove heating effectDistribute quicklyLighting and heating apparatusElectric heating systemBaseboardUnderfloor heating

The invention relates to an indoor heating system. The indoor heating system comprises an electric heating type skirting board installed on a wall surface and a heat conduction profile floor laid on the ground, wherein the electric heating type skirting board comprises a bottom plate tightly attached to the wall surface and a cover plate covering the bottom plate, and the heat conduction profile floor comprises a base plate laid on the ground and a face plate covering the base plate; an air blower is arranged in a channel arranged between the bottom plate and the cover plate, the air blower can enable hot air formed after air is heated by an electric heating element in the channel to move in the length direction of the channel, and the hot air is exhausted from the air ports located in thebottom end of the skirting board in an accelerated mode, so that heat in the channel is rapidly and circularly dissipated to the floor; and heat pipes in the floor serve as passive heat transfer elements, the heat pipes have efficient heat conductivity and temperature uniformity, heat of the electric heating type skirting board can be rapidly conducted to the next floor step by step, so that theheat is rapidly transmitted to each place of a room, the heating effect of the indoor environment is accelerated, the defect that a traditional floor heating mode is very slow in temperature rise is overcome, and energy consumption is greatly reduced.

Owner:王旭

A method for preparing transparent conductive electrodes based on 3D printing technology

ActiveCN104409171BSimplify cumbersome processImprove the quality rateCable/conductor manufactureOrganic solventModeling software

The invention relates to a method for preparing a transparent conducting electrode based on a 3D (three-dimensional) printing technique. The method is characterized by comprising the following steps of 1) providing a 3D printing device which comprises a collosol generation cavity, 3D printing heads and laser printing heads, 2) performing modeling: designing a model of the transparent conducting electrode by using computer modeling software and converting a software instruction of the model into a mechanical instruction of 3D printing, 3) preparing collosol: sequentially adding an inorganic metallic compound or organic metallic compound A and an organic solvent B to the collosol generation cavity to generate the collosol used for preparing the transparent conducting electrode, and 4) printing the transparent conducting electrode by using the 3D printing device, wherein the collosol generation cavity comprises a collosol generation cavity body and a stirring rod. The method effectively simplifies the complicated process of preparing the transparent conducting electrode in the prior art, increases the yield and the accuracy of the transparent conducting electrode, and lowers the preparation cost.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

Biaxial hinge device for swinging connection

InactiveCN112681916ASimplify cumbersome processEasy installation, disassembly and maintenanceWing fastenersPin hingesChain linkChain drive

Owner:HANGZHOU MEISHIMEIKE IOT TECH CO

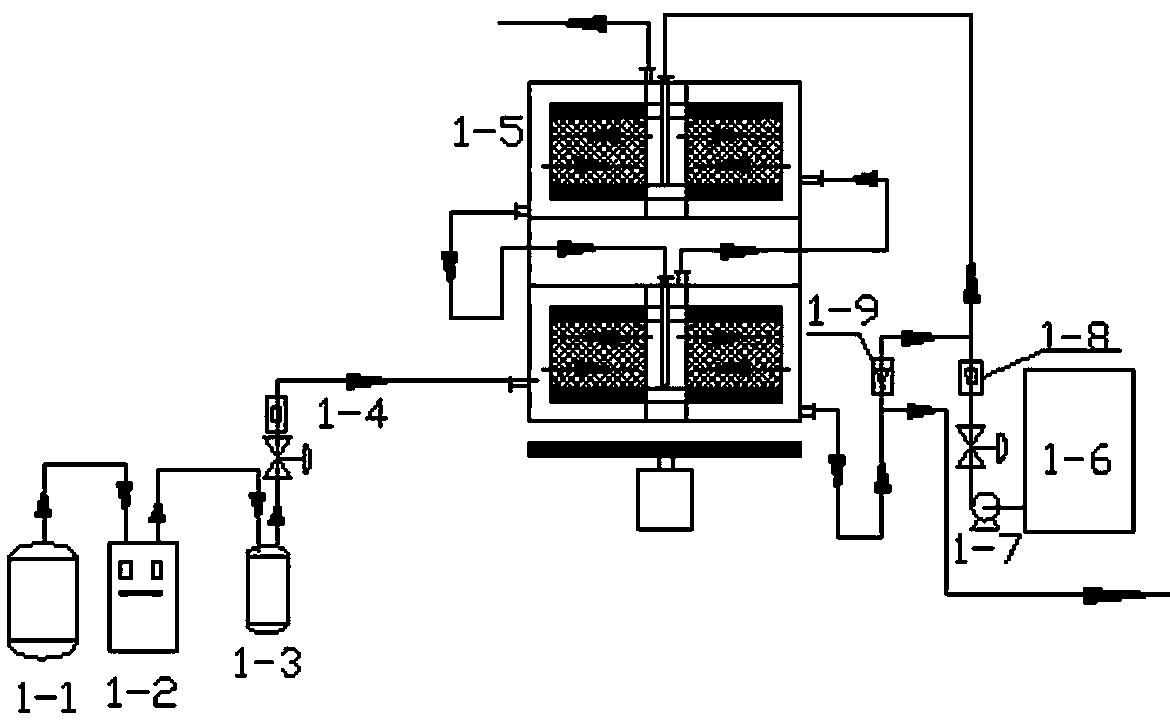

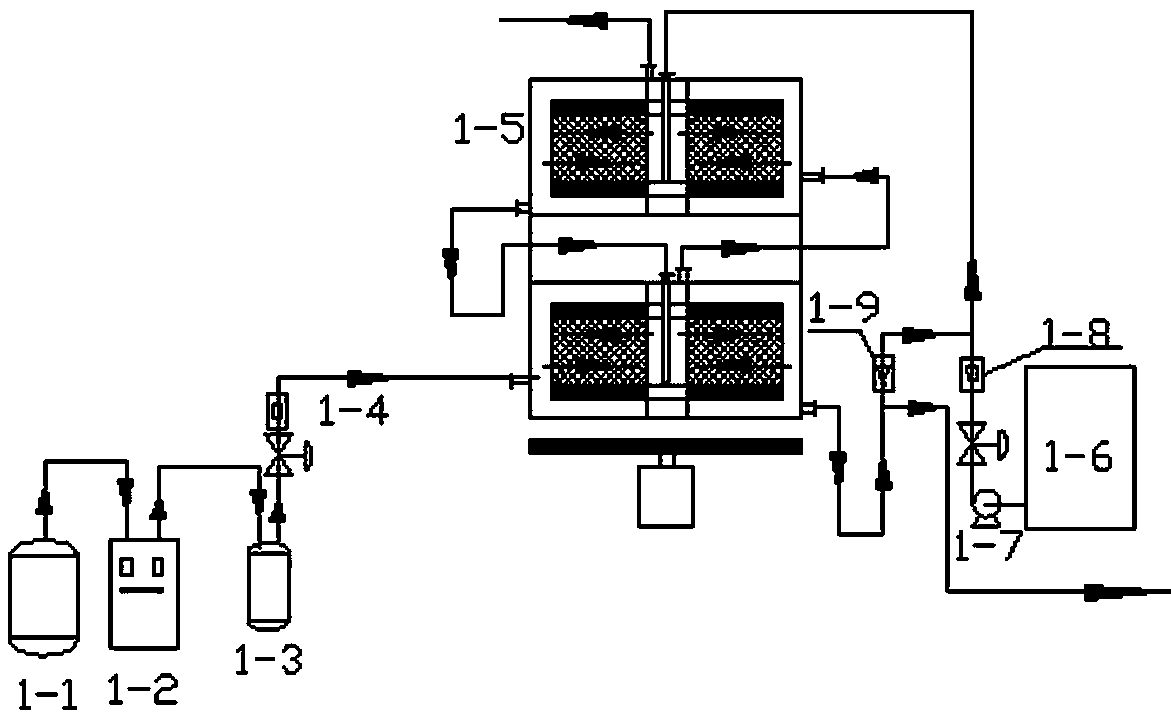

Method for deep oxidation treatment of industrial wastewater by ozone

InactiveCN109835976AIncrease profitImprove reaction efficiencyWater contaminantsWater/sewage treatment by oxidationOzone generatorIndustrial waste water

A method for deep oxidation treatment of industrial wastewater by ozone is disclosed, the industrial wastewater from a wastewater tank is subjected to flow rate regulation by a liquid flowmeter and then enters a second-order micro-mixing reactor through a water inlet of the second-order micro-mixing reactor; a catalyst is continuously added into the second-order micro-mixing reactor from a catalyst adding port, and a reflux flow meter is adjusted to achieve full reflux; an ozone generator is started, ozone formed by an ozone generator from oxygen in an oxygen gas storage tank enters the gas inlet of the second-order micro-mixing reactor through a buffer tank and a gas flowmeter, and the ozone in the second-order micro-mixing reactor is fully contacted and reacted with the industrial wastewater; every 10 minutes, the ozone content of a tail gas outlet and the COD value of the water in a wastewater outlet are respectively taken, when the water quality requirement is met, the reflux flowmeter is closed, and the treated wastewater meeting the requirements is collected; the treated wastewater flows out of the water outlet of the second-order micro-mixing reactor, and part of the wastewater and the original wastewater flow back into the second-order micro-mixing reactor, and part of the wastewater is discharged up to the standard; the tail gas after fully reacting is discharged fromthe gas outlet of the second-order micro-mixing reactor to the standard.

Owner:HENAN CHEM IND RES INST

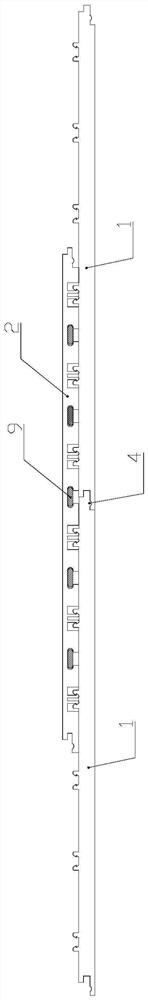

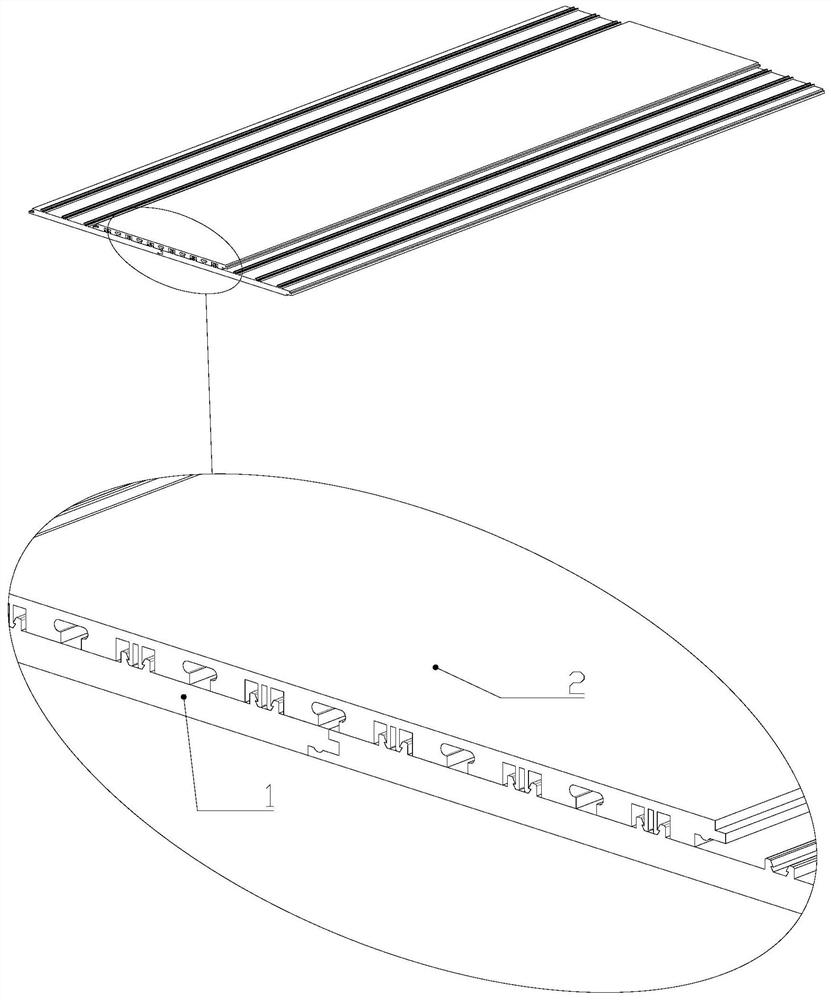

Heat-conducting profile floor

InactiveCN112211367AEfficient thermal conductivityEfficient temperature uniformityCovering/liningsIndirect heat exchangersBaseboardUnderfloor heating

The invention relates to a heat-conducting profile floor. The floor comprises a bottom plate laid on the ground and a panel matching the bottom plate and covering the bottom plate, combination parts connected to the adjacent bottom plate or panel are arranged at the two ends of the bottom plate or panel, the bottom plate and the panel are connected in an inserted mode through a plurality of pairsof mortises and tenons, a plurality of parallel heat conduction pipe grooves are formed in the panel in a length direction, heat pipes are placed in the heat conduction pipe grooves, the evaporation ends of the heat pipes are heated by a skirting line plate heating device arranged on the wall surface, and the condensation ends of the heat pipes are in butt joint with the evaporation ends of the heat pipes of the adjacent panel. The heat pipes are adopted as passive heat transfer elements, the heat pipes have efficient heat conductivity and temperature uniformity, heat emitted by the skirting line plate heating device can be rapidly transferred to each place of a room, a temperature rise speed is high, the heat transfer efficiency is high, the defect that a traditional floor heating mode isvery slow in temperature rise is overcome, and energy consumption is greatly reduced.

Owner:王旭

A high temperature enamel for high chromium white cast iron

The invention discloses high-temperature enamel for high-chromium white cast iron. The high-temperature enamel is characterized by being prepared from the following ingredients in percentage by weight: 15 to 35 percent of Al2O3, 11.5 to 45 percent of SiO2, 3 to 16 percent of ZrO2, 1 to 4 percent of CoO, 2.5 to 13.5 percent of TiO2, 1.5 to 7.9 percent of Cr2O3, 0.5 to 12 percent of Fe2O3, 3 to 6 percent of CaO, 1 to 15 percent of Li2O, 3 to 8 percent of K2O, 2.5 to 9.3 percent of MgO and 3 to 18 percent of P2O5. The high-temperature enamel can be directly coated onto the surface of the high-chromium white cast iron; through firing at 1250 to 1300 DEG C and natural cooling, the hard and bright enamel surface is formed on the surface of the high-chromium white cast iron; excellent high-temperature anti-corrosion anti-oxidation performance is realized; rapid cooling and quick heating are performed in a Stokerfeed boiler with temperature being 1050 to 1200 DEG C; then, the enamel and the high-chromium white cast iron are firmly bonded; no peeling and oxidation phenomena exist; the high-temperature enamel can be widely applied in various severe high-temperature environments or sulphur-containing high-temperature environments, and can also be used in high-temperature wear-resistant environments.

Owner:赵庭玉

A kind of preparation method of lotus root juice beverage

ActiveCN108432987BImproves antioxidant activityReduce generationNatural extract food ingredientsBiotechnologyOxidative enzyme

The invention provides a method for preparing a lotus root juice beverage, which belongs to the technical field of fruit and vegetable juice beverage processing. The invention uses the whole lotus root as a raw material, and prepares the lotus root juice beverage through the steps of cleaning, cutting, color protection, beating, vacuum microwave heating, two-stage ultrasonic-assisted compound enzymolysis, centrifugation and filtration. The invention simplifies the cumbersome process of peeling and removing knots in the processing of lotus root juice, reduces the generation of processing waste, and increases the polyphenol content in the lotus root juice; vacuum microwave heating is carried out on the lotus root pulp to rapidly passivate the oxidation of polyphenols Enzyme activity, reducing the loss of polyphenols oxidation; ultrasonic-assisted composite enzymatic hydrolysis technology promotes the dissolution of polyphenols, and improves the antioxidant activity of lotus root juice. At the same time, the pretreatment time is shortened, the polyphenolic components of the lotus root juice beverage are retained to the greatest extent, its antioxidant activity is significantly improved, and the product quality is improved.

Owner:JIANGSU ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com