Movable improved fabricated box culvert formwork and construction method thereof

A prefabricated, box culvert technology, applied in vertical shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of large transportation cost, cumbersome process, high construction cost, reduce damage and pollution, simplify cumbersome processes, The effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

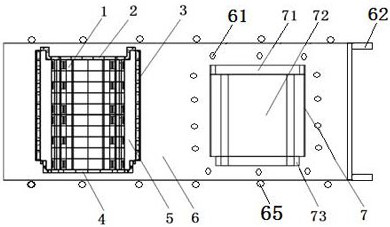

[0060] Example 1: see Figures 1 to 12 , a mobile improved assembled box culvert formwork, including threaded rods 9, bolts 11 and nuts 12. like Figure 11 As shown in the figure, the front and rear ends of each box culvert body 7 are provided with mutually matched butting convex edges 73 ends and butting grooves 71 ends, and two adjacent mobile improved assembled box culverts are inserted through the butting convex edges 73 ends. The end of the butt groove 71 is connected and fixed end to end.

[0061] The mobile improved assembled box culvert formwork also includes a mobile base table 6, an outer formwork 3, an inner formwork 1, a concave-end formwork 2, and a convex-end formwork 4. The mobile base table is the bottom formwork of the Taozhu box culvert body, and the health and mobile pedestals. The upper end of the mobile base table is provided with the outer formwork, the inner formwork, the concave-end formwork, the convex-end formwork and the built health shed of the Ta...

Embodiment 2

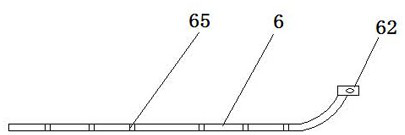

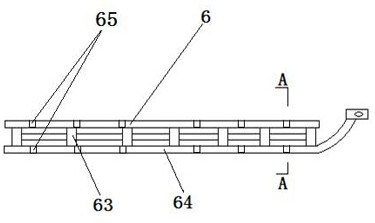

[0097] Example 2: see Figures 3 to 4 , Different from Embodiment 1: the mobile base table 6 can also be the bottom formwork, health care and mobile base of the Taozhu box culvert. The mobile base table is rectangular, and the mobile base table is made of steel plates with a thickness of 20 to 25 mm. The plinths 33 at the lower ends of the outer formwork, the concave-end formwork and the convex-end formwork are provided on the base table corresponding to the lower ends of the outer formwork, the concave-end formwork and the convex-end formwork. There is a sled board 64 on the side, the bottom bracket, the sled board and the lower end of the mobile base platform are fixed by welding. There is a shed pole fixing cylinder 65 for supporting the lower end of the shed pole 13 on the side corresponding to the Taozhu box culvert. The sled board is made of steel plate with a thickness of 20-25mm. The sum of the widths of the plates is less than the width of the mobile base table. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com