Patents

Literature

45results about How to "Small work area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Valley-type refuse landfill series multi-partition rain and sewage shunting device and method

Owner:青岛市环境卫生科研所

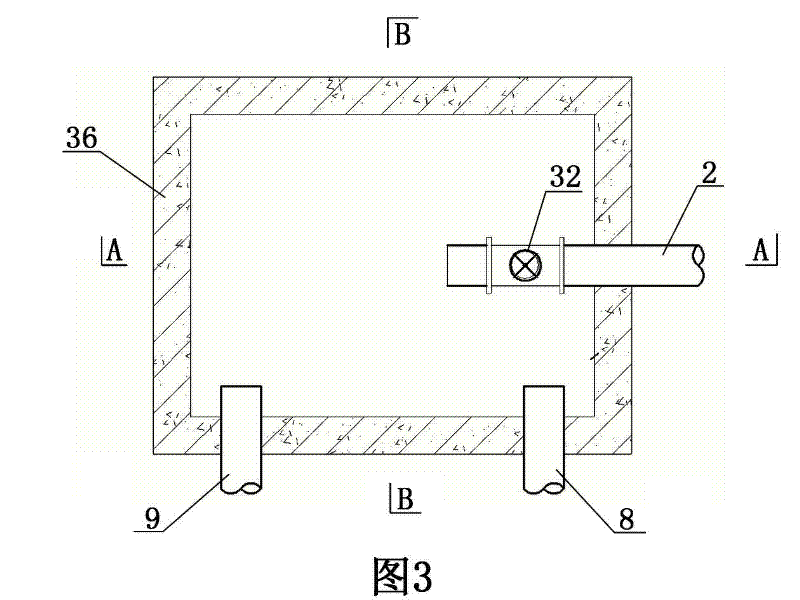

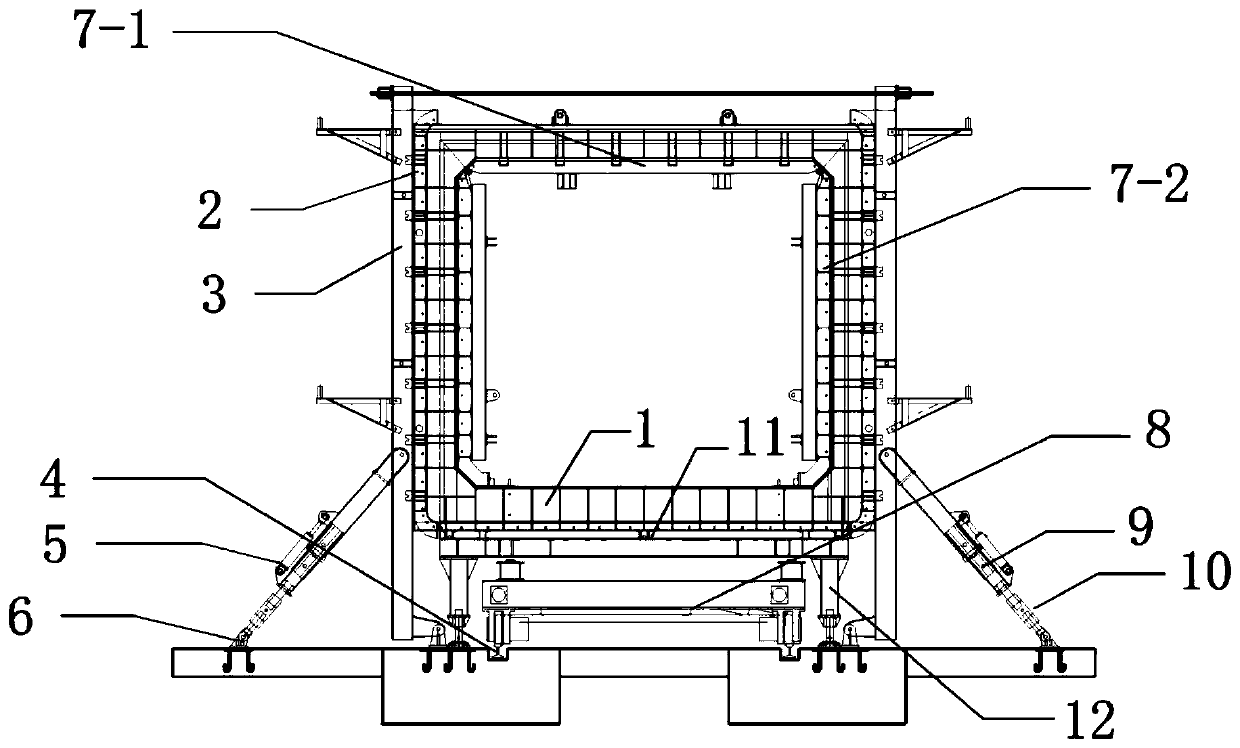

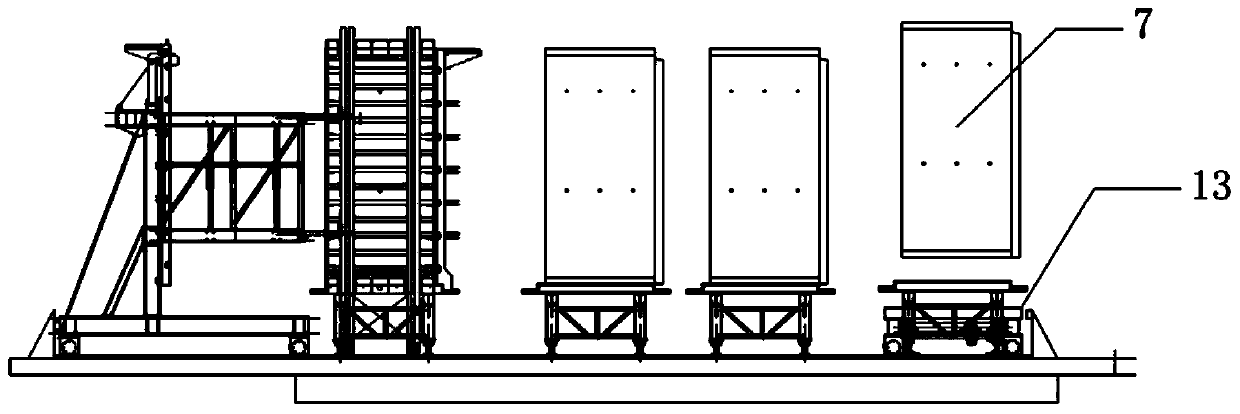

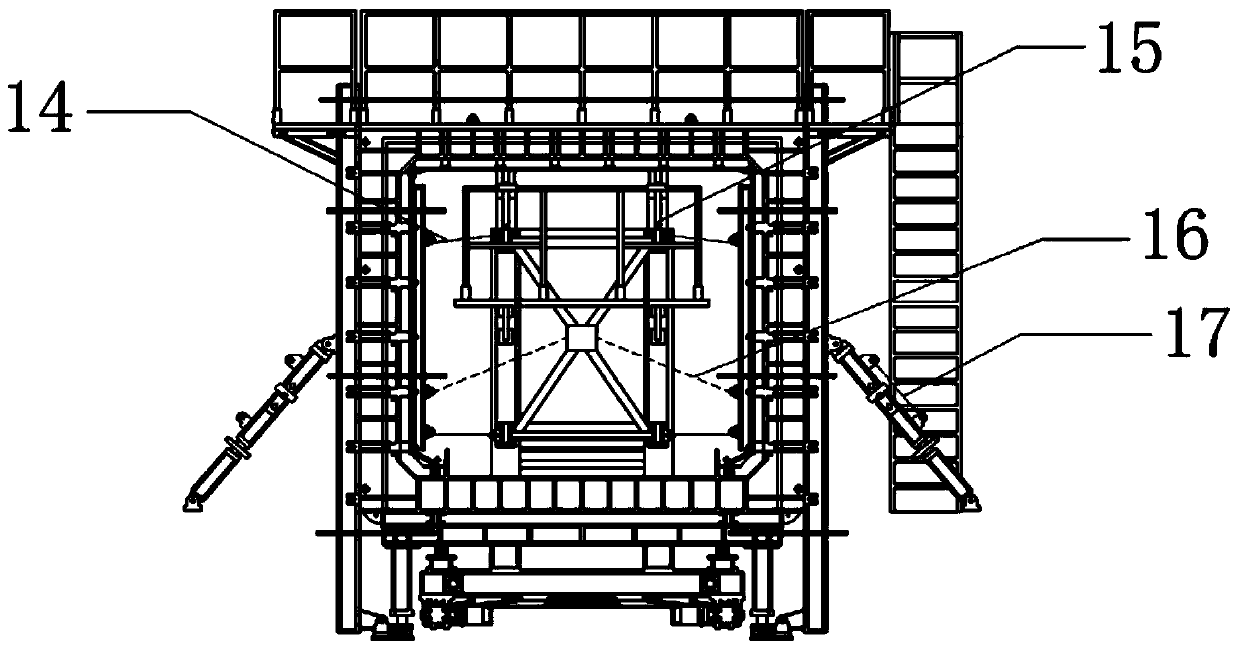

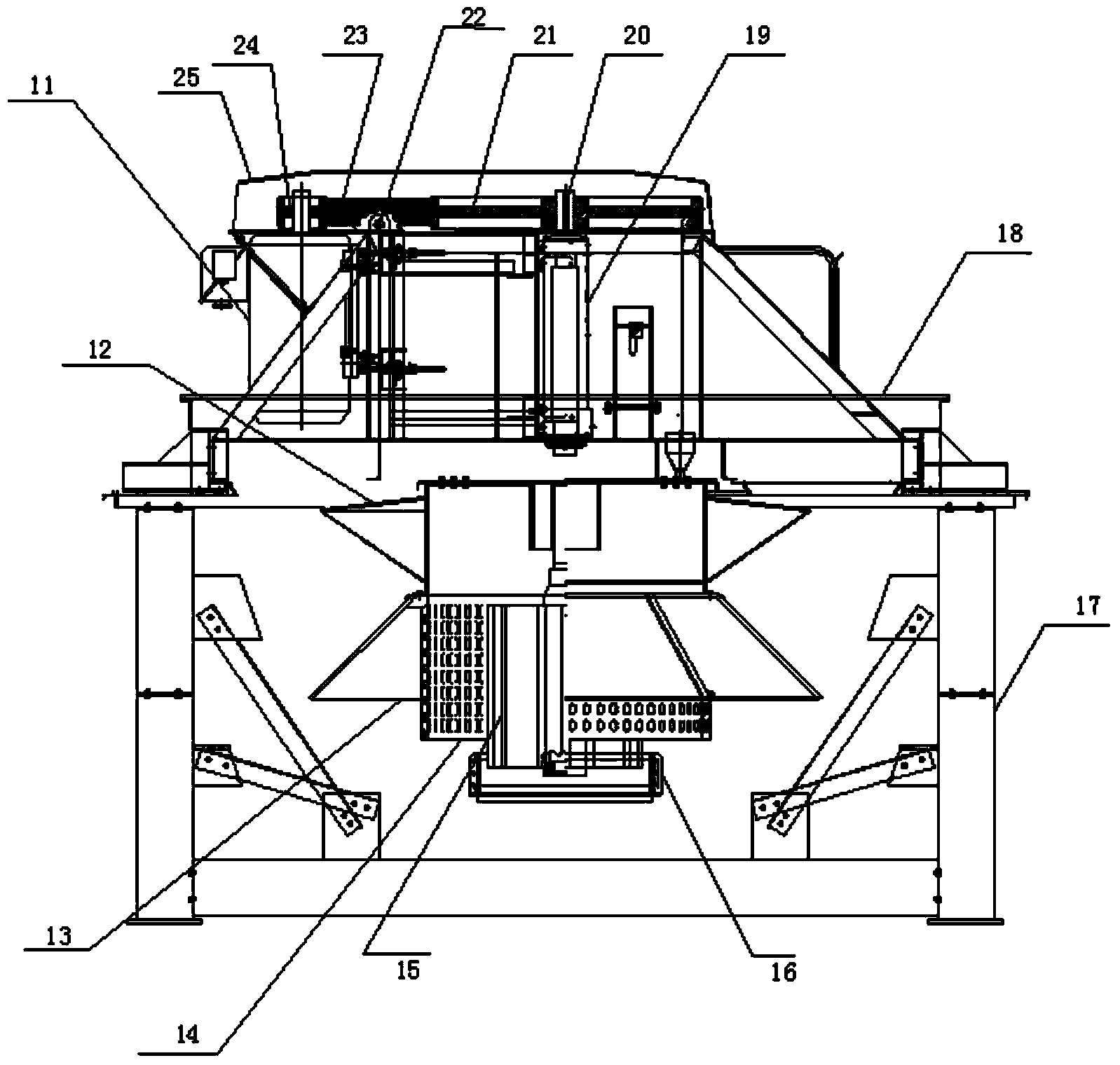

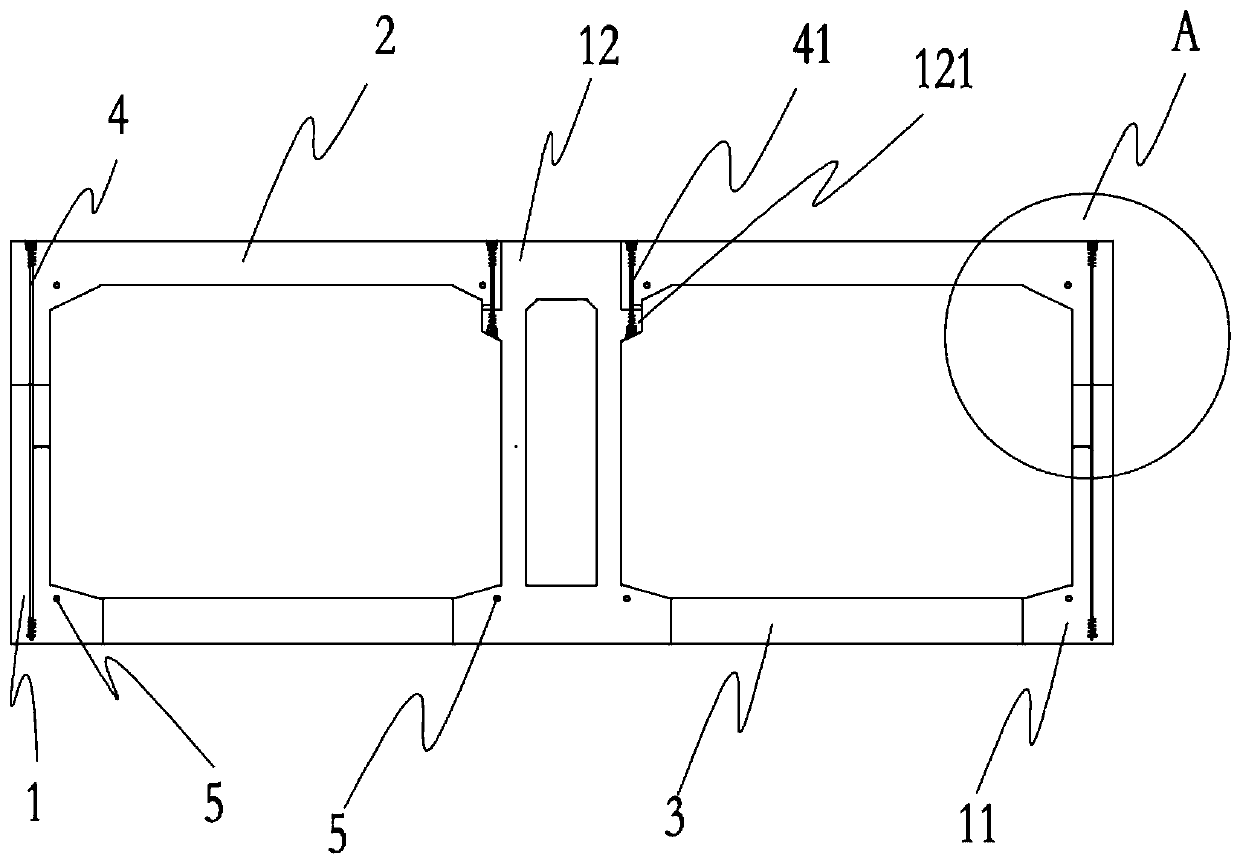

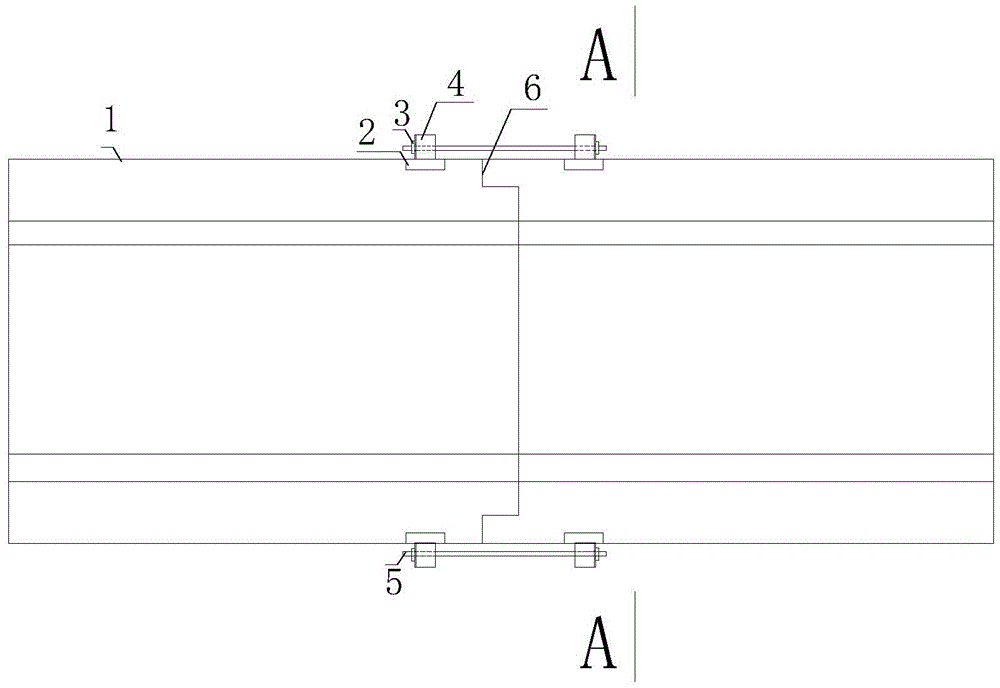

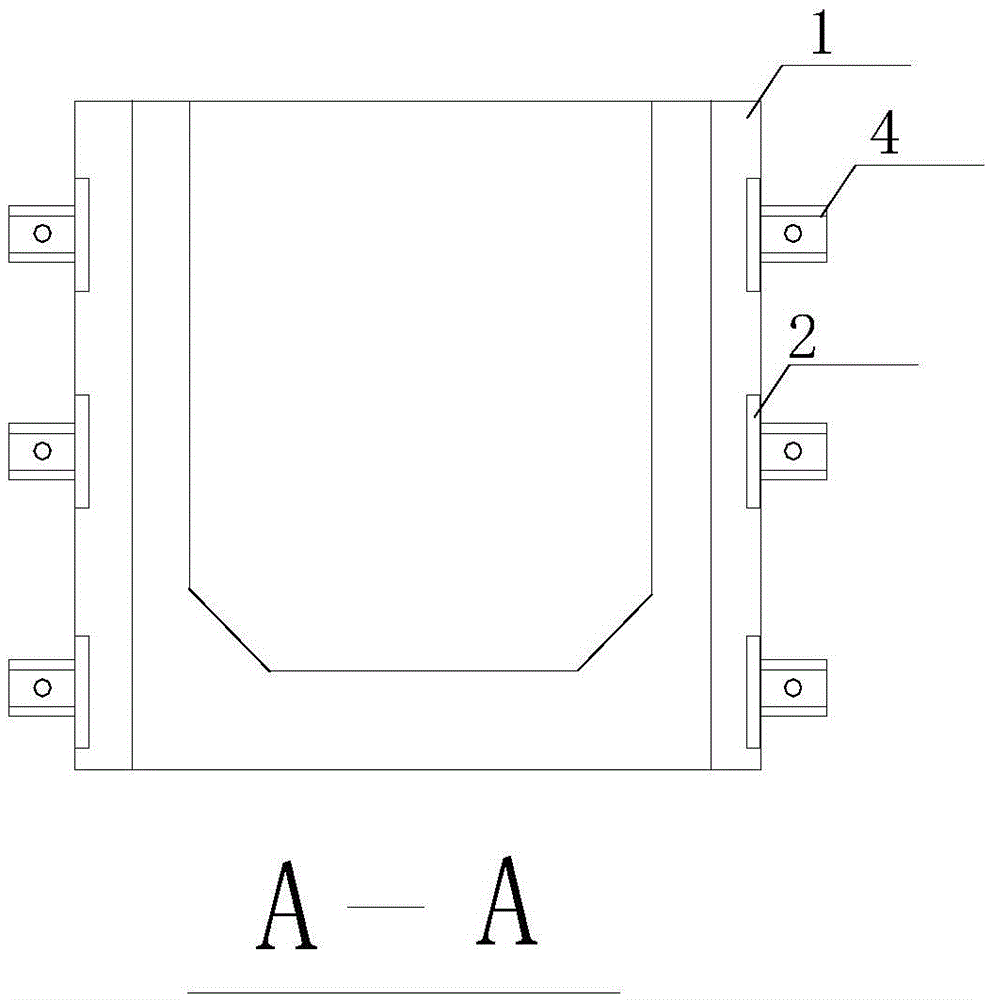

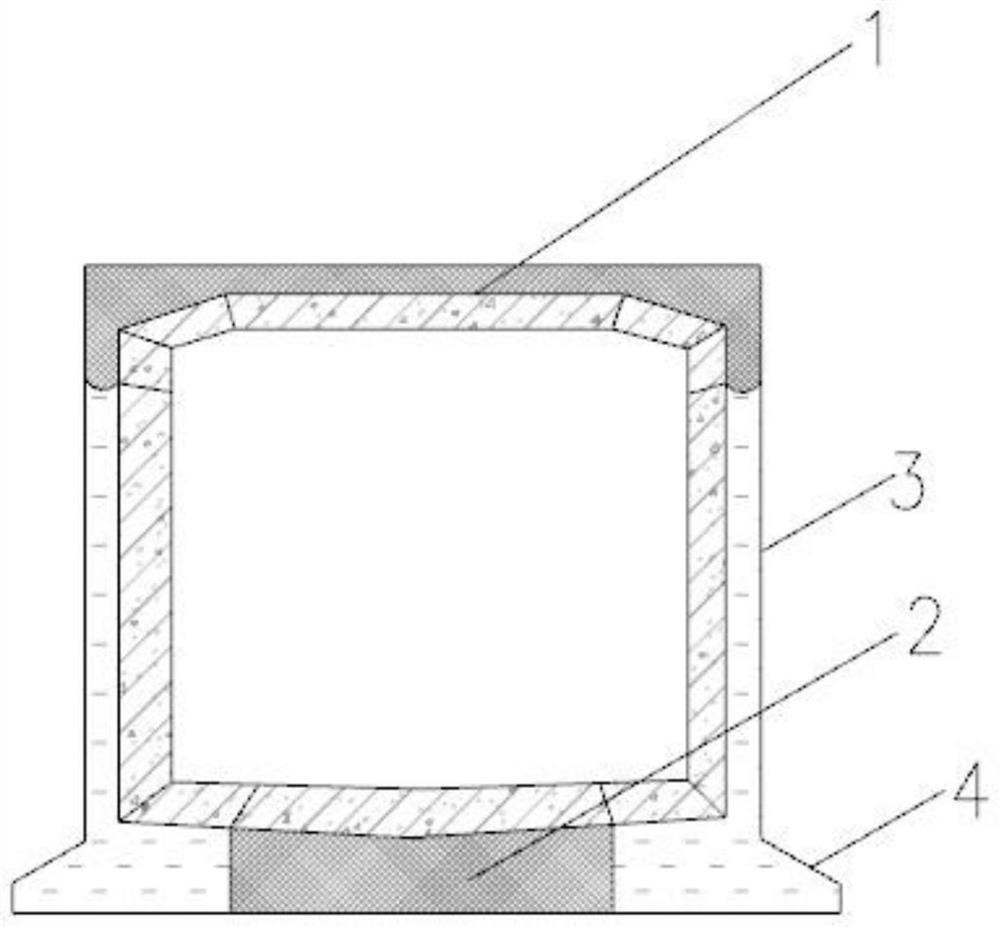

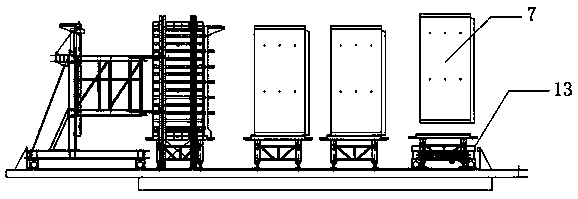

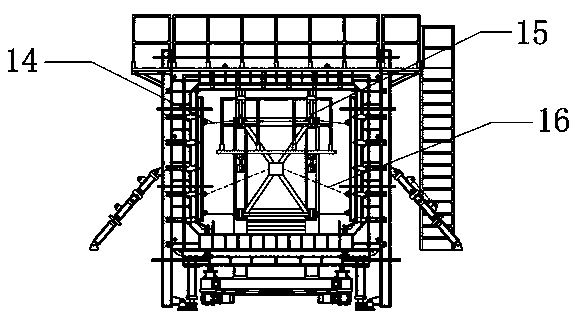

Assembly type hydraulic box culvert template and construction method of prefabricated assembly type box culvert of assembly type hydraulic box culvert template

ActiveCN110421687AImprove entity qualityImprove pass rateDischarging arrangementGround-workSocial benefitsRebar

The invention provides an assembly type hydraulic box culvert template and a construction method of a prefabricated assembly type box culvert of the assembly type hydraulic box culvert template, and belongs to the field of highway engineering construction. The assembly type hydraulic box culvert template comprises a template, a hydraulic power system and an adjusting support. The construction method comprises the steps that the assembly type hydraulic box culvert template is installed; the template is used; steel bars are machined and installed; a steel bar framework is hoisted put into the template; an internal mold is installed; the template is installed while concrete is poured; the concrete is poured; the concrete is cured; and the template is removed, and finally the prefabricated assembly type box culvert is prepared. The box culvert can be prefabricated in a centralized mode, and is installed on site, so that a lot of concrete is saved, the construction progress is accelerated,construction cost is reduced, damage and pollution to underground water and soil are greatly reduced, and the box culvert is especially prominent in green and environment-protecting aspects; and the entity quality of culverts is effectively improved, the yield of the appearance and a protection layer is greatly improved, and good economic and social benefits are obtained.

Owner:INNER MONGOLIA ROAD & BRIDGE

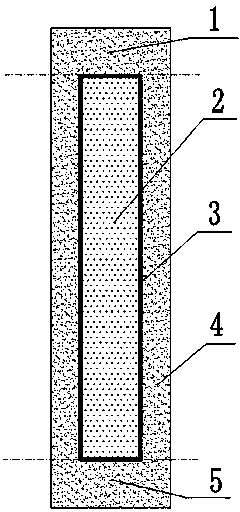

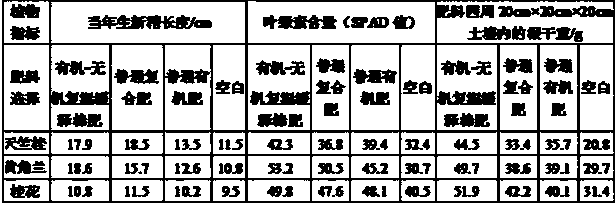

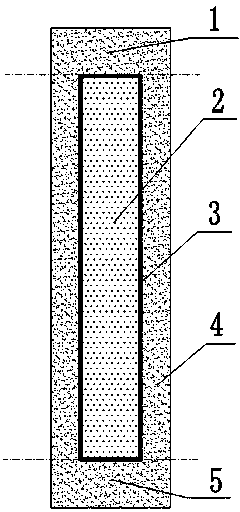

Manufacturing method for organic-inorganic compound slow-release fertilizer rod

ActiveCN106336275ADoes not cause root burnPromote growthFertiliser formsFertilizer mixturesInorganic nutrientOrganic inorganic

The invention relates to a manufacturing method for an organic-inorganic compound slow-release fertilizer rod. The manufacturing method comprises the following steps: compacting organic fertilizer to form the outer layer of the fertilizer rod; coating the inner wall of the outer layer with a slow-release membrane; injecting inorganic fertilizer and multifunctional auxiliary additives into the inner layer of the fertilizer rod; carrying out capping with organic fertilizer; and then carrying out final pressing so as to obtain the organic-inorganic compound slow-release fertilizer rod. The manufacturing method is simple to operate, can prepare the organic-inorganic compound slow-release fertilizer rod with a specific structure and allows the organic-inorganic compound slow-release fertilizer rod to have the advantages of high organic nutrient content, slow release of inorganic nutrients, sufficient and long-lasting fertilizer efficiency, etc.

Owner:CHONGQING LANDSCAPE & GARDENING RES INST

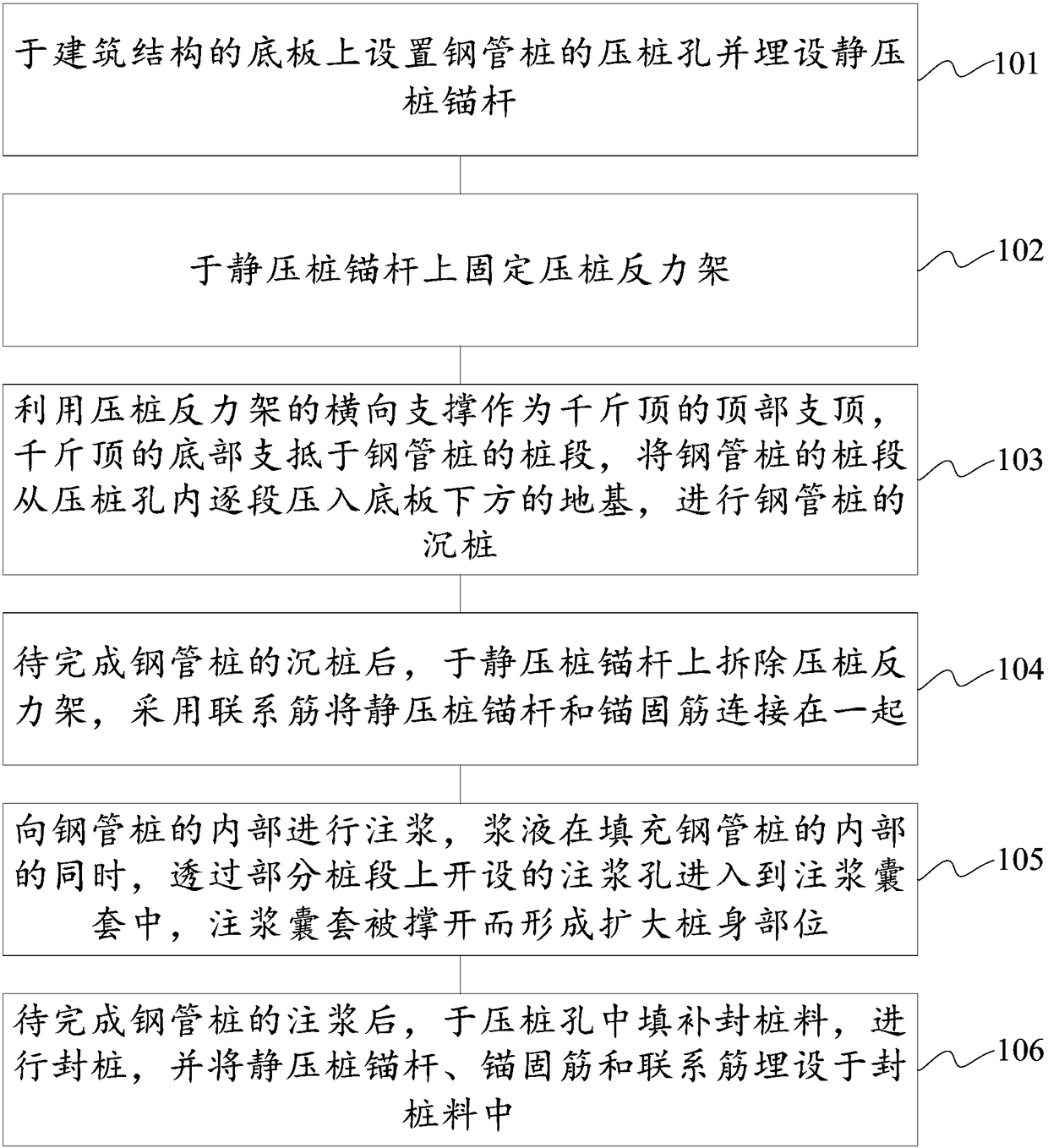

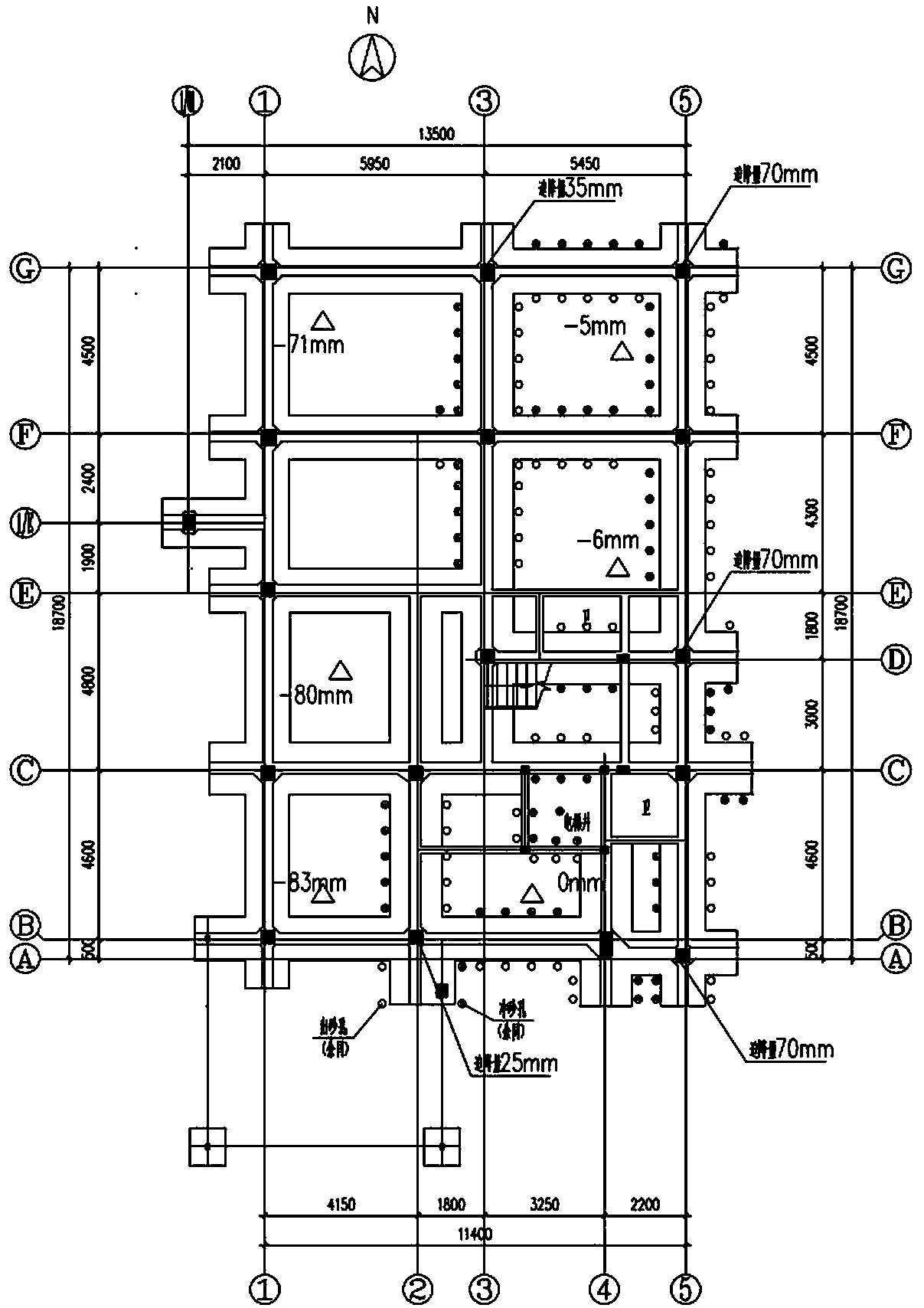

Soft soil foundation new construction post pile pressing technology and construction method thereof

InactiveCN101858082AShort construction periodShorten the construction periodBulkheads/pilesBuilding under constructionFoundation engineering

The invention discloses soft soil foundation new construction post pile pressing technology and a construction method thereof. The technology is characterized in that: an anchor rod is embedded and a pressing plate reaction frame is fixed in a foundation under construction, by using the self weight of a building under construction, the prefabricated pile sections are pressed into the soil section by section in a foundation reserved or dug pile pressing hole by anchor static pressure pile technology, and the pile foundation is fixedly connected with the foundation. Therefore, the aims of improving the bearing capacity of foundation soil and controlling the building subsidence are fulfilled. The construction method comprises the following steps of: measuring and placing an axis and a pile; reserving the pile pressing hole; embedding the anchor rod; and pressing and sealing the pile. The technology and the construction method have the advantages of simple and convenient construction, environmental protection, energy conservation, high speed and high efficiency, and are particularly applied to the foundation engineering in which a natural foundation cannot be directly adopted or a pile foundation cannot be constructed in order.

Owner:SHANGHAI ZHIPING FOUNDATION ENG CO LTD

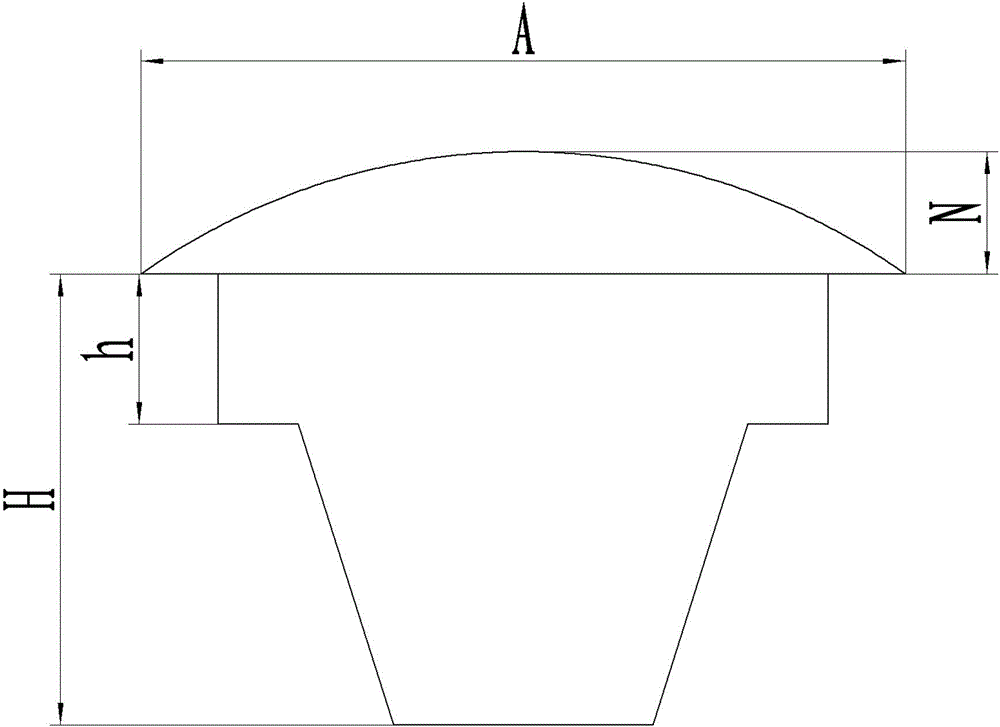

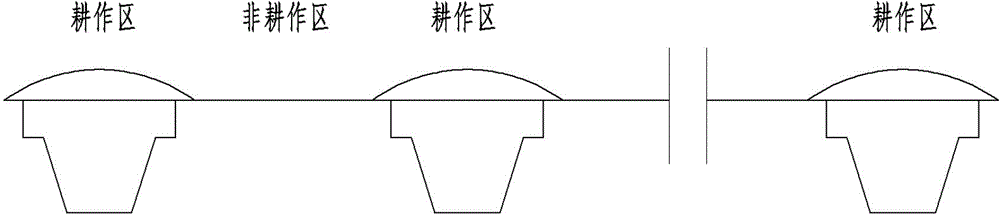

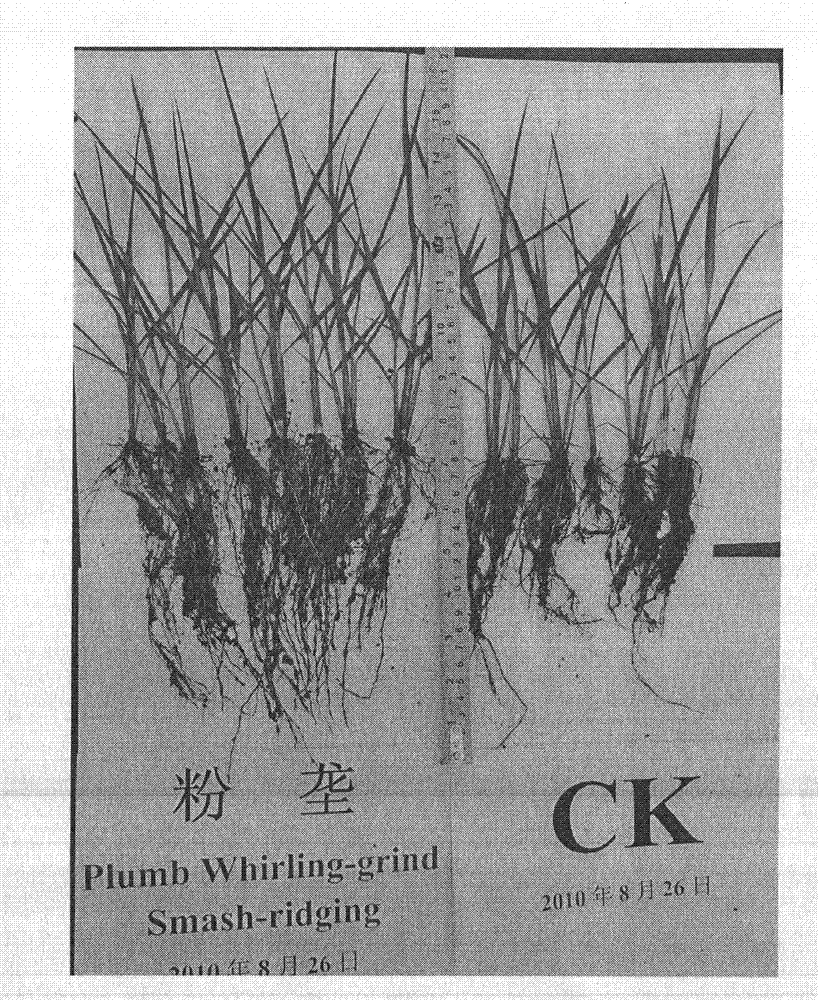

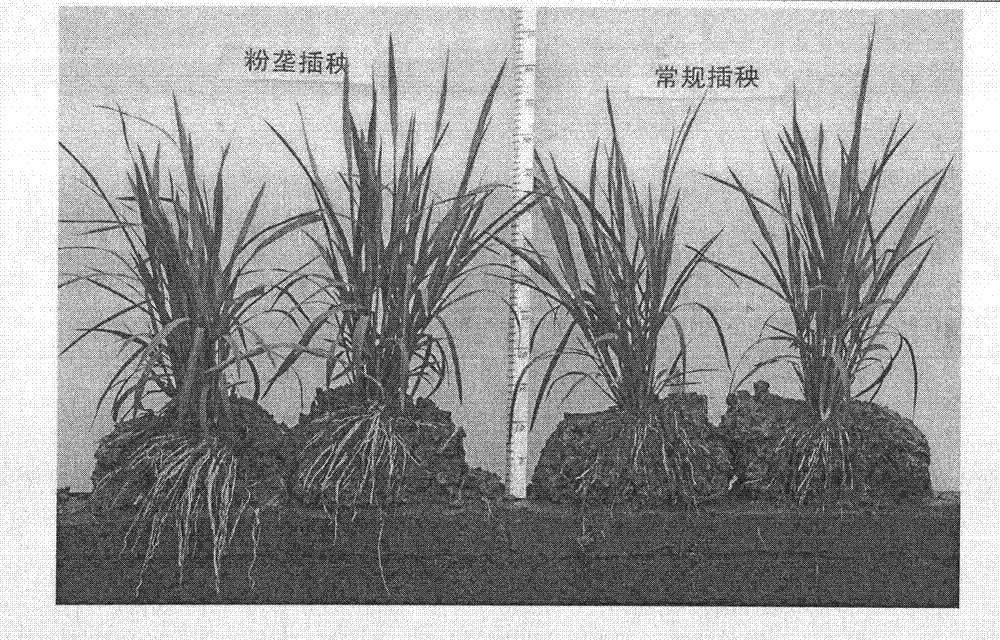

Powder ridge deep-cyclone water-storage seedling-retaining growth promoting and cultivation method in arid and semi-arid regions

InactiveCN104303635AHighlight substantive featuresSignificant progressPlant protective coveringsSoil-working methodsWater storageSoil science

The invention discloses a powder ridge deep-cyclone water-storage seedling-retaining growth promoting and cultivation method in arid and semi-arid regions. The middle of a cultivating area is deep-ploughed by using a rotary tillage spiral type machine while the two sides of the cultivating area are shallow-ploughed; the soils are milled at the same time; the soils are naturally ridged after the soils are rotated in a deep mode and loosened so as to form a T-shaped ridge land of which the two sides are surrounded by shallow loosening soils and the inclined surfaces have a certain angle. Drainage channels are arranged in a non-cultivation area, a film covers the ridge land, planting holes are formed in the ridge land, and a water-storage tank for storing water and retaining water is established around the planting holes; meanwhile, standardization farm operations such as fertilizer application and pesticide application are carried out, so that the operation is finished mechanically and integrally once, and the labor efficiency is greatly improved; by using the cultivating method, the water content of the soil is effectively increased by more than 30 percent, the production of crops is increased by more than 40 percent, and the economic benefit is obviously increased; moreover, a new ecological balance system is established, and the method has a great popularization value in the northwest arid region.

Owner:广西壮族自治区农业科学院经济作物研究所

Road and bridge transition section grouting construction method used during jacking construction

InactiveCN102392402AControl settlement deformationImprove driving safetyRoadwaysFoundation engineeringEconomic benefitsFluid level

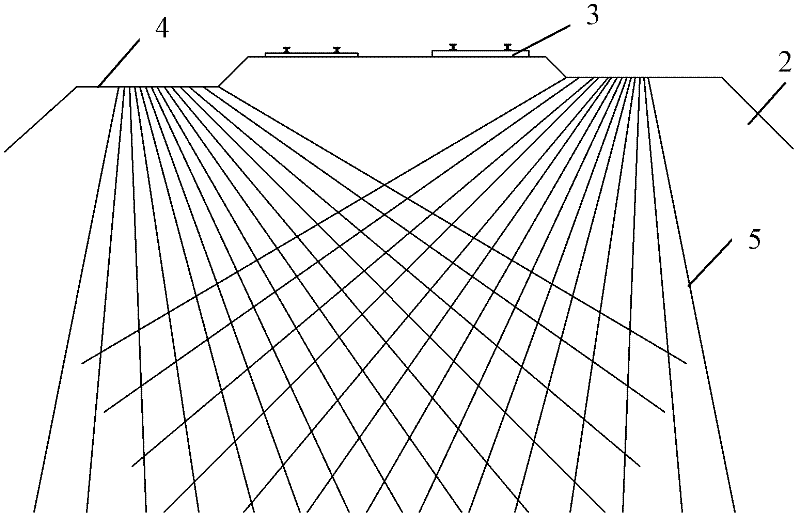

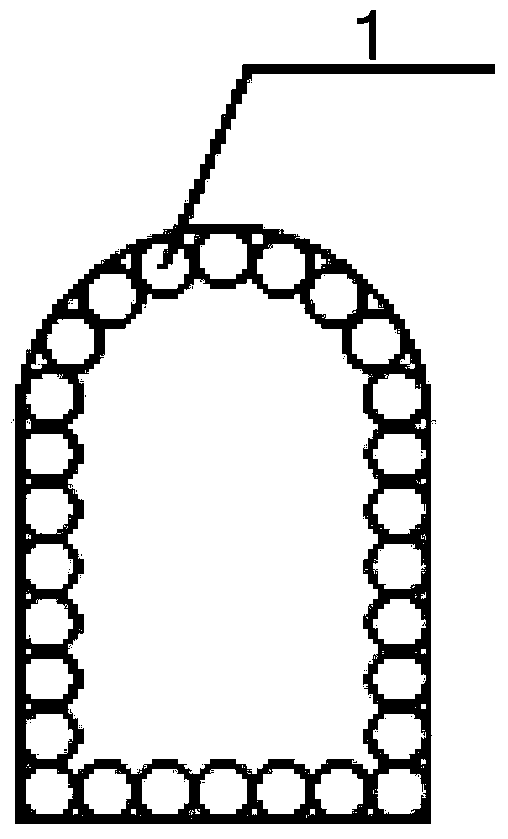

The invention relates to a road and bridge transition section grouting construction method used during jacking construction. According to the method, with a drilling pipe, a plurality rows of scallop grouting holes are drilled from railway shoulders on two sides of a road and bridge transition section towards the lower part of the railway with an inclined downward scallop manner; when one hole is produced, the drilling pipe is fetched, a shock tunnel is inserted into the hole, and grouting fluid is injected; when the grouting fluid level is 2 meters far from the ground, grouting is stopped, a grouting port is sealed, and the next hole is proceeded; an included angle range of the grouting scallop area relative to a subgrade plane is 15-75 DEG, and an adjustment range of adjacent two grouting holes 5 is 5 DEG. With the road and bridge transition section grouting construction method provided by the invention, road and bridge transition sections can be strengthened without breaking normal railway operation; the work space is small; the operation is convenient; and subsidence deformation of the road and bridge transition sections can be effectively controlled, such that uneven subsidence between the road and bridge transition sections and mass boxes can be prevented. Therefore, the method is beneficial for traffic security and personal security of a railway, and provides substantial economic benefits.

Owner:CHINA RAILWAY SIXTH GROUP +1

Power tunnel construction method

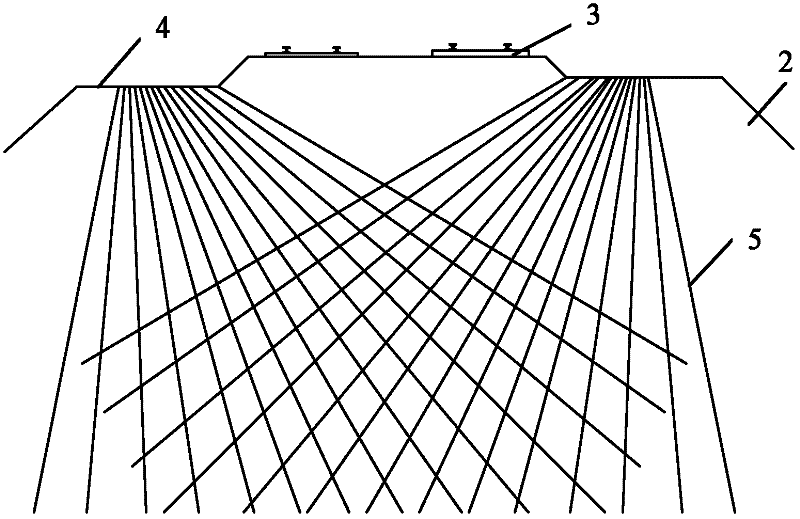

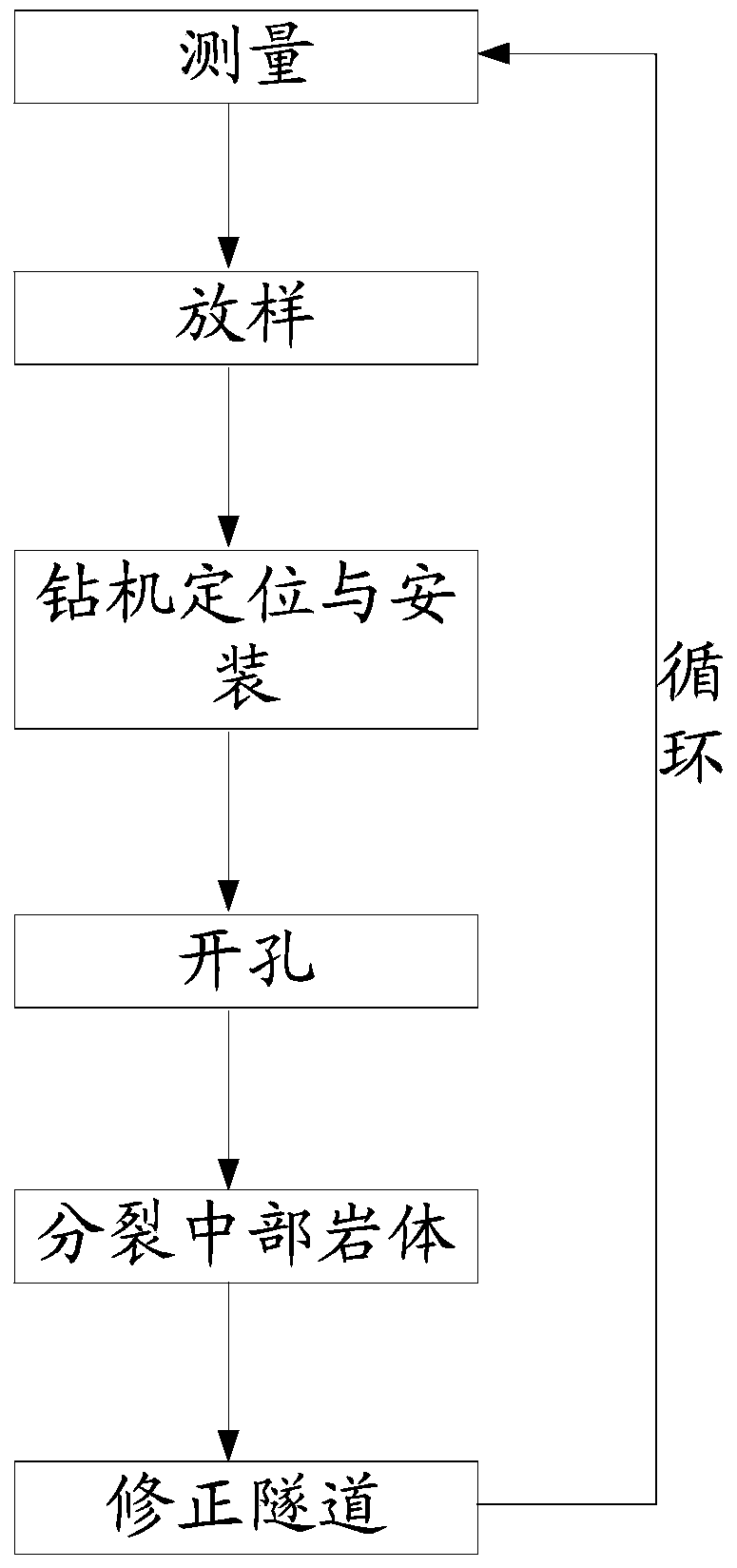

The invention discloses a power tunnel construction method which comprises the following steps: measuring, namely, confirming the tunnel cross section position by taking a ground control point as a reference point, marking a tunnel rim line, and detecting at regular time by using a measurement instrument; sampling, namely, arranging core taking points along the tunnel rim line, marking core point hole positions, wherein the core point hole positions are tangent to the tunnel rim line; positioning and mounting a drilling machine; paving a track, wherein a tower rack platform is arranged on the rack, a horizontal drilling machine of a drill is fixed on the tower rack platform, and the drilling machine is positioned by using fine tuning equipment so as to enable the axis of the drilling tube of the drilling machine to be parallel to the tunnel axis; trepanning, namely, coring and trepanning by using the horizontal drilling machine; splitting a middle rock body, namely, after all core points are trepanned, vertically cracking the middle rock body by using a vertical impact force; correcting a tunnel, namely, correcting the interior of the tunnel so as to form the complete tunnel cross section; circulating the steps till the tunnel is finally formed.

Owner:重庆电力设计院有限责任公司

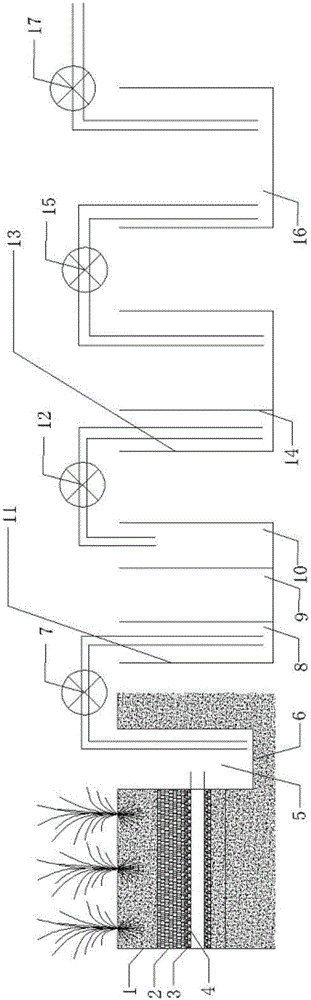

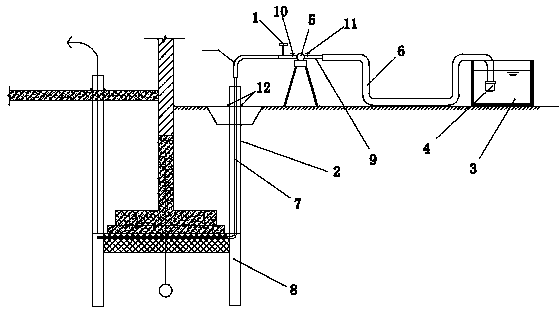

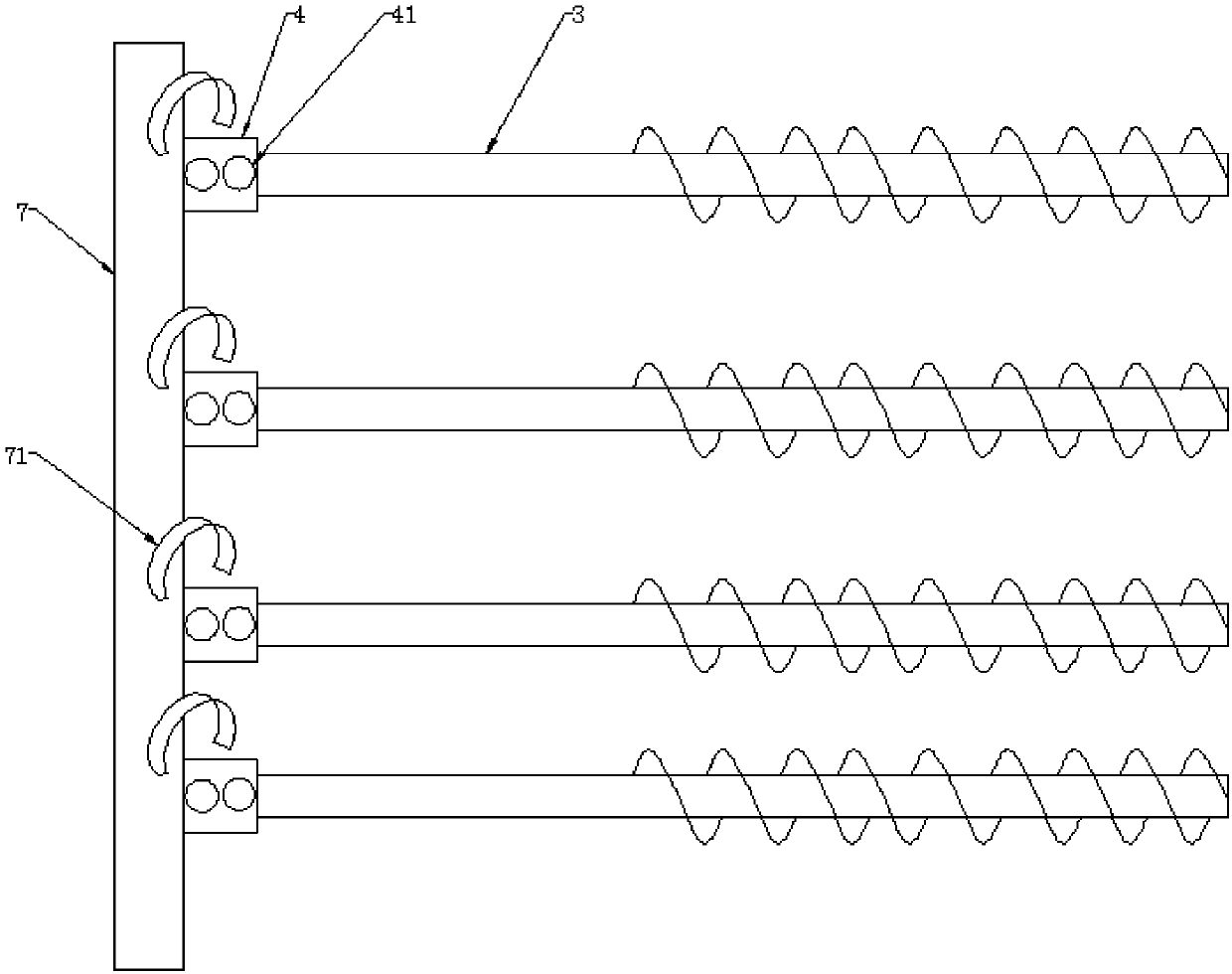

Circular leaching system for farmland polluted soil repair treatment

InactiveCN106734150AAchieve the purpose of repairDoes not affect growthContaminated soil reclamationDouble wallPlant soil

The invention discloses a circular leaching system for farmland polluted soil repair treatment. The system comprises an irrigation leaching system, a decontamination purifying system and a pure water storage and recharge system connected in sequence; drained water of the pure water storage and recharge system is supplied to the irrigation leaching system; the irrigation leaching system mainly consists of planting soil, an organic matter filter layer, a coarse sand filter layer, a double-wall corrugated seepage pipe and a water collecting pool; the planting soil, the organic matter filter layer, the coarse sand filter layer and the double-wall corrugated seepage pipe are arranged in sequence from top to bottom; an outlet of the double-wall corrugated seepage pipe is connected with the water collecting pool; and an outlet of the water collecting pool is connected with the decontamination purifying system. The system adopts the leaching method to reduce the content of pollutants in soil, and meanwhile, lowers the underground water level to prevent repeated pollution; and after polluted water permeated after soil leaching is decontaminated and purified, and the polluted water is recharged for irrigation leaching of the soil again, so that the pollutants in the soil are removed, farmlands are irrigated, and meanwhile, secondary pollution is not generated.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

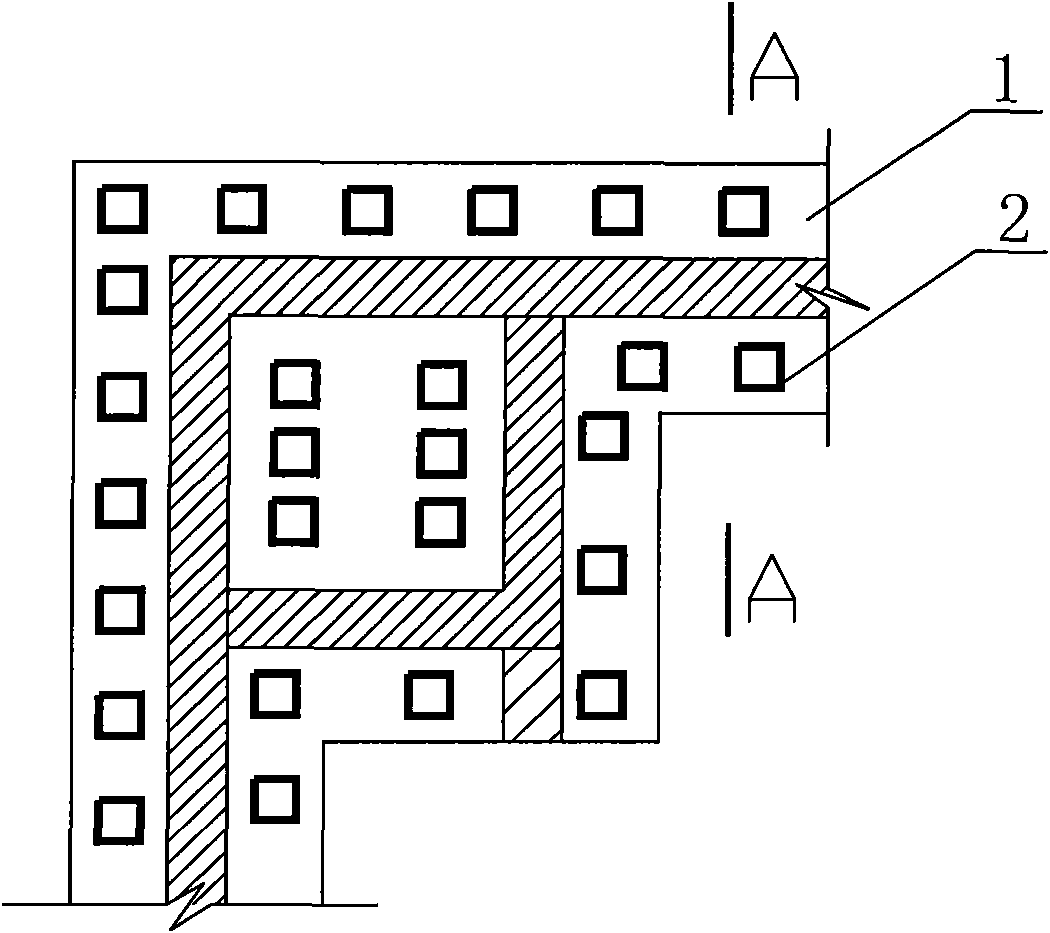

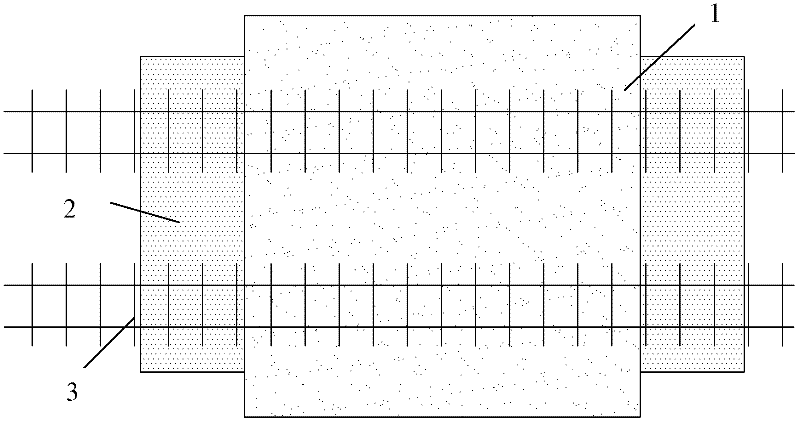

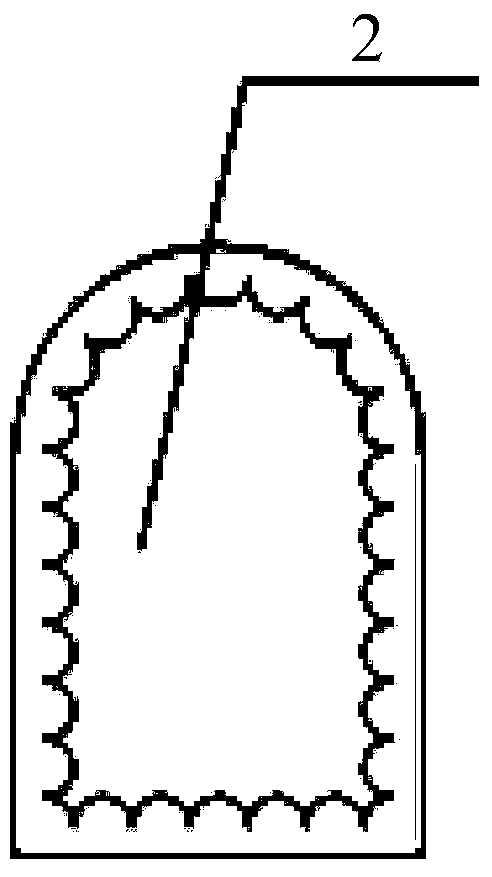

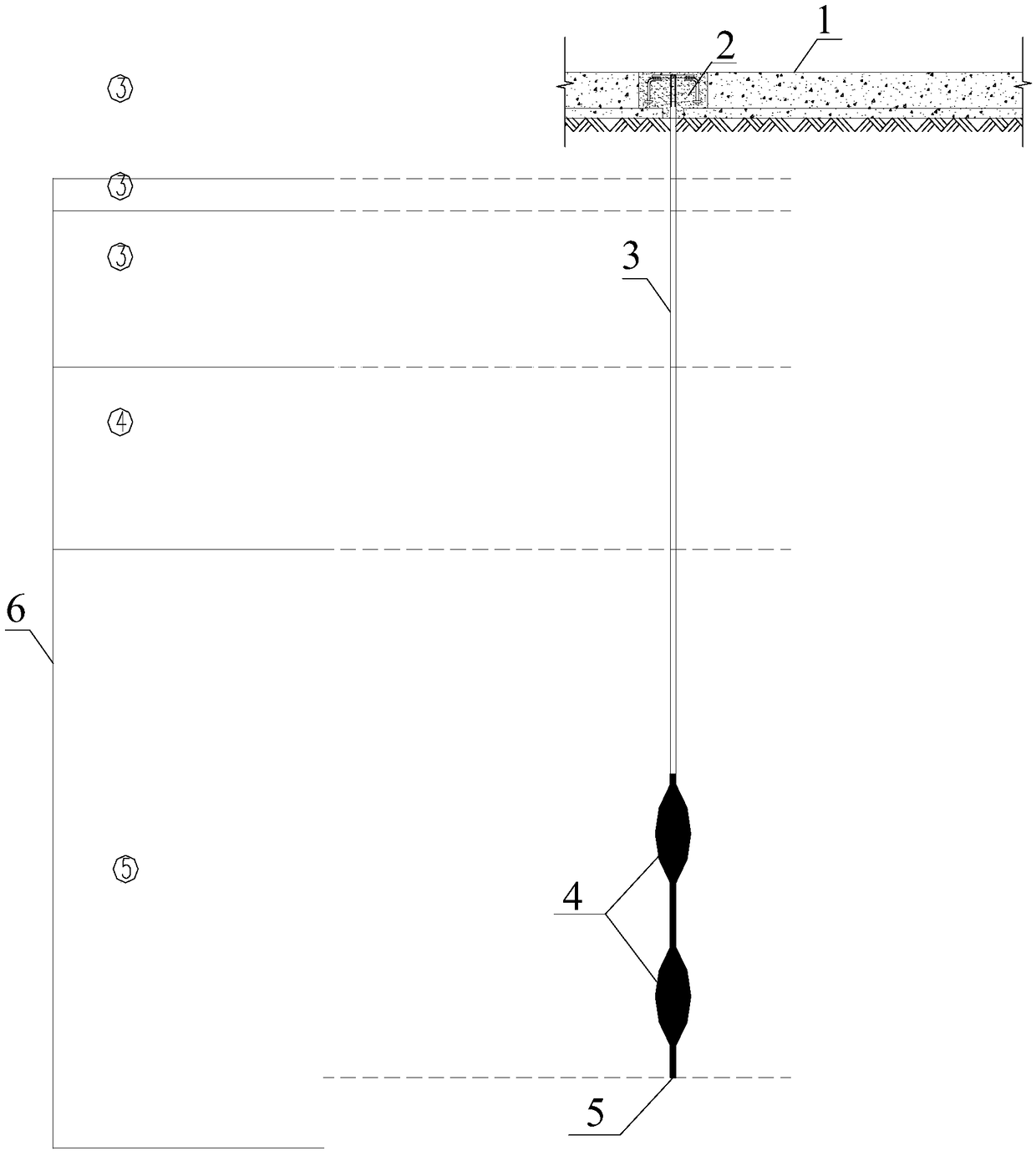

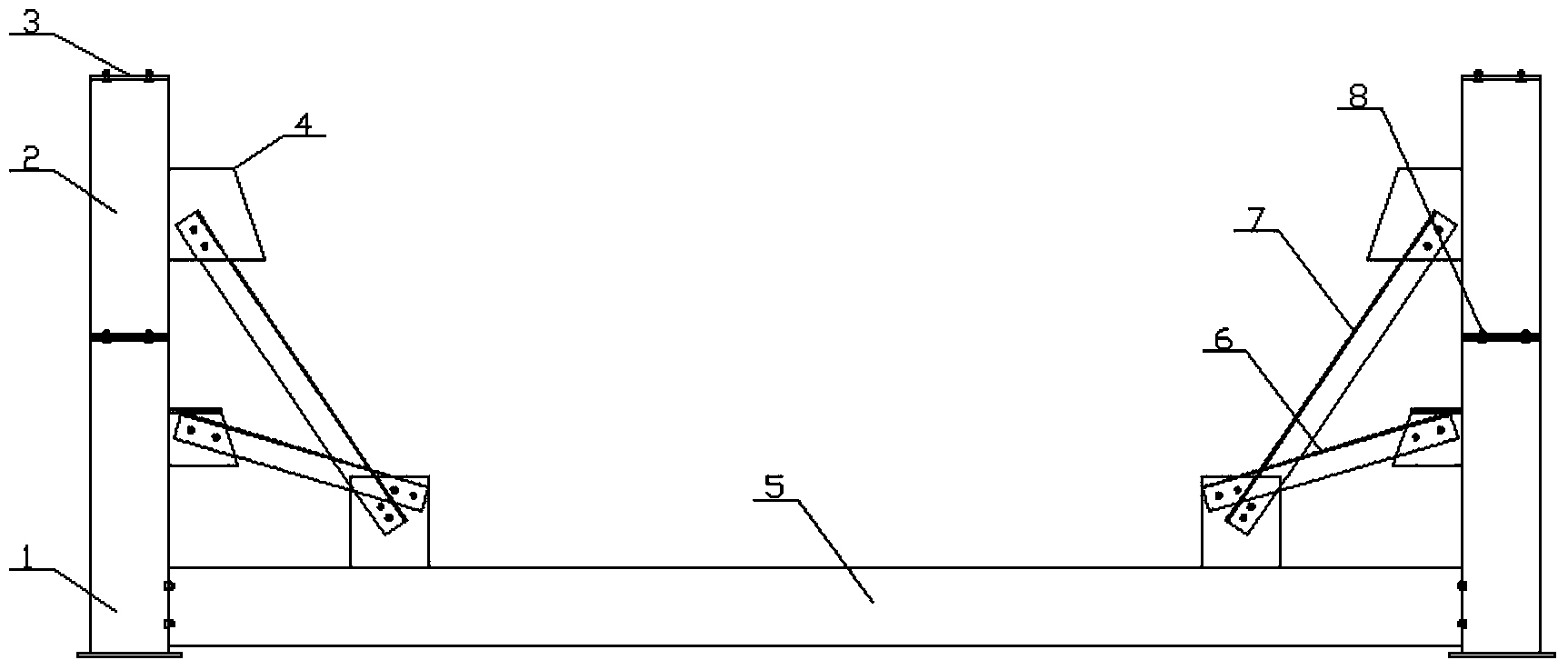

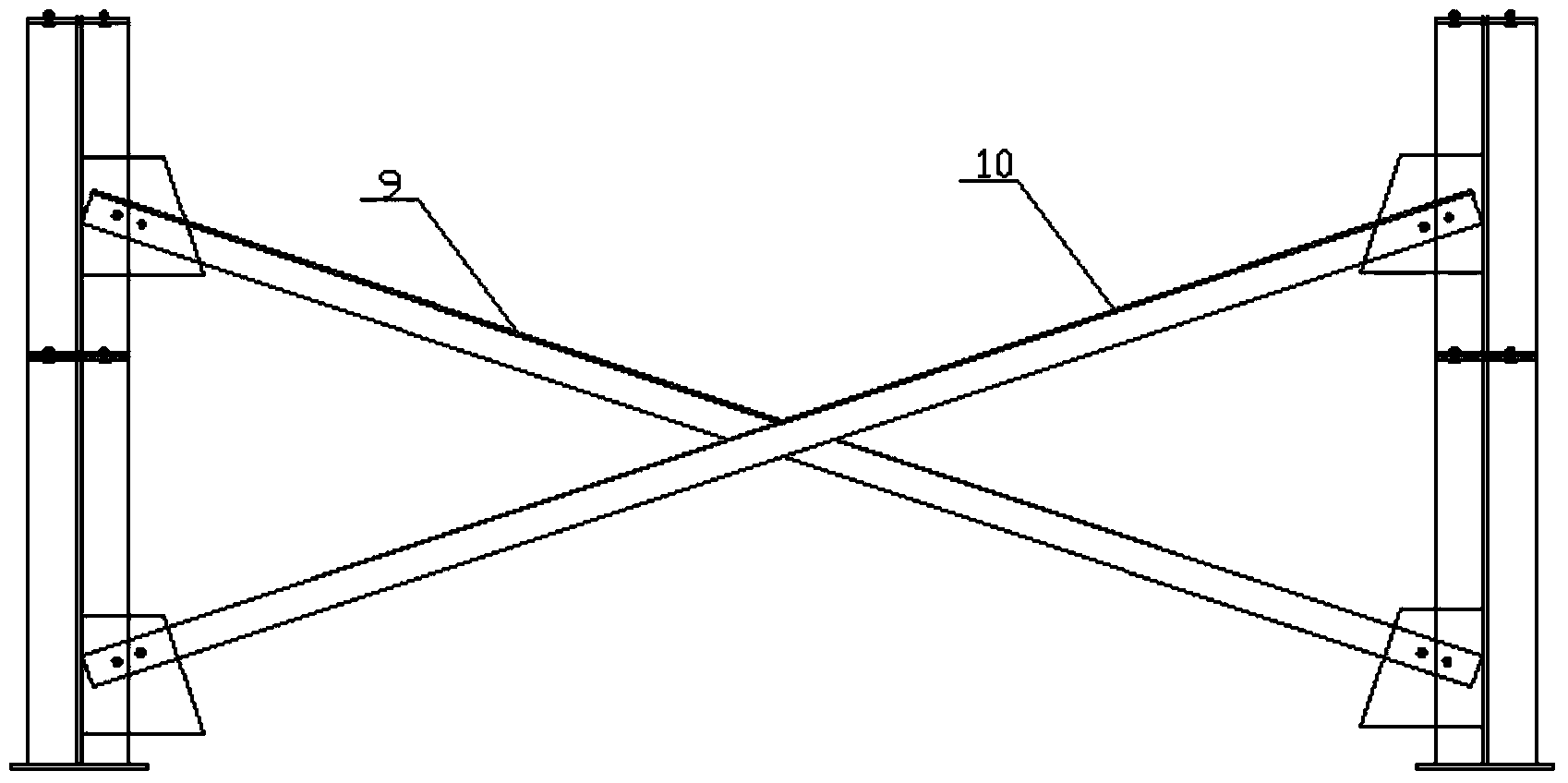

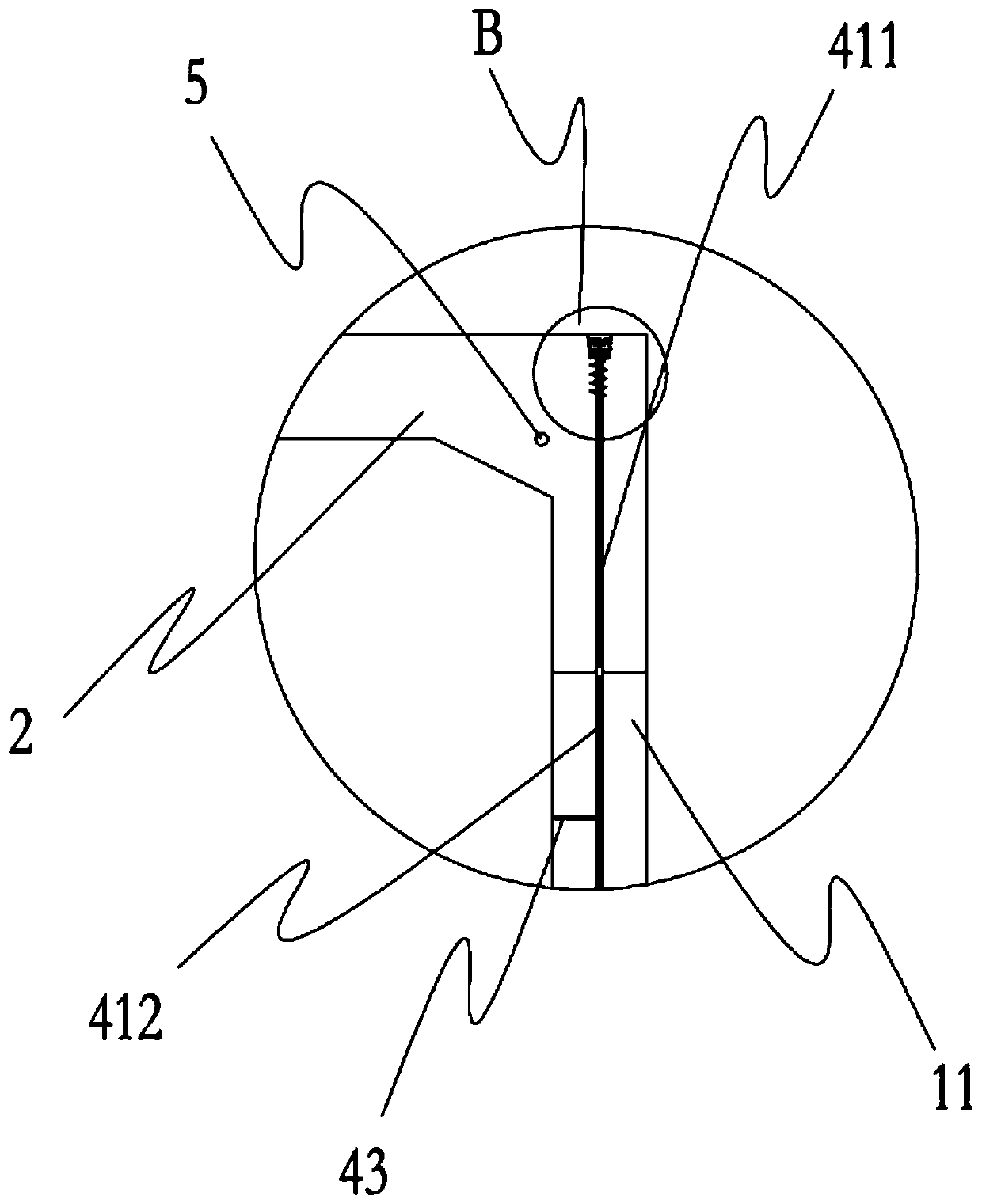

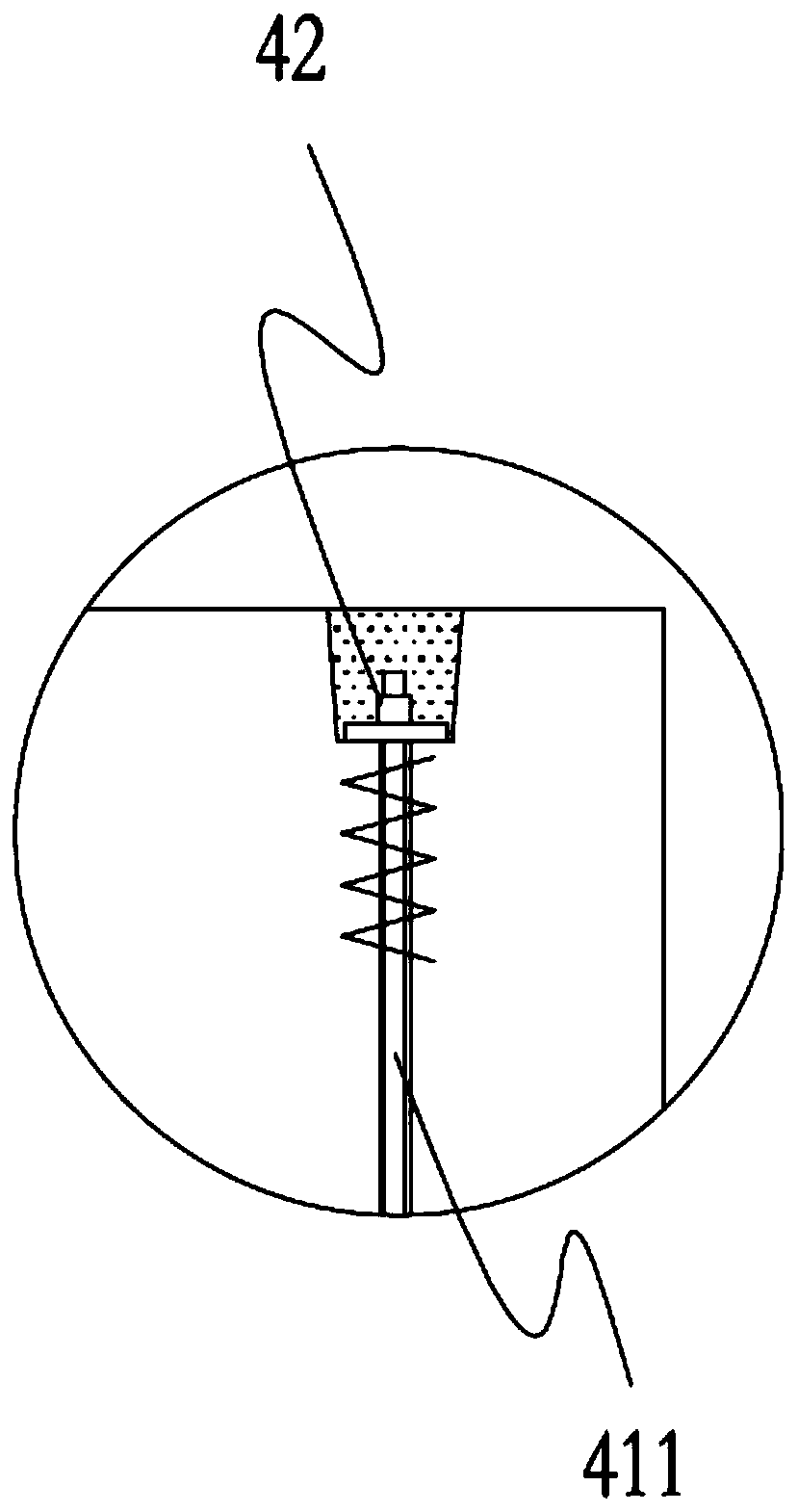

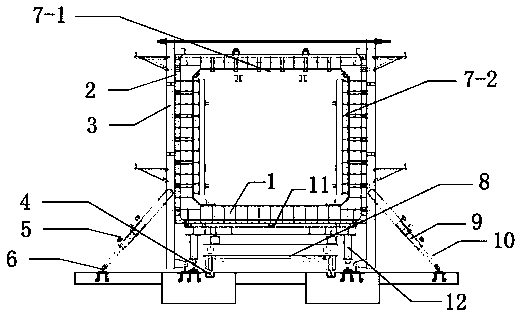

Grouted steel pipe pile foundation strengthening system and construction method thereof

PendingCN108265718AEasy constructionSmall work areaBulkheads/pilesSoil preservationSedimentationBearing capacity

The invention provides a grouted steel pipe pile foundation strengthening system and a construction method thereof. A static pile pressing anchor rod is embedded in a bottom plate of a building structure to fix a pile pressing counter force frame, the self-weight loads capable of being applied by the building structure serves as pile pressing counter force, a jack is used for pressing pile sections of the steel pipe pile into the foundation section by section through a pile pressing hole reserved or chiseled in the bottom plate, construction is convenient, and the operation face and the operation space are small. During pile sealing, after the anchor rod is bent, connection ribs are used for being connected with anchoring ribs on the top of a steel pipe column into a whole. The non-contractible grouting material is used for connecting a pile head with the bottom plate of the building structure together, the purposes of improving the foundation bearing force and controlling sedimentation are achieved, and the enough length is designed according to the specific stress situation. Restraint type grouting is adopted in a lower pile body of the steel pipe pile, an enlarged pile body partis formed, the bond stress of the pile body and the surrounding soil body is enhanced, and therefore after grouting, the single-pile pulling resistance (anti-pressing) bearing force of the steel pipepile is enhanced, and integral stress is formed through the pile head and foundation rigidity connecting combination.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Advanced positioning directly-buried anchor bolt prefabricated pipeline support construction technology based on BIM

InactiveCN111853347AAvoid buryingAvoid drilling holesPipe laying and repairBuilding material handlingLine tubingConstruction engineering

The invention discloses an advanced positioning directly-buried anchor bolt prefabricated pipeline support construction technology based on BIM. The technology comprises the following steps of (1) construction preparation; (2) optimizing a BIM pipeline; (3) drawing a directly-buried anchor bolt installation drawing; (4) main body pre-burying construction; (5) manufacturing a support; and (6) mounting the support. According to the construction technology, the construction procedure of an original pipeline support and hanger is improved, the construction period of the pipeline support is effectively shortened by combining the precise positioning technology of BIM and machining and distribution of factory supports, meanwhile, the steps of on-site welding and paint brushing processes are reduced, the green construction requirement is met, and the construction quality is remarkably improved; and pipeline integration and collision inspection are carried out through BIM, the pipeline is optimized and adjusted, positioning and paying-off are carried out on the surface of a formwork according to an optimized drawing, the directly-buried anchor bolt is fixed to the formwork, and accurate pre-burying of the anchor bolt is completed in advance through construction of main body concrete.

Owner:QINGDAO XINHUAYOU CONSTR GROUP

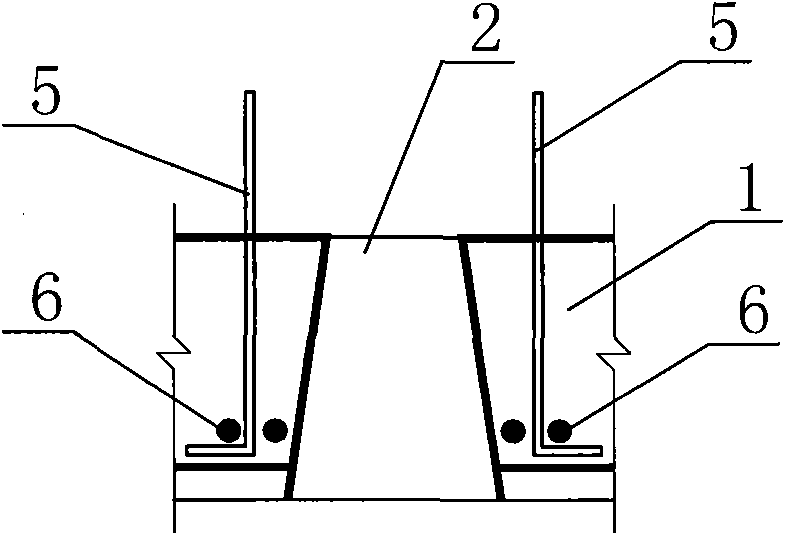

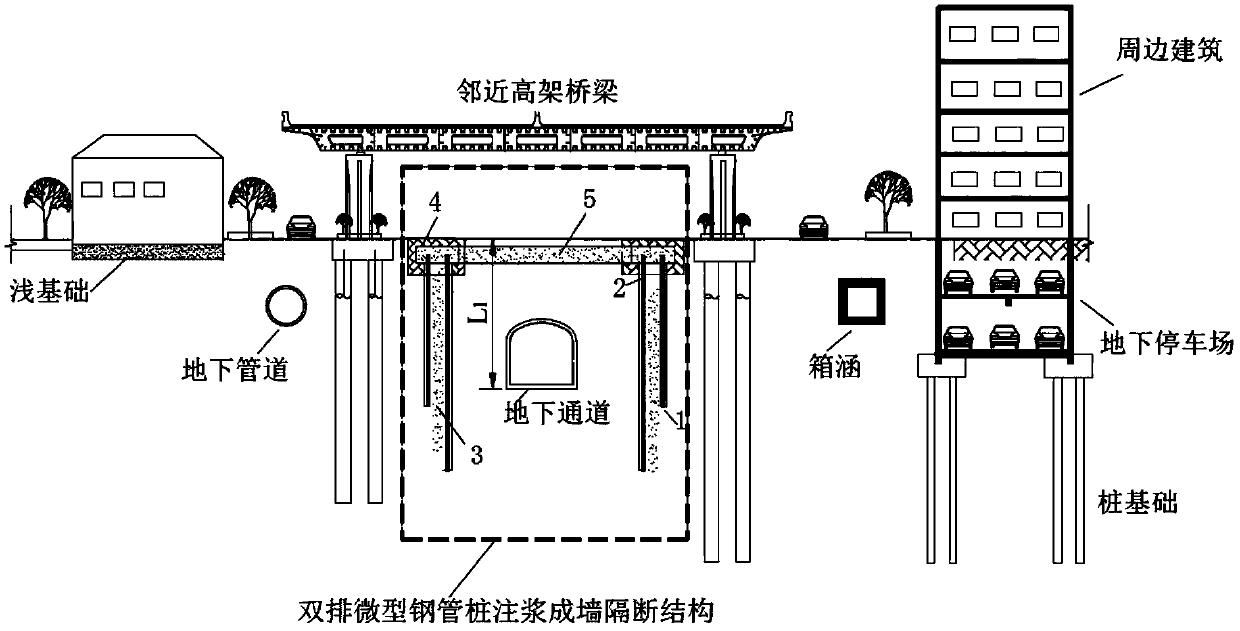

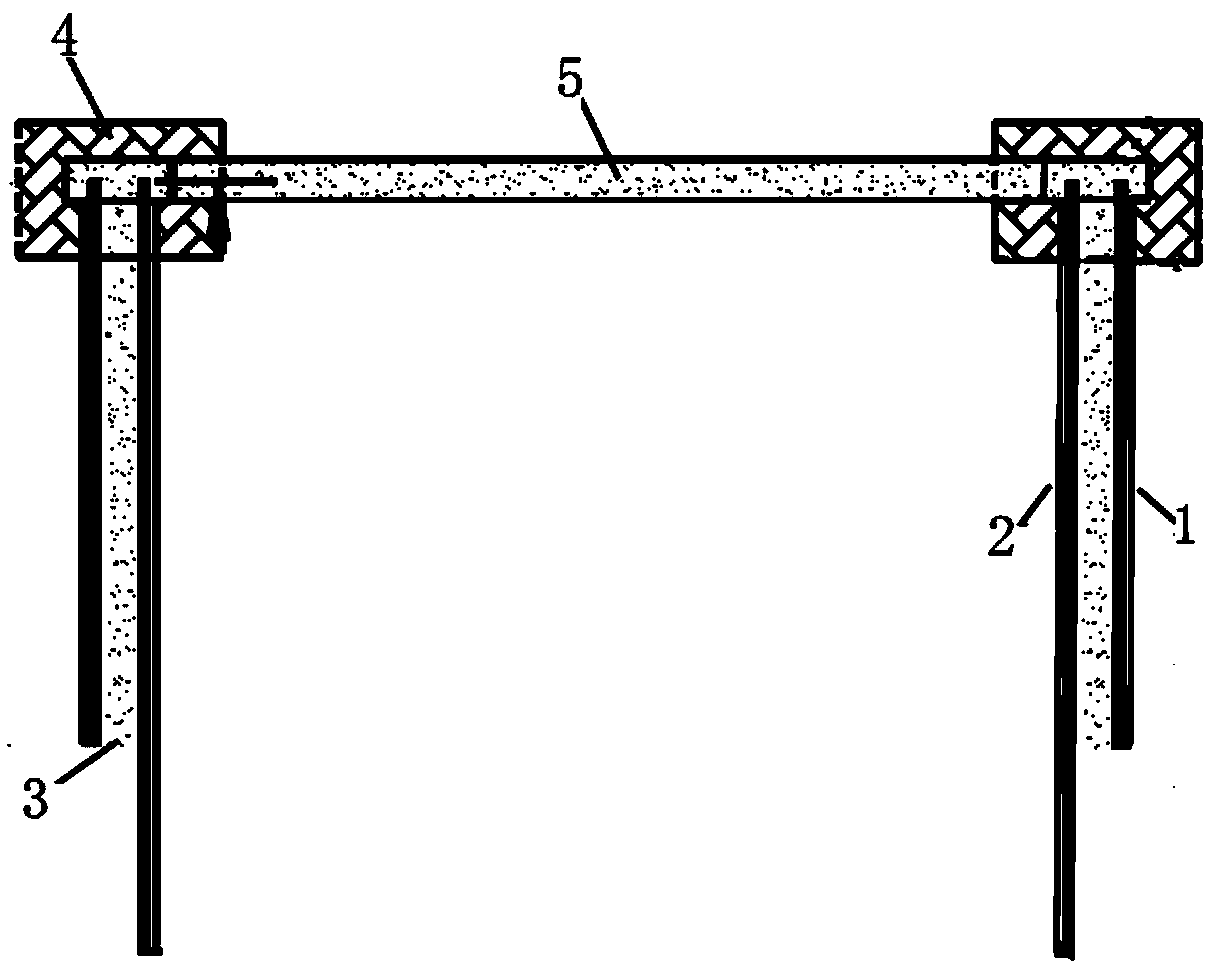

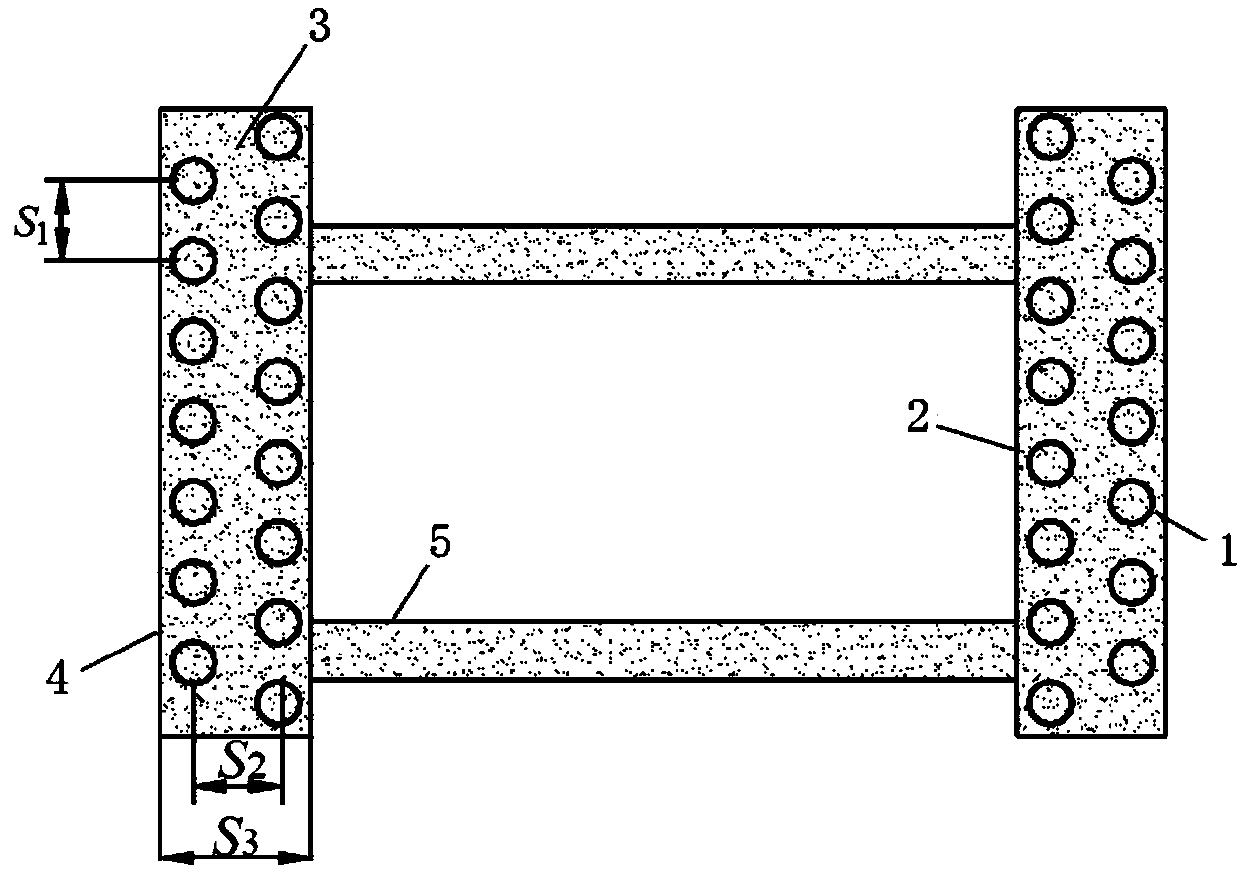

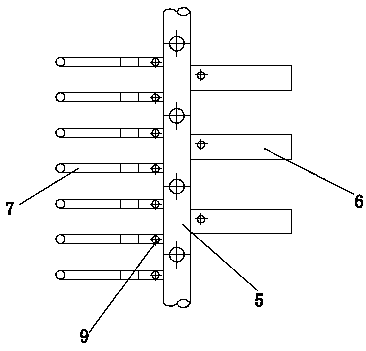

Double-row micro steel pipe pile grouting-into-wall partition structure and method

ActiveCN108677924AResistance to lateral extrusionIncrease stiffnessBulkheads/pilesSlurryCement grout

The invention discloses a double-row micro steel pipe pile grouting-into-wall partition structure and a method. The partition structure comprises a pair of double-row pile support mechanisms, crown beams disposed at the top of each double-row pile support mechanism and a connecting beam for connecting the two crown beams. The double-row pile support mechanisms each comprise a rear row pile, a front row pile and an intermediate high-pressure jet grouting pile, wherein the front row pile is located on the outside of the rear row pile, and the rear row pile and the front row pile are both steel pipe piles. The steel pipe piles include steel pipes and mixed grout of cement and water glass filling in the steel pipes, and the steel pipes are provided with a plurality of grouting holes in the axial direction. The intermediate high-pressure jet grouting piles are disposed between the rear row piles and the front row piles and connect the two into a whole to form a water retaining curtain wallbetween the piles, and the intermediate high-pressure jet grouting piles are cement grout sprayed on soil between the rear row piles and the front row piles in a high-pressure jet grouting mode. The double-row micro steel pipe pile grouting-into-wall partition structure can be used as a reinforcement protection measure for an existing adjacent infrastructure in the construction process of underground engineering.

Owner:WUHAN MUNICIPAL CONSTR GROUP +1

Crushing and ridging culture method of rice

InactiveCN102246676BHighlight substantiveSignificant progressRice cultivationSoil-working methodsSoil scienceInsect pest

Owner:韦本辉

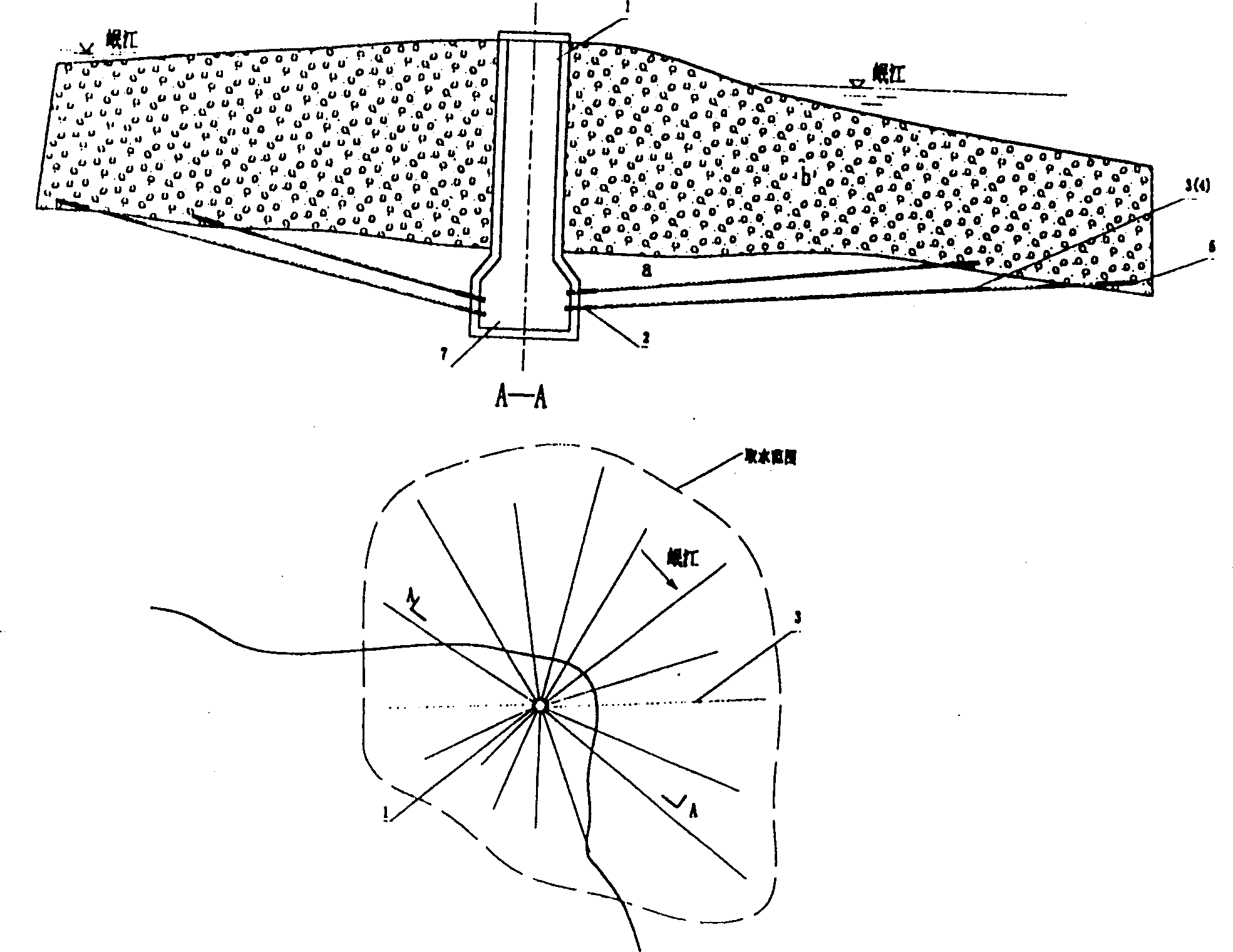

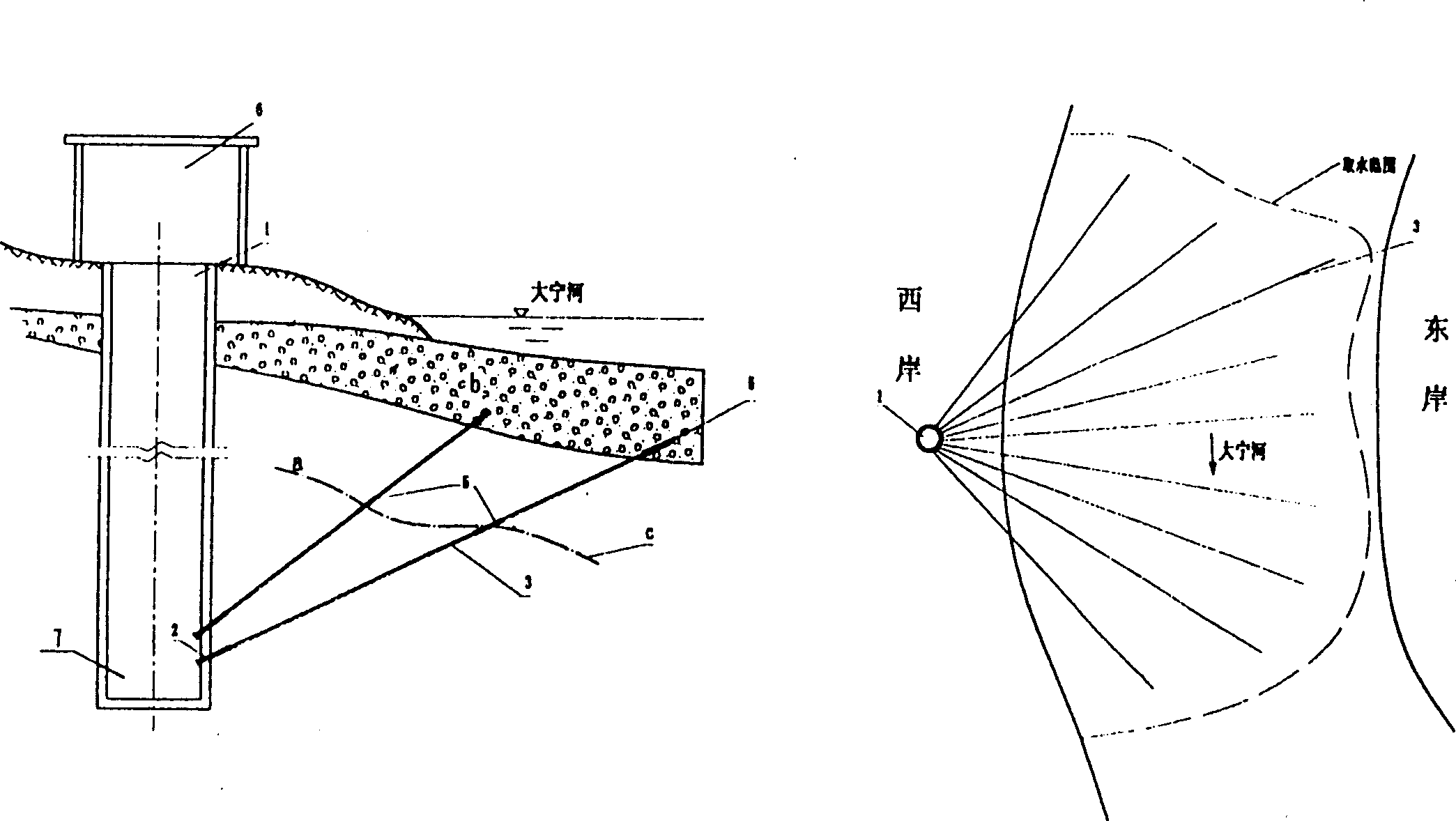

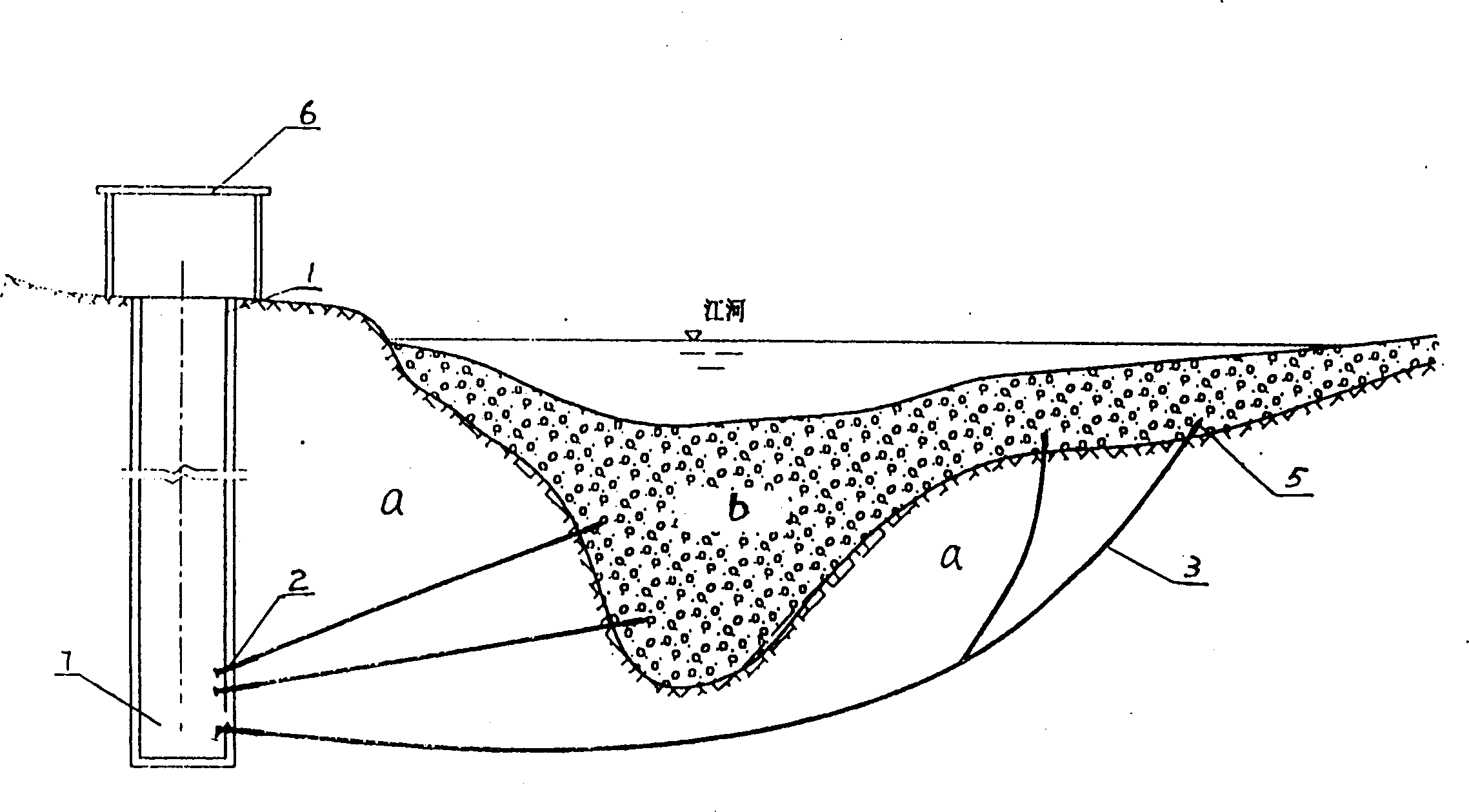

Percolation water intaking method of new engineering structure

InactiveCN1239791CImprove work efficiencyReduce engineering costsWater/sewage treatmentPumping plantsEcological environmentWater quality

The present invention relates to underground water taking and collecting method, and is new engineering structure for taking percolation water. The present invention features that the collecting well is embedded into base rock stratum for at least 5 m, controlled directional percolation holes are drilled into grit stratum under the base rock stratum around the well, and filters are set in the hole parts corresponding to the water bearing stratums. The said engineering structure makes the taken underground water need no further processing in the water producing system, and has the merits of both radiation well and natural filtering bed percolation well, including simple engineering structure, being safe and reliable, no damage to ecological environment, etc.

Owner:重庆泓源渗滤取水科技有限公司

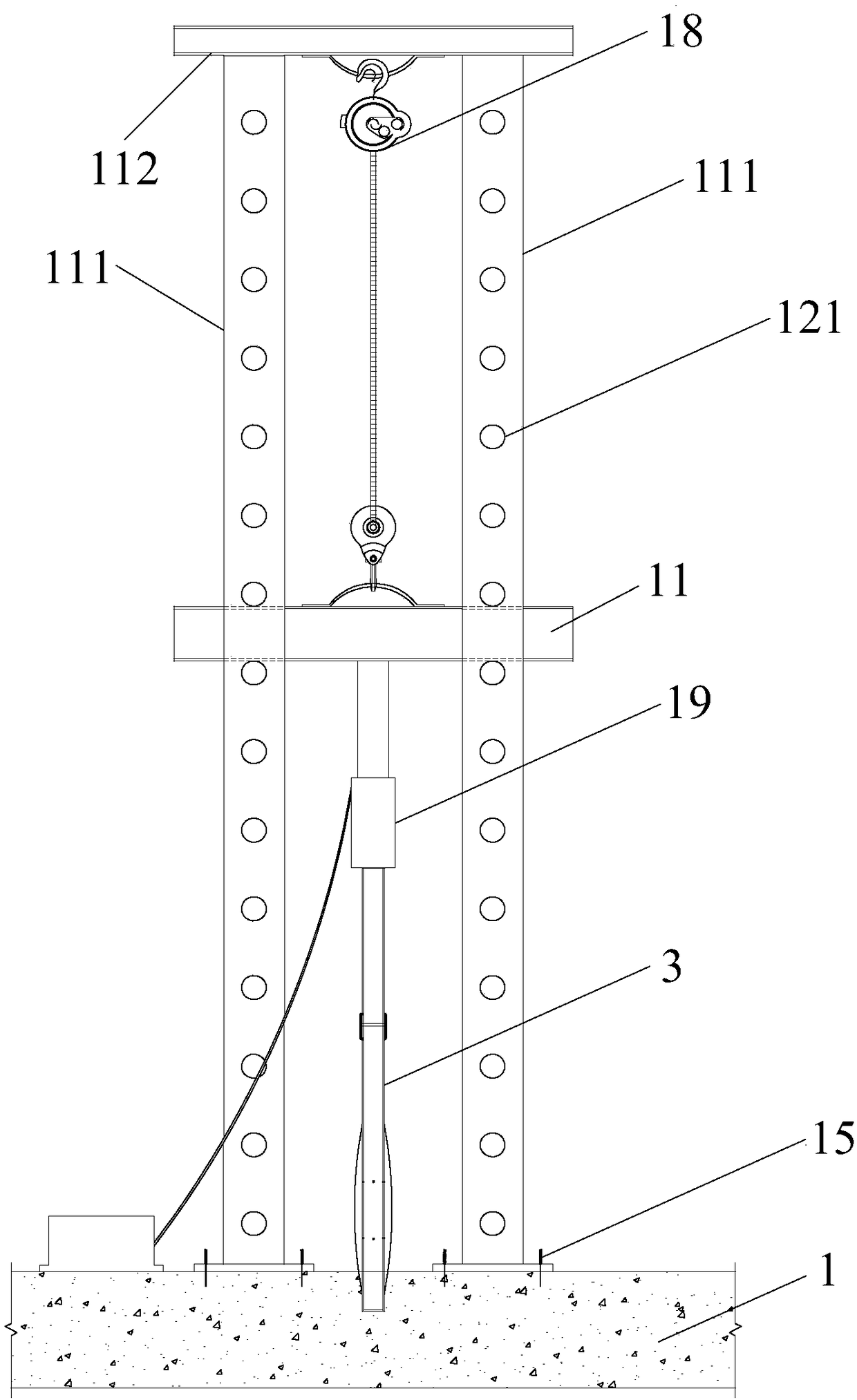

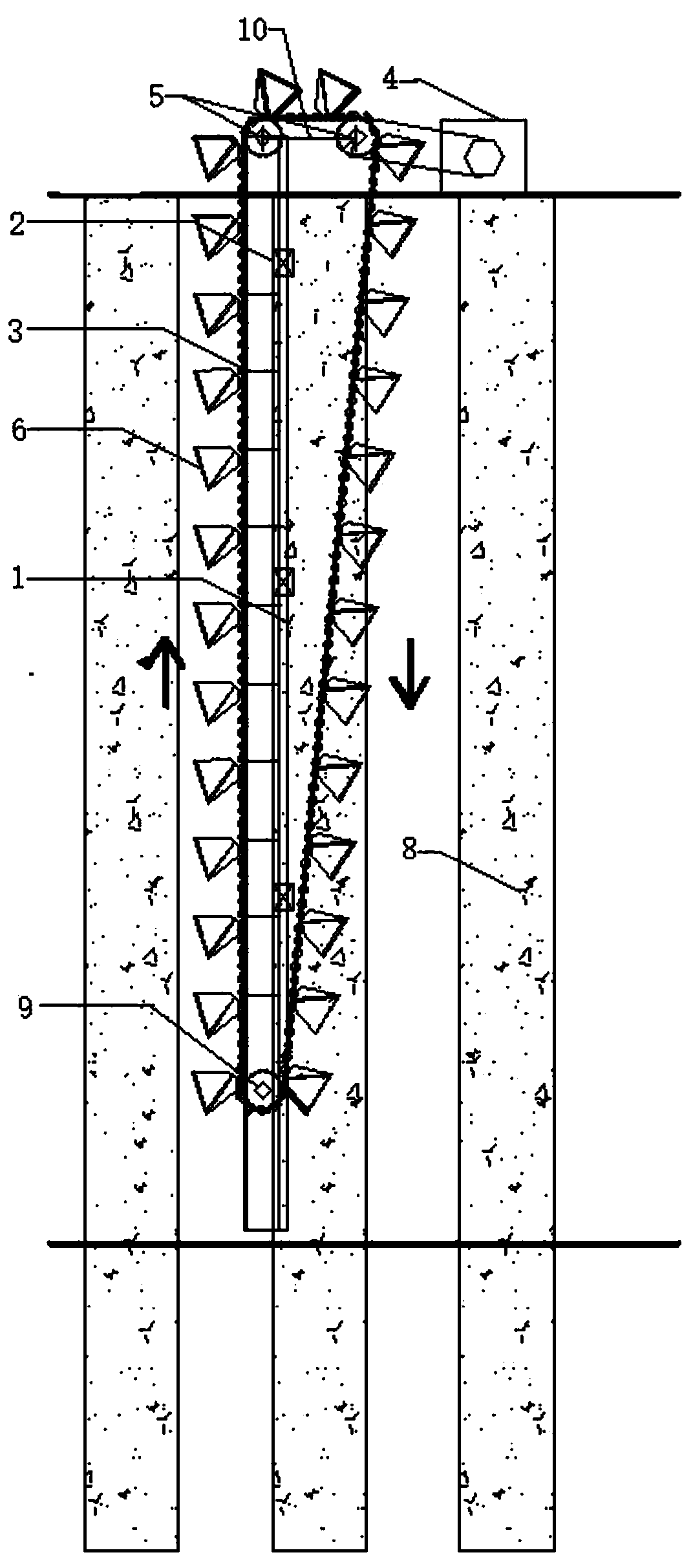

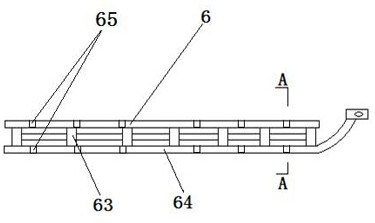

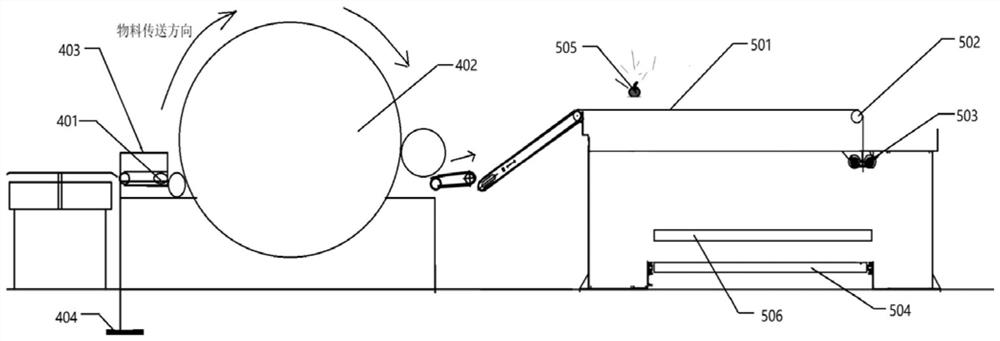

Deep foundation pit earthwork vertical soil sampling equipment

PendingCN109720781AEfficient vertical transportImprove transportation efficiencyConveyorsStructural engineering

The invention discloses deep foundation pit earthwork vertical soil sampling equipment. The equipment comprises attached pieces fixed to a foundation pit supporting structure or a retaining structure,a framework vertically stretching into a foundation pit and mounted on the attached pieces, a lower roller arranged at the bottom of the framework, two upper rollers arranged at an outlet of the foundation pit, a driving mechanism driving the upper rollers to rotate, and a traction chain wound on the lower roller and two upper rollers in a closed mode, hoppers uniformly distributed on the traction chain, a chute located between the two upper rollers, and a soil connecting tank connected with the tail end of the chute. The upper rollers can drive the traction chain to move while rotating, theedges of openings of the hoppers are hinged to the traction chain, the openings of the hoppers on the rising side of the traction chain face upwards, the openings of the hopers on the falling side face downwards, the hoppers can sample soil when winding across the lower roller and can pour the sampled soil into the chute when winding across the first upper roller, efficient vertical transporting of deep foundation pit earthwork is achieved through the equipment, a required operating surface is small, the transporting efficiency is high, the structure is simple, and mounting is convenient.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Off-line assembling method of large flotation machine rotor

ActiveCN103920600AImprove construction efficiencyTake advantage ofFlotationEngineeringSpace operations

The invention relates to an off-line assembling method of a large flotation machine rotor. The assembling method includes the steps that (1) a special supporting device is manufactured; (2) the large flotation machine rotor is assembled; (3) a flotation machine barrel is installed on an equipment installing site in a factory building; (4) the assembled rotor and the support are stored and transported integrally, after arriving at the equipment installing site in the factory building, linkage bolts of the rotor and the support are loosened, and the rotor is hoisted to the flotation machine barrel through a lug to finish assembly of the large flotation machine rotor. The rotor assembled in an off-line mode in advance is installed in an on-line mode on the equipment installing site in the factory building. Because off-line assembly and on-line installation are not on the same working face, the occupied area of operation face of the installation site is small, so that construction equipment, manpower and other resources are used sufficiently, construction efficiency of on-line installation of the rotor is improved, the overall installation construction period of flotation equipment is shortened, meanwhile, intersection, high-altitude and limited space operation is reduced, and safety risks of construction are reduced.

Owner:MCC TIANGONG GROUP

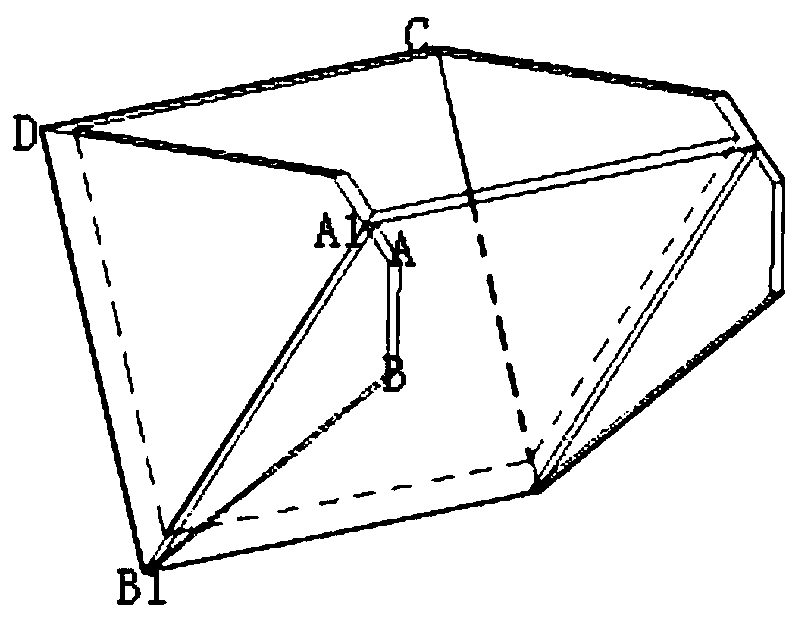

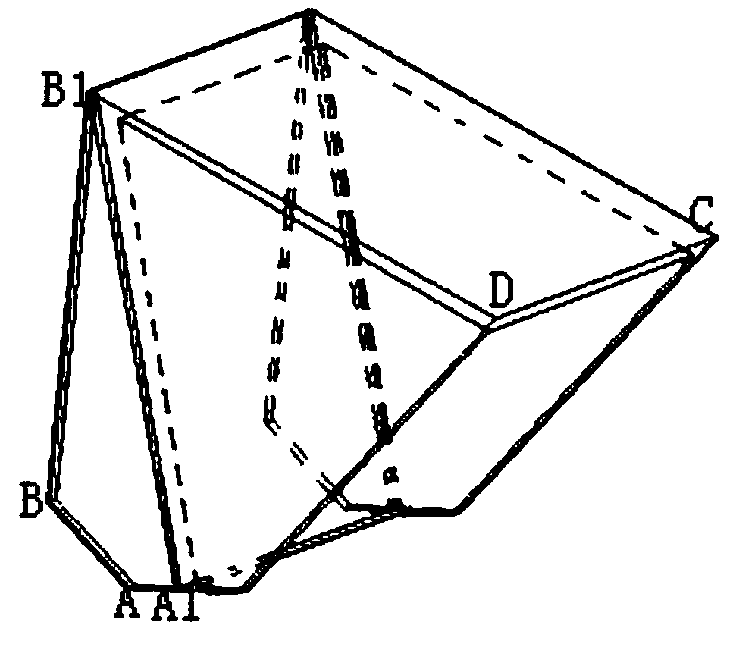

Prefabricated assembled tunnel and construction method thereof

InactiveCN111305870AReduce the impactReduce construction conditionsUnderground chambersTunnel liningArchitectural engineeringFastener

The invention relates to a prefabricated assembled tunnel and a construction method thereof. The tunnel comprises a plurality of prefabricated plates. Each prefabricated plate comprises upper cover plates and vertical supporting plates, wherein a segment bin is defined by at least two vertical supporting plates and at least one upper cover plate. In one segment bin, a bottom plate is arranged between the lower end portions of two adjacent vertical supporting plates. In one segment bin, the upper ends of the vertical supporting plates support the upper cover plates, and vertical fastening pieces are connected between the upper cover plates and the vertical supporting plates. The multiple segment bins are spliced into the tunnel in the longitudinal direction, and longitudinal fastening pieces are connected between two adjacent segment bins. Compared with an existing open cutting cast-in-place construction manner, the construction quality can be optimized, and the advantages that the construction period is short, and influences on the environment are weak are achieved.

Owner:GUANGZHOU NO 2 MUNICIPAL ENG CO LTD

Concrete roofing and ground anti-seepage leak-proof agent and anti-seepage leak-proof method

InactiveCN105952174AImprove liquidityImprove ductilityBuilding repairsEnvironmental engineeringCement

The invention relates to a concrete roofing and ground anti-seepage leak-proof agent and an anti-seepage leak-proof method. The anti-seepage leak-proof agent is made of tung oil and cement. The invention also provides an anti-seepage leak-proof method. By means of the provided anti-seepage leak-proof agent, the anti-seepage leak-proof structure and method, the anti-seepage leak-proof agent can penetrate in cracks and be well combined with concrete roofing or ground into one body; the invention has advantages such as anti-demixing or anti-aging, and lasting anti-seepage effect.

Owner:卢武策

House shallow vertical punching sand pumping deskewing device and method

PendingCN110847260ASimple structureEasy to implementSoil preservationHigh pressure waterAir compressor

The invention discloses a house shallow vertical punching sand pumping deskewing device and method. The house shallow vertical punching sand pumping deskewing device comprises a water supply system, an air compressor and steel sleeves, wherein the water supply system comprises a water tank, a water pump, a main water supply pipe, a high-pressure pipe and water flushing pipes; the water pump is arranged in the water tank; one end of the high-pressure pipe is connected with the water pump; the other end of the high-pressure pipe is connected with the main water supply pipe; a plurality of waterflushing pipes are connected onto the main water supply pipe; the other end of each water flushing pipe is inserted into the steel sleeve; each steel sleeve is arranged in a soil taking hole in an inserted and connected way; and a flow dividing pipe is arranged on each water flushing pipe, and is connected with the air compressor. High pressure water and high pressure air are used for performing water flushing and air inflation onto a substrate; substrate sand is pumped out; soil grooves are gradually formed one by one; the stress state of foundation soil is changed through strong compaction and lateral extrusion of residual contact soil; the foundation is promoted to continuously and slowly generate forced settlement; the structure and the method are simple; the implementation is easy; the cost is low; and the environmental pollution is small.

Owner:杭州圣基建筑特种工程有限公司

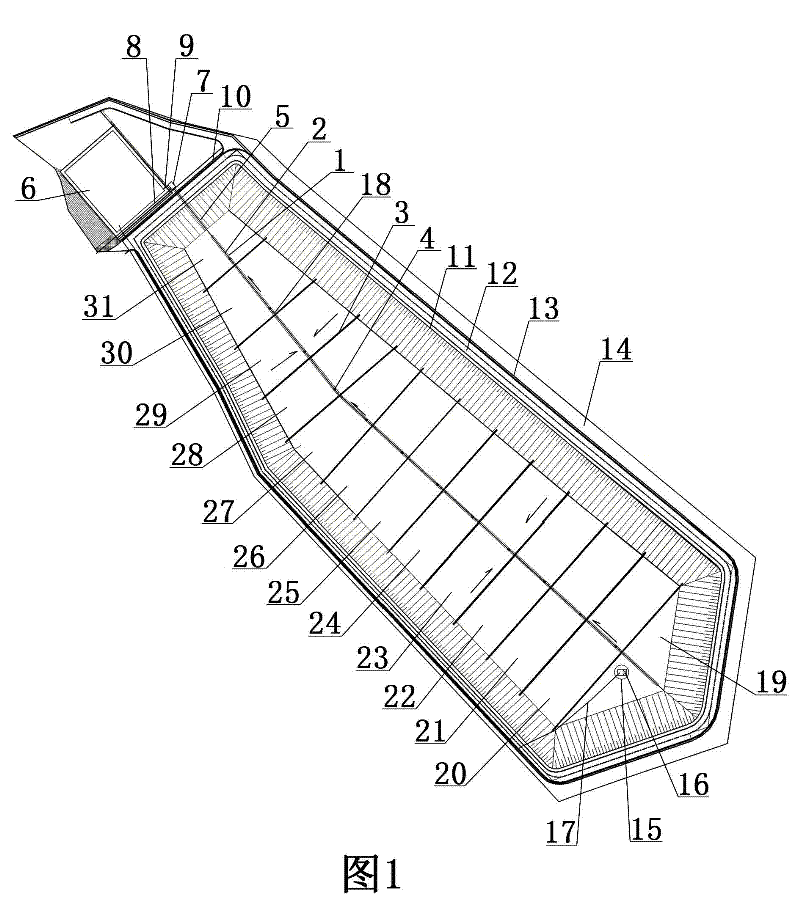

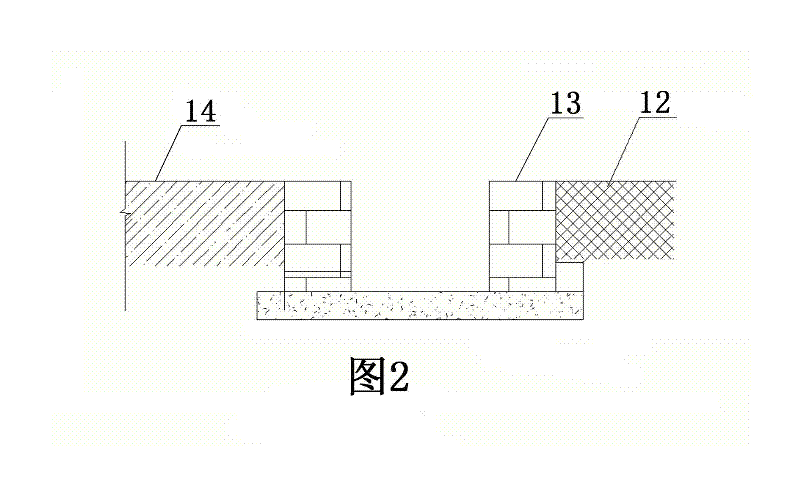

Construction process of precast concrete channel

InactiveCN105544701ANot affectedEasy constructionArtificial water canalsSewer pipelinesReinforced concreteCrushed stone

The invention provides a construction process of a precast concrete channel. The construction process comprises the following steps: a, sectioning, namely, according to the load capacity of a vertical transportation machine, reasonably sectioning according to the length of a channel, wherein the channel refers to a reinforced concrete channel; b, channel processing, namely, processing and precasting the sectioned channels in a sectioning mode and in a template form, and pre-burying embedded parts on the two sides of the connecting openings of the channels, wherein the connecting openings are designed according to the seaming process; c, foundation treatment and cushion layer construction, namely, excavating out the soft soil of the cushion layers of the channel, filling the cushion layers with sand or broken stone and leveling, tamping in layers till the compactness satisfying the design requirement is achieved, and pouring the cushion layers of the channels; d, surveying and positioning; e, hoisting in-position of the sectioned channels; f, connecting and fixing; and g, acceptance inspection. According to the construction process of the precast concrete channel, the construction is convenient and rapid, the quality of the product is effectively controlled, and the influences of weather and geographical environments are eliminated; the construction speed is high, and the influences caused by mounting civil engineering cross constructions are reduced to the minimum; good anti-permeability and anti-seismic property are achieved; the working plane is small, and the influences to the surrounding environment are low.

Owner:CHINA ENERGY ENG GRP TIANJIN ELECTRIC POWER CONSTR CO LTD

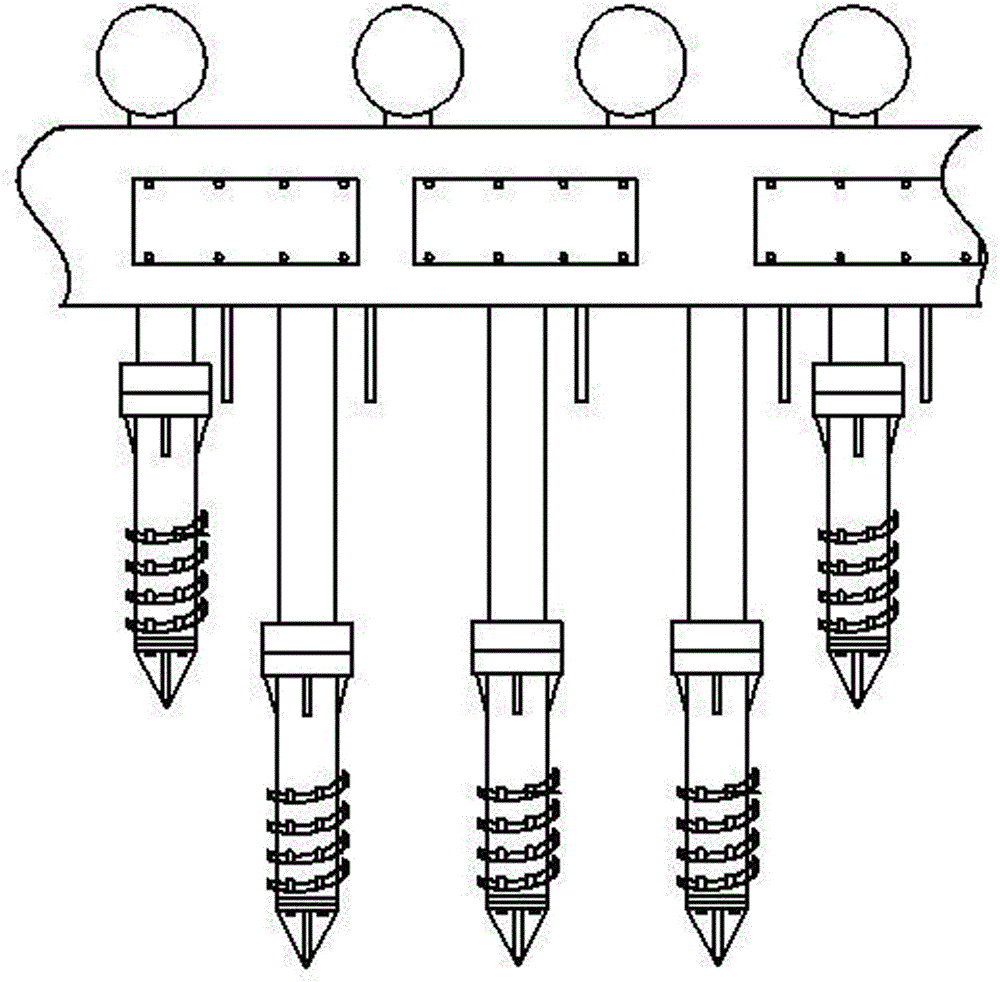

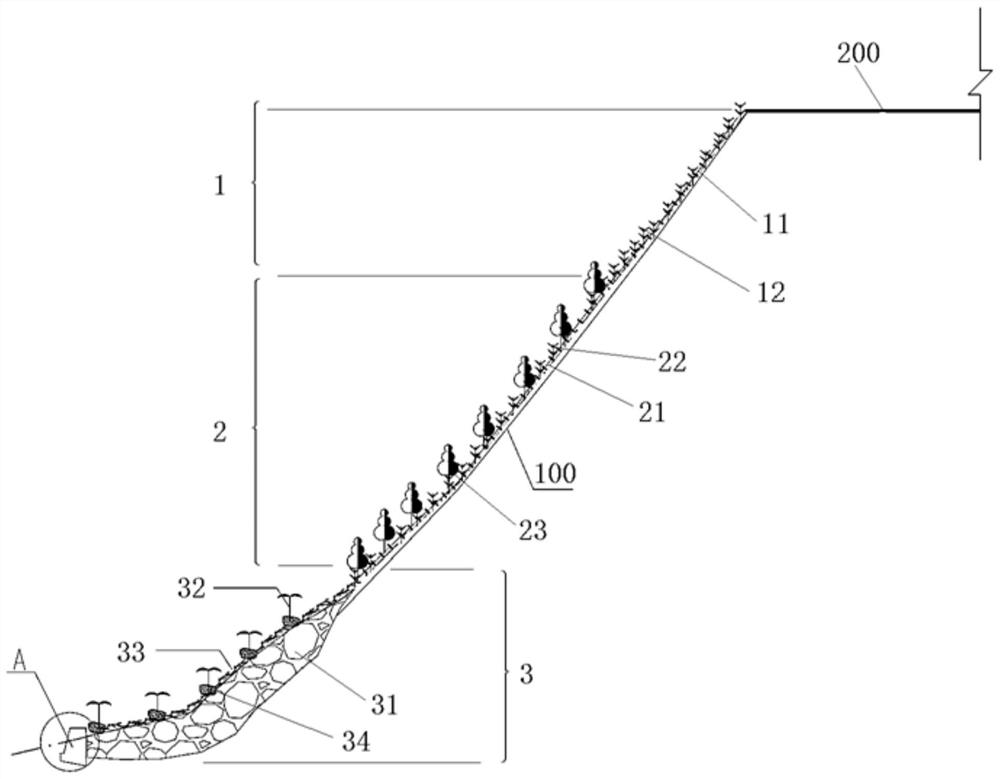

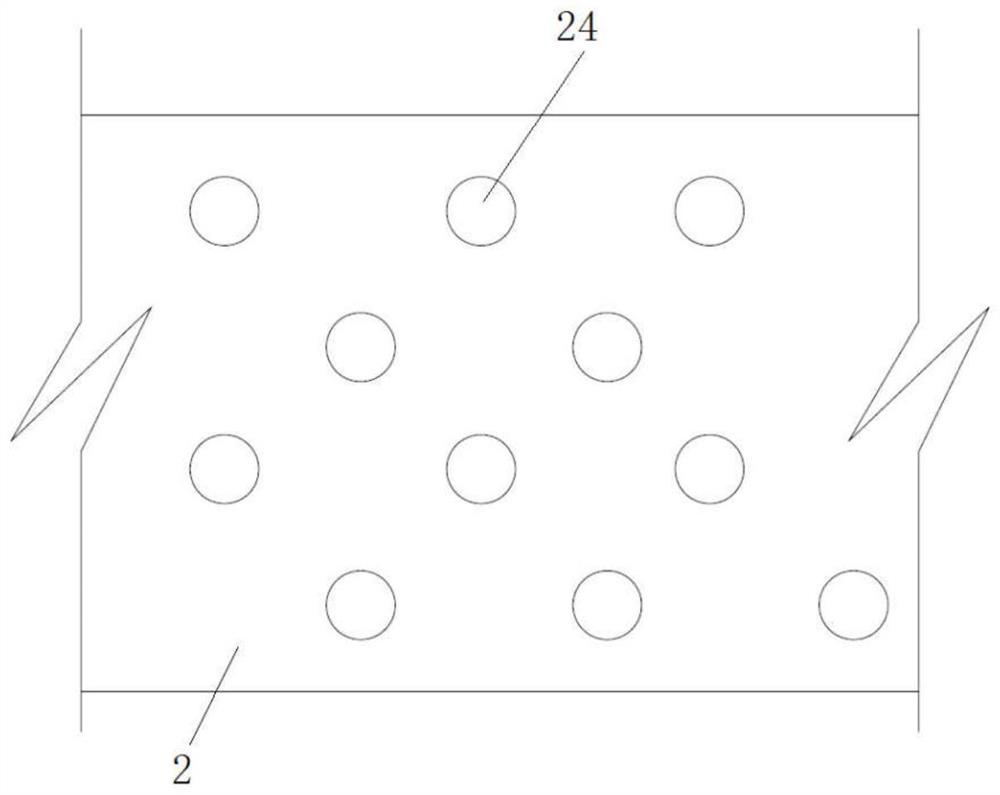

Rapid greening protection slope for oligotrophic soil slope as well as construction method thereof

PendingCN107975051ASmall work areaFast constructionRoot feedersGrowth substratesRoot systemSoil horizon

The invention belongs to the technical field of slope greening, and in particular relates to rapid greening protection slope for an oligotrophic soil slope as well as a construction method thereof. The existing slope protection technology has the defect that the stability is low because a vegetation root system and the oligotrophic soil slope form a whole body difficultly. According to the technical scheme of the invention, the rapid greening protection slope for the oligotrophic soil slope comprises a three-dimensional geonet, nutritional soil columns, spiral steel piles and a base material layer; the nutritional soil columns and the spiral steel piles are arranged in soil below the three-dimensional geonet in a drilling way; the base material layer is arranged on the three-dimensional geonet; and the base material layer comprises a nutritional soil layer and a grass seed layer. The spiral steel piles are blade type spiral steel piles. The nutritional soil columns and the base material layer provide nutrition for the growth of vegetations on the oligotrophic soil slope and can promote rapid development of the slope vegetation root system. After the vegetations grow up, the root system, the vegetations, the three-dimensional geonet, the spiral steel piles and the slope form a whole body. The rapid greening protection slope for the oligotrophic soil slope is suitable for greening and slope protection under the oligotrophic soil environment.

Owner:GUYUAN CHENTONG TECH DEV CO LTD

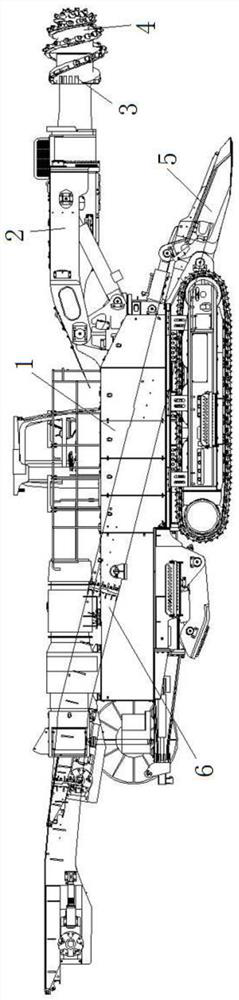

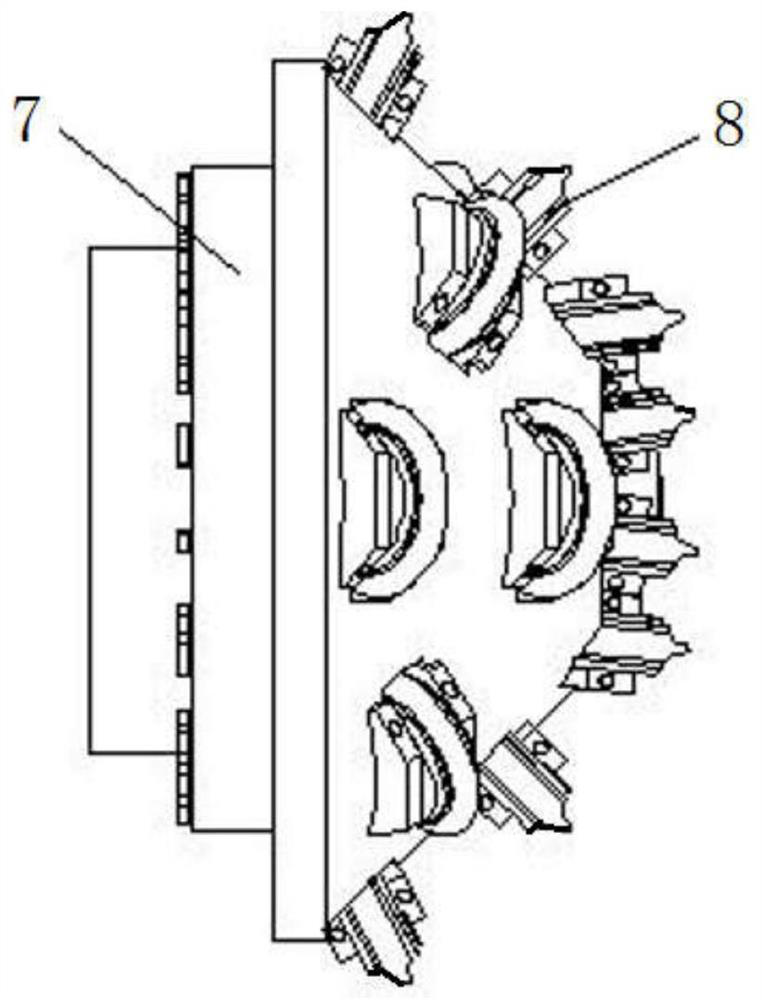

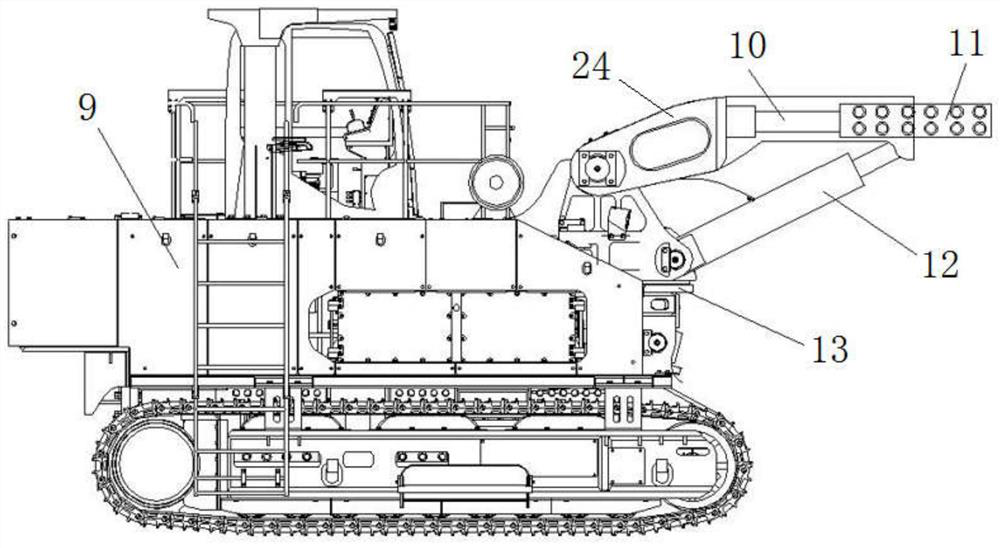

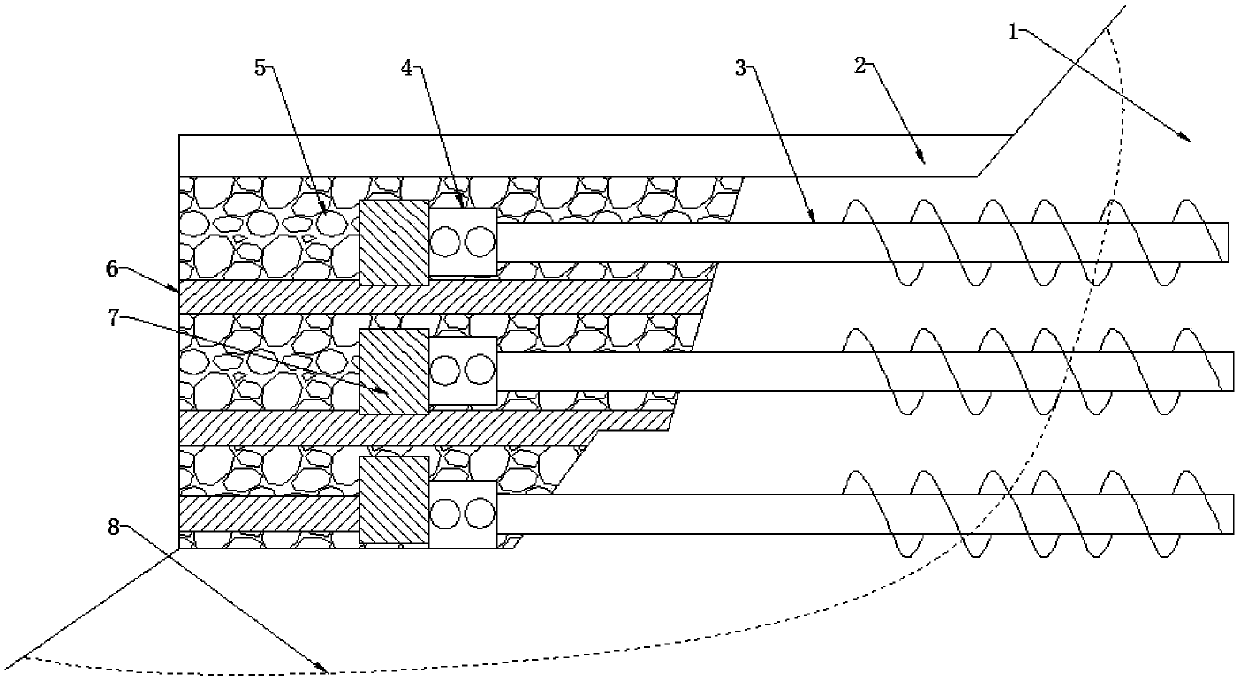

Swelling and pressing rock breaking equipment and tunnel swelling and pressing rock breaking construction method

InactiveCN113356847AImprove adaptabilityReduce wearDisloding machinesSlitting machinesSlagStructural engineering

The invention provides swelling and pressing rock breaking equipment and a tunnel swelling and pressing rock breaking construction method. The swelling and pressing rock breaking equipment comprises a rock breaking vehicle body (9), a mechanical arm (24) and a hydraulic swelling and breaking device (11) which are sequentially arranged; the mechanical arm (24) can make the hydraulic swelling and breaking device (11) move up and down; the hydraulic swelling and breaking device (11) comprises an outer shell (16); and piston rods (17) are arranged on the left side and the right side or the two sides of the outer shell (16) and can stretch and retract in the left-right direction. The tunnel swelling and pressing rock breaking construction method comprises the steps that firstly, a vertical groove and an annular groove are dug in a tunnel face; secondly, the swelling and pressing rock breaking equipment acts on a formed cutting groove, a rock ridge is swelled and broken through hydraulic extrusion, and rock slag falls off from the tunnel face; and finally, the rock slag is cleared out of a tunnel through a forklift and a slag conveying vehicle, and excavation of the whole tunnel can be completed through repeated actions. Abrasion of metal cutters can be reduced, and the construction efficiency can be improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

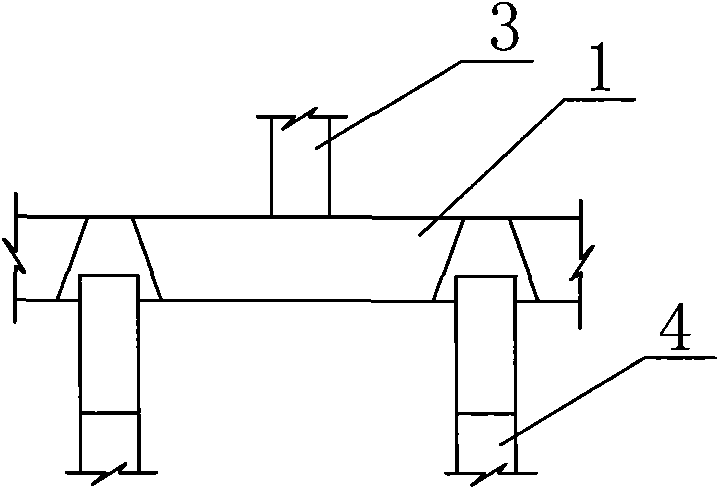

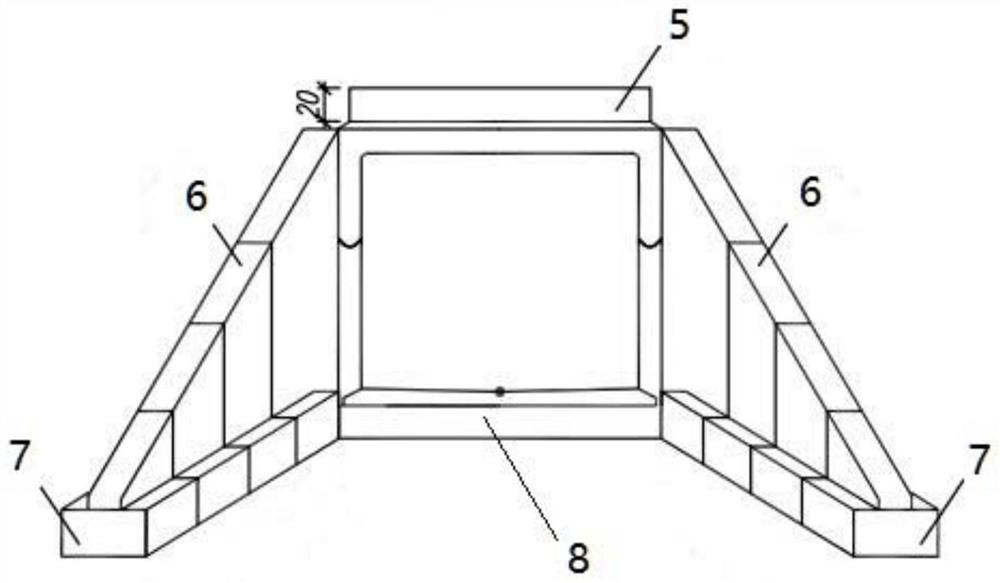

Prefabricated installation construction method for fabricated box culvert

The invention discloses an assembly type box culvert prefabrication installation construction method, an assembly type box culvert comprises a plurality of mutually connected box culvert sections and holes at two ends, each box culvert section comprises a top plate, a bottom plate and side walls, two ends of each top plate are respectively spliced with the side walls, the bottoms of the two side walls are in cast-in-place connection, a cast-in-place part is the bottom plate, and a cast-in-place part is connected with the bottom plate; the top plates, the bottom plate and the two side walls form a box-shaped channel, supporting feet protruding outwards are arranged at the bottoms of the side walls, two connectors of the top plates and the side walls are in an elbow shape and are freely hinged, and when different box-shaped culvert sections are connected, the top plates are connected through bent bolts. Prefabrication can be performed in the field in advance, the construction time is greatly shortened, the construction period is shortened, and civilized and green construction is promoted; during excavation construction, the working face is small, and damage and pollution to ground surface underground water and soil are greatly reduced; the quality of the culvert can be effectively improved, the appearance and the percent of pass of a protective layer are greatly improved, and good economic and social benefits are achieved.

Owner:CHINA FIRST HIGHWAY ENG

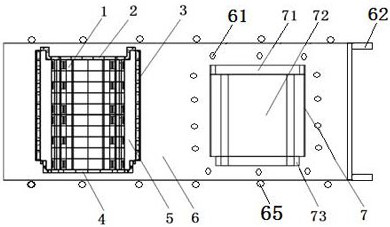

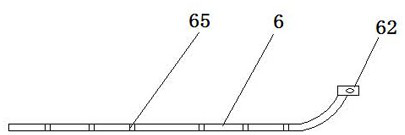

Movable improved fabricated box culvert formwork and construction method thereof

PendingCN114855658AReduce shipping costsSimplify cumbersome processGround-workUnderground chambersArchitectural engineeringPrefabrication

The invention relates to a movable improved assembly type box culvert template and a construction method thereof, the movable improved assembly type box culvert template comprises a threaded pull rod, a bolt and a nut, and the movable improved assembly type box culvert template further comprises a movable base table, an outer template, an inner template, a concave end template and a convex end template, according to the cast box culvert, construction of a transportation road and prefabrication factory construction do not need to be carried out, casting, maintenance and installation of the box culvert can be completed beside a foundation pit where a box culvert line is arranged, and synchronous propelling can be kept along with propelling of a construction line; the transportation cost can be reduced, the tedious process is simplified, and the construction speed is increased.

Owner:NO 1 ENG CO LTD OF FHEC OF CCCC

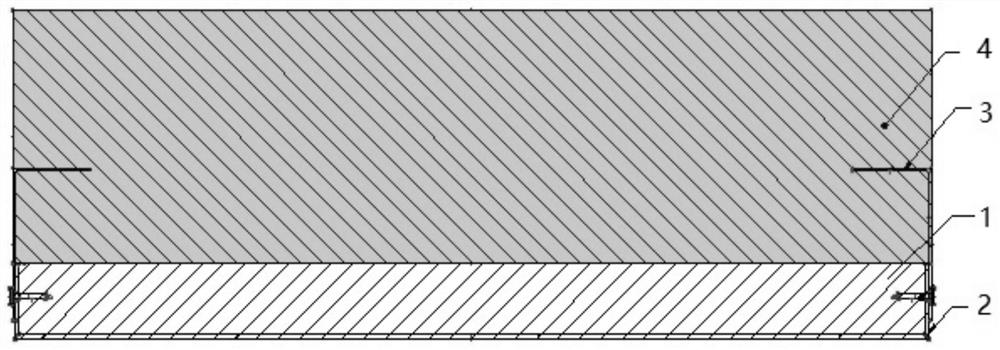

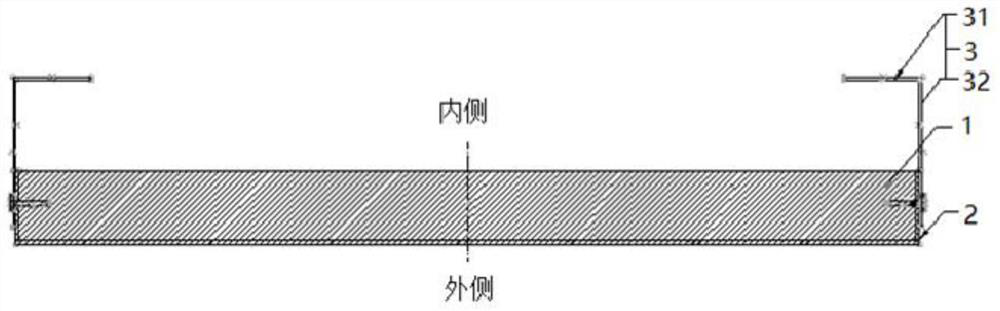

A prefabricated building exterior wall

ActiveCN112031265BEasy constructionQuality is easy to controlDischarging arrangementFeeding arrangmentsFiberThermal insulation

The invention provides an exterior wall of a prefabricated building, which includes a thermal insulation board, a cover layer, an L-shaped embedded part and a cement layer. For all the panels except the inner panels, the L-shaped embedded parts include intersecting inner arms and outer arms. The length of the outer arms is greater than the thickness of the insulation board. On the wall, the end connecting the inner arm faces the cement layer inside the insulation board, the free end of the inner arm is inserted into the cement layer, and the insulation board, cover layer, L-shaped embedded part and cement are connected through the connecting piece pierced by the L-shaped embedded part. Layers are connected as one. The insulation board includes 100 parts of inorganic fiber and 1-13 parts of phenolic resin. The prefabricated building exterior wall in the present invention, through a reasonable structural layout, makes the structure of the prefabricated exterior wall simple, the exterior wall processing is convenient, combined with the new thermal insulation material, the fire prevention, isolation and mechanical properties are greatly improved.

Owner:BEIJING SATELLITE MFG FACTORY

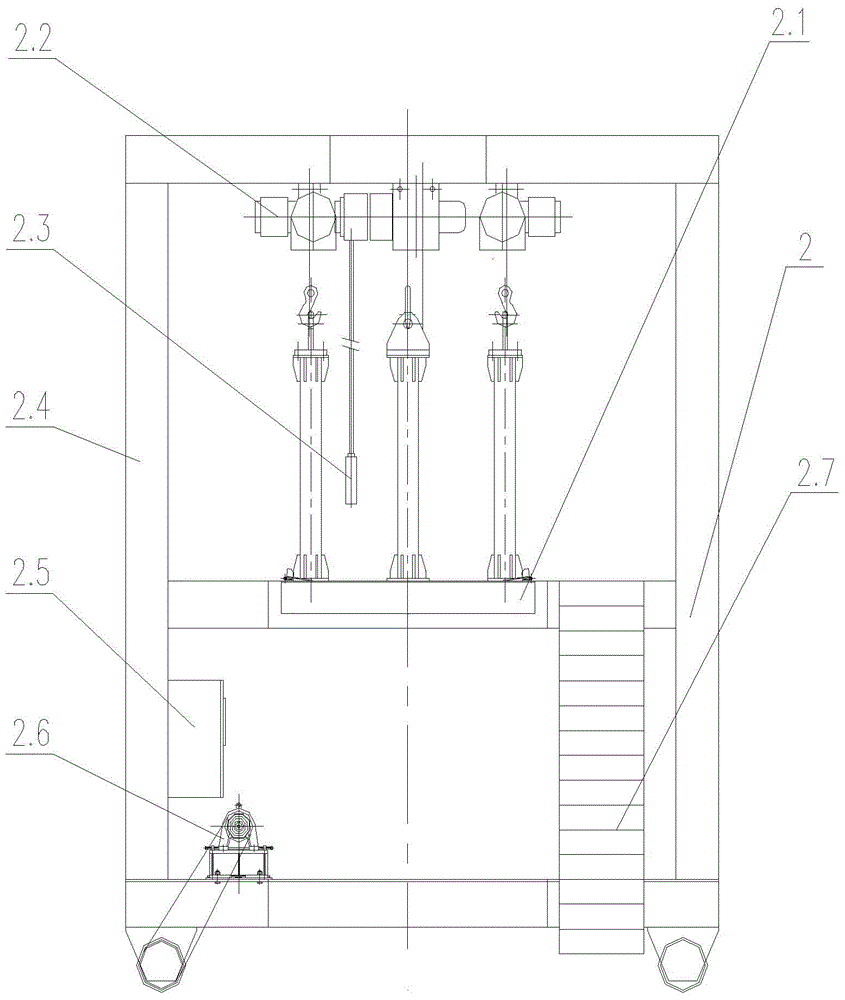

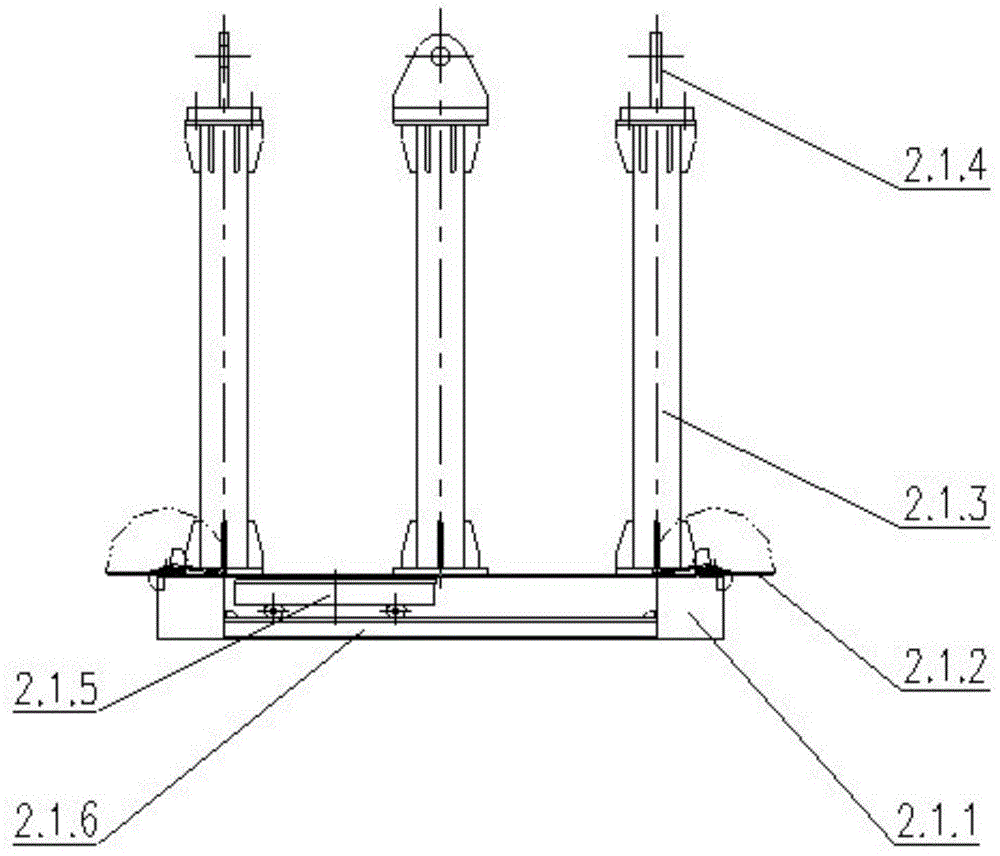

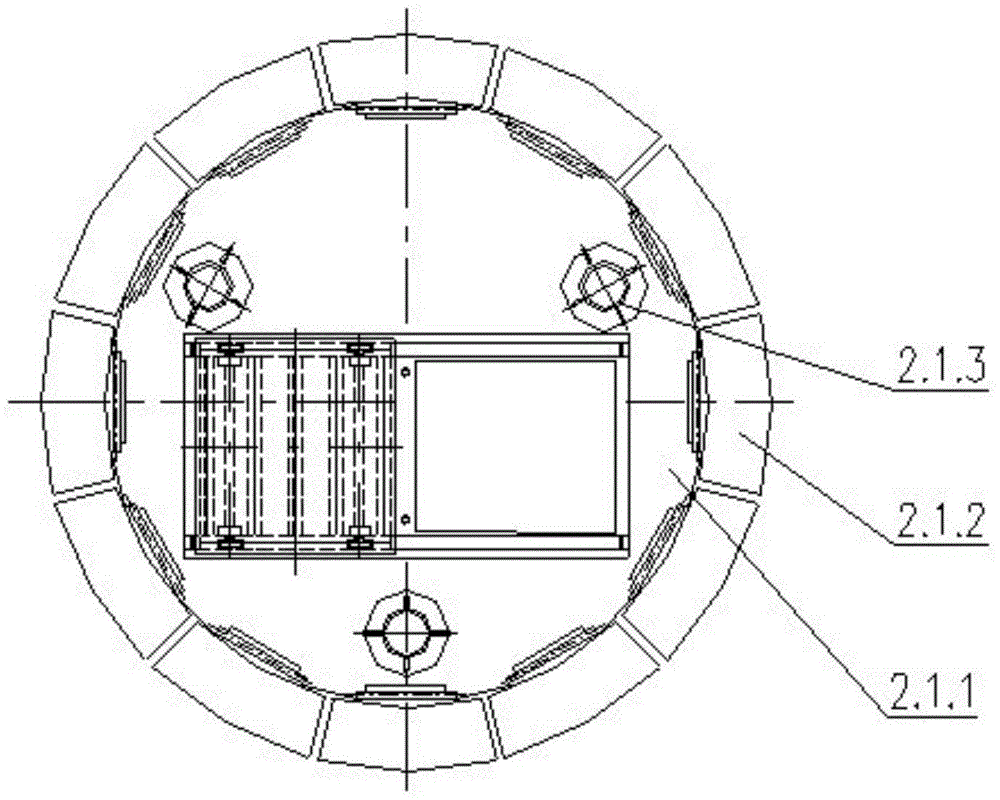

A rh vacuum tank repairing device

ActiveCN104726647BShorten the lifting strokeReduce the overall heightVehicle frameArchitectural engineering

The invention discloses an RH vacuum tank building device. The RH vacuum tank building device comprises a building trolley, wherein the building trolley comprises a frame; the frame is a three-layer steel structure frame; a lifting mechanism is fixed on the top layer, and a lifting platform is hung on the lifting mechanism; the lifting mechanism is electrically connected with a lifting controller and is controlled by the lifting controller; a mobile controller and a driving mechanism are installed on the bottom layer of the frame; the driving mechanism is electrically connected with the mobile controller and is controlled by the mobile controller; a straight ladder is arranged between the middle layer and the bottom layer of the frame. The driving mechanism is controlled by the mobile controller, so that the building trolley is horizontally moved to the building position; the lifting mechanism is controlled by the lifting controller for providing power to the lifting platform, and then the lifting mechanism is declined from the upper tank to the tank body and the worker can enter the tank; when the lifting platform reaches the position near the bottom part of the lower tank, a cover plate trolley is moved away, and the worker descends to the bottom part of the lower tank to build through an opened manhole. The tank body placing position and the work plane height are reduced and the lifting route of the building platform is shortened. The RH vacuum tank building device has the characteristics of reliable lifting and convenient and safe operation.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

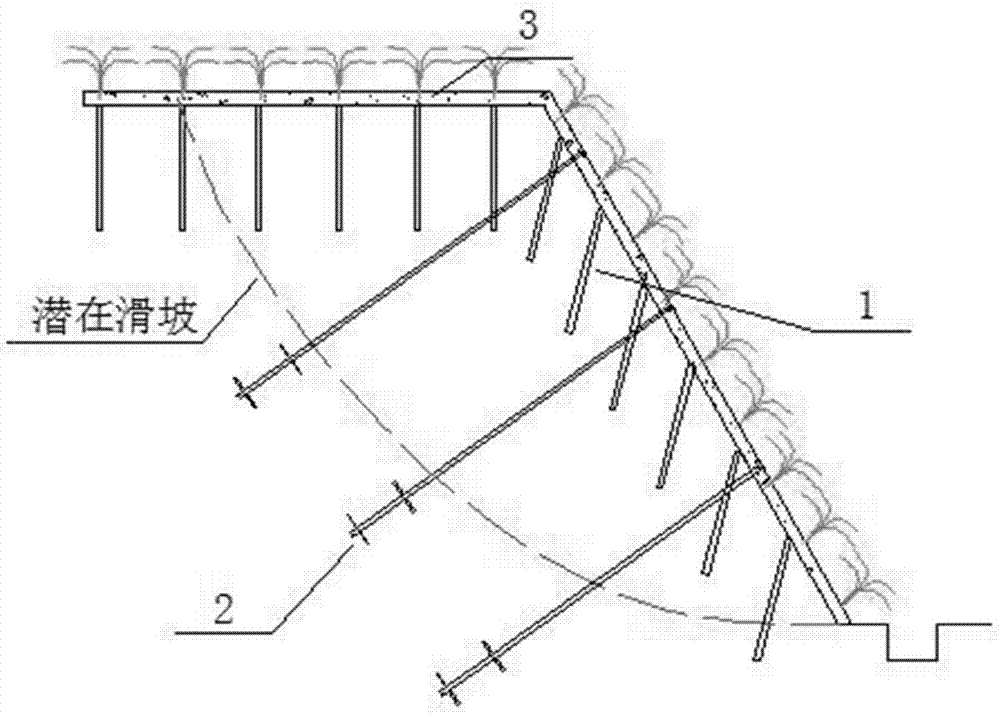

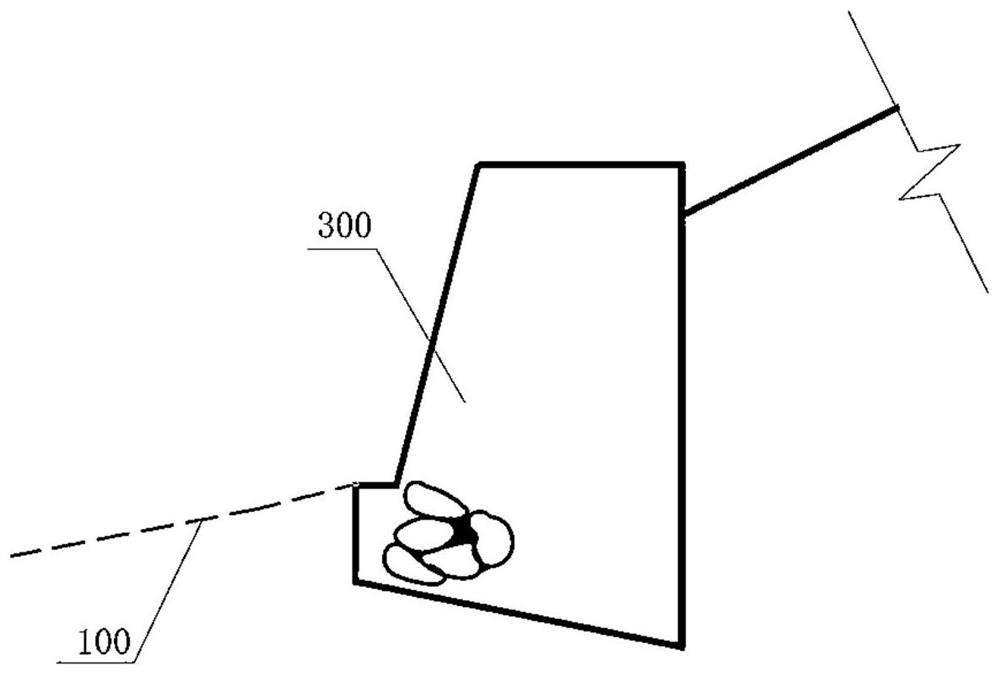

Cast-in-situ lightweight concrete structure based on spiral steel piles and construction method thereof

The invention discloses a cast-in-situ lightweight concrete structure based on spiral steel piles and a construction method thereof, belonging to the technical field of slope roadbed strengthening, and solving the filling problem of high roadbeds of a high speed railway or a high way on a steep slope. The concrete structure comprises lightweight concrete casted on the side surface of a potential landslide layer of an original slope, wherein an upper structure is arranged at the upper end of the lightweight concrete, connecting rods are arranged at one end, close to the potential landslide layer, of the lightweight concrete, and a plurality of inversely-hung rapid joints are arranged on the connecting rods and are connected with spiral steel piles. According to the concrete structure, the advantages that cast-in-situ lightweight concrete is low in density, high in strength and low in construction disturbance and can be vertically casted can be adequately utilized, and meanwhile, the advantages that the spiral steel pile is wide in applicability, small in work plane, high in construction speed and good in durability are utilized, so that the stability of the original slope is improved, and the integrity of a lightweight concrete embankment and the original slope is improved.

Owner:GUYUAN CHENTONG TECH DEV CO LTD

High and steep gravelly soil slope ecological restoration structure system and restoration method

PendingCN114467609AEnsure stabilityAvoid churnArtificial islandsHops/wine cultivationEnvironmental engineeringSteep slope

The invention discloses an ecological restoration structure system and method for a high and steep gravelly soil slope. The slope of the ecological restoration structure system is divided into an upper area, a middle area and a lower area from top to bottom. The upper area is sequentially provided with a cushion layer and a spray-seeding surface layer from the original ground line to the outside, the spray-seeding surface layer is formed in a spray-seeding mode, and shrub seeds and grass seeds are arranged in the surface layer; a transverse drainage ditch and a plurality of holes are formed in the slope surface of the middle area, and shrub seedlings and grass seedlings are planted in the holes in a hill-seeding mode; the lower area is provided with a boulder accumulation layer, a plant-growing bag layer is arranged on the boulder accumulation layer, and vines and shrubs are planted in the plant-growing bag layer in a cuttage mode; and a transversely arranged retaining wall is arranged at the slope toe of the lower area. The problems that high and steep slope repairing construction is difficult, and the effect is slow are solved.

Owner:中国水电顾问集团桂阳新能源有限公司

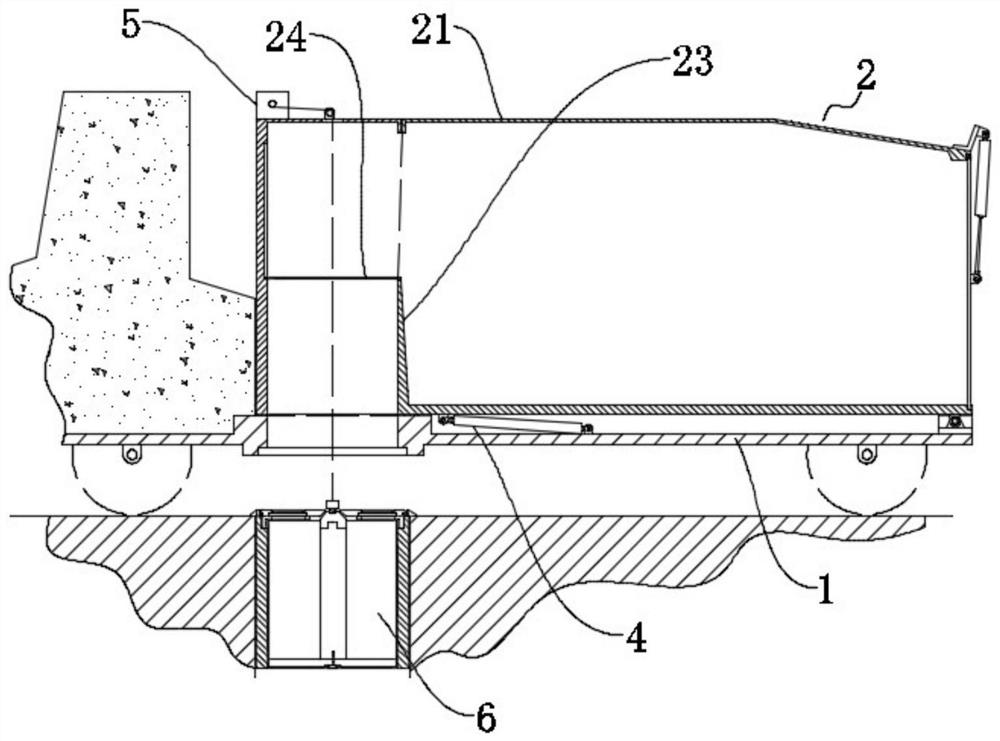

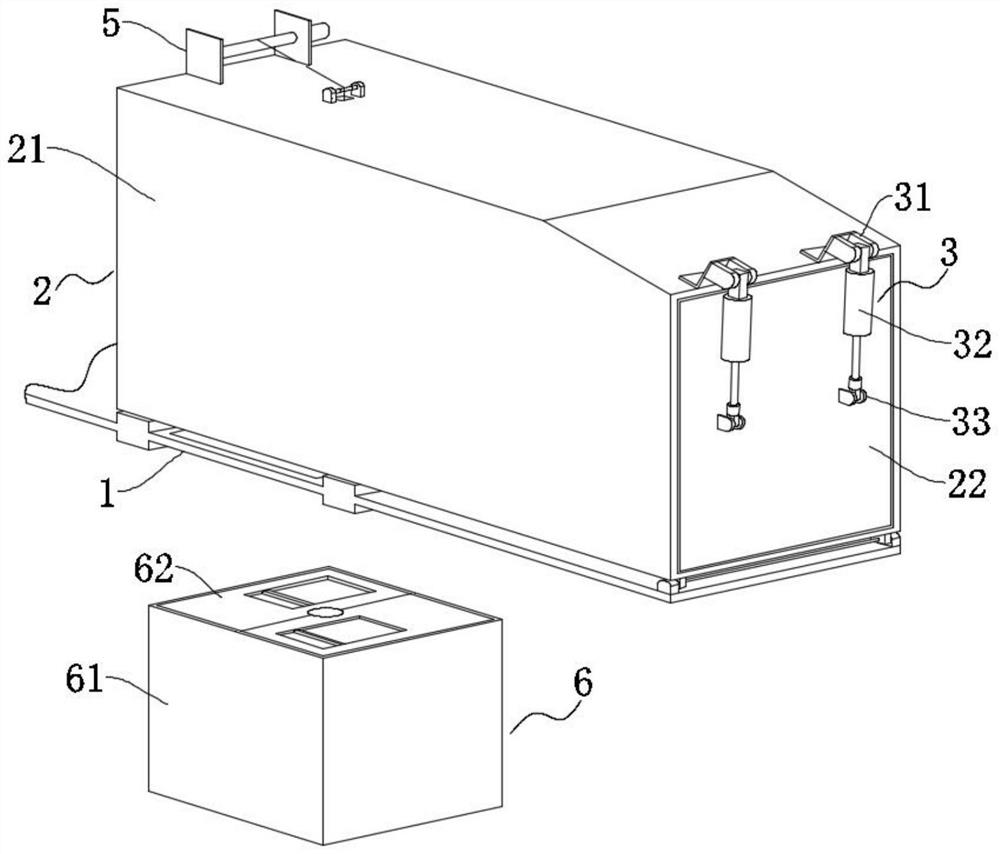

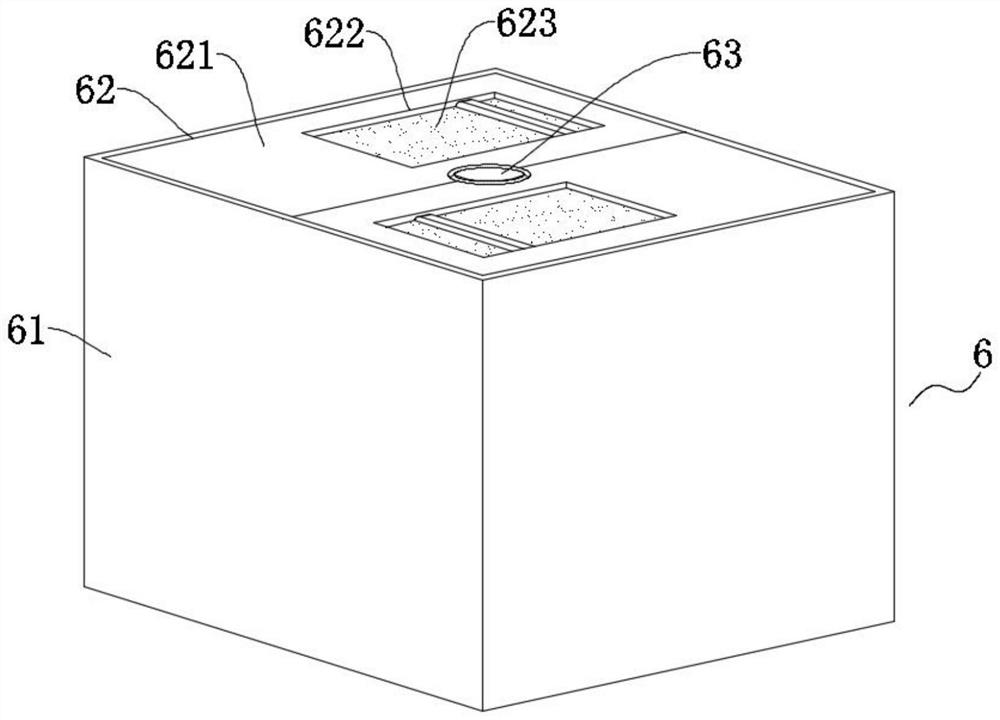

Buried garbage can facilitating garbage collection and garbage collection vehicle

InactiveCN114560210AFast chargingEasy to layWaste collection and transferRefuse receptaclesVehicle frameGarbage collection

The invention relates to the technical field of garbage temporary storage or garbage removal, in particular to a buried garbage can convenient for garbage collection and a garbage collection truck, the buried garbage can convenient for garbage collection comprises a frame and a buried garbage can, the bottom of the frame is provided with a through opening, the frame is movably provided with a garbage hopper, and the garbage hopper comprises a first box body; a partition plate is fixed in the first box body and divides the interior of the first box body into a garbage storage cavity and a garbage throwing cavity, a garbage inlet is formed in the lower surface of the first box body, one end of the garbage inlet is opposite to the through opening, and the other end of the garbage inlet communicates with the garbage throwing cavity; the bottom of one end of the first box body is rotationally connected with the frame through a shaft pin, and a lifting mechanism is assembled on the top of the other end of the first box body. Through mutual cooperation of the garbage collection vehicle and the buried garbage can, quick garbage collection is achieved, laying is facilitated, and the garbage collection vehicle is suitable for large-scale municipal use.

Owner:苏州苏工重工科技有限公司

A prefabricated hydraulic box culvert formwork and a construction method for the prefabricated box culvert

ActiveCN110421687BSave amountSave materialDischarging arrangementGround-workSocial benefitsArchitectural engineering

The invention provides an assembly type hydraulic box culvert template and a construction method of a prefabricated assembly type box culvert of the assembly type hydraulic box culvert template, and belongs to the field of highway engineering construction. The assembly type hydraulic box culvert template comprises a template, a hydraulic power system and an adjusting support. The construction method comprises the steps that the assembly type hydraulic box culvert template is installed; the template is used; steel bars are machined and installed; a steel bar framework is hoisted put into the template; an internal mold is installed; the template is installed while concrete is poured; the concrete is poured; the concrete is cured; and the template is removed, and finally the prefabricated assembly type box culvert is prepared. The box culvert can be prefabricated in a centralized mode, and is installed on site, so that a lot of concrete is saved, the construction progress is accelerated,construction cost is reduced, damage and pollution to underground water and soil are greatly reduced, and the box culvert is especially prominent in green and environment-protecting aspects; and the entity quality of culverts is effectively improved, the yield of the appearance and a protection layer is greatly improved, and good economic and social benefits are obtained.

Owner:INNER MONGOLIA ROAD & BRIDGE

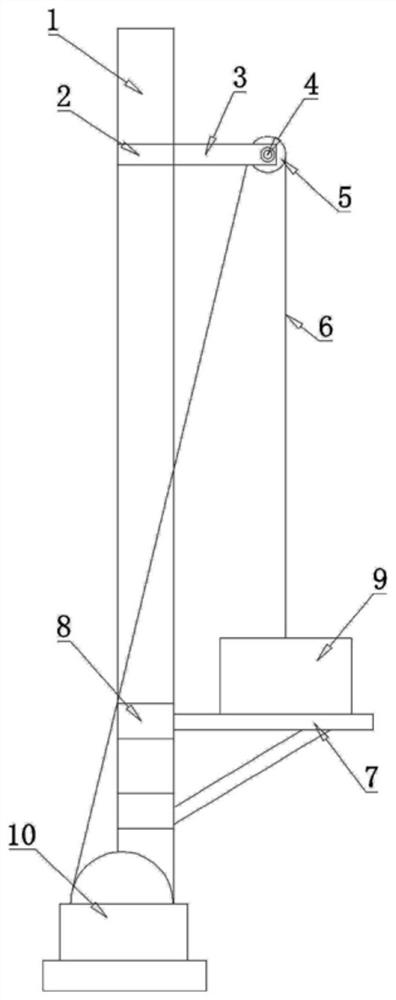

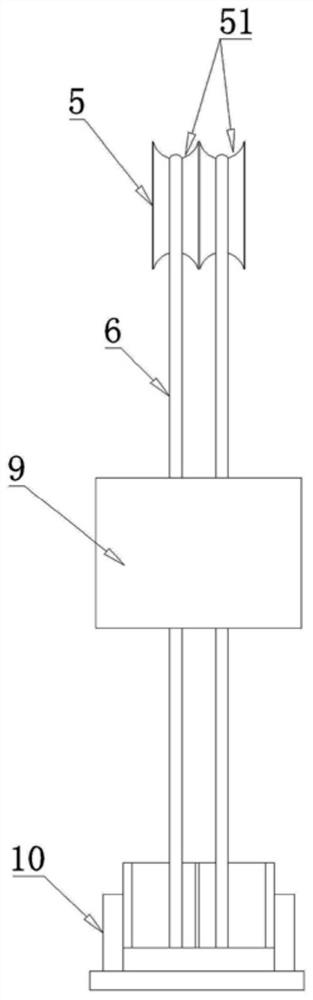

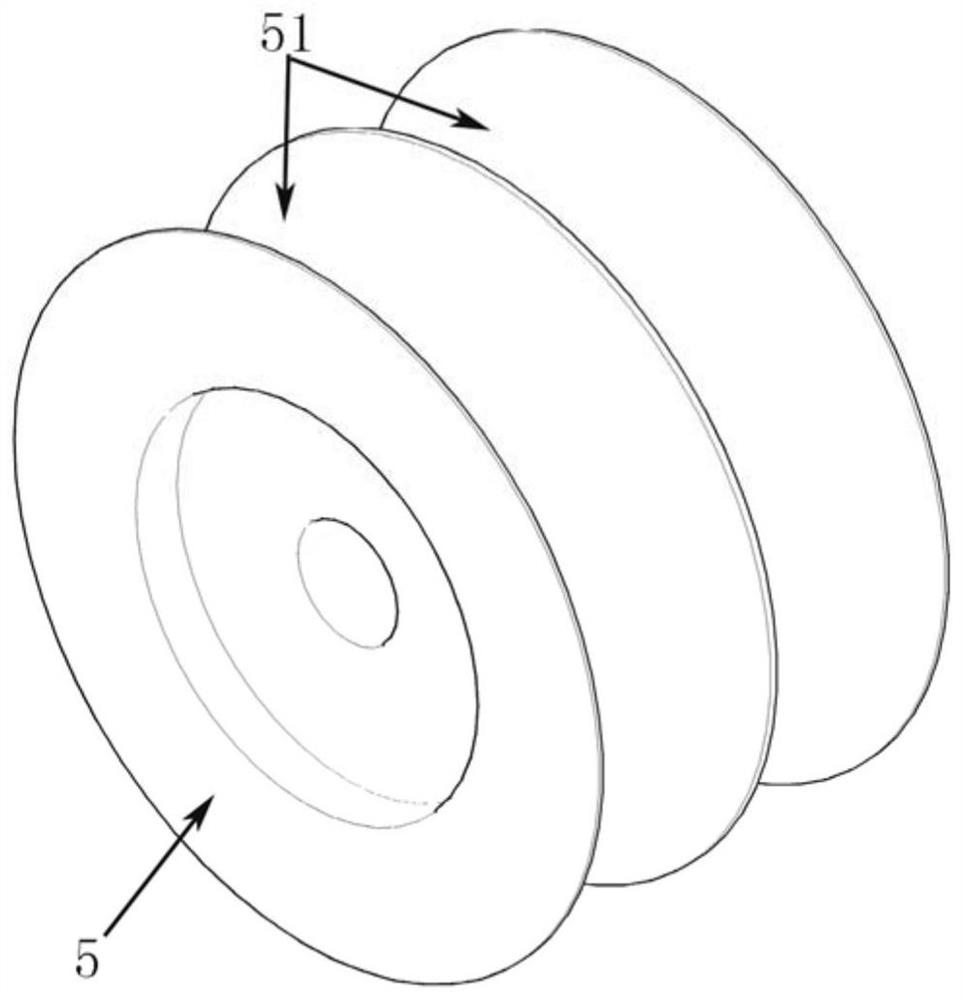

Lifting appliance and method for mounting pole-mounted switch

PendingCN113401826AEnsure personal safetySmall work areaPortable liftingSwitchgearControl theoryPulley

The invention discloses a lifting appliance and method for mounting a pole-mounted switch, and belongs to the technical field of lifting appliances for mounting pole-mounted switches. The lifting appliance comprises an electric pole, a fixing hoop is arranged on the electric pole, a bearing frame is arranged on the fixing hoop, a double-track fixed pulley is arranged on the bearing frame, and a lifting rope is wound on the double-track fixed pulley. One end of the lifting rope is connected with the pole-mounted switch, and the other end of the lifting rope is connected with a hoisting mechanism which is arranged on the ground. The lifting appliance is specially designed for hoisting the pole-mounted switch, the working face is small, the terrain influence is small, the lifting appliance can be used on common ground or slopes, traditional single-rope hoisting is abandoned, double ropes are creatively used for hoisting the pole-mounted switch, the pole-mounted switch can stably ascend in the hoisting process, the unhooking problem is avoided, personal safety of ground operators is guaranteed, and normal installation of the pole-mounted switch is guaranteed.

Owner:国网山东省电力公司肥城市供电公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com