A prefabricated hydraulic box culvert formwork and a construction method for the prefabricated box culvert

A construction method and prefabricated assembly technology, which is applied in the direction of manufacturing tools, molds, unloading devices, etc., can solve the problems of difficult control of construction quality, long construction period, high accuracy requirements, etc., and achieve the improvement of appearance and pass rate of protective layer, The effect of good economic and social benefits and speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The materials and equipment used in the present invention are all common commercially available products, so their sources are not specifically limited.

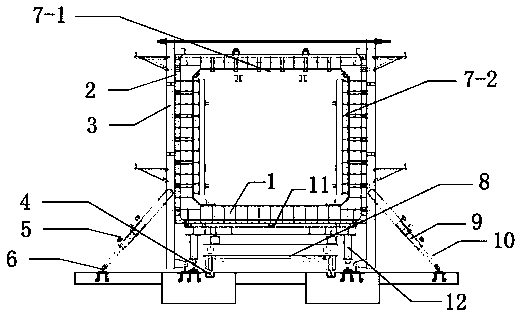

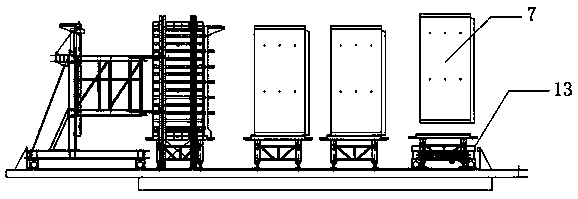

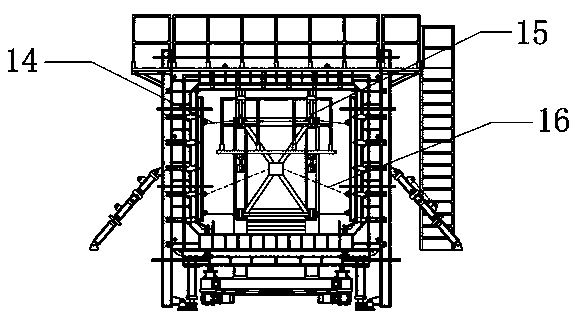

[0090] An assembled hydraulic box culvert formwork, such as Figure 1-3 As shown, it includes: template, hydraulic power system and adjustment support; the template includes bottom mold 11, outer mold 2, end mold 1 and inner mold 7; hydraulic power system includes bottom mold trolley 8 and inner mold trolley 13; adjustment support includes Inner mold trolley 13, bottom mold support 12 and outer mold hydraulic system support.

[0091] Wherein, the inner mold includes an inner mold top mold 7-1 and an inner mold side mold 7-2; the end mold 1 includes a convex end mold, a concave end mold and a flat end mold, wherein the flat end mold is only used for the first and last culvert ends. Prefabrication, that is, the two ends of the entire box culvert, and the rest of the culverts are connected by the concave end mold and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com