Cast-in-situ lightweight concrete structure based on spiral steel piles and construction method thereof

A light-weight concrete and construction method technology, which is applied in the direction of foundation structure engineering, sheet pile walls, roads, etc., can solve the problems of easy differential settlement and low cohesion, and achieve internal and external stability problems, Increased stability, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

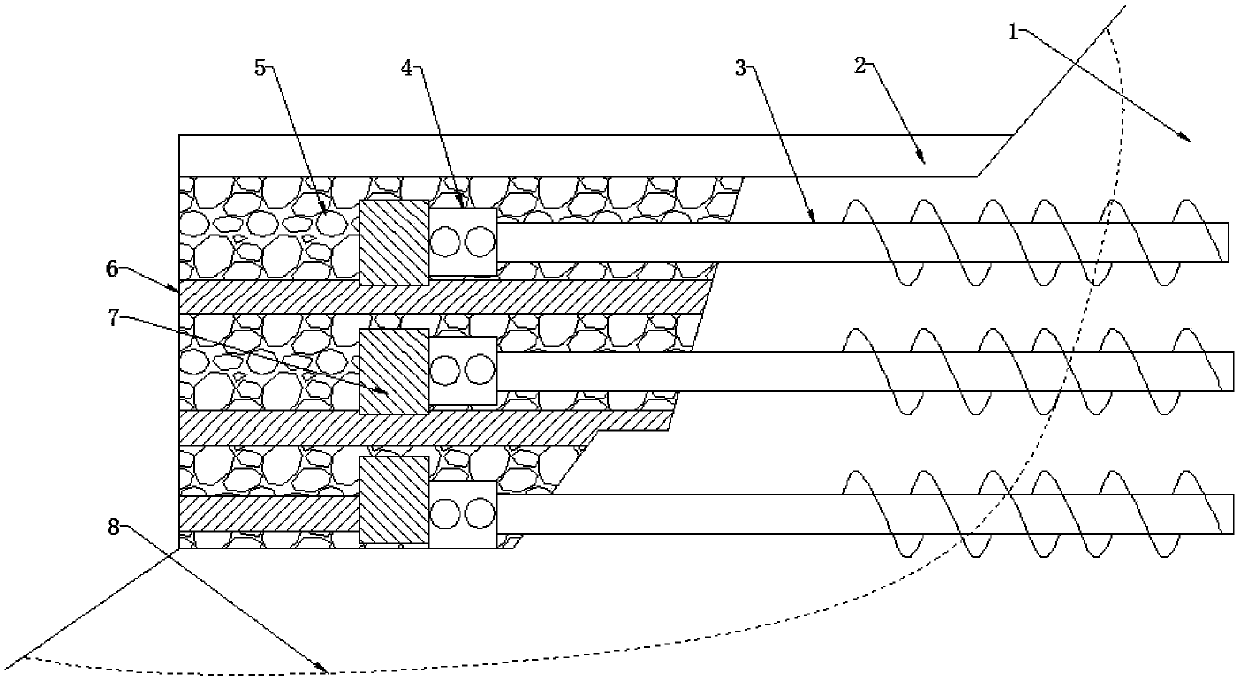

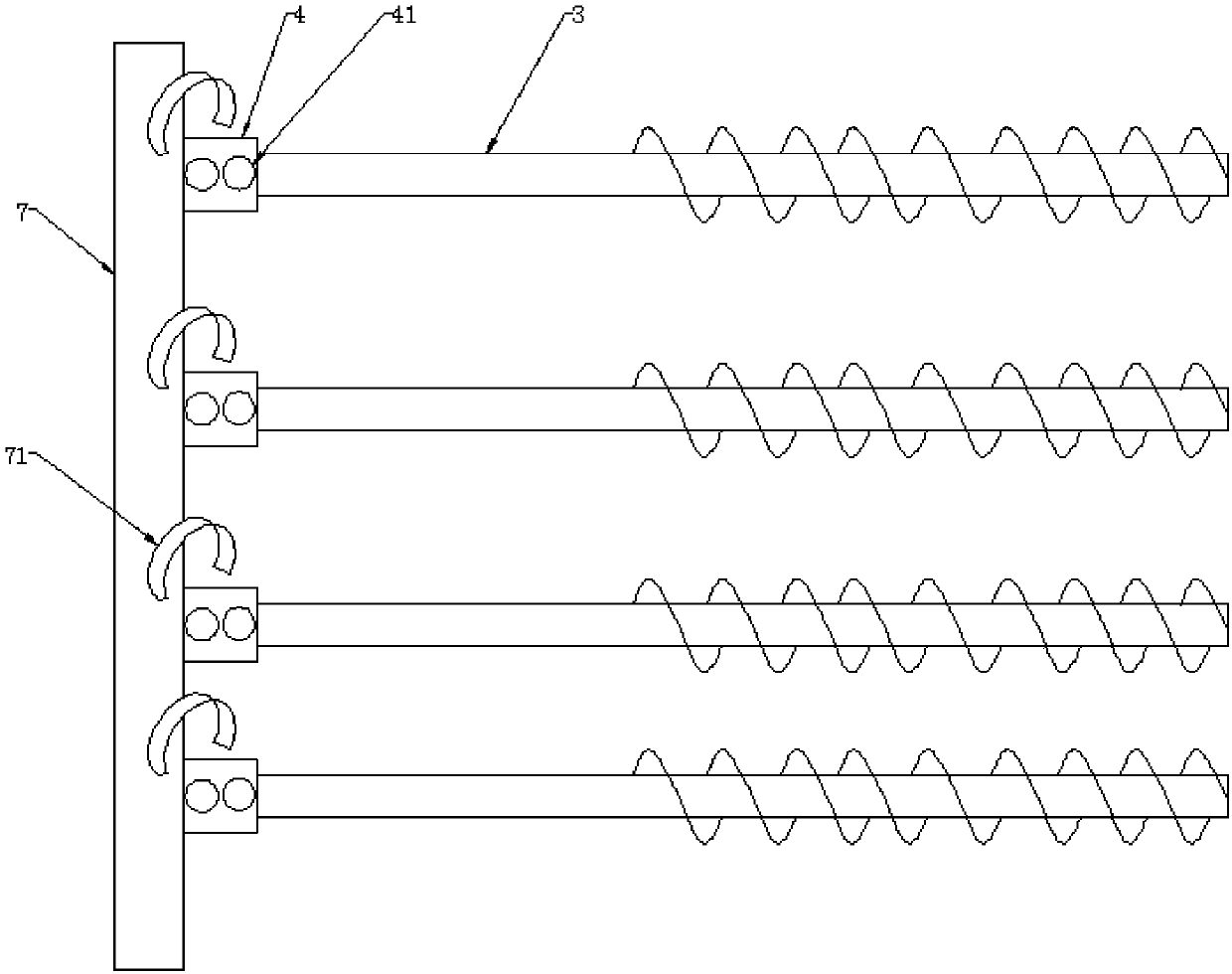

[0030] The present invention is based on a cast-in-situ lightweight concrete structure supported by spiral steel piles, which is characterized in that it comprises a lightweight concrete 5 poured on the side of the potential landslide layer 8 of the original hillside 1, and a plurality of connecting rods are arranged in the lightweight concrete 5 7. The connecting rod 7 is connected with a plurality of upside-down quick joints 4, and each upside-down quick joint 4 is connected to a spiral steel pile 3 with spiral blades, and the spiral blades on the spiral steel pile 3 pass through the potential landslide Layer 8.

[0031] Preferably, the connecting rod 7 is located in the lightweight concrete 5 on the side close to the potential landslide layer 7.

[0032] Preferably, the lightweight concrete 5 is further provided with a reinforcement layer 6 which is a high-strength geogrid or a galvanized metal mesh, and the reinforcement layer 6 is distributed at intervals in the vertical direc...

Embodiment 2

[0051] The present invention is based on a cast-in-situ lightweight concrete structure supported by spiral steel piles, which is characterized in that it comprises a lightweight concrete 5 poured on the side of the potential landslide layer 8 of the original hillside 1, and a plurality of connecting rods are arranged in the lightweight concrete 5 7. The connecting rod 7 is connected with a plurality of upside-down quick joints 4, and each upside-down quick joint 4 is connected to a spiral steel pile 3 with spiral blades, and the spiral blades on the spiral steel pile 3 pass through the potential landslide Layer 8.

[0052] Preferably, the connecting rod 7 is located in the lightweight concrete 5 on the side close to the potential landslide layer 7.

[0053] Preferably, the lightweight concrete 5 is further provided with a reinforcement layer 6 which is a high-strength geogrid or a galvanized metal mesh, and the reinforcement layer 6 is distributed at intervals in the vertical direc...

Embodiment 3

[0072] The present invention is based on a cast-in-situ lightweight concrete structure supported by spiral steel piles, which is characterized in that it comprises a lightweight concrete 5 poured on the side of the potential landslide layer 8 of the original hillside 1, and a plurality of connecting rods are arranged in the lightweight concrete 5 7. The connecting rod 7 is connected with a plurality of upside-down quick joints 4, and each upside-down quick joint 4 is connected to a spiral steel pile 3 with spiral blades, and the spiral blades on the spiral steel pile 3 pass through the potential landslide Layer 8.

[0073] Preferably, the connecting rod 7 is located in the lightweight concrete 5 on the side close to the potential landslide layer 7.

[0074] Preferably, the lightweight concrete 5 is further provided with a reinforcement layer 6 which is a high-strength geogrid or a galvanized metal mesh, and the reinforcement layer 6 is distributed at intervals in the vertical direc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com