Patents

Literature

45 results about "Filling Problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

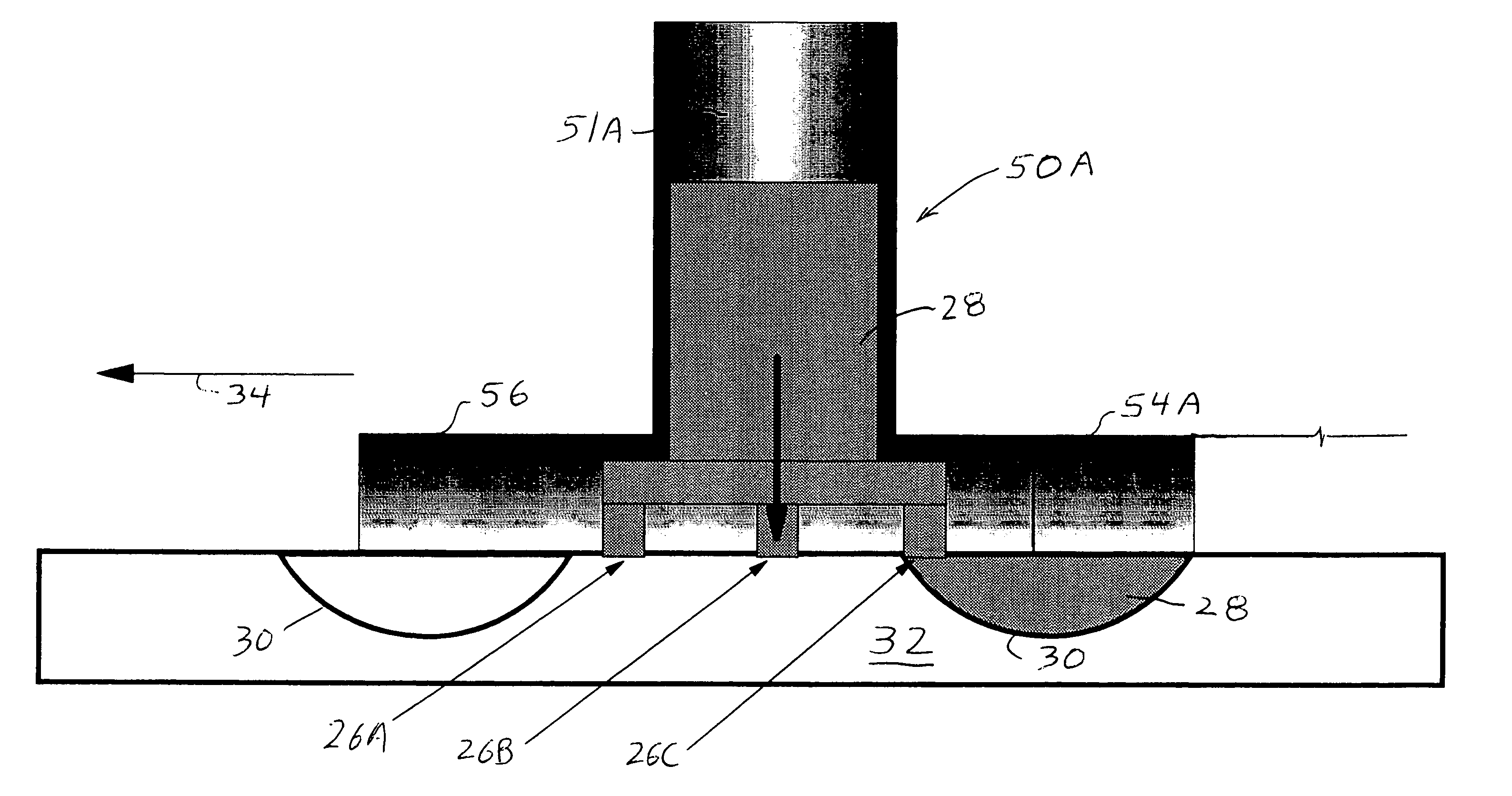

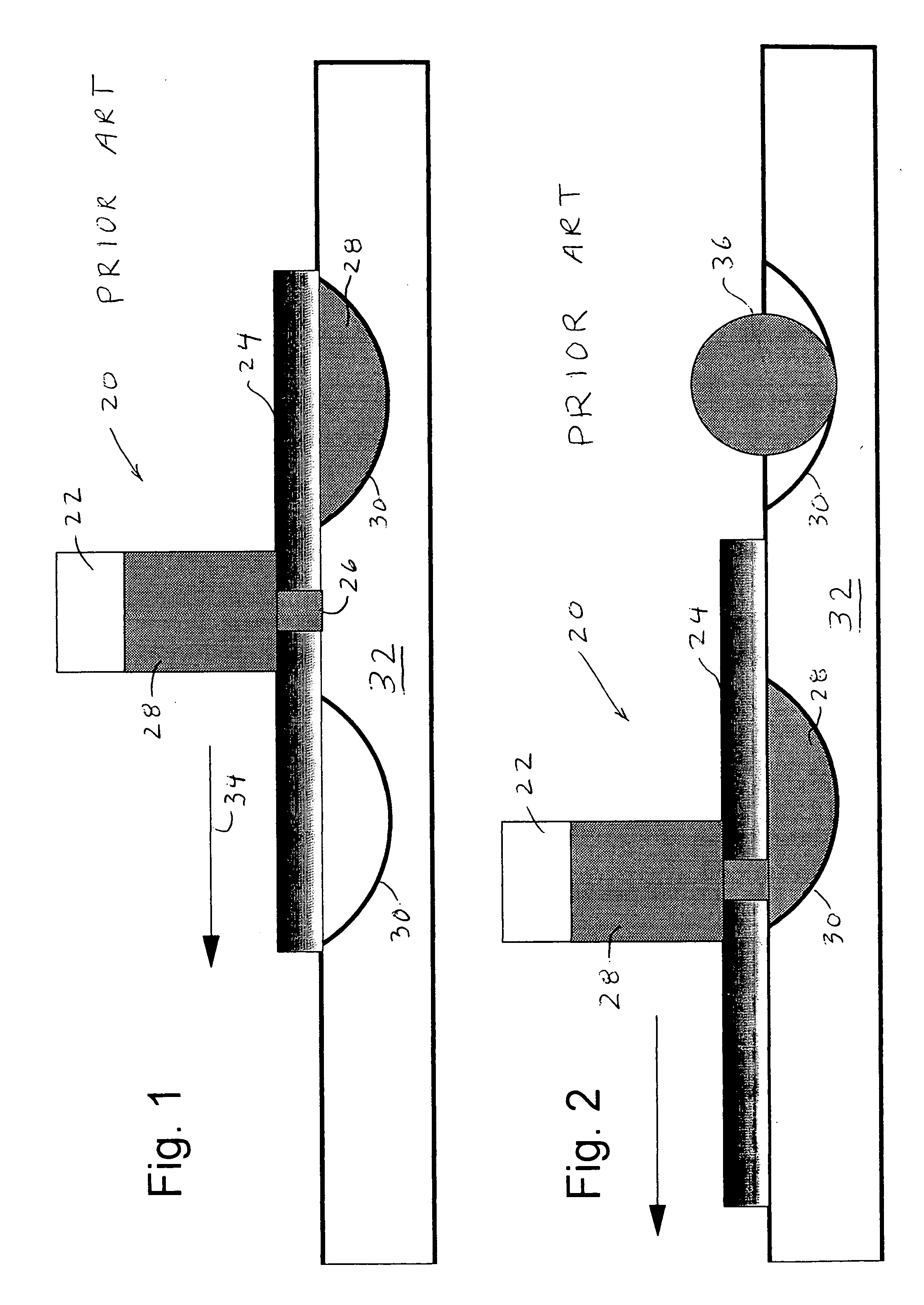

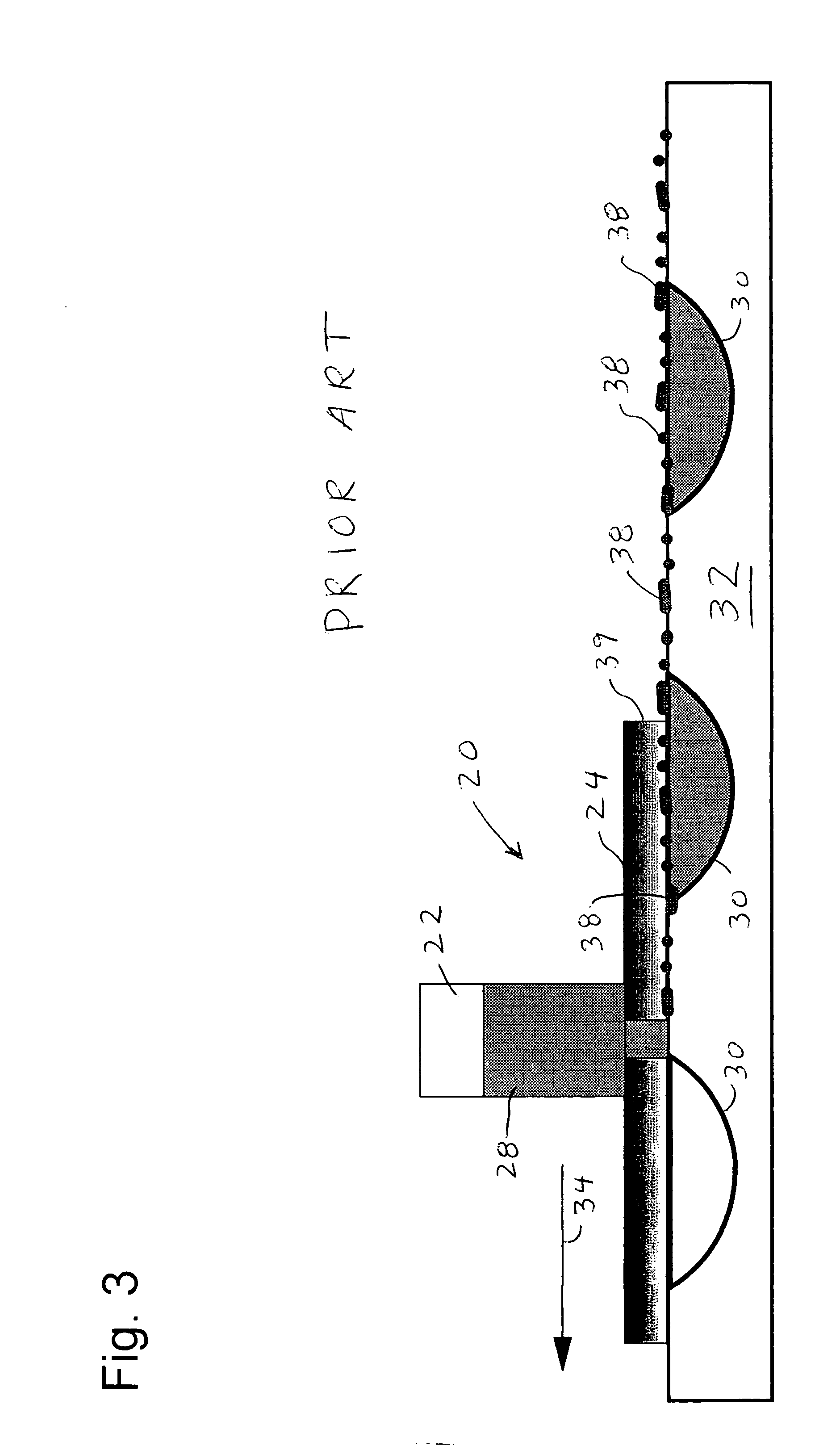

Injection molded continuously solidified solder method and apparatus

InactiveUS20050263571A1Accurate storageAccurately and completely fill the cavitiesPrinted circuit assemblingWelding/cutting media/materialsMetallurgyMaterials science

A method and apparatus for forming solder bumps by molten solder deposition into cavity arrays in a substrate immediately followed by solidification of molten solder such that precise replication of cavity volumes is consistently achieved in formed solder bump arrays. Various solder filling problems, such as those caused by surface tension and oxidation effects, are overcome by a combination of narrow molten Solder dispense slots and solidification of dispensed molten solder.

Owner:BELANGER LUC +12

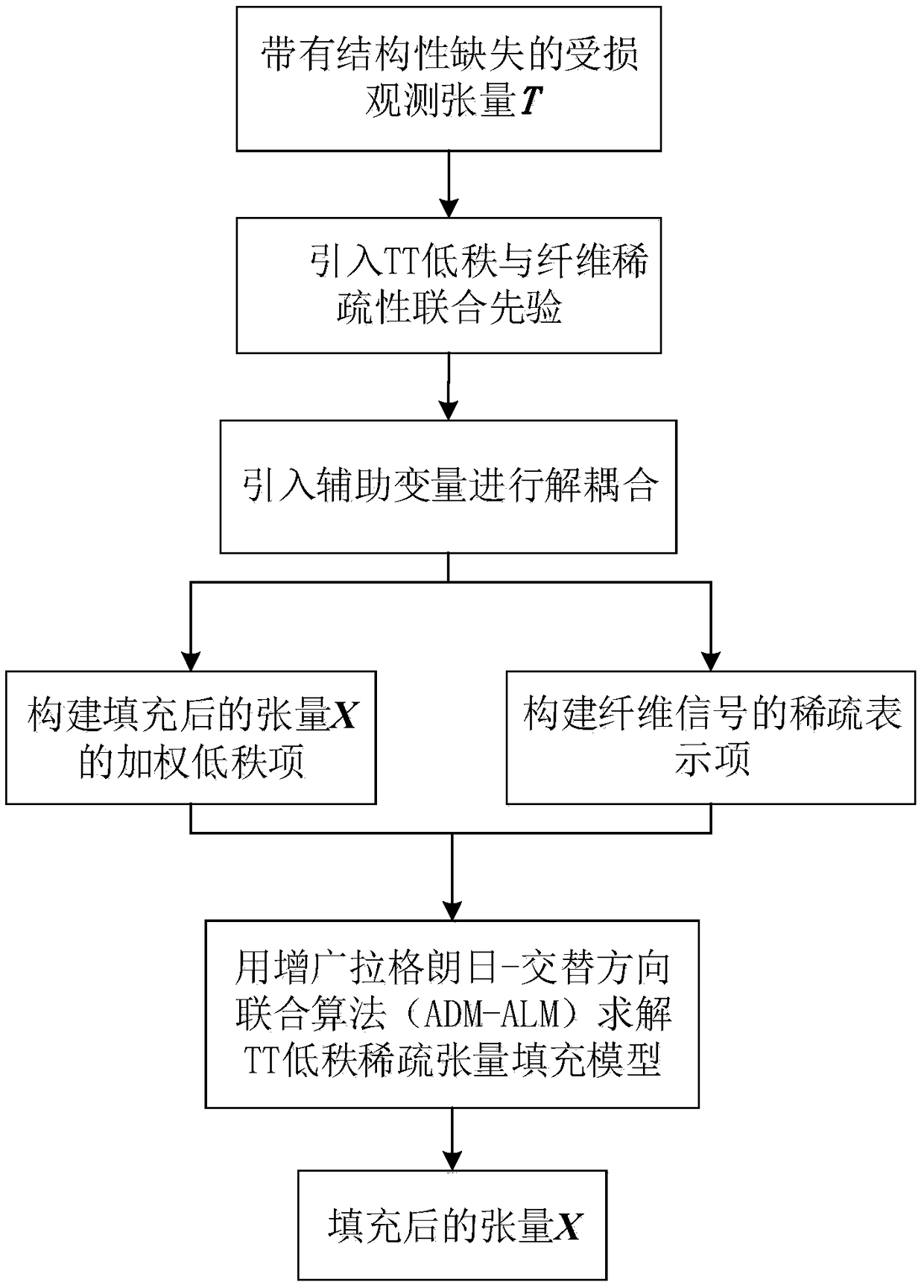

Tensor structural missing filling method based on joint low rank and sparse representation

PendingCN109241491ARealize the solutionAccurate fillingComplex mathematical operationsData dredgingFiber

The invention relates to the field of computer vision. In order to propose a tensor structural missing filling method and realize the accurate filling of the structural missing tensor, the tensor structural missing filling method based on the combination of low rank and sparse representation and the TT low rank tensor filling theory are introduced into the TT low rank prior to constrain the potential tensor. At the same time, considering that the fiber signal along each dimension of the tensor can be sparsely represented by a dictionary, and the missing fiber of the previous dimension can be recovered by sparse constraint on the fiber signal in the next dimension, sparse constraint is introduced for each dimension of the fiber signal; based on the sparse apriori of the combined TT low rankand each dimension, the tensor filling problem with structural defects is formulated as a constrained optimization problem, so that the tensor filling problem with structural defects can be realized.The invention is mainly applied to video image inpainting, recommendation system, data mining and multi-classification learning occasions.

Owner:TIANJIN UNIV

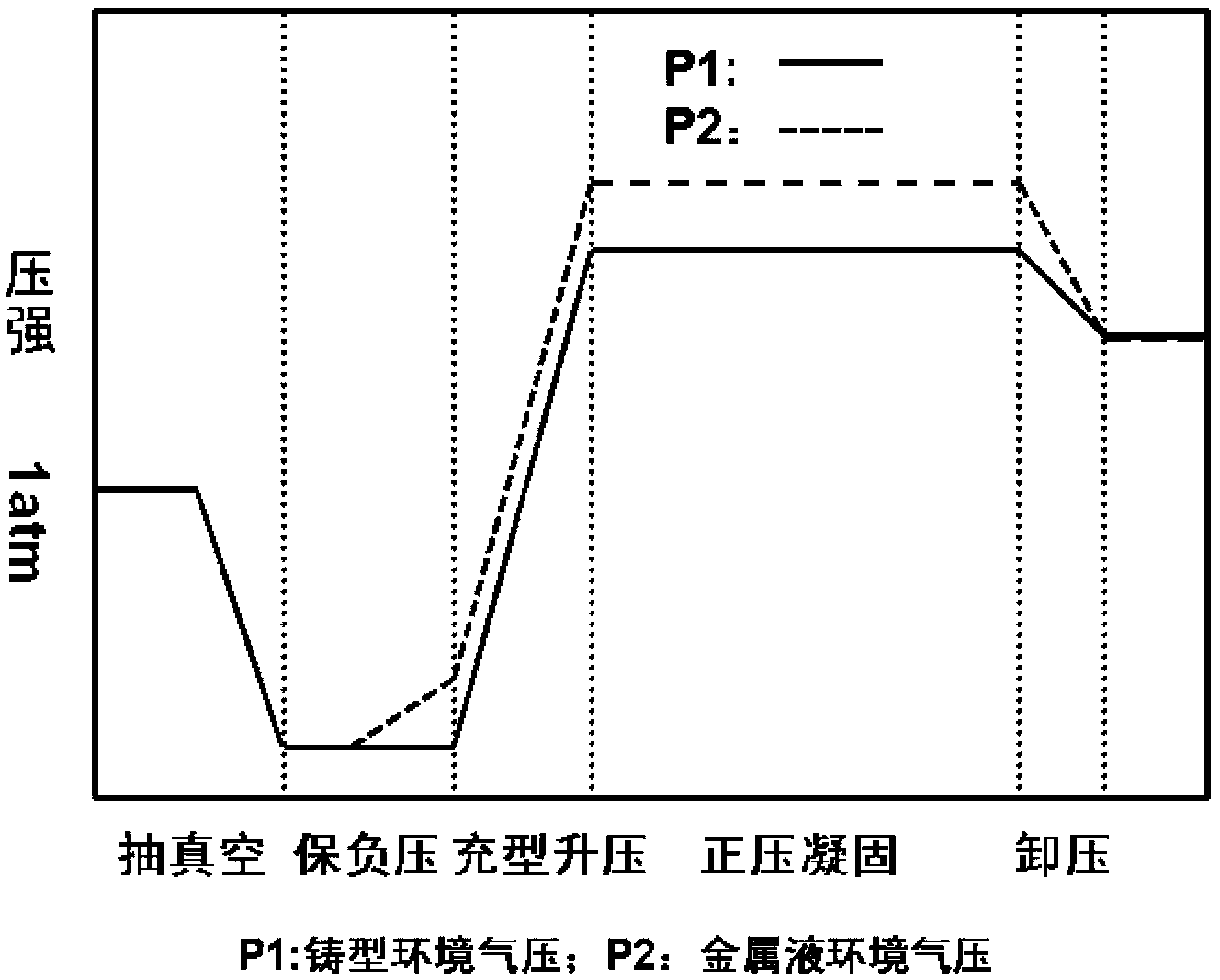

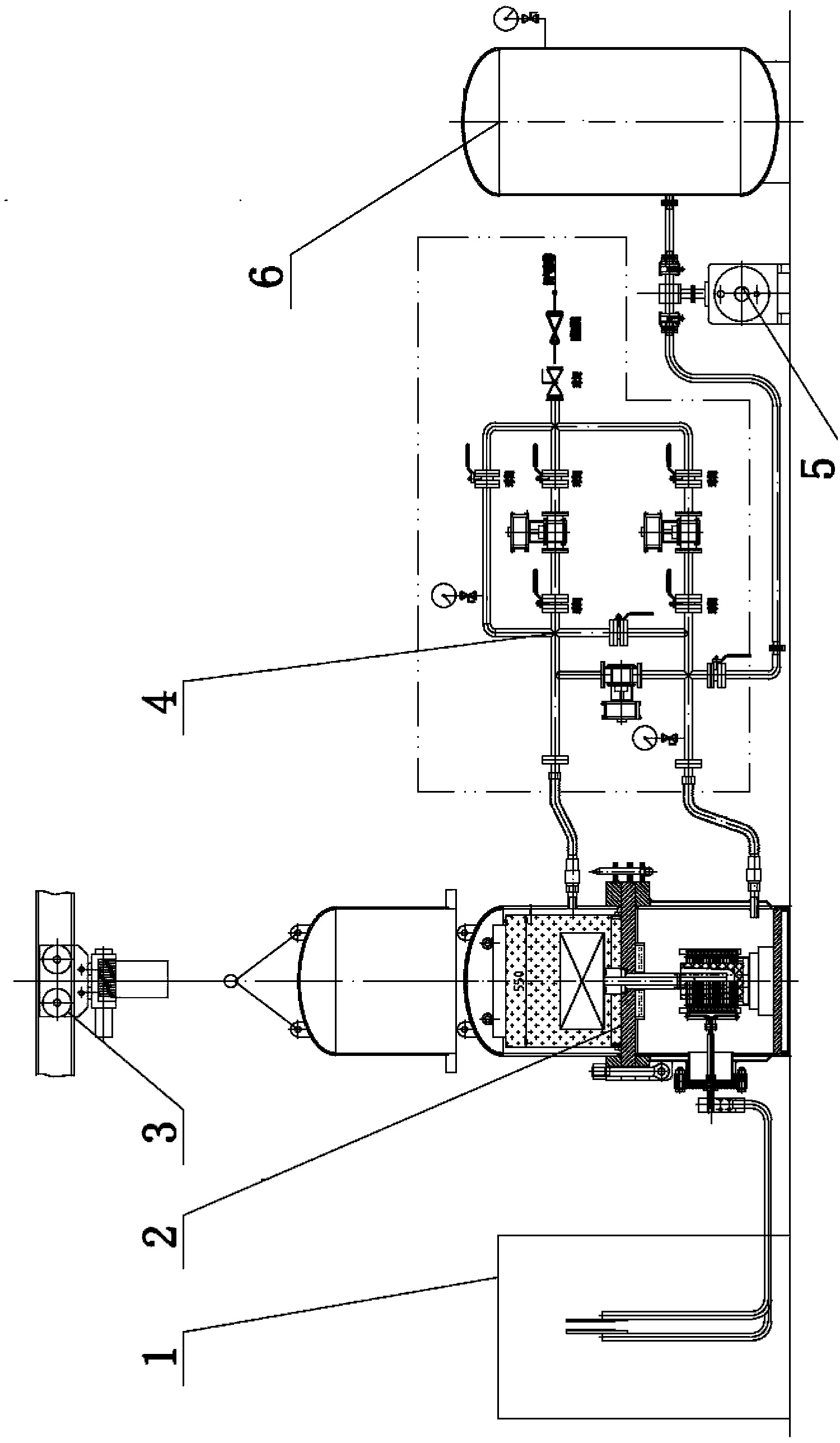

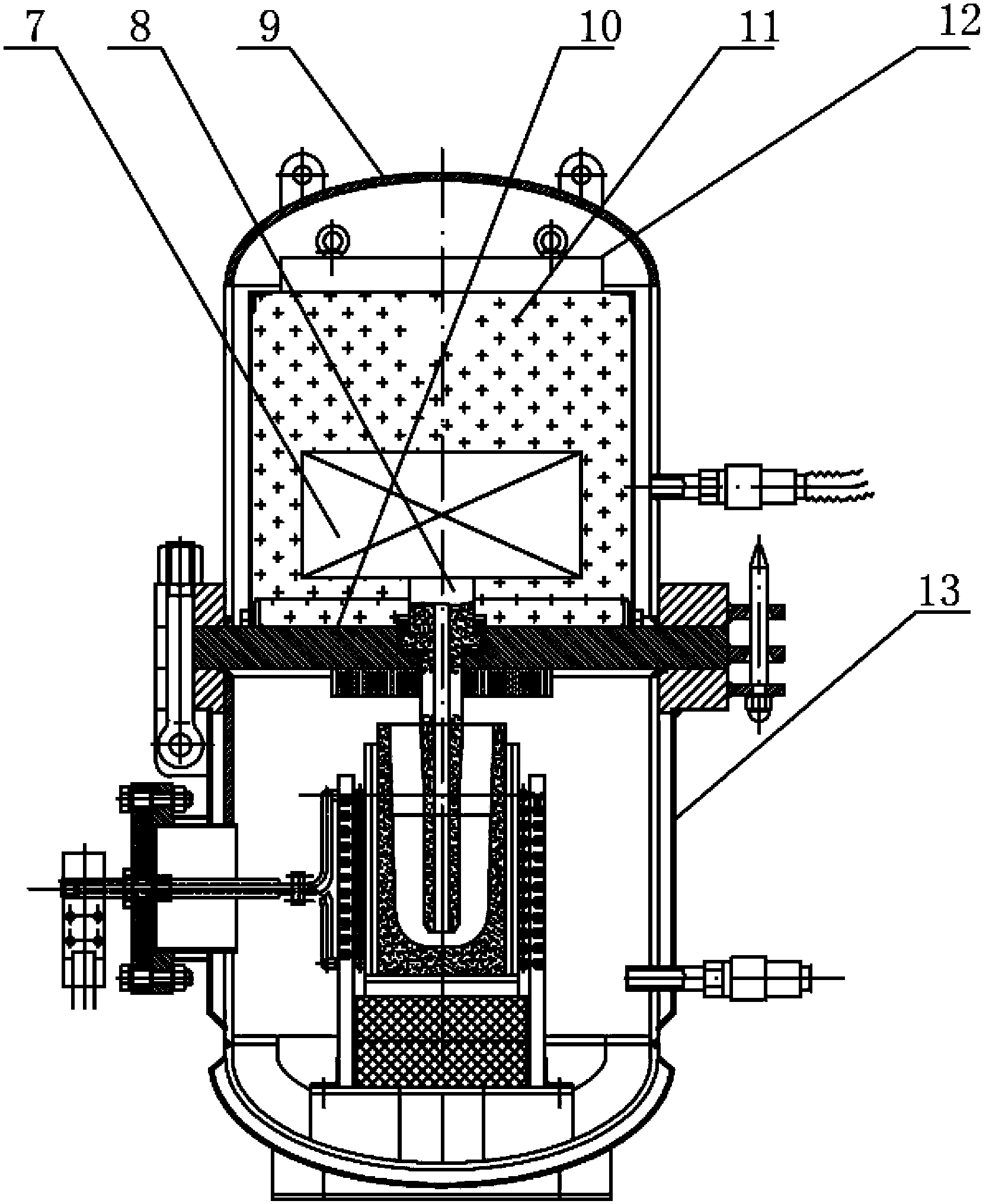

Precesion casting method for high temperature alloy complex thin-walled castings

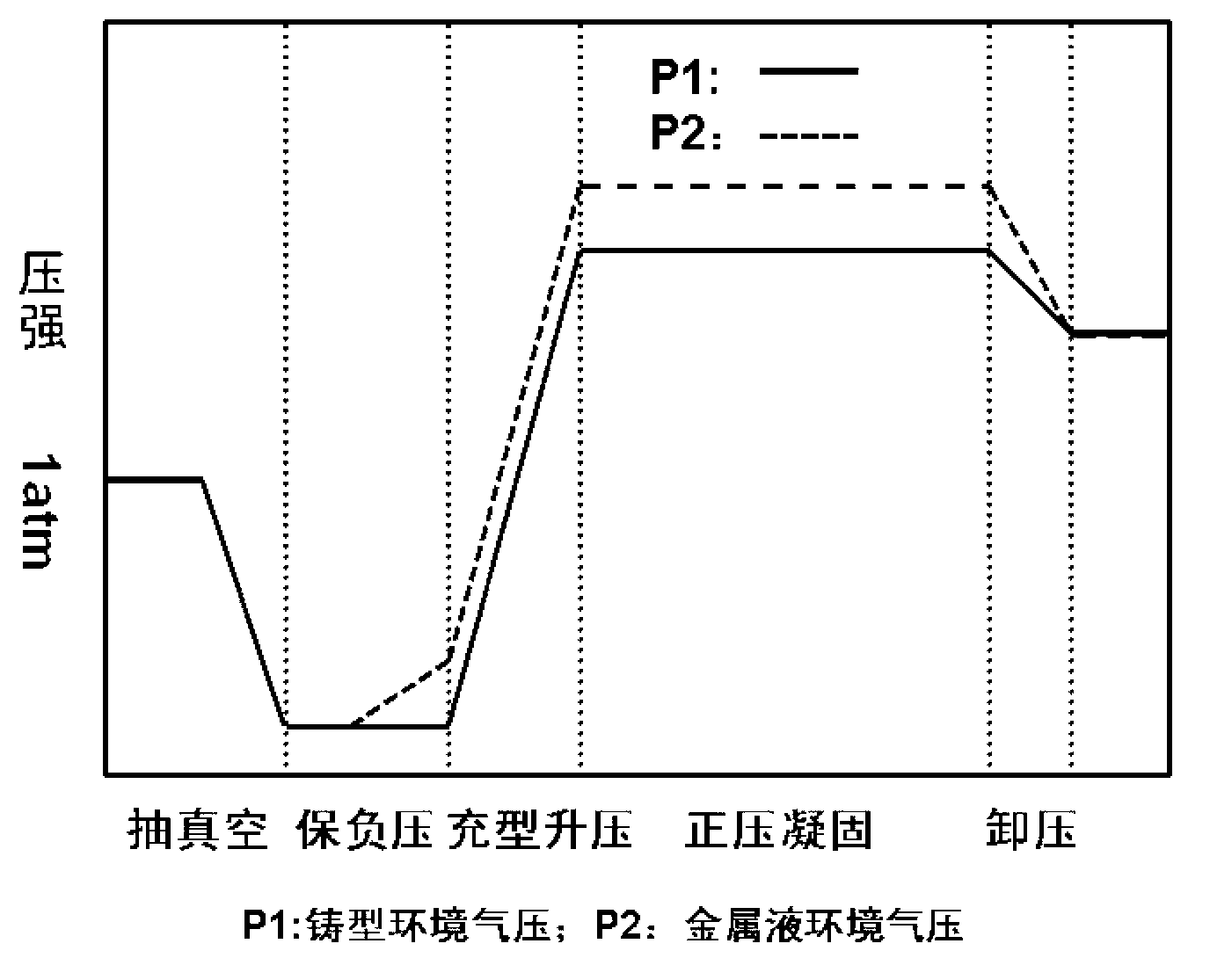

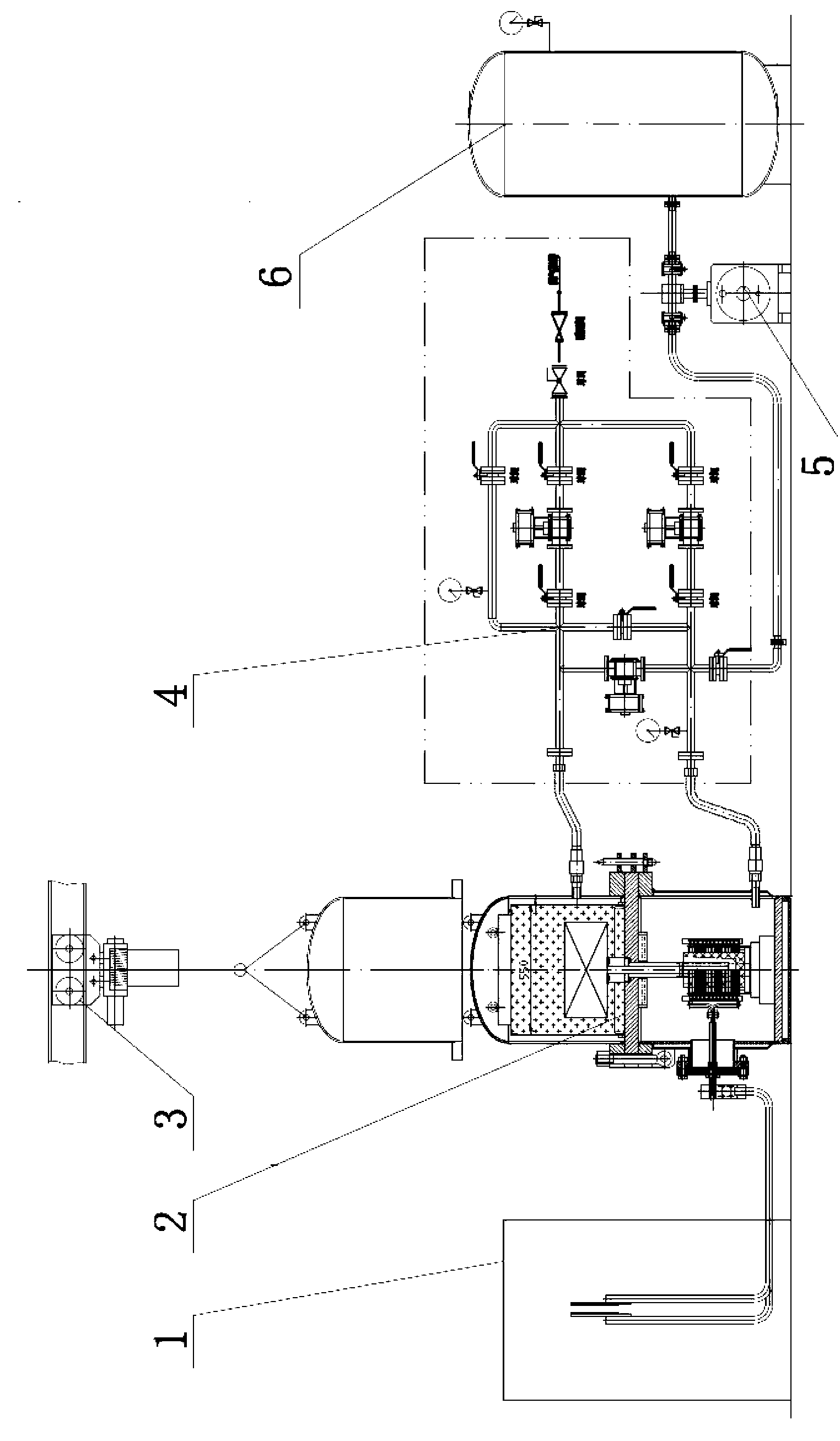

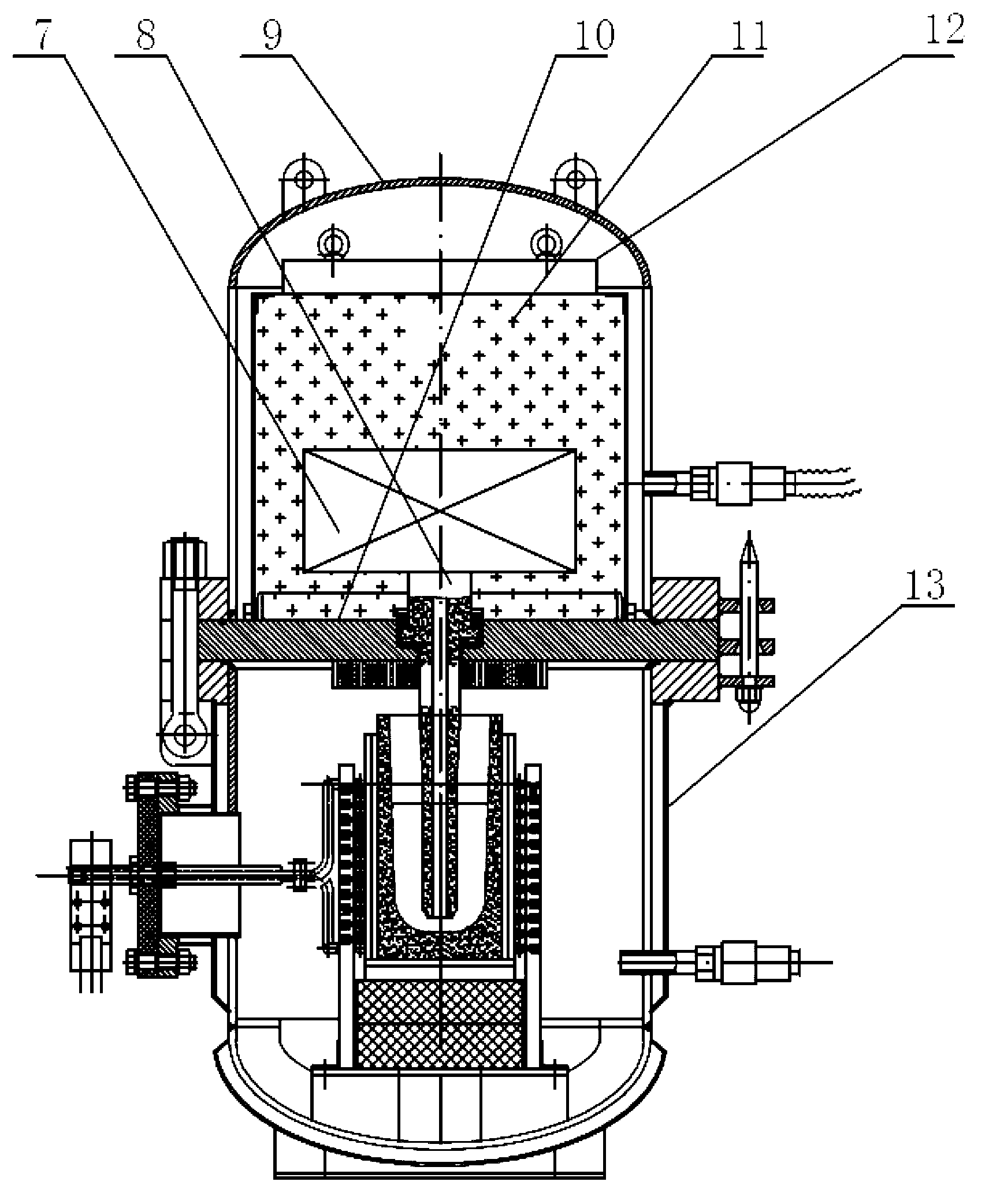

ActiveCN102699311ASolve filling problemsReduce air permeabilityFoundry mouldsFoundry coresIntermediate frequencyMold filling

The invention discloses a precision casting method for high temperature alloy complex thin-walled castings. The method comprises the following steps of: utilizing a medium frequency induction heating power supply to melt the alloy, utilizing a medium baffle to separate an upper tank and a lower tank, and utilizing an electric hoist to elevate the upper tank when a casting mold and a liquid rising tube are installed; after the installation is completed, utilizing a gas circuit control pipeline, a vacuum system and a gas tank to realize vacuum and pressure regulation in a pressure regulating furnace. By adopting the method disclosed by the invention, stable and efficient mold filling is realized, the castings is solidified sequentially, utilization efficiency of the material can be effectively improved, and the space for near-end net shape casting can be supplied; the complex, thin-walled and integral metal castings which are difficult to cast through other molding methods can be produced, so as to solve the filling problem in the pouring process of the complex thin-walled castings, and in particular, the filling capacity for the thin-walled castings with the wall thickness of less than 3mm is greatly improved. Accurate castings with high dimensional accuracy can be obtained through high temperature alloy pressure regulating investment precision casting, and the accuracy of the casting can reach between CT4 and CT6.

Owner:SHANGHAI JIAO TONG UNIV

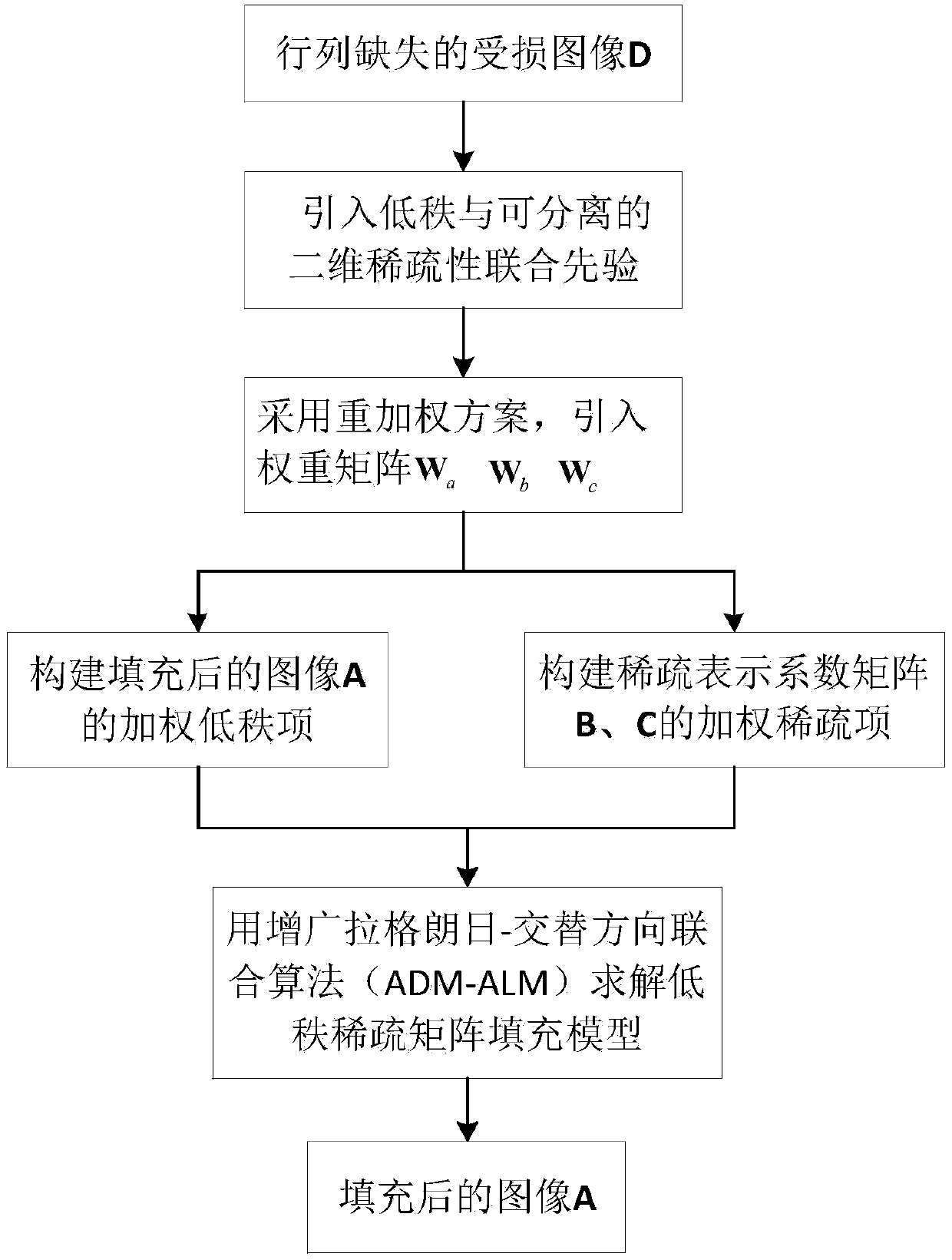

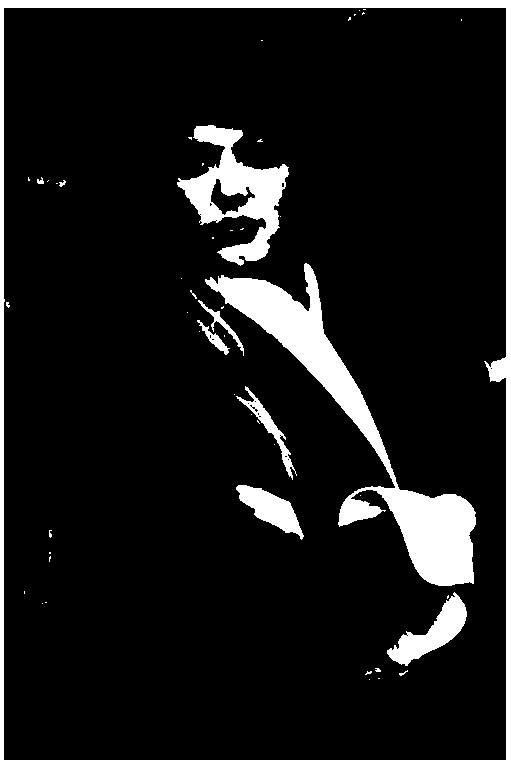

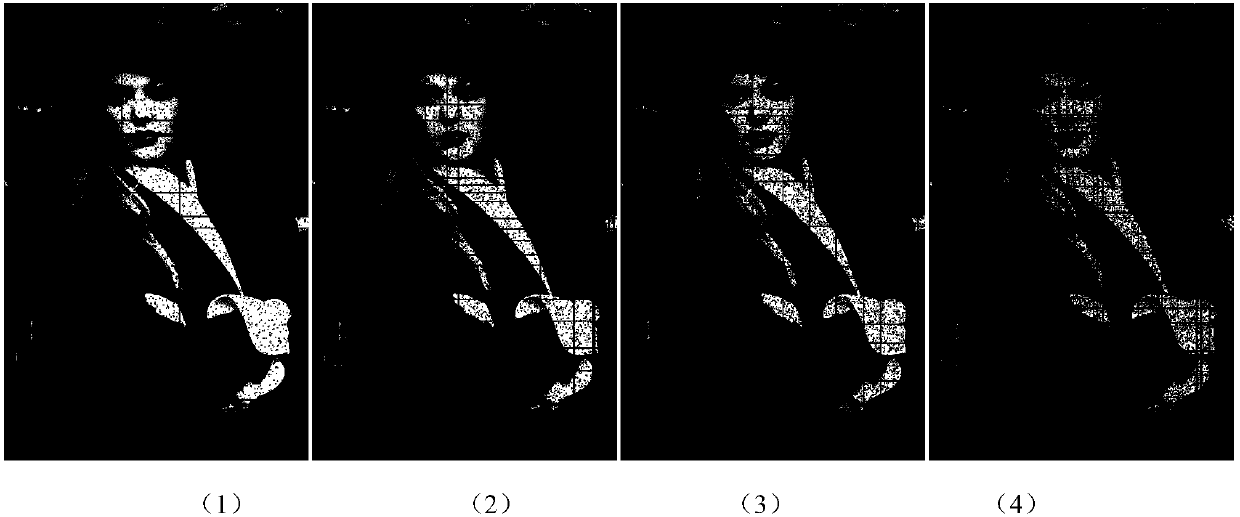

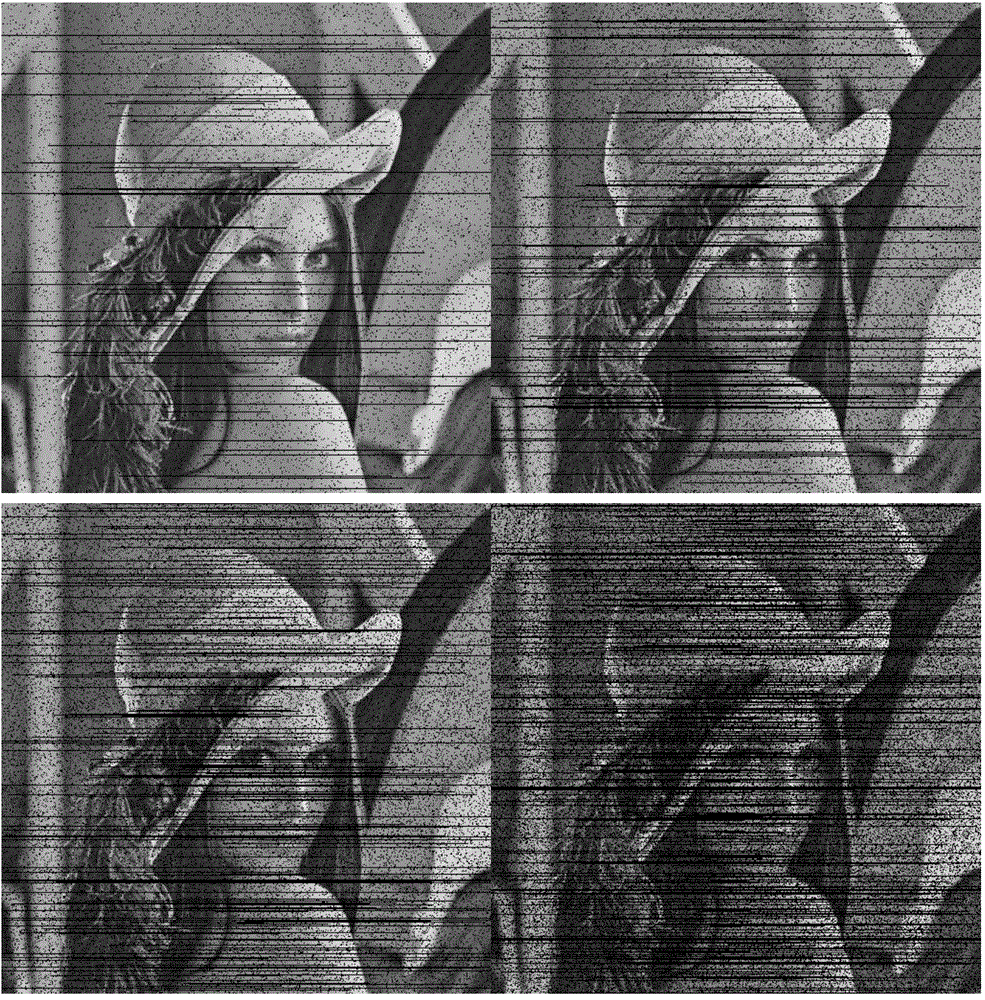

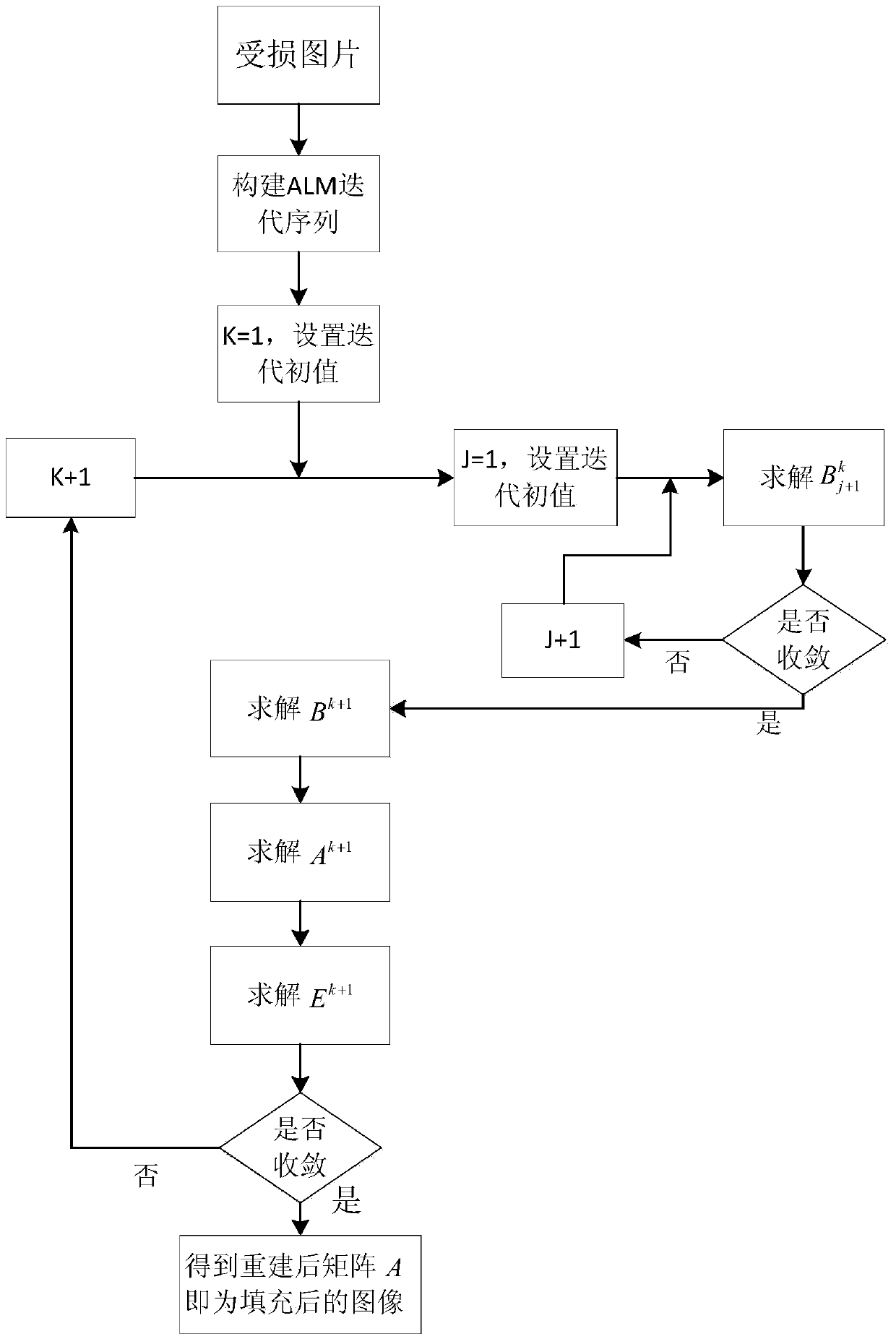

Row and column loss image filling method based on low-rank matrix reconstruction and sparse representation

InactiveCN107133930ARealize the solutionAccurate fillingImage enhancementCharacter and pattern recognitionVision processingAlgorithm

The invention belongs to the field of computer vision, and aims at achieving the accurate filling of a pixel row and column loss image. The technical scheme employed in the invention is that a row and column loss image filling method based on low-rank matrix reconstruction and sparse representation comprises the steps: introducing low-rank priori to carry out the constraining of a potential image based on the low-rank matrix reconstruction theory; introducing a separable two-dimensional sparse priori based on the sparse representation theory with the consideration to a condition that the sparse representation of each column of a row loss image can be achieved through a column dictionary and the sparse representation of each row of a column loss image can be achieved through a row dictionary; specifically describing a filling problem of an image with the row and column loss into a solving problem of a constraint optimization equation based on the above combined low-rank and separable two-dimensional sparse priori, thereby achieving the filling of the row and column loss image. The method is mainly used for a computer vision processing occasion.

Owner:TIANJIN UNIV

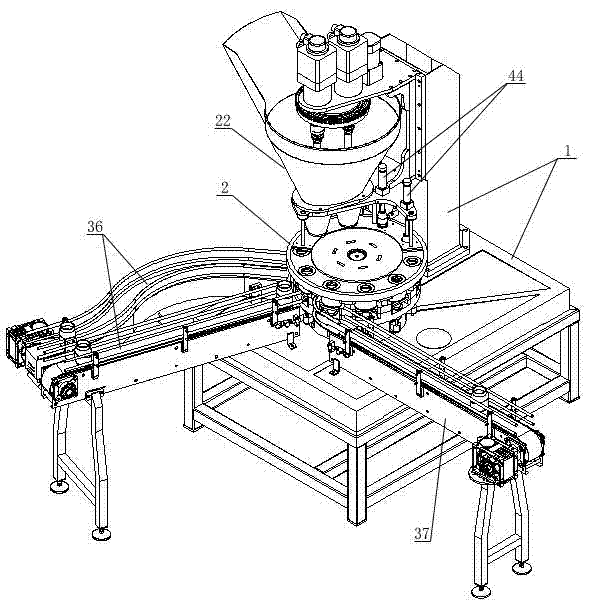

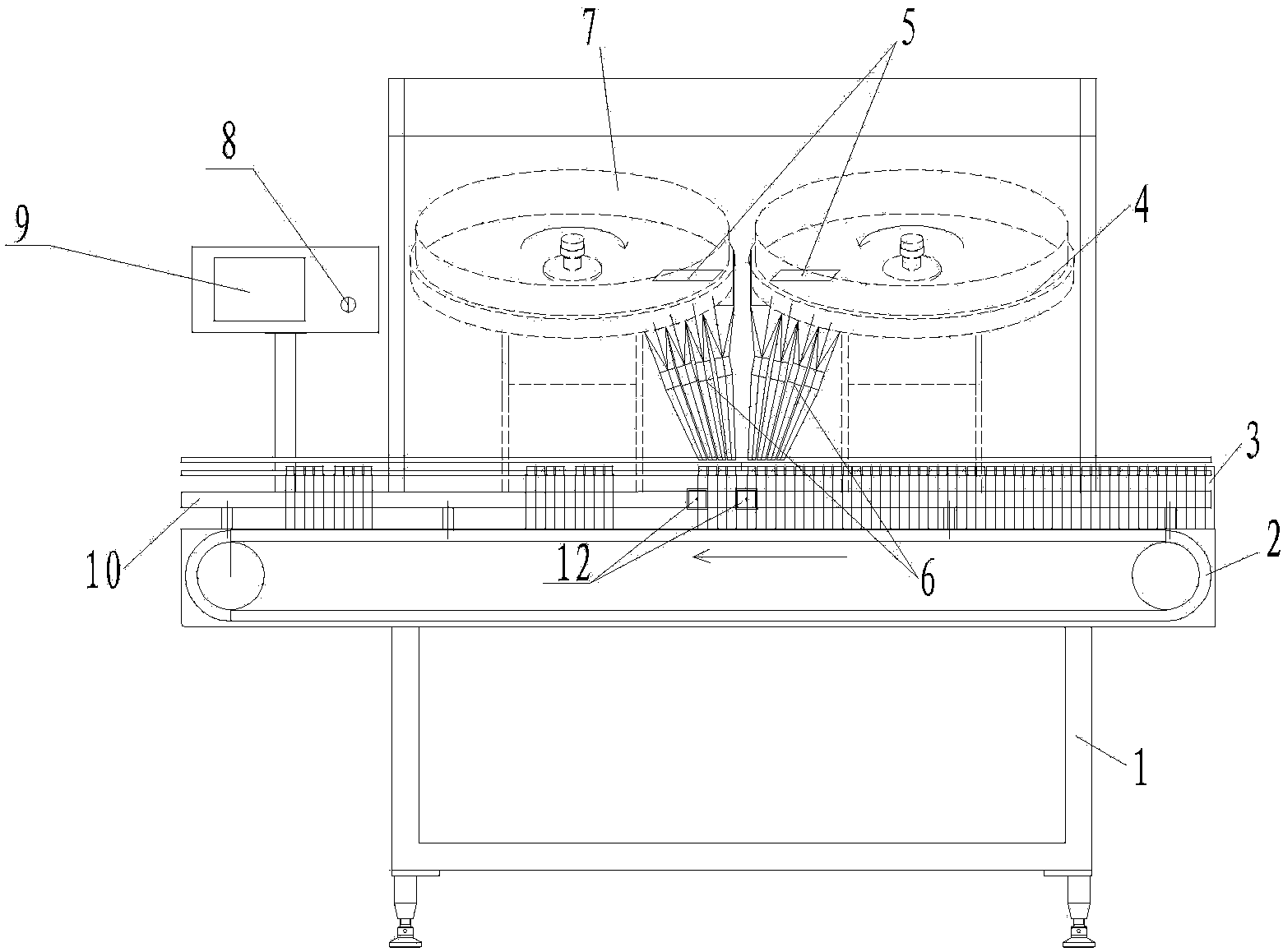

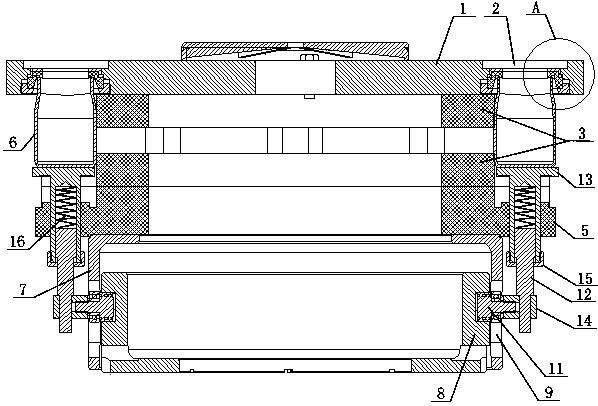

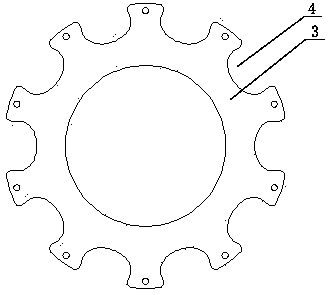

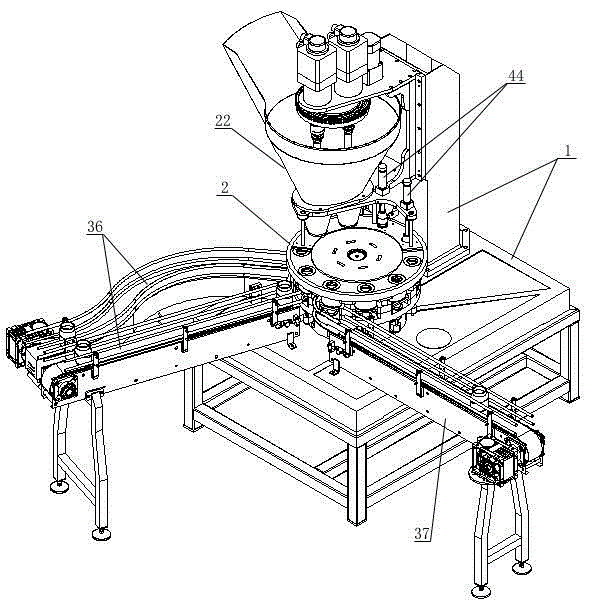

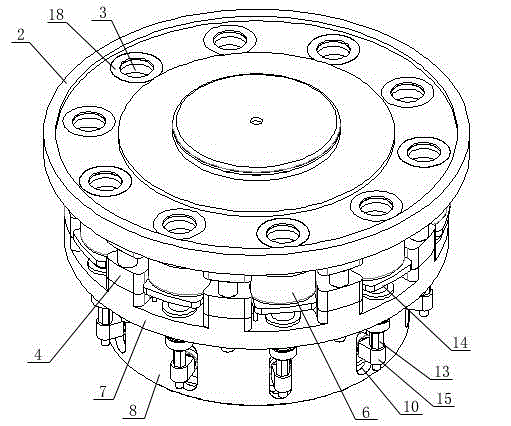

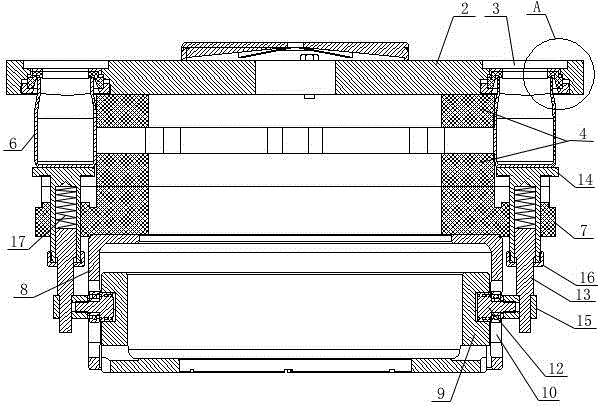

Full-automation filling machine

The invention discloses a full-automation filling machine which comprises a rack, a discharging device, a rotation plate device, a baiting device and a conveying device, wherein the discharging device, the rotation plate device, the baiting device and the conveying device are arranged on the rack. The rotation plate device comprises a rotation plate and multiple baiting through holes. A bottle clamping plate is arranged below the rotation plate, multiple bottle clamping grooves are formed in the periphery of the bottle clamping plate and a bottle ejecting mechanism is arranged below the ejector rod fixing plate. The discharging device is located above the rotation plate. A discharging opening of the discharging device is communicated with the baiting through holes in the rotation plate. The baiting device is located above the rotation plate and matched with the baiting through holes corresponding to baiting stations. The conveying device corresponds to the bottle clamping grooves at bottle inlet stations and bottle outlet stations. According to the full-automation filling machine, the bottle clamping plate is used for clamping and fixing filling bottles and a bottle jacking mechanism is used for jacking the corresponding filling bottle, so that the filling bottle totally corresponds to the corresponding baiting through hole of the rotation plate. In the whole filling process, the filling bottles can rotate synchronously along with the rotation plate and the filling problem due to the fact that the filling bottles do not align with a baiting hopper in an existing structure is solved.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

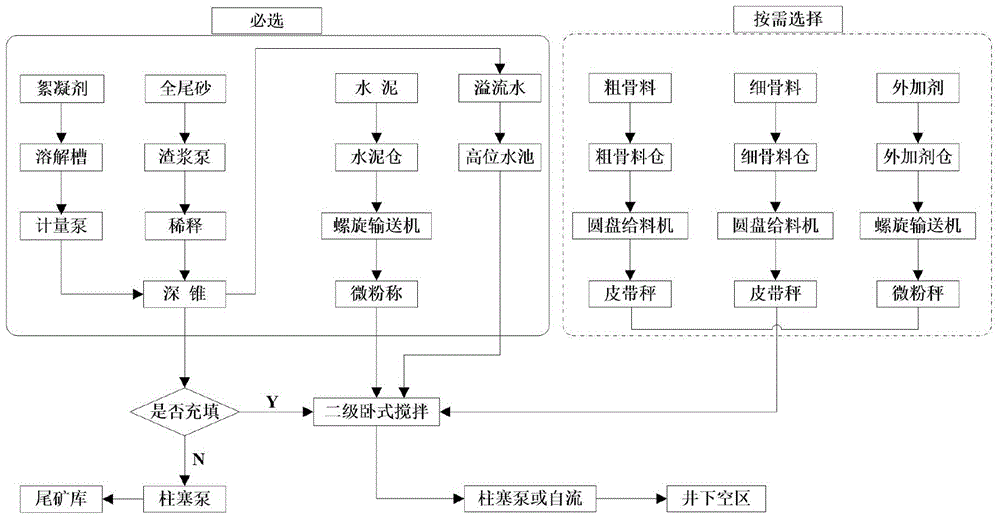

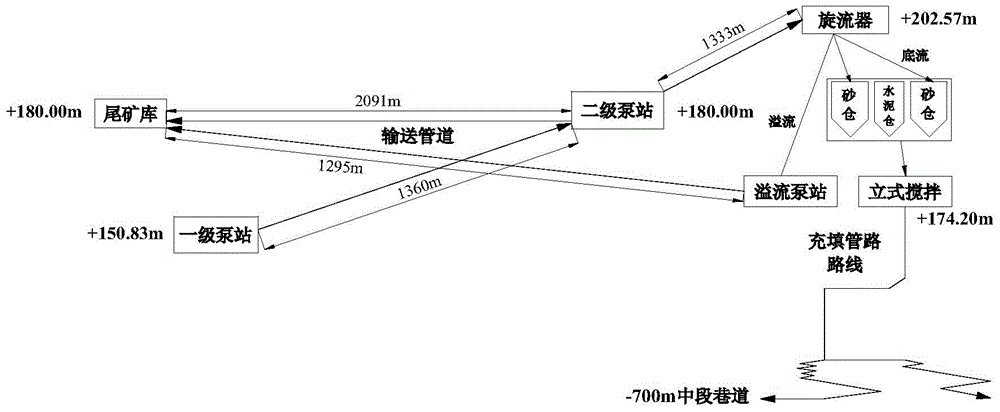

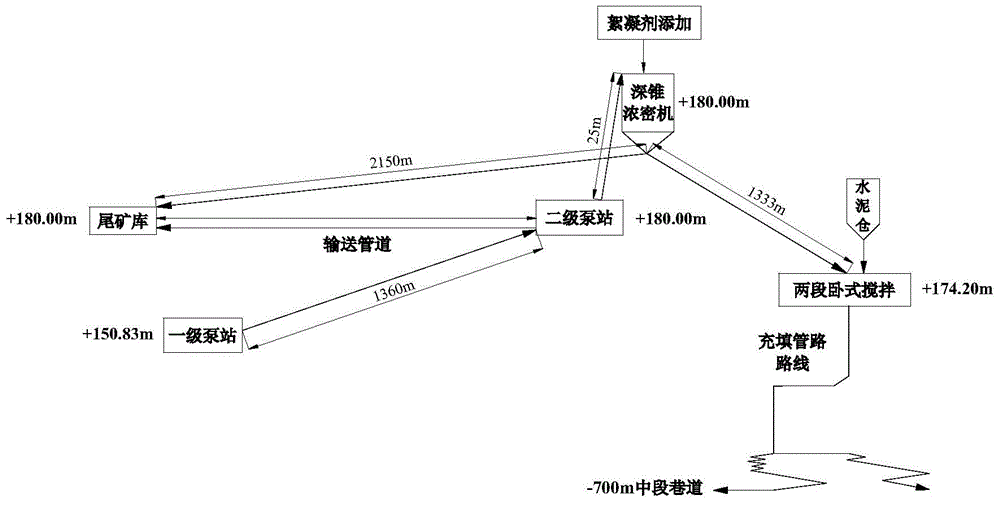

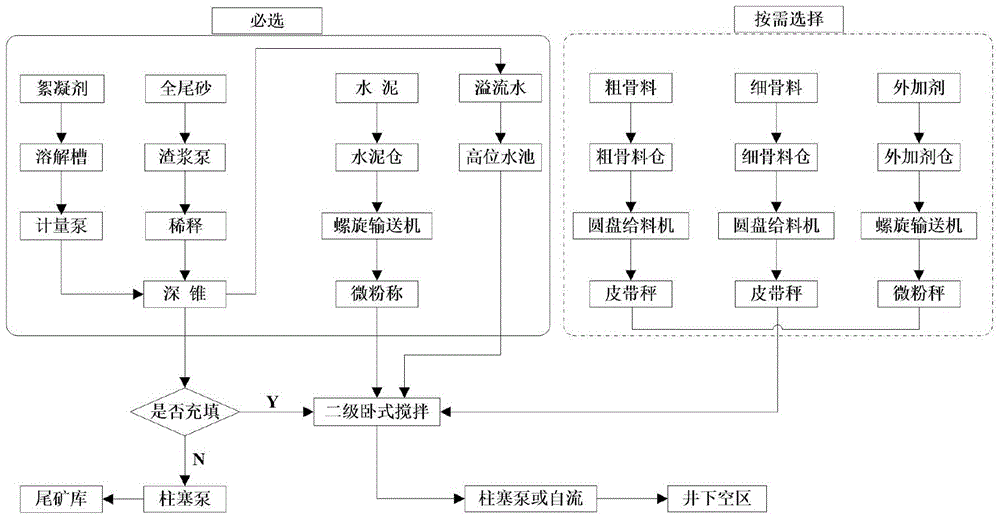

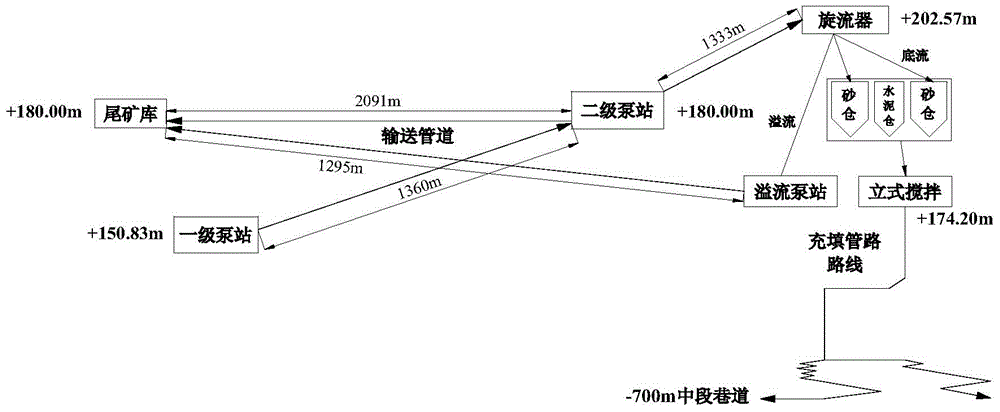

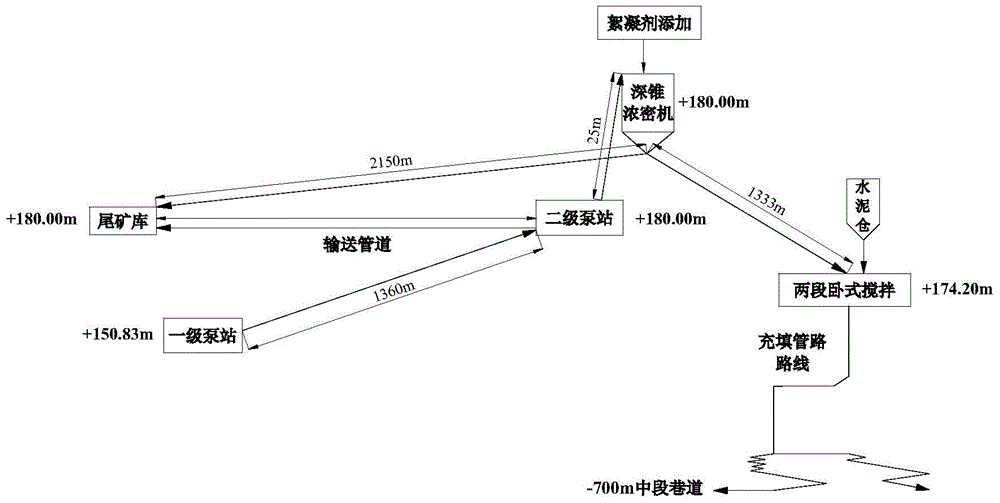

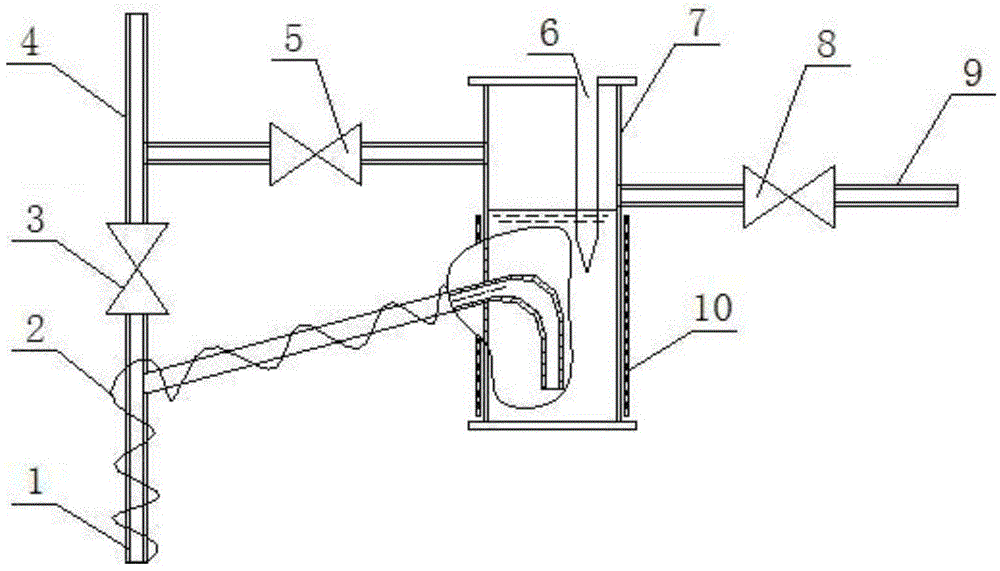

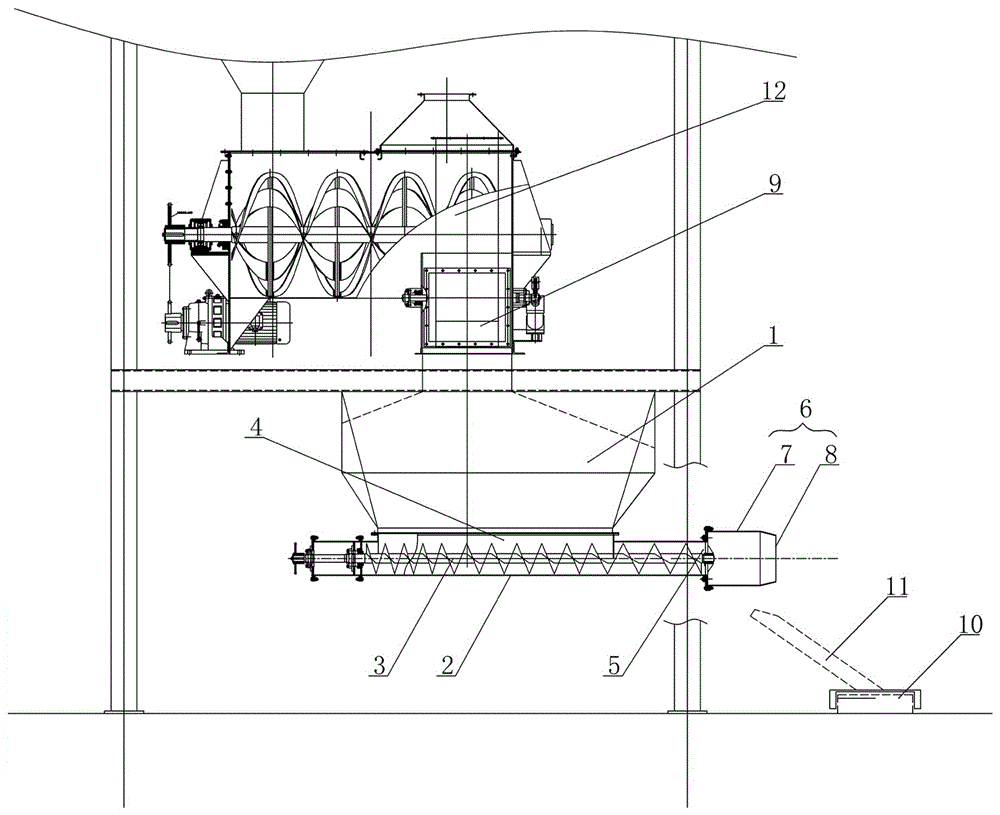

Total-tailings paste filling and stockpiling combined treatment method based on deep-cone thickener

ActiveCN104929683AHigh emission concentrationImprove security levelMaterial fill-upMining engineeringCombined treatment

The invention relates to a total-tailings paste filling and stockpiling combined treatment method based on a deep-cone thickener. A combined treatment system is composed of a one-stage or multi-stage pump station, the deep-cone thickener and a two-segment horizontal stirring device. The deep-cone thickener is arranged near the multi-stage pump station. A continuous feeding and discharging mode is adopted for achieving the continuous concentration process, and the two functions of filling and tailings stockpiling are both taken into consideration. In the running process of a filling system, total tailings of a concentration plant are completely thrown into the deep-cone thickener through the one-stage or multi-stage pump station. When filling is needed, deep-cone bottom flow is pumped to the two-segment stirrer through a mortar pump and is mixed with cement, and qualified paste is prepared and flows to or is pumped to a stope. When filling is not needed, the bottom flow is pumped by a plunger pump to a tailings pond by means of the pump station, and stockpiling of paste is performed. The method can well solve the filling problem of a gob and the stockpiling problem of tailings at the same time, filling cost is greatly reduced, the strength of filling bodies is improved, discharge of the tailings is reduced to the maximum extent, and meanwhile tailings paste is discharged.

Owner:UNIV OF SCI & TECH BEIJING +1

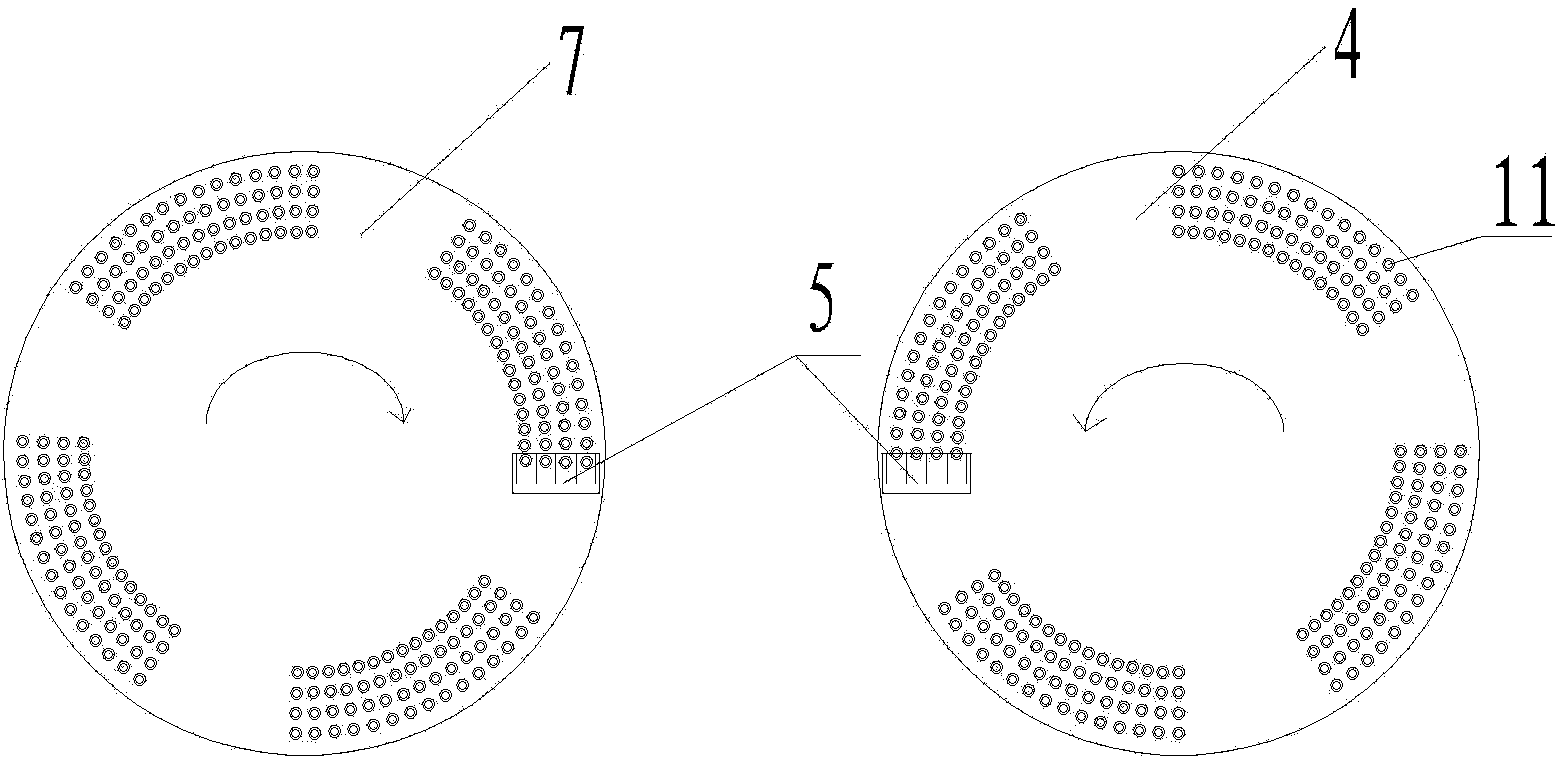

Multi-column orderly automatic blanking device of swing capsule counting machine

InactiveCN103587760AAvoid walkingAvoid man-made pollutionPackaging automatic controlEngineeringMedicine bottles

The invention discloses a multi-column orderly automatic blanking device of a swing capsule counting machine, and belongs to the technical field of medicine production. The multi-column orderly automatic blanking device of the swing capsule counting machine comprises a rack, a conveying belt for conveying medicine bottles is arranged on the rack, capsule counting rotary tables are arranged above the conveying belt, a plurality of capsule counting holes are evenly distributed in the capsule counting rotary tables at equal intervals, blanking holes are formed in the lower portions of the capsule counting rotary tables, a plurality of V-shaped grooves aligned to the blanking holes are formed below the capsule counting rotary tables, the lower ends of the V-shaped grooves correspond to the positions of the medicine bottles of the conveying belt, locating air cylinders limiting the walking of the medicine bottles are arranged on the conveying belt, and the locating air cylinders are arranged below the V-shaped grooves and above the conveying belt. The multi-column orderly automatic blanking device of the swing capsule counting machine solves the capsule counting and filling problem of a long and thin bottle (the diameter of a bottle mouth is smaller than the total length of a capsule), greatly improves labor productivity, and avoids man-made pollution caused by manual counting and filling.

Owner:SICHUAN EMEISHAN PHARMA

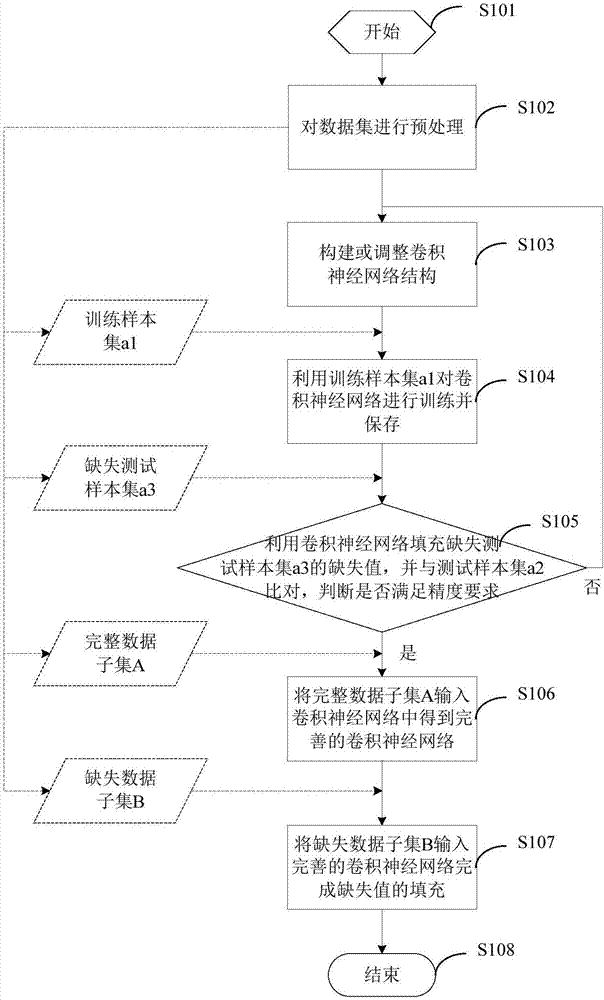

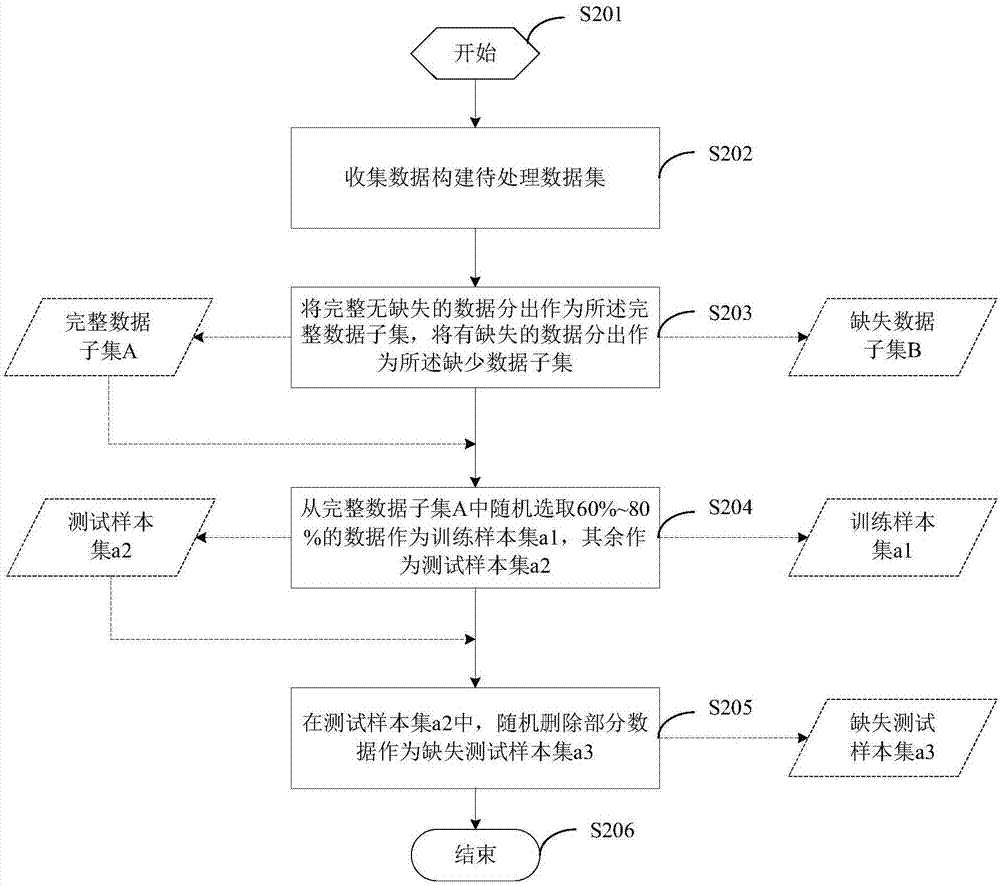

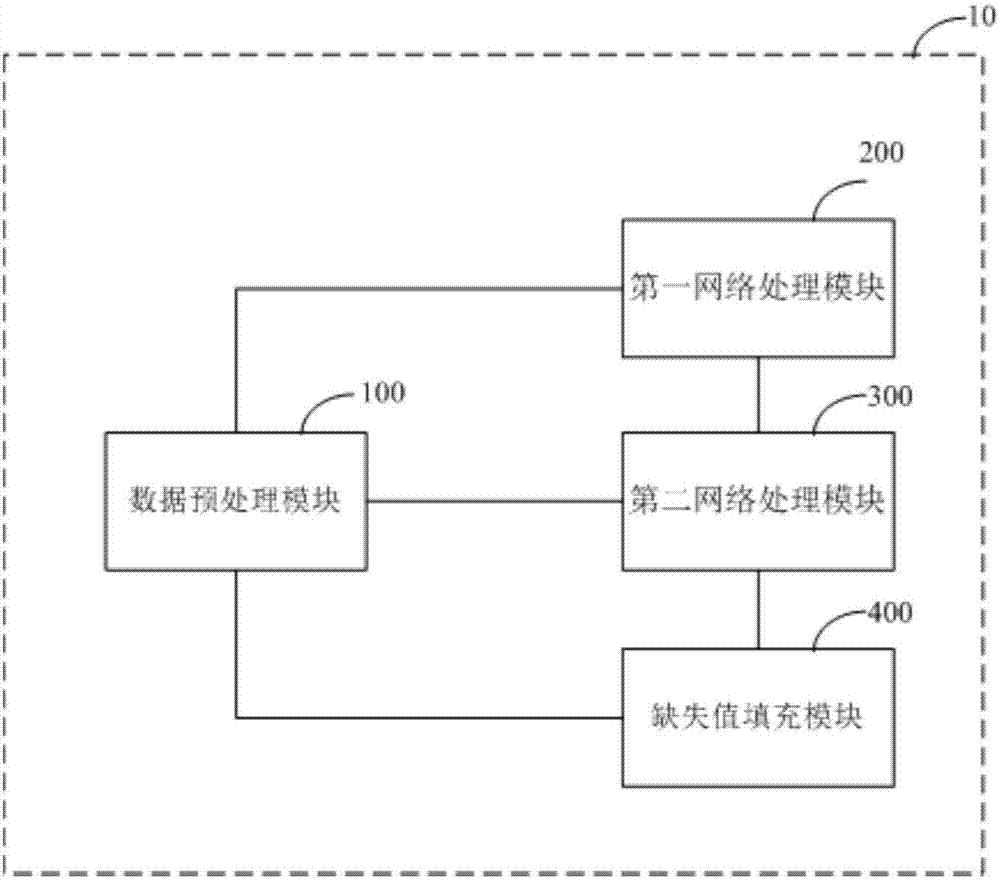

Deep learning-based missing value filling method and system

ActiveCN107273429AReduce fitReduce in quantityNeural architecturesNeural learning methodsComplete dataMissing data

The invention provides a deep learning-based missing value filling method and system. The method comprises the following steps of preprocessing a data set; training and storing a preliminarily constructed convolutional neural network by utilizing a training sample set, carrying out missing value filling on a missing test sample set by using the trained convolutional neural network, comparing the filling result with a test sample set, and adjusting a network structure of the convolutional neural network and iterating the training and verification steps until a precision requirement met when the precision requirement is not met; inputting a complete data subset into the convolutional neural network so as to obtain a perfect convolutional neural network; and inputting a missing data subset into the perfect convolutional neural network to complete missing value filling. According to the method and system provided by the invention, the database missing value filling problem is solved, the effects of higher correctness and higher efficiency are achieved, and the missing data can be restored more really and rapidly.

Owner:工创集团有限公司

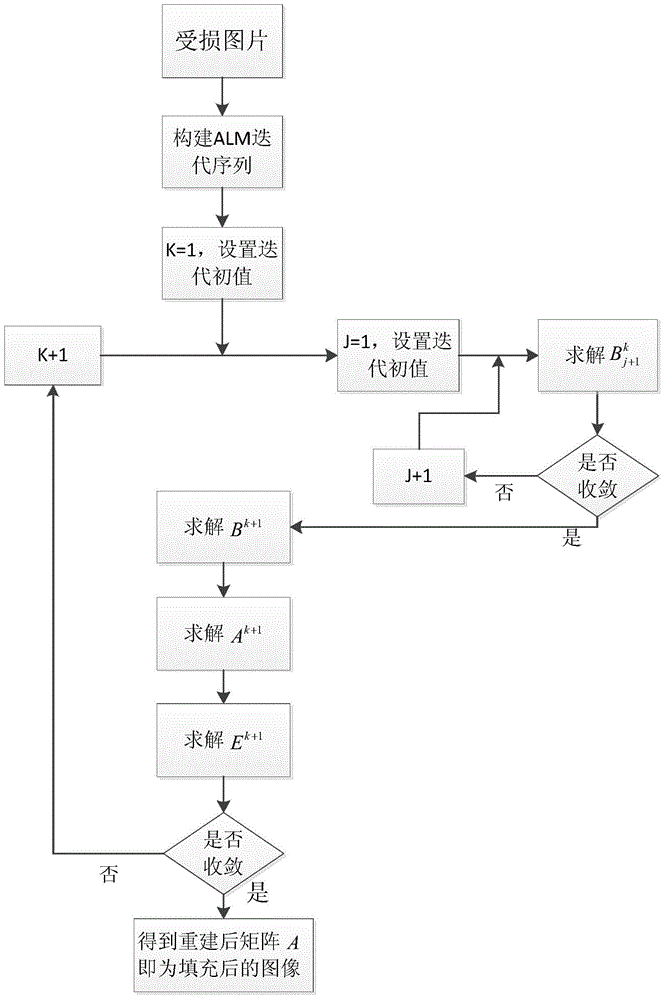

Structural lack image filling method based on low rank matrix reconstruction

The invention belongs to the computer vision field and aims at realizing filling to pixel structural lack images. The structural lack image filling method based on low rank matrix reconstruction comprises the following steps: 1) taking the image as a matrix, using a matrix A to represent an original image and converting a pixel structural lack image filling problem into a solving optimization equation; 2) training a dictionary fai; 3) using an alternative direction method ADM to convert a sequence into a sequence so as to carry out solving and then carrying out iteration solving according to steps so as to acquire a final result. The method in the invention is mainly used for computer image processing.

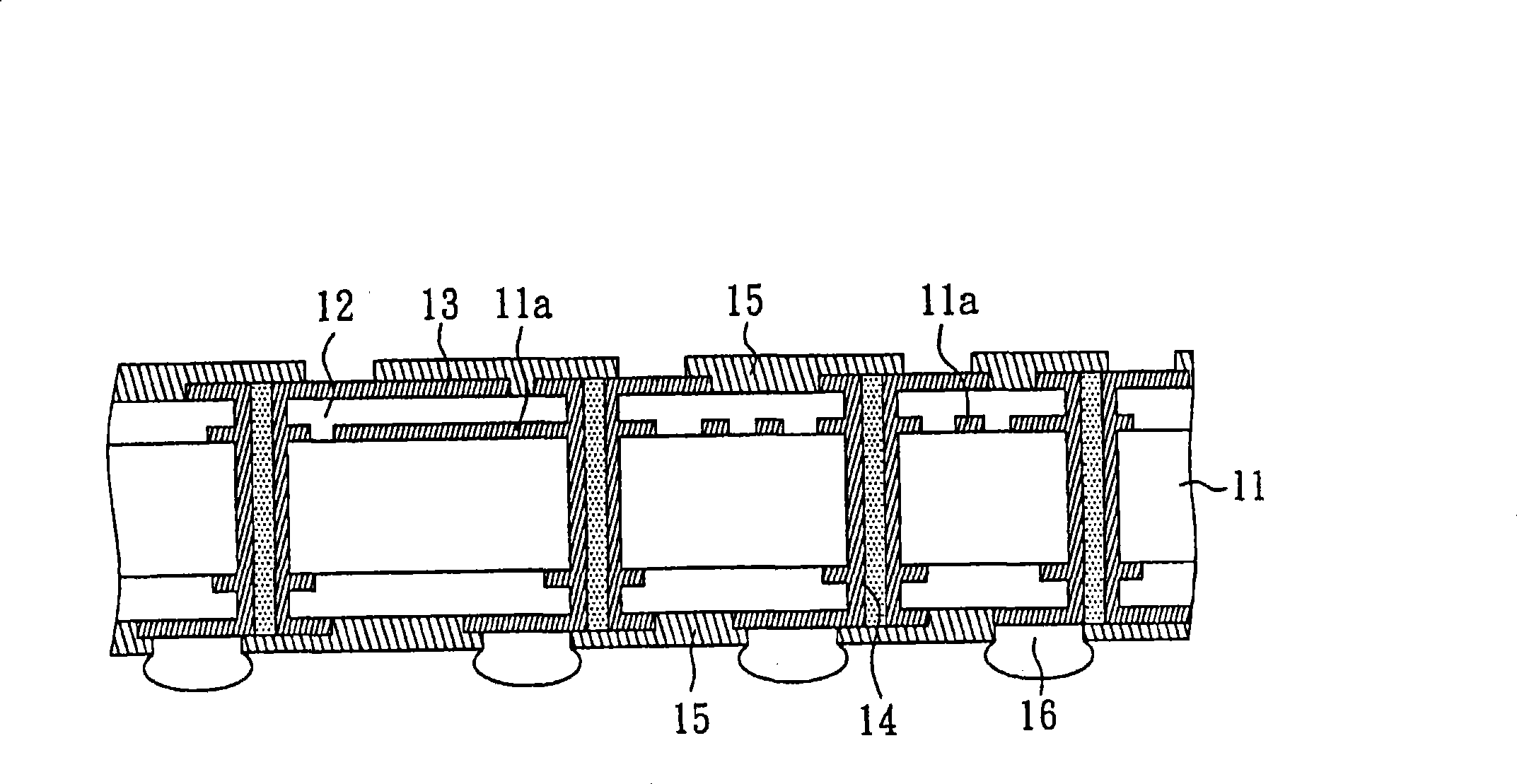

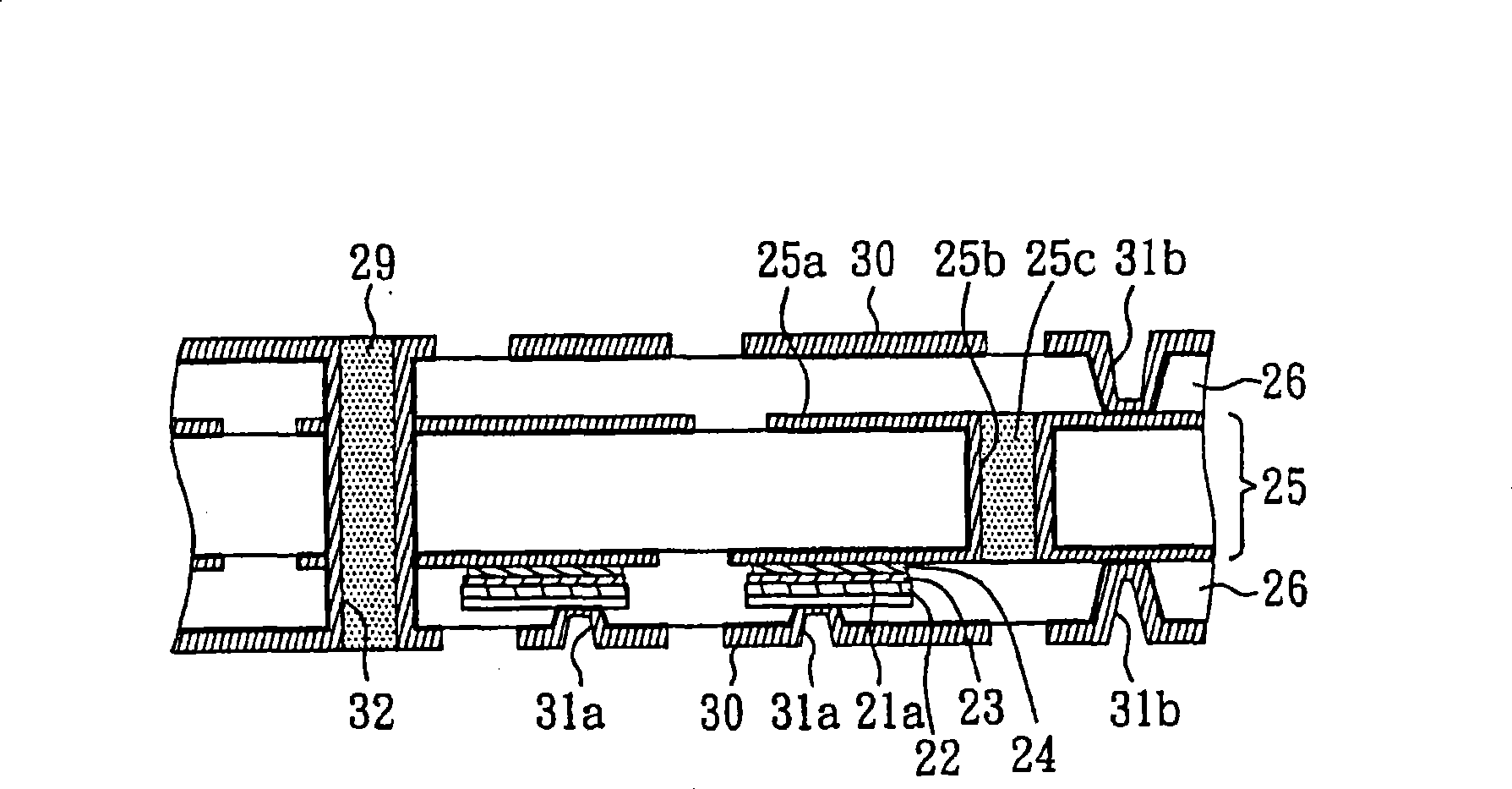

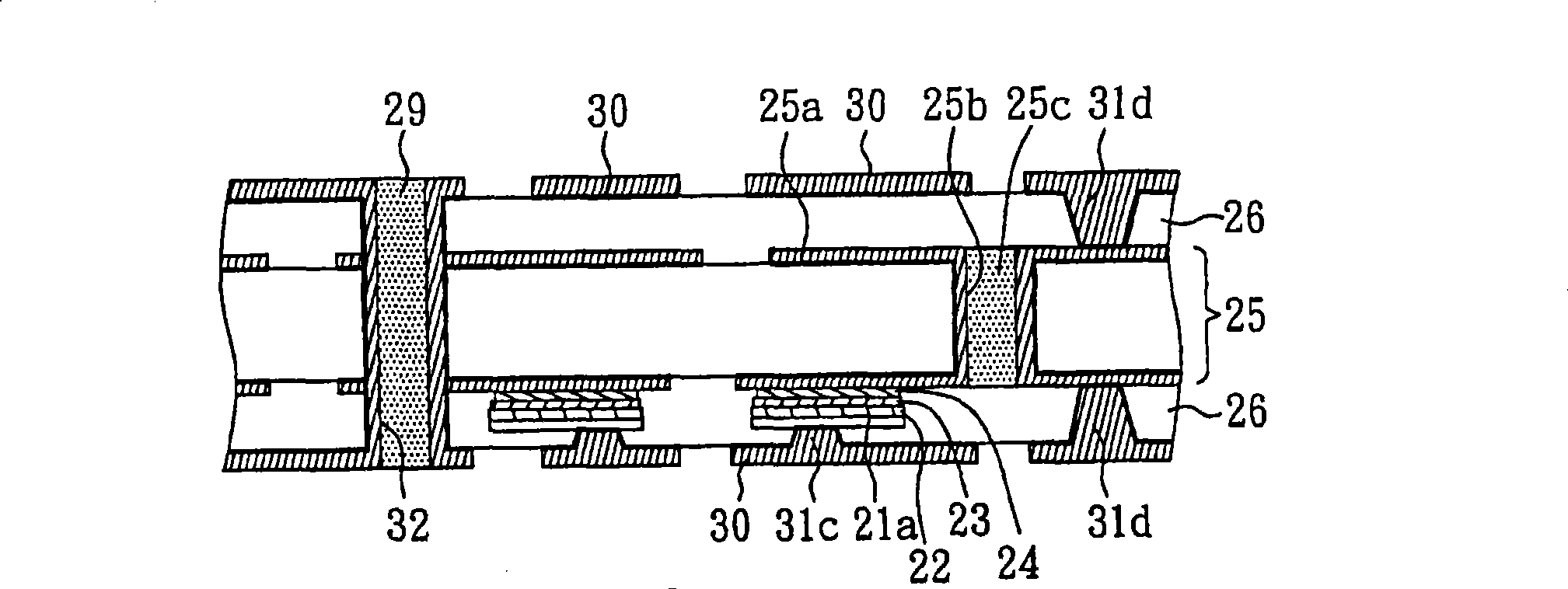

Capacitor embedded semi-conductor package substrate construction and preparation thereof

InactiveCN101364583AThe number of deployments increasedIncrease the usable areaPrinted circuit assemblingSemiconductor/solid-state device detailsCapacitanceThin metal

The invention relates to a semiconductor encapsulated baseplate structure, in which a capacitance component is embedded. The structure comprises an inner layer circuit board, a dielectric layer and an outer circuit layer, wherein, the dielectric layer is disposed on both sides of the inner layer circuit board and provided with a first conductive blind hole which is communicated with the inner layer circuit board through a thin metal layer, a capacitance material, an electrode layer and an adhesive layer in sequence; the external circuit layer is disposed on the surface of the dielectric layer; and herein, the thin metal layer, the capacitance material and the electrode layer are taken as a capacitance component. The invention further provides a method for manufacturing the semiconductor encapsulated baseplate structure. Compared with the capacitance material formed by compressing the whole piece of high-dielectric material, the capacitance component embedded in the semiconductor encapsulated baseplate has the advantages of saving material, solving the pore-filling problem and avoiding creepage of the capacitance between circuits.

Owner:PHOENIX PRECISION TECH CORP

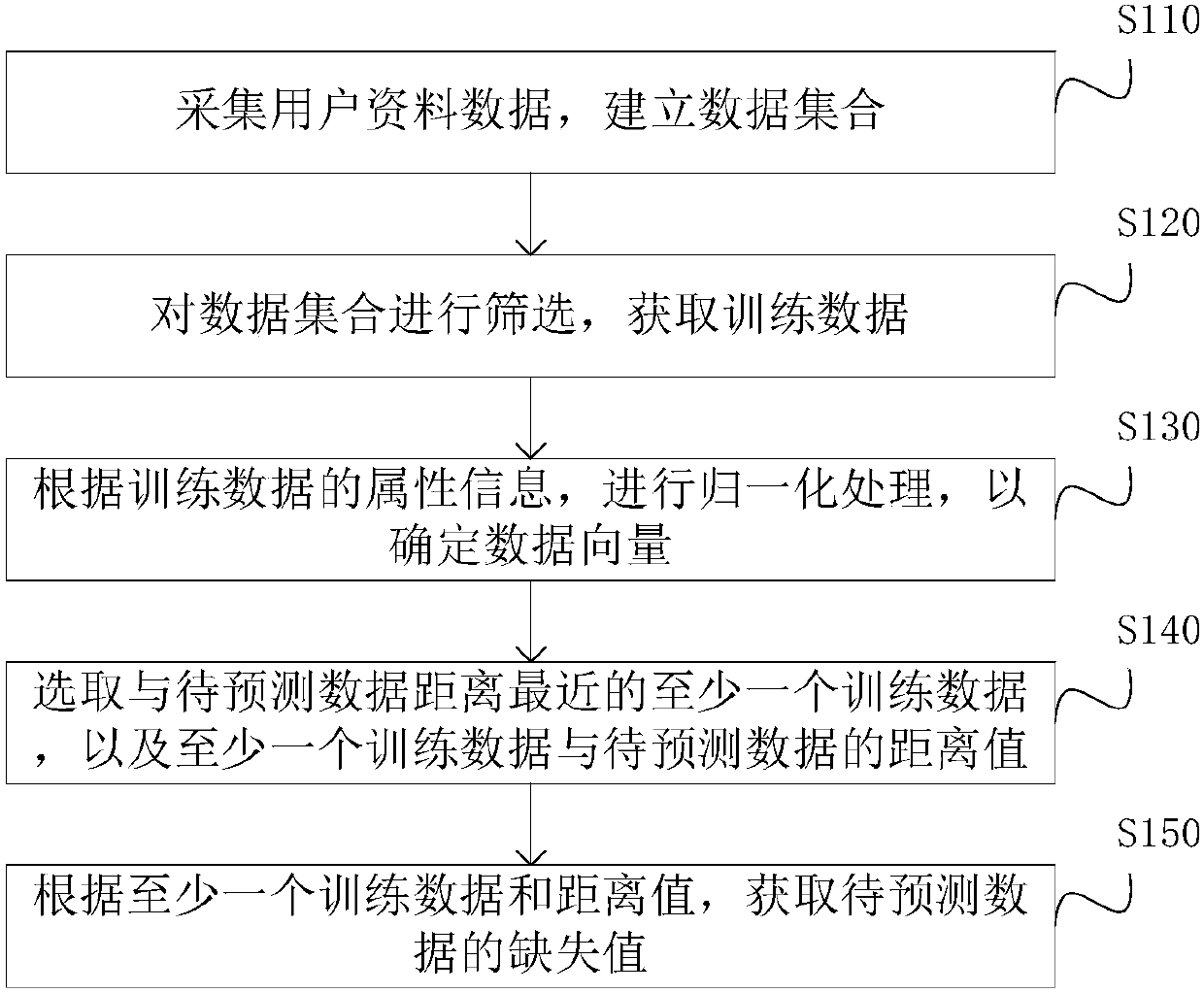

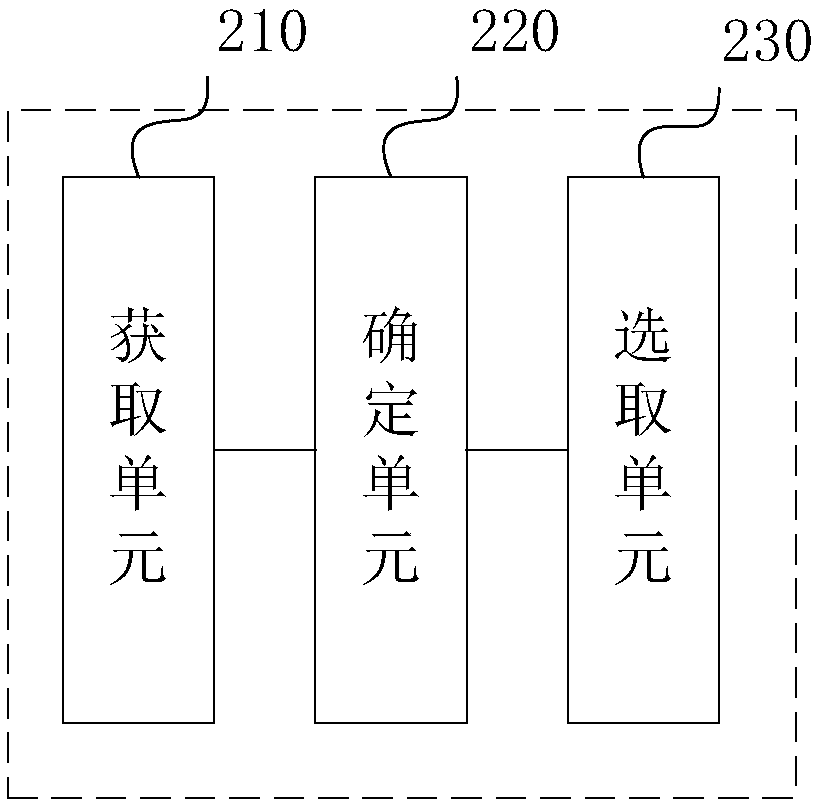

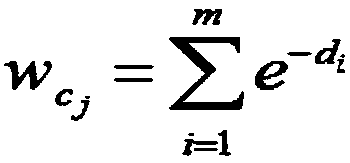

User data prediction method and system

InactiveCN108256538ASolve the missing value filling problemImprove interpretabilityCharacter and pattern recognitionData setData prediction

The present invention relates to a user data prediction method and system. The method comprises the steps of: screening a data set, and obtaining training data; according to attribute information of the training data, determining data vectors; in the data vectors, selecting at least one training data being closest to data to be predicted and distance values of the at least one training data and the data to be predicted; and according to the at least one training data and the distance values, obtaining a missing value of the data to be predicted. The prediction method solves the missing value filling problem of classification data and value data, improves the accuracy of the filling missing value and enhances the result interpretability.

Owner:BEIJING KUWO TECH

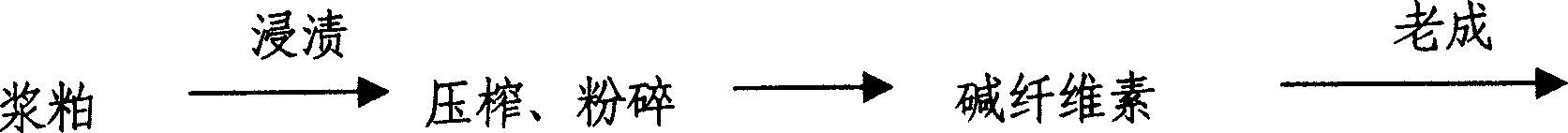

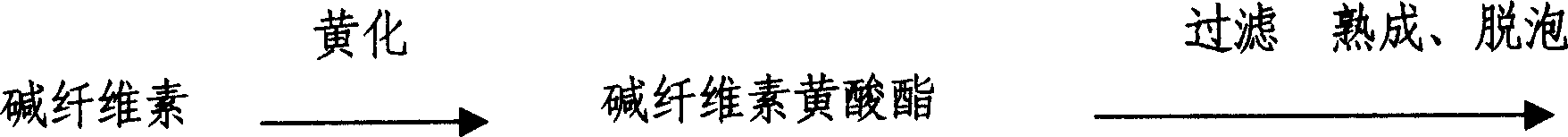

Far infrared viscose filament and preparing method thereof

InactiveCN1528959AImprove efficacyImprove spinnabilityMonocomponent cellulose artificial filamentWet spinning methodsTextile technologyMetallurgy

The invention is a kind of far infrared viscose filament yarn and the manufacturing method, which belongs to textile technology field, and which is used to solve the filling problem of functional material. The far infrared viscose rayon silk contains alpha fiber 83-84%, far infrared ceramic powder 3-3.5%, water 13%, the particle size of far infrared ceramic powder is 0.1-1.0 um which content is more than 95%. The residue particles' size is not greater than 2 um. Adds in far infrared ceramic powder mother liquid in fiber xanthate ester dissolving process or textile front glue, the thickness is 5-10%, the invention has character of persistent function, and good textile property. The far infrared transmitting power reaches 86%.

Owner:SWAN FIBER

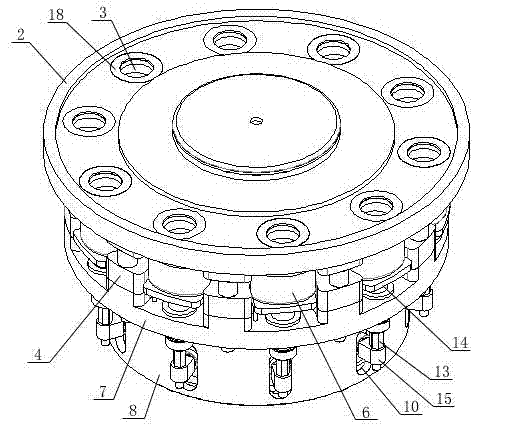

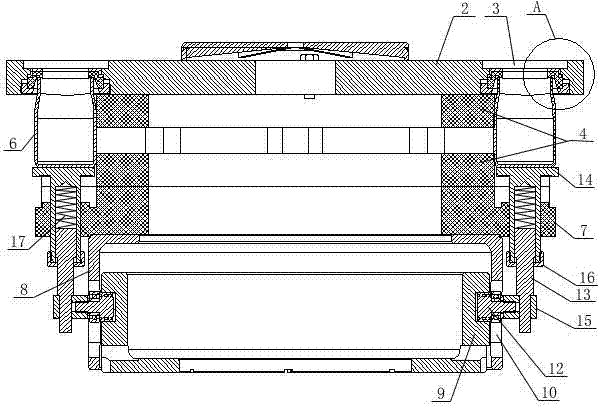

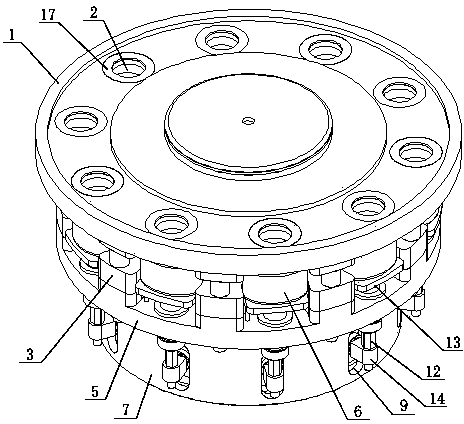

Turntable device for filling machine

The invention discloses a turntable device for a filling machine. The turntable device comprises a turntable and a plurality of blanking through holes uniformly formed in the turntable, wherein a bottle clamping disk is arranged below the turntable; a plurality of bottle clamping slots corresponding to the blanking through holes are formed in the periphery of the bottle clamping disk and are matched with the shapes of filling bottles; a mandril fixing plate is arranged below the bottle clamping disk; the turntable, the bottle clamping disk and the mandril fixing plate are connected with one another through connection pieces to form a whole; a plurality of bottle jacking mechanisms corresponding to the bottle clamping slots are arranged below the mandril fixing plate; the upper ends of the bottle jacking mechanisms penetrate through the mandril fixing plate to jack up the filling bottles arranged in the bottle clamping slots, so that bottlenecks of the filling bottles can be jacked to the blanking through holes of the turntable. According to the turntable device for the filling machine, the filling bottles are clamped through the bottle clamping disk, so that the filling bottles can completely correspond to the blanking through holes of the turntable one by one and synchronously rotate along with the turntable in the whole filling process; therefore, the filling problem caused by a fact that the filling bottles do not correspond to a blanking hopper in an existing structure can be thoroughly solved.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

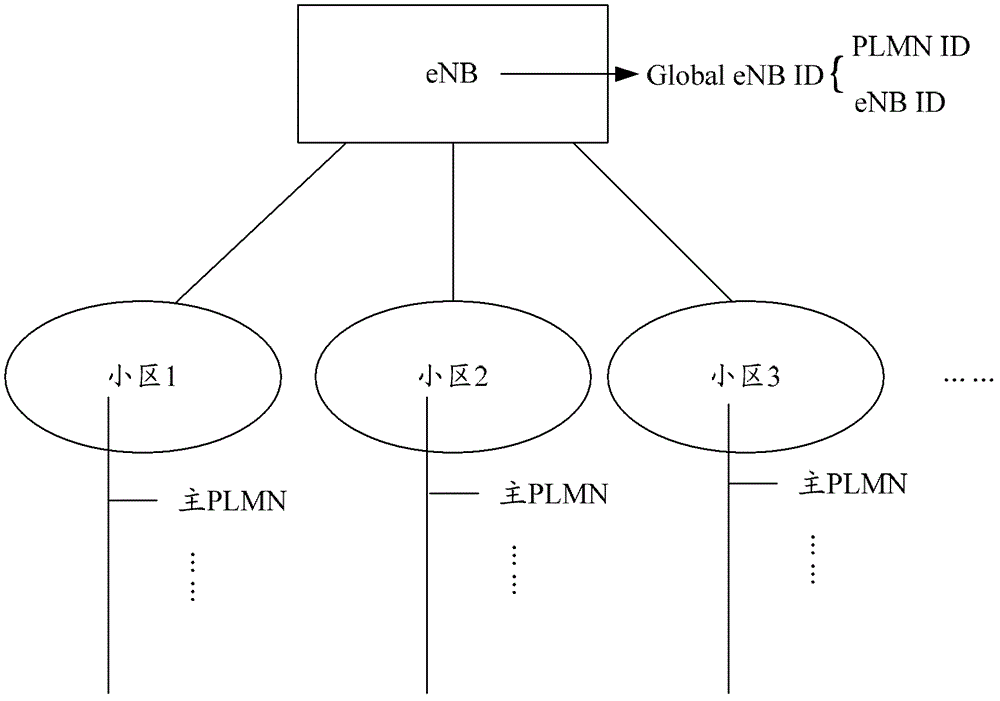

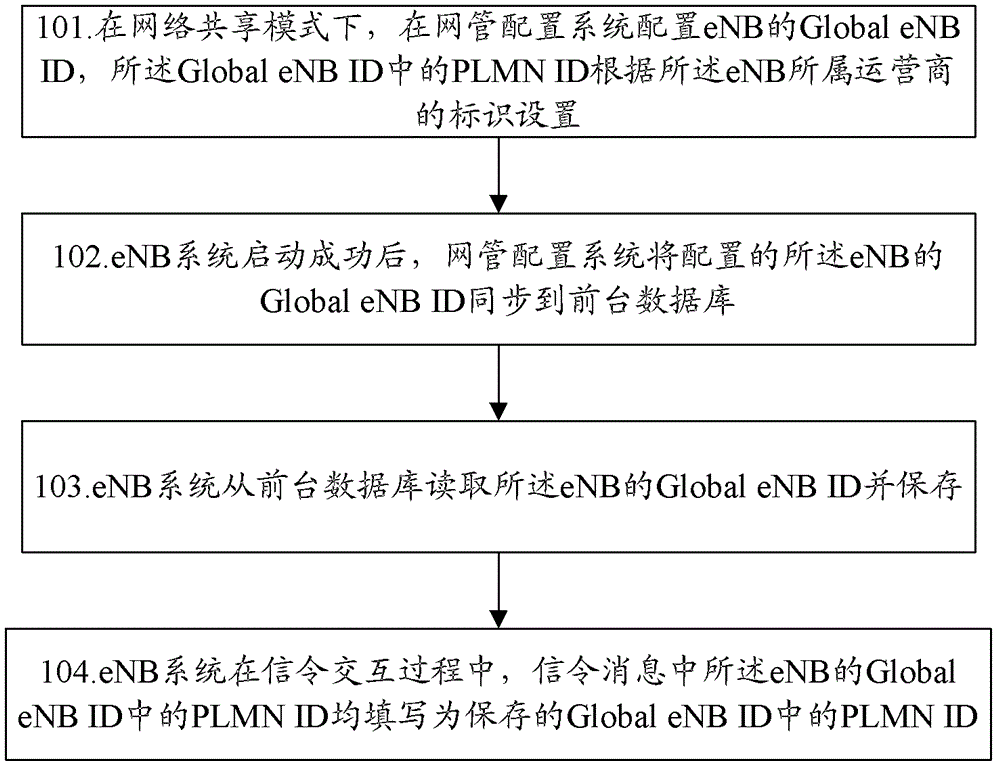

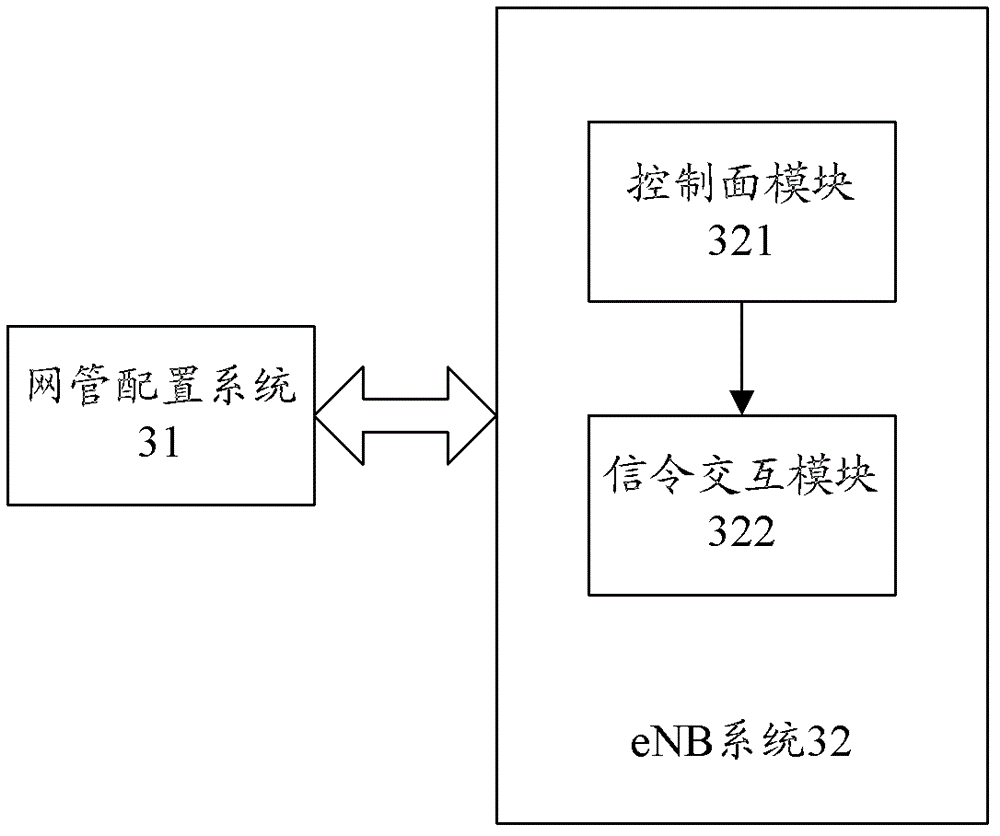

Method and system for effective noise bandwidth (eNB) global identification configuration and eNB system

ActiveCN103067912ASolve the filling problemNetwork data managementNoise bandwidthPublic land mobile network

The invention discloses a method for effective noise bandwidth (eNB) global identification configuration. Under a network sharing mode, the global eNB identification (ID) of eNB is configured in a web master configuration system. The public land mobile network (PLMN) ID of the global eNB ID is set according to the identification of a service provider, and the eNB belongs to the service provider. When an eNB system is successfully started, the global eNB ID of the eNB is sent to a foreground data base in a synchronous mode through the web master configuration system. The eNB system reads the global eNB ID of the eNB and stores the global eNB ID of the eNB. During a signal interactive process, the PLMN ID in the global eNB ID of the eNB of signal information is filled as the PLMN ID of the stored global eNB ID. The invention further discloses a system for eNB global identification configuration and an eNB system. The eNB can be accurately and uniquely identified under the network sharing mode, and a filling problem of the PLMN ID in the global eNB ID is solved.

Owner:ZTE CORP

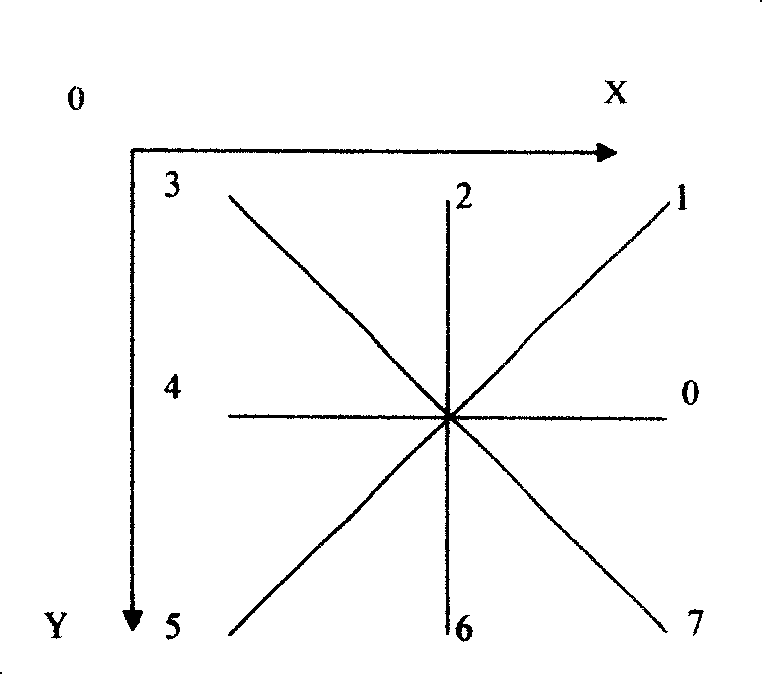

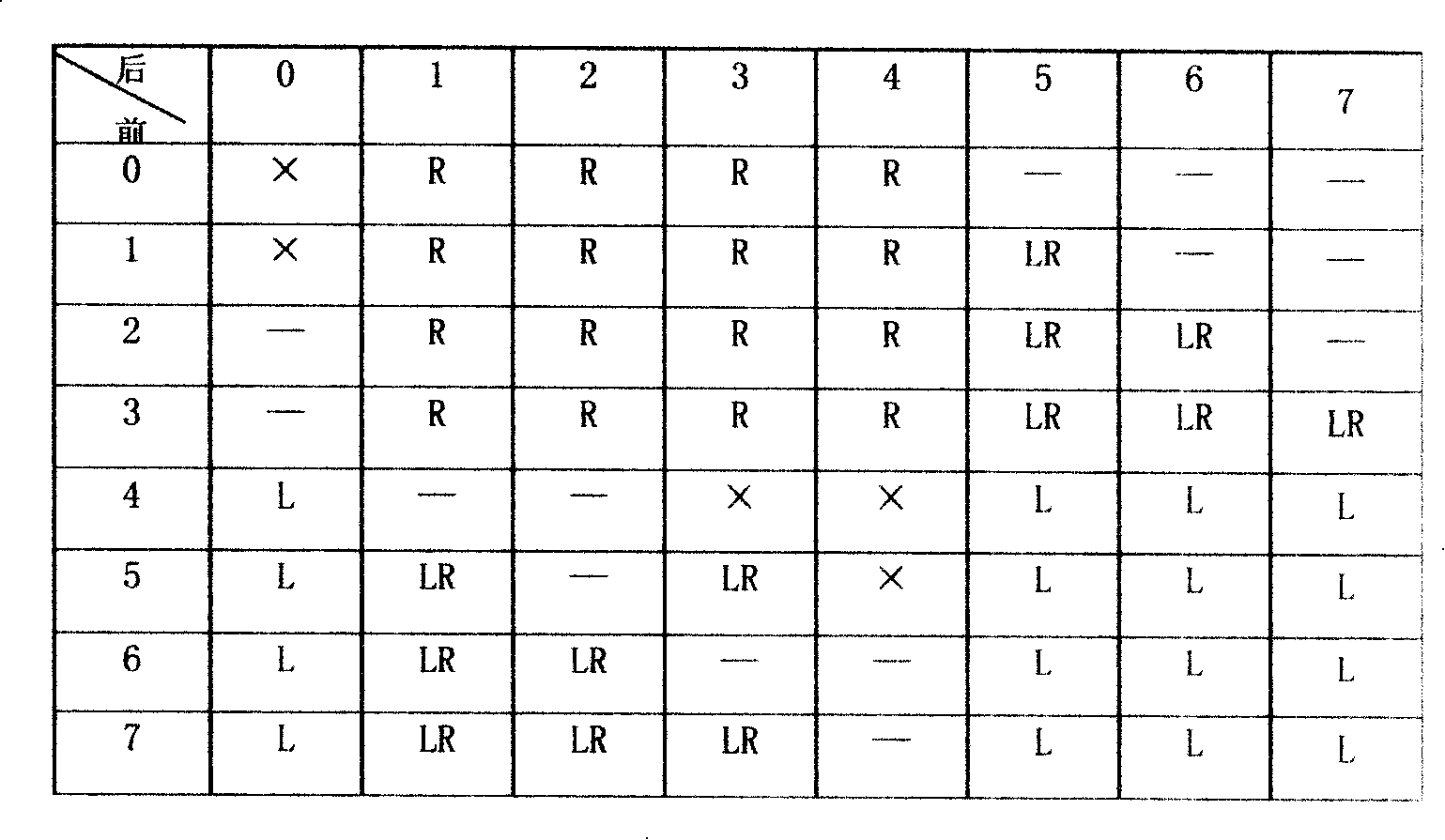

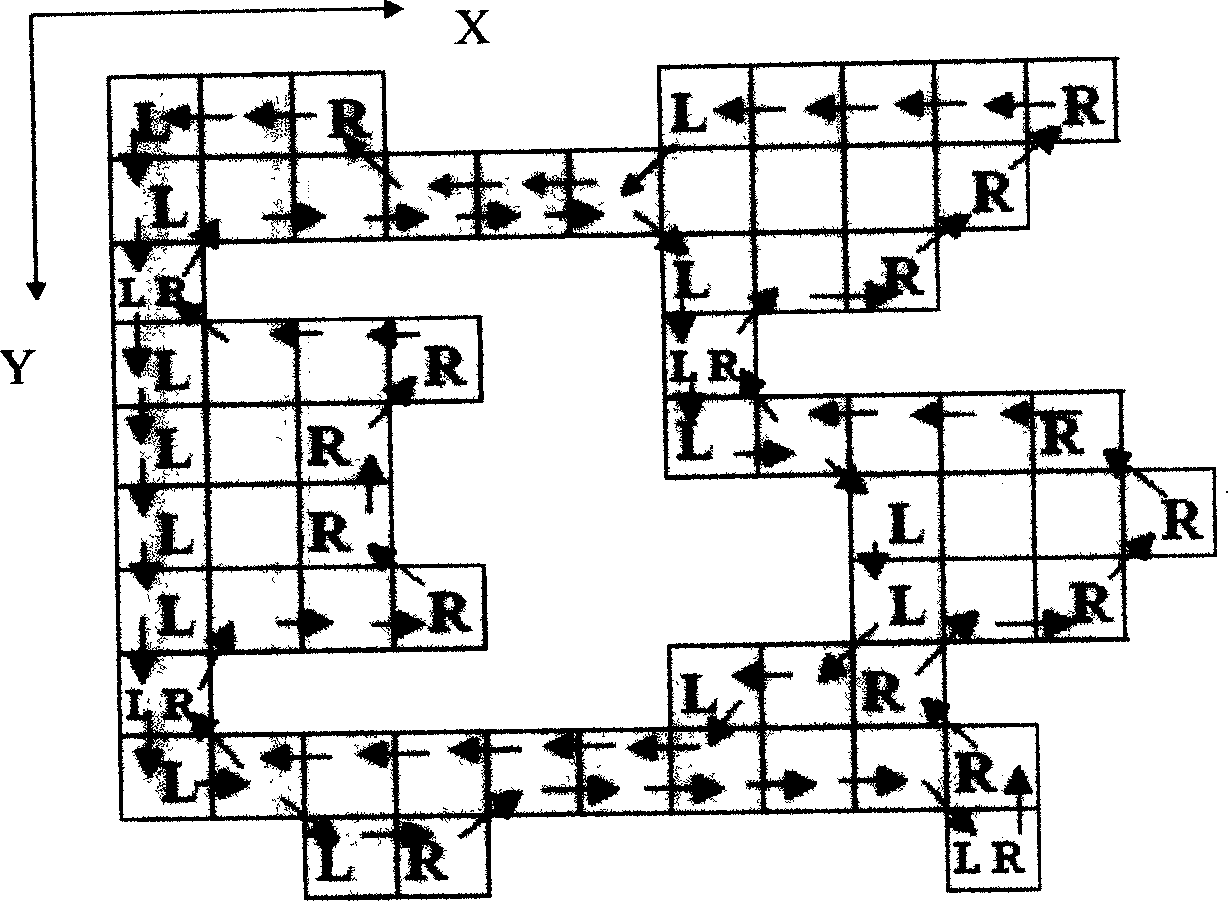

Filling algorithm for rapidly matching pair of left and right boundary point

The invention relates to a filling algorithm method for quick matching of left and right boundary points, belongs to the computer image processing technology field and essentially solves image filing problem in known Freeman chain code. The filling algorithm method is characterized in that according to the features of the Freeman chain code at zone boundary, the boundary points are divided into three types of a left end point, a right end point and a cuspidal point. The filling algorithm method approaches to the minimum time complexity, namely, the area of filling zone and girth thereof without adding memory and auxiliary marker color. The technical proposal is that: a boundary is searched quickly to determine the position of the right end point and color the right end point in a image directly; the boundary is searched again to find out pixel of the left end point and color the pixel of the left end point and the pixel of the right side thereof in sequence till encountering the colored right end point. After finishing treatment of all chain codes, the filling algorithm method is completed. The filling algorithm method is applied to display of simply connected image or multiply connected image in digital image processing field, obtaining the common region of two objects and relations of two regions or storing binary image.

Owner:SHANGHAI JILIANG SOFTWARE TECH

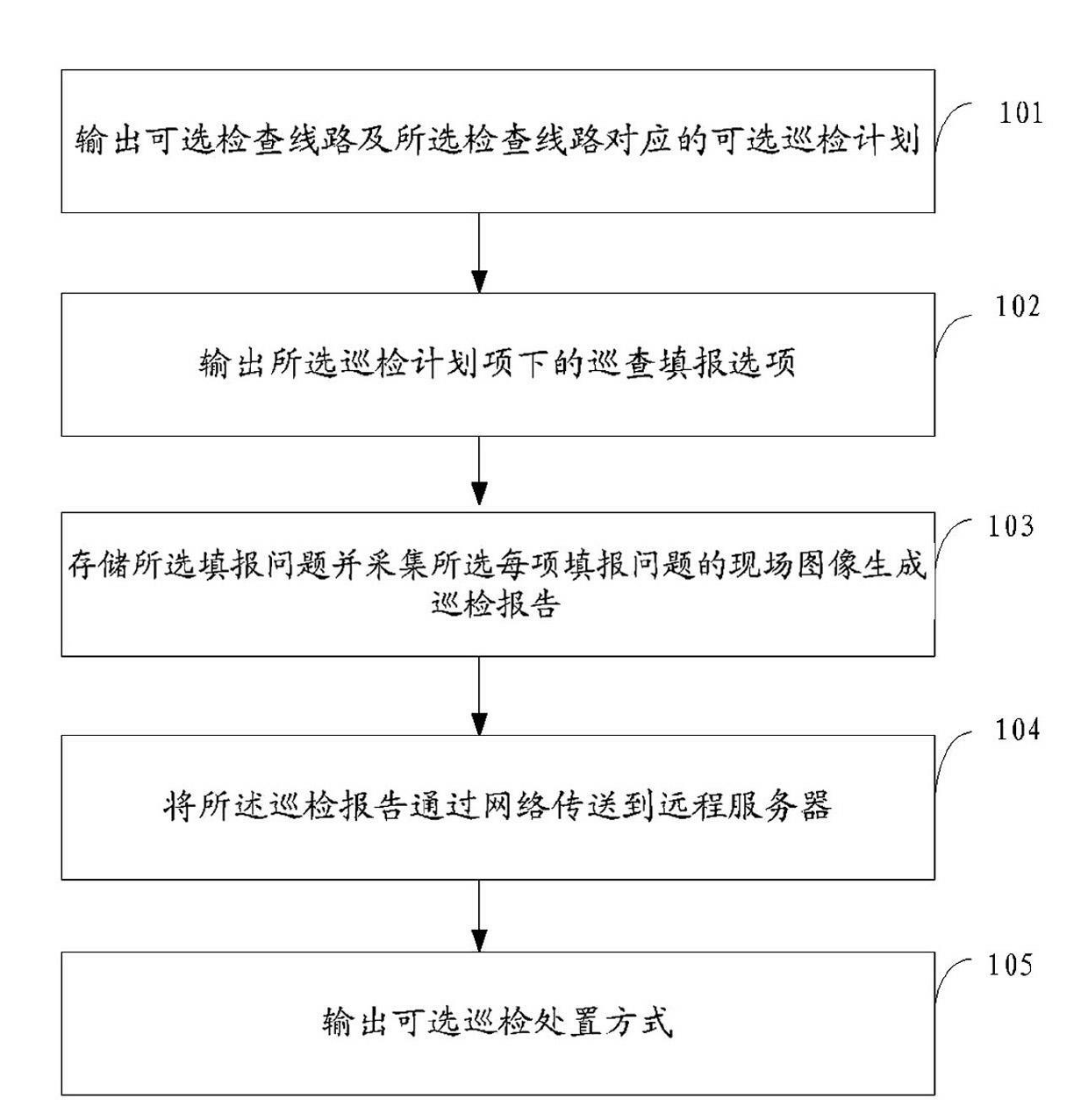

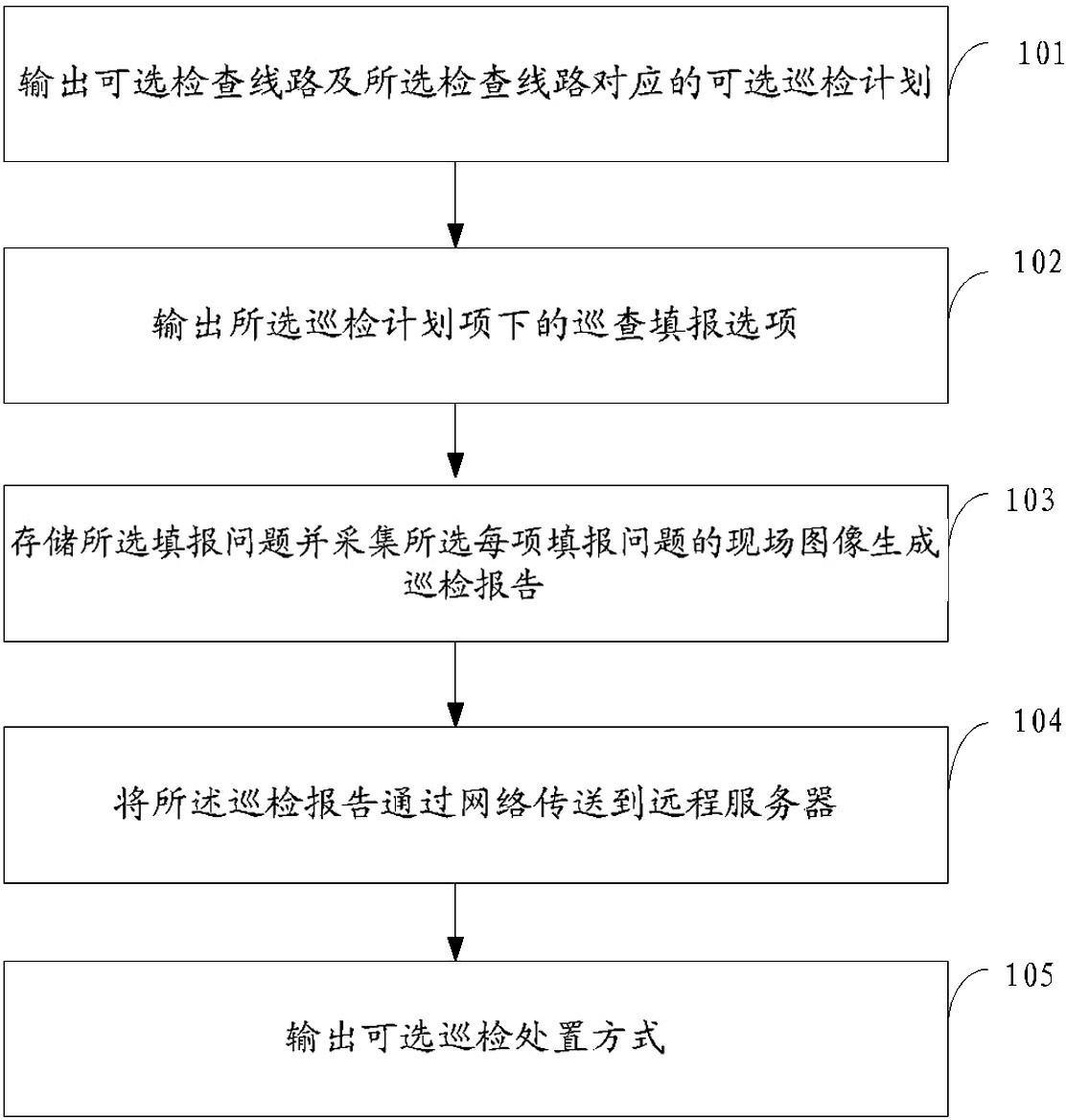

WINCE system-based rail transit real-time detection system and detection method

InactiveCN102127885AImprove work efficiencyImprove the quality of workMining devicesTrack maintainenceEngineeringRail transit

The invention is suitable for the technical field of rail transit detection, and provides a Windows CE (WINCE) system-based rail transit real-time detection system and a WINCE system-based rail transit real-time detection method. The method comprises the following steps of: outputting selectable inspection lines and an inspection plan corresponding to the selected inspection line; outputting inspection filling options under the selected inspection plan item; storing the selected filling problem and acquiring a field image of the selected filling problem to generate an inspection report; transmitting the inspection report to a remote server through a network; and outputting selectable processing modes. The inspection report with characters and images is generated according to stored selected filling problem contents and the acquired field image, and is transmitted to the remote management server through the network in real time, and the corresponding processing modes are provided for selection, so that new working standards are brought to the rail transit detection, and the efficiency and quality of rail transit detection work are greatly improved.

Owner:BEIJING MUNICIPAL ENG RES INST +1

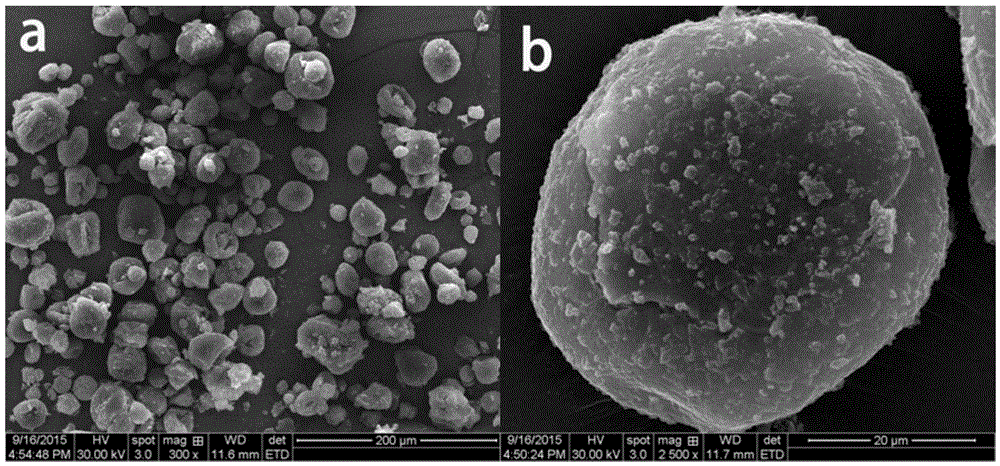

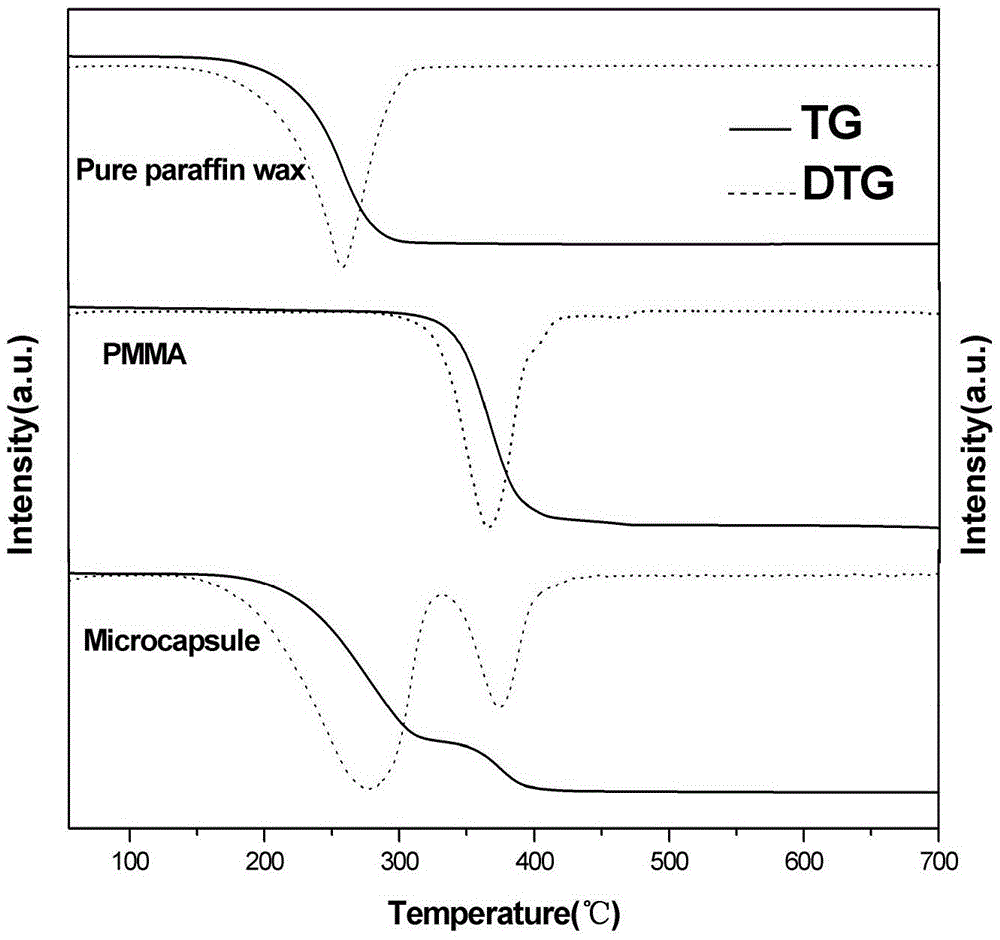

Multifunctional microcapsule corrosion inhibitor and preparation method thereof

ActiveCN105601456AReduces ablative wearReduce heat transferMicroballoon preparationNon-explosive/non-thermic compositionsParaffin waxHigh resistance

The invention discloses a multifunctional microcapsule corrosion inhibitor and a preparation method thereof. The multifunctional microcapsule corrosion inhibitor takes a heat-absorbing material, namely paraffin, as a capsule core material, an organic polymer as a capsule wall material and amphiphilicity-modified inorganic nanoparticles as a capsule wall addition agent, and is obtained according to the steps of firstly, subjecting the inorganic nanoparticles to amphiphilic modification through an atom transfer radical polymerization method, then mixing the paraffin, the amphiphilicity-modified inorganic nanoparticles and monomers with an emulsifier and a co-emulsifier to obtain oil-water emulsion under high-speed shearing, and finally adding an initiator to react. The multifunctional microcapsule corrosion inhibitor has the advantages that the filling problem of the high-energy propellant charge filling corrosion inhibitor is solved, and different substances in microcapsules achieve synergistic effects, namely heat-absorbing characteristic of the paraffin, compatibility of the organic polymer and propellant charge, increase of CO / CO2 ratio in a laminar boundary layer and high resistance to heat and wear and low heat conductivity of the inorganic nanoparticles, so that ablation resistance of a gun barrel is reduced in multiple angles.

Owner:NANJING UNIV OF SCI & TECH

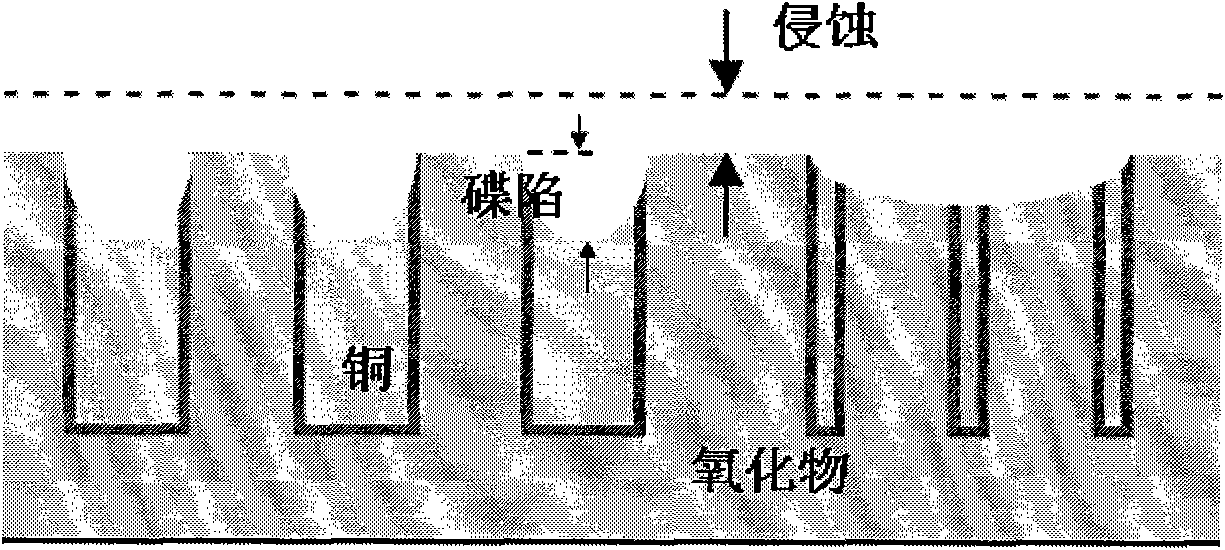

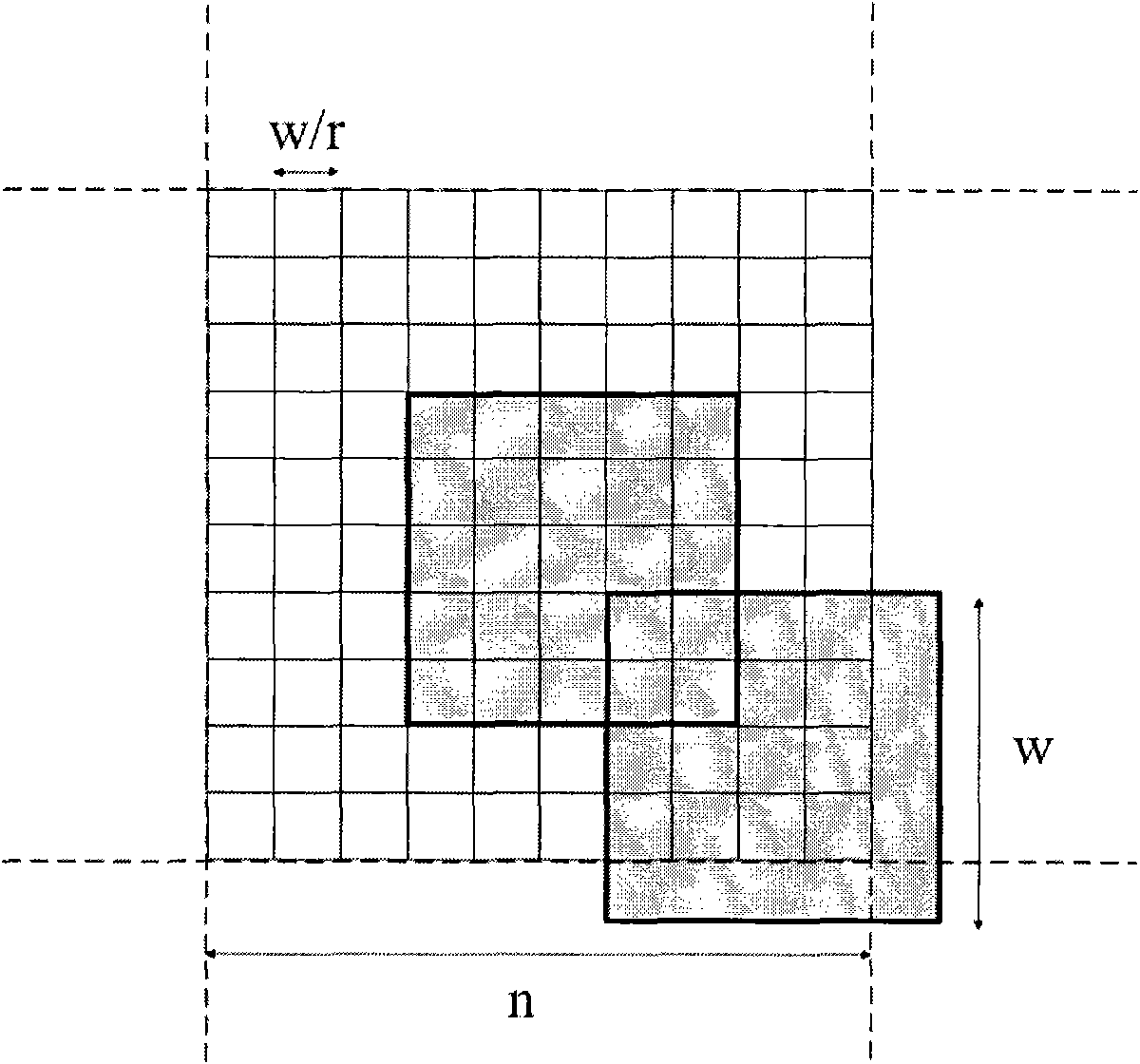

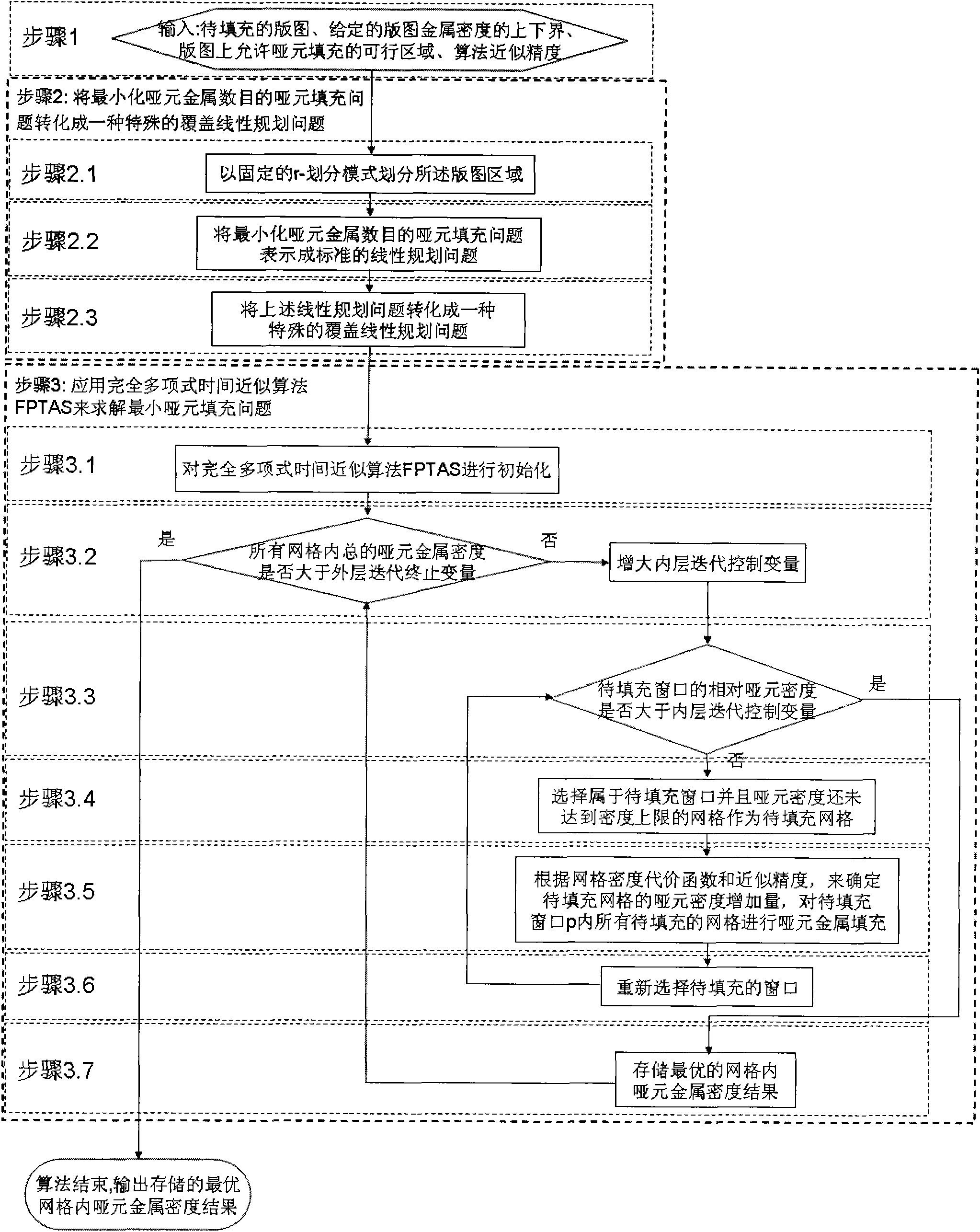

Dummy filling method of chemical-mechanical polishing process

ActiveCN101964001AGuaranteed linear complexityGuaranteed ε-optimalitySpecial data processing applicationsRound complexityCombinatorial optimization

The invention belongs to the technical field of manufacturing of integrated circuit semiconductors, and relates to a dummy filling method of a chemical-mechanical polishing process. By the method, a dummy filling problem that a minimum dummy metal number is solved is converted into one type of special coverage linear programming CLP problems and the minimum dummy filling problem is solved by applying one full polynomial time approximation algorithm FPTAS in the combinatorial optimization field according to the characteristics of the CLP problem. The method can ensure the epsilon optimality of a final result and realize the compromise of the final result accuracy and the calculating speed, so that the problem that the speed and the accuracy cannot be simultaneously taken into consideration existing in the conventional method is solved; and by the method, the approximately least dummy filling number can also be acquired under the linear time complexity, and the method can be used for solving the large-scale territory dummy filling problem.

Owner:FUDAN UNIV

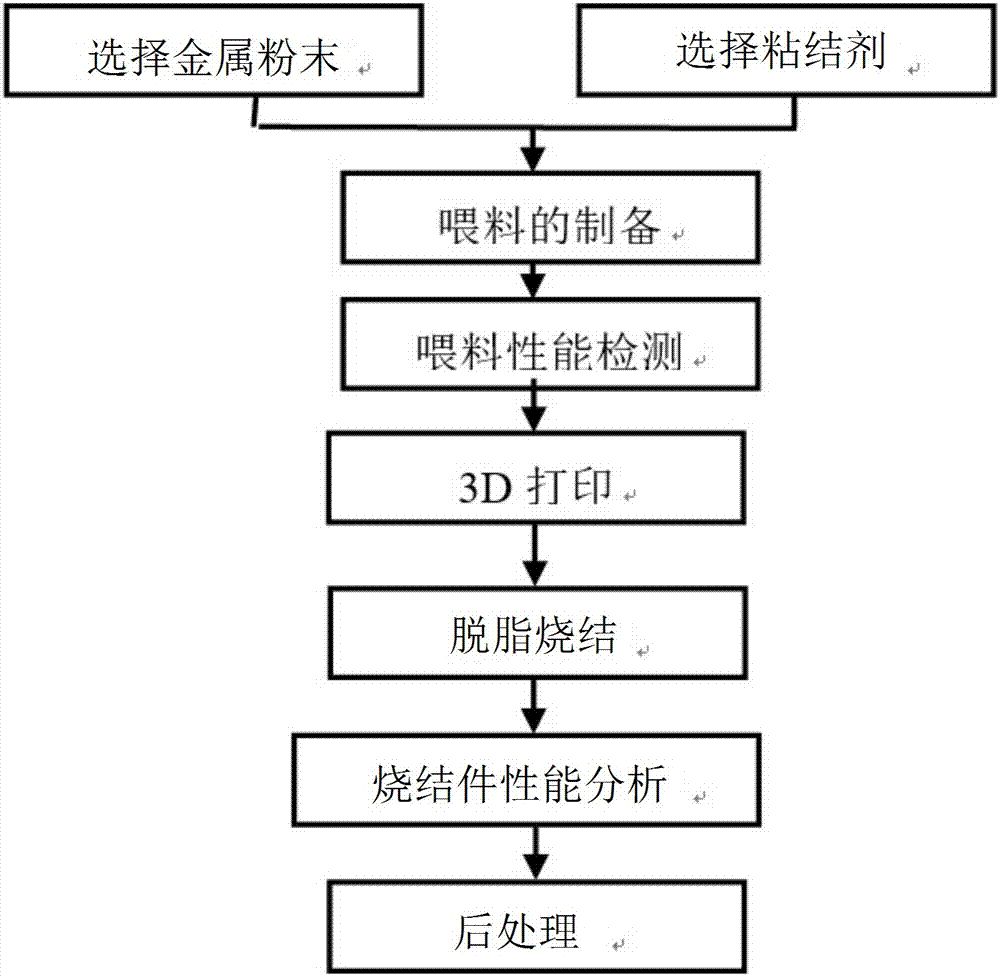

3D printing additive manufacturing method of Ti6Al4V injection molding feedstock

InactiveCN106984819AImprove surface qualityHigh dimensional accuracyAdditive manufacturing apparatusFilling ProblemTitanium

The invention relates to a 3D printing additive manufacturing method of Ti6Al4V injection molding feed, which comprises the following steps: 1), selecting metal powder and binder; 2), using the selected metal powder and binder to prepare feed 3) using the feeding materials in the 3D printer to directly print titanium alloy parts; 4) degreasing and sintering the printed titanium alloy parts. The invention directly adopts injection molding feeding materials to 3D print titanium alloy parts, which solves the problems of flow lines and insufficient filling in the injection molding stage of injection molding technology, so that the parts after sintering and post-processing have good surface quality and low size. High precision and strong comprehensive mechanical properties further improve the application of 3D printing technology in the field of aviation manufacturing.

Owner:东莞市依诺电子科技有限公司

Prefabricated roadbed with blocks formed by solidifying and sealing of solid waste and poor soil

ActiveCN108360323ASolve the filling problemHigh strengthRoadwaysSolid waste managementRoad surfaceEngineering

The invention discloses a prefabricated roadbed with blocks formed by solidifying and sealing of solid waste and poor soil. The prefabricated roadbed is characterized in that the prefabricated roadbedcomprises the multiple solidified and sealed prefabricated blocks; the multiple solidified and sealed prefabricated blocks are assembled and subjected to interlayer bonding through geogrids or geotextiles; each solidified and sealed prefabricated block comprises a sealed bag used for containing the solid waste or the poor soil; the sealed bags are provided with extraction openings which can adjust the compactness of the solidified and sealed prefabricated blocks; and each sealed bag comprises a face layer and a waterproof layer, and the waterproof layers are arranged on the inner sides of theface layers. The sealed bags are filled with the solid waste or the poor soil for solving the solid waste and poor soil roadbed filling problem; and the solidified and sealed prefabricated blocks areassembled into the prefabricated roadbed, thus the overall strength and the bearing capability of a foundation are improved, differential settlement of the constructed roadbed is effectively controlled, and the engineering quality problem that in the prior art, a roadbed is insufficient in stability, and consequently road surface cracking is prone to occurring is solved.

Owner:海灿(宁波)工程科技有限公司

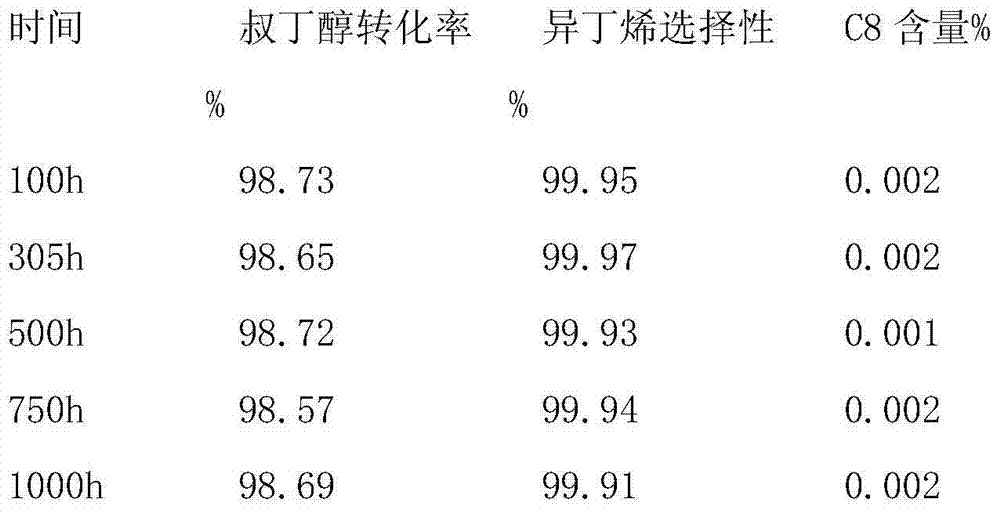

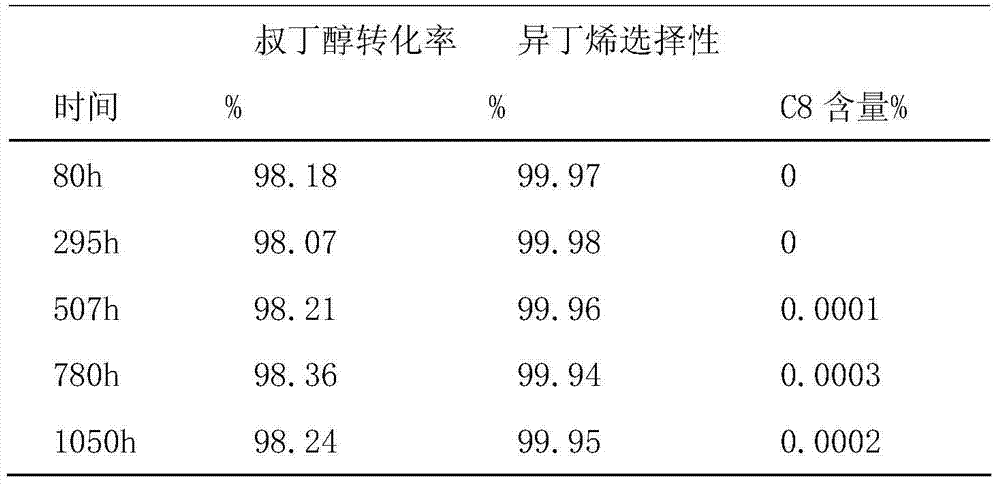

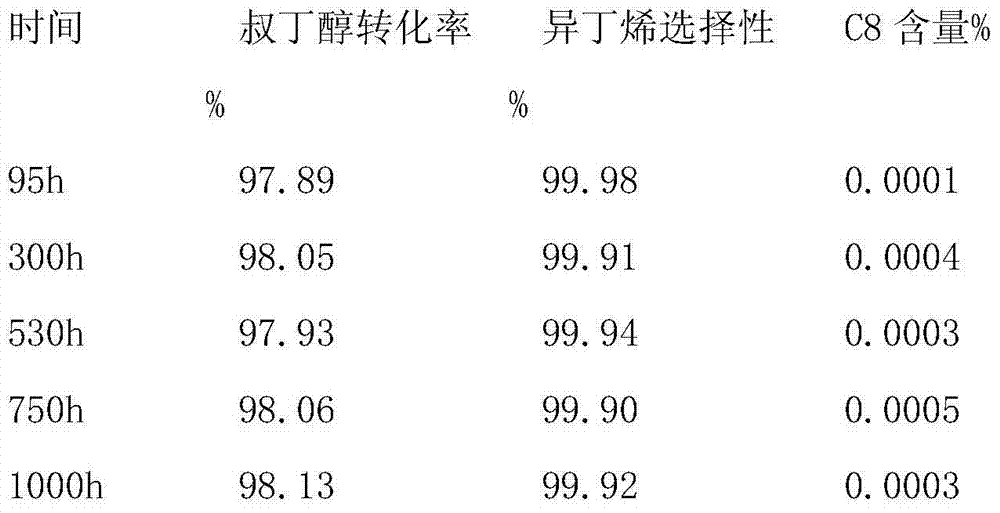

Catalyst for preparing isobutene by dehydrating tertiary butanol and preparation method of catalyst

ActiveCN103934035AGuaranteed activityGuaranteed efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon purification/separationButanolPolymerization

The invention provides a catalyst for preparing isobutene by a liquid phase method and a preparation method of the catalyst. The formula of the catalyst is [A.B]<+>L<->, wherein A is a catalyst base body, B is a polymerization inhibition part and L is an acidic ion; the content of the acidic ion L is 1wt%-35wt%, preferably 5wt%-15wt%; the polymerization inhibition part B is composed of a polymerization inhibitor and an auxiliary agent by a reaction; the content of the polymerization inhibition part B is 0.01wt%-5wt%, preferably 0.1wt%-1.5wt%; the balance is the catalyst base body A. In the presence of the catalyst, tertiary butanol is rectified and dehydrated by the reaction to prepare isobutene; the selectivity of isobutene can be improved obviously and a polymer is prevented from being generated; the grade of condensed water is lowered; meanwhile, the filling problem of a catalyst in an existing reaction rectification process is solved; the catalyst meets an economical and green chemical idea.

Owner:WANHUA CHEM GRP CO LTD +1

Precesion casting method for high temperature alloy complex thin-walled castings

ActiveCN102699311BImprove utilization efficiencySolve filling problemsFoundry mouldsFoundry coresIntermediate frequencyMold filling

The invention discloses a precision casting method for high temperature alloy complex thin-walled castings. The method comprises the following steps of: utilizing a medium frequency induction heating power supply to melt the alloy, utilizing a medium baffle to separate an upper tank and a lower tank, and utilizing an electric hoist to elevate the upper tank when a casting mold and a liquid rising tube are installed; after the installation is completed, utilizing a gas circuit control pipeline, a vacuum system and a gas tank to realize vacuum and pressure regulation in a pressure regulating furnace. By adopting the method disclosed by the invention, stable and efficient mold filling is realized, the castings is solidified sequentially, utilization efficiency of the material can be effectively improved, and the space for near-end net shape casting can be supplied; the complex, thin-walled and integral metal castings which are difficult to cast through other molding methods can be produced, so as to solve the filling problem in the pouring process of the complex thin-walled castings, and in particular, the filling capacity for the thin-walled castings with the wall thickness of less than 3mm is greatly improved. Accurate castings with high dimensional accuracy can be obtained through high temperature alloy pressure regulating investment precision casting, and the accuracy of the casting can reach between CT4 and CT6.

Owner:SHANGHAI JIAO TONG UNIV

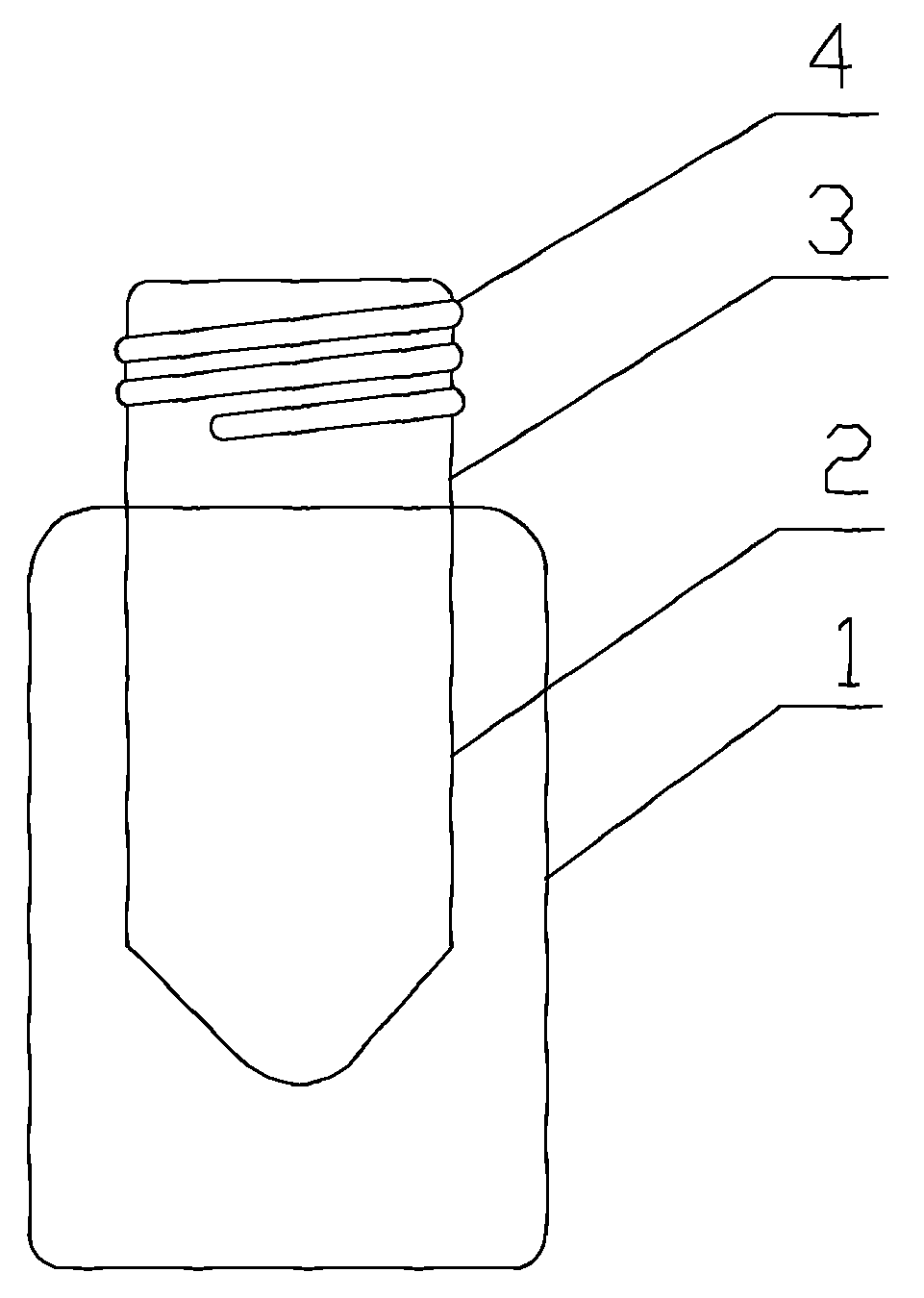

Inner liner type medicine bottle for ketorolac tromethamine spray

InactiveCN103099735ASmall qualityLittle stabilityPharmaceutical containersMedical packagingMedicineKetorolac Tromethamine

The invention discloses an inner liner type medicine bottle for ketorolac tromethamine spray. The inner liner type medicine bottle for the ketorolac tromethamine spray comprises a bottle neck (3), an outer bottle (1) and an inner liner bottle (2) which is arranged inside the outer bottle (1). The inner liner type medicine bottle for the ketorolac tromethamine spray is characterized in that the bottle neck (3) extends to the interior of the bottle body of the outer bottle (1) to form the inner liner bottle (2) in a sealing mode, and a plurality of outer threads (4) are formed in the outer surface of the bottle neck (3). The inner liner type medicine bottle for the ketorolac tromethamine spray is light in weight, and solves the filling problem of small size liquid medicament, and simultaneously improves safety of medicament transportation and stability of long-time placement of the medicament.

Owner:江苏省药物研究所有限公司

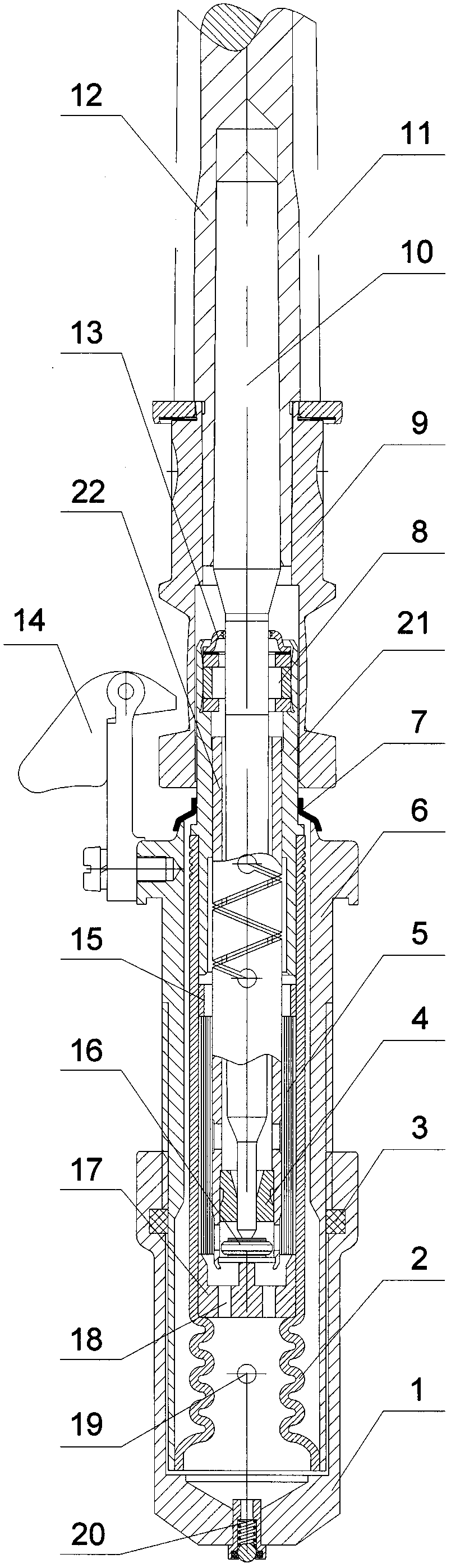

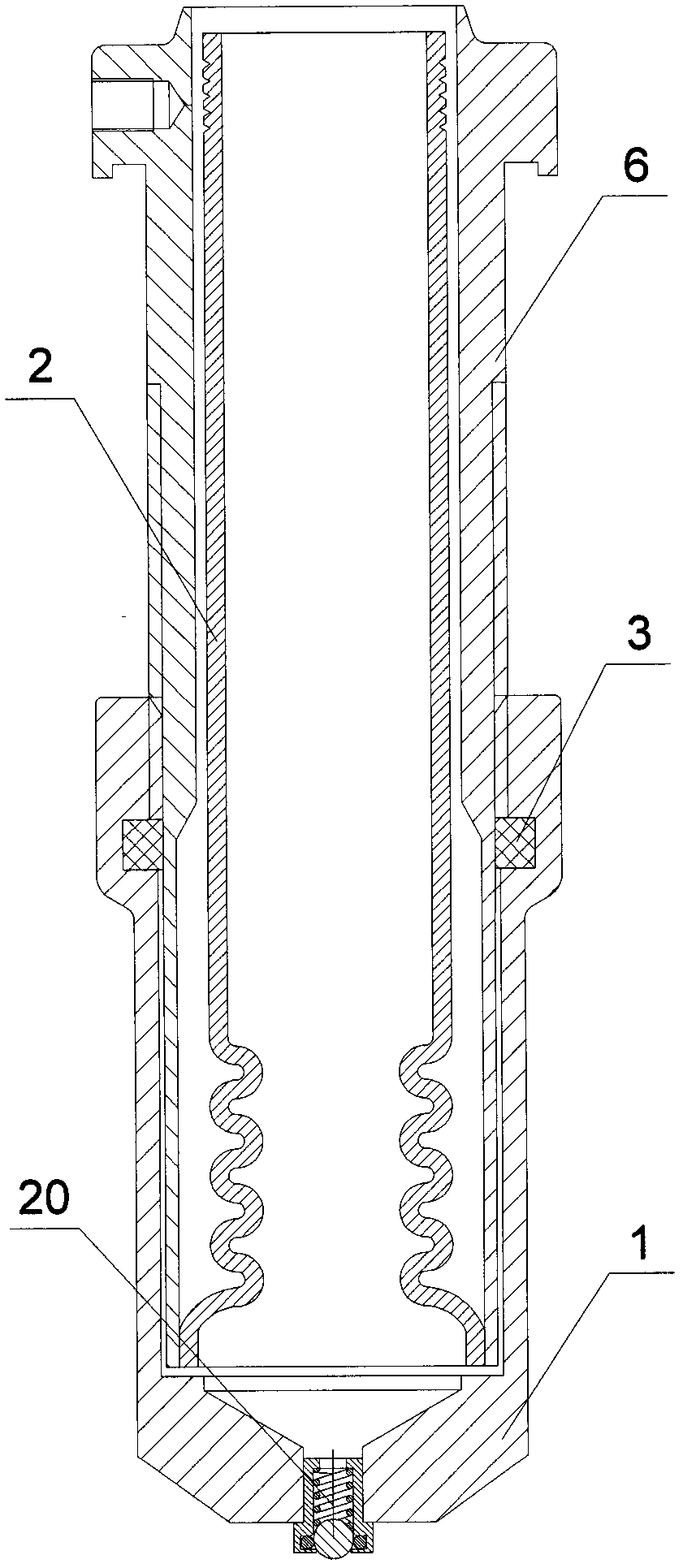

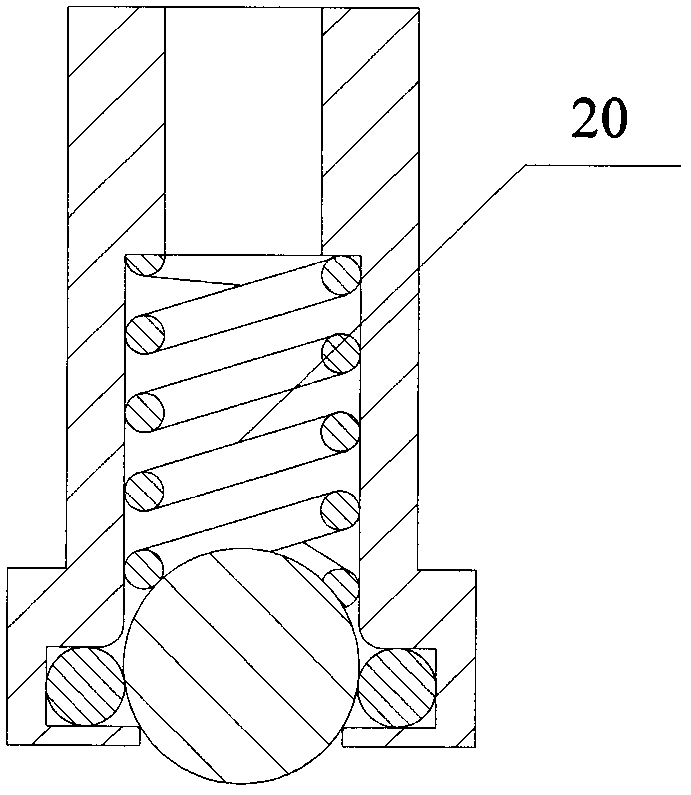

Grease stain resistance separation-type high-speed energy-saving spinning spindle

ActiveCN109338532AEffective absorptionImprove quality and efficiencyTextiles and paperEconomic benefitsEngineering

The invention discloses a grease stain resistance separation-type high-speed energy-saving spinning spindle. The grease stain resistance separation-type high-speed energy-saving spinning spindle is characterized by comprising a spindle bolster base, an inner spindle bolster tube, a sealing ring, an outer spindle bolster tube, an inner and outer spindle bolster tube sealing cover, a support block,a through hole, an outer spindle bolster oil valve and a spindle bottom oil valve; the inner spindle bolster tube, the outer spindle bolster tube and the spindle bolster base are each an independent body and form a spindle bolster together, wherein the lower end of the inner spindle bolster tube tightly cooperates with the outer spindle bolster tube, the portion between the inner spindle bolster tube and the outer spindle bolster tube is filled with damping oil, oil filling operation is completed by the outer spindle bolster oil valve, and the upper end of the inner spindle bolster tube and the upper end of the outer spindle bolster tube are sealed by the inner and outer spindle bolster tube sealing cover. The grease stain resistance separation-type high-speed energy-saving spinning spindle has the advantages that due to the separation-type spindle bolster, the washing and oil filling problems of spinning spindles are effectively solved; due to the inner spindle bolster tube, oil storage space is enlarged, the oil change period of the spindle is prolonged, the high-speed vibration absorption and energy saving function of a dual vibration absorption system is significant, and not only can actual engineering requirements in the textile spinning be met to fill a technical gap, but also great social and economic benefits can be generated.

Owner:TIANJIN POLYTECHNIC UNIV

A joint disposal method of full tail paste filling and stockpiling based on deep cone thickener

ActiveCN104929683BHigh emission concentrationImprove security levelMaterial fill-upMining engineeringCombined treatment

The invention relates to a total-tailings paste filling and stockpiling combined treatment method based on a deep-cone thickener. A combined treatment system is composed of a one-stage or multi-stage pump station, the deep-cone thickener and a two-segment horizontal stirring device. The deep-cone thickener is arranged near the multi-stage pump station. A continuous feeding and discharging mode is adopted for achieving the continuous concentration process, and the two functions of filling and tailings stockpiling are both taken into consideration. In the running process of a filling system, total tailings of a concentration plant are completely thrown into the deep-cone thickener through the one-stage or multi-stage pump station. When filling is needed, deep-cone bottom flow is pumped to the two-segment stirrer through a mortar pump and is mixed with cement, and qualified paste is prepared and flows to or is pumped to a stope. When filling is not needed, the bottom flow is pumped by a plunger pump to a tailings pond by means of the pump station, and stockpiling of paste is performed. The method can well solve the filling problem of a gob and the stockpiling problem of tailings at the same time, filling cost is greatly reduced, the strength of filling bodies is improved, discharge of the tailings is reduced to the maximum extent, and meanwhile tailings paste is discharged.

Owner:UNIV OF SCI & TECH BEIJING +1

Device and method for metal filling

InactiveCN104609349AFilling is achievedSafe and convenient operationLiquid bottlingExhaust valveInlet valve

The invention relates to a device and method for filling a container with material, and provides a device and method for metal filling, in order to solve the metal filling problem of a single-port thin pipe and ensure a good filling effect. The device for metal filling comprises a storage tank, a filling pipeline, a vacuumizing pipeline, an air inlet pipe, an air inlet valve, an exhaust valve and a vacuumizing valve, wherein a heating module is arranged at the outer part of the storage tank; a heating wire is arranged at the outer part of the filling pipeline. The method for metal filling comprises the following steps: (1), pouring metal into the storage tank and solidifying; (2), connecting a single-port thin pipe to be filled; (3), heating the corresponding structure to above the melting point of the metal to be poured; (4), feeding inert gas to pour the metal. According to the device and the method for metal filling, the metal filling problem of the single-port thin pipe can be solved, in the filling process, the metal is prevented from being oxidized and polluted, and no air column and bubble is generated, quantitative filling is easy to implement, the filling accuracy is high, the repeatability is excellent, and a higher cost of adopting a special valve is avoided.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Efficient ultramicro crushing material bagging device

InactiveCN106742112ASolve filling problemsAvoid dischargeSolid materialEngineeringMechanical engineering

The invention relates to an efficient ultramicro crushing material bagging device, which belongs to the technical field of powder filling. The efficient ultramicro crushing material bagging device comprises a temporary storage bin and a powder pushing assembly, wherein the powder pushing assembly comprises a cylinder, an auger and a power mechanism, a feed opening which communicates with the temporary storage bin is formed in the side of the cylinder, the power mechanism is arranged on one end of the cylinder, a discharge opening is formed in the other end of the cylinder, a degassing filling sleeve is coaxially butted with the cylinder in the position of the discharge opening, and the inside diameter of the degassing filling sleeve is larger than that of the cylinder. According to the efficient ultramicro crushing material bagging device, the filling problem caused by the gas holding capacity of powder can be effectively solved, secondary exhaust is realized through the temporary storage bin and the degassing filling sleeve, and the powder is compacted and prepressed in the degassing filling sleeve, so that gas in the powder is effectively discharged, natural sedimentation of the powder does not need to be waited, and the whole filling efficiency is improved, and additionally, the whole filling process is sealed, so that a pollution source of dust is solved.

Owner:郑州佰沃科技发展有限公司

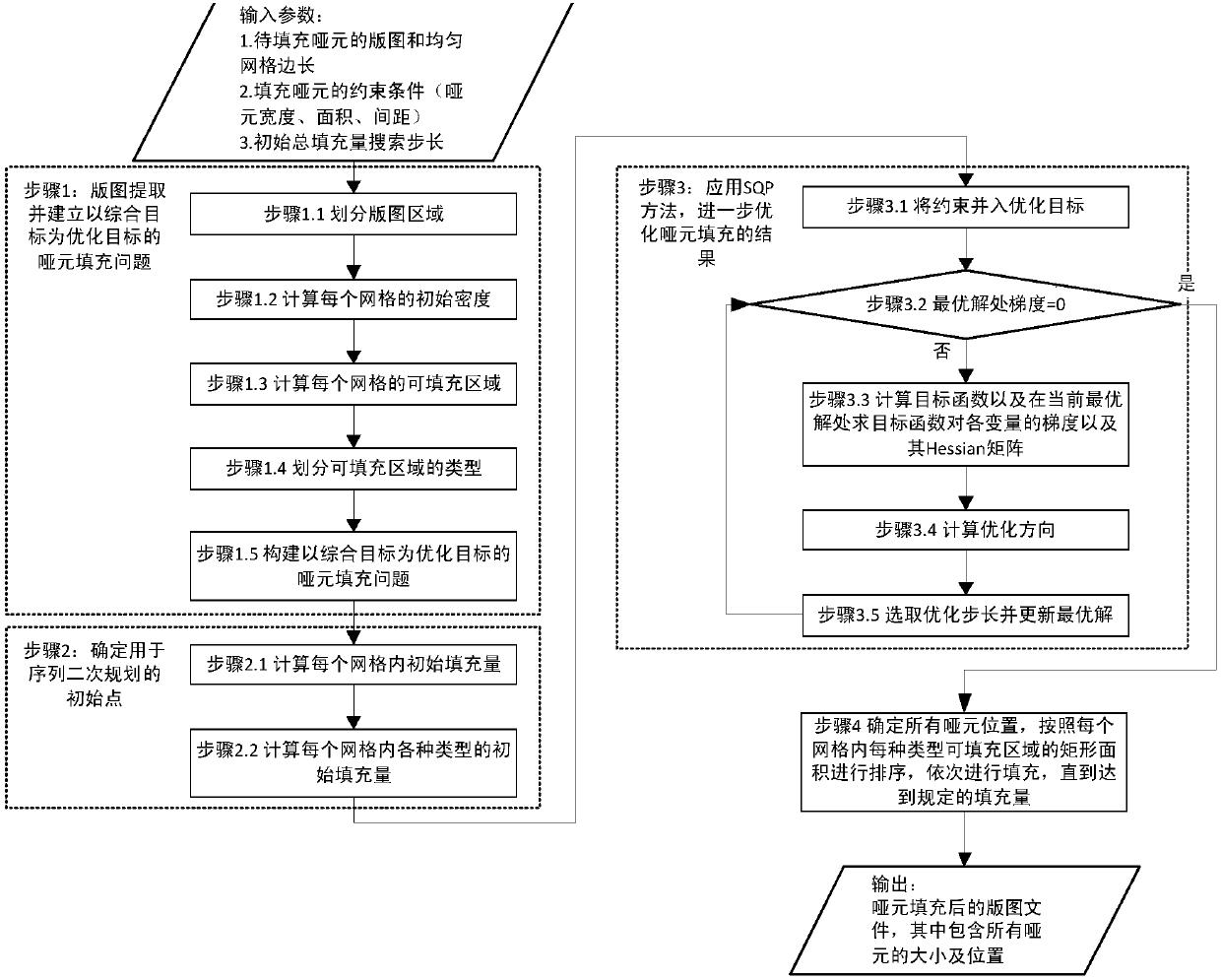

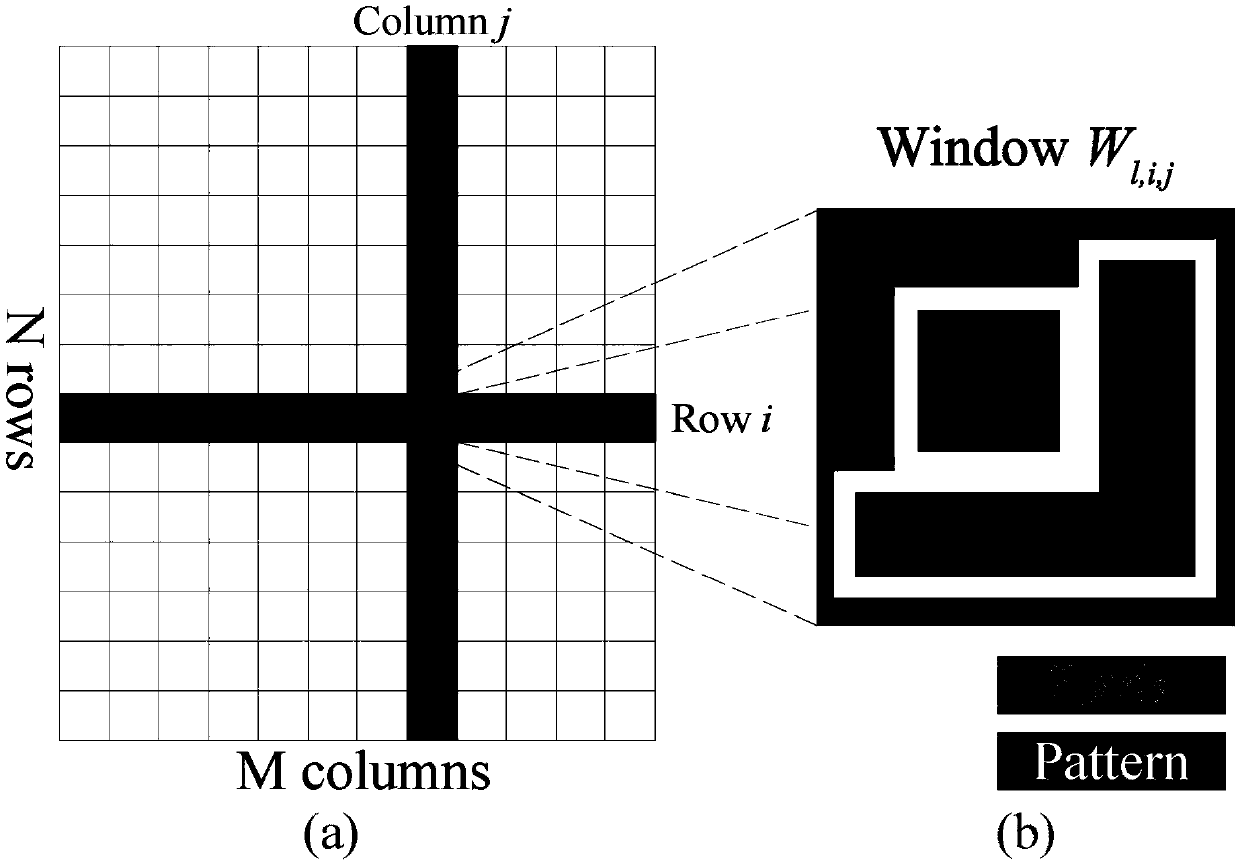

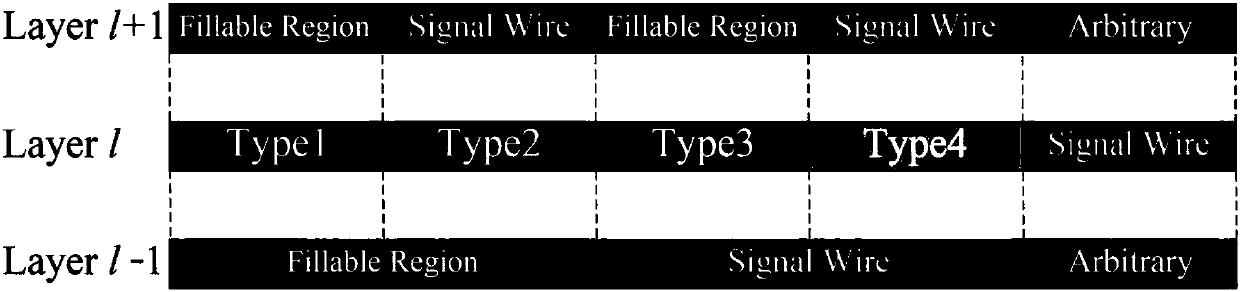

Dummy fill insertion method based on unified framework of sequential quadratic programming method

ActiveCN107798150AQuality improvementImprove filling qualitySpecial data processing applicationsManufacturing technologyRunning time

The invention belongs to the field of integrated circuit semiconductor manufacturing technology and relates to a dummy fill insertion method for a chemical mechanical polishing process. The dummy fillinsertion method is unified without model approximation, a sequential quadratic programming method is adopted to directly solve a dummy fill insertion problem, and therefore a high-quality dummy fillinsertion result can be obtained. In specific implementation, the method of estimating an overlapping area before determining a dummy position is proposed and used for improving optimization efficiency. Through the method, a complicated dummy fill insertion target can be optimized under bearable operating time, a high-quality dummy fill insertion scheme can be obtained, acceleration can be well performed through parallel computing, and the method is used for solving the dummy fill insertion problem of a large-scale layout.

Owner:FUDAN UNIV

A Filling Method for Structural Missing Images Based on Low-rank Matrix Reconstruction

The invention belongs to the computer vision field and aims at realizing filling to pixel structural lack images. The structural lack image filling method based on low rank matrix reconstruction comprises the following steps: 1) taking the image as a matrix, using a matrix A to represent an original image and converting a pixel structural lack image filling problem into a solving optimization equation; 2) training a dictionary fai; 3) using an alternative direction method ADM to convert a sequence into a sequence so as to carry out solving and then carrying out iteration solving according to steps so as to acquire a final result. The method in the invention is mainly used for computer image processing.

Owner:TIANJIN UNIV

Full-automation filling machine

The invention discloses a full-automation filling machine which comprises a rack, a discharging device, a rotation plate device, a baiting device and a conveying device, wherein the discharging device, the rotation plate device, the baiting device and the conveying device are arranged on the rack. The rotation plate device comprises a rotation plate and multiple baiting through holes. A bottle clamping plate is arranged below the rotation plate, multiple bottle clamping grooves are formed in the periphery of the bottle clamping plate and a bottle ejecting mechanism is arranged below the ejector rod fixing plate. The discharging device is located above the rotation plate. A discharging opening of the discharging device is communicated with the baiting through holes in the rotation plate. The baiting device is located above the rotation plate and matched with the baiting through holes corresponding to baiting stations. The conveying device corresponds to the bottle clamping grooves at bottle inlet stations and bottle outlet stations. According to the full-automation filling machine, the bottle clamping plate is used for clamping and fixing filling bottles and a bottle jacking mechanism is used for jacking the corresponding filling bottle, so that the filling bottle totally corresponds to the corresponding baiting through hole of the rotation plate. In the whole filling process, the filling bottles can rotate synchronously along with the rotation plate and the filling problem due to the fact that the filling bottles do not align with a baiting hopper in an existing structure is solved.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com