Full-automation filling machine

A filling machine, fully automatic technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve the problems that affect the filling process, affect the filling action, and cannot guarantee the complete correspondence of the filling bottle, so as to ensure the filling The effect of device stability and accuracy, lower production cost, and higher production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

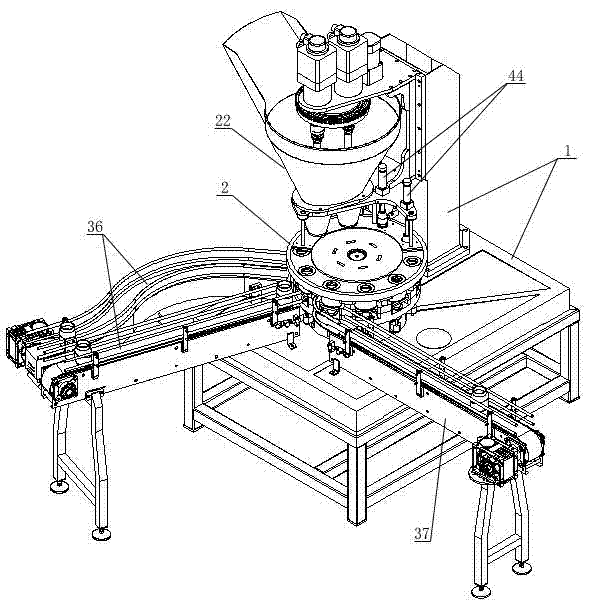

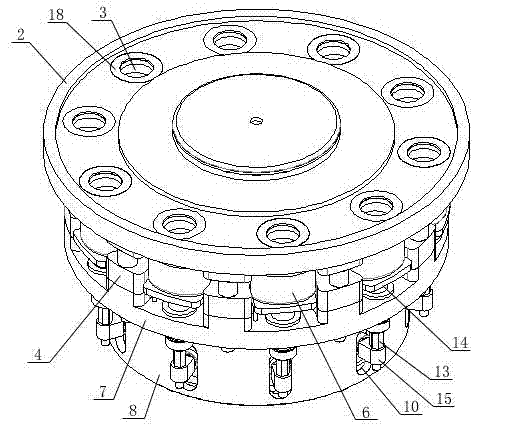

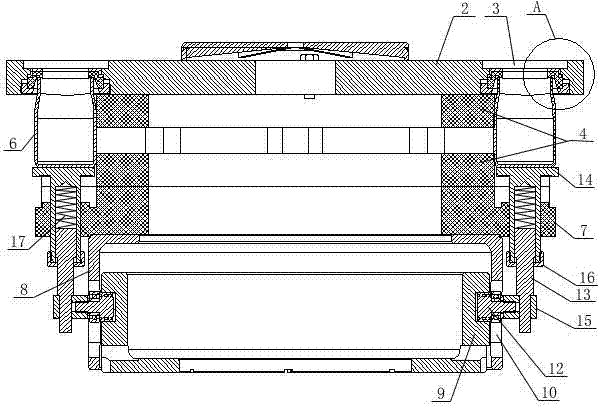

[0036] Embodiment 1: as Figure 1-5 As shown, a fully automatic filling machine includes a frame 1 and a discharge device arranged on the frame 1, a turntable device, a feeding device and a conveying device, and the turntable device includes a turntable 2 connected to a rotary drive mechanism And a number of blanking through holes 3 evenly distributed on the turntable 2, a bottle clamping plate 4 is arranged below the rotary plate 2, and a number of bottle clamping grooves corresponding to the blanking through holes 3 are arranged around the bottle clamping plate 4 5. The bottle clamping groove 5 is matched with the shape of the filling bottle 6, and the ejector pin fixing plate 7 is arranged under the bottle clamping plate 4, and the turntable 2, the bottle clamping plate 4 and the ejector pin fixing plate 7 are connected by The parts are connected as a whole. Below the ejector pin fixing plate 7, several bottle jacking mechanisms corresponding to the bottle clamping groove 5...

Embodiment 2

[0043] Embodiment 2: as Figure 13 As shown, a sealing plate 41 fixedly connected to the frame 1 is provided above the turntable 2, and a discharge hole corresponding to the blanking through hole 3 is provided on the sealing plate 41 corresponding to the blanking station. An adjustable measuring cup 42 is arranged above the sealing plate 41, and the adjustable measuring cup 42 is connected to the measuring cup turntable 43 above it, and a plurality of holes corresponding to the adjustable measuring cup 42 are arranged on the measuring cup turntable 43 , the discharge port of the discharge device communicates with the hole on the measuring cup turntable 43 correspondingly, and the lower end of the adjustable measuring cup 42 forms a relatively airtight gap with the sealing plate 41 when it is in the filling station and the bottle feeding and discharging station. The material-holding space, when it is at the material-discharging station, its lower end opening communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com