Method and device for evacuating turbine condenser

A technology of condenser and auxiliary condenser, applied in steam/steam condensers, steam engine installations, machines/engines, etc., can solve problems such as loss of propulsion steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

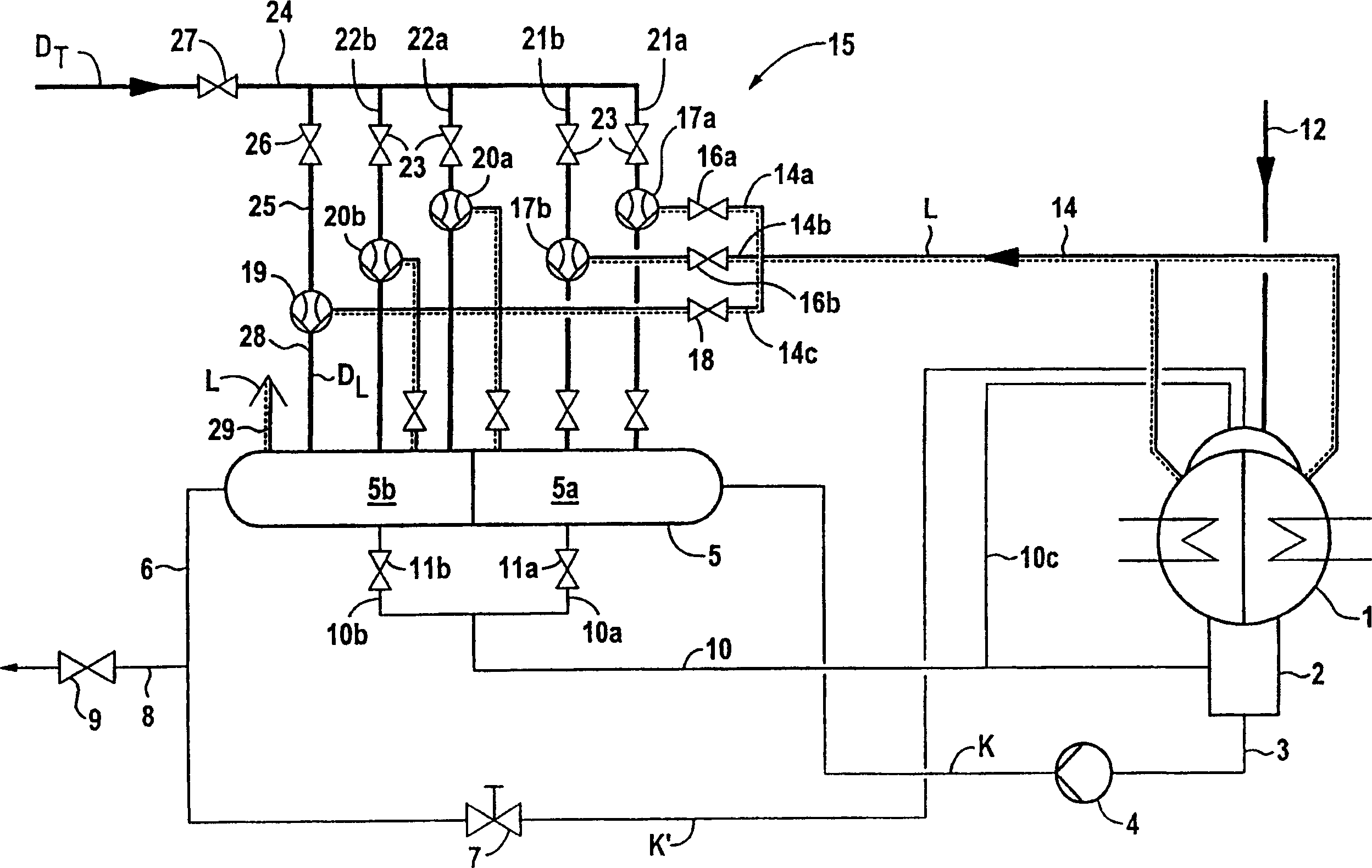

[0013] The main condenser or turbo condenser 1 of a steam turbine plant (not shown) is connected at its outlet end by means of its condensate collector 2 to a condensate main 3 which is connected via a condensate pump 4 to the inlet end of an auxiliary condenser 5 . At its outlet end, the secondary condenser 5 is connected to the main condenser 1 via a condensate header 6 . In the condensate main 6, there is a flow control valve 7 for regulating the amount of cooling condensate required for start-up operation. For example, the condensate is directed to the steam generator heating surface and a circulation main 8 is connected to the condensate main 6 with a control valve 9 which is closed during start-up operation.

[0014] The condensed water K collected in the auxiliary condenser 5 is guided to the condensed water collector 2 of the main condenser 1 through the condensed water main 10 . For this purpose, the condensate main 10 is connected to the first pressure stage 5a or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com