Patents

Literature

87results about How to "Avoid filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

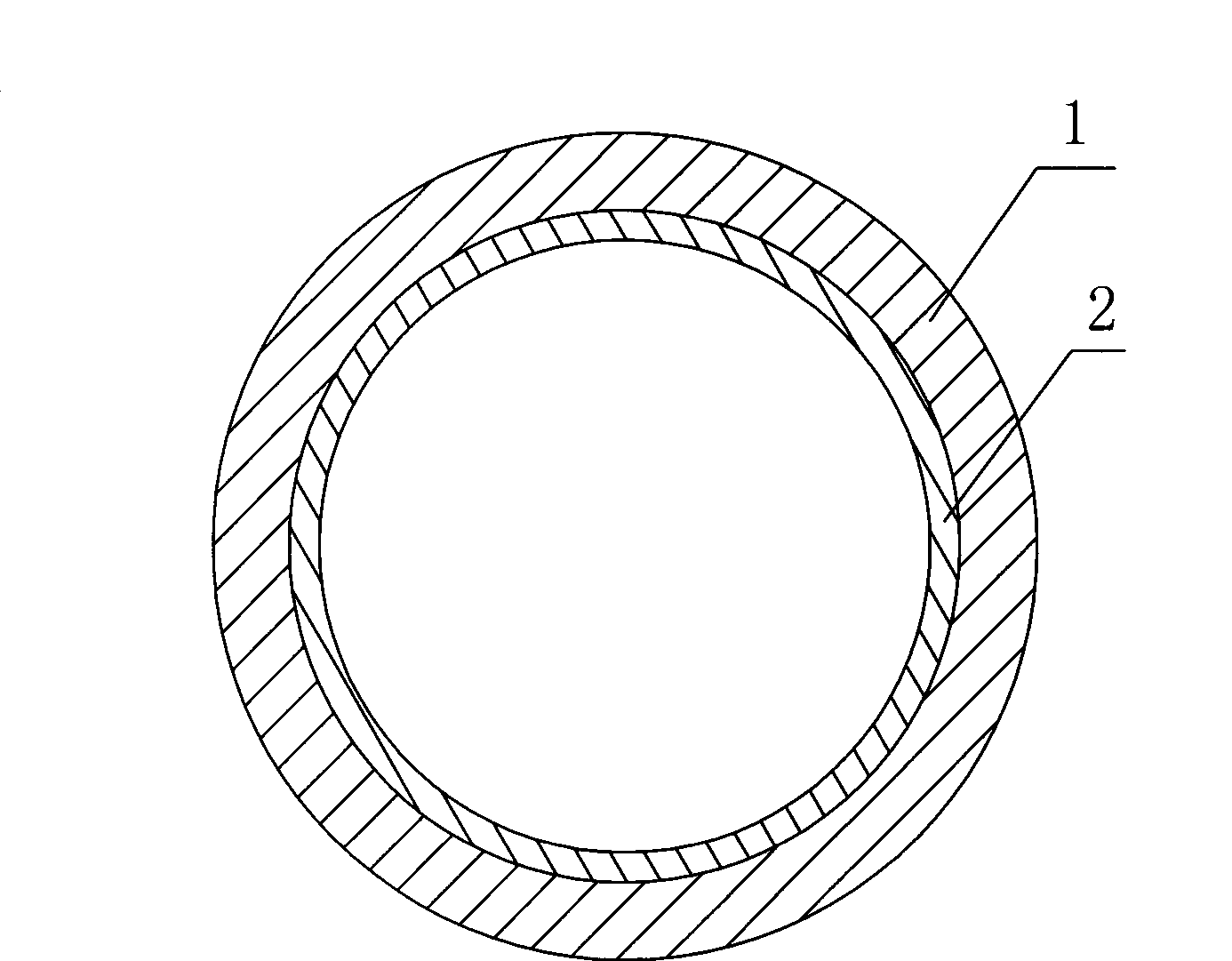

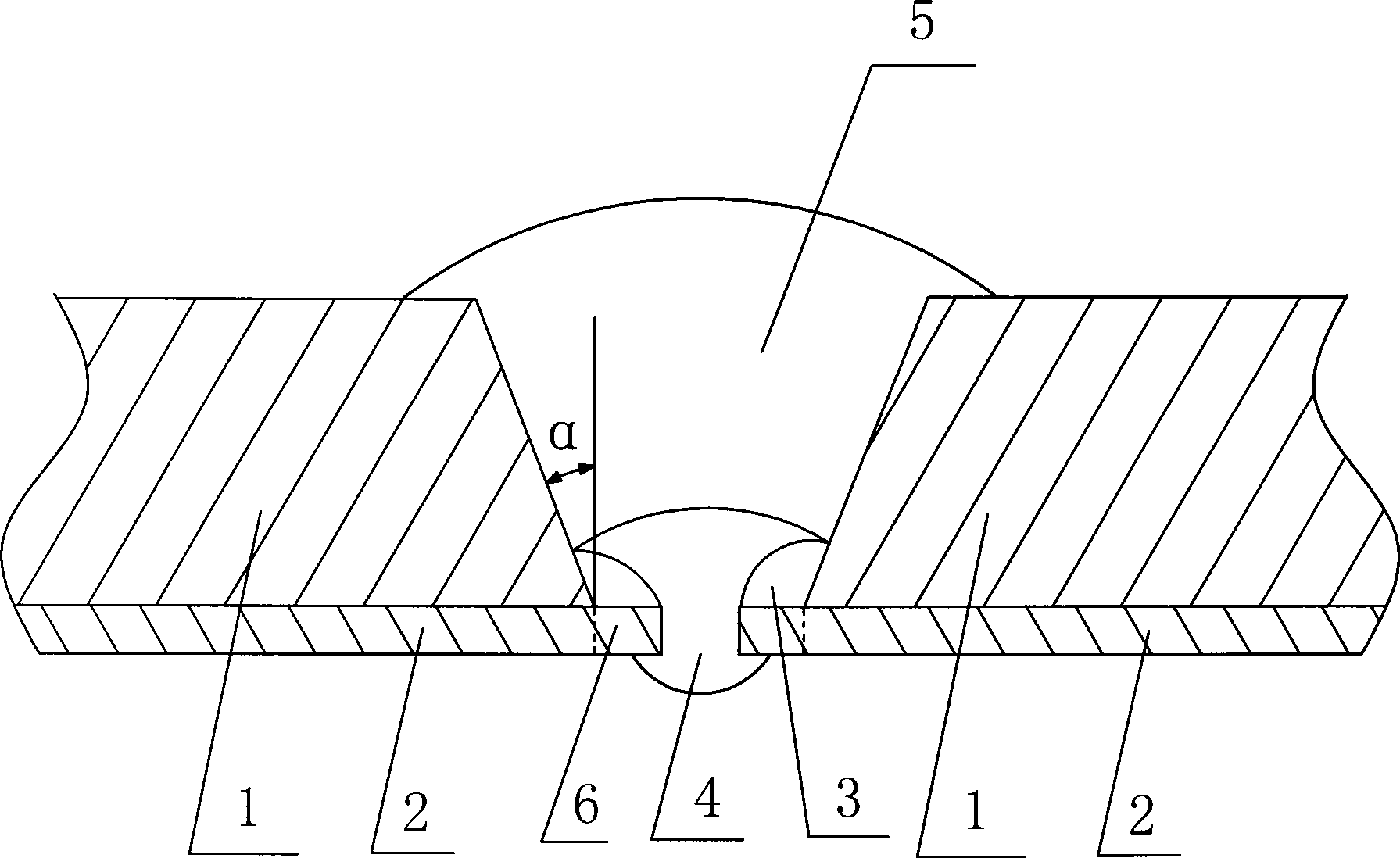

Girth welding method of duplex stainless steel bimetal composite pipe

InactiveCN101362249ASimple welding processExcellent weld mechanical properties and corrosion resistanceArc welding apparatusWelding/soldering/cutting articlesCarbon steelDouble phase

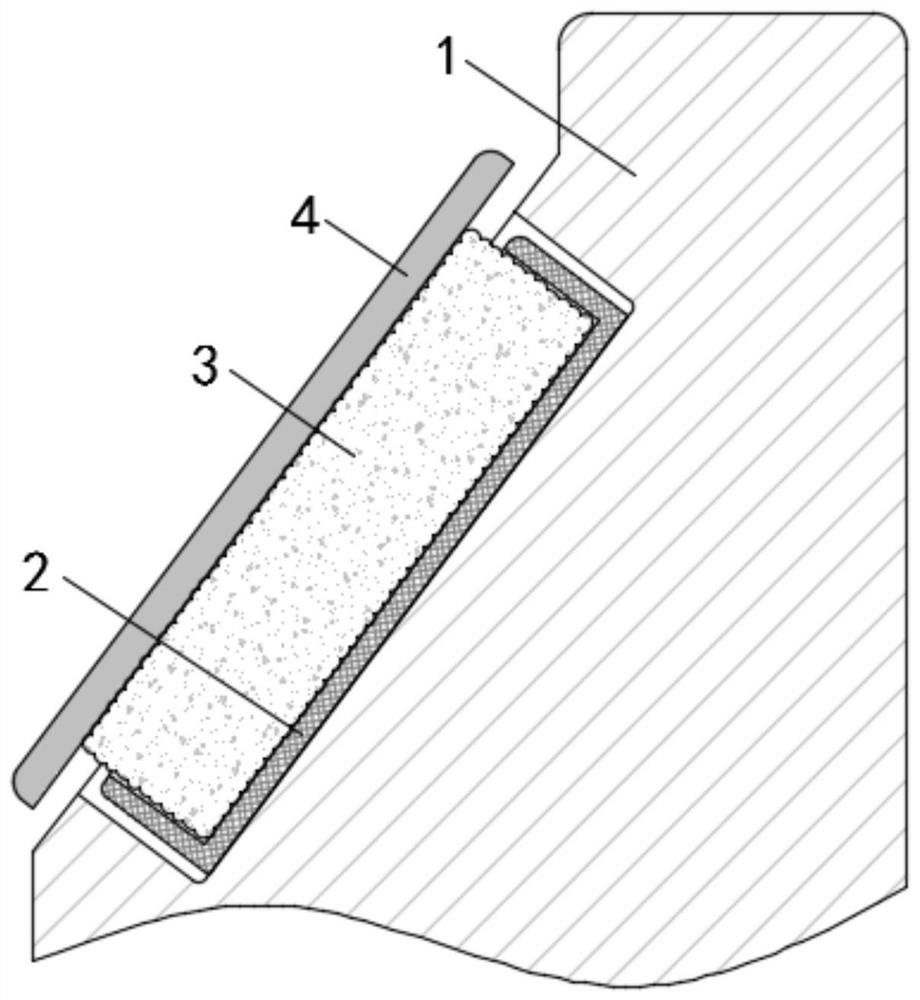

The invention discloses a method for girth welding for double-phase stainless steel bimetal composite tubes. The method comprises the following steps of: firstly, groove processing: the double-phase stainless steel bimetal composite tube consists of a double-phase stainless steel lining tube and a carbon steel base tube, the welding surface of the base tube is processed into a V-shaped groove at an angle of 45-55 degree, and the lining tube is 2-3 mm longer than the base tube; secondly, caulk welding: the connection ports between the base tube and the lining tube are welded through argon tungsten-arc welding, double-phase stainless steel welding wires are adopted, and the welding current is 65-80 A; thirdly, backing welding: the connection ports of lining tube are welded through argon tungsten-arc welding, double-phase stainless steel welding wires are adopted, and the welding current is 60-90 A; fourthly, base tube welding: the connection ports of the base tube are welded through arc welding, and double-phase stainless steel welding wires are adopted. The procedures and the steps are simple, the used welding material is in a small amount, the welding qualification rate is high, the welding defect can be reduced or avoided, and the production efficiency can be greatly improved.

Owner:XIAN SUNWARD AEROSPACE MATERIAL

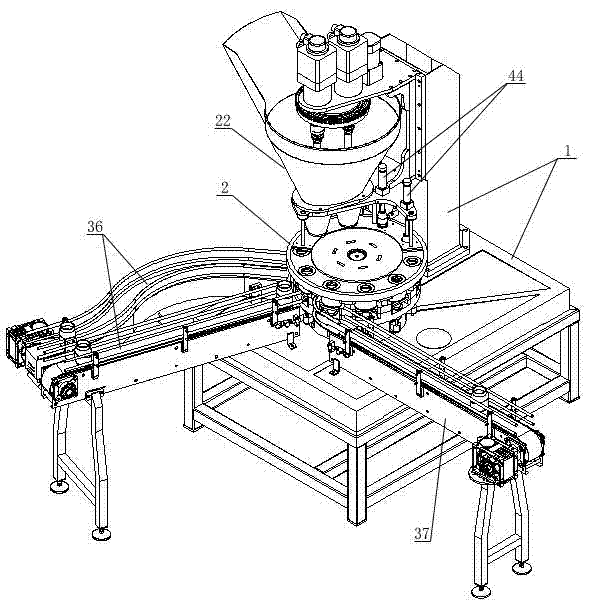

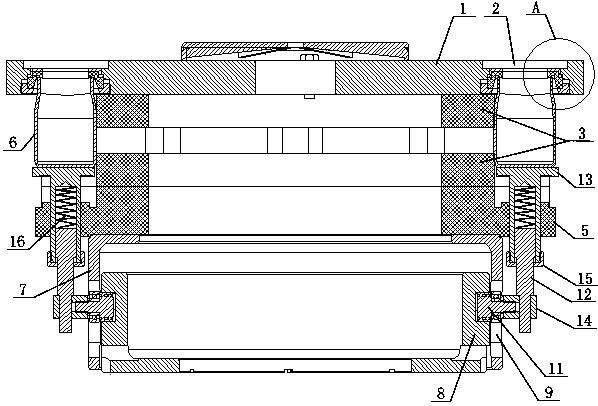

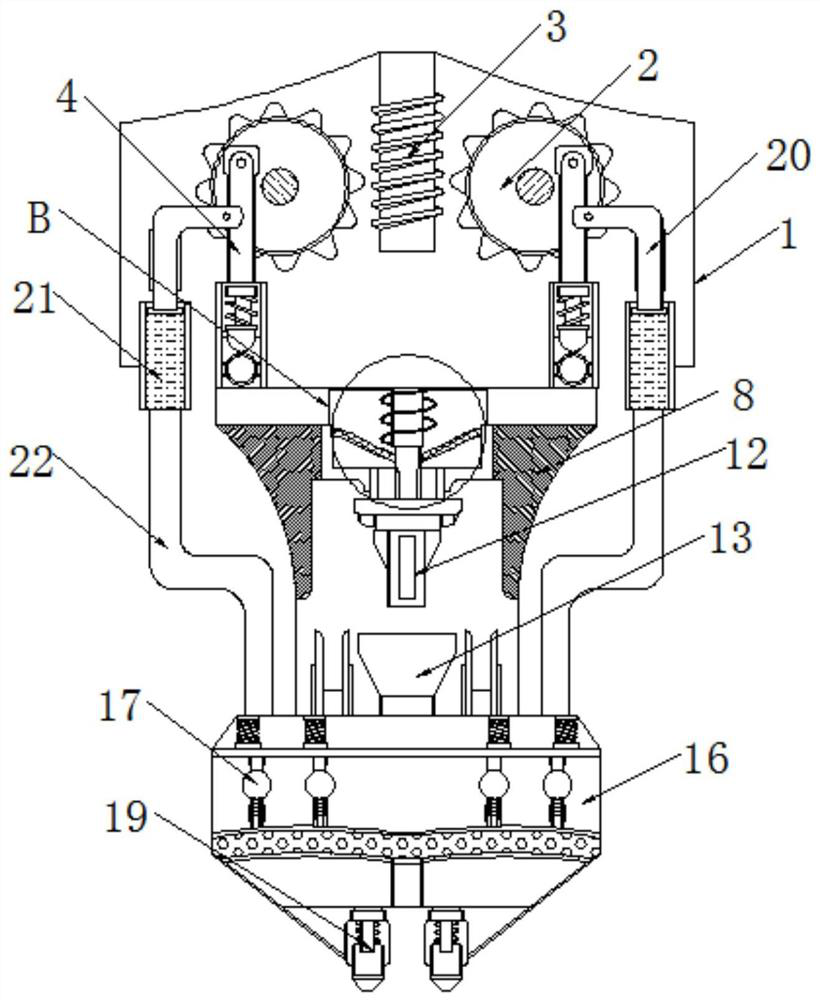

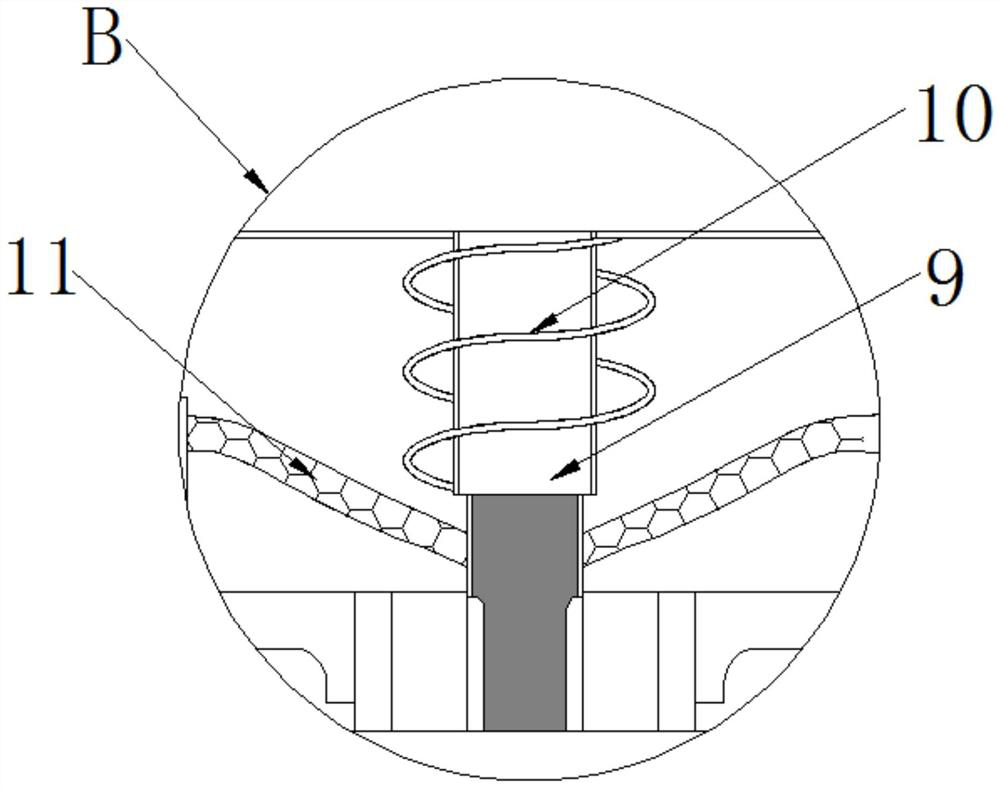

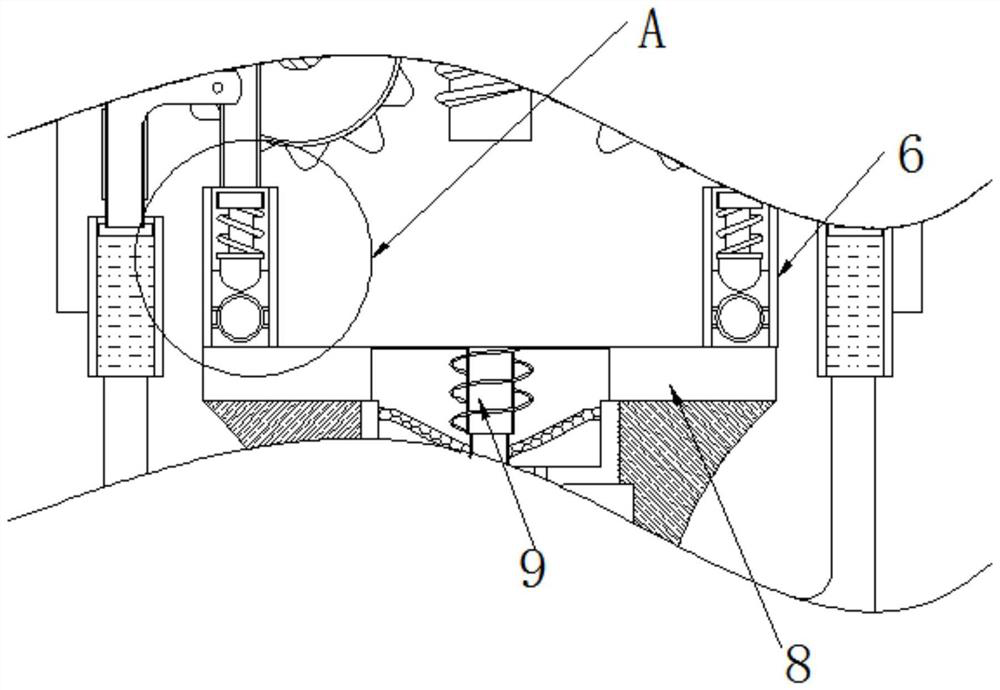

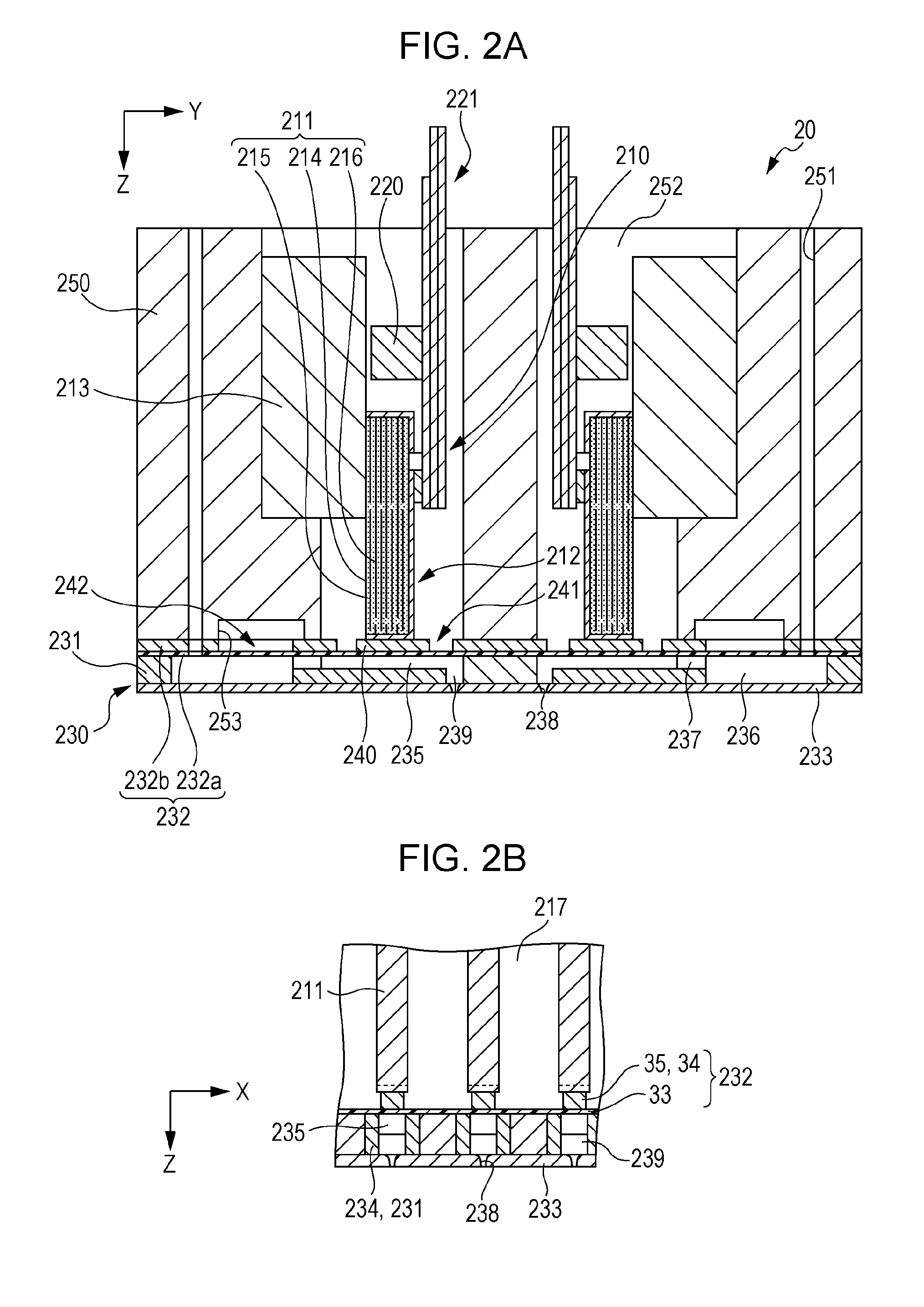

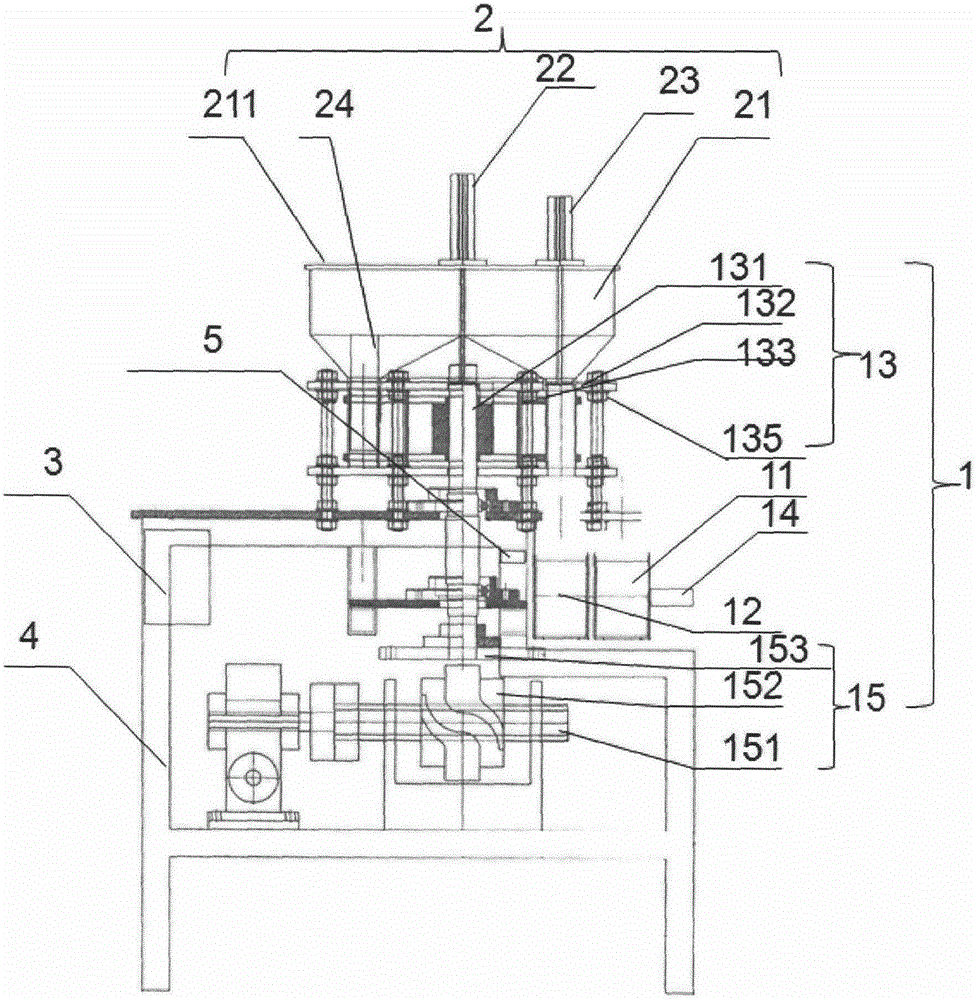

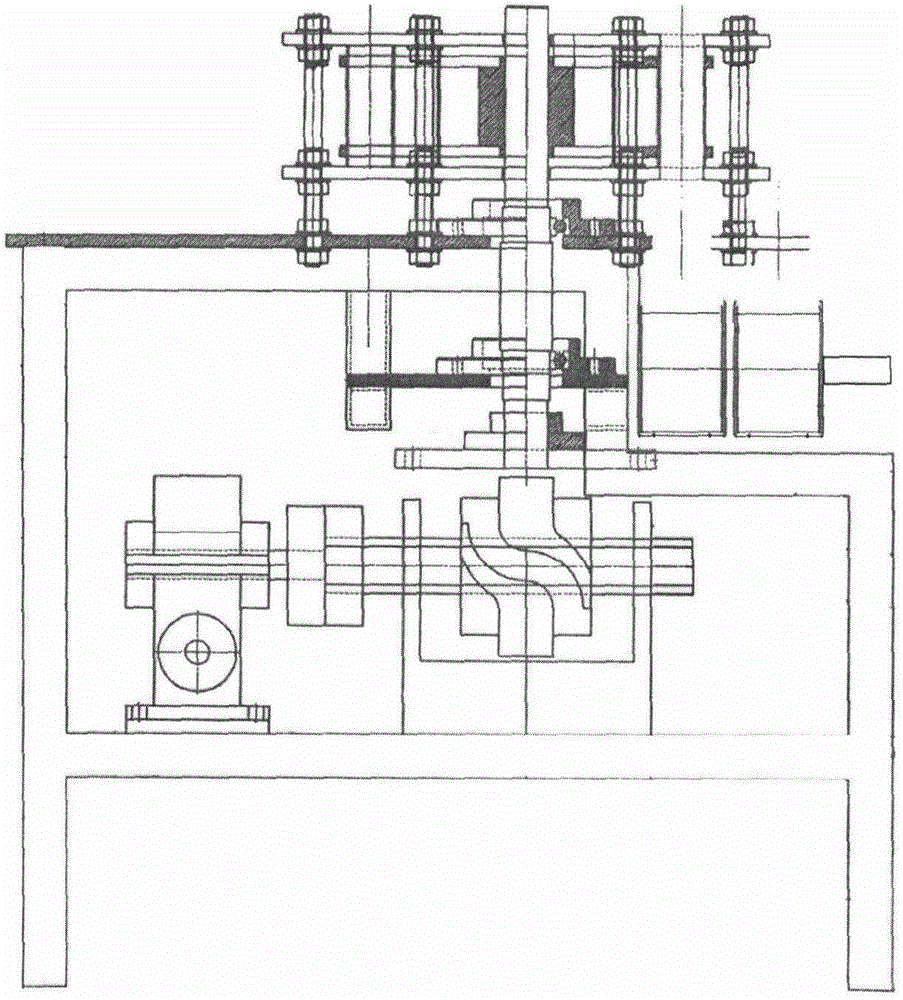

Full-automation filling machine

The invention discloses a full-automation filling machine which comprises a rack, a discharging device, a rotation plate device, a baiting device and a conveying device, wherein the discharging device, the rotation plate device, the baiting device and the conveying device are arranged on the rack. The rotation plate device comprises a rotation plate and multiple baiting through holes. A bottle clamping plate is arranged below the rotation plate, multiple bottle clamping grooves are formed in the periphery of the bottle clamping plate and a bottle ejecting mechanism is arranged below the ejector rod fixing plate. The discharging device is located above the rotation plate. A discharging opening of the discharging device is communicated with the baiting through holes in the rotation plate. The baiting device is located above the rotation plate and matched with the baiting through holes corresponding to baiting stations. The conveying device corresponds to the bottle clamping grooves at bottle inlet stations and bottle outlet stations. According to the full-automation filling machine, the bottle clamping plate is used for clamping and fixing filling bottles and a bottle jacking mechanism is used for jacking the corresponding filling bottle, so that the filling bottle totally corresponds to the corresponding baiting through hole of the rotation plate. In the whole filling process, the filling bottles can rotate synchronously along with the rotation plate and the filling problem due to the fact that the filling bottles do not align with a baiting hopper in an existing structure is solved.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

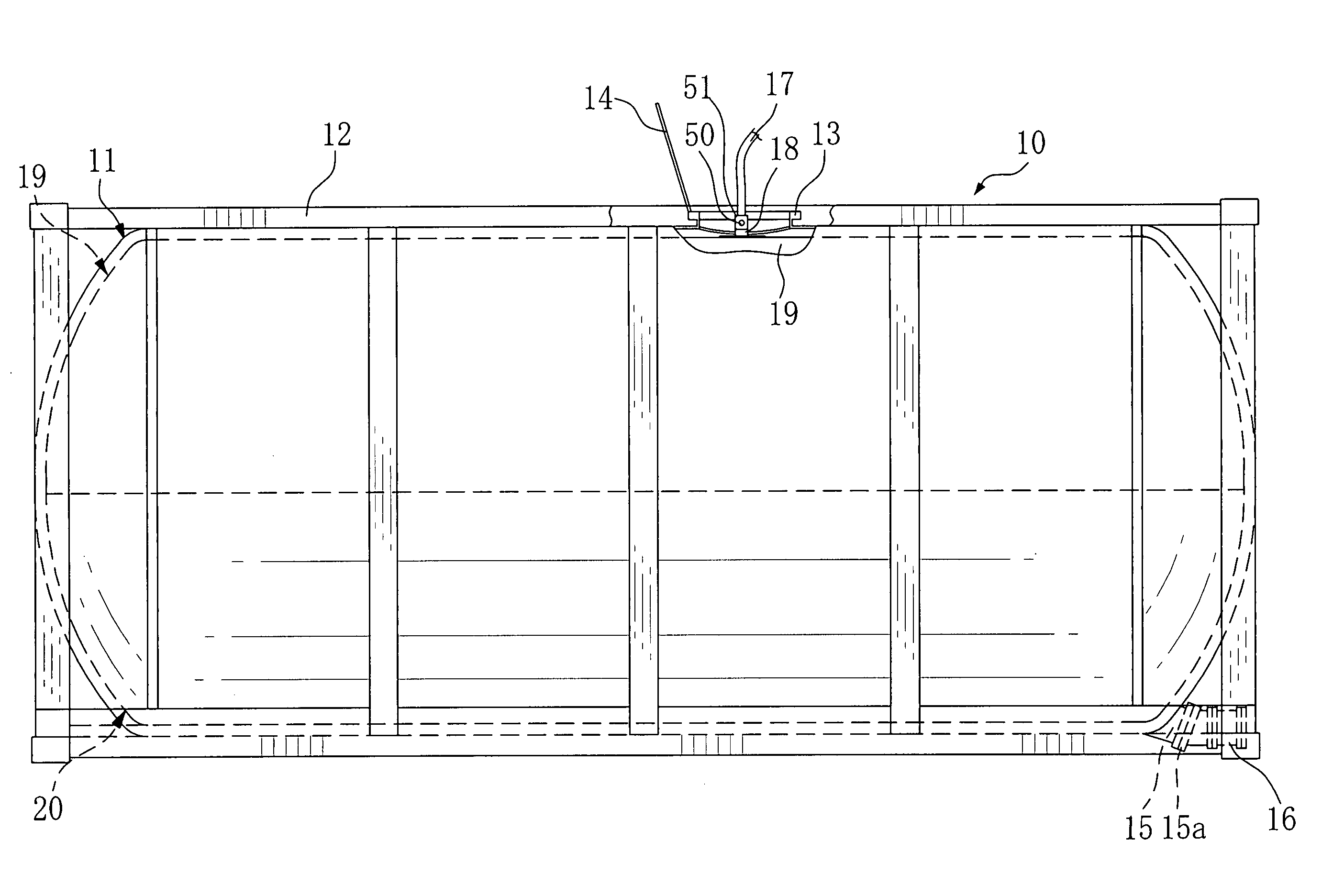

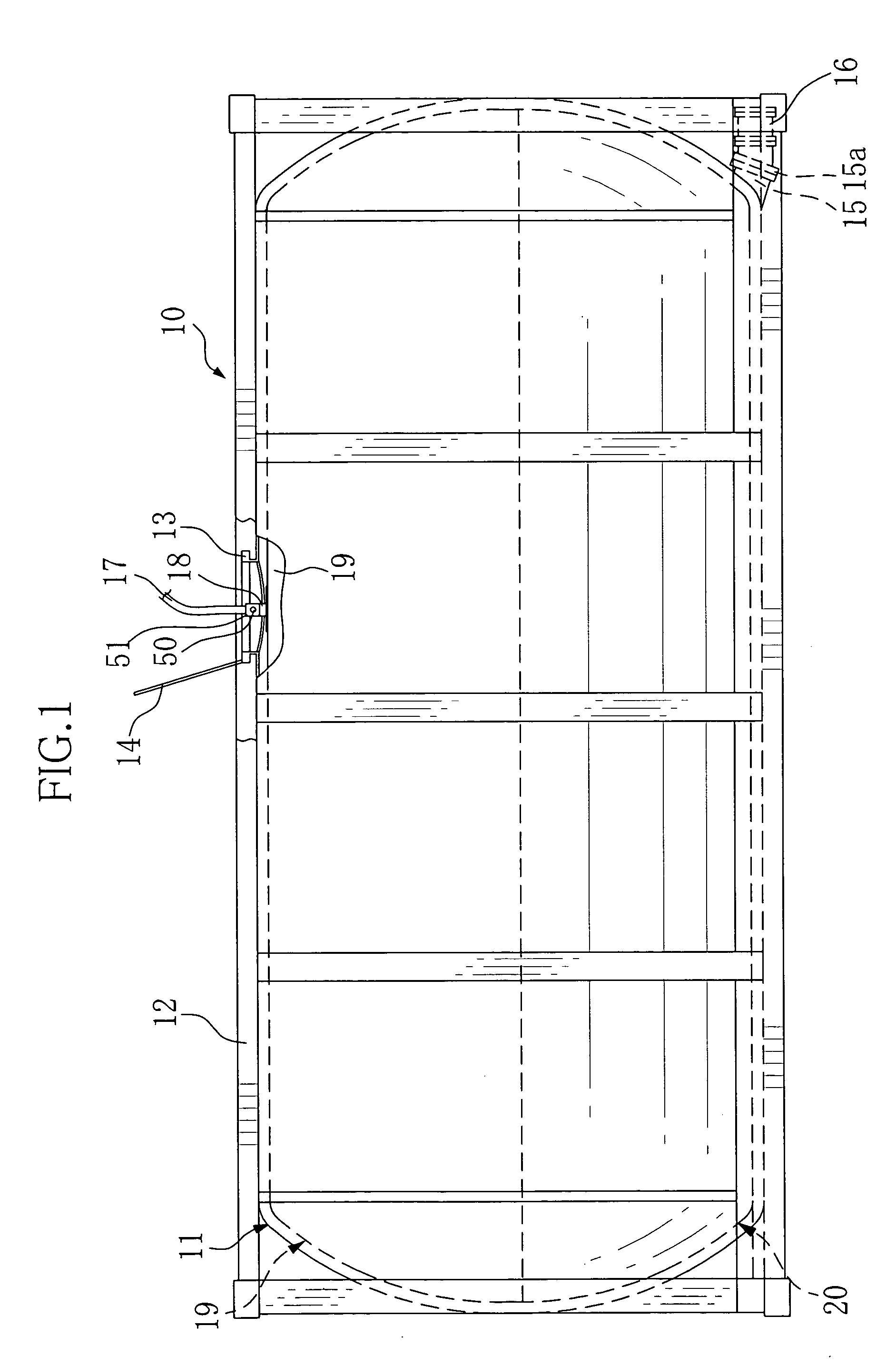

Transport tank and transporting method thereof

InactiveUS20050189357A1Avoid fillingPrevent movementLarge containersItem transportation vehiclesEngineeringTank container

A transport inner bag and a pressure inner bag are loaded in a tank body of a tank container. A supply-discharge opening for the transport inner bag is provided in a position corresponding to a tank supply-discharge opening, and cargo is filled through the opening. A supply-discharge opening for the pressure inner bag is provided in a position corresponding to a hatch of the tank body, and air is filled through the opening to expand the pressure inner bag, so that a space between the transport inner bag and an inner surface of the tank body is filled as well as the gap in between. This prevents the transport inner bag from moving in the tank body in transporting in a state that the cargo is not fully loaded in the transport inner bag, so that the breakage of the transport inner bag caused by the movement is prevented.

Owner:FUJIFILM CORP

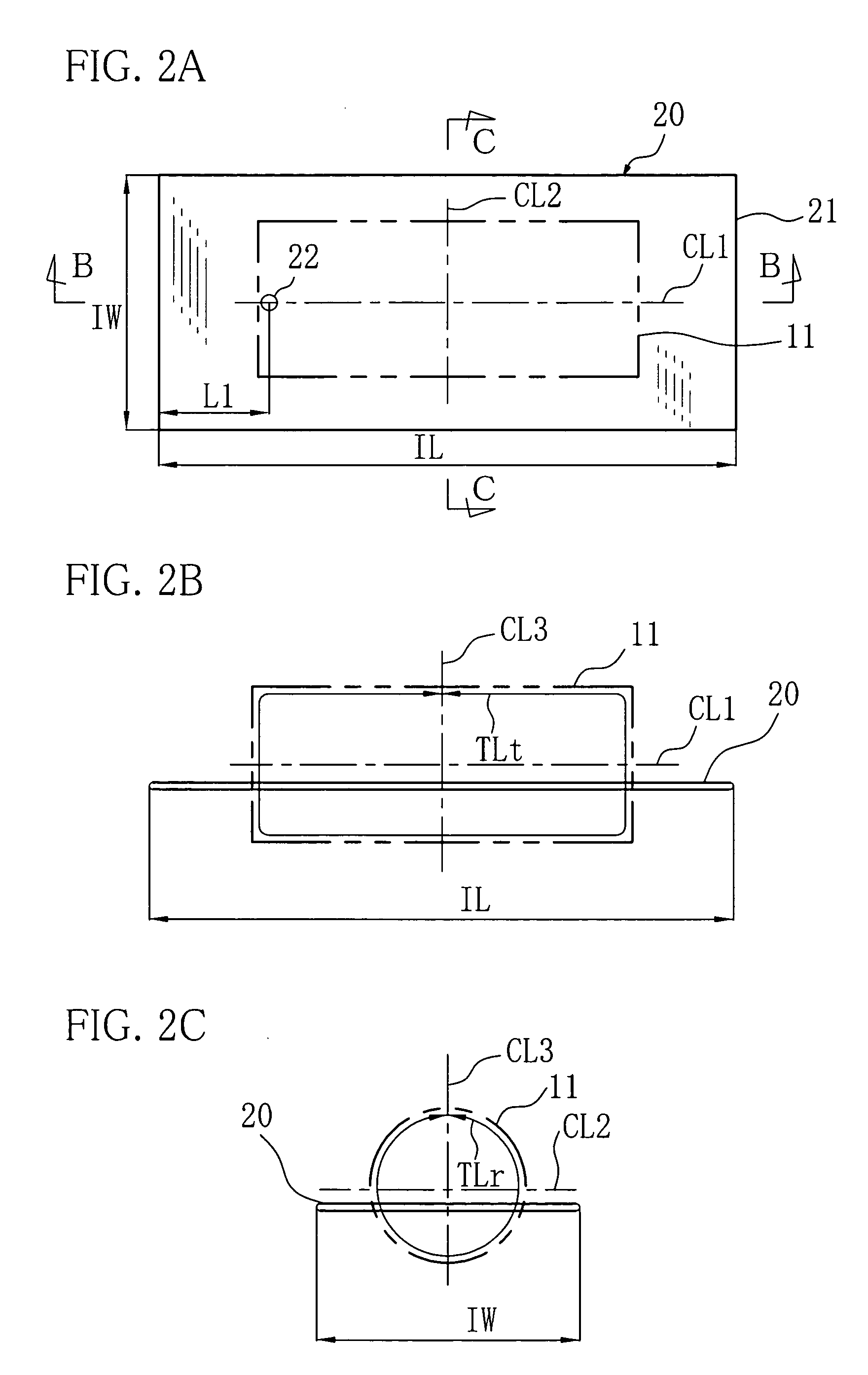

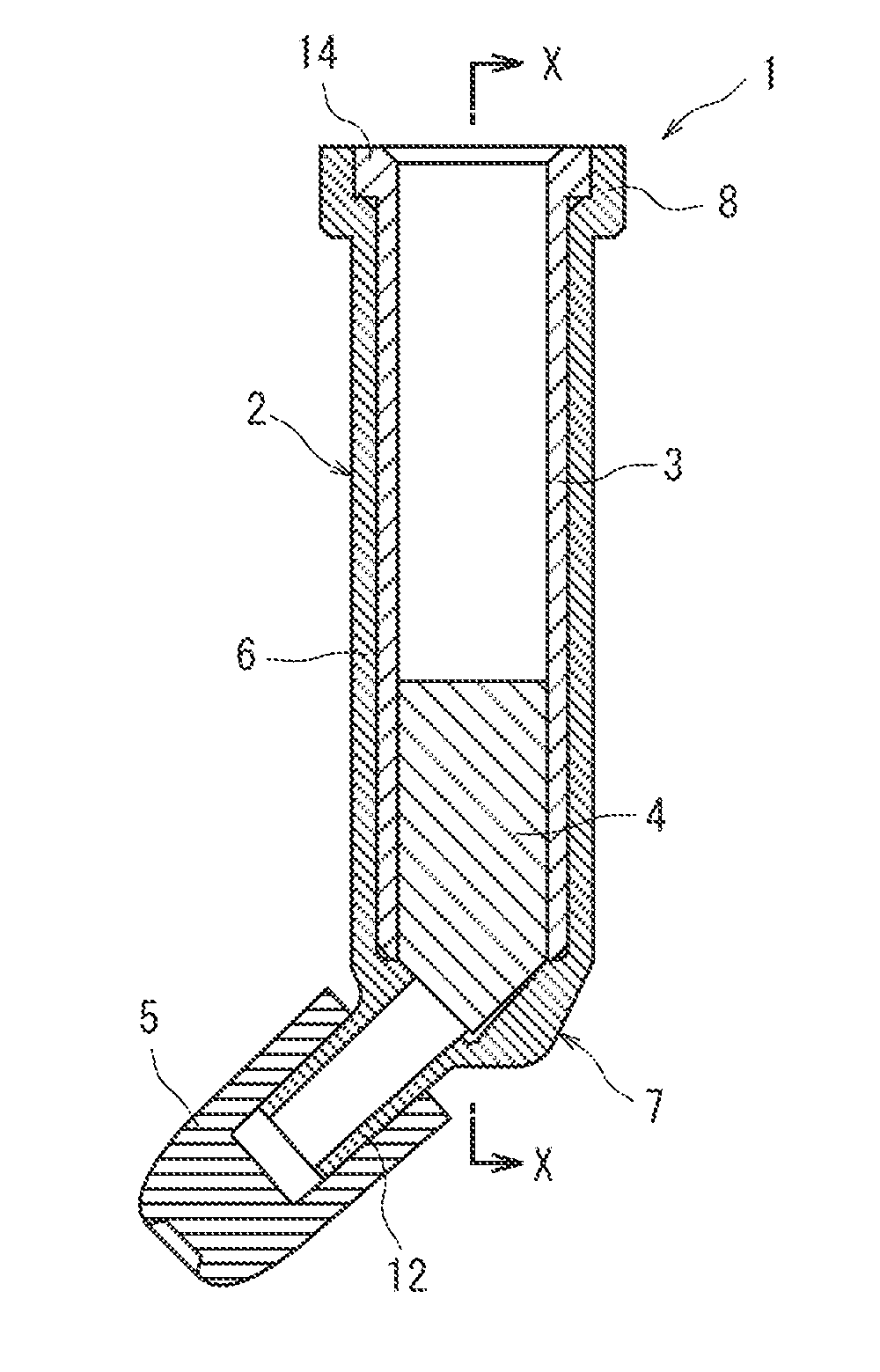

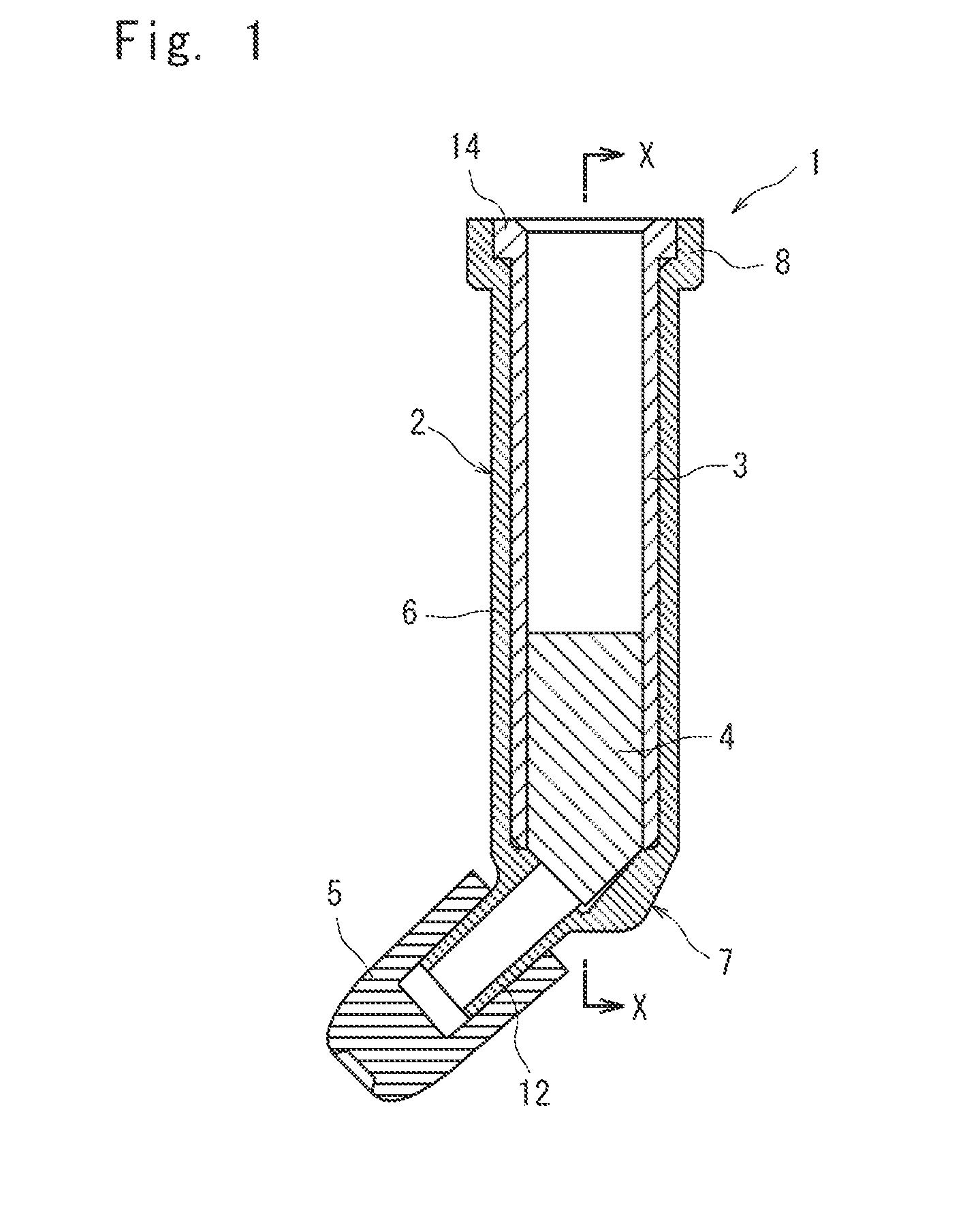

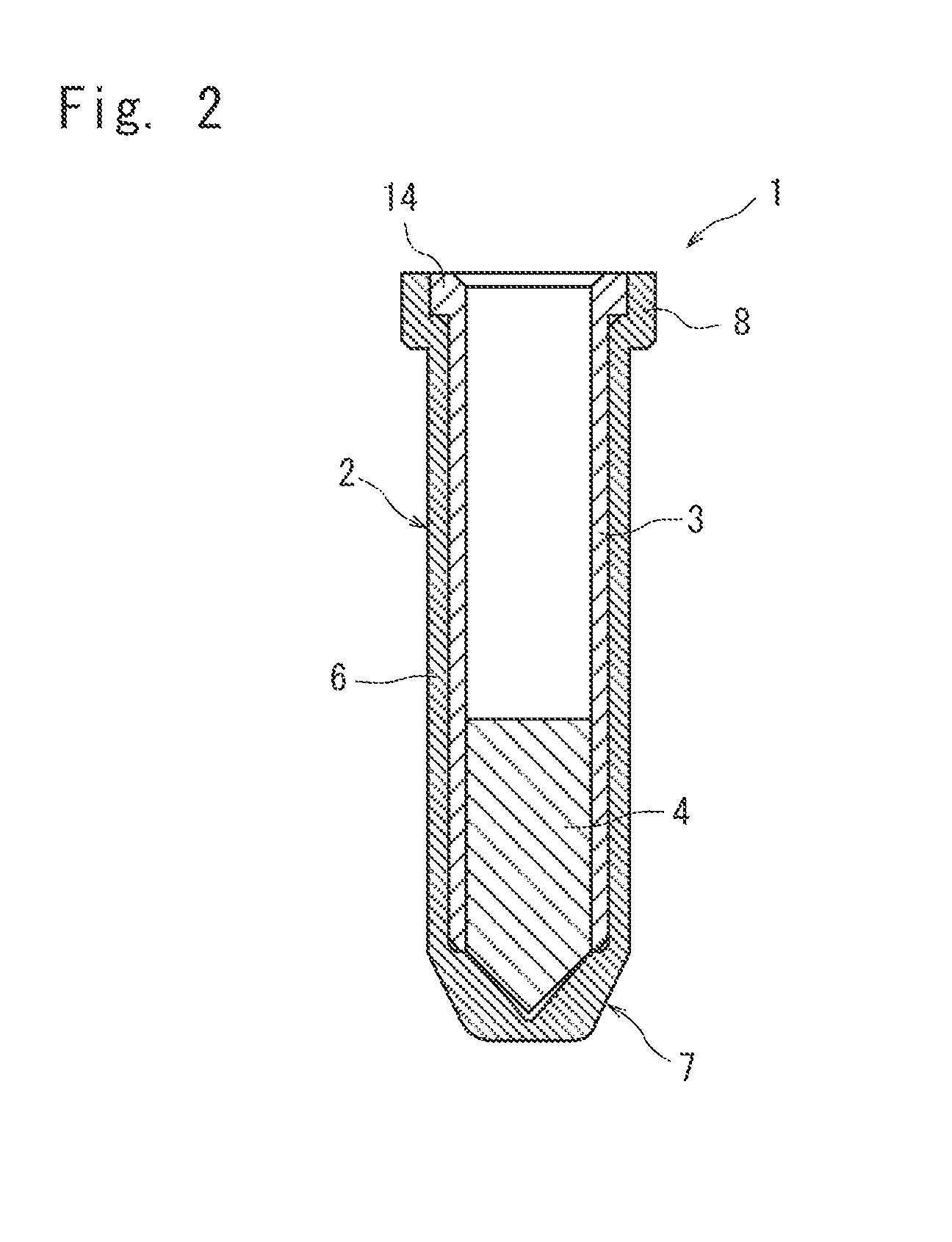

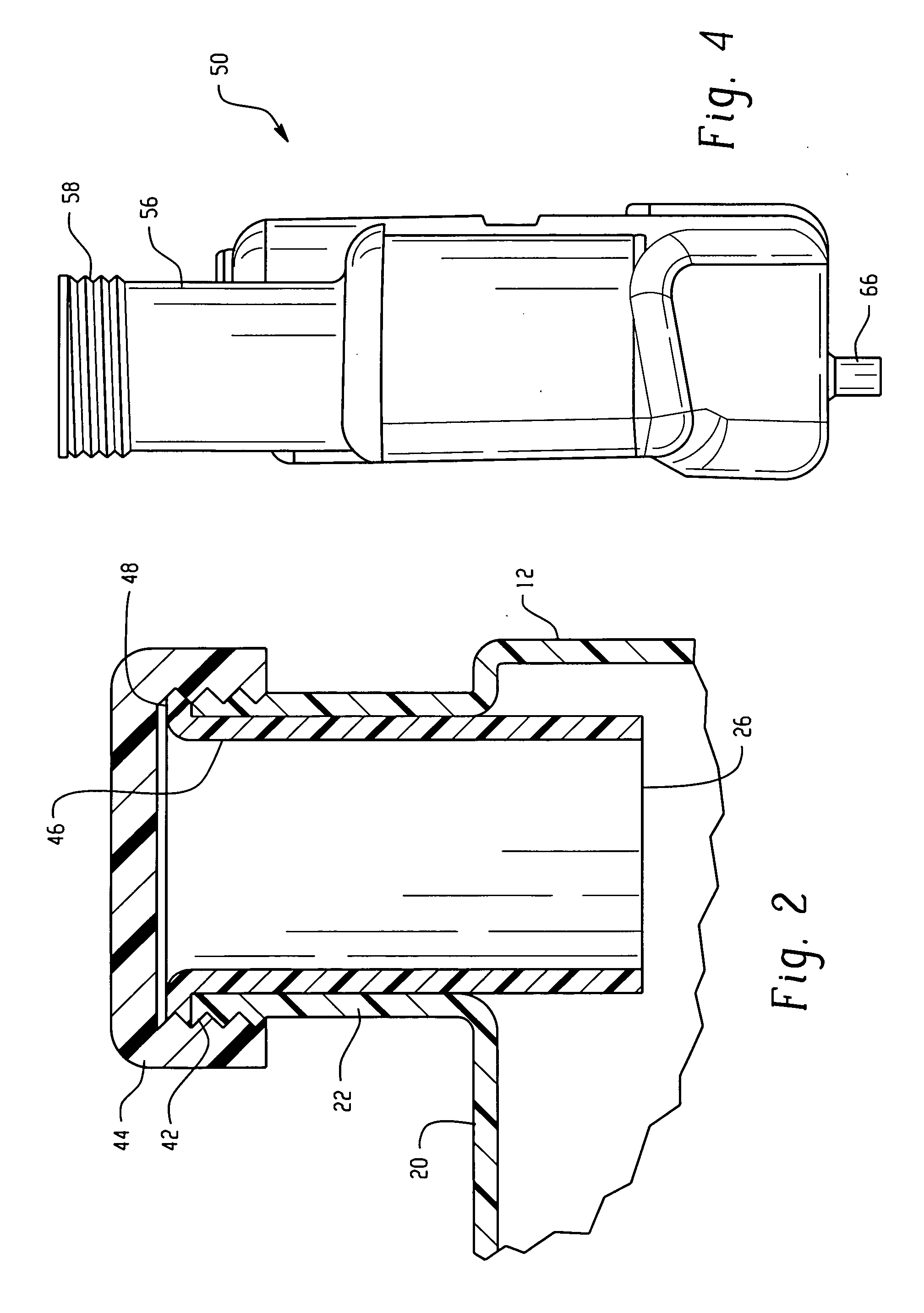

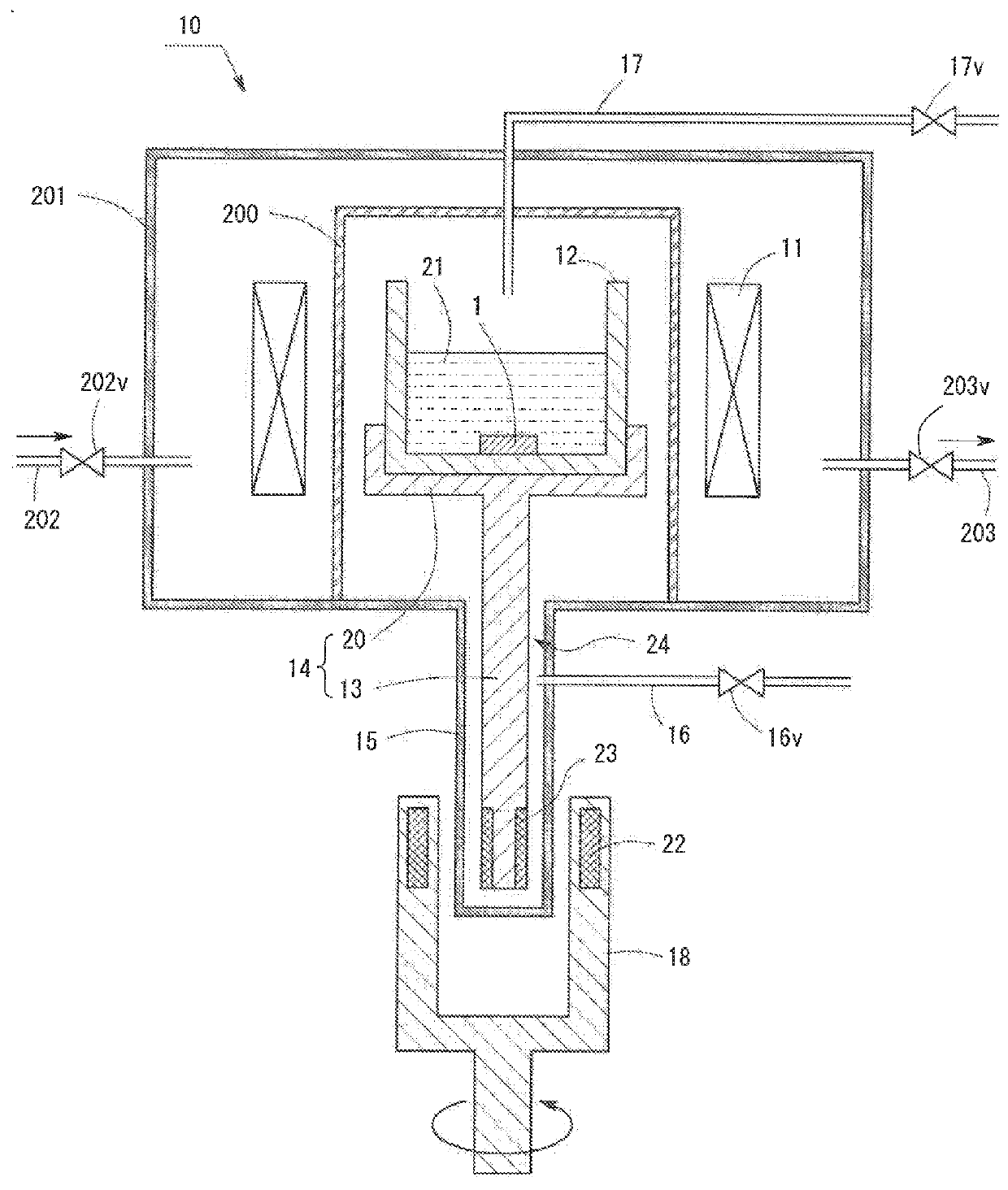

Ejection device and method of filling the ejection device with a material

ActiveUS20130032241A1Avoid separationReduce fillingLiquid surface applicatorsLiquid transferring devicesFilling materialsEngineering

[Problems] To fill a container with a material without applying a high pressure to the material that is to be filled.[Means for Solution] An ejection device 1 comprises a filling chamber 24 formed in a cylindrical member for containing a material to be filled, a discharge portion 7 having a discharge nozzle 12 for pouring out the filled material to the exterior, and a piston 4 that pushes the filled material toward the front end side of the filling chamber 24 to discharge the filled material through the discharge nozzle 12. In the ejection device 1, the discharge portion 7 is formed separately from the filling chamber 24 and in a manner to be fitted to an opening on one end side of the cylindrical member 24, the opening serving as a filling port for filling the material to be filled, and after the material to be filled is poured into the filling chamber 24 through the filling port, the discharge portion 7 is coupled to the filling chamber 24.

Owner:TOKUYAMA DENTAL CORP

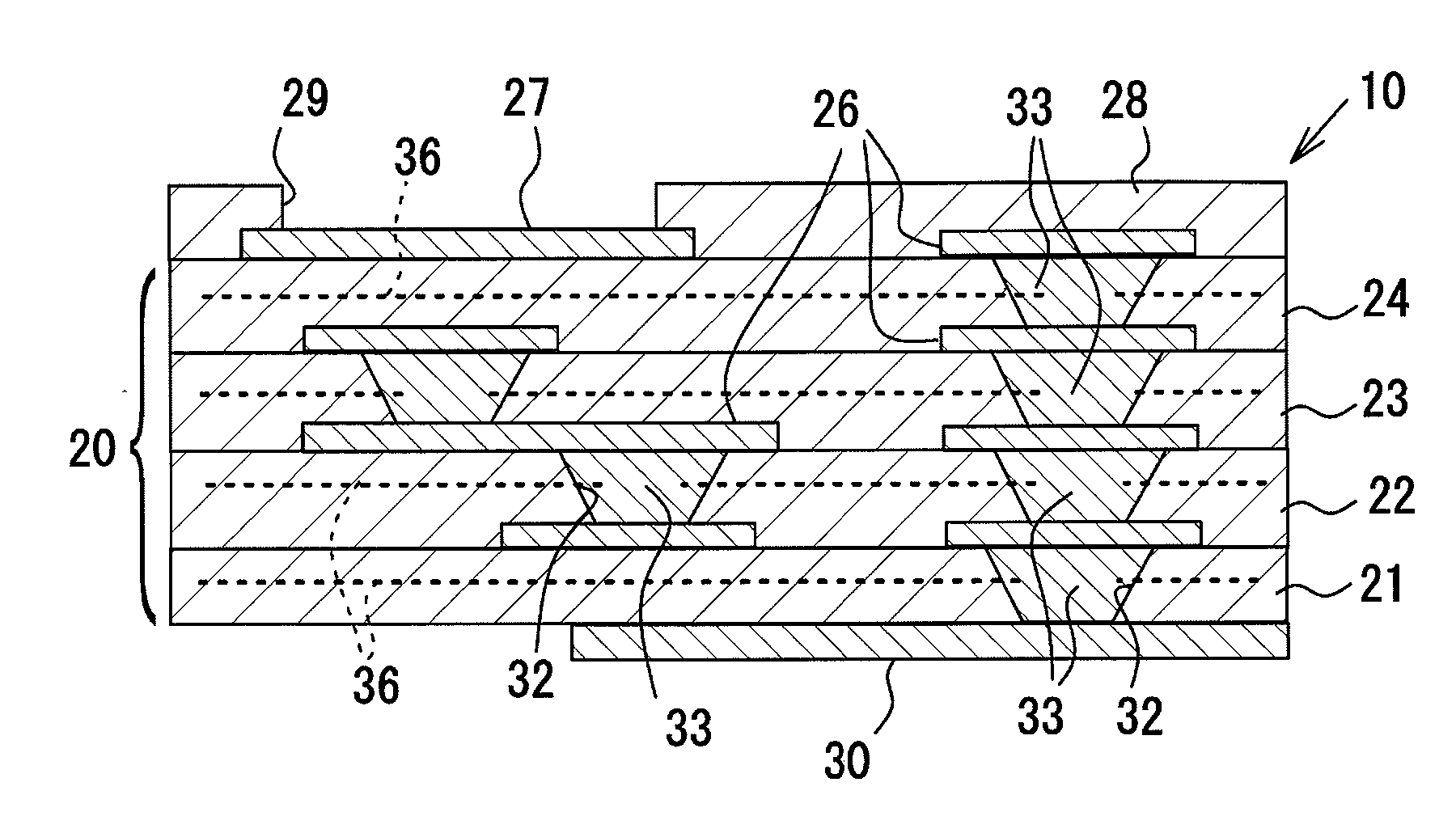

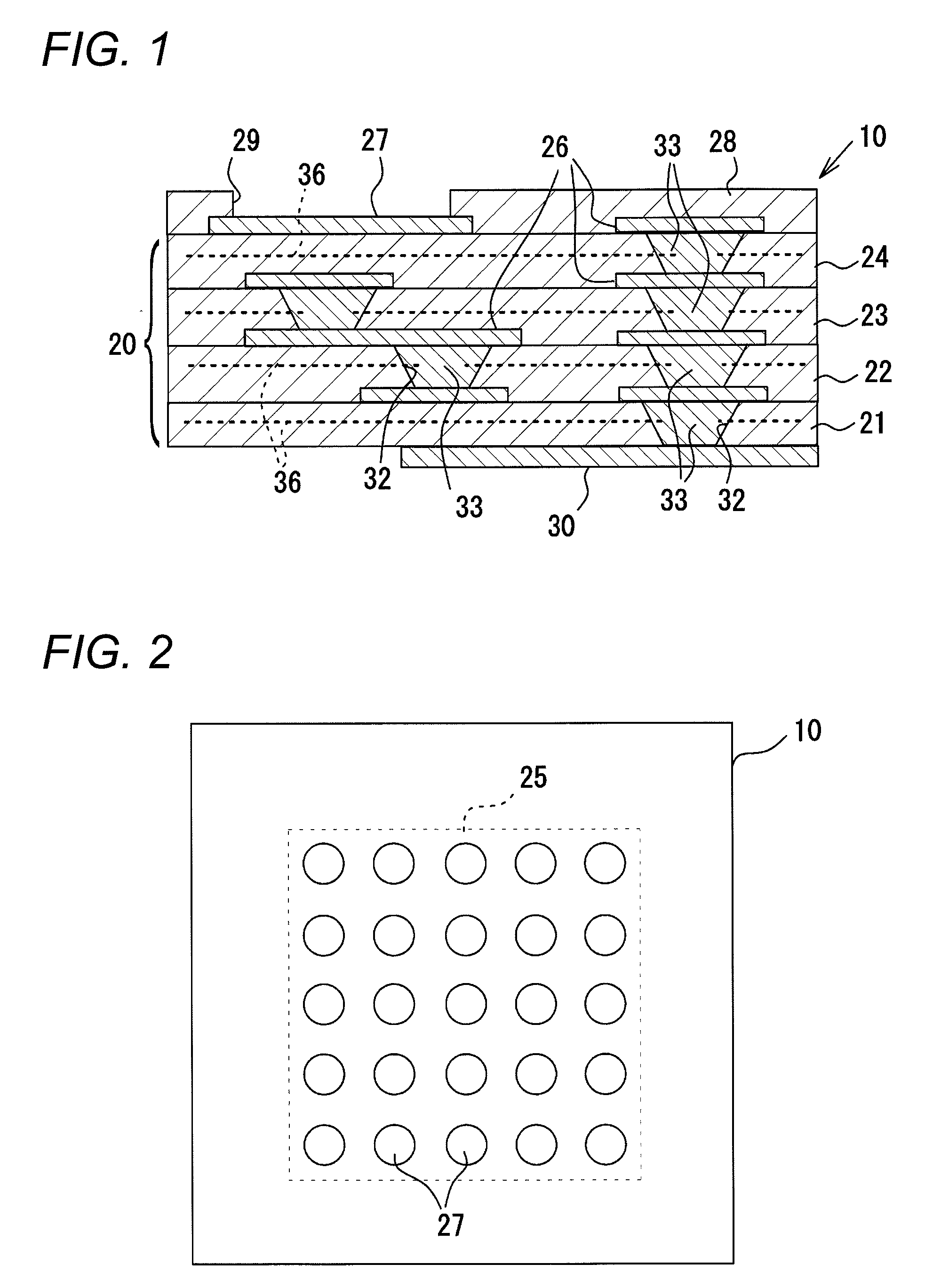

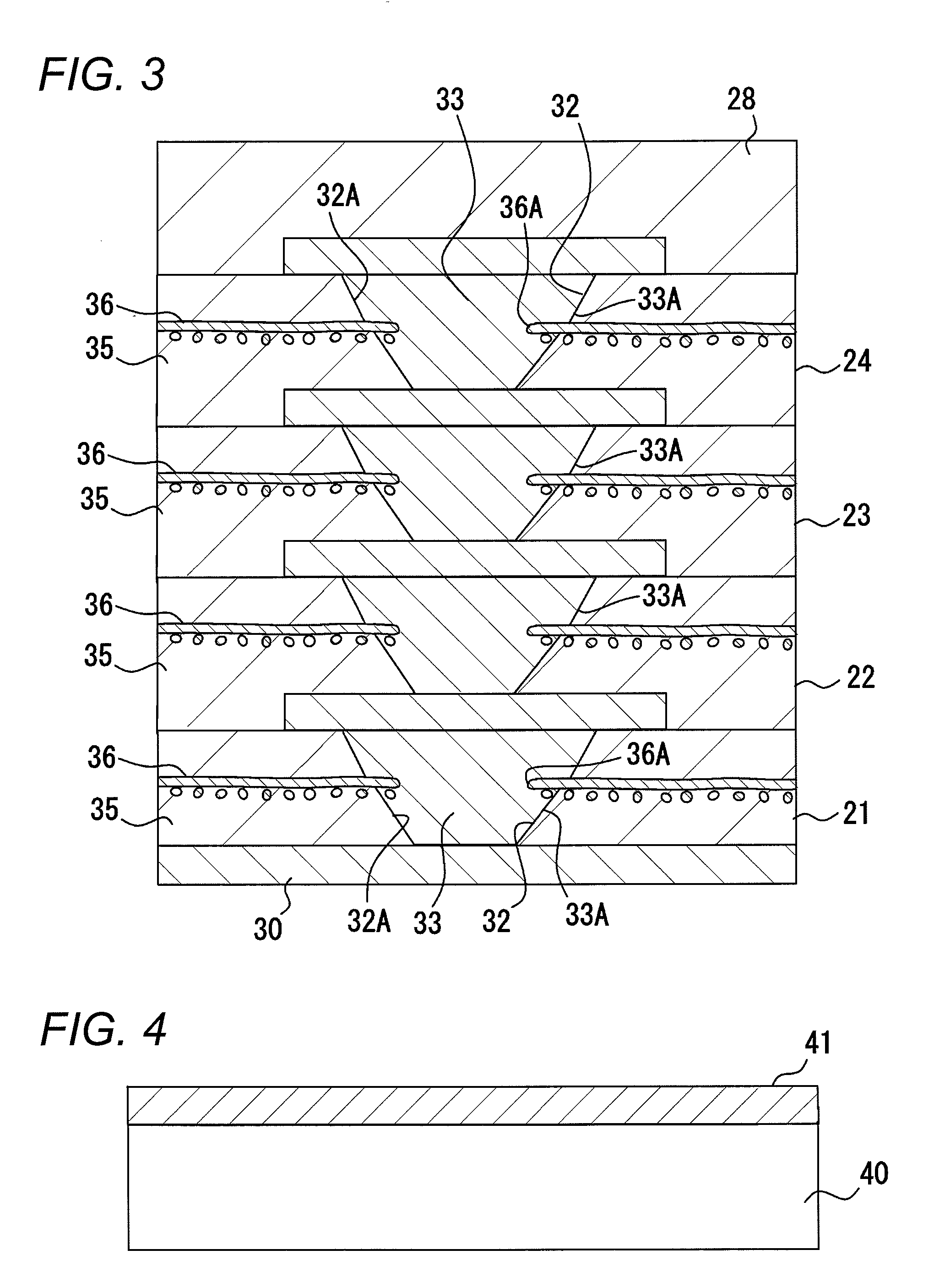

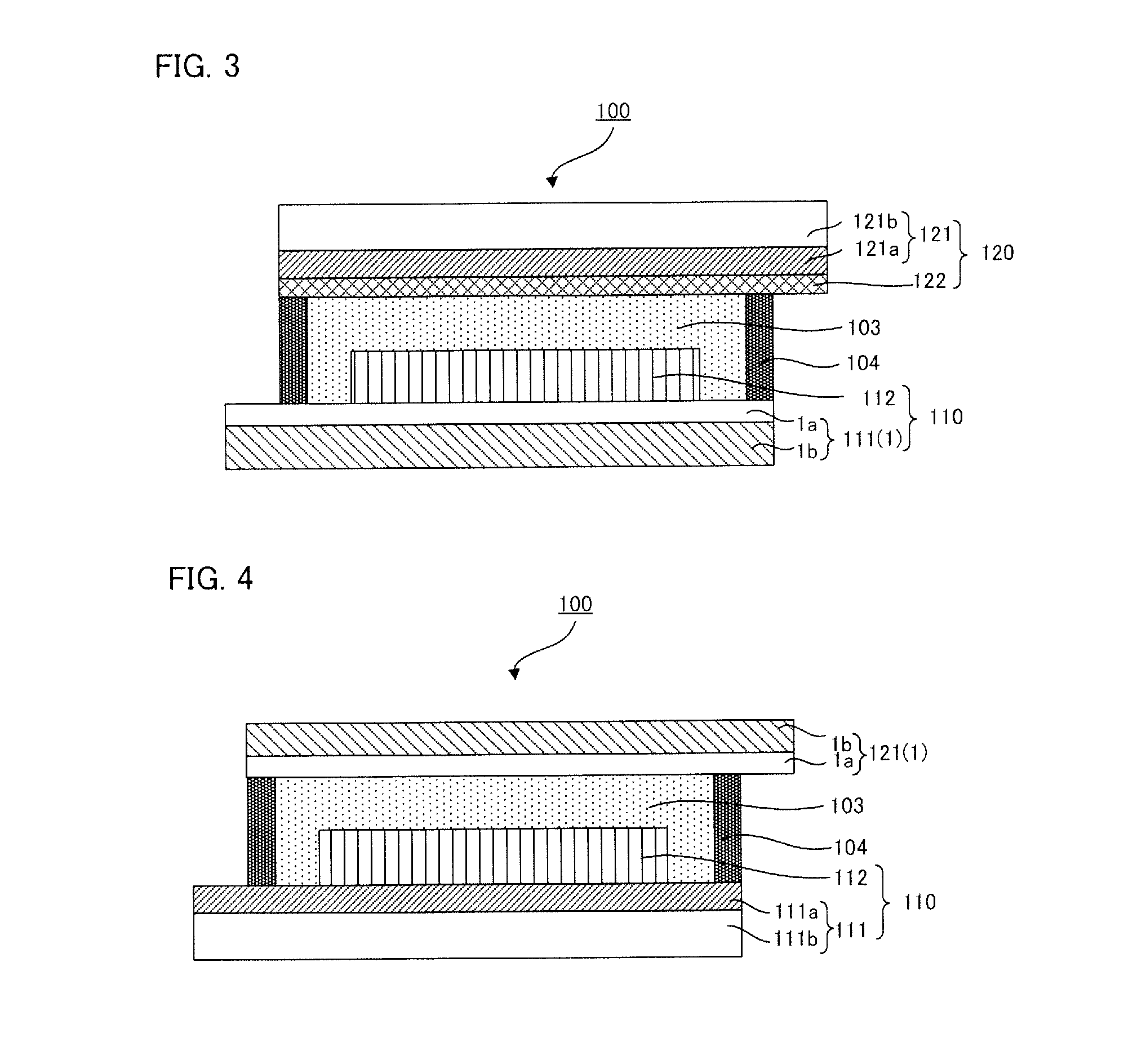

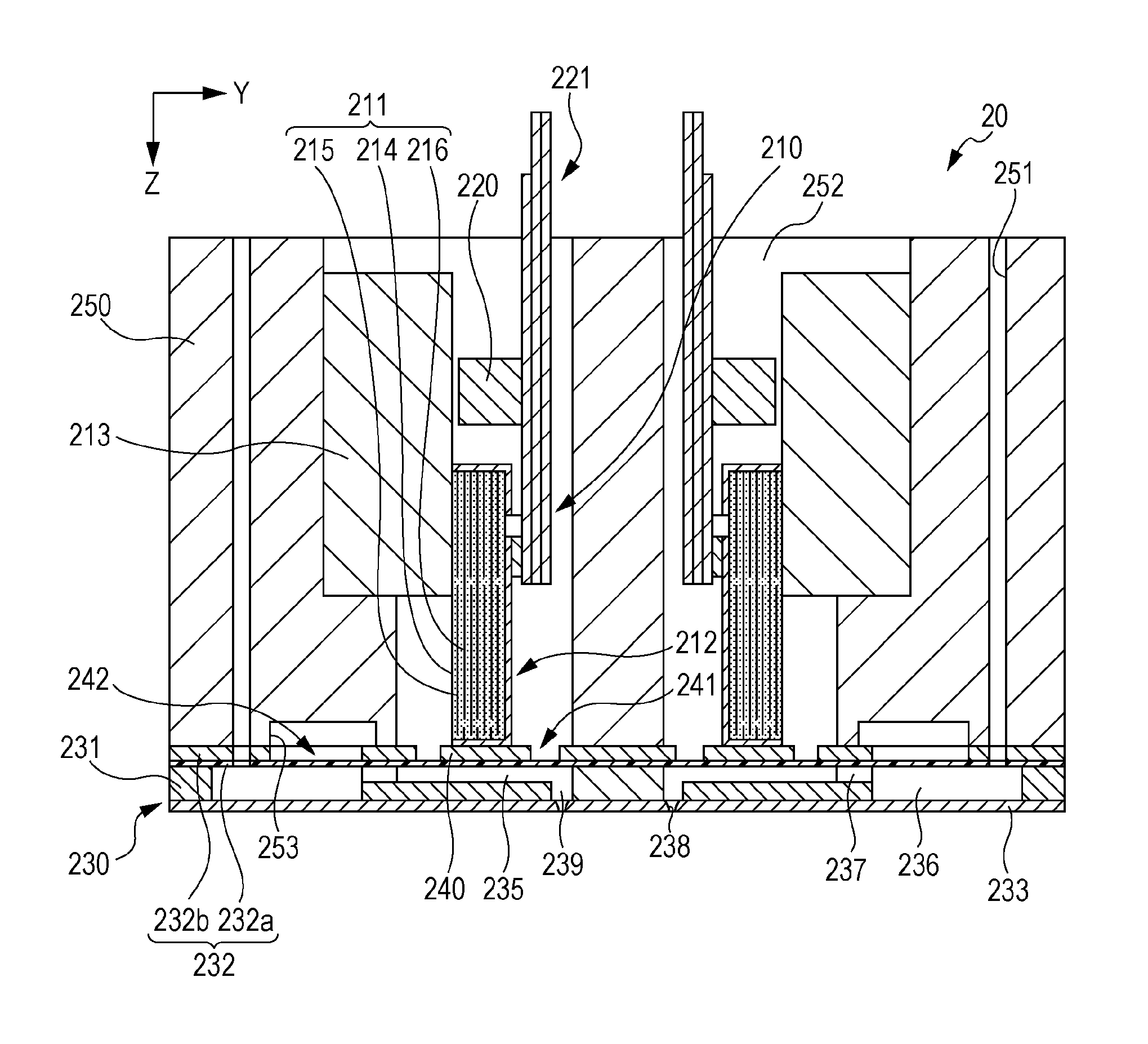

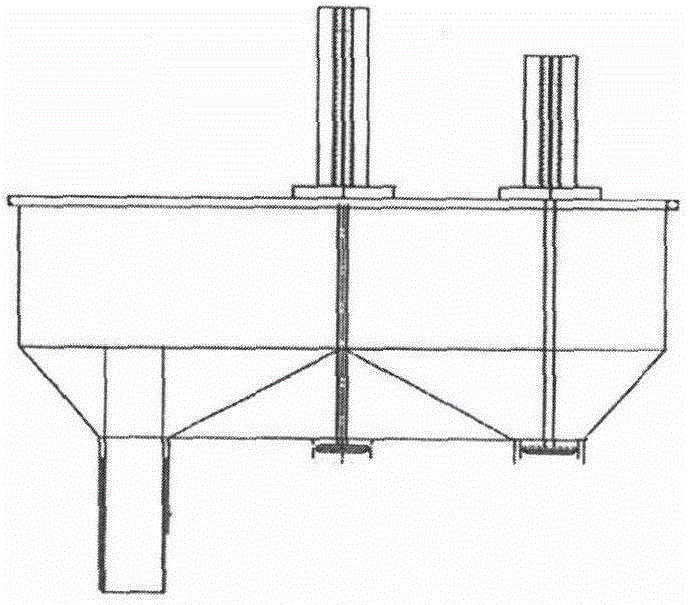

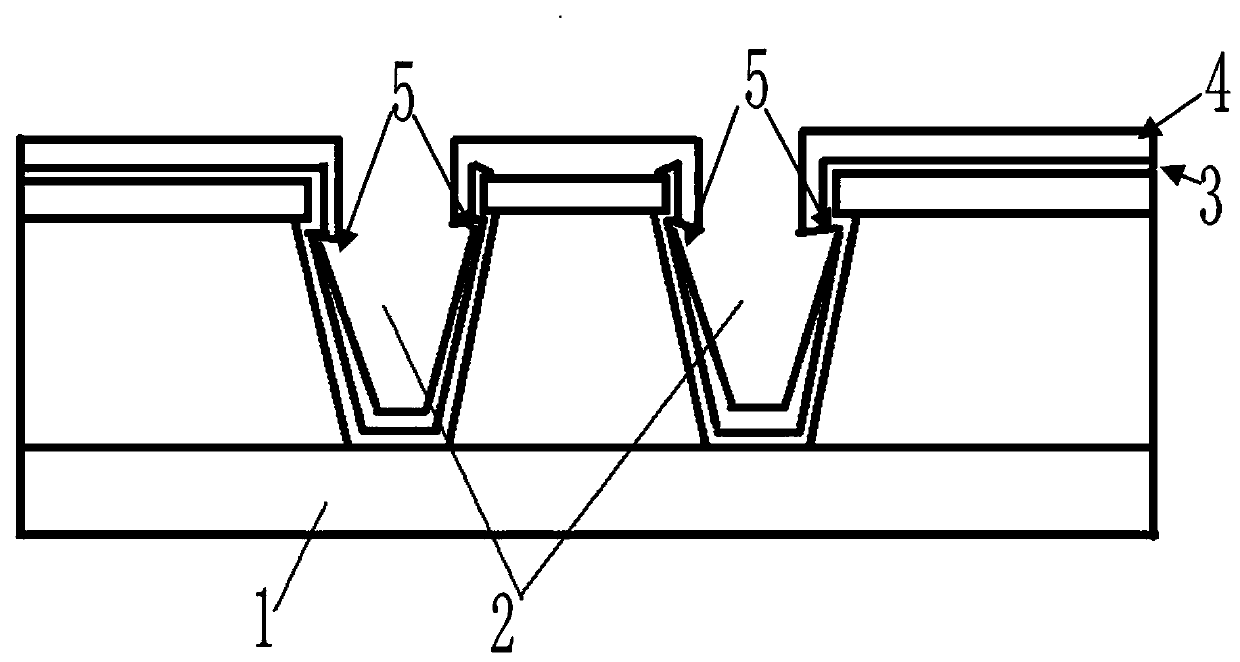

Multilayer wiring board and method of manufacturing the same

ActiveUS20090236138A1High bonding strengthImprove production yieldSemiconductor/solid-state device detailsPrinted circuit aspectsEpoxyElectrical conductor

A coreless wiring board has no core board but a laminated structure in which a conductor layer and resin insulating layers are alternately laminated into a multilayer. Each of the resin insulating layers is formed to contain a glass cloth in an epoxy resin. A plurality of via holes is formed to penetrate each of the resin insulating layers, and a filled via conductor for electrically connecting the conductor layers is formed in the via holes respectively. A tip of the glass cloth contained in each of the resin insulating layers is protruded from an internal wall surface of the via hole and cuts into a sidewall of the filled via conductor.

Owner:NGK SPARK PLUG CO LTD

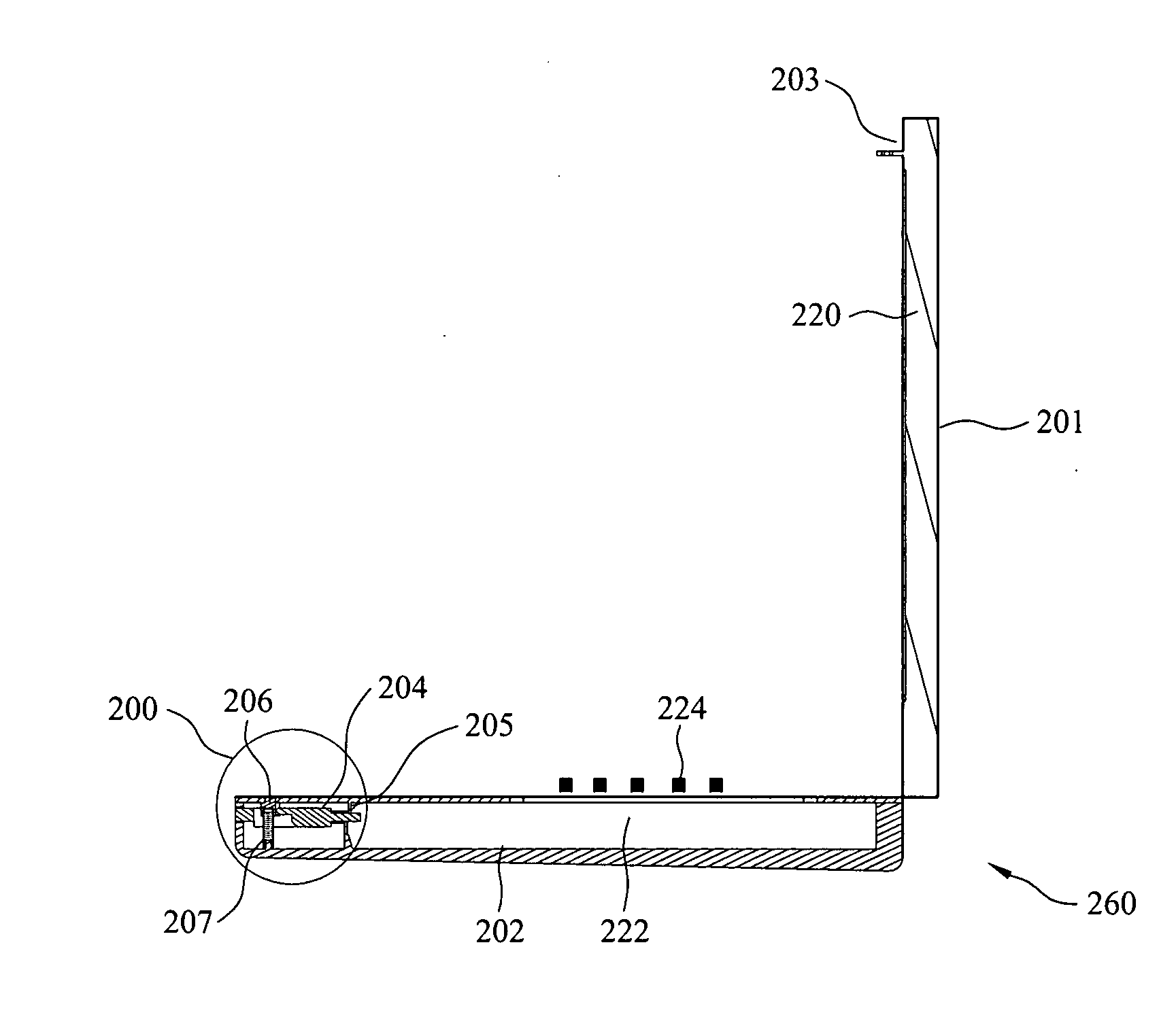

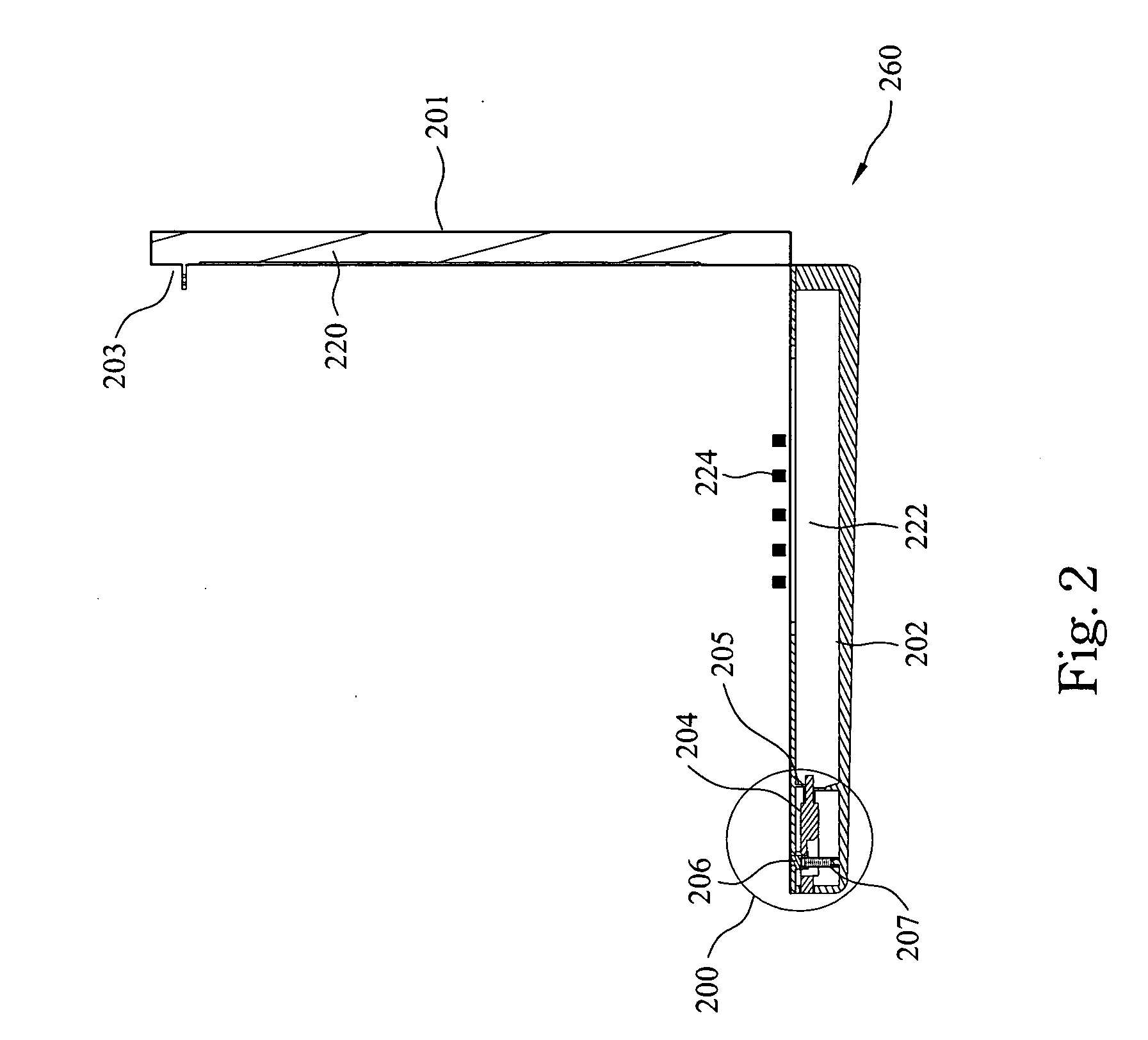

Case structure of portable electronic device

ActiveUS20060279919A1Avoid fillingEasy to liftWing fastenersDetails for portable computersEngineeringMechanical engineering

A case structure of an electronic device comprises a first shell, a second shell, a first engagement element, a second engagement element, a first spring element, a second spring element and a plug element. The first engagement element protrudes from the first shell. The second shell having a first penetrating opening allows the first engagement element to pass through. The second engagement element having a button portion passes through a second penetrating opening of the second shell. The second engagement element is driven by the button portion and the first spring element to control the second engagement element and the first engagement element to engage or disengage from each other. The plug element located in the second shell is pushed for filling in the first penetrating opening by the second spring element.

Owner:ASUSTEK COMPUTER INC

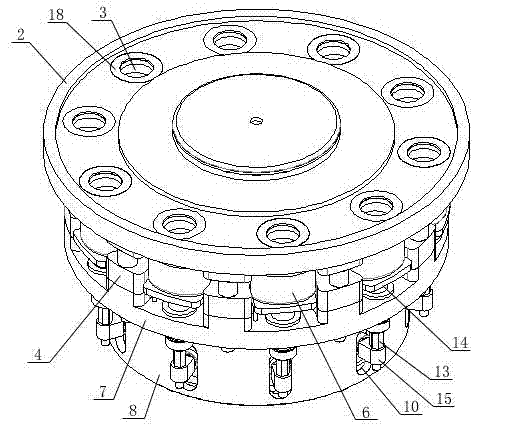

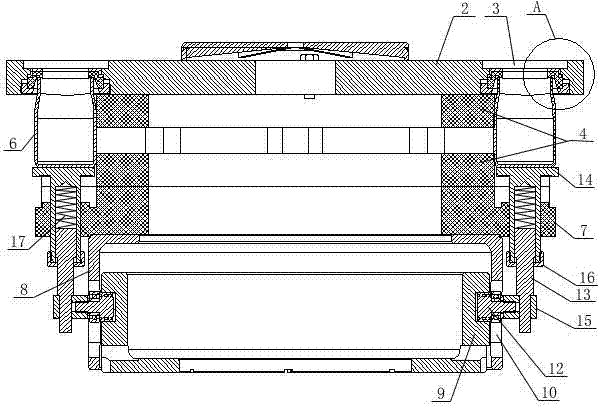

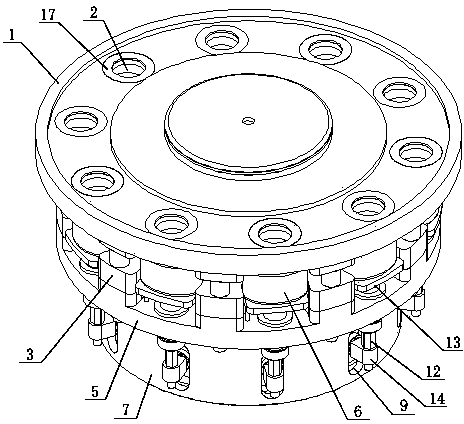

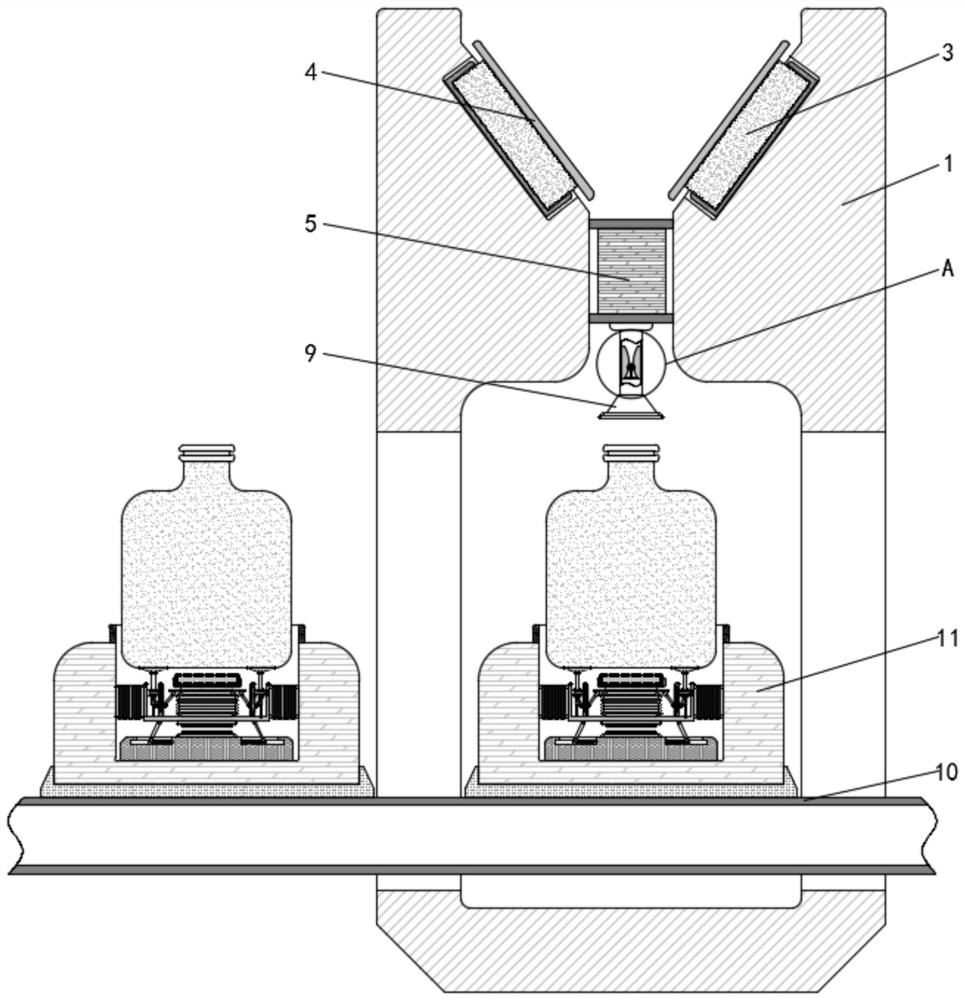

Turntable device for filling machine

The invention discloses a turntable device for a filling machine. The turntable device comprises a turntable and a plurality of blanking through holes uniformly formed in the turntable, wherein a bottle clamping disk is arranged below the turntable; a plurality of bottle clamping slots corresponding to the blanking through holes are formed in the periphery of the bottle clamping disk and are matched with the shapes of filling bottles; a mandril fixing plate is arranged below the bottle clamping disk; the turntable, the bottle clamping disk and the mandril fixing plate are connected with one another through connection pieces to form a whole; a plurality of bottle jacking mechanisms corresponding to the bottle clamping slots are arranged below the mandril fixing plate; the upper ends of the bottle jacking mechanisms penetrate through the mandril fixing plate to jack up the filling bottles arranged in the bottle clamping slots, so that bottlenecks of the filling bottles can be jacked to the blanking through holes of the turntable. According to the turntable device for the filling machine, the filling bottles are clamped through the bottle clamping disk, so that the filling bottles can completely correspond to the blanking through holes of the turntable one by one and synchronously rotate along with the turntable in the whole filling process; therefore, the filling problem caused by a fact that the filling bottles do not correspond to a blanking hopper in an existing structure can be thoroughly solved.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

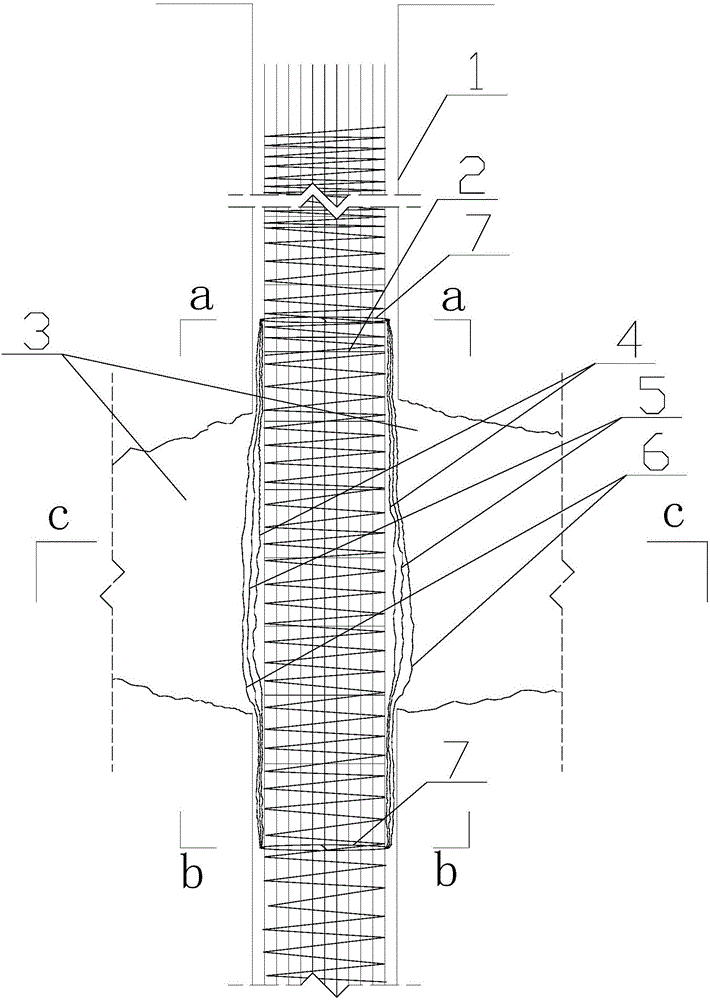

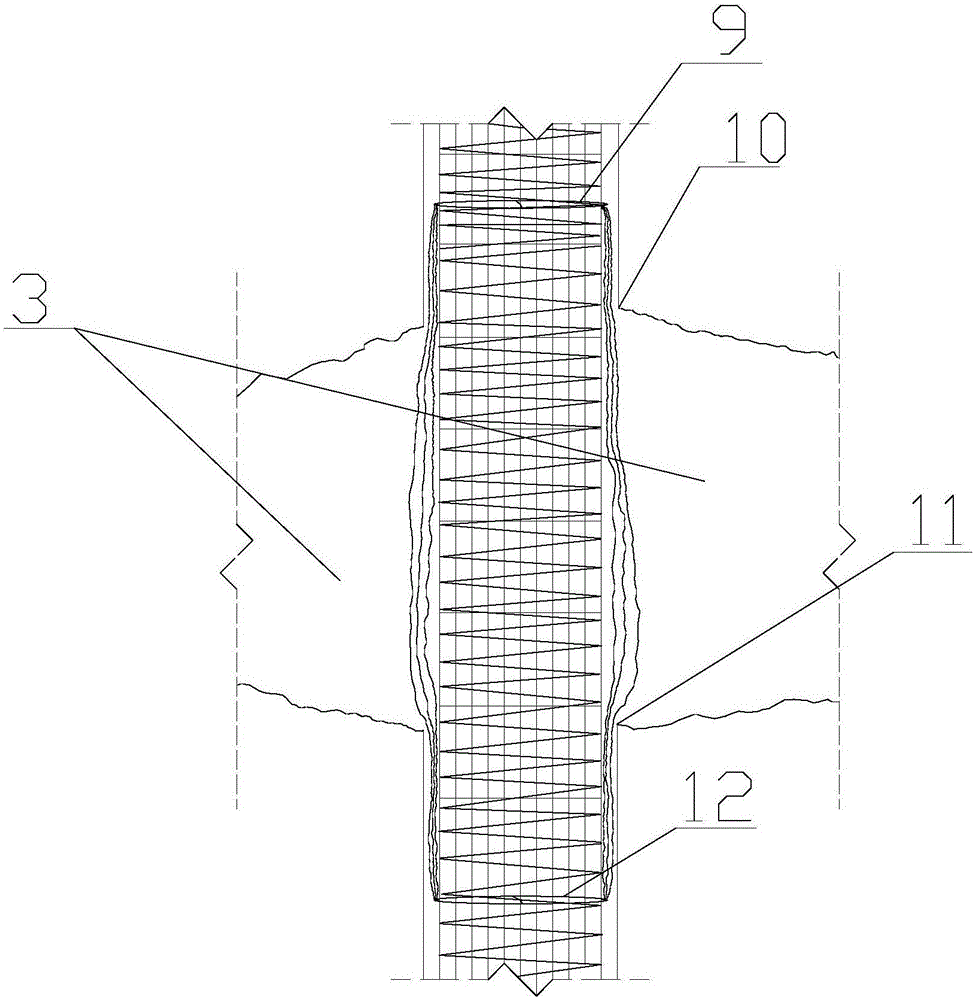

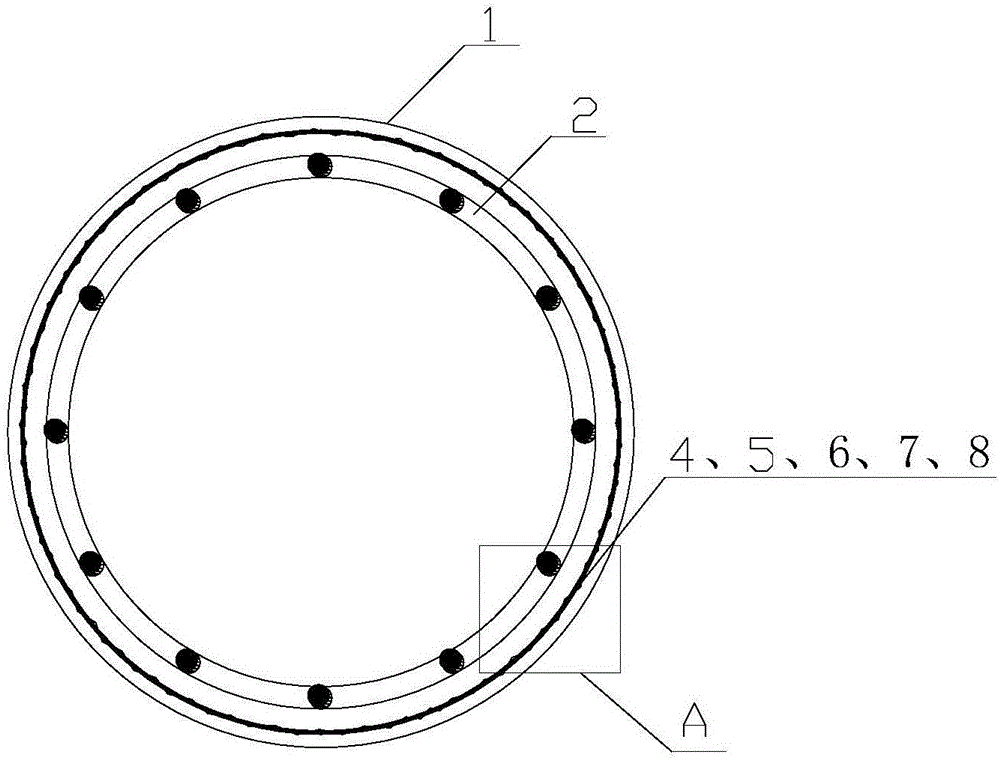

Protection device and protection method for pouring for poured pile in cave stratum

InactiveCN106759307AAvoid fillingGuaranteed pouring of concreteBulkheads/pilesRebarConstruction aggregate

The invention discloses a protection device and a protection method for pouring for a poured pile in a cave stratum. In the protection device, two location hoops are sequentially arranged on the outer ring of a reinforcement cage in a sleeving manner in the length direction, the upper location hoop is higher than the top elevation of a cave, and the lower location hoop is lower than the bottom elevation of the cave; the outer ring of the reinforcement cage between the two location hoops is sequentially wrapped with a concrete aggregate loss prevention layer, a concrete mortar loss prevention layer and a fixing layer from inside to outside; and the two ends of each of the concrete aggregate loss prevention layer, the concrete mortar loss prevention layer and the fixing layer are connected with the two location hoops respectively. The protection device is capable of safely and effectively ensuring concrete pouring for a pile foundation in a cave area, convenient to construct, free from potential safety hazards, simple in structure, capable of realizing field material taking, easy to machine, simple to install, capable of saving the construction period, increasing the construction efficiency and lowering the construction difficulty, and high in safety factor.

Owner:CHINA FIRST METALLURGICAL GROUP

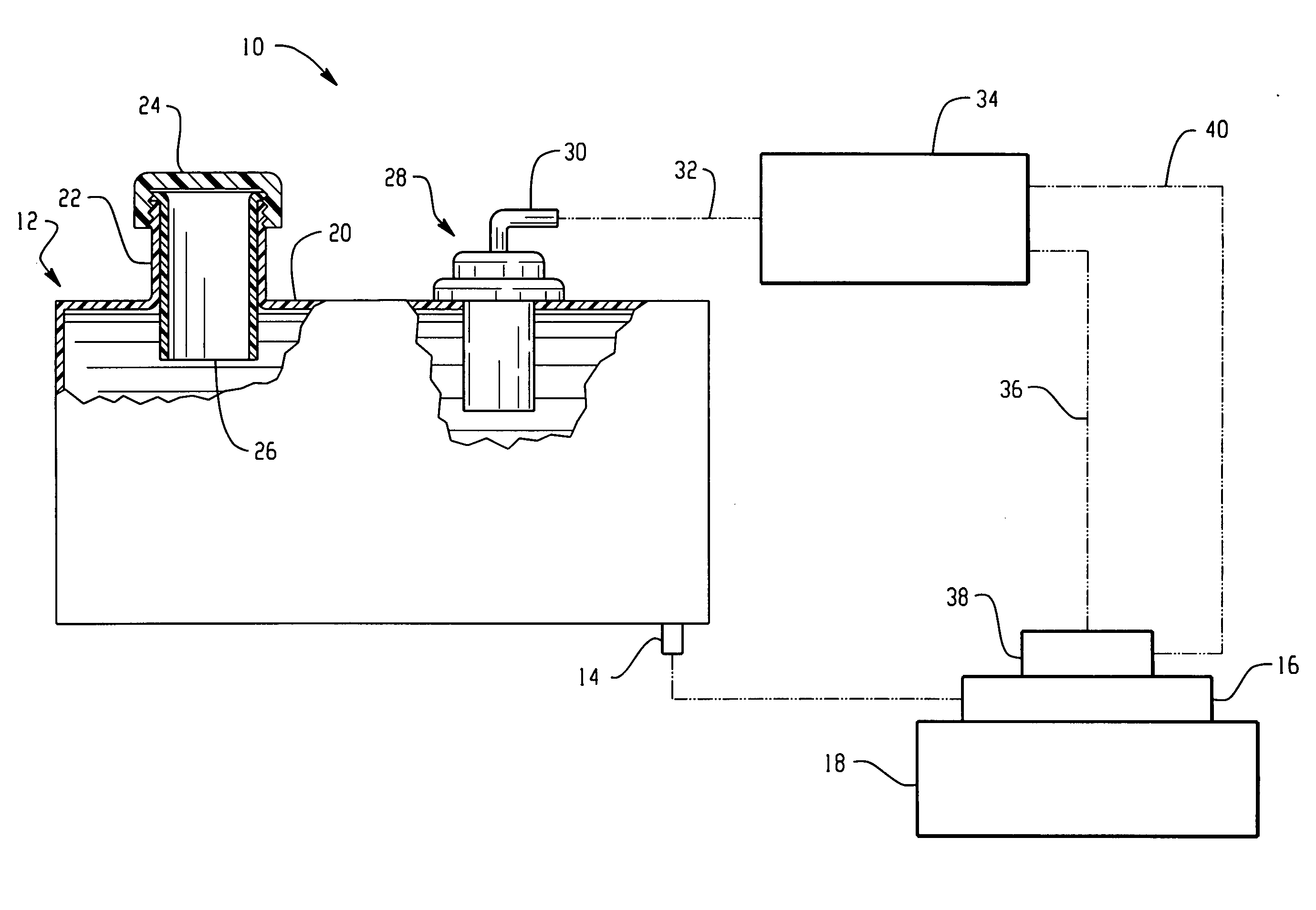

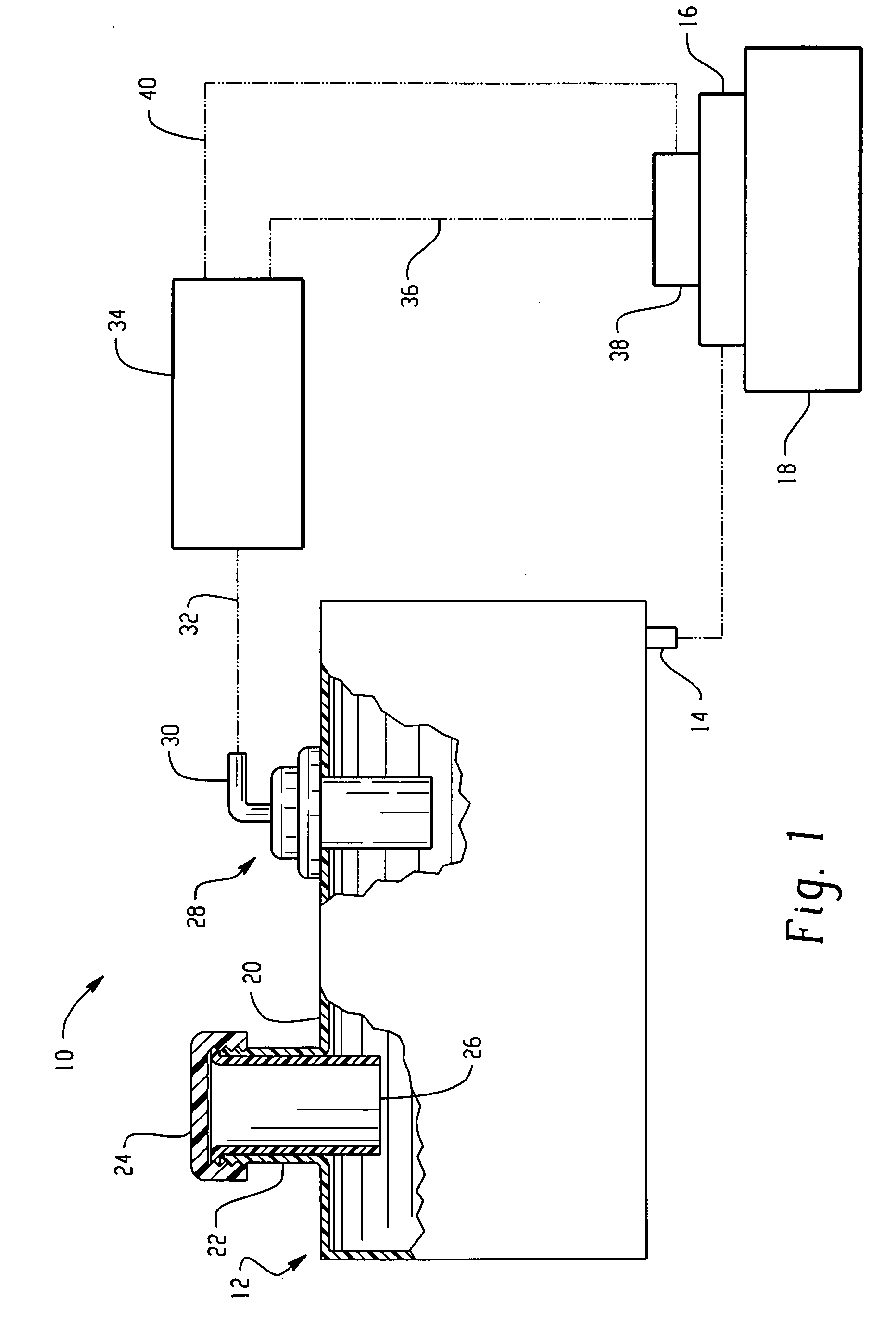

System and method for controlling fuel vapor emmission in a small engine

ActiveUS20060213487A1Avoid fillingAvoid paddingNon-fuel substance addition to fuelWing accessoriesSmall enginePolyamide

A small engine fuel system has a tank with an integrally formed filler tube having the lower end located at a level below the upper portion of the tank wall which is formed of vapor impermeable material which may include HDPE interspersed with EVOH or polyamide. In one exemplary embodiment the filler neck is disposed in a depression in the upper portion of the tank wall; and in another exemplary embodiment the filler tube has an insert which extends into the tank to a position below the upper portion of the tank wall to form a vapor space. The tank includes a fill limiting vapor vent / tipping valve with its outlet connected to a storage canister which outputs to the engine and which has an atmospheric air vent.

Owner:EATON INTELLIGENT POWER LIMITED

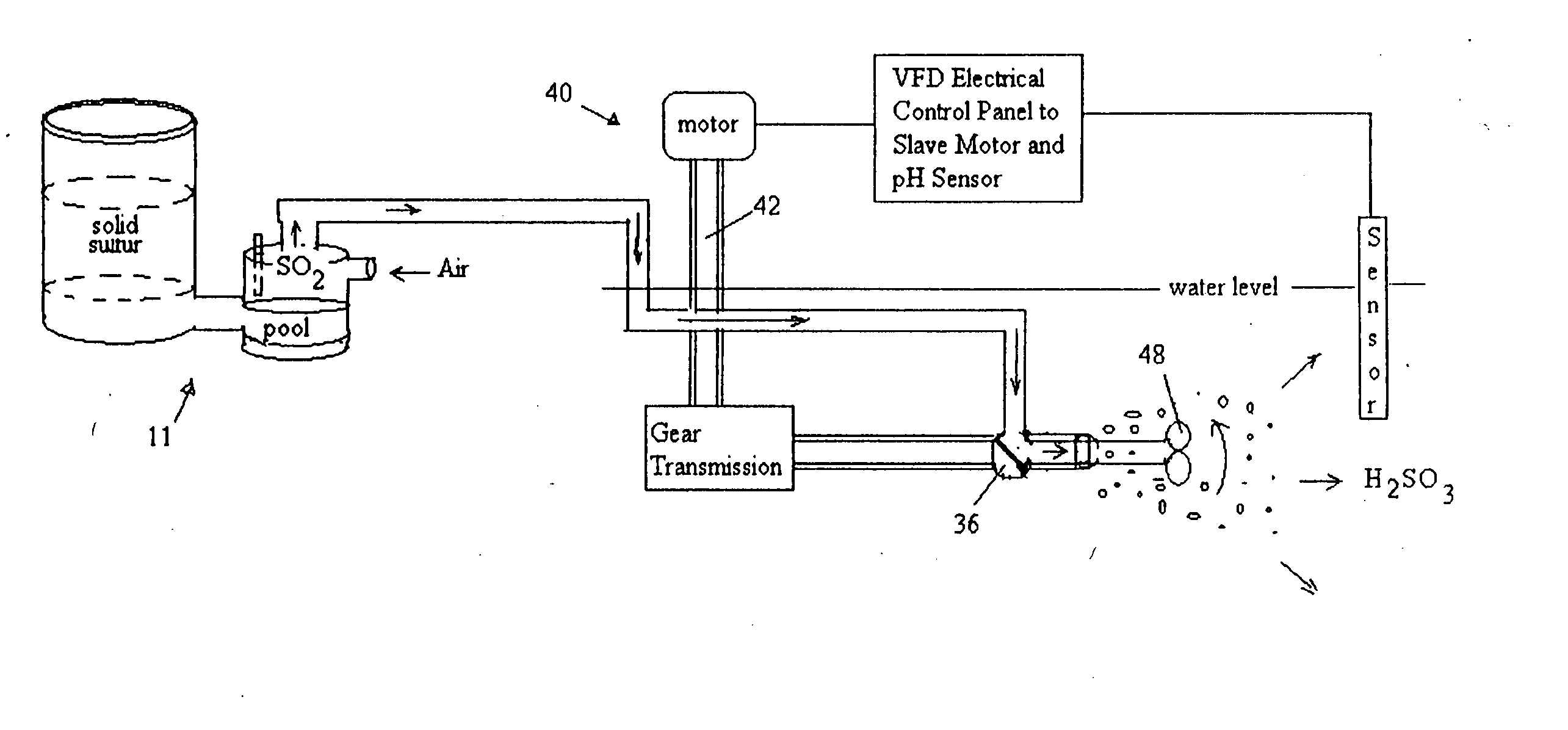

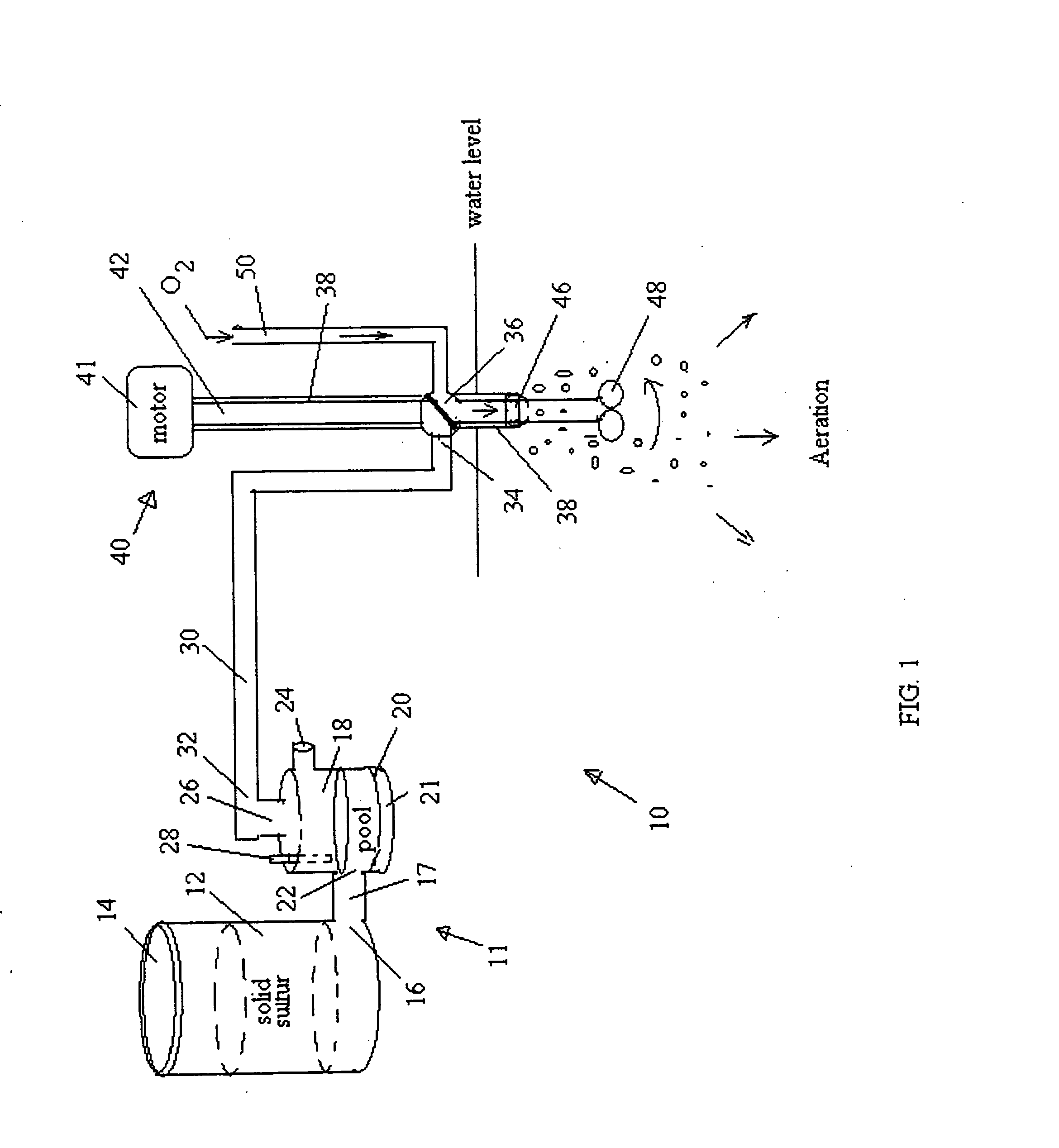

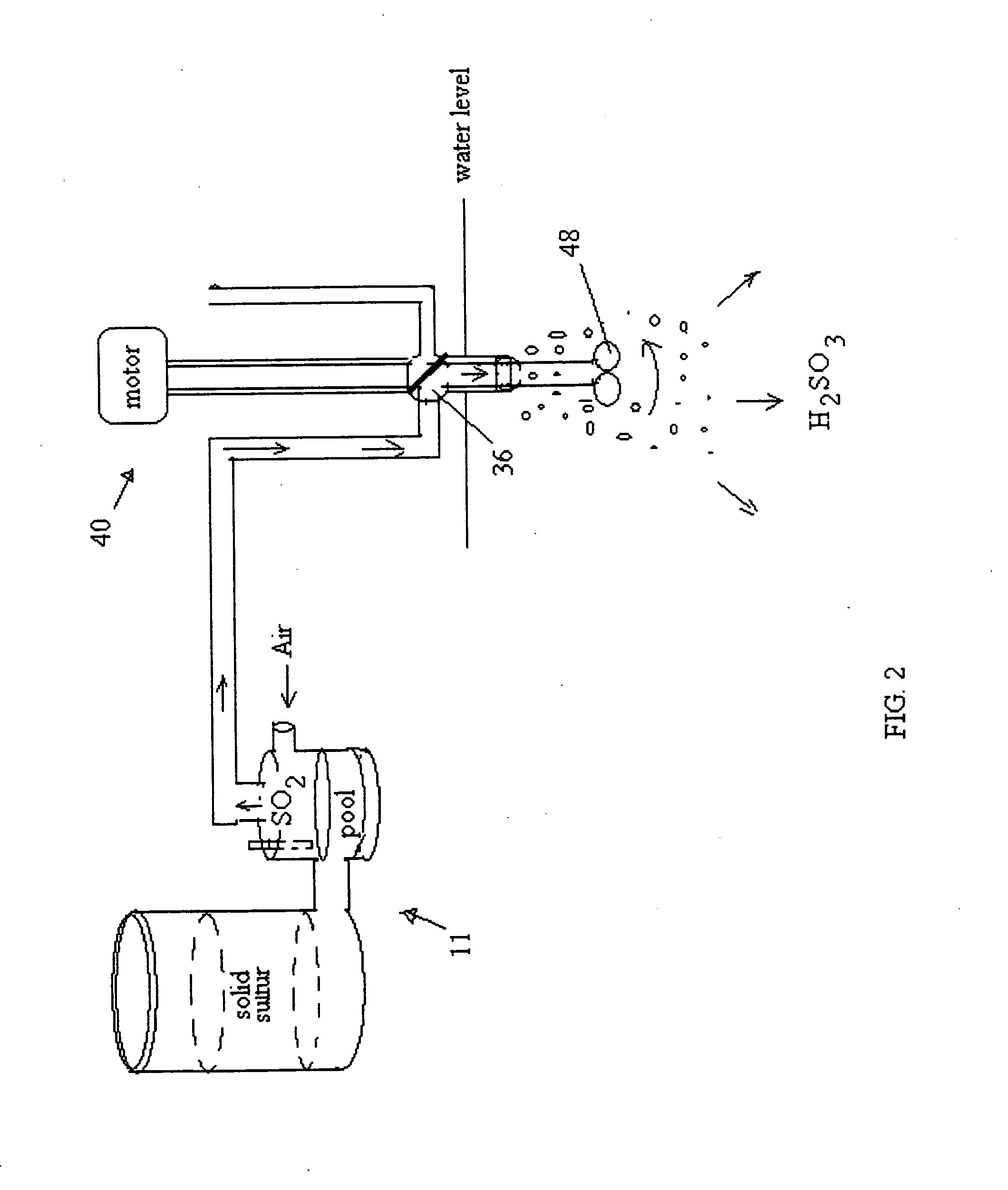

Sulfur dioxide generator with aqueous gas mixer/aerator

InactiveUS20110318239A1Sufficient flow resistanceAvoid paddingGaseous chemical processesSulfur-dioxide/sulfurous-acidSulfurSulfur dioxide

An apparatus for burning sulfur to produce sulfur dioxide, which sulfur dioxide is associated with a multi-channel gas valve associated with other gas sources to selectively be blended each into water by a combination mixer / aerator to aerate water in one monde, admix sulfur dioxide with water to form sulfurous acid in another mode, and stir and mix water without gases in a third mode.

Owner:EARTH RENAISSANCE TECH

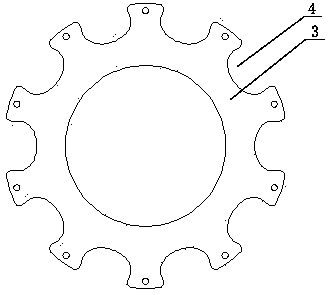

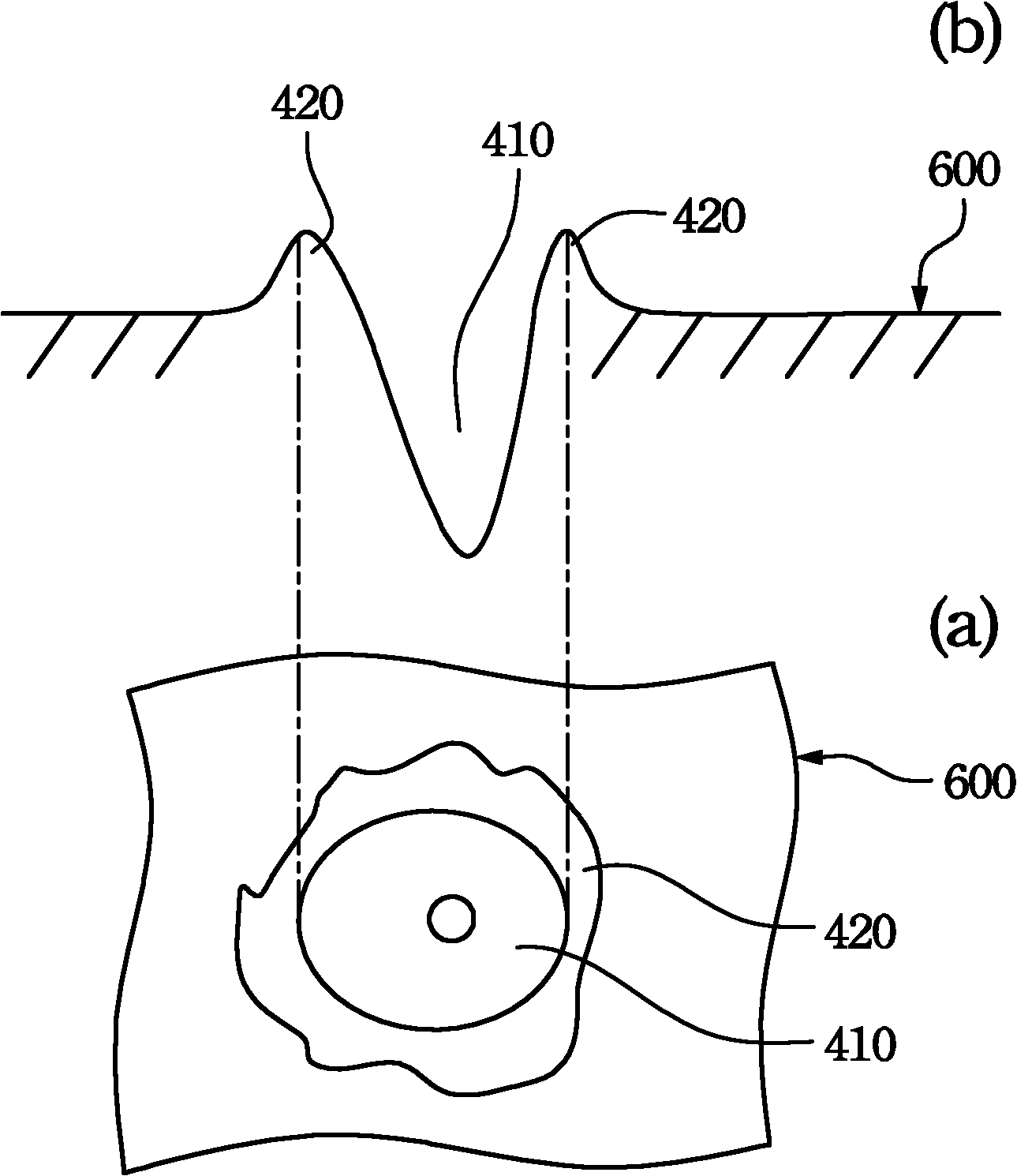

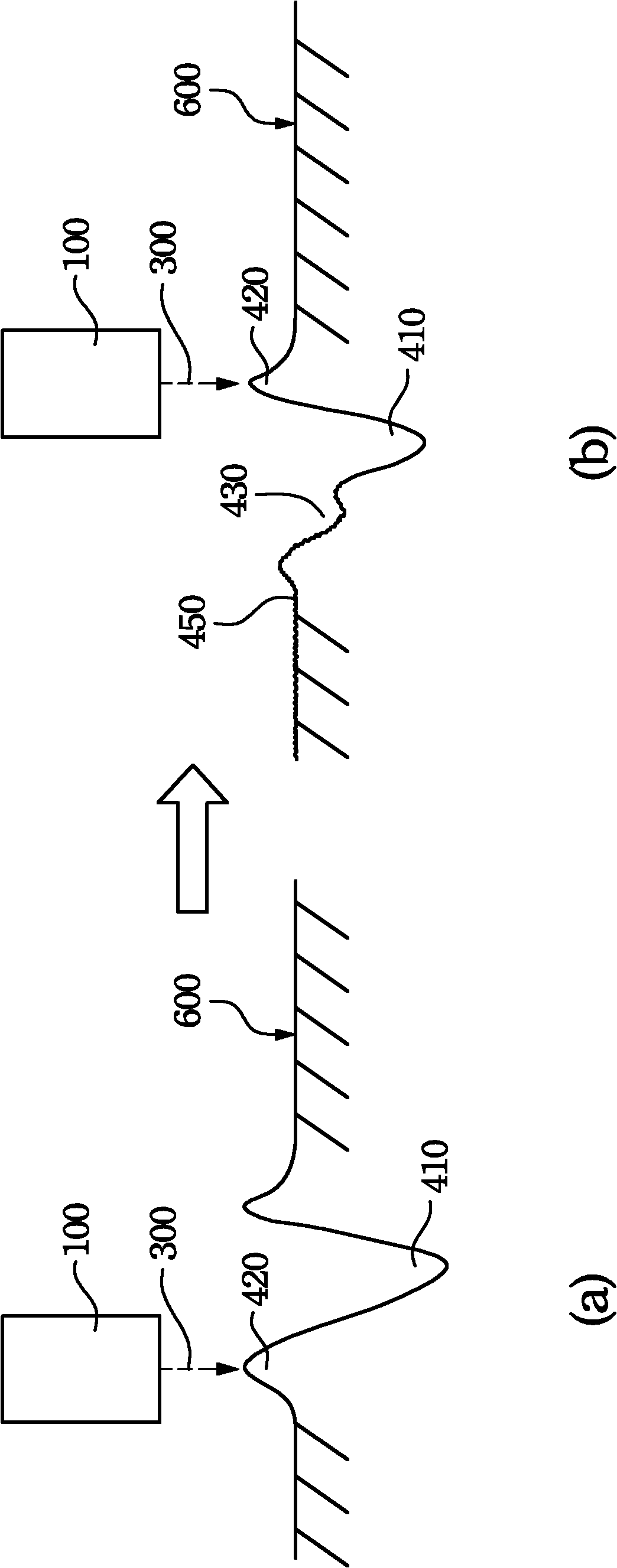

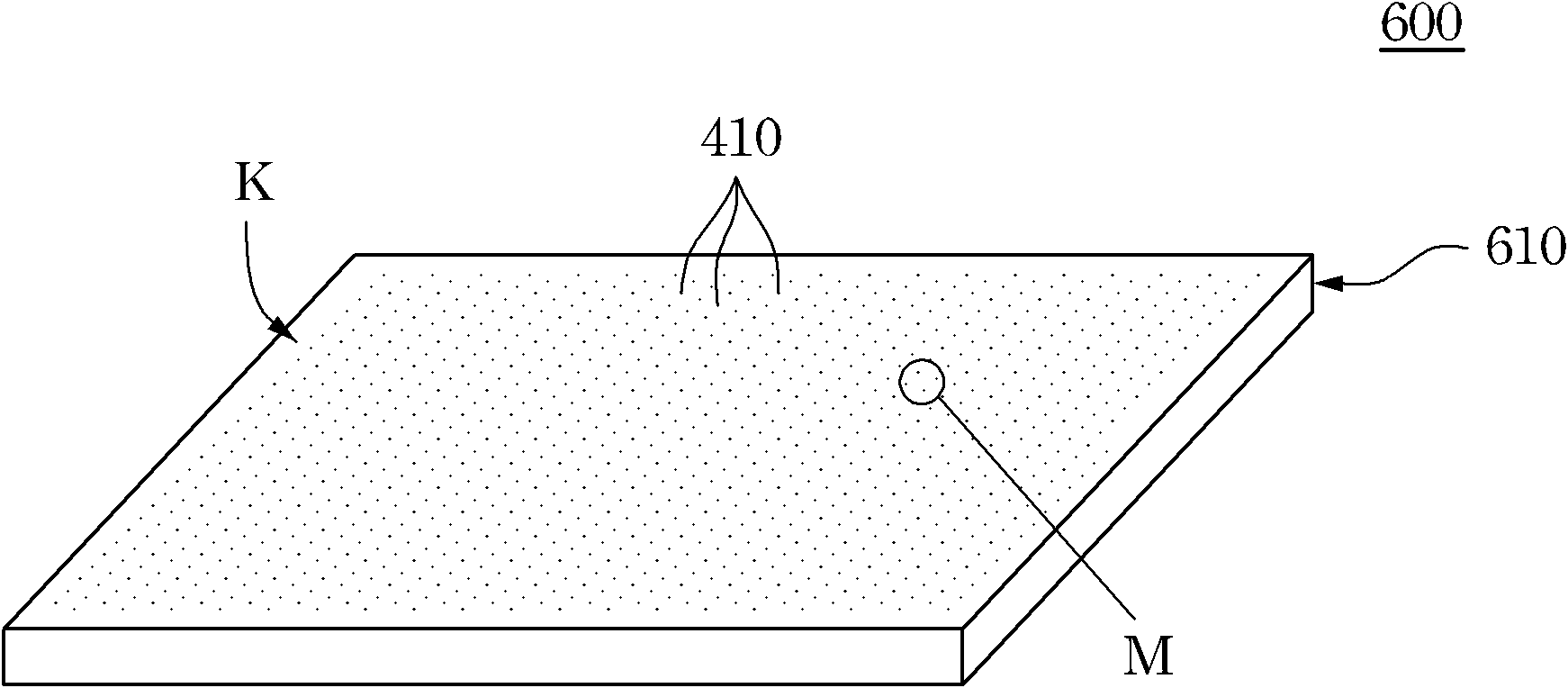

Stamping die and light guide plate thereof

The invention relates to a stamping die and a light guide plate thereof. The stamping die comprises a die body and a micropore aggregation pattern, wherein the die body comprises a stamping surface; the micropore aggregation pattern is distributed on the stamping surface and comprises a plurality of micro concave holes, at least one bulge is arranged on the periphery of each micro concave hole, and a molten surface is respectively arranged on the periphery of each micro concave hole and the top surface of the bulge of the micro concave hole. By the invention, the opportunity that the bulges on the peripheries of the micro concave holes fall off to fill the micro concave holes can be reduced, even avoided, thereby further avoiding the problem that a correct optical microstructure pattern can not be stamped on the surface of the light guide plate when the stamping die is used for the optical microstructure pattern on the light guide plate in the following process step; in addition, the service life of a product of the stamping die is also prolonged.

Owner:苏州向隆塑胶有限公司

Energy-saving and environment-friendly flour quantitative filling and collecting device for dough processing

PendingCN112849458AAvoid continuing to fillReduce labor intensitySolid materialProcess engineeringBiology

The invention provides an energy-saving and environment-friendly flour quantitative filling and collecting device for dough processing. The energy-saving and environment-friendly flour quantitative filling and collecting device for dough processing comprises a main body, wherein the inner wall of the main body is provided with a buffer plate; the main body is internally provided with a feeding device; the lower side of the feeding device is fixedly provided with a feeding pipe; the lower end of the feeding pipe is fixedly provided with a feeding port; and a conveying belt is mounted at the bottom of the inner wall of the main body. According to the energy-saving and environment-friendly flour quantitative filling and collecting device for dough processing, flour in a collecting mechanism is continuously increased, when the flour reaches a certain amount, a first induction piece is promoted to make contact with a second induction piece, at the moment, current changes, an electric signal is sent out, and flour making equipment stops continuously pouring the flour, so that the continuous filling of the flour is avoided; and through automatic operation of the equipment, the labor intensity of workers is effectively reduced, meanwhile, the flour filling effect is improved, and the filling efficiency of manufacturers is further improved.

Owner:雷忠亮

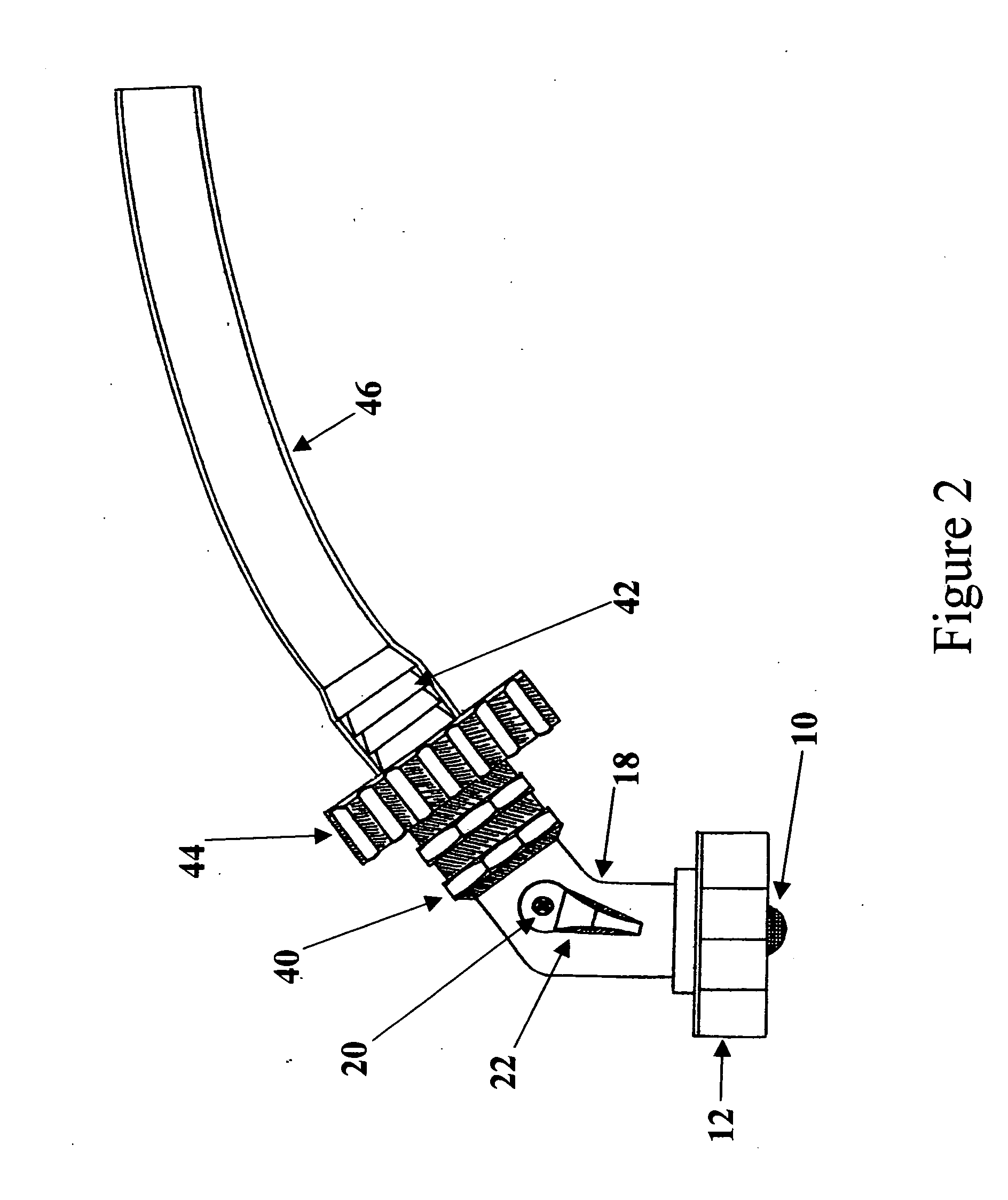

Hands free device for filling tanks

ActiveUS20070175541A1Avoid componentsAvoid damageLiquid transferring devicesSolid materialHands freeMechanical engineering

Owner:VALTERRA PRODS

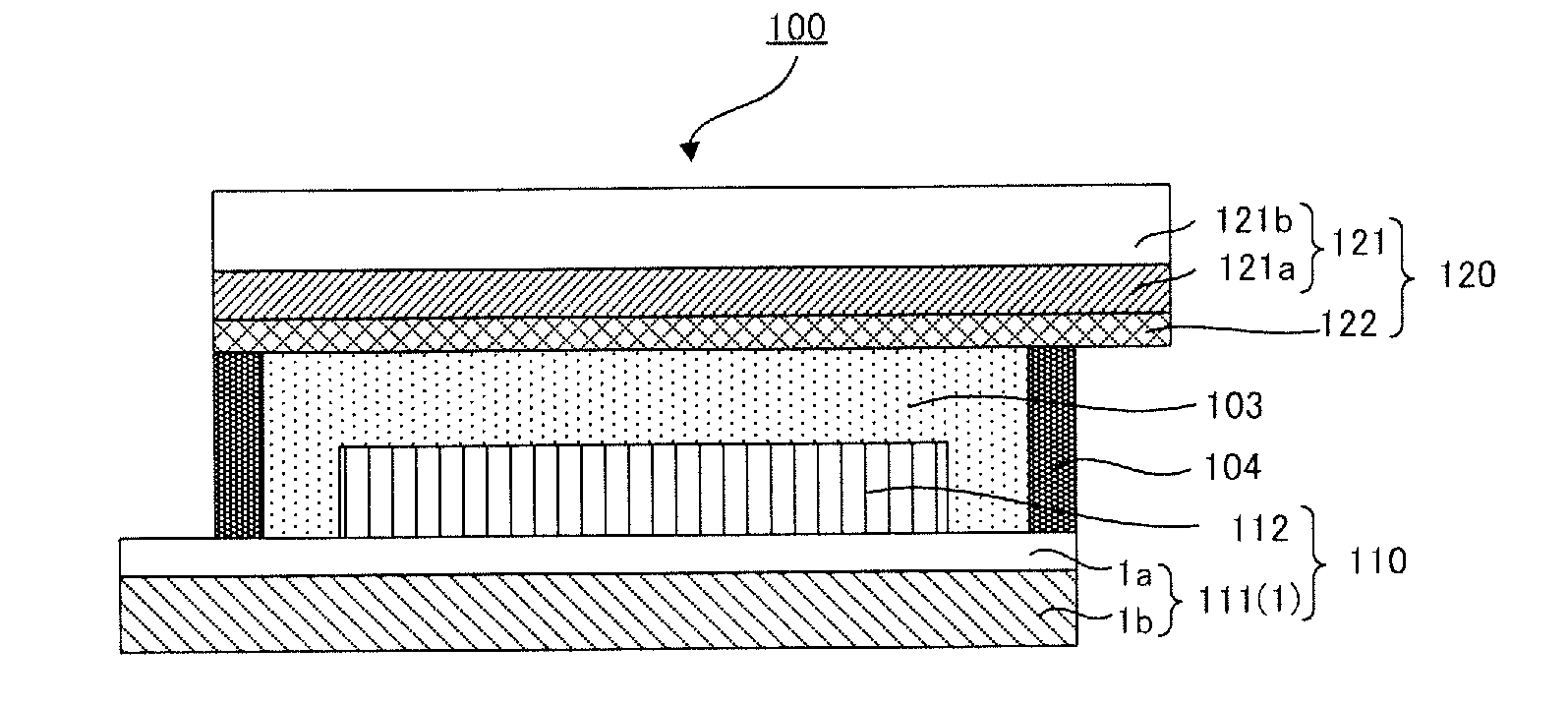

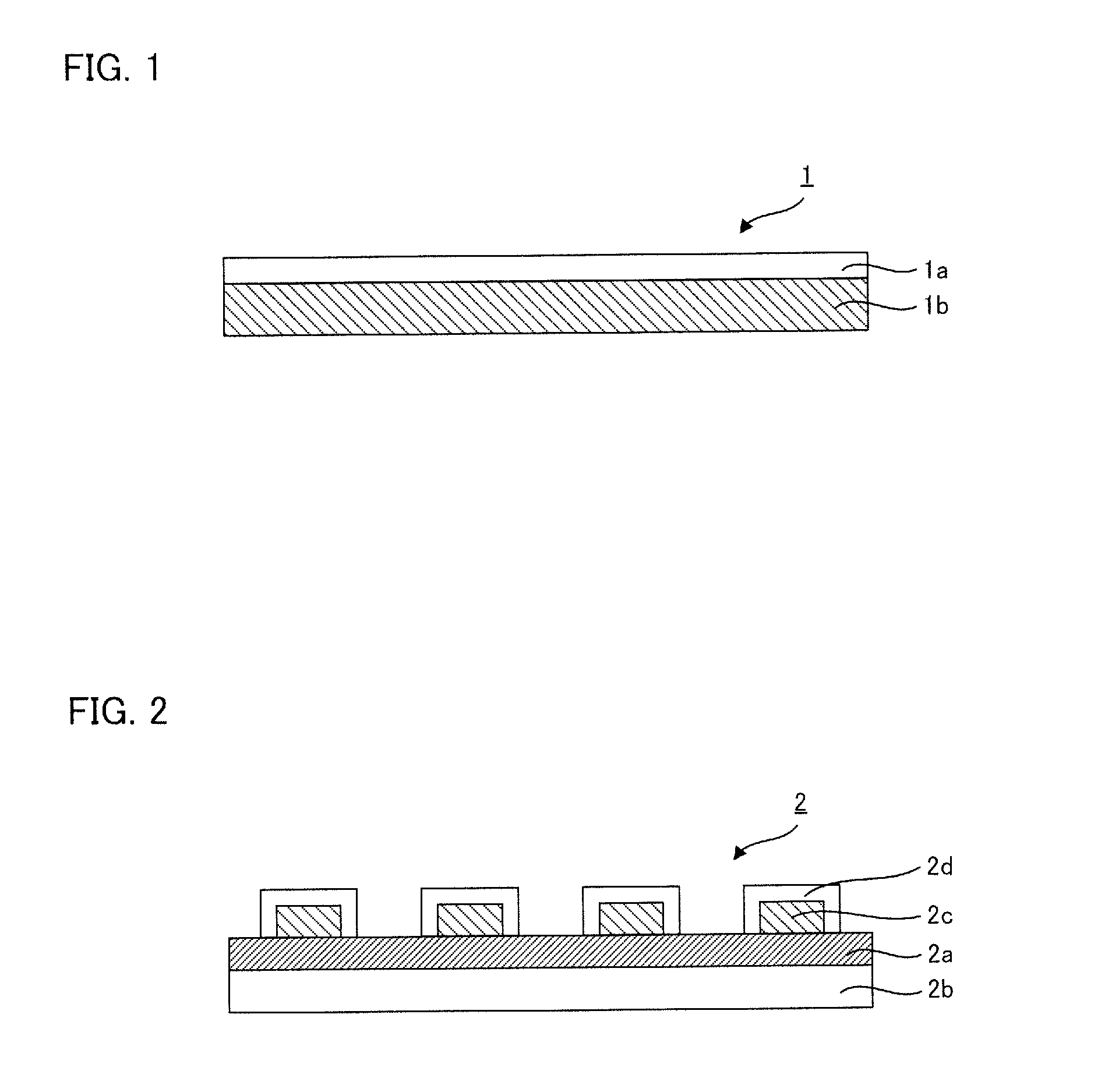

Dye-sensitized solar cell

InactiveUS20110220170A1Increase resistanceLess likely can be degradedElectrolytic capacitorsPV power plantsPhysicsDye-sensitized solar cell

An object of the present invention is to provide a conductive base material for dye-sensitized solar cell and a transparent conductive base material for dye-sensitized solar cell which, when used as electrode base materials of a dye-sensitized solar cell, have high resistance to corrosion by iodide ions contained in an electrolyte layer and can prevent a reduction in the fill factor and conversion efficiency of the dye-sensitized solar cell to achieve high power generation efficiency, a dye-sensitized solar cell and a dye-sensitized solar cell module using such conductive base materials. To attain the object, provided is the conductive base material for dye-sensitized solar cell comprising: a first metal layer made of a metal having a specific resistance of 6×10−6 Ω·m or less; and a second metal layer formed on the first metal layer, made of any one of metals of Ti, Cr, Ni, Mo, Ta, W, Nb, and Pt, and having a thickness of 500 nm or less.

Owner:DAI NIPPON PRINTING CO LTD

Light bar glue dispenser capable of preventing glue head from being blocked during LED (Light Emitting Diode) production

ActiveCN111992432AAvoid uneven dispensingAvoid cloggingLiquid surface applicatorsSpraying apparatusPhysicsEngineering

The invention belongs to the technical field of LED (Light Emitting Diode) lamps, and particularly relates to a light bar glue dispenser capable of preventing a glue head from being blocked during LED(Light Emitting Diode) production. A rotation gear is rotatably connected in a processing seat; a thread stud is rotatably connected in the processing seat; the outer surface of the rotation gear isrotatably connected with a rotation rod; one end of the rotation rod is fixedly connected with an elastic rod; one end of the elastic rod penetrates through the inside of a pressure reduction seat; onone end of the elastic rod, an air pressure bag is arranged in the pressure reduction seat; one end of the pressure reduction seat penetrates through the inside of a conveying pipeline; a telescopicrod is movably connected in the conveying pipeline; the outer surface of the telescopic rod is sheathed with a telescopic spring; and the left side and the right side of the telescopic rod are independently rotatably connected with a regulation rod. During utilization, residual glue in a glue injection head can be sucked out, a blockage phenomenon caused since the residual glue is in the presencein the glue injection head for a long time can be avoided, and the device is guaranteed to be normally used.

Owner:海宁海之利照明有限公司

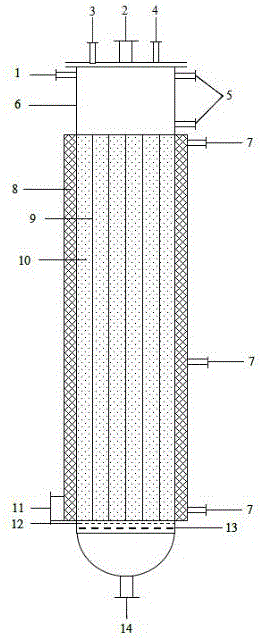

Silica gel regeneration adsorption tower and method thereof

ActiveCN106669356AHeating up fastAchieve desorptionDispersed particle separationHeat conductingEconomic benefits

The invention relates to the field of chemical equipment, mainly relates to silica gel regeneration adsorption equipment and particularly provides a silica gel regeneration adsorption tower and a method thereof. The silica gel regeneration adsorption tower comprises a tower body, heat conducting plates, a sintering plate, a feeding distributor and a far infrared heater, wherein the tower body is filled with silica gel, and is coated with the far infrared heater; the upper part of the tower body extends out of the far infrared heater upwards; the feeding distributor is arranged at the upper part of the tower body which extends out of the far infrared heater and is close to the top end of the tower body; the uniformly distributed heat conducting plates are arranged in the tower body vertical to the bottom surface and are laminated with silica gel; a vacuum pump is also arranged at the lower part of the tower body; and a discharge hole is arranged in the lower part of the vacuum pump. According to the silica gel regeneration adsorption tower, regeneration of the silica gel in the tower is achieved, repeated taking and filling are avoided, the production cost is reduced, the silica gel is repeatedly used, silica gel adsorption oil can be recovered and the silica gel regeneration adsorption tower has considerable economic benefits, and is simple in operation, economic and environment-friendly.

Owner:深圳市三环再生科技有限公司

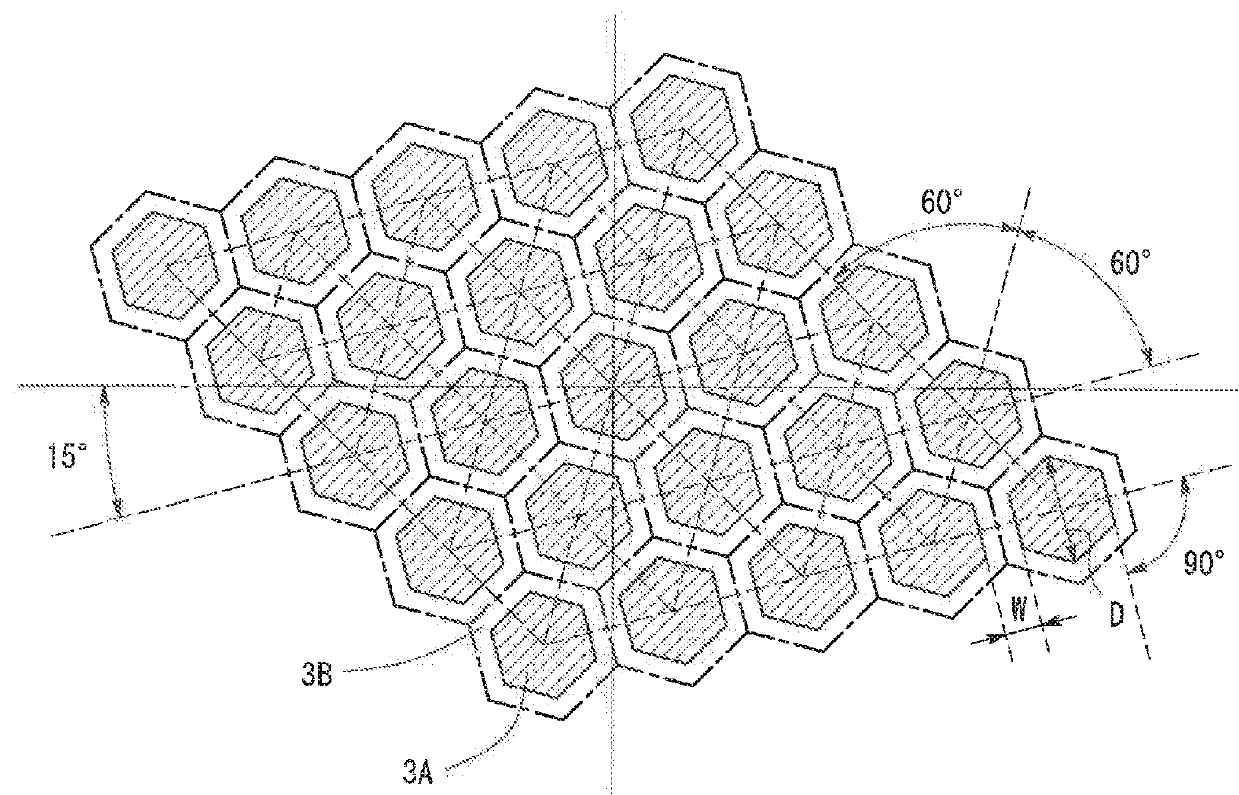

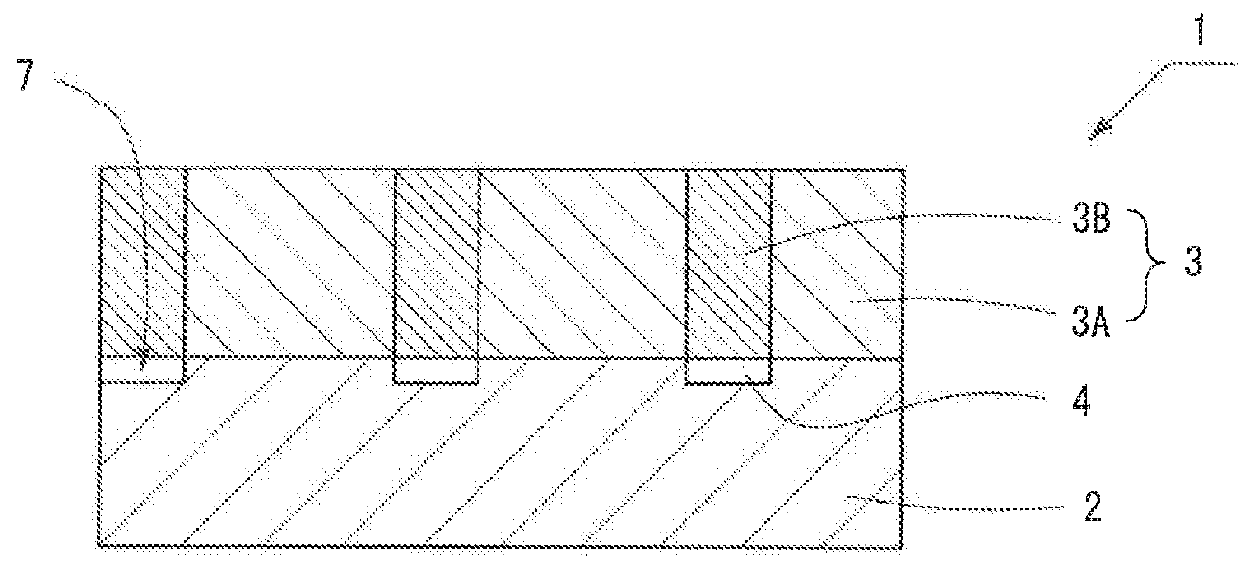

Method for Producing Group III Nitride Semiconductor, Seed Substrate and Group III Nitride Semiconductor Crystal

ActiveUS20180097142A1Peeling propertyAvoid paddingPolycrystalline material growthLiquid-phase epitaxial-layer growthHoneycomb PatternVolumetric Mass Density

The seed substrate comprises a base substrate and a base layer comprising a Group III nitride semiconductor formed on the base substrate, which has a high dislocation density region and a low dislocation density region. The planar pattern of the high dislocation density region is a honeycomb pattern. A hollow exists between the base substrate and the low dislocation density region. The object layer is grown through a flux method using the seed substrate. The high dislocation density region is melted back at an initial stage of crystal growth, and thereafter, the object layer is grown on the top surface of the low dislocation density region. A cavity remains between the high dislocation density region and the object layer. The presence of the cavity and the hollow makes easy to peel the object layer from the seed substrate.

Owner:TOYODA GOSEI CO LTD

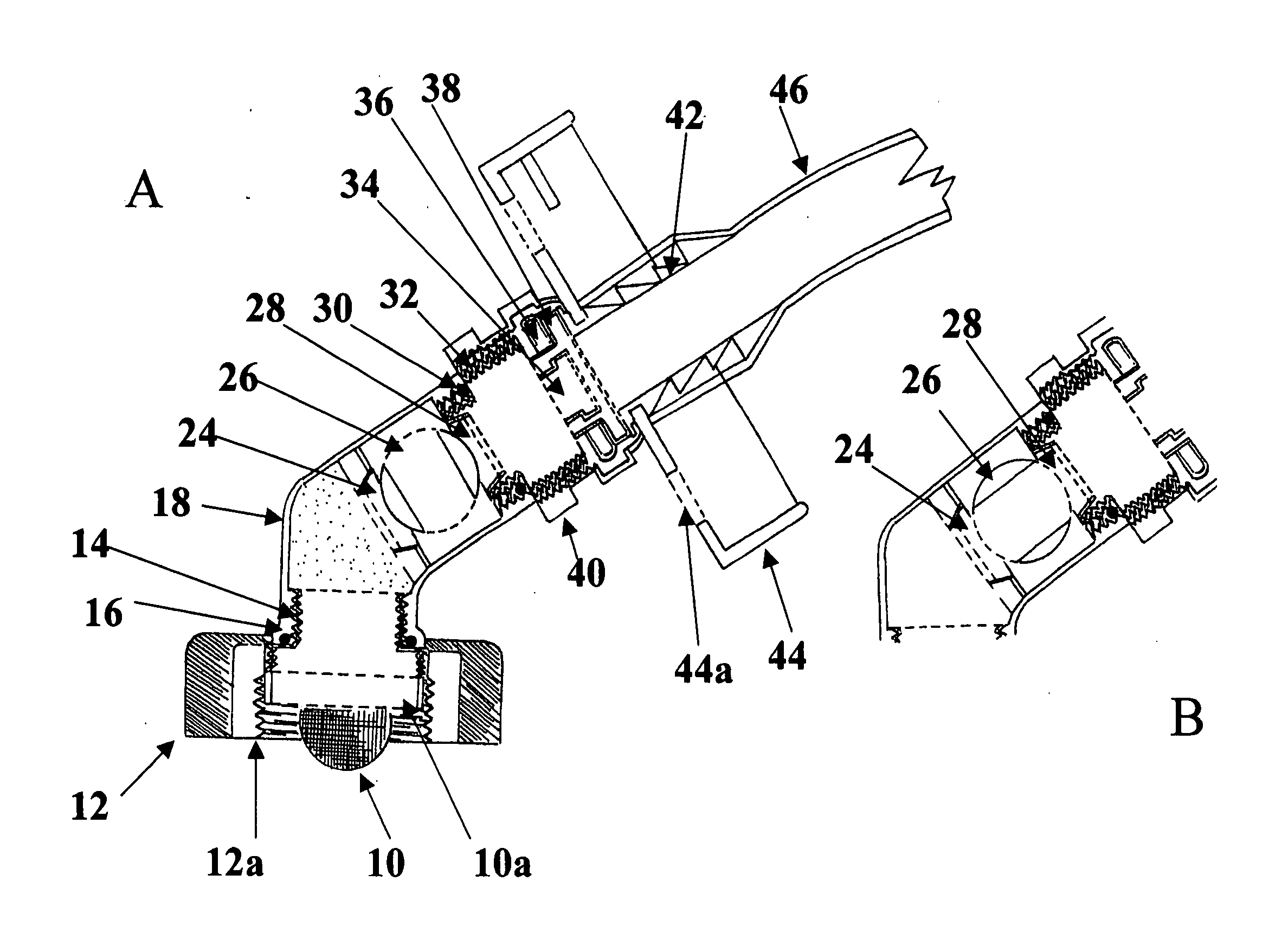

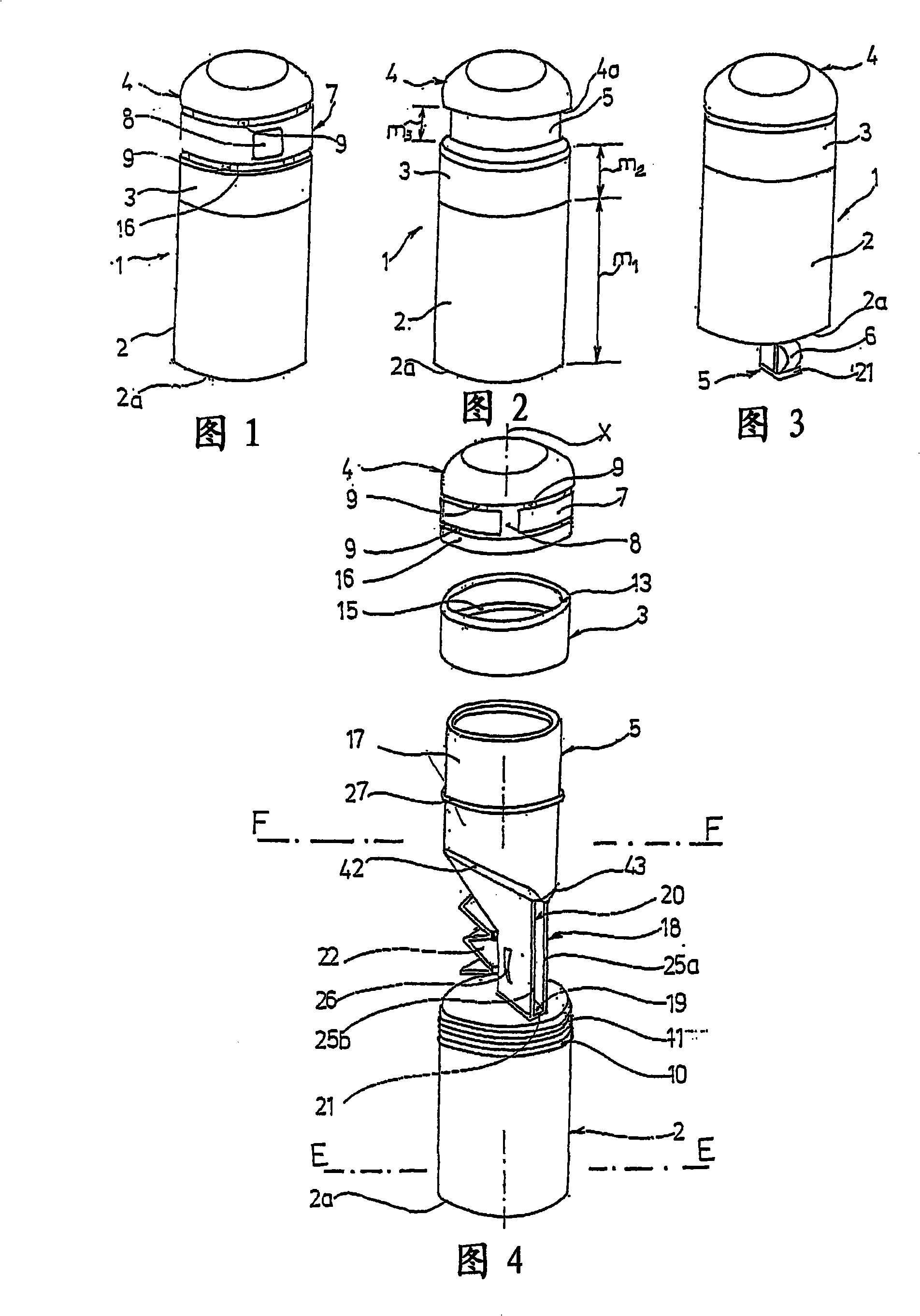

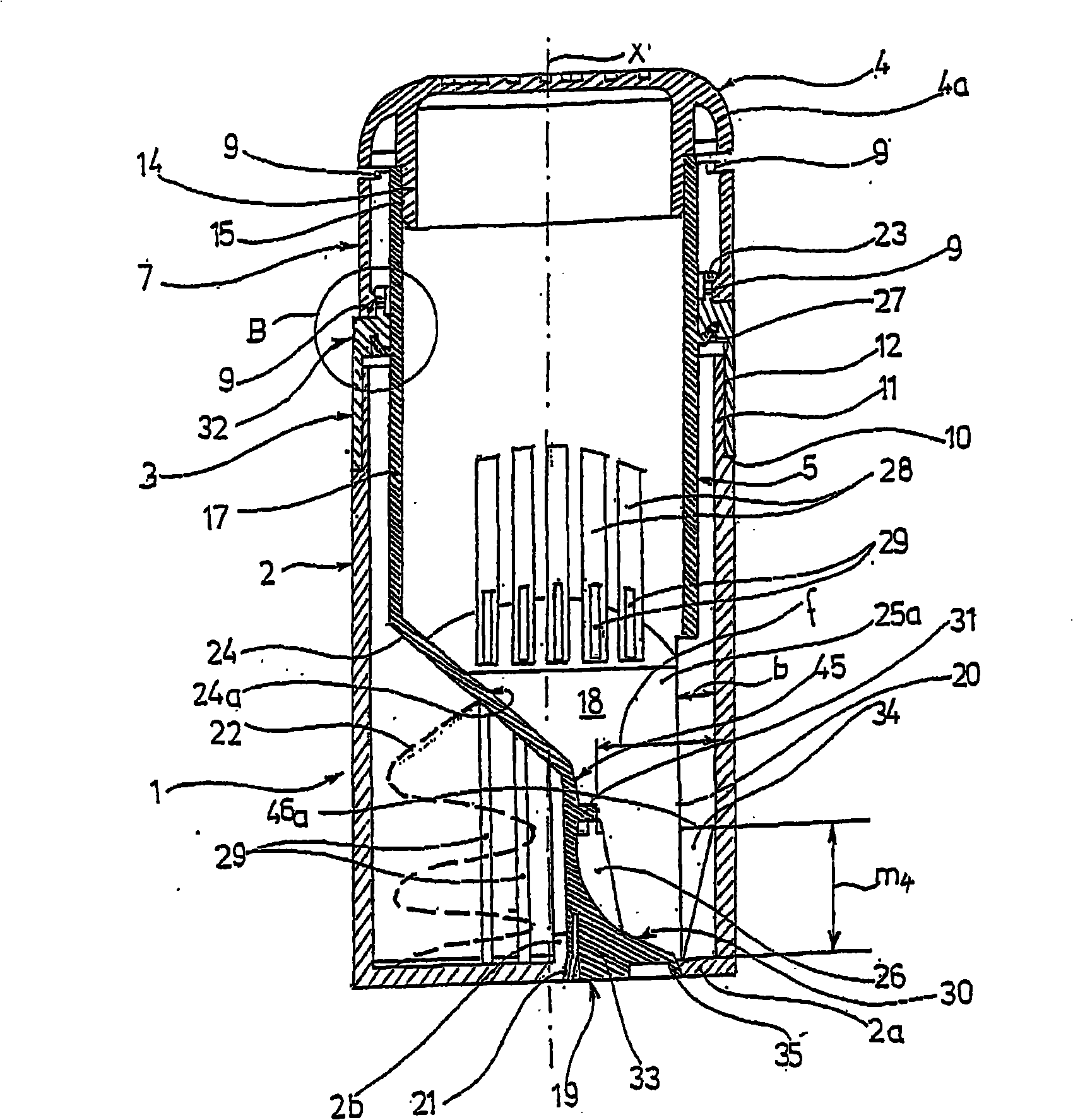

Device for the packaging and dispensing of solid shaped bodies, especially oral tablets or/and capsules

InactiveCN101277875AAvoid fillingAvoid enteringSmall article dispensingTamper-indication equipmentsMechanical engineeringPiston

The invention relates to a device for the packaging and dispensing of solid shaped bodies, especially oral tablets or / and capsules, which device has a container sealed with a cap suitable for storing shaped bodies, a dispensing opening, and tools forwarding the shaped bodies from the inside of the container to the dispensing opening. The container (5) is constructed in a house (1) in a way that it can be moved like a piston against elastic returning force.; The dispensing opening (35) is situated in the bottom (2a) of the house (1) ; when the device is in a position when it is not used for dispensing, the end-part of the container (5) , with an opening (20) for releasing one shaped body at a time situated opposite the end of the container (5) sealed with a cap, fits into the dispensing opening (35) by sealing it, and it is constructed in a way that in the course of the dispensing operations it makes it possible to dispense favourably one shaped body at a time outside of the house (1) .

Owner:CHINOIN GYOGYSZER & VEGYESZETI TERMEKEK GYARA RT

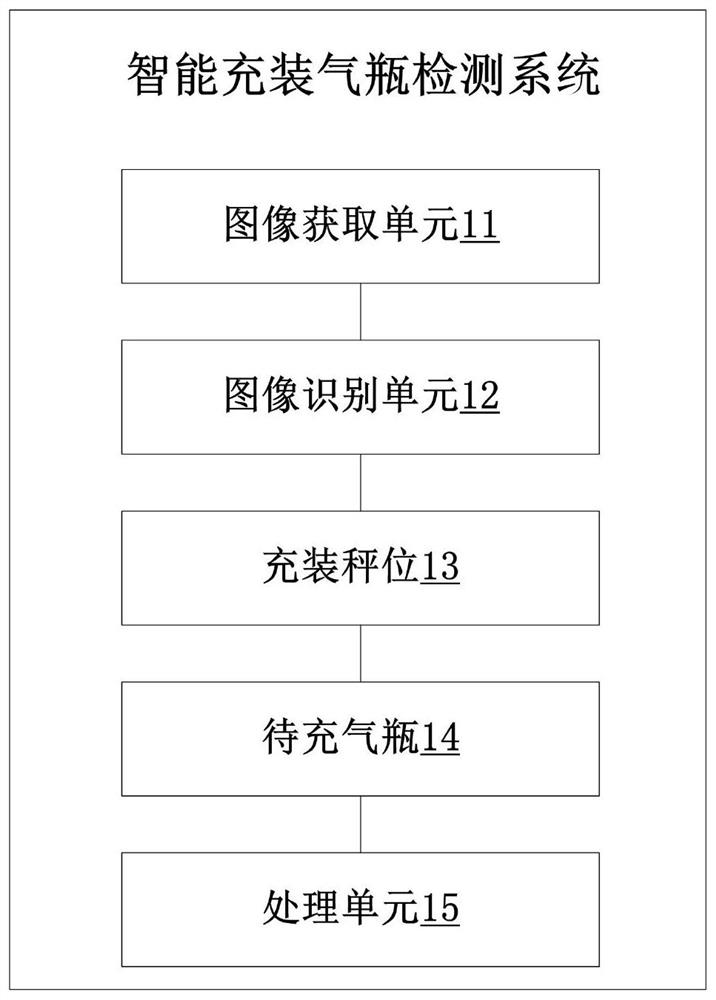

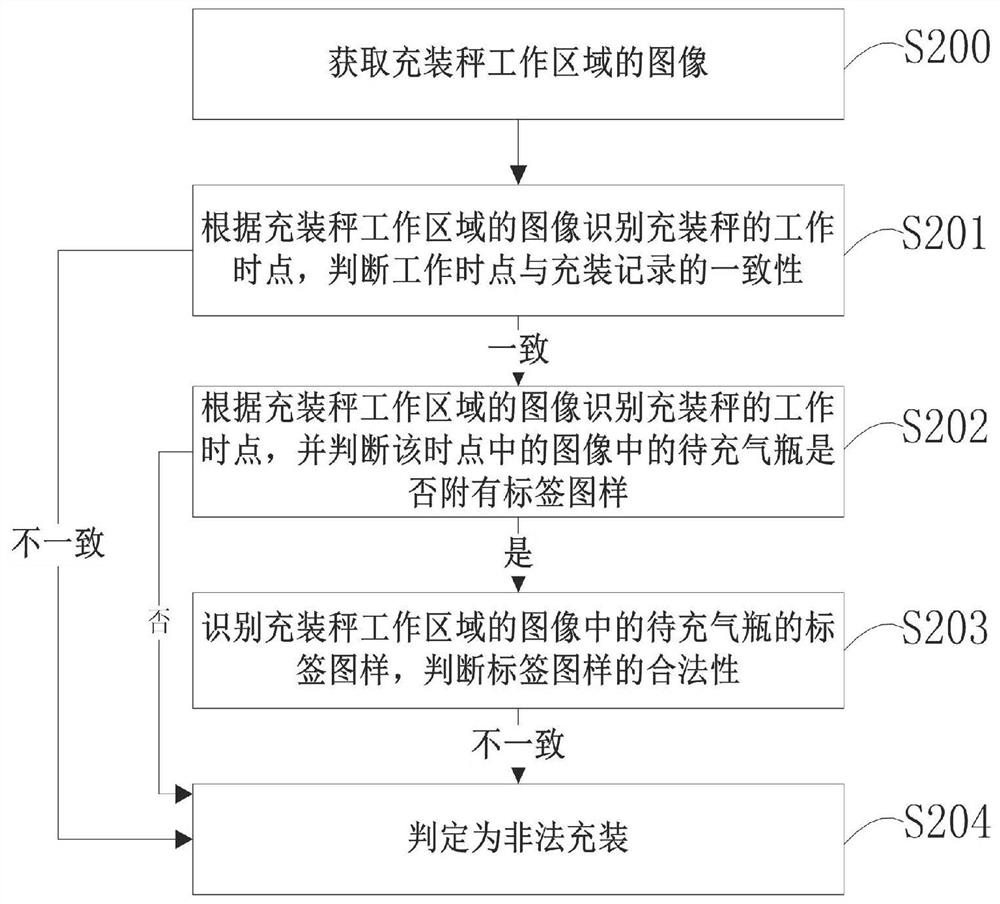

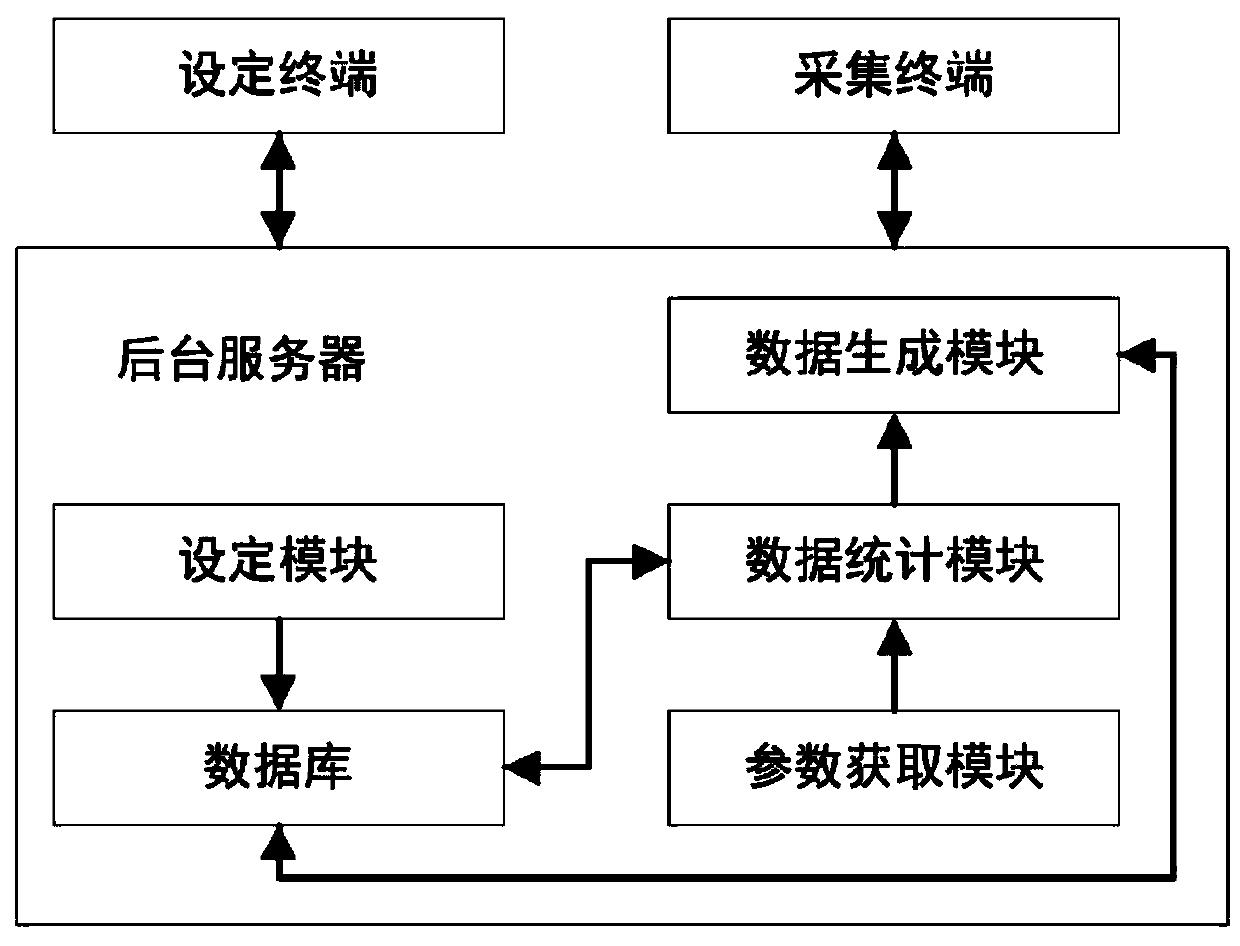

Intelligent filled gas cylinder detection system and method

ActiveCN112270262AAvoid fillingSolve the technical problem of monitoring illegal fillingContainer filling methodsCharacter and pattern recognitionGas cylinderWorkspace

The invention discloses an intelligent filled gas cylinder detection system and method. The system comprises an image acquisition unit, an image recognition unit, a filling weighing position, a to-be-filled gas cylinder and a processing unit. The image acquisition unit is used for acquiring an image of a working area of the filling weighing position, and the image recognition unit is used for recognizing a working time point when the to-be-filled gas cylinder is filled at the filling weighing position according to the image of the working area of the filling weighing position. The processing unit is used for identifying and judging the consistency between the working time point when the to-be-filled gas cylinder is filled at the working area of the filling weighing position and the gas cylinder filling record time point uploaded by the weighing position, and if the working time point when the to-be-filled gas cylinder is filled at the working area of the filling weighing position is identified and judged to be inconsistent with the gas cylinder filling record time point uploaded by the weighing position, it is determined to be illegal filling. According to the technical scheme, theworking time point is obtained by identifying the image of the working area, so that other gas cylinders are prevented from being filled at the filling weighing position by using a non-working time point, and the technical problem of monitoring illegal filling is solved.

Owner:FUZHOU JUNZE INFORMATION TECH

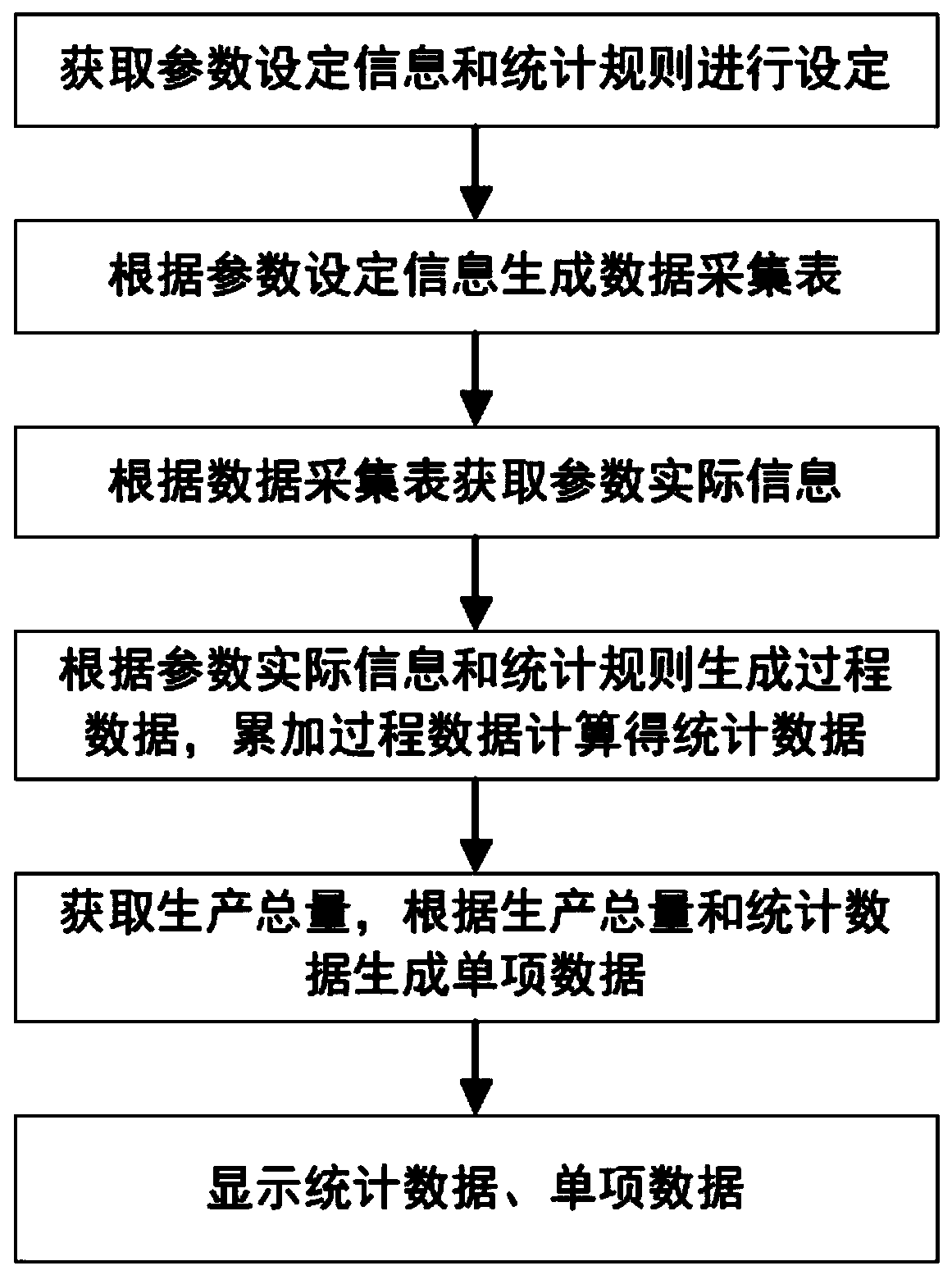

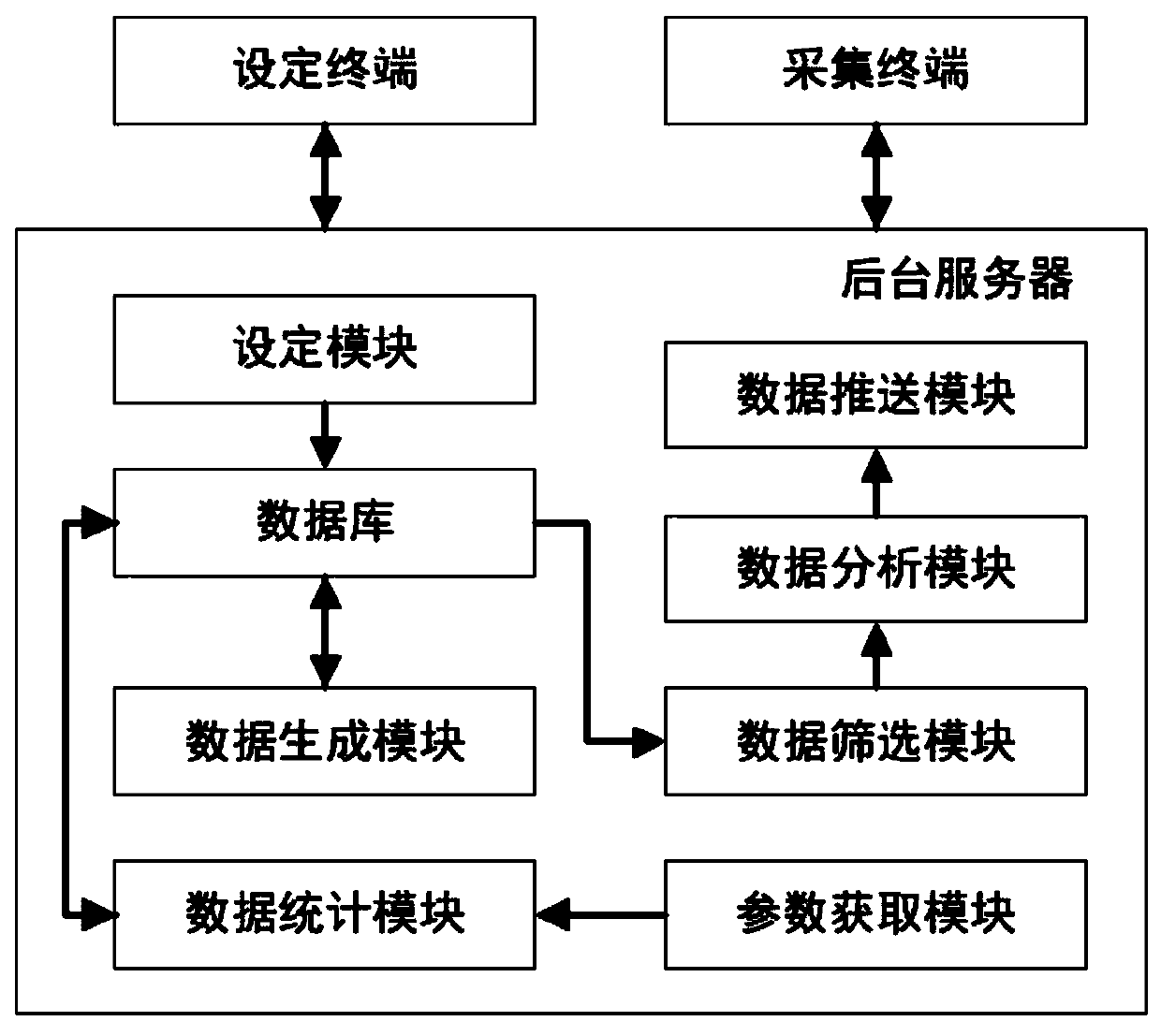

Refined cost analysis system and method

InactiveCN110288246ATimely detection of cost anomaliesEasy to calculate dataResourcesCost analysisData acquisition

The invention relates to the field of real-time cost analysis, in particular to a refined cost analysis system and method, and the system comprises a parameter obtaining module which is used for obtaining the actual information of parameters; a data statistics module which is used for generating statistics data according to the parameter actual information and the statistics rule; and a data generation module which is used for generating single data according to the total production amount and the statistical data. The method comprises the following steps: a rule setting step: acquiring parameter setting information, a statistical period and a statistical rule, and generating a data acquisition table; a parameter obtaining step: obtaining actual parameter information, and obtaining the total production amount; a data statistics step: generating statistical data according to the actual parameter information, the statistical period and the statistical rule; and a data generation step of generating single data according to the statistical data and the total production amount. By adopting the scheme, the cost of the single product on the day can be automatically calculated according to the obtained data, and the accidental cost abnormity problem can be found out in time.

Owner:重庆回形针信息技术有限公司

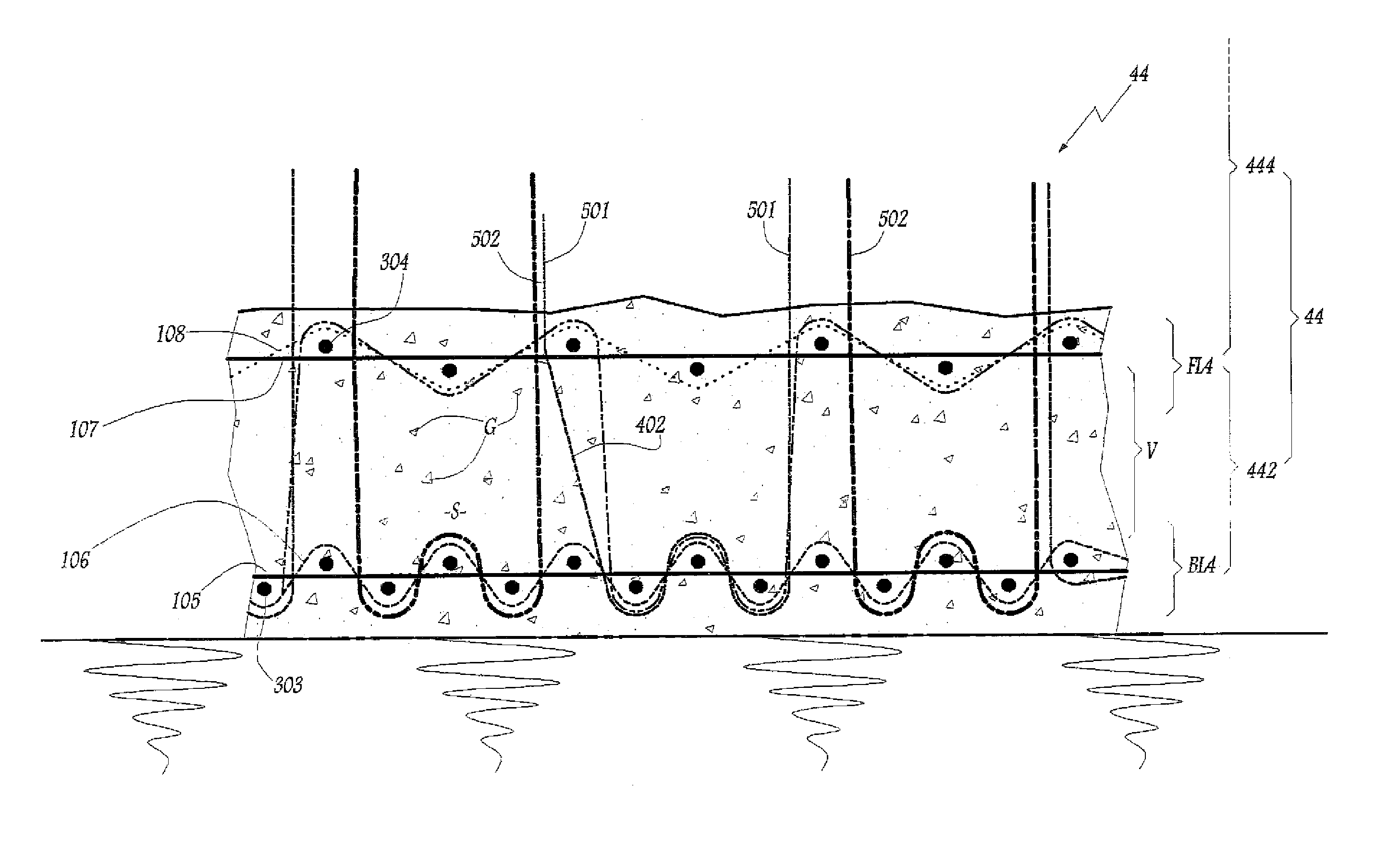

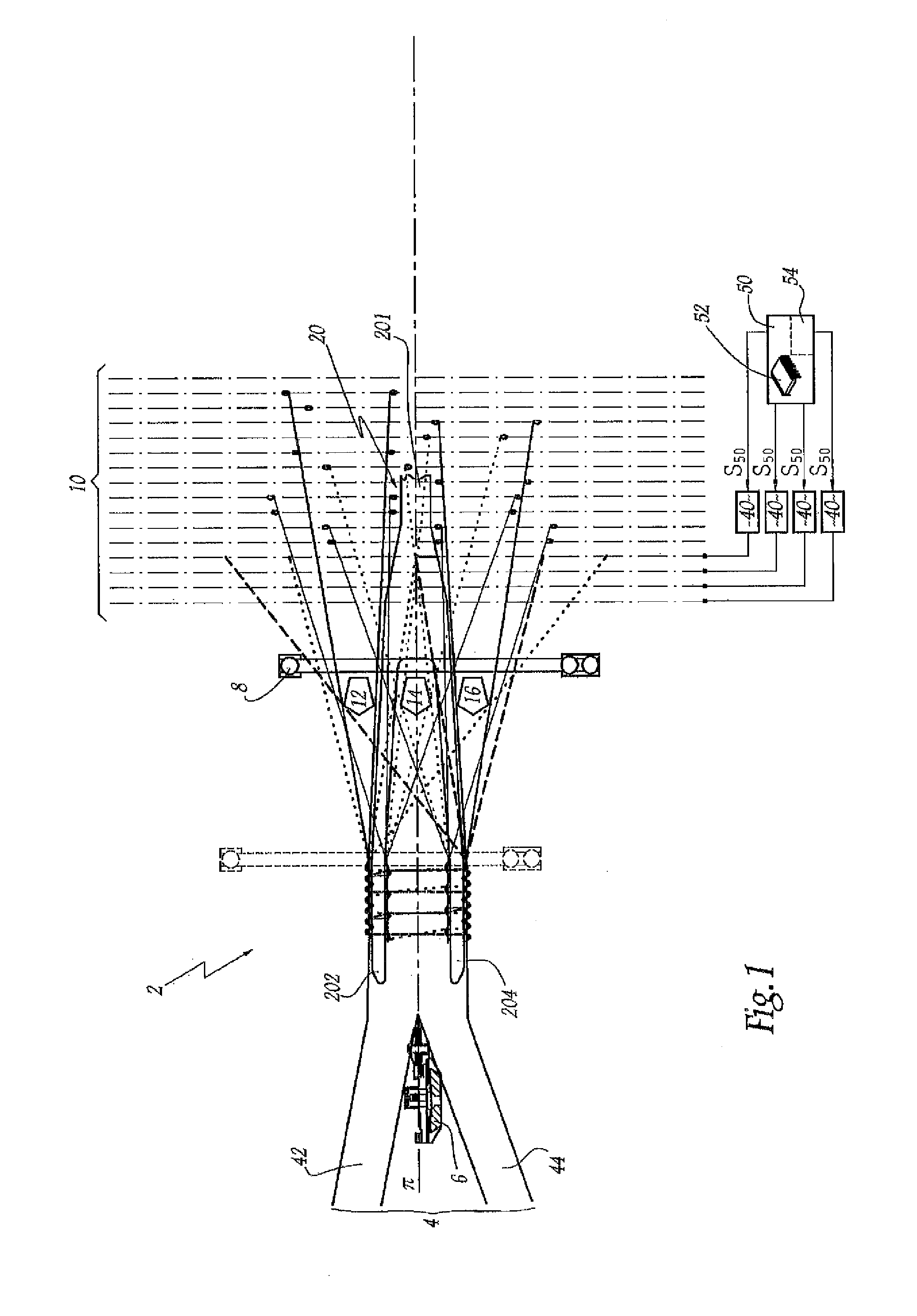

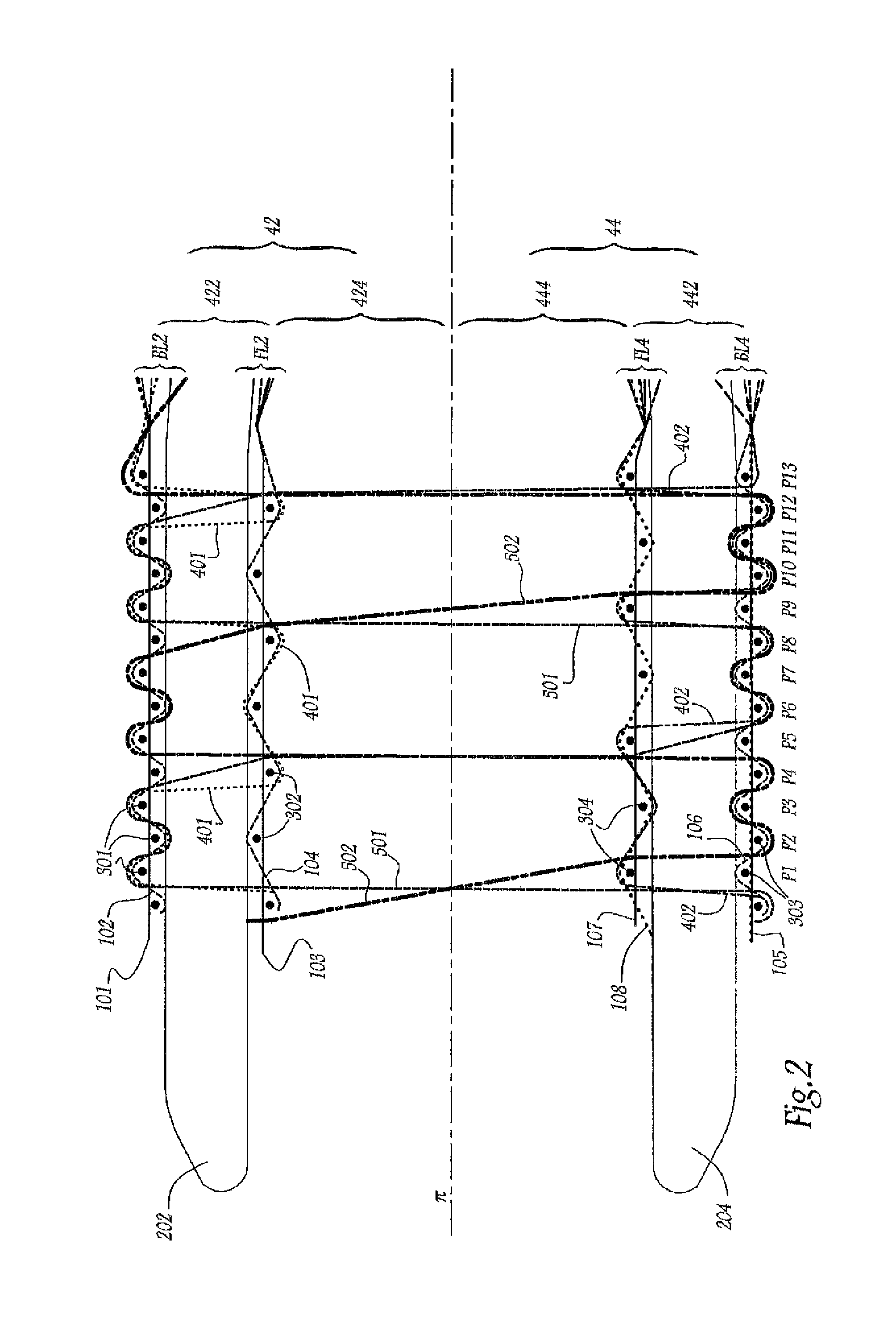

Fabrics simultaneously woven from two distance fabrics

A fabric material consisting of two distance fabrics (42, 44) which are simultaneously weaved on a loom and provided with piles (424, 444) and which have an inner layer (FL2, FL4) and an outer layer (BL2, BL4) for each distance fabric, the inner and outer layers are bound with connecting warp yarns (401-404) extending between the inner and outer layers, pile warp yarns (501, 502) are woven between the distance fabrics. During weaving, the inner and outer layers of each distance fabric are kept apart by respective lancet means (202, 204) and each pick (P1-P13) and for each connecting warp yarn (401-404) and each pile warp yarn (501, 502), one selects on the basis of the information relating to the layer (BL2, FL2, BL4, FL4) in which the warp yarn has been interlaced in a previous pick, on the basis of the shedding pattern and amongst several predetermined positions, a position (A1-A8, B1-B12) was taken by a shedding element (10) driving the warp yarn (401-404, 501, 502) during the pick.

Owner:SCHONHERR TEXTILMASCHBAUU

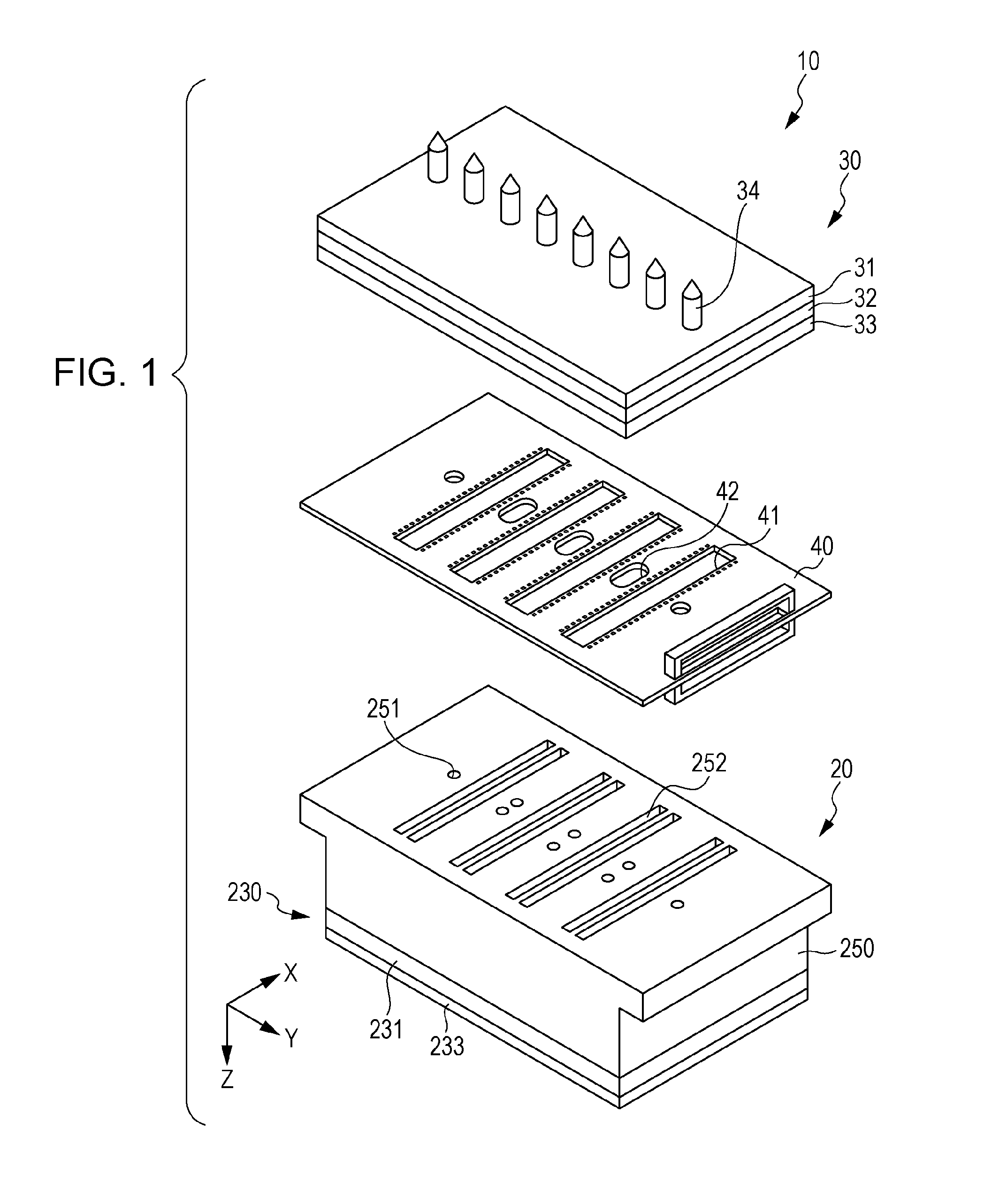

Liquid ejecting head and liquid ejecting apparatus

Owner:SEIKO EPSON CORP

Construction method for avoiding generation of water bubbles on epoxy floor

InactiveCN109838058AAvoid filling processSave raw materials and constructionCovering/liningsFlooringEnvironmental geologyResidual moisture

The invention mainly relates to the technical field of epoxy floors, and discloses a construction method for avoiding generation of water bubbles on an epoxy floor. The construction method for avoiding generation of the water bubbles on the epoxy floor comprises the steps that a base surface is cleaned, a primary primer is coated, putty is applied, a secondary primer is coated, and an epoxy surface is coated. According to the construction method for avoiding generation of the water bubbles on the epoxy floor, the method is simple, the surface of the prepared epoxy floor is smooth and flat, theglossiness is good, the generation of the water bubbles and shrinkage cavities can be avoided, the strength and wear resistance of the epoxy floor are enhanced, and the using performance of the epoxyfloor is enhanced; firstly, debris protruding from the surface of the base surface is removed and cleaned, the flatness of the base surface is increased, the bonding fastness between the epoxy floorand the base surface is increased, and the generation of water bubbles and shrinkage cavities is avoided; then the cleaned base surface is painted with acrylic waterproof coating to prevent the generation of the water bubbles due to oozing out of the residual moisture on the base surface.

Owner:严勇

Full-automatic pickled vegetable filling machine

ActiveCN105416631AAvoid empty pickle jar outputAvoid fillingPackaging automatic controlLiquid materialPickled vegetablesEngineering

The invention relates to the technical field of production and packaging of pickled vegetables, in particular to a full-automatic pickled vegetable filling machine. The full-automatic pickled vegetable filling machine comprises a conveying mechanism, a filling mechanism and a control system which are arranged on a rack, and the conveying mechanism comprises a bottle conveying mechanism, a filling conveying mechanism and a bottle outgoing mechanism which are sequentially connected; the filling mechanism comprises a hopper, a blender and cylinders, the blender and the cylinders are connected with the hopper, the cylinders are used for filling, discharge and compression of the pickled vegetables, and material storage cups are arranged on the lower portion of the hopper; the filling conveying mechanism comprises a main shaft, fixed discs and feeding rotating discs fixed to the fixed discs, and the feeding rotating discs are fixedly connected with the material storage cups; the control system is used for controlling work of the filling mechanism. By means of the full-automatic pickled vegetable filling machine, the filling speed of the pickled vegetables can be increased, and the filling quality is not affected.

Owner:镇江市恒威制曲机有限公司

Design method for non-reversible hidden engineering embedding

InactiveCN101100874ANovel ideaImprove the quality of workBuilding constructionsShop drawingComputer science

This is a design method for built-in fittings of non-reversible concealed work. Because of the non-reversible character of built-in fittings, a specific design on the fittings among every area are collectively marked and compiled on the layout. The design contents include general description of construction, cutline, ichnography, serial number table and detail drawings.

Owner:姚军

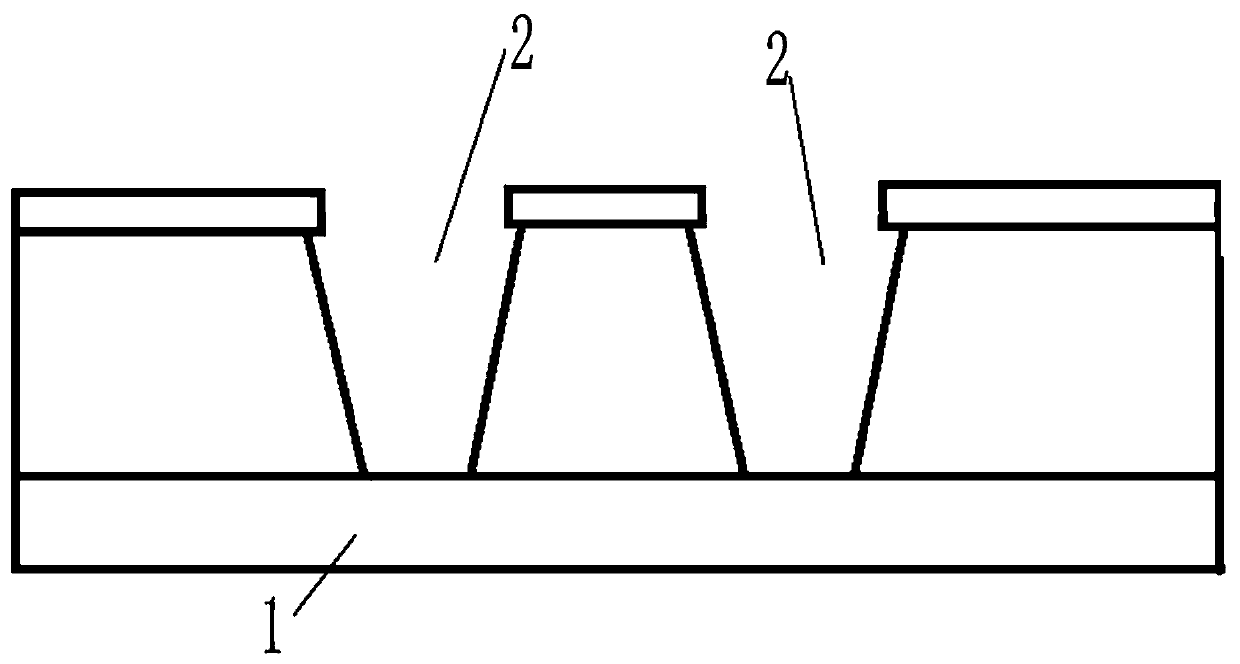

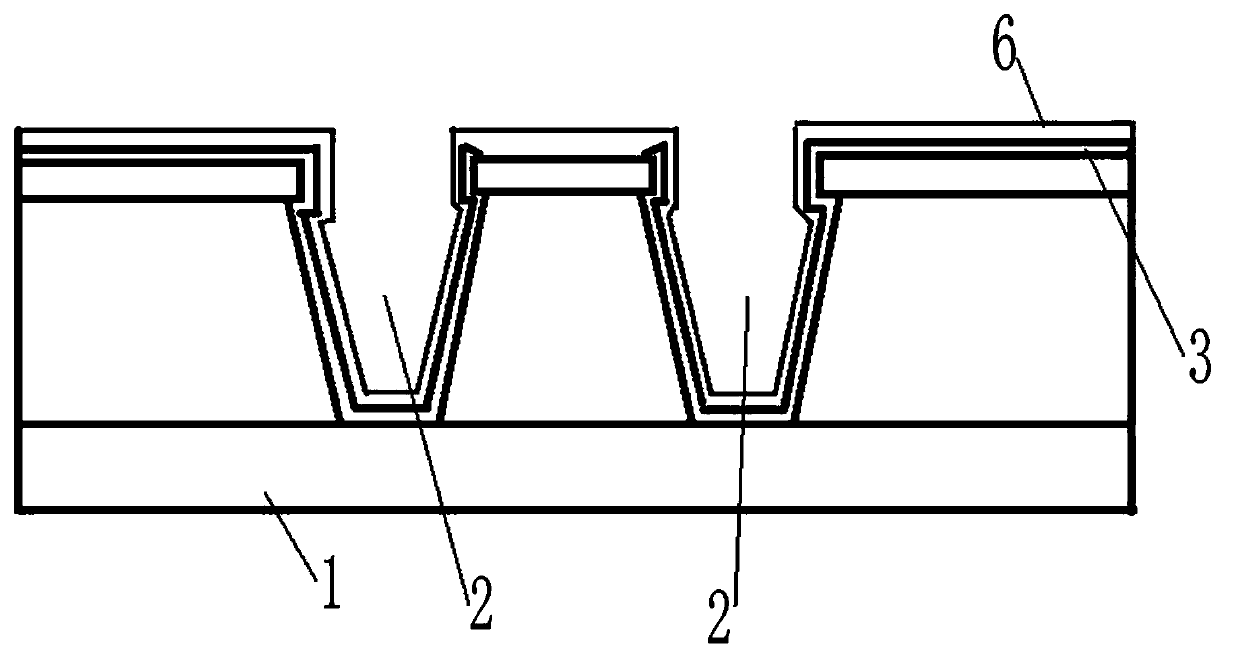

P-surface metal preparation method of ridge-type GaAs-based laser with deep groove

ActiveCN111490454AImprove stabilityLow production rateOptical wave guidanceLaser detailsPhysical chemistryManufactured material

The invention discloses a P-surface metal preparation method of a ridge-type GaAs-based laser with a deep groove. The method is characterized by coating negative photoresist on a silicon dioxide passive film, roughening an Au layer at the uppermost end in a metal layer on the negative photoresist, and preparing an Au conducting layer after roughening treatment, so that the covering stability of the Au conducting layer can be improved; the preparation rate of the metal layer is relatively low, the growth rates of the Au conducting layer from the first Au layer to the fourth Au layer are sequentially increased, vapor deposition of a P-surface metal layer composed of the metal layer and the Au conducting layer of the ridge waveguide structure laser with the groove depth larger than 2 micronscan be completed through different growth rates, so that P-surface polymer filling and leveling-up are avoided, and metal faults are prevented; operation is convenient, the process steps are simplified, and the production period is shortened; and meanwhile, consumption of raw materials is reduced, and repeatability and stability of the whole process are improved.

Owner:潍坊华光光电子有限公司

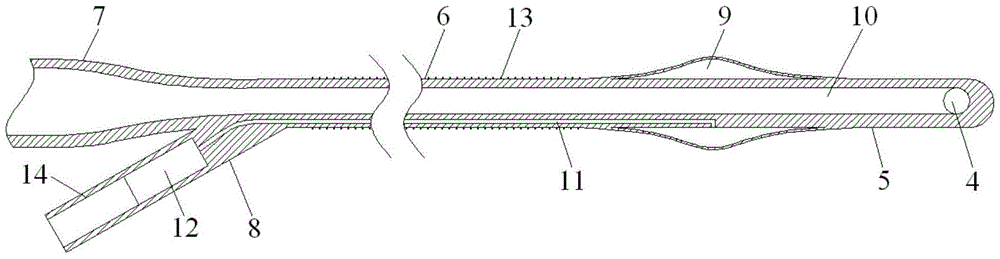

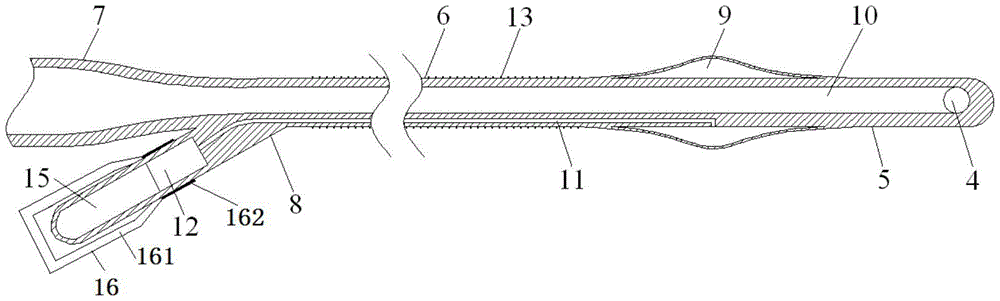

A nasopharyngeal irrigator

The invention provides a nasopharynx flusher which comprises a liquid storage bottle, a pressurizing device and a flushing hose with a flushing hole in the end. The flushing hose is a three-way tube and comprises a head part for liquid output, a middle part for liquid guiding and two tail parts for liquid feeding. An arc face is arranged at the top end of the head part, the flushing hole is formed in the top end of the head part of the flushing hose, and an airbag is arranged at the joint of the head part and the middle part. The middle part comprises a cleaning liquid channel and a pressurized fluid channel separated from the cleaning liquid channel. Hand touch scales protruding outwards are arranged on the outer surface of the middle part. The tail parts comprise the first tail part communicated with the flushing hole through the cleaning liquid channel and the second tail part communicated with the airbag through the pressurized fluid channel. The liquid storage bottle communicates with the first tail part through the pressurizing device, the pressurizing device is a liquid pump, and a check valve is arranged in the second tail part. The nasopharynx flusher is easy and convenient to use, can flush the nasal cavity and the nasopharynx, and can carry out hemostasis by compression to deal with the situation that the pharyngonasal cavity bleeds.

Owner:吴媛 +1

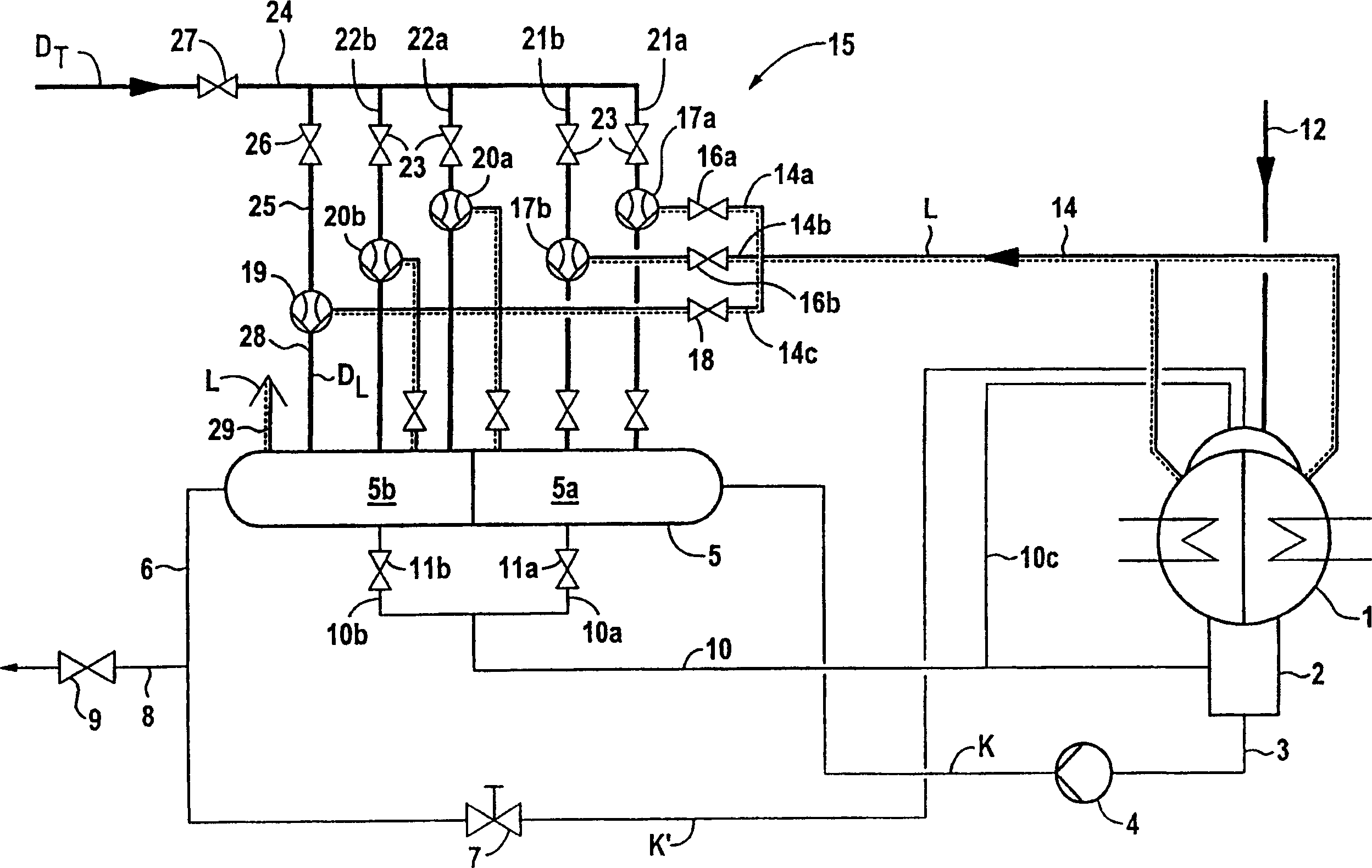

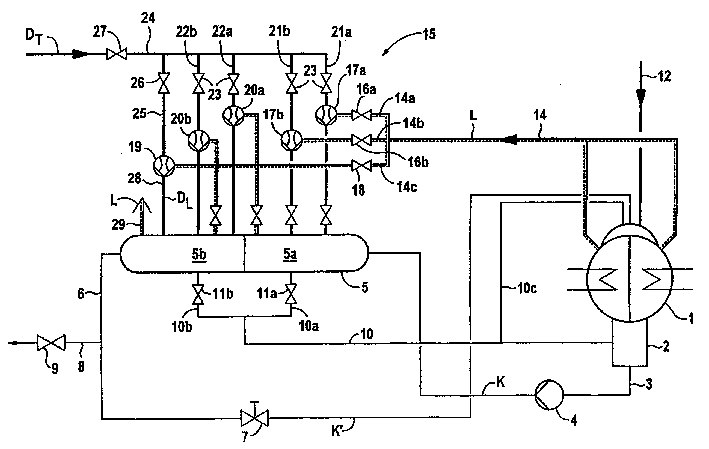

Method and device for evacuating turbine condenser

In order to evacuate a turbine condenser, air (L) contained in the turbine condenser (1) is suctioned using propellant steam from a starting jet pump (19). According to the invention, the propellant steam (D) and the air (L) are guided into an auxiliary condenser (5) which is arranged downstream from said turbine condenser (1).

Owner:SIEMENS AG

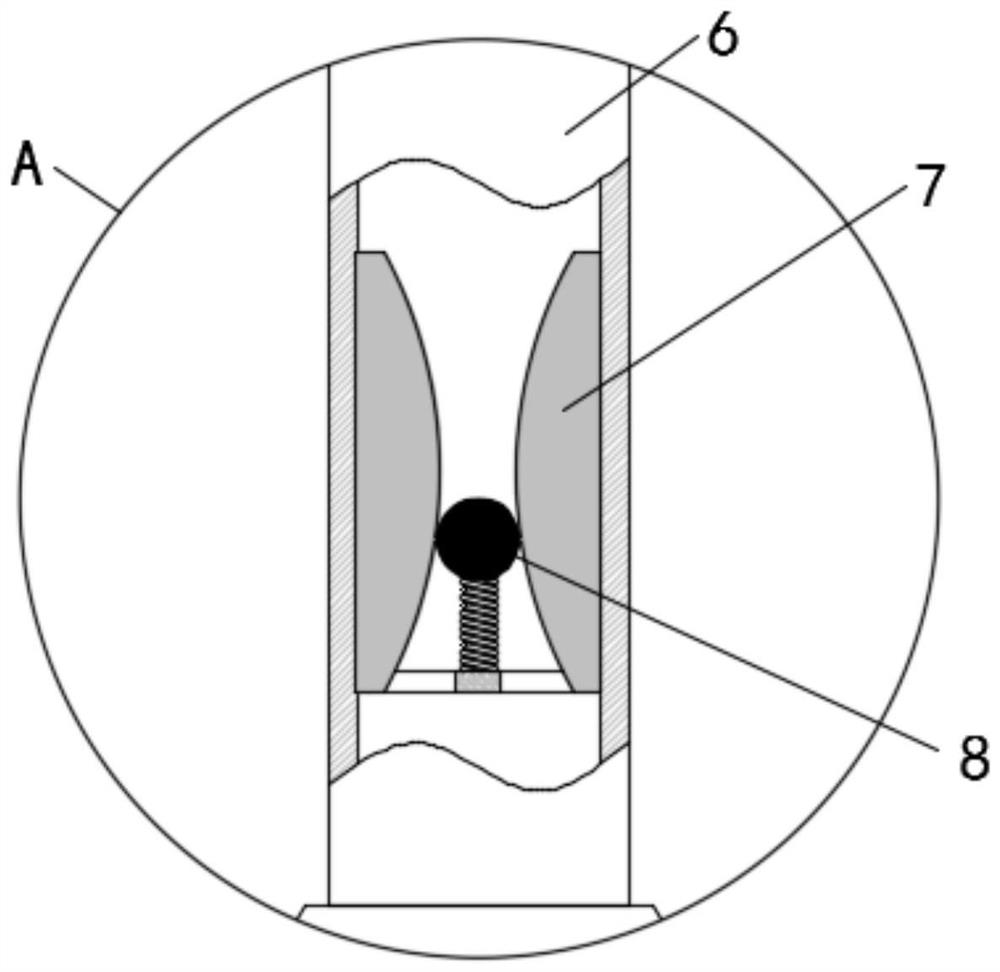

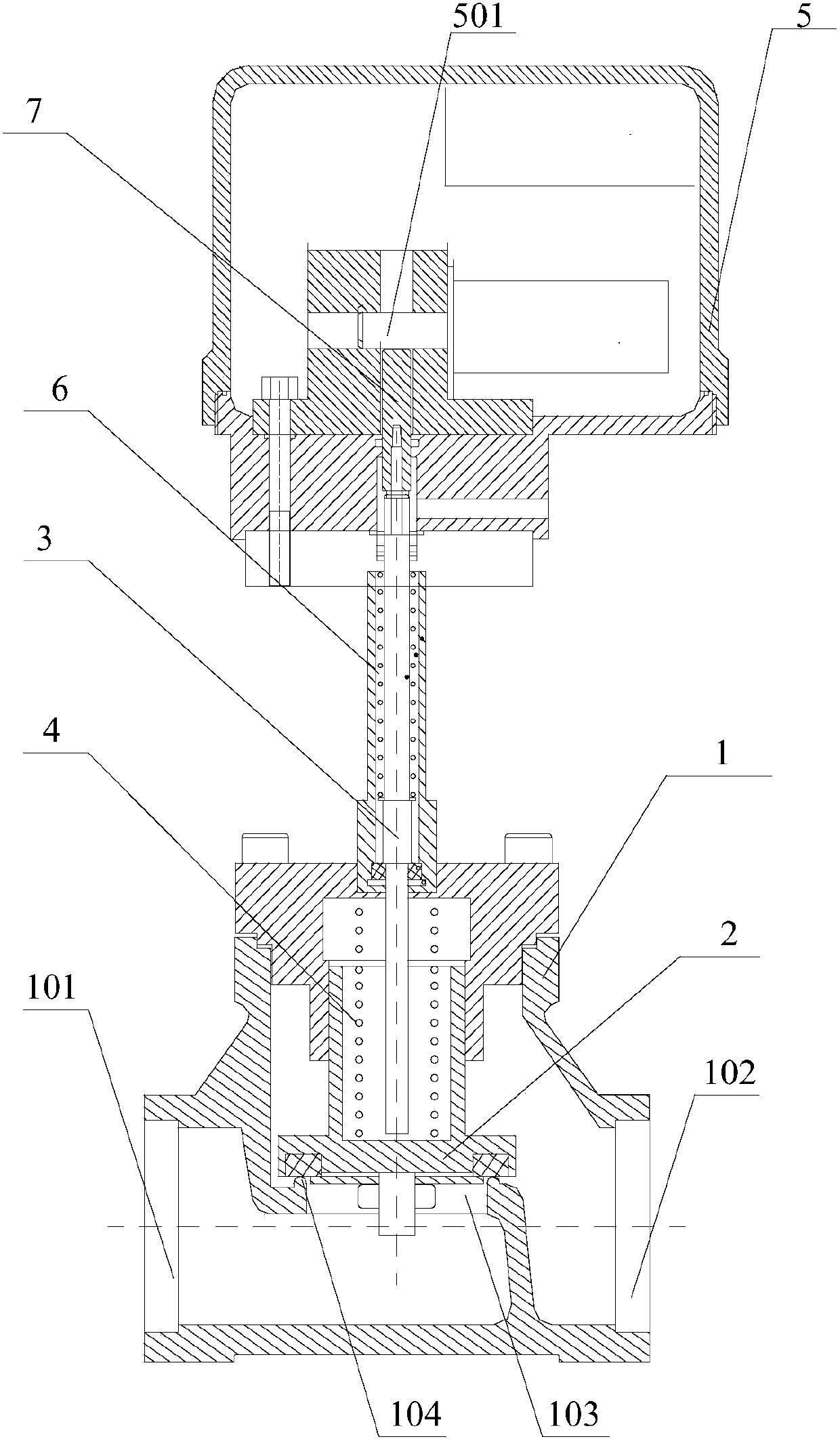

Intelligent one-way valve

PendingCN110043700APrevent theftOvercoming stressCheck valvesPreventing unauthorised/accidental actuationSolenoid valveEngineering

The invention discloses an intelligent one-way valve. The intelligent one-way valve comprises a valve body. The valve body is provided with a liquid inlet and a liquid outlet. A valve element, a pushrod and an electromagnetic valve are further included. A seal port is formed in the valve body, the opening direction of the seal port is arranged towards the liquid outlet, and the valve element cantightly press an opening of the seal port. The first end of the push rod is connected with the valve element, the push rod is sleeved with a first spring, the first spring is in a compressed state, the bottom end of the first spring abuts against the top end of the valve element, and the top end of the first spring abuts against the inner top face of the valve body. A piston of the electromagneticvalve is pressed at the top end of the push rod. When the electromagnetic valve is powered on, the piston is moved away so that the push rod can ascend. When the electromagnetic valve is powered off,the piston moves and is pressed at the top end of the push rod. Even when a gas source is externally connected, under the action that the piston is pressed on the push rod, opening of the valve element cannot be achieved, other people are prevented from filling natural gas into natural gas utilization equipment comprising the disclosed intelligent one-way valve, and accordingly other people are prevented from stealing and using the natural gas utilization equipment.

Owner:杭州云气控股有限公司

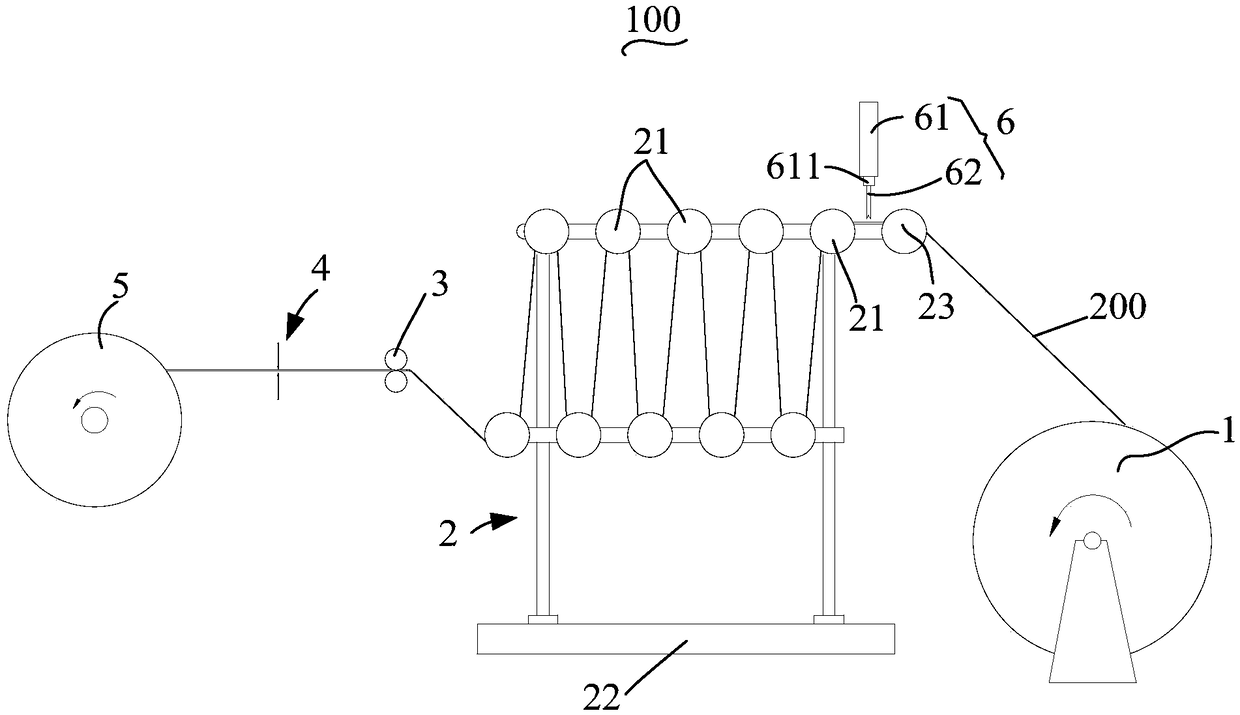

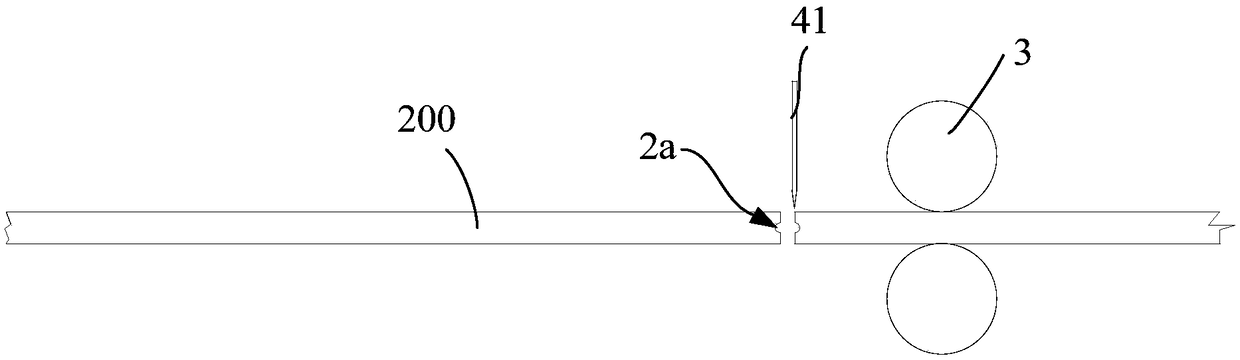

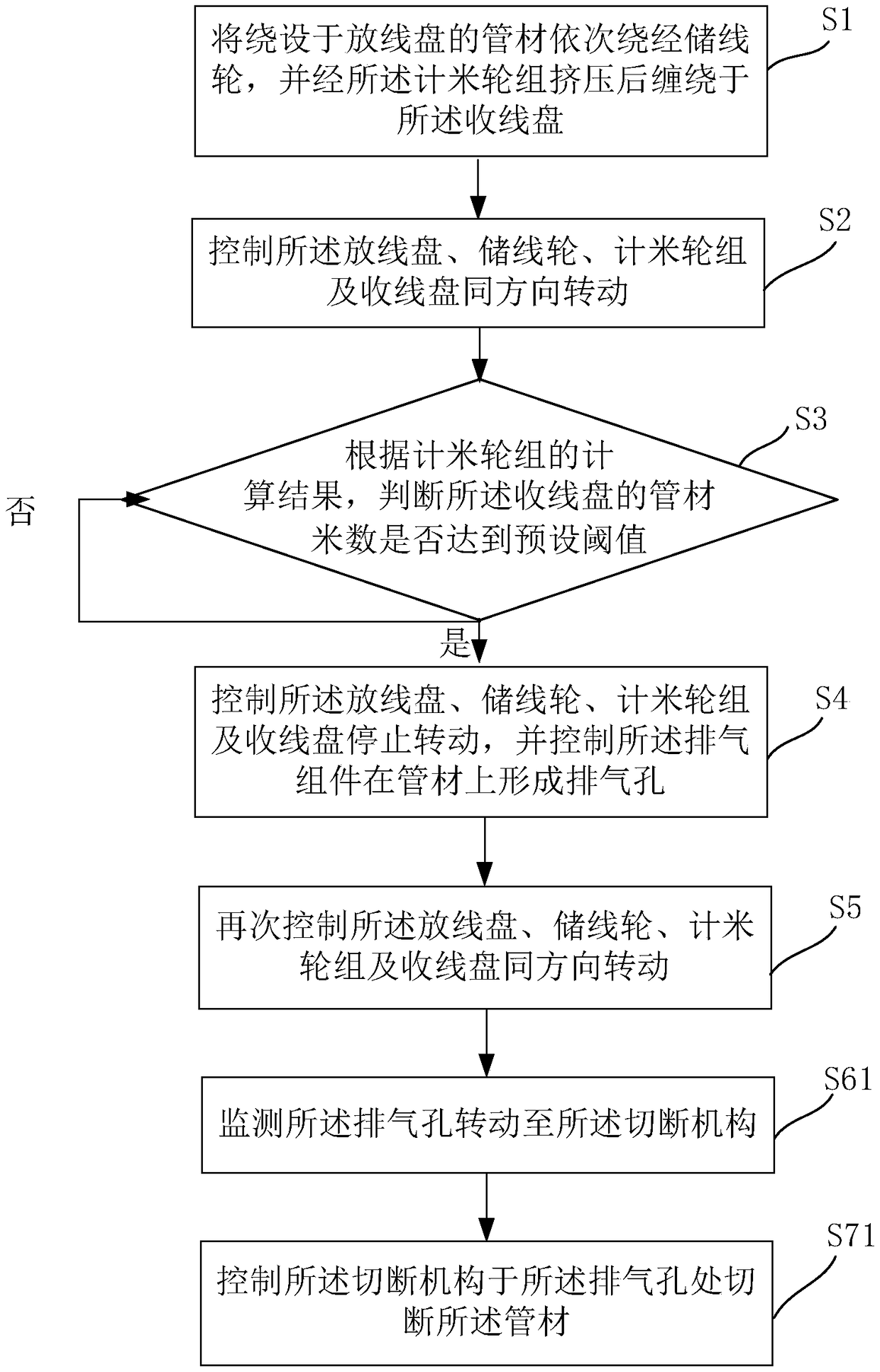

Pipe take-up device and method

The invention discloses a pipe take-up device and method. The pipe take-up device comprises a pay-off spool, a wire storage wheel set, a meter counting wheel set and a take-up spool. The pay-off spool, the wire storage wheel set, the meter counting wheel set and the take-up spool are sequentially placed in an assembly line manner and rotate in the same direction. The wire storage wheel set comprises at least one wire storage wheel. A cut-off mechanism is arranged between the meter counting wheel set and the take-up spool. An exhaust assembly is arranged between the pay-off spool and the wire storage wheel set or is arranged in the wire storage wheel set. Pipes are wound on the pay-off spool. The pipes wound out from the pay-off spool are wound around the wire storage wheels and are wound on the take-up spool after being squeezed by the meter counting wheel set. The exhaust assembly and the cut-off mechanism are located above or below the pipes. The exhaust assembly is used for formingexhaust holes in the pipes. The cut-off mechanism is used for cutting off the pipes when the take-up spool reaches a preset meter number. By means of the technical scheme, gas in the pipes can be effectively removed, and the curling and packaging stability of the pipes can be improved.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com