Silica gel regeneration adsorption tower and method thereof

An adsorption tower, silica gel technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of inconvenient operation, uneconomical, waste of oil products, etc., avoid repeated removal and filling, and save production. Cost, the effect of considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

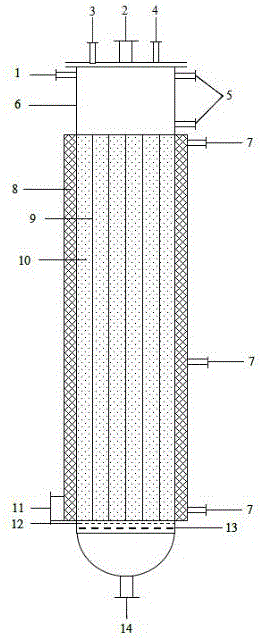

[0021] A silica gel regenerative adsorption tower, comprising a tower body 6, a heat conduction plate 9, a sintered plate 12, a feed distributor 1 and a far-infrared heater 8, the tower body 6 is filled with silica gel 10, and is covered with far-infrared heating device 8, the top of the tower body 6 extends upwards beyond the far-infrared heater 8, and the described feed distributor 1 is located on the upper part of the tower body 6 beyond the far-infrared heater 8, and is close to the top of the tower body 6, in the tower body The inside of 6 is provided with evenly distributed heat conduction plates 9 perpendicular to the bottom surface and connected with silica gel 10. A vacuum pump is also installed below the tower body 6, and a discharge port 14 is provided below the vacuum pump. Silica gel is a poor conductor of heat. Using a heat conduction plate can realize the rapid temperature rise of silica gel, which brings feasibility to the desorption of silica gel, that is, vacu...

Embodiment 2

[0036] With reference to embodiment 1, do further detailed description:

[0037] A silica gel regenerative adsorption tower, comprising a tower body 6, a heat conduction plate 9, a sintered plate 12, a feed distributor 1 and a far-infrared heater 8, the tower body 6 is filled with silica gel 10, and is covered with far-infrared heating device 8, the top of the tower body 6 extends upwards beyond the far-infrared heater 8, and the described feed distributor 1 is located on the upper part of the tower body 6 beyond the far-infrared heater 8, and is close to the top of the tower body 6, in the tower body The inside of 6 is provided with evenly distributed heat conduction plates 9 perpendicular to the bottom surface and connected with silica gel 10. A vacuum pump is also installed below the tower body 6, and a discharge port 14 is provided below the vacuum pump. Silica gel is a poor conductor of heat. Using a heat conduction plate can realize the rapid temperature rise of silica g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com