Patents

Literature

585 results about "Infrared heater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An infrared heater or heat lamp is a body with a higher temperature which transfers energy to a body with a lower temperature through electromagnetic radiation. Depending on the temperature of the emitting body, the wavelength of the peak of the infrared radiation ranges from 780 nm to 1 mm. No contact or medium between the two bodies is needed for the energy transfer. Infrared heaters can be operated in vacuum or atmosphere.

Gas fired portable unvented infrared heater

InactiveUS6884065B2Reduce the temperatureIncrease air velocityMechanical apparatusDomestic stoves or rangesFresh airEngineering

A portable heater adapted for use in a recreational enclosure or temporary work enclosure includes a housing having an air inlet on the lower front face. A gas supply is partially enclosed by the housing which provides propane to the mouth of a burner venturi located within the housing. Air is drawn through the air inlet and also enters the mouth of the burner venturi. The air and gas are mixed thoroughly as they travel upwardly through the burner venturi. A chimney effect increases fresh air flow velocity into the burner venturi and allows the heater to operate at a reduced fuel gas pressure. Upon exiting the burner venturi, the air / gas mixture is to a plenum and radiant surface where combustion takes place. Any conventional means may be provided to ignite the air / gas mixture in order to cause combustion. The combustion products deflect off a deflector, which is cooled on a rear face by air flow through the housing, which decreases the temperature of the combustion products before exiting an outlet. An oxygen depletion system (ODS) shuts off the portable heater when oxygen levels begin to drop and consequently carbon monoxide levels begin to rise.

Owner:ENERCO GROUP

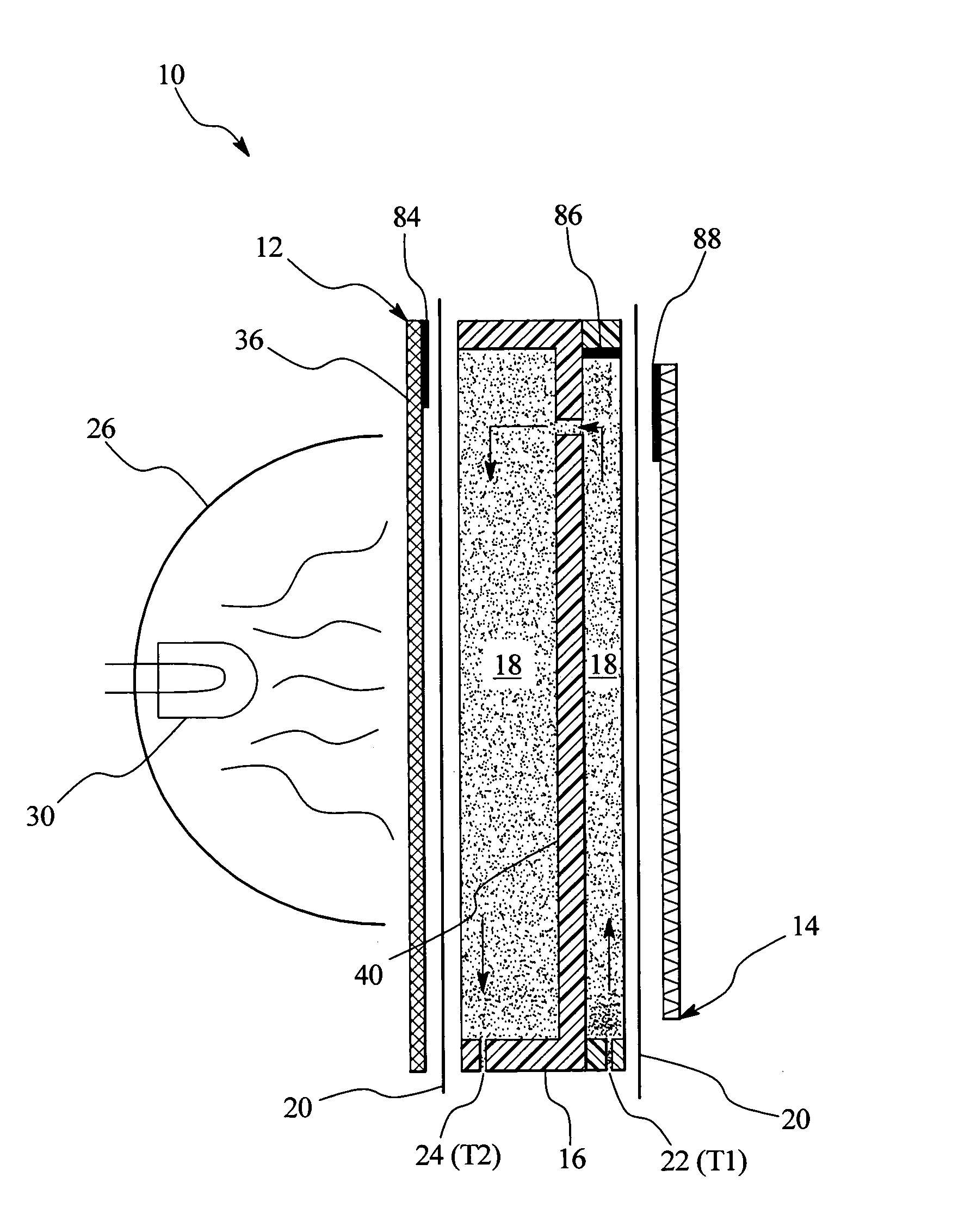

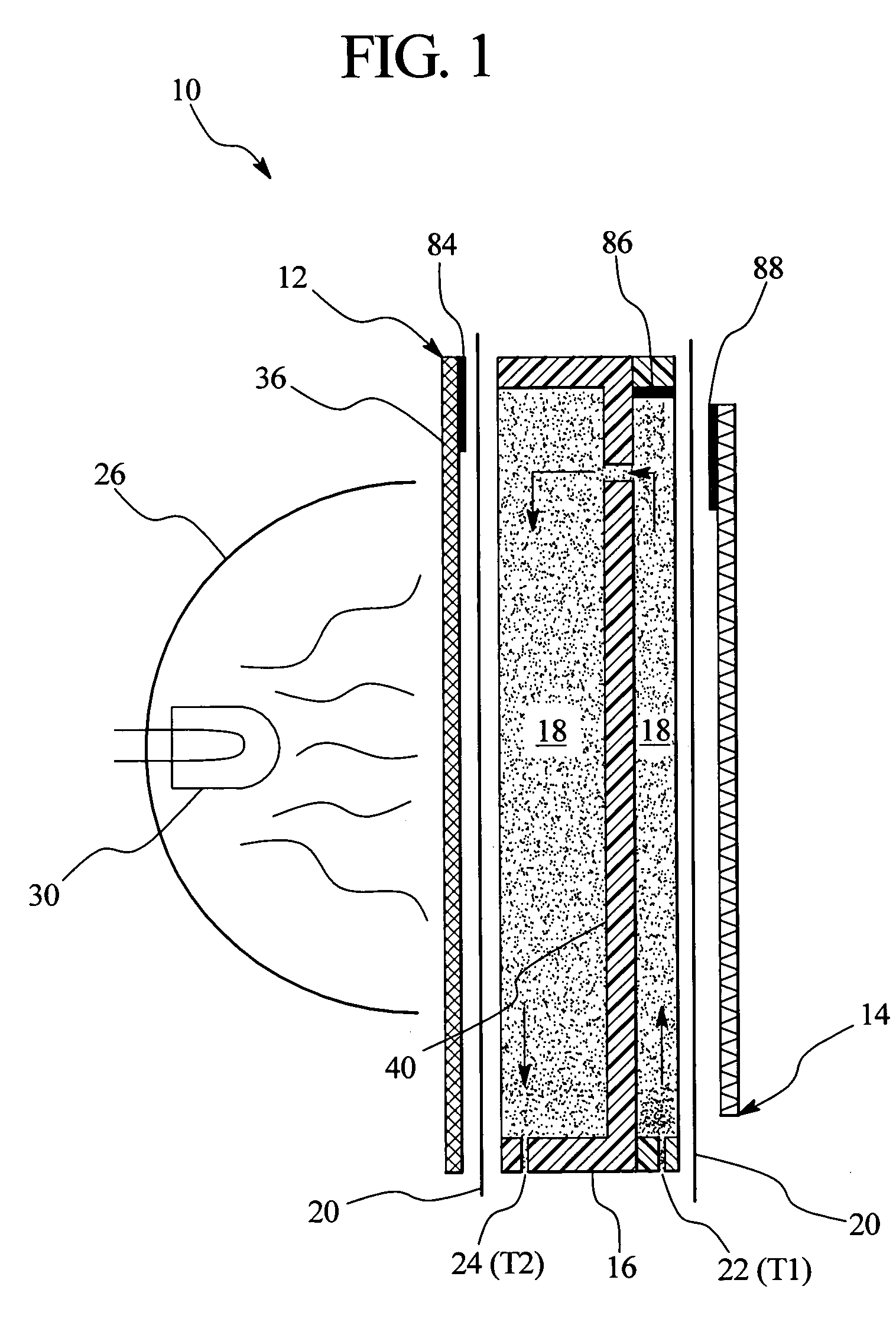

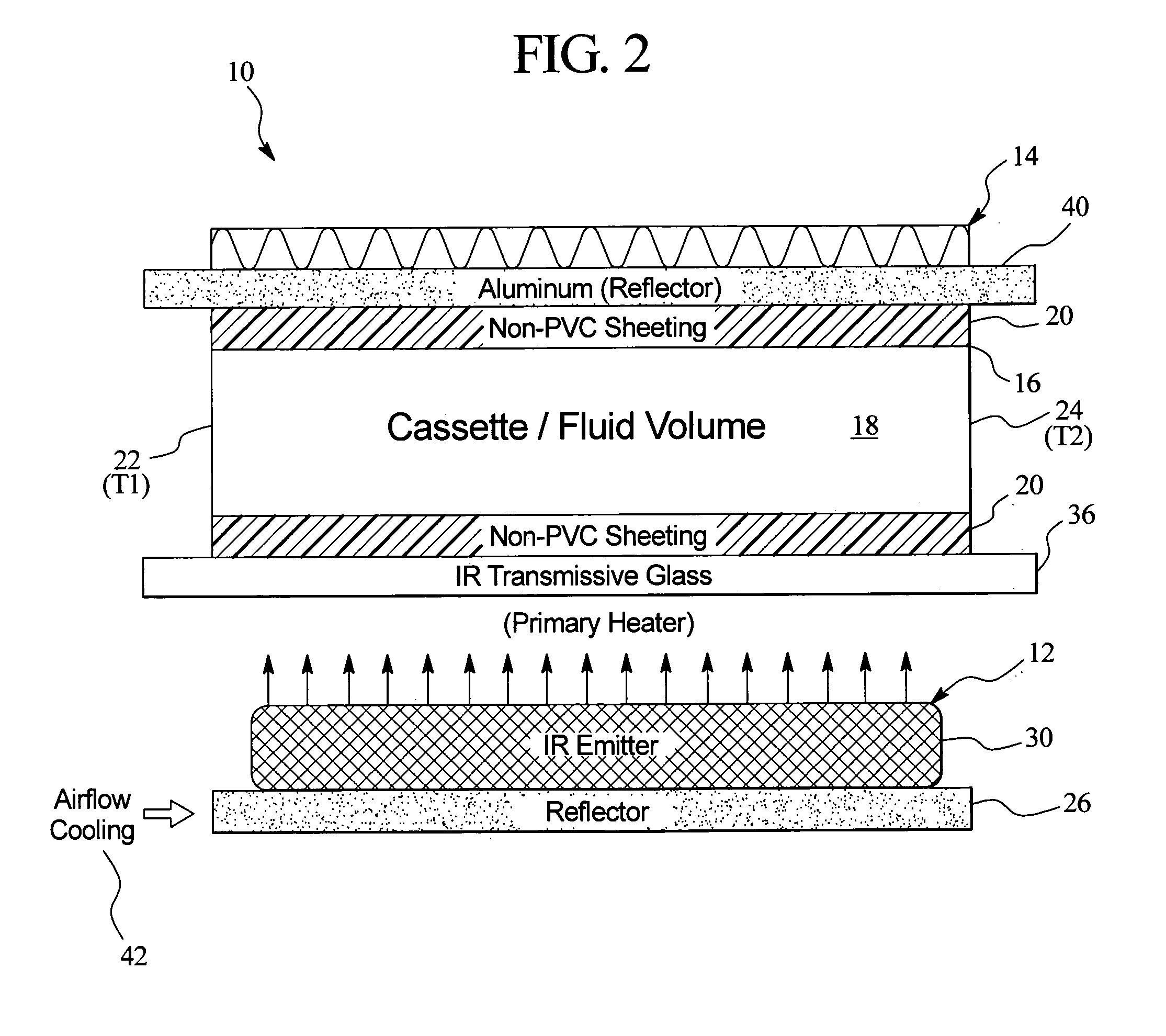

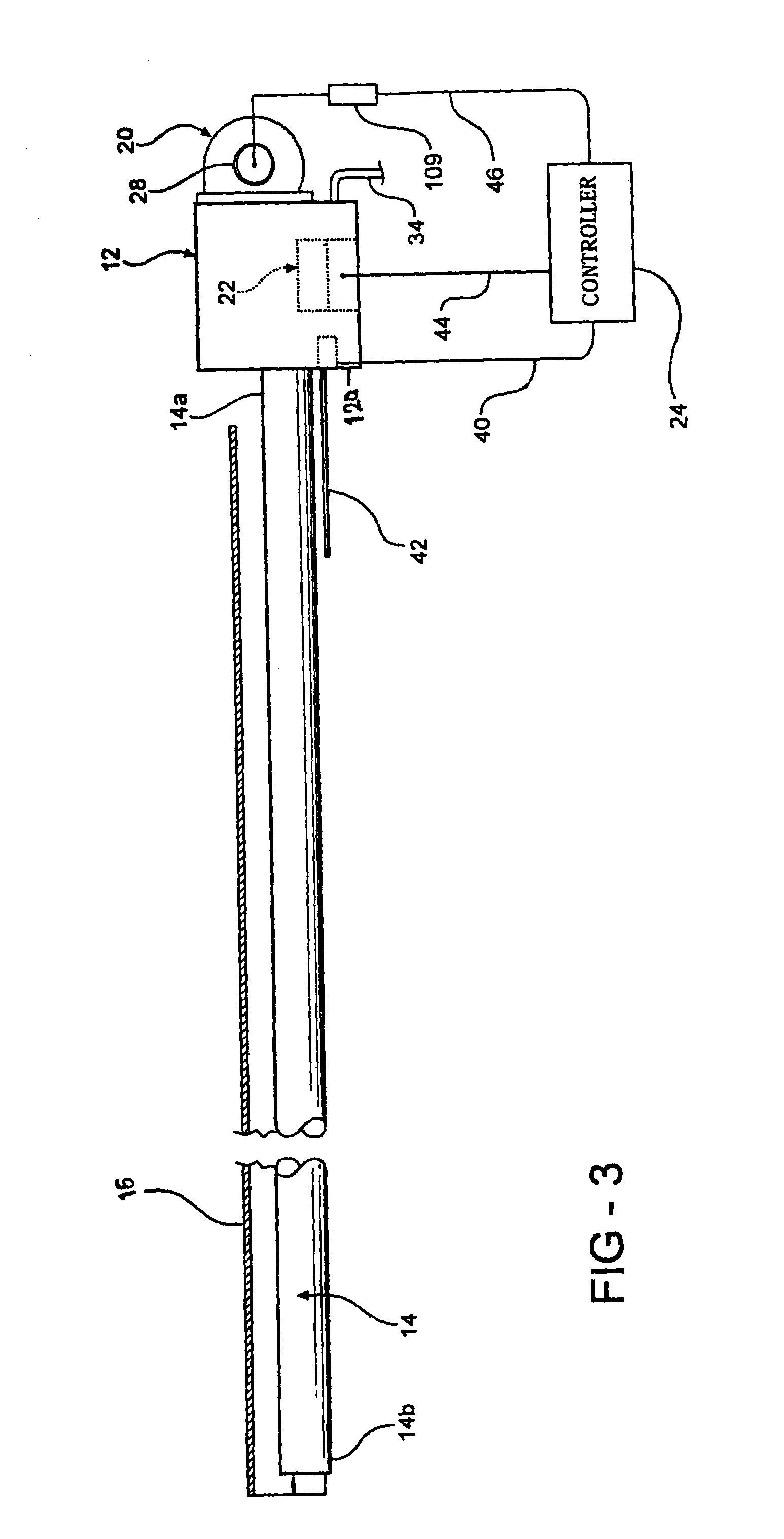

Medical fluid heater using radiant energy

InactiveUS7153285B2Simple systemSimple methodMedical devicesIntravenous devicesEngineeringDialysis fluid

An in-line fluid heater for heating fluid, such as dialysis fluid for use in dialysis therapy is provided. The fluid heater is a dual heater having a primary infrared heater and a secondary plate heater. A controller is operatively connected to the infrared heater and to the plate heater and operates one or both of the infrared heater and the plate heater to maintain a temperature of the fluid.

Owner:BAXTER INT INC +1

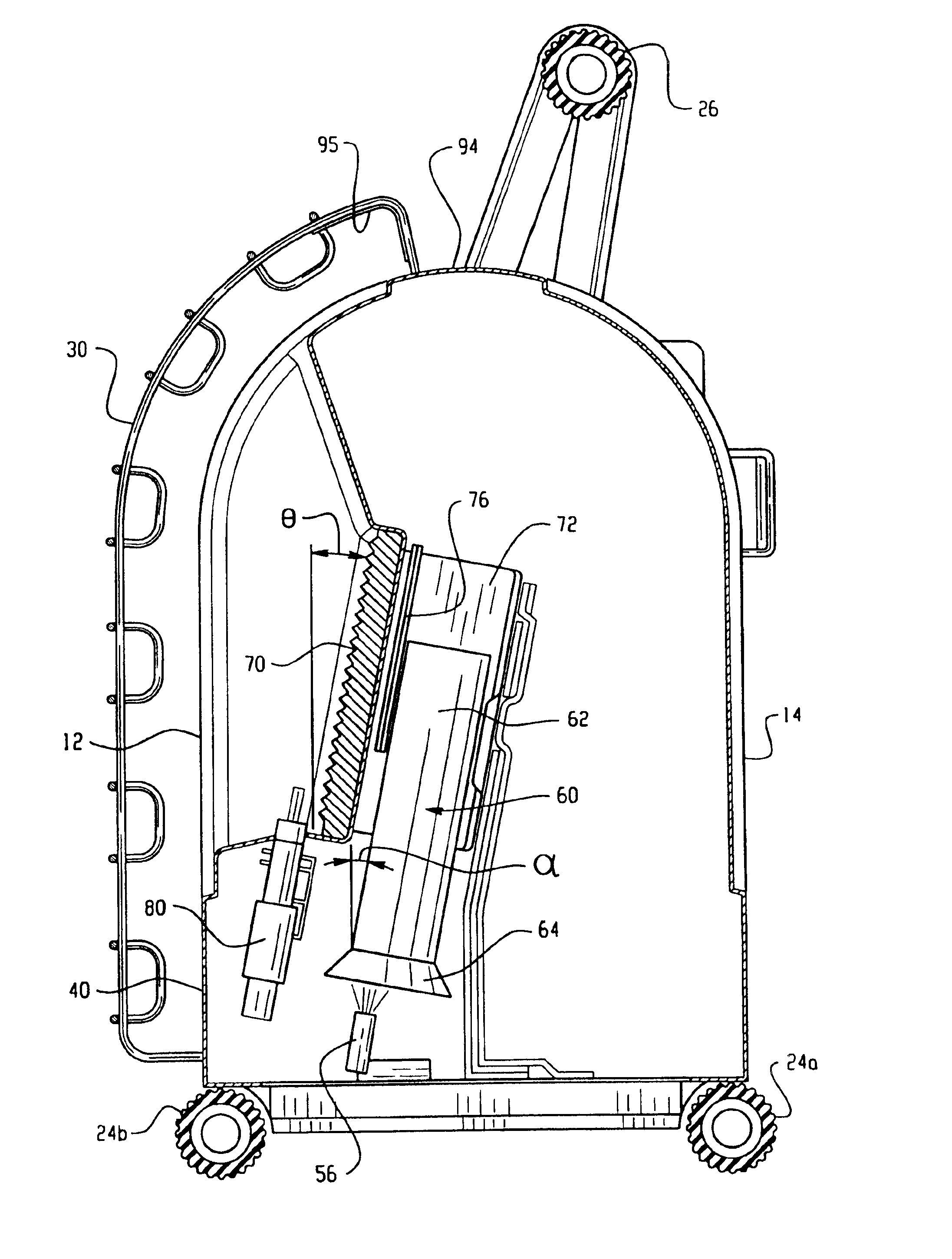

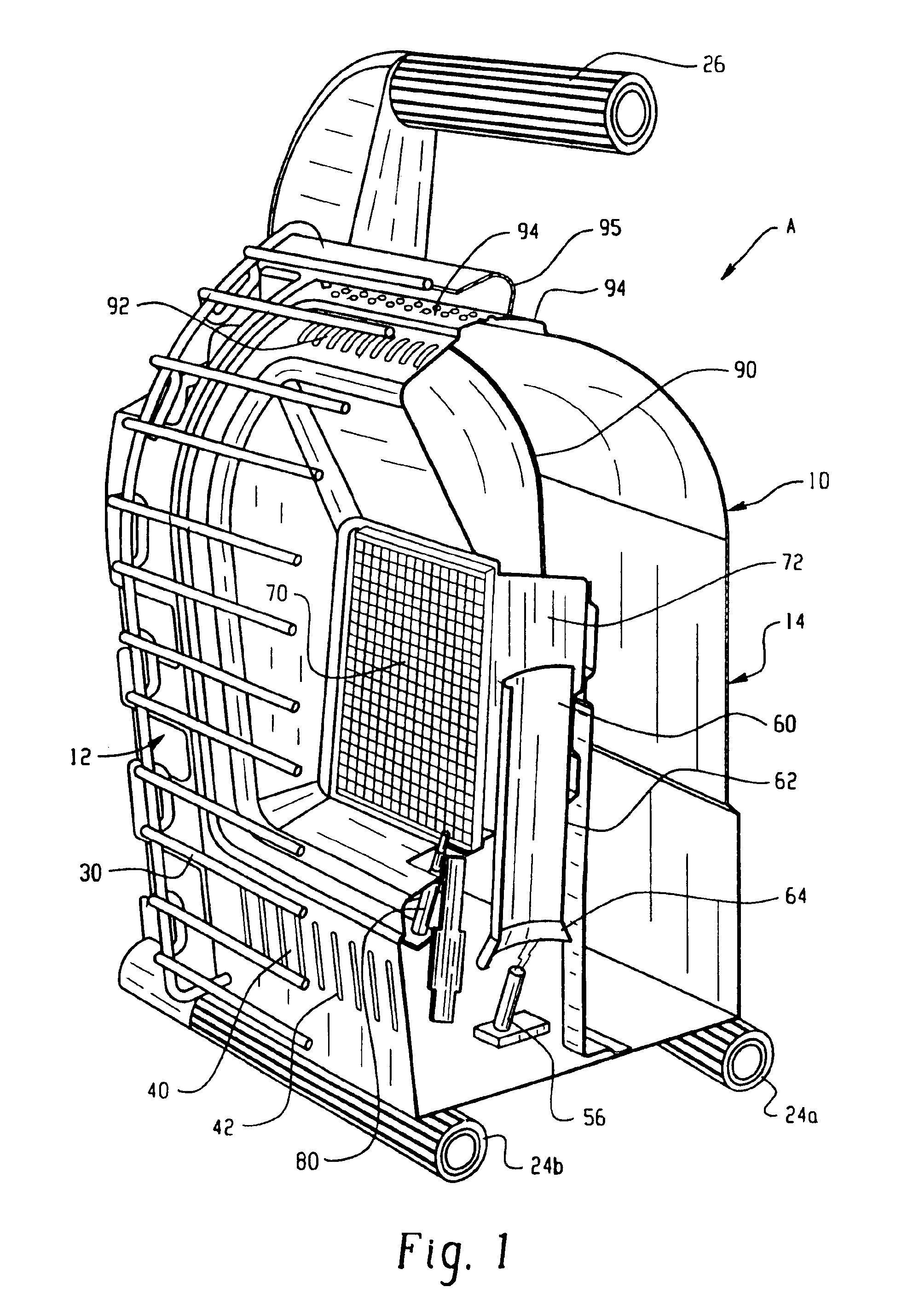

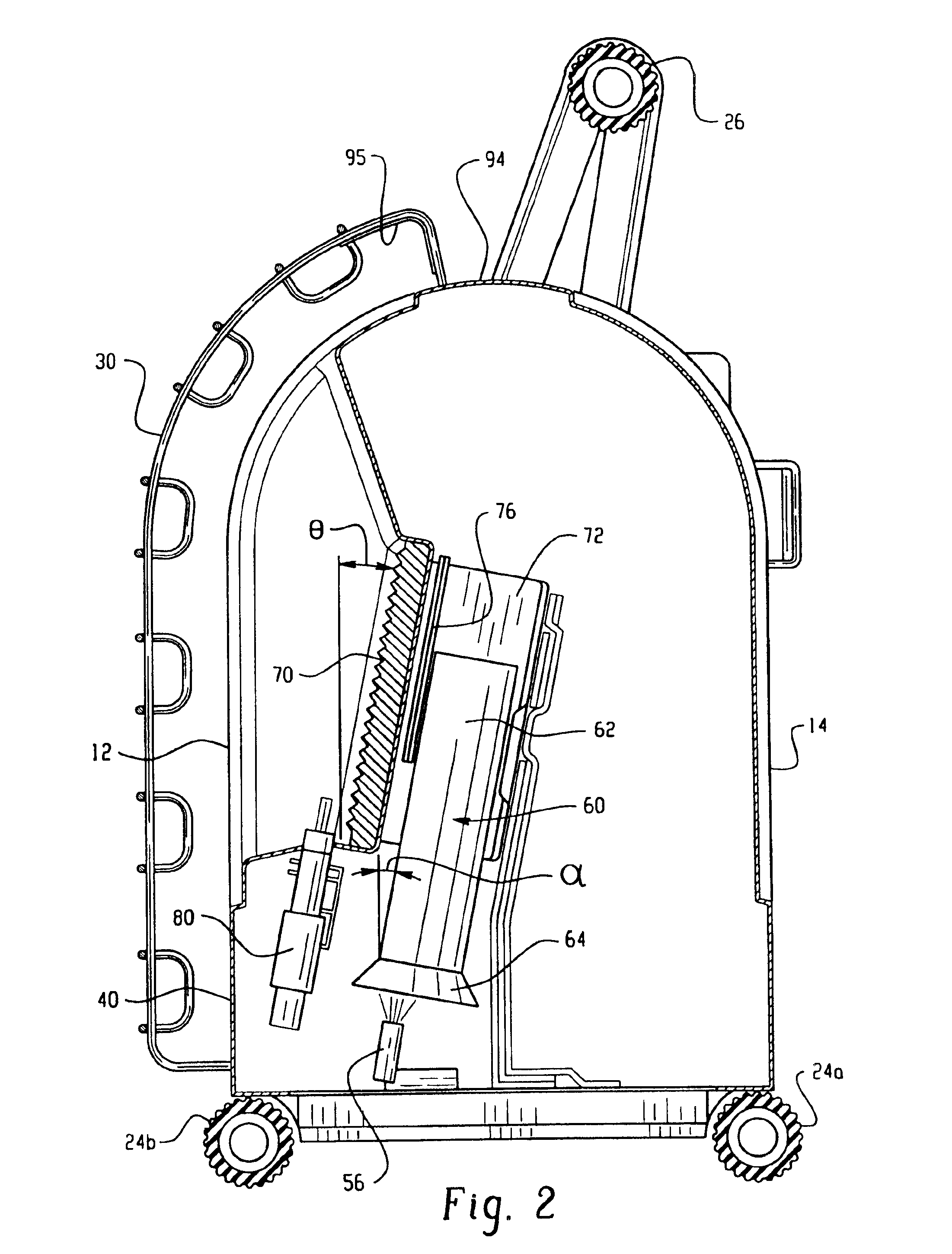

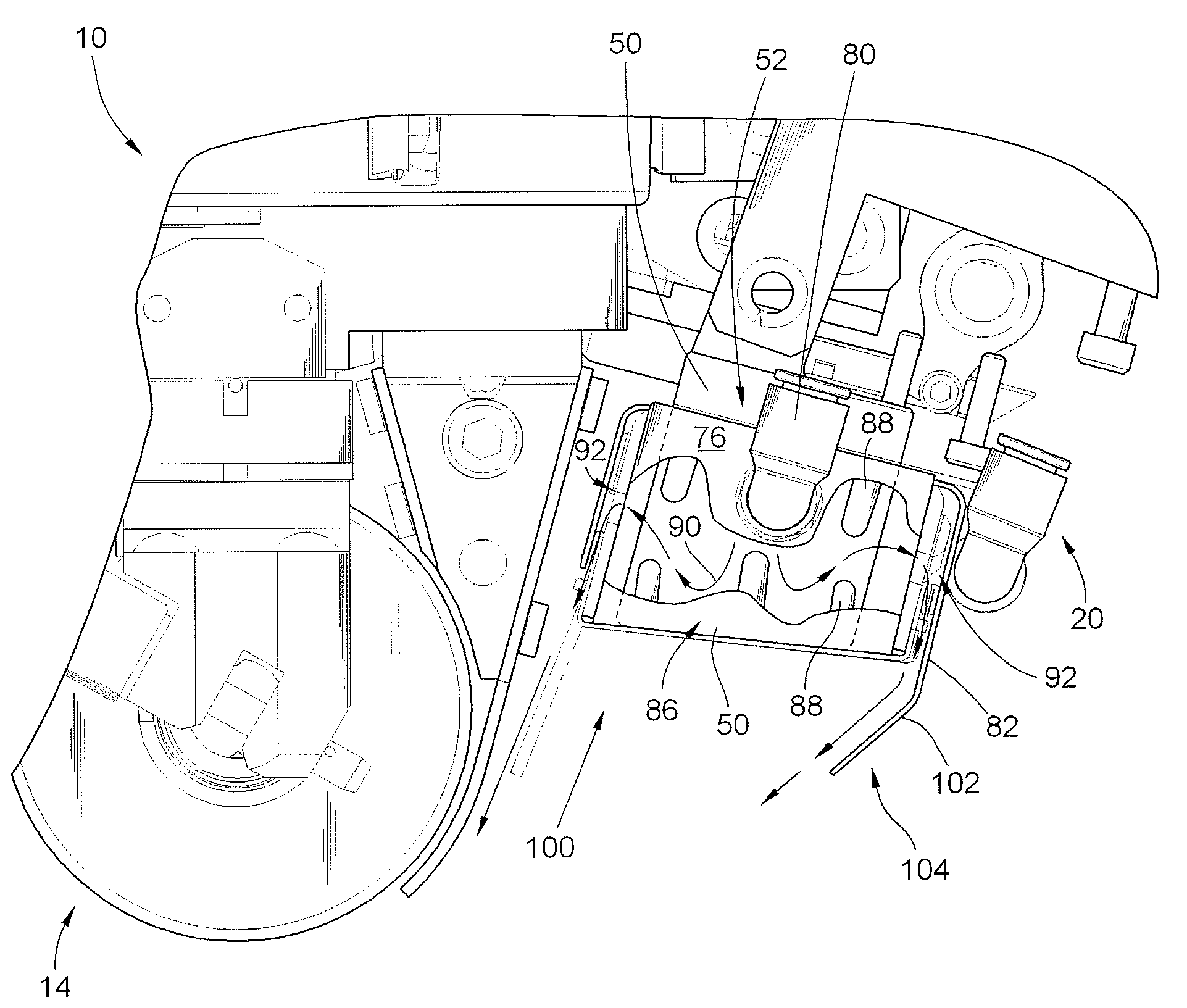

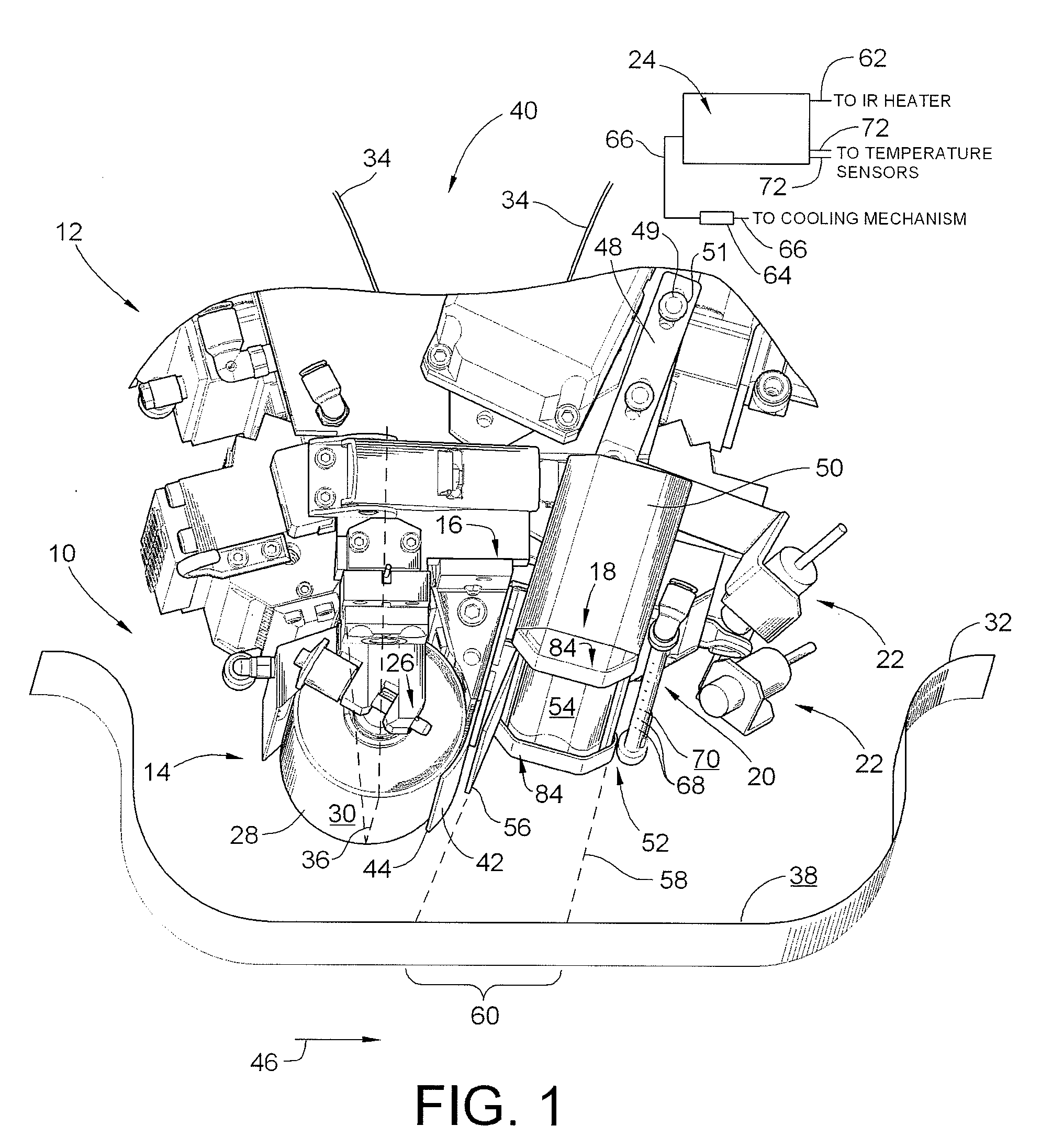

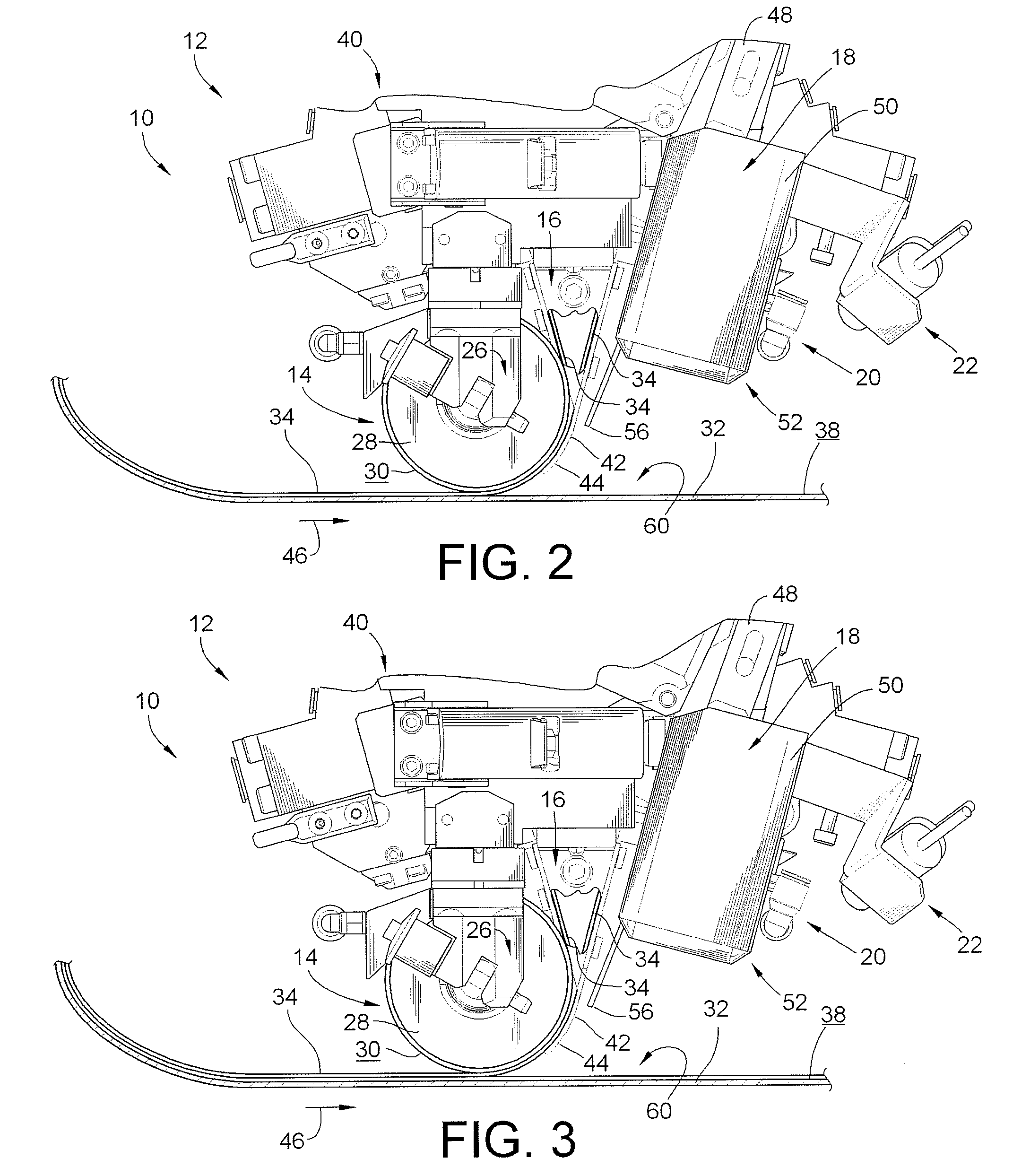

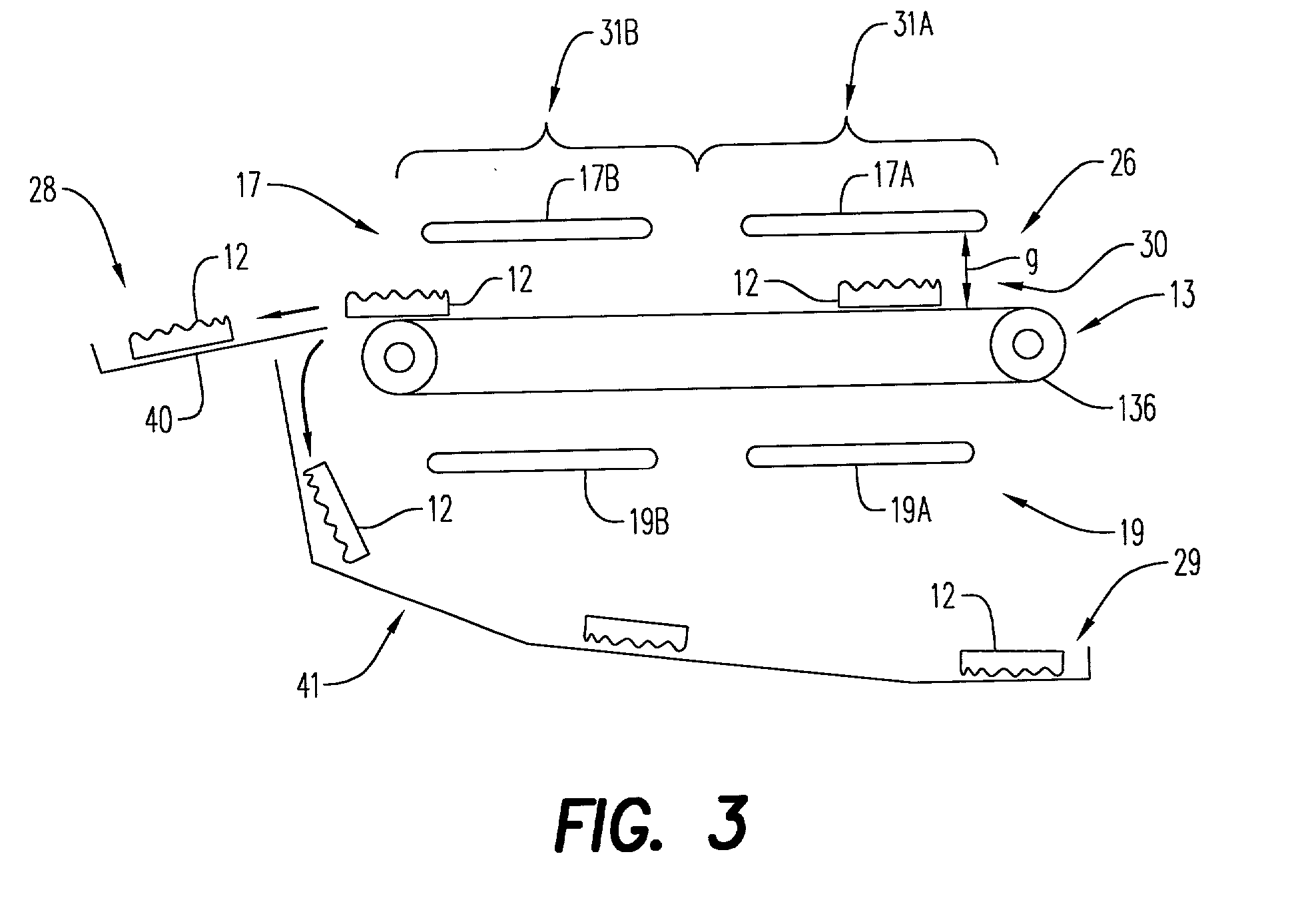

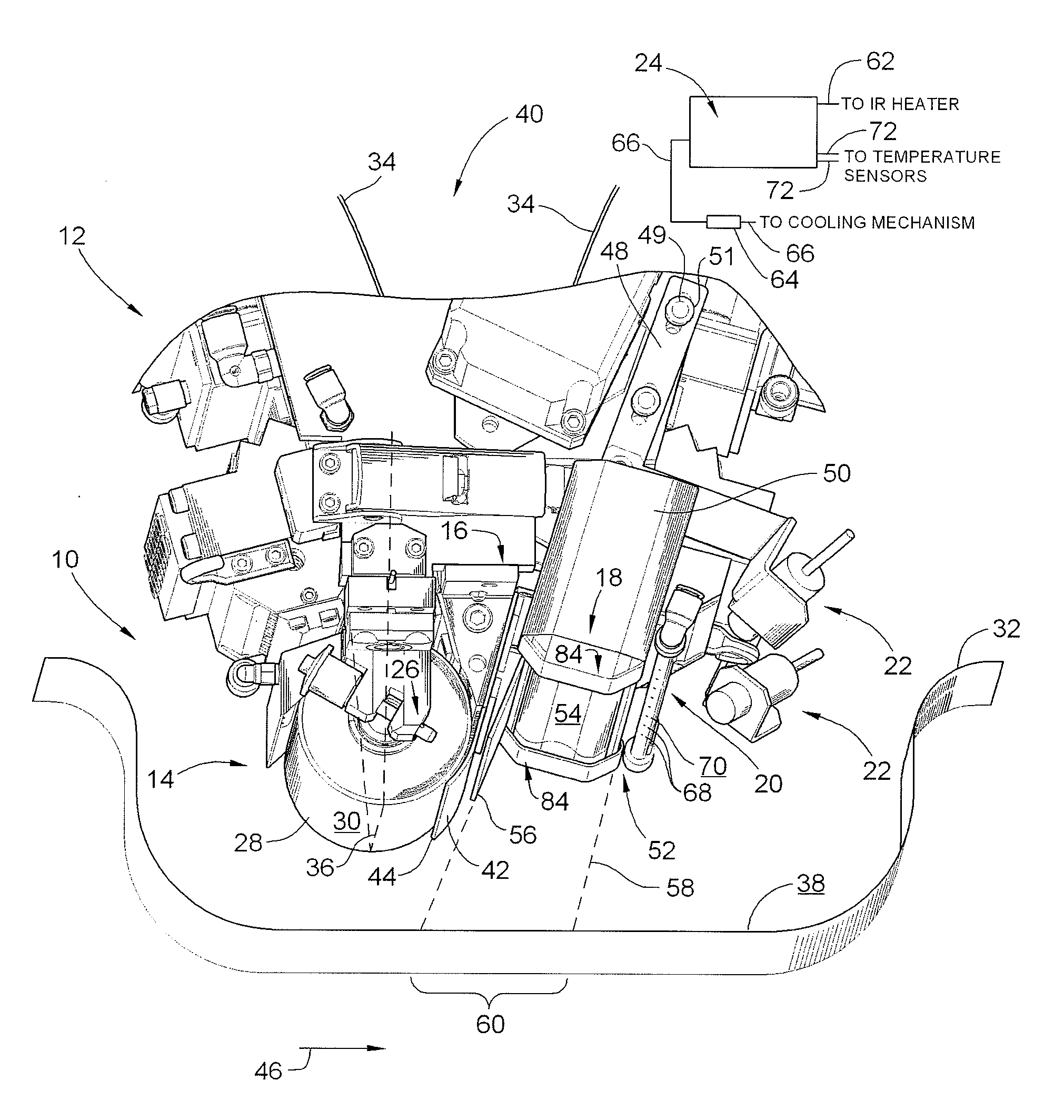

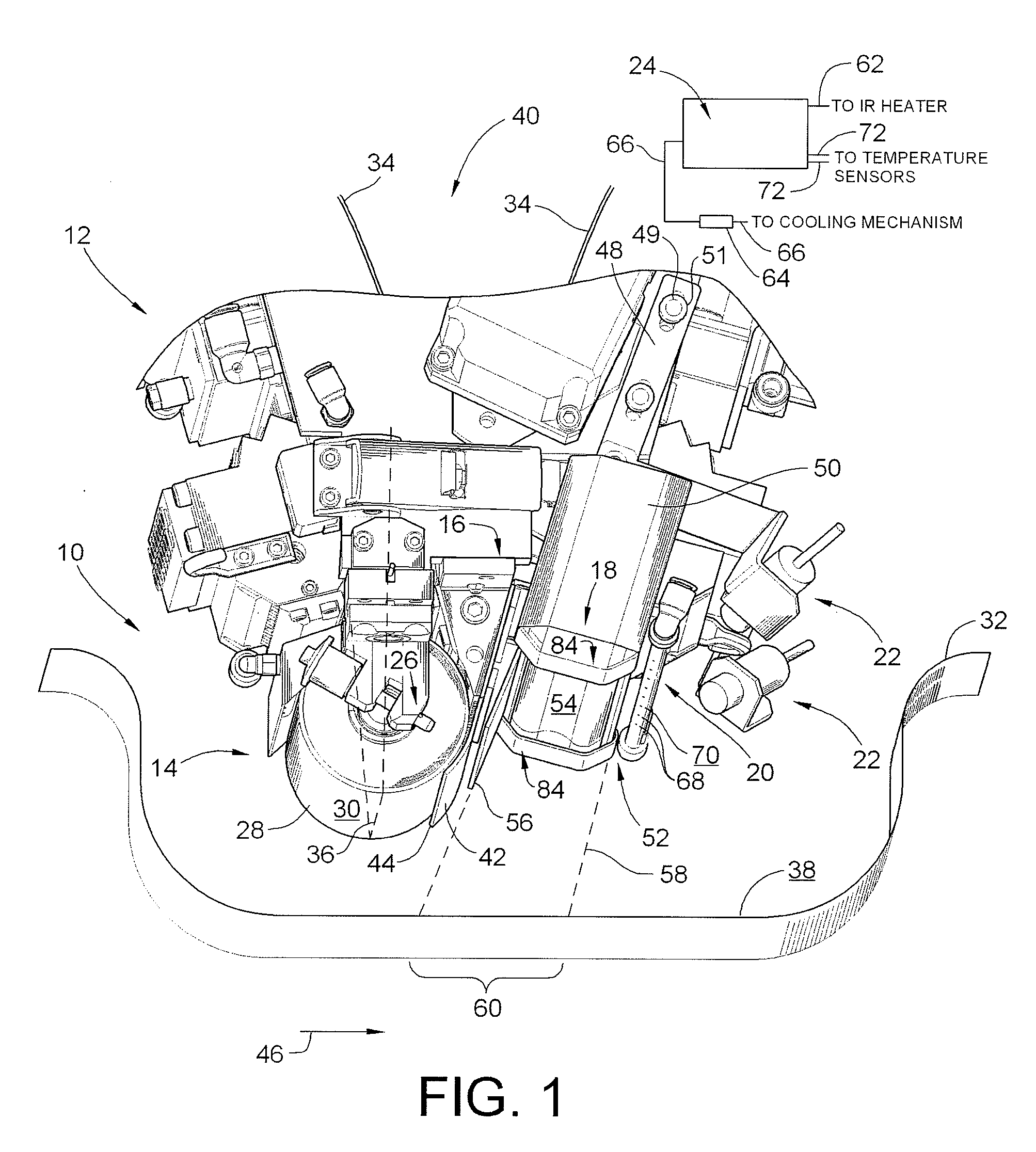

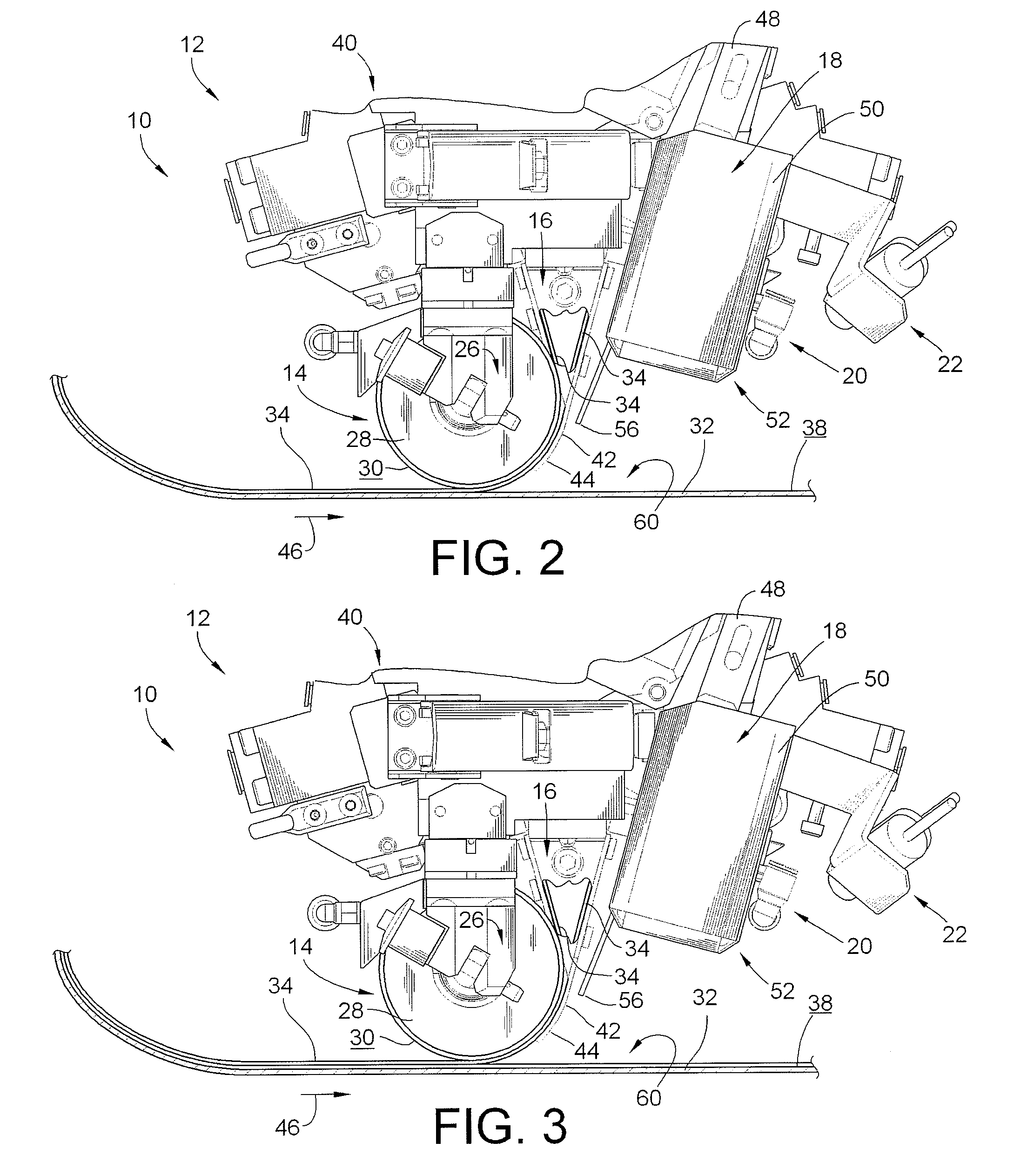

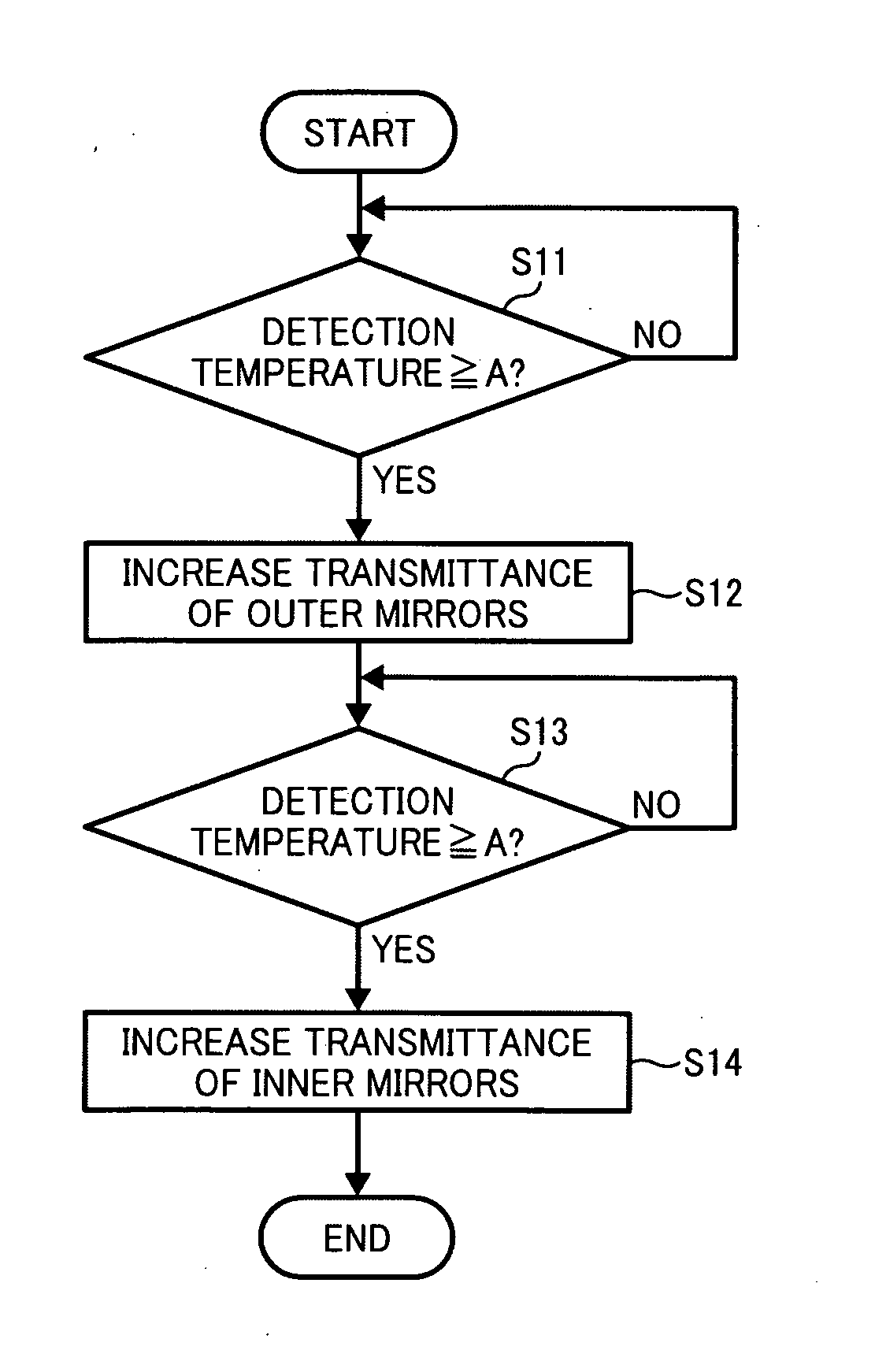

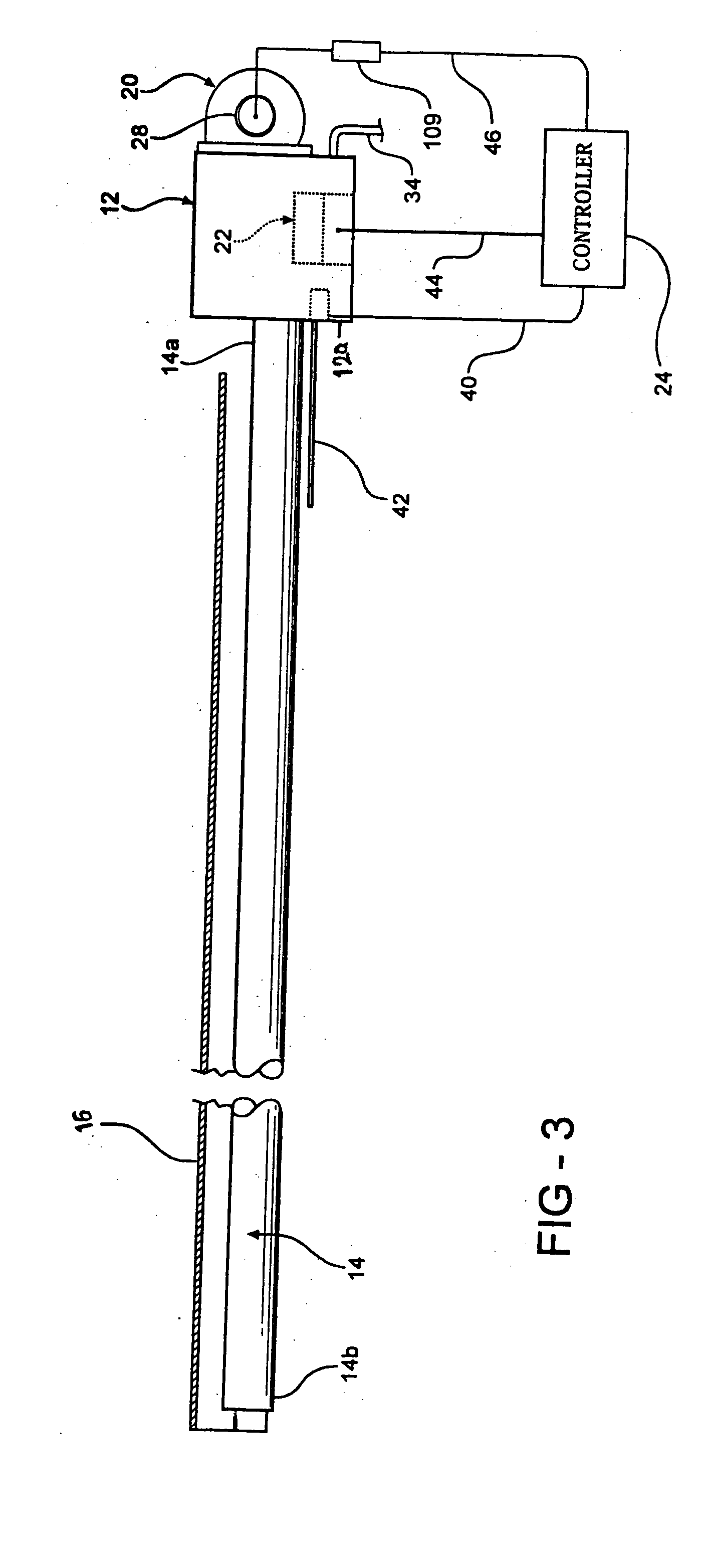

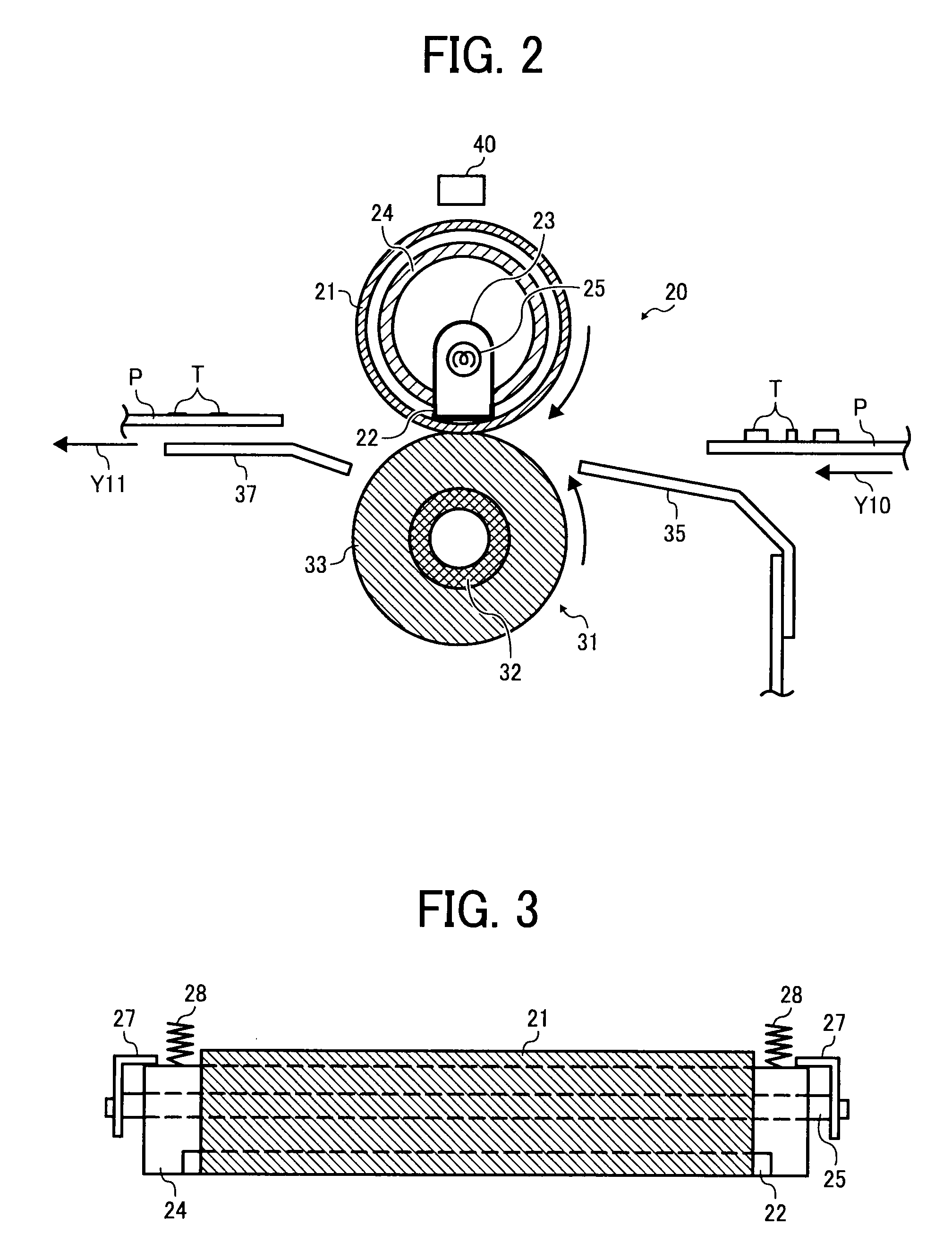

System and method for heating carbon fiber using infrared radiation in a fiber placement machine

ActiveUS7731816B2Heating fastInexpensive and quick to reactLamination ancillary operationsLaminationFiberCarbon fibers

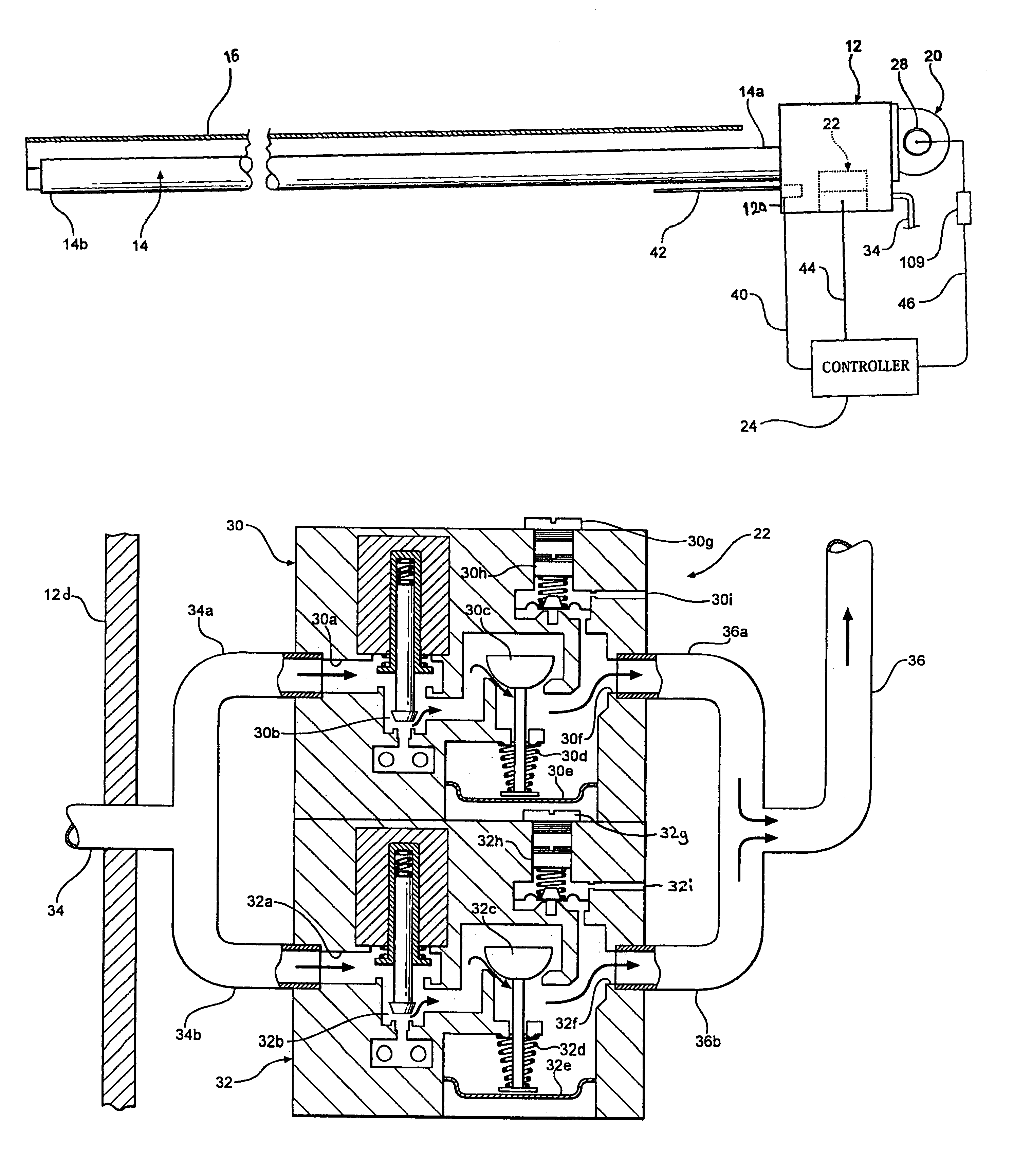

An apparatus comprising a fiber placement head assembly and an infrared heating assembly is provided. The fiber placement head assembly includes a compaction roller assembly and a feeder assembly. An infrared heating assembly, a cooling mechanism, temperature sensors, and a controller are operably coupled to the fiber placement head assembly. The infrared heating assembly includes an infrared heater that generates a heating profile. The heating profile defines a heating zone on either a tool or previously laid tows. If the burn point of either the tool or previously laid tows within the heating zone is approached, the controller, which receives temperature readings from the temperature sensors, simultaneously disables the infrared heater and activates the cooling mechanism. As such, the tool and the previously laid tows are protected from being ruined due to an over temperature condition.

Owner:INGERSOLL MACHINE TOOLS

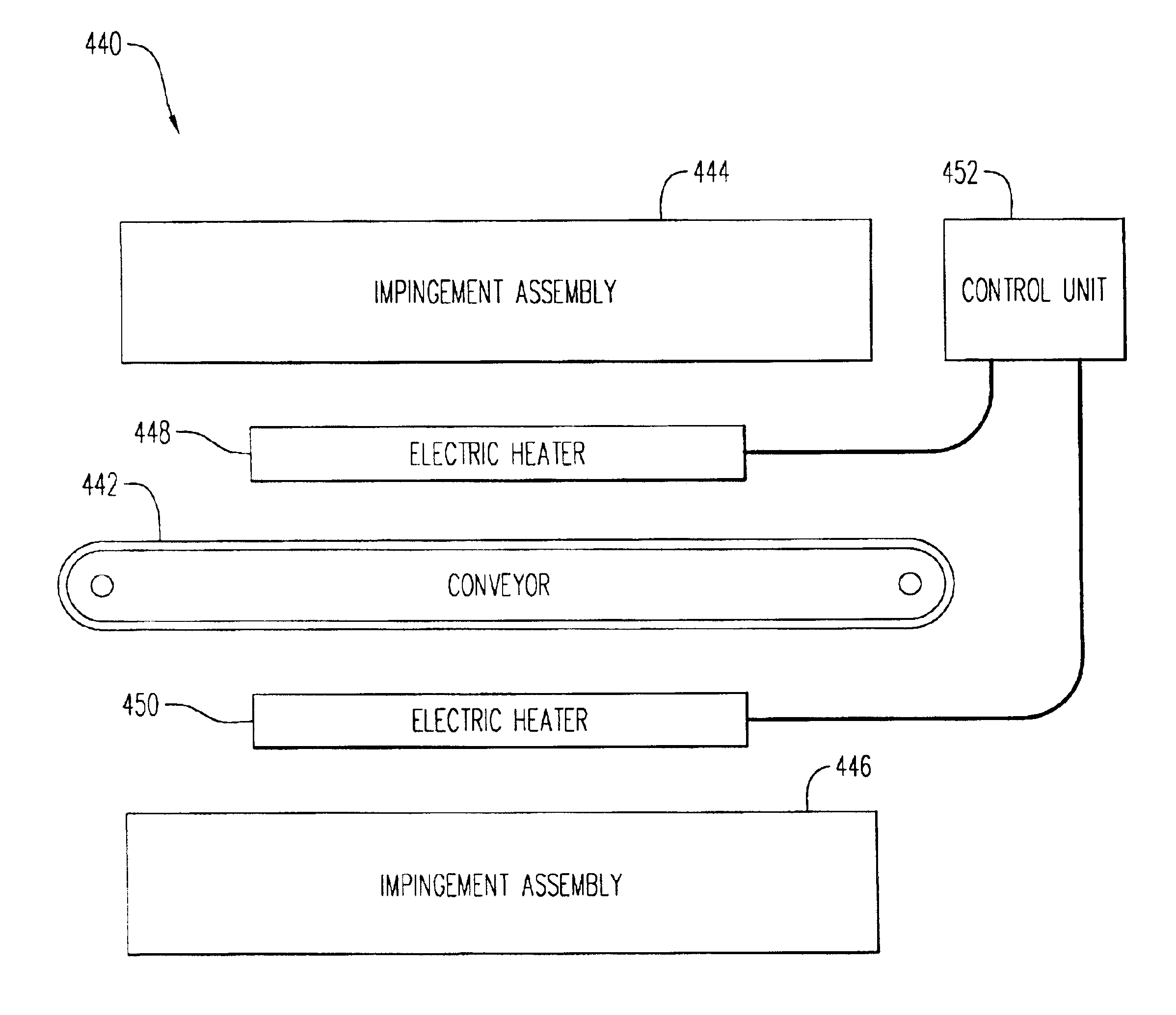

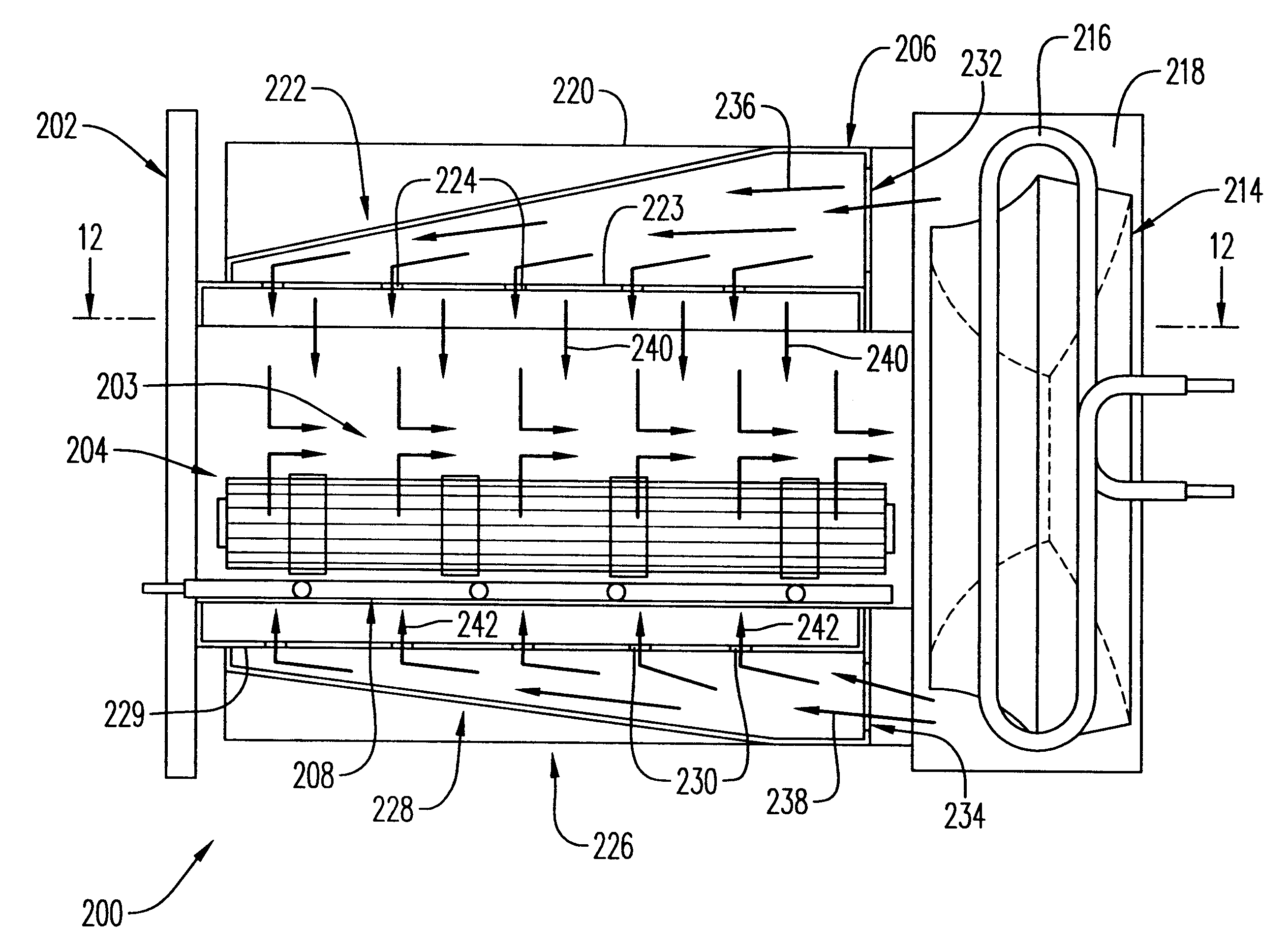

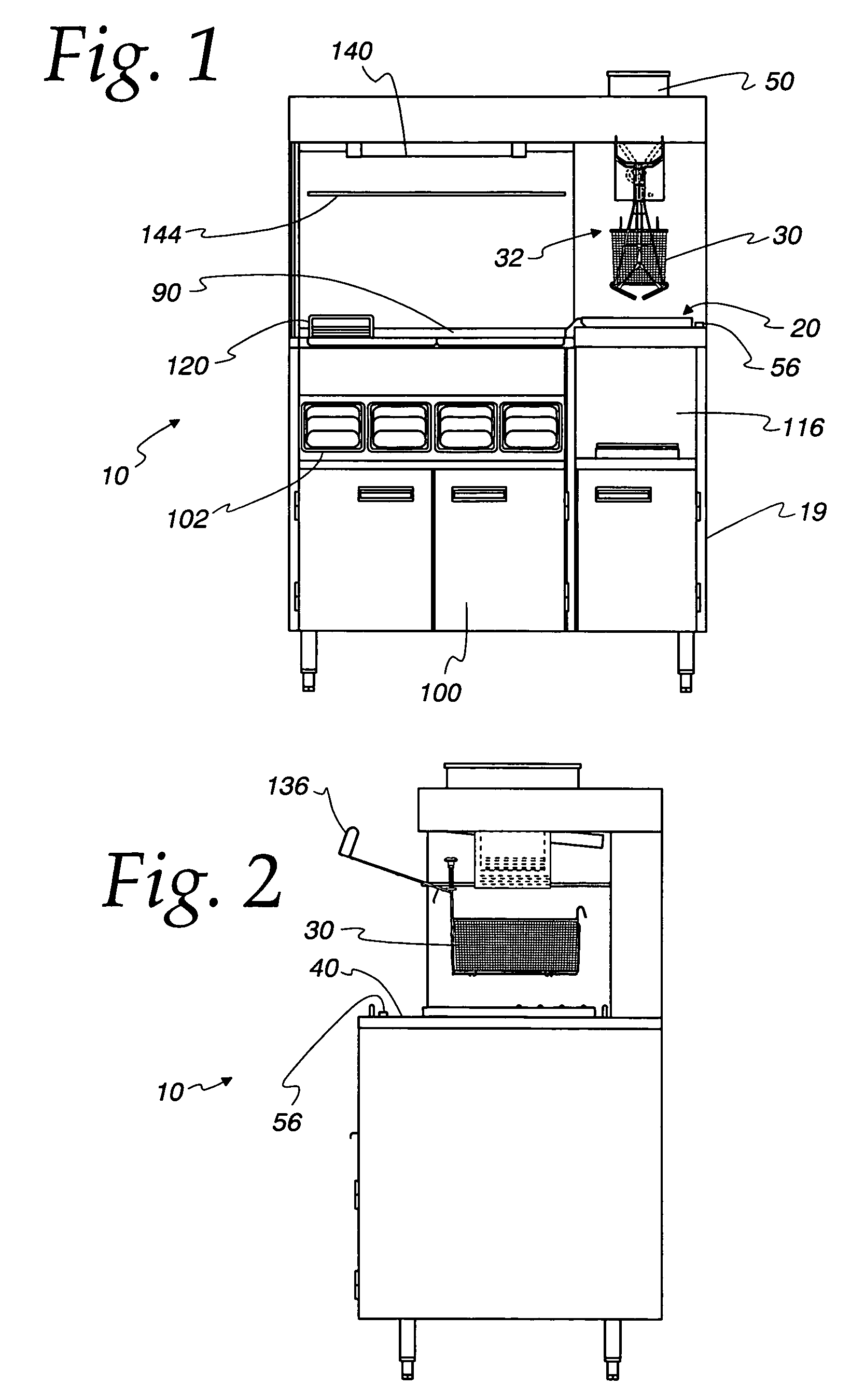

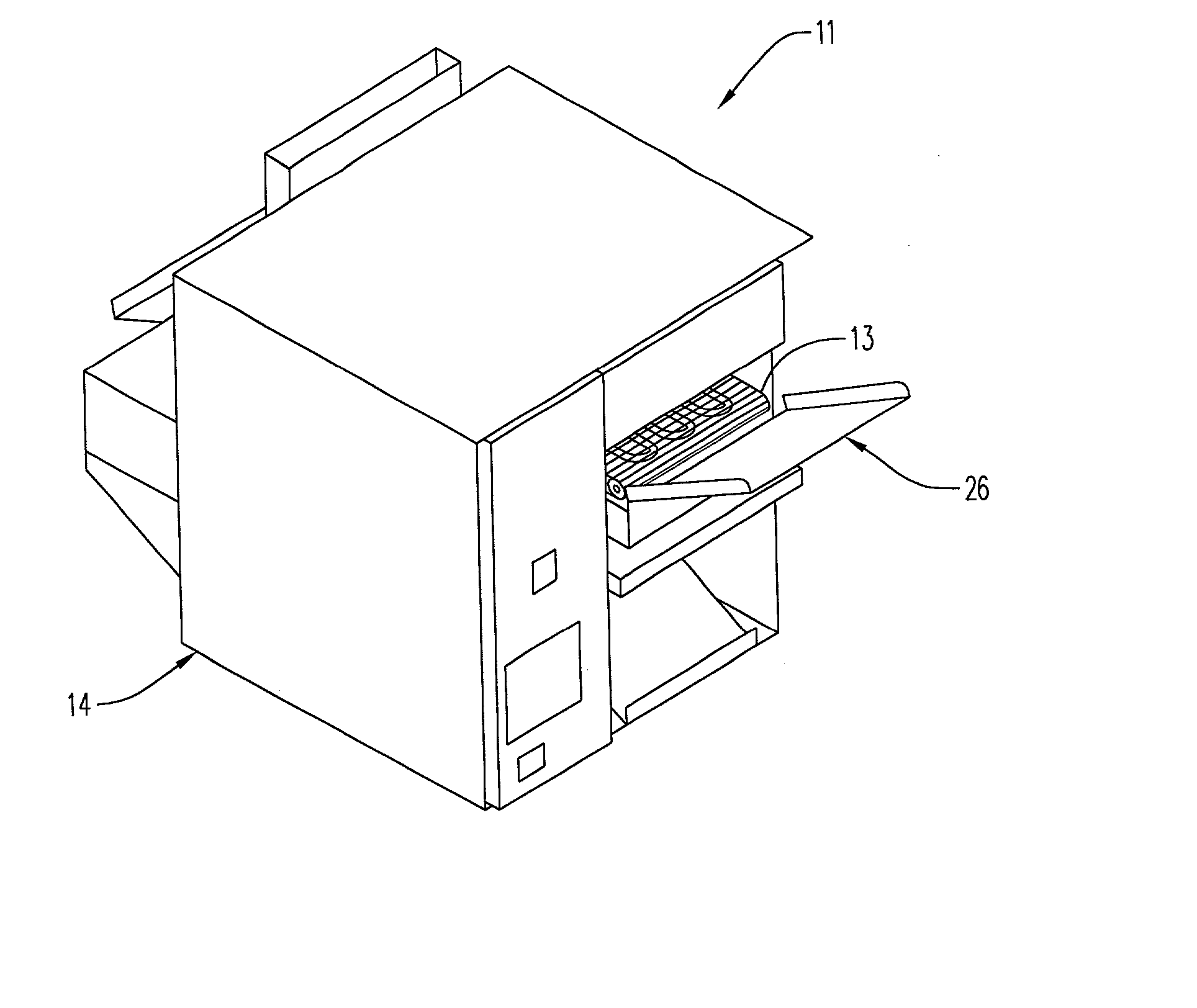

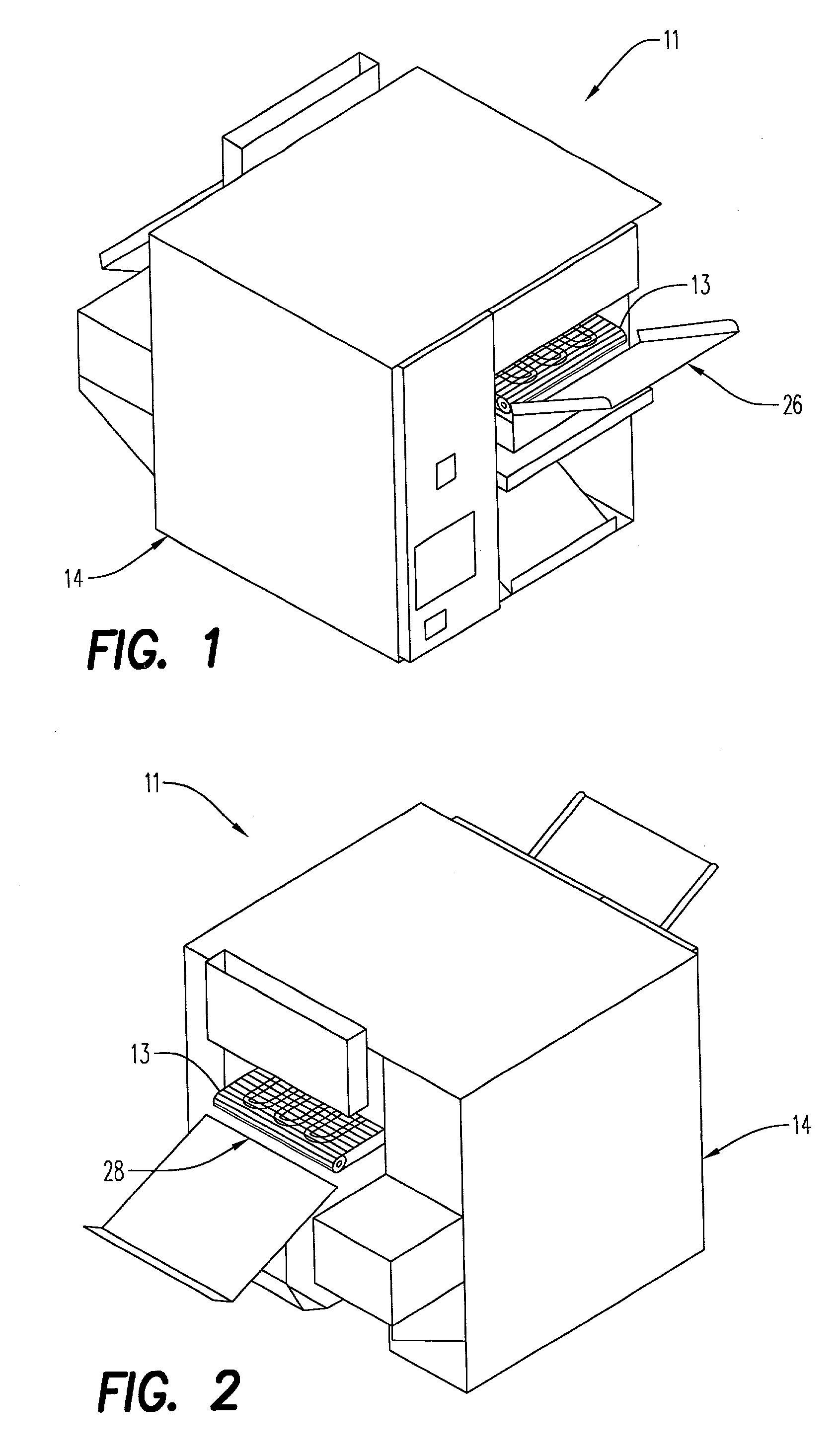

High speed cooking device and method

InactiveUS6817283B2Improve the heating effectDouble toasting/cooking capabilityDomestic stoves or rangesLighting and heating apparatusThermal energyProcess engineering

A cooking device that is capable of rapidly cooking food products such as in toasting bread products or cooking pizza. The cooking device uses air impingement from above and / or below the food product. In some cases an infrared heater is additionally used to impart a desired color and crunchiness about a surface of the food product. In some cases, a boost in thermal energy is applied to the bottom of the food product vis-à-vis the top thereof. In some cases, the boost is due to an extra heater, which may be gas or electric. The device is particularly adapted for toasting bread products, cooking sandwich products (toasting the bread and heating the sandwich filler) and / or cooking pizza. Rapid cooking times are achieved by delivering more thermal energy to the top or bottom of the food product, depending on the type thereof, to give quality and speed. For example, a pizza can be cooked to have a crisp bottom without burning a cheese topping.

Owner:LINCOLN FOODSERVICE PRODS

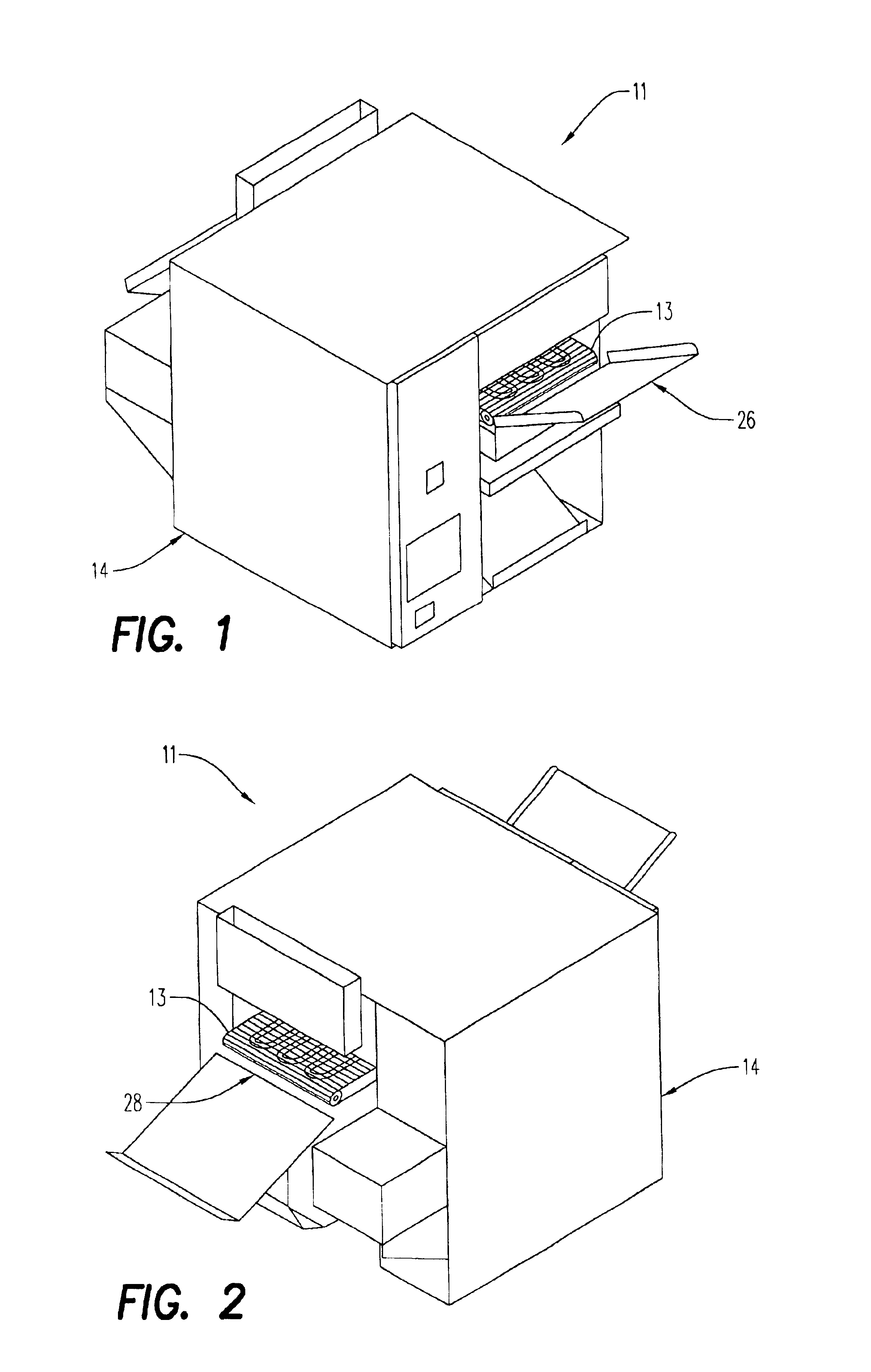

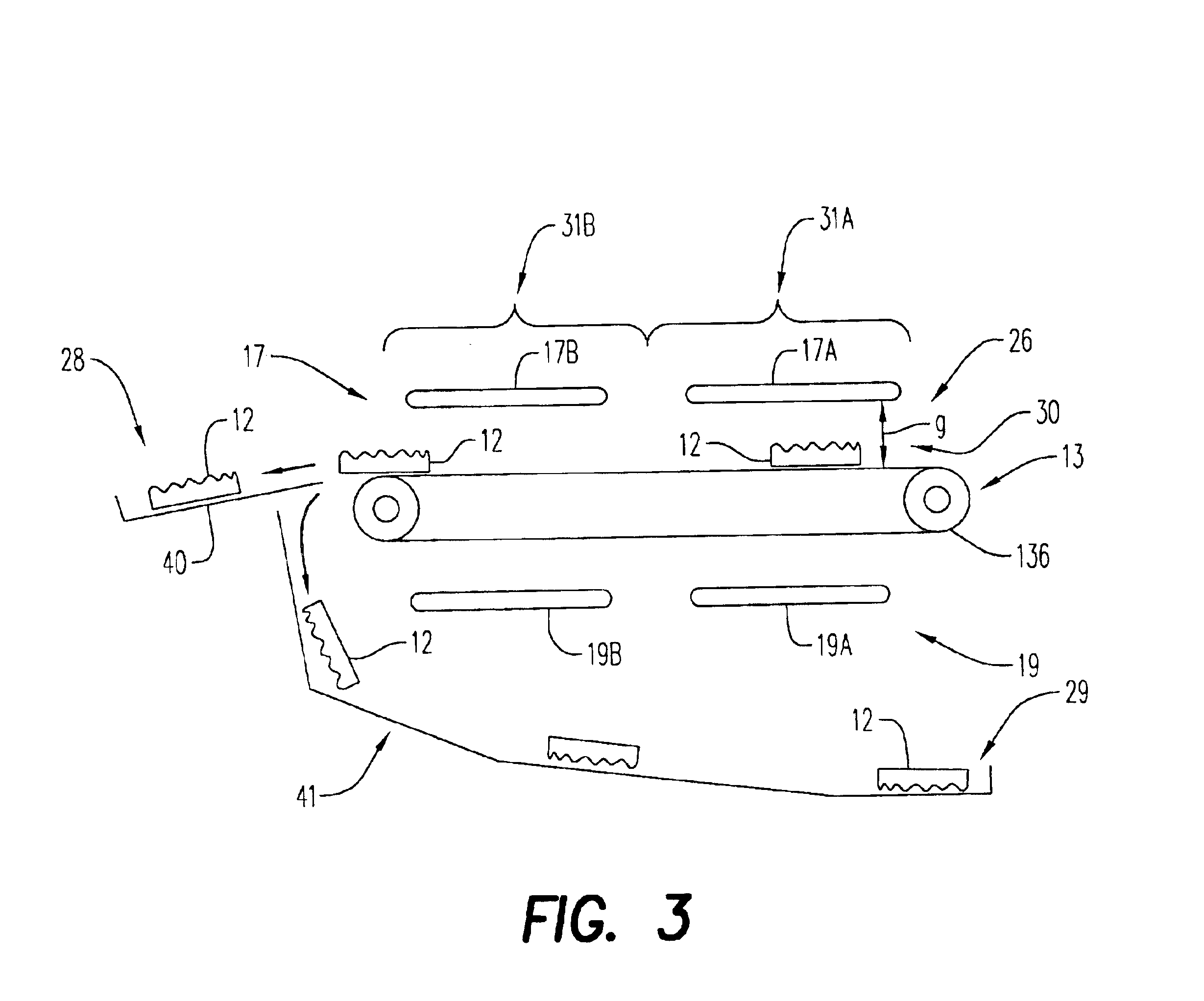

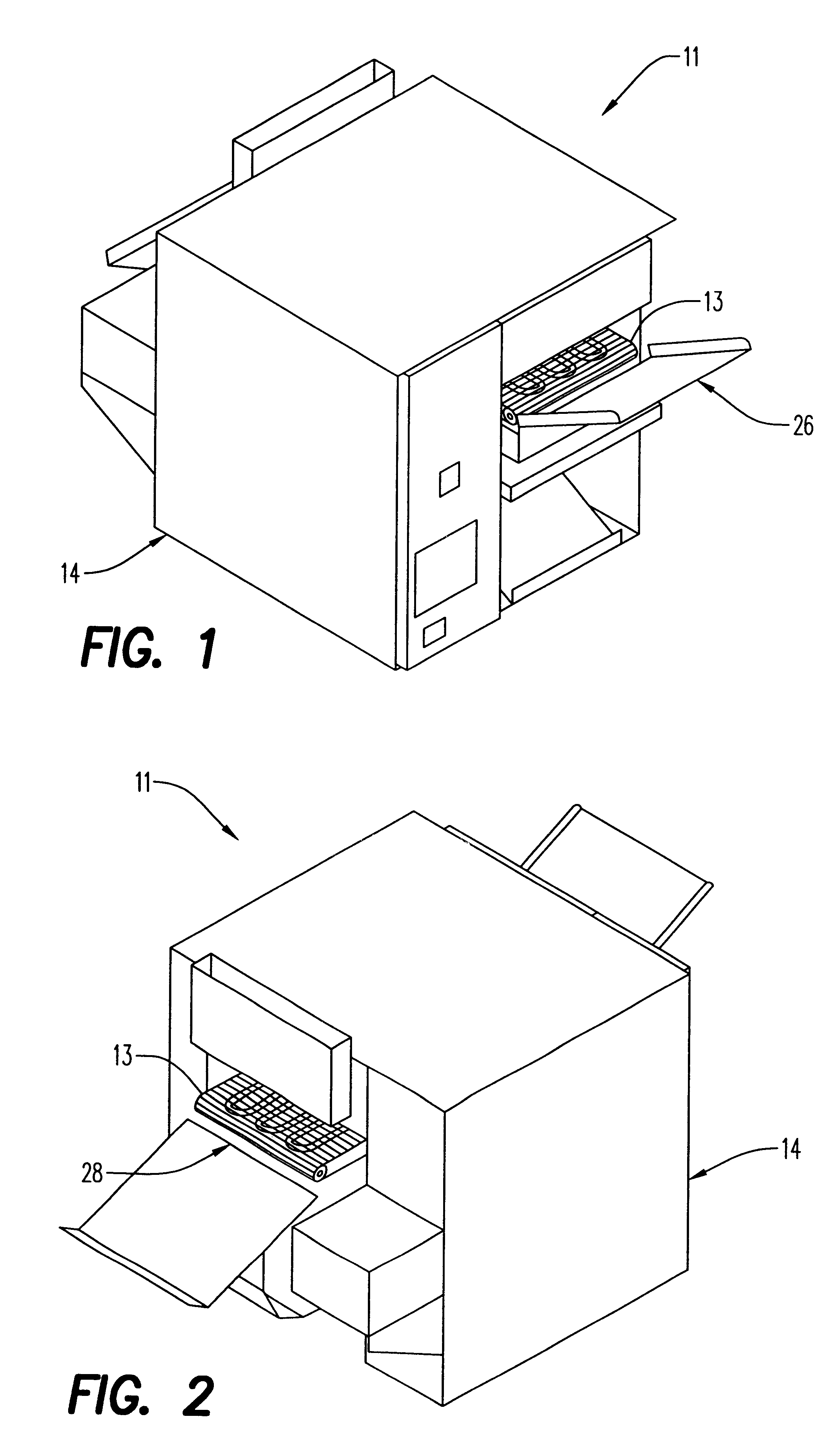

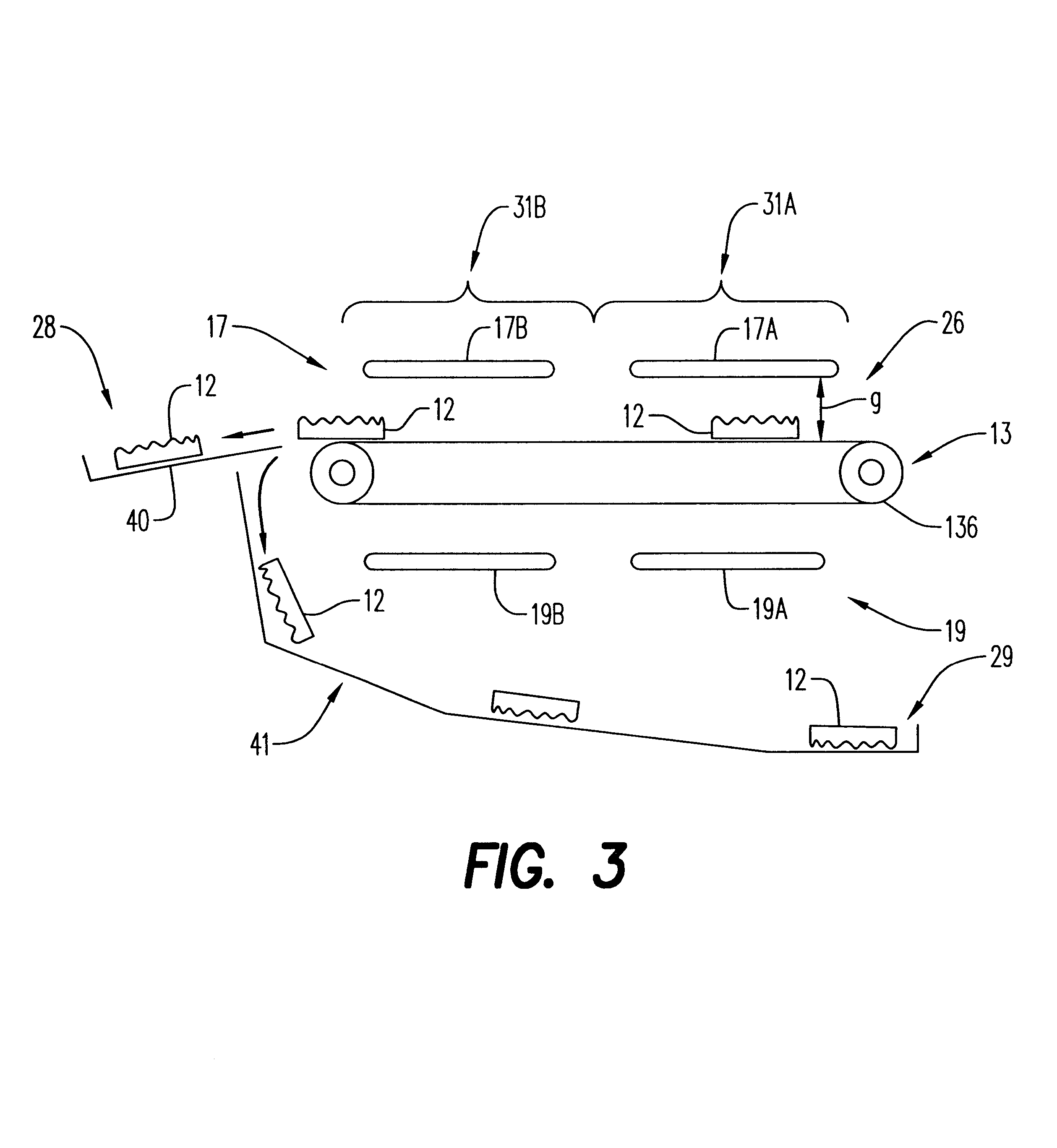

High speed variable size toaster

InactiveUS6595117B1Improve the heating effectAir-treating devicesDomestic stoves or rangesEngineeringCooked food

A cooking appliance which is capable of rapidly toasting a food product disposed therein by air impingement and infrared heating to provide a cooked food product having the desired color and crunchiness about its surface. The appliance is particularly adapted for cooking sandwich products, toasting the bread and heating the sandwich filler. The appliance includes an air impingement assembly that delivers columns of heated air to the food product and an infrared heater assembly that produces infrared energy. The appliance delivers the impingement air from above the food product and the infrared energy from below. Alternatively, the appliance delivers the impingement air from above and below the food product and the infrared energy from below.

Owner:LINCOLN FOODSERVICE PRODS

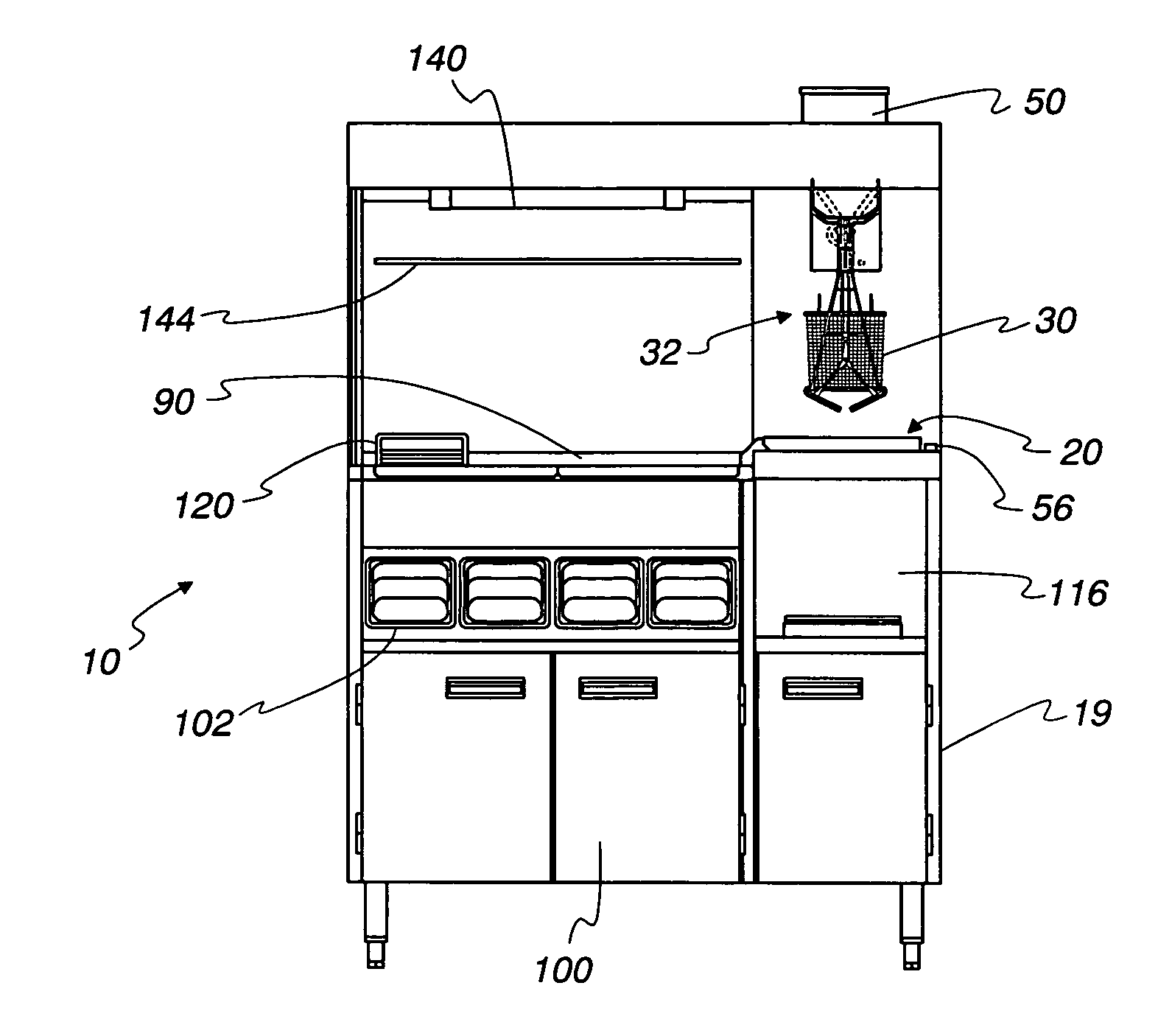

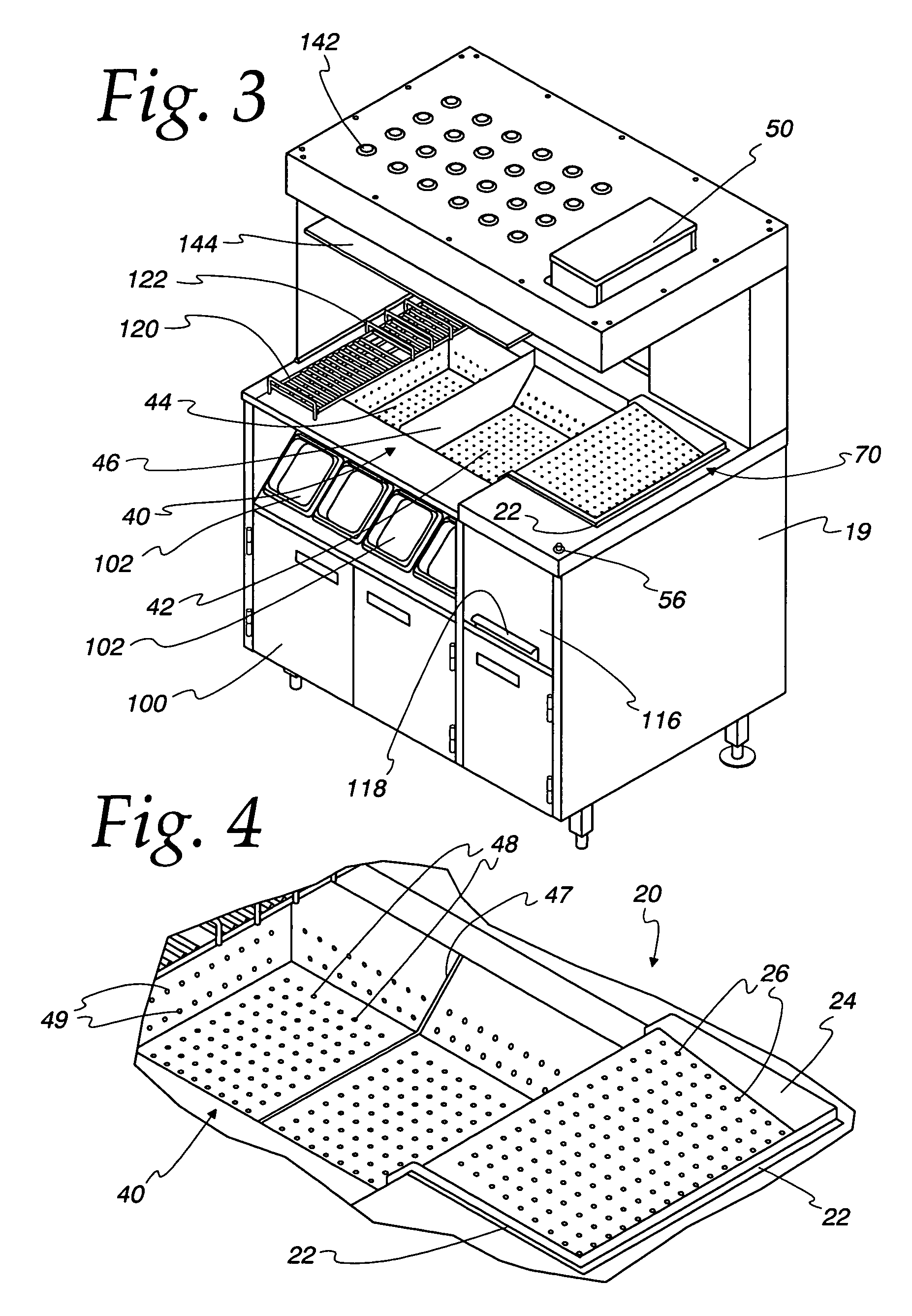

Storage and packaging of bulk food items and method

InactiveUS20070251397A1Seasoning adhesionSalted so quicklyLiquid surface applicatorsConfectioneryEngineeringLength wave

A semi-automated food processing station, system and method is provided that allows food to be dispensed, stored and packaged in a suitable container, which may be an individual portion-sized container for serving to a customer. In one embodiment, the system includes an automated salting device, and may include a pivotable food receiving tray that automatically transfers the food items to one or more storage bins, where an infrared heater maintains the temperature of the food items by directing infrared radiation thereon. In a preferred embodiment, the infrared radiation passes through a filter that filters out the wavelengths of infrared radiation that may be irritating to an operator.

Owner:RESTAURANT TECH

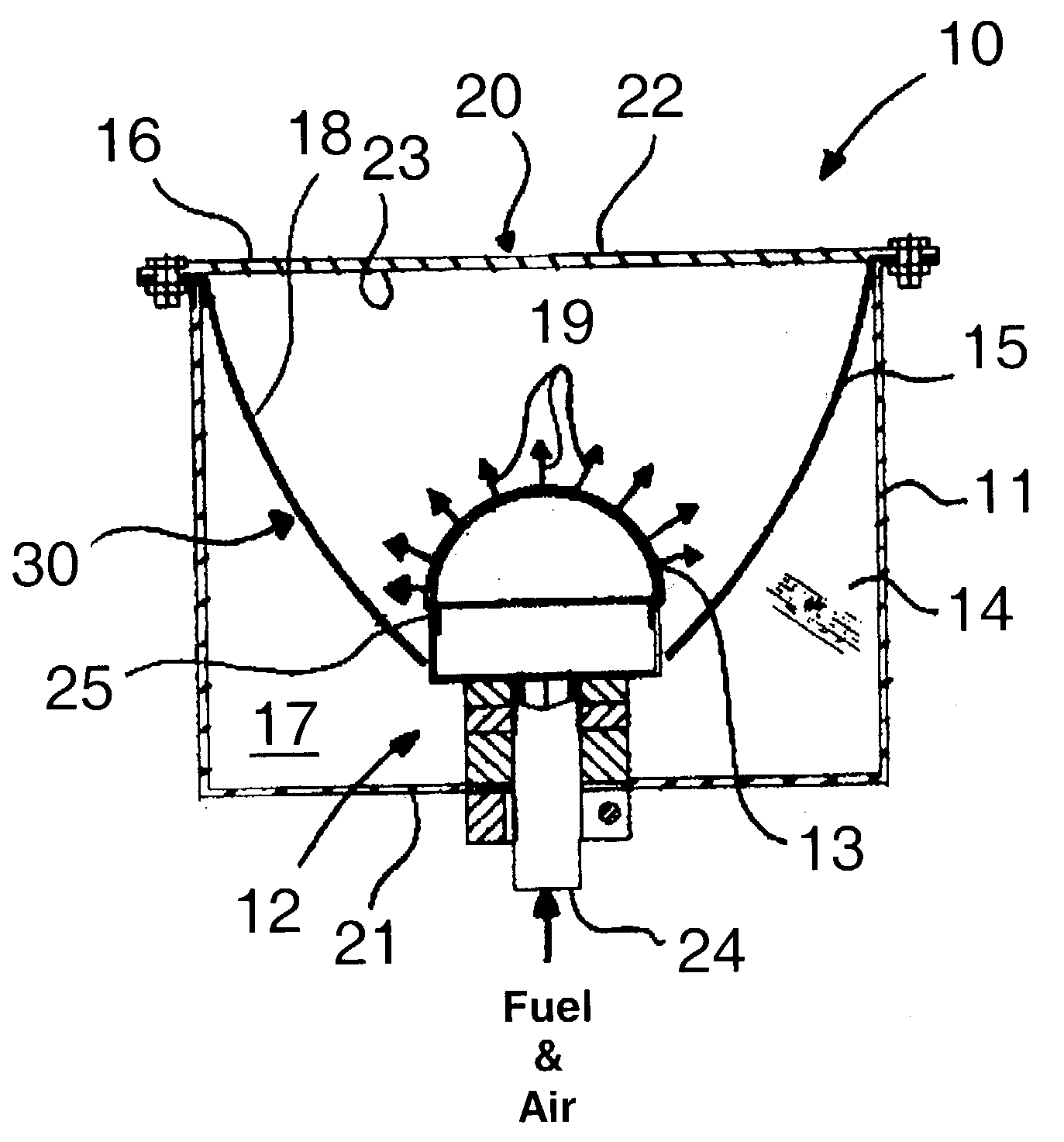

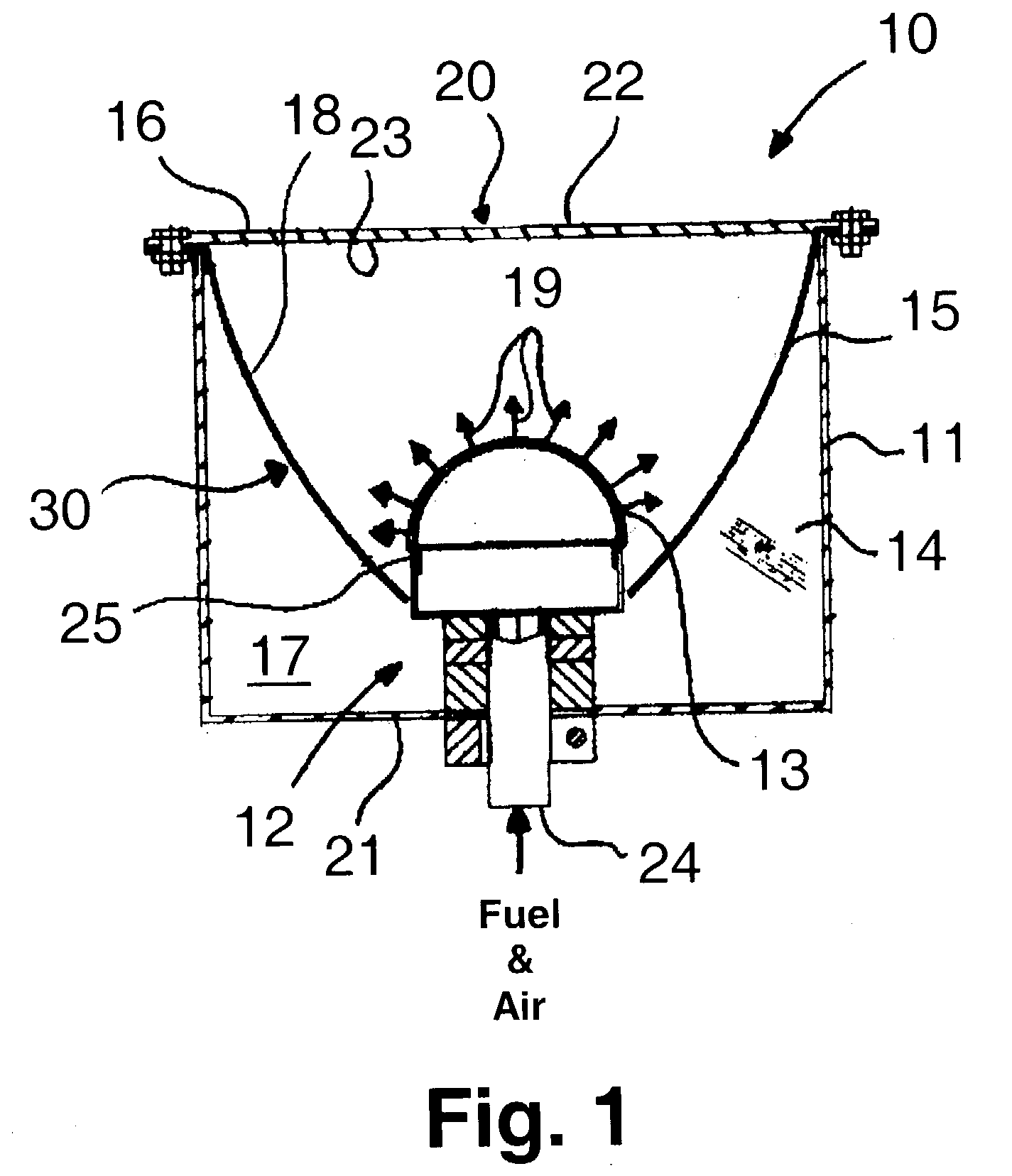

Flame-less infrared heater

InactiveUS20040152028A1Extended stayEven heat distributionDomestic stoves or rangesCapillary burnersCombustorEngineering

A heating apparatus including a housing having a radiant energy output side and an oppositely disposed burner side. The radiant energy output side includes at least one re-radiating surface. Disposed within the housing proximate the burner side and having a burner outlet facing the radiant energy output side is a burner. At least one concave reflector is disposed around the burner and is oriented to reflect heat from said burner toward said radiant energy output side of said housing.

Owner:GAS TECH INST

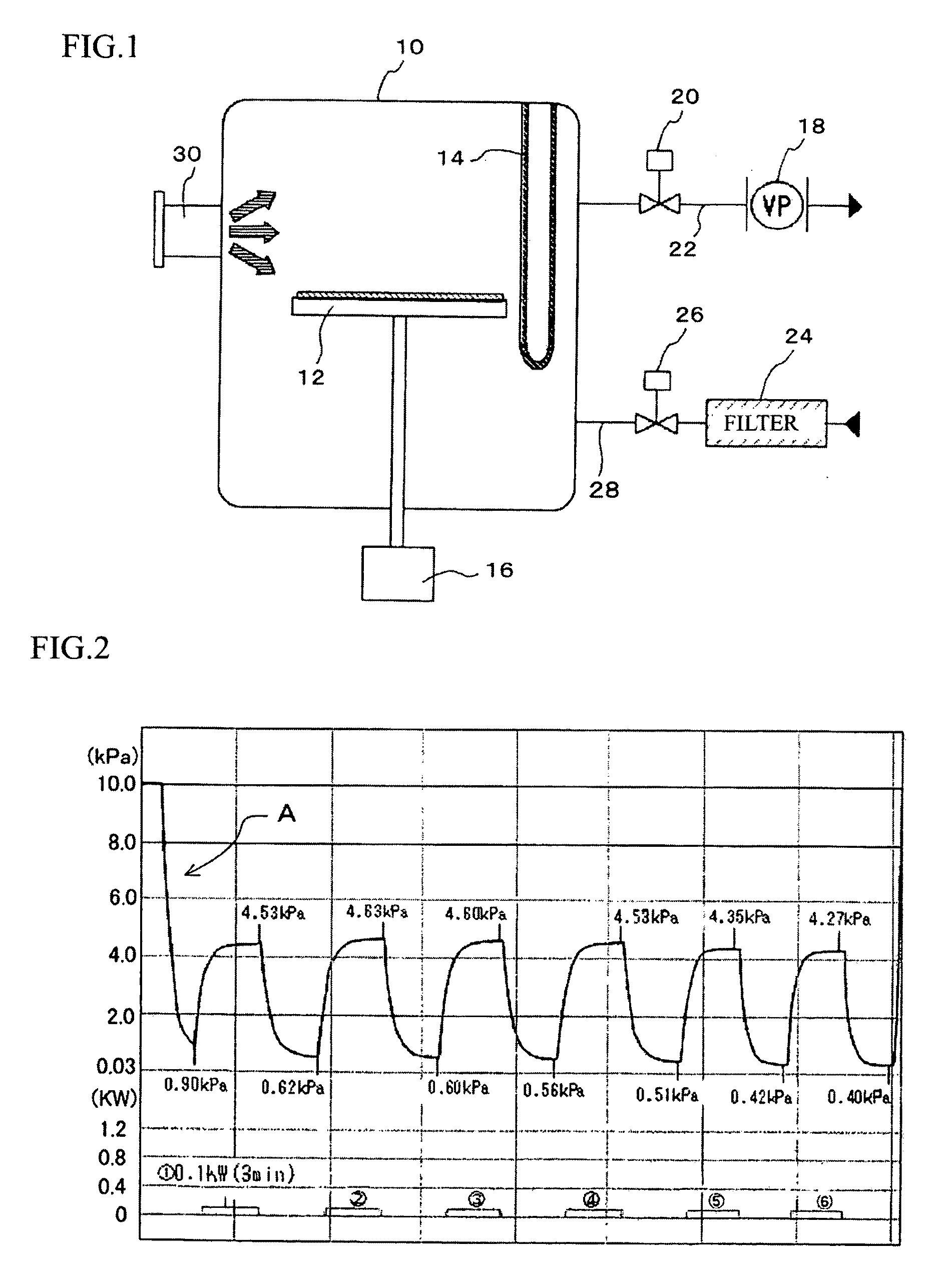

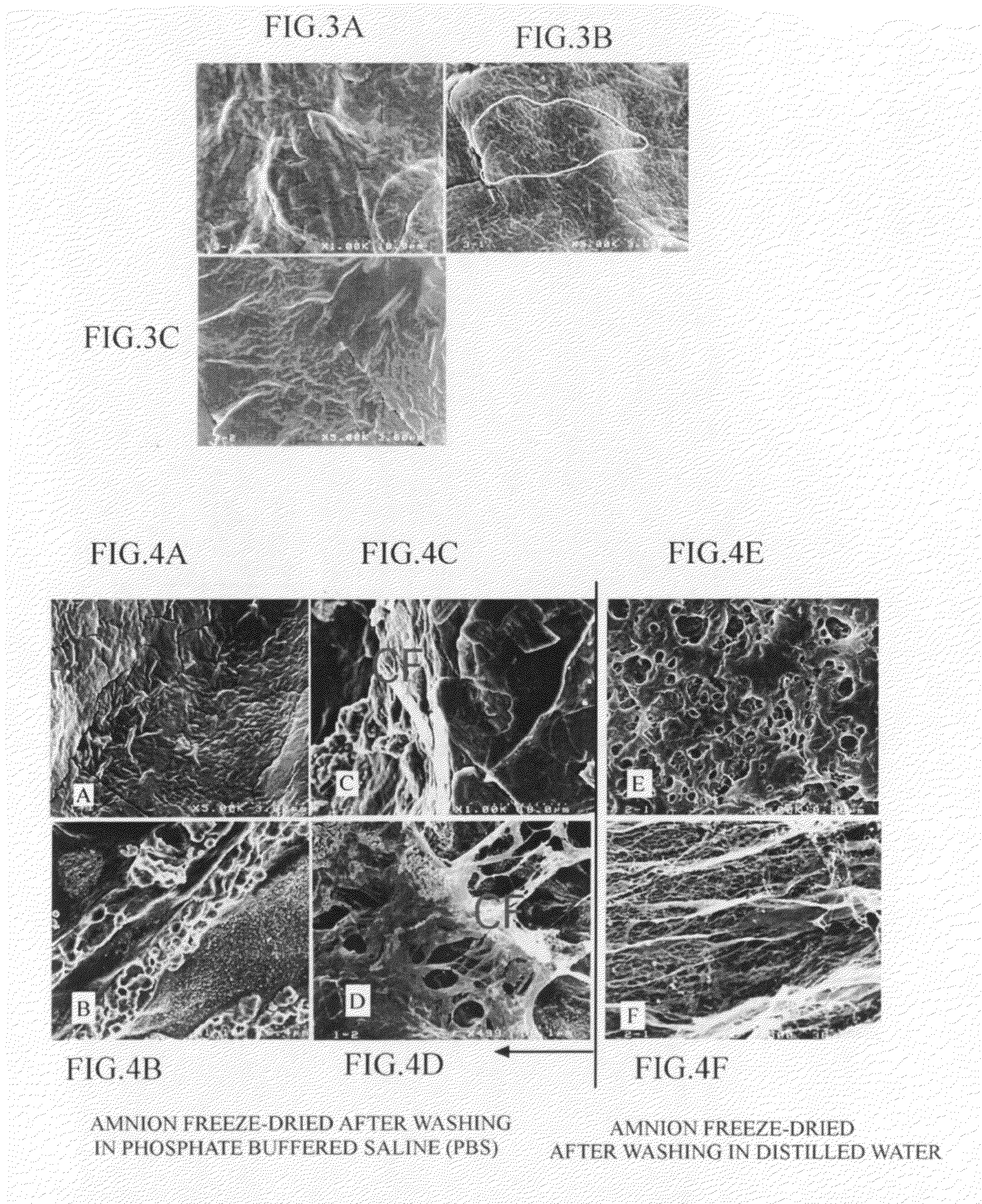

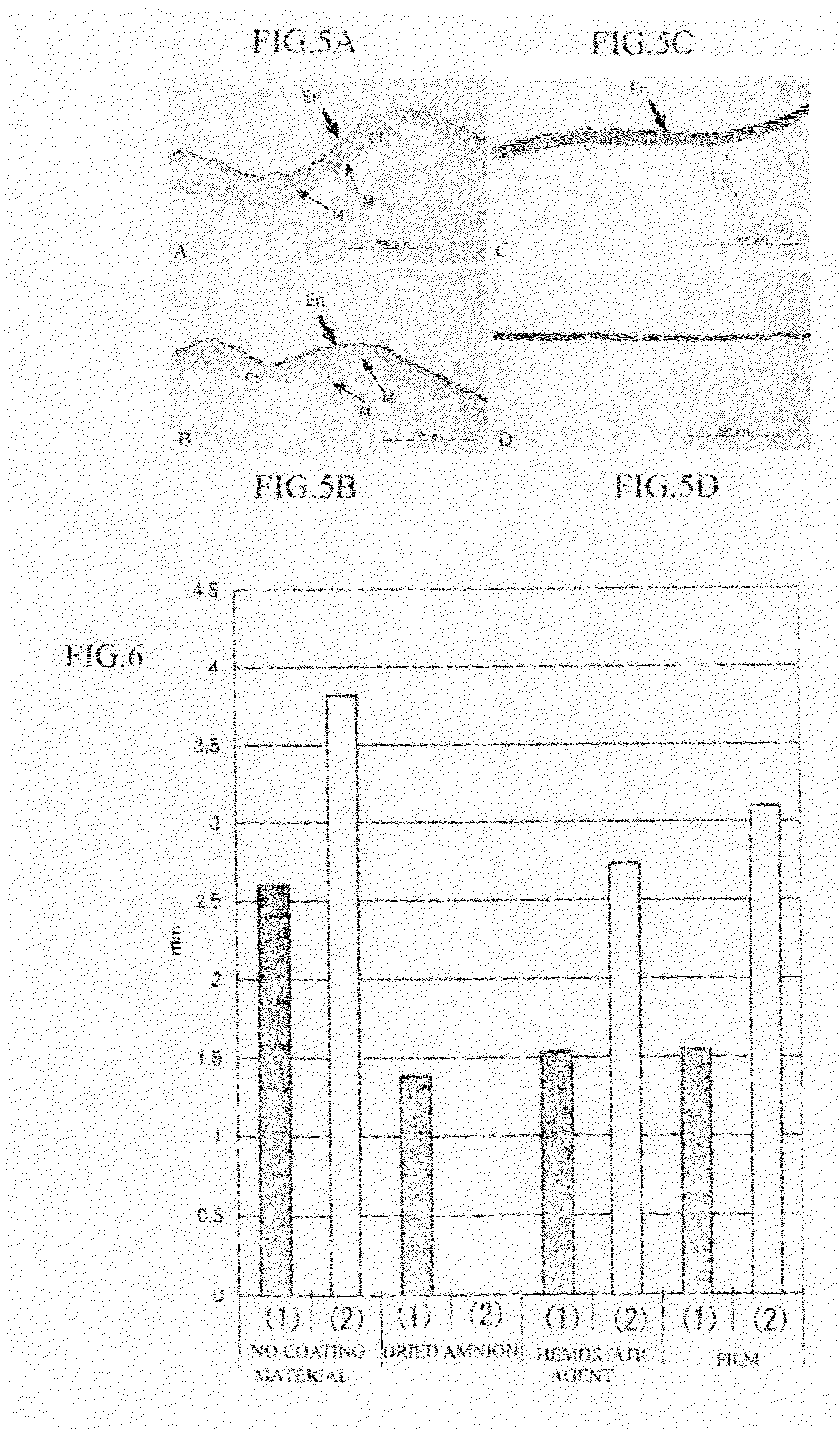

Dried amnion and method for drying teatment of amnion

ActiveUS20090258082A1Reduce pointsAvoid overall overheatingSenses disorderDead animal preservationBasementMicrowave

The present invention provides a dried amnion which is dried with maintaining tissues of a raw amnion and can be easily stored for a prolonged period of time. An amnion which is dried with maintaining cells and tissues of a raw amnion can be produced by repeating a pressure-reducing operation and a pressure-recovery operation several times, the pressure-reducing operation comprising continuously heating a raw amnion placed in a treatment vessel by a far-infrared heater provided in the treatment vessel and reducing the pressure of the inside of the treatment vessel, and the pressure-recovery operation comprising recovering the reduced pressure of the inside of the treatment vessel with heating the amnion by microwaves irradiated from a microwave heating apparatus provided outside of the treatment vessel, and the amnion is characterized by retaining basement membranes and connective tissues which are constituents of the raw amnion.

Owner:AMNOS

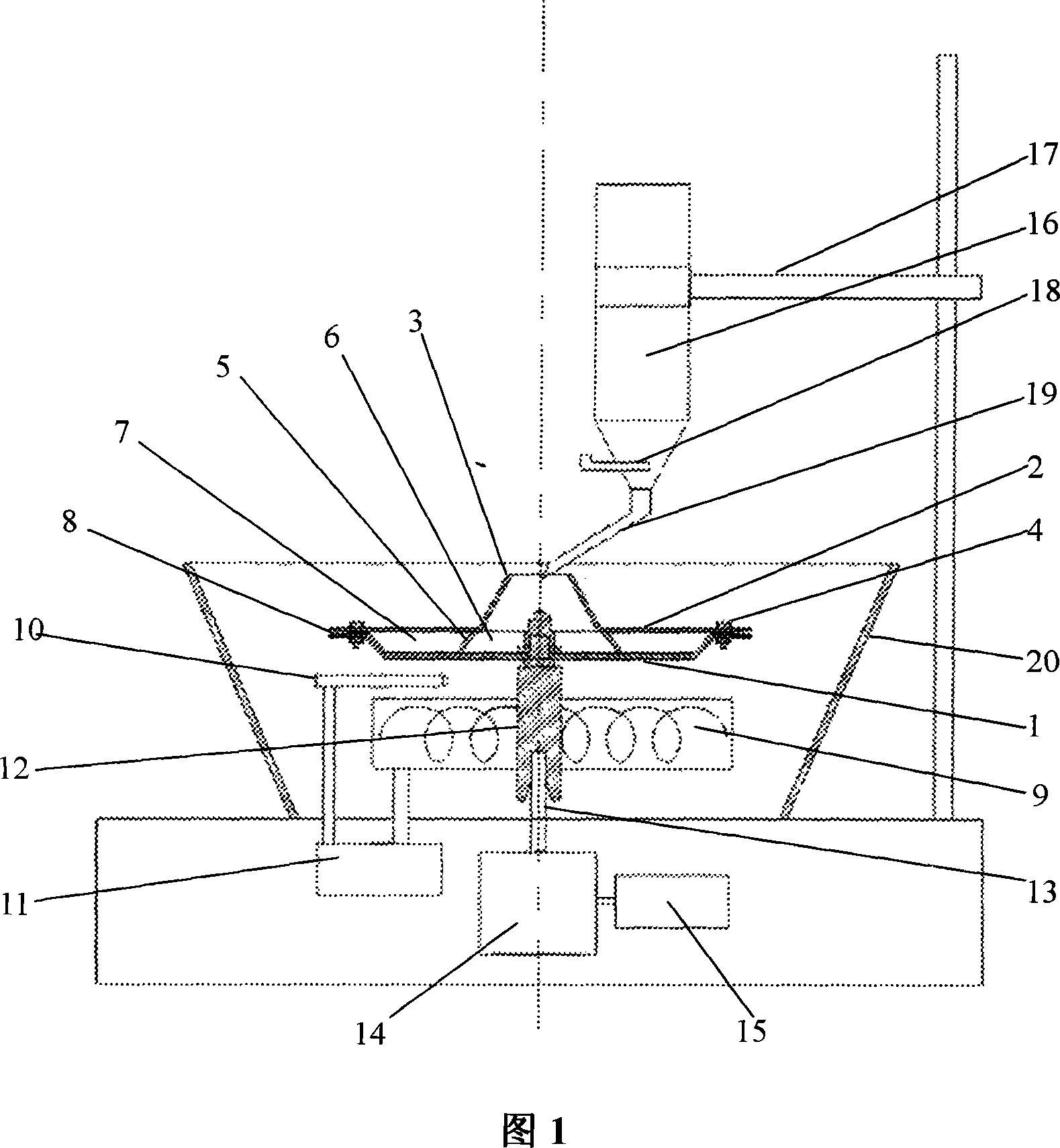

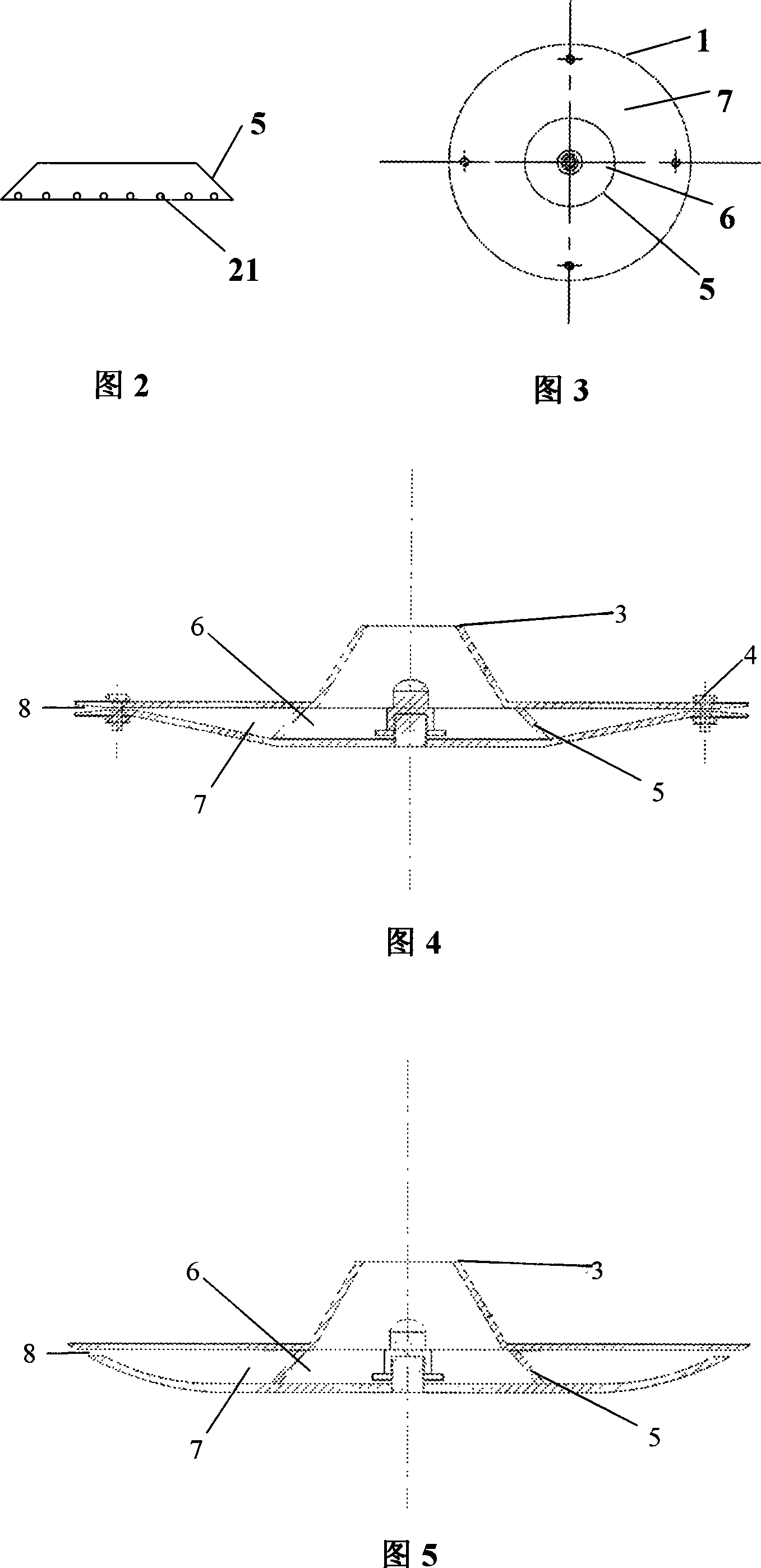

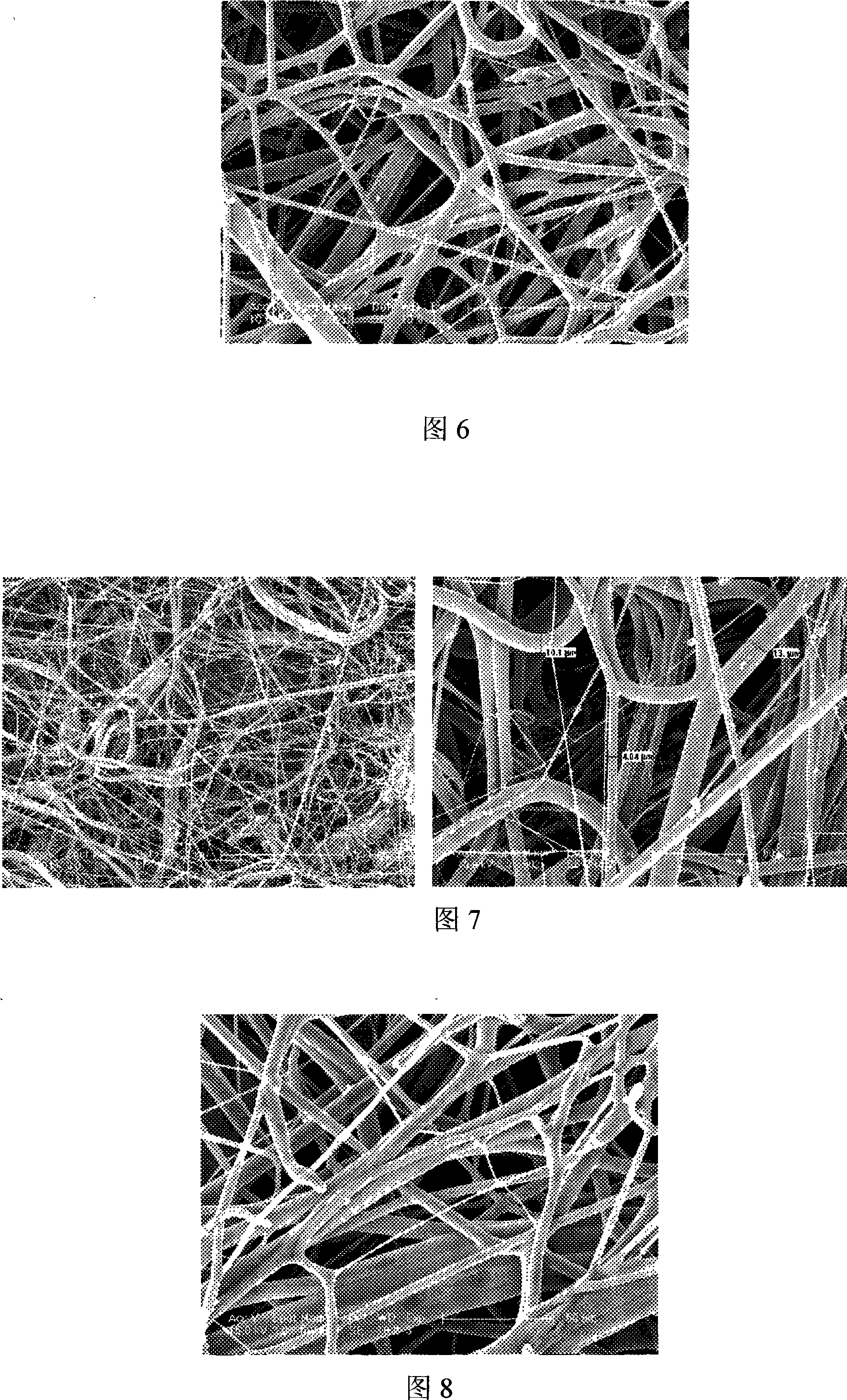

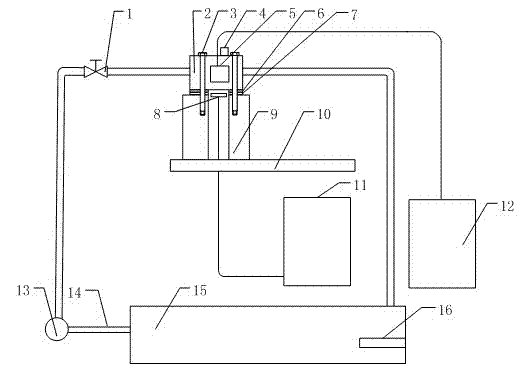

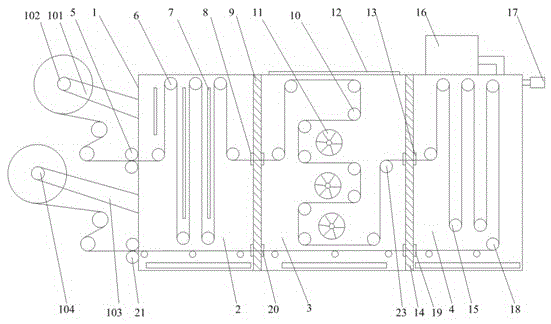

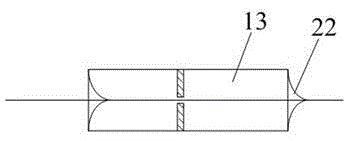

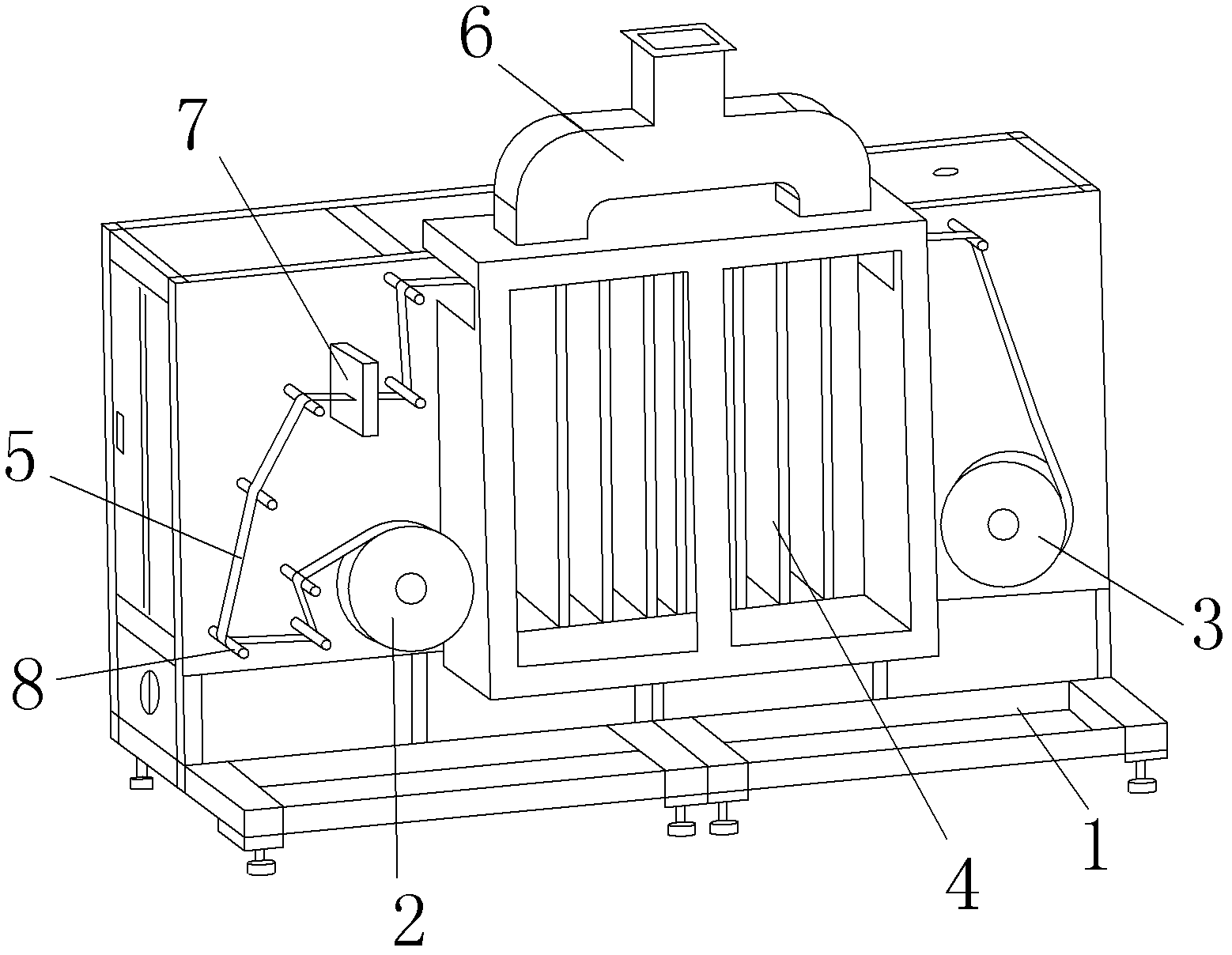

Device for producing nonwoven fabric with fused mass and solution centrifugal spinning

InactiveCN101220544AHigh mechanical strengthWide range of sizesMelt spinning methodsNon-woven fabricsTemperature controlEngineering

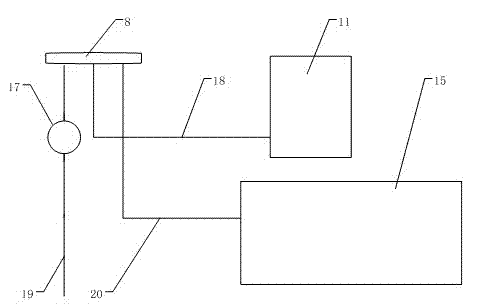

The invention relates to a device of a melt and solution centrifugal spinning preparation of a non-woven fabric which comprises (1) a rotating disk, the side of which is in the shape of an inverted truncated cone or the symmetric rotating surfaces; (2) a cover of the rotating disk; (3) a feed inlet; (4) a bolt; (5) a ring-shaped spacer with holes; (6) an internal cavity of the rotating disk; (7) an external cavity of the rotating disk; (8) a spinning nozzle of the rotating disk; (9) a homothermal infrared heater; (10) a temperature-sensitive probe; (11) a temperature-controlled device; (12) a stationary shaft of the rotating disk; (13) a motor transmission shaft; (14) a main motor; (15)a pressure regulating device; (16)a container; (17)a bracket; (18)a flashboard; (19) a delivery pipe; (20) a fiber receiver; and holes (21) of the ring-shaped spacer (5). The device of the melt and solution centrifugal spinning preparation of the non-woven fabrics provided by the can be used for not only the non-woven fabrics which are made by the melt and solution centrifugal spinning preparation but also the non-woven fabrics which are made by the invention of the device.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

High speed cooking device and method

InactiveUS20030056658A1Improve the heating effectDouble toasting/cooking capabilityDomestic stoves or rangesLighting and heating apparatusThermal energyProcess engineering

A cooking device that is capable of rapidly cooking food products such as in toasting bread products or cooking pizza. The cooking device uses air impingement from above and / or below the food product. In some cases an infrared heater is additionally used to impart a desired color and crunchiness about a surface of the food product. In some cases, a boost in thermal energy is applied to the bottom of the food product vis-à-vis the top thereof. In some cases, the boost is due to an extra heater, which may be gas or electric. The device is particularly adapted for toasting bread products, cooking sandwich products (toasting the bread and heating the sandwich filler) and / or cooking pizza. Rapid cooking times are achieved by delivering more thermal energy to the top or bottom of the food product, depending on the type thereof, to give quality and speed. For example, a pizza can be cooked to have a crisp bottom without burning a cheese topping.

Owner:LINCOLN FOODSERVICE PRODS

System and Method for Heating Carbon Fiber Using Infrared Radiation in a Fiber Placement Machine

ActiveUS20070187021A1Heating fastInexpensive and quick to reactMechanical working/deformationLamination ancillary operationsFiberCarbon fibers

An apparatus comprising a fiber placement head assembly and an infrared heating assembly is provided. The fiber placement head assembly includes a compaction roller assembly and a feeder assembly. An infrared heating assembly, a cooling mechanism, temperature sensors, and a controller are operably coupled to the fiber placement head assembly. The infrared heating assembly includes an infrared heater that generates a heating profile. The heating profile defines a heating zone on either a tool or previously laid tows. If the burn point of either the tool or previously laid tows within the heating zone is approached, the controller, which receives temperature readings from the temperature sensors, simultaneously disables the infrared heater and activates the cooling mechanism. As such, the tool and the previously laid tows are protected from being ruined due to an over temperature condition.

Owner:INGERSOLL MACHINE TOOLS

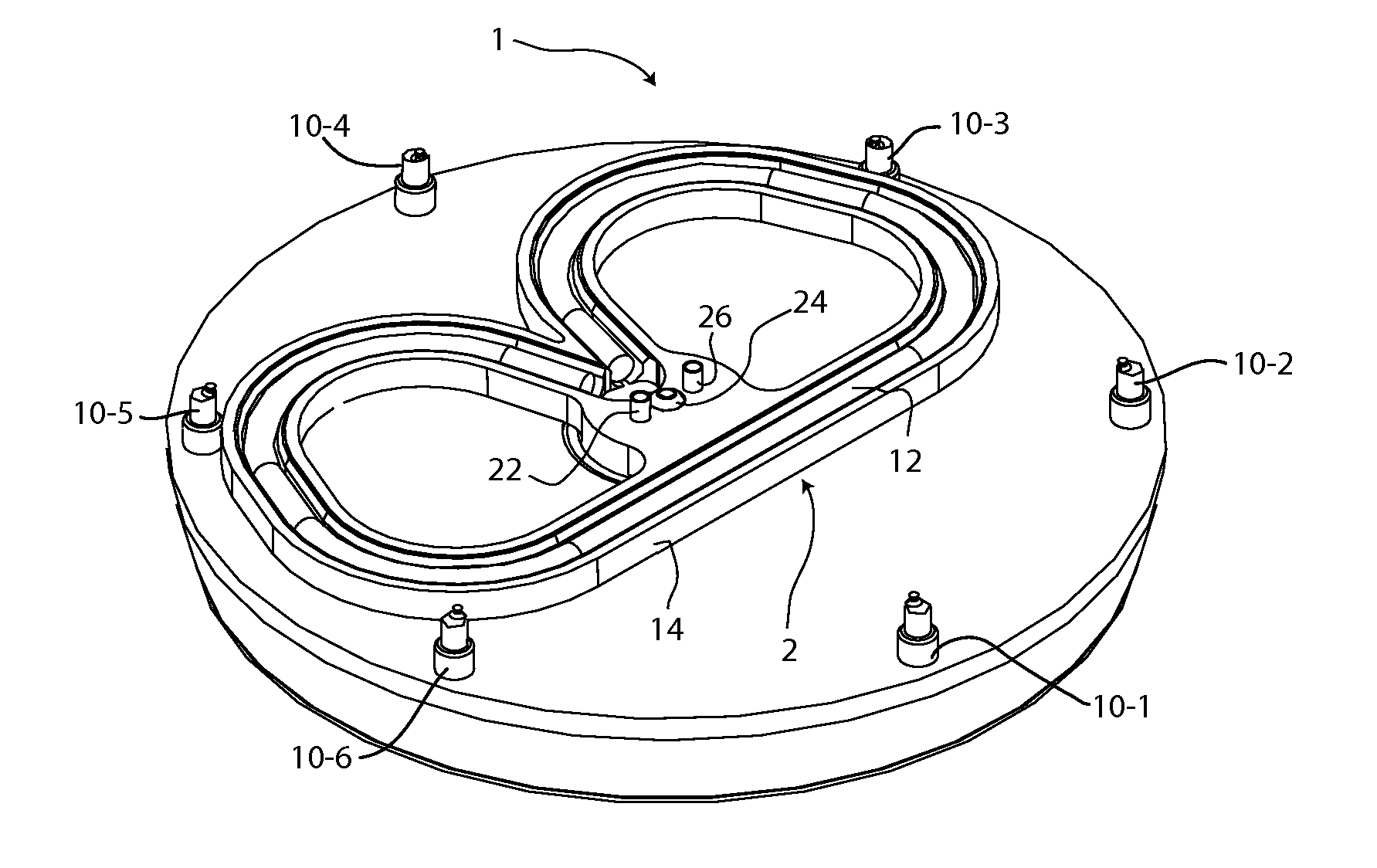

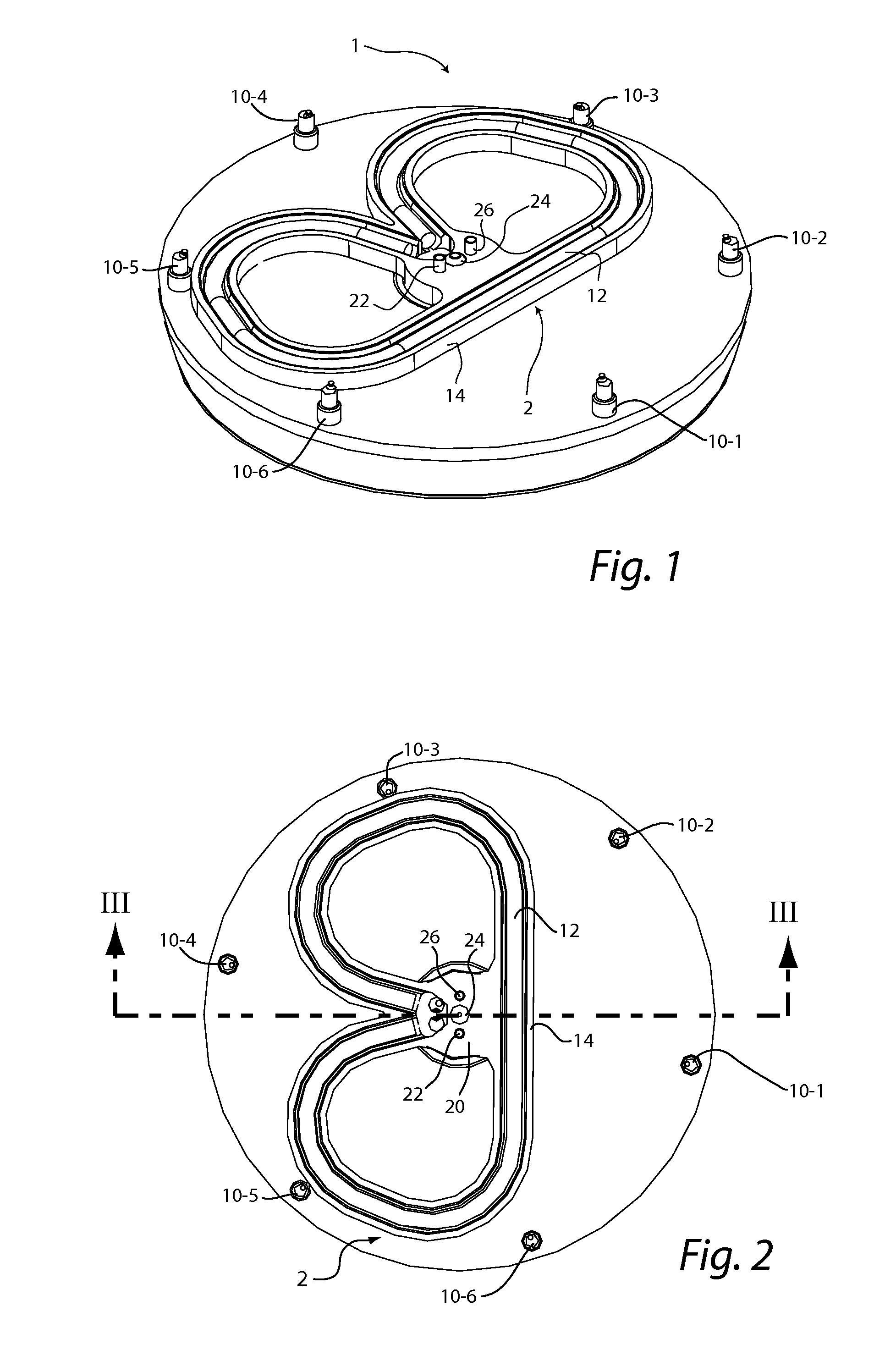

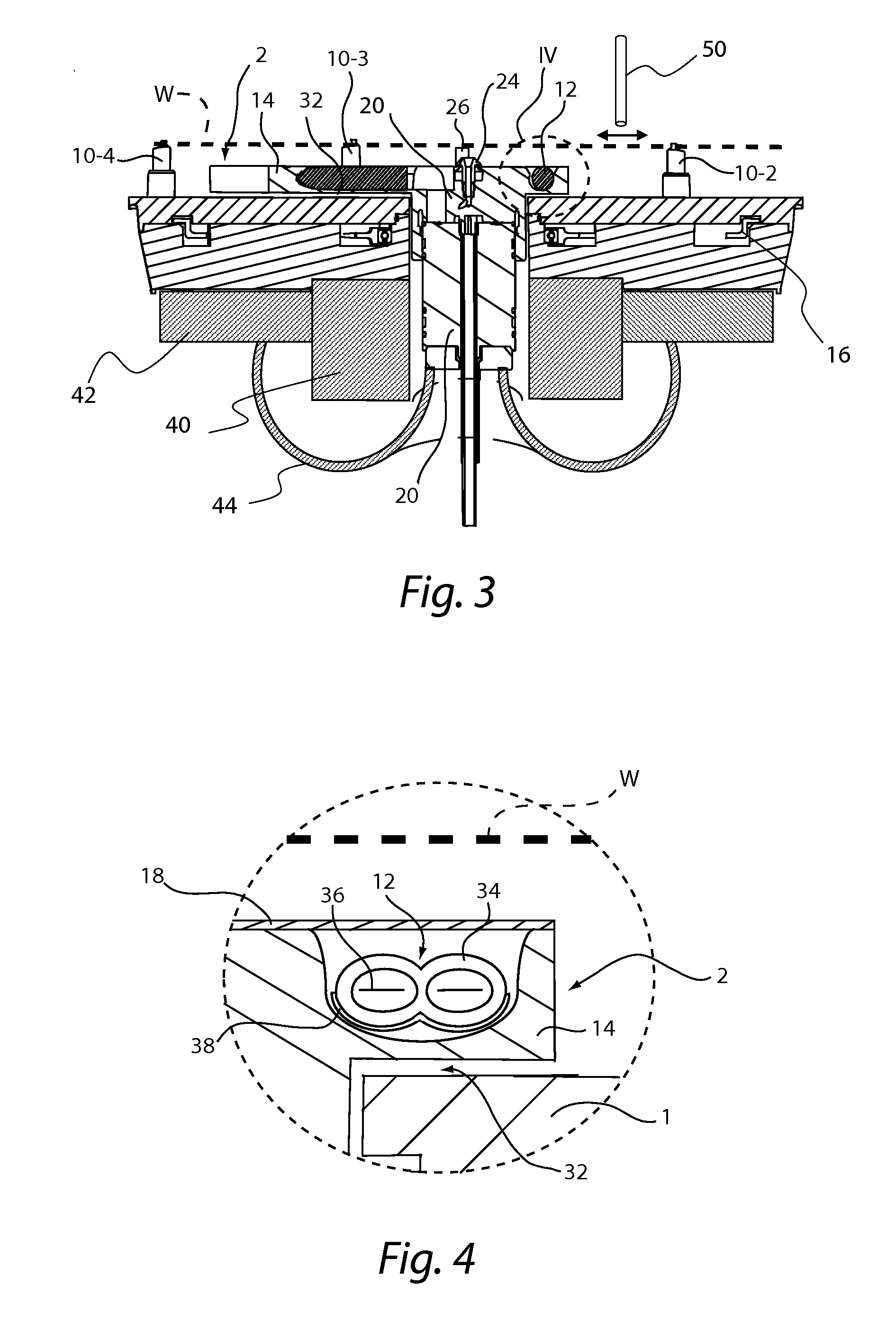

Method and apparatus for liquid treatment of wafer shaped articles

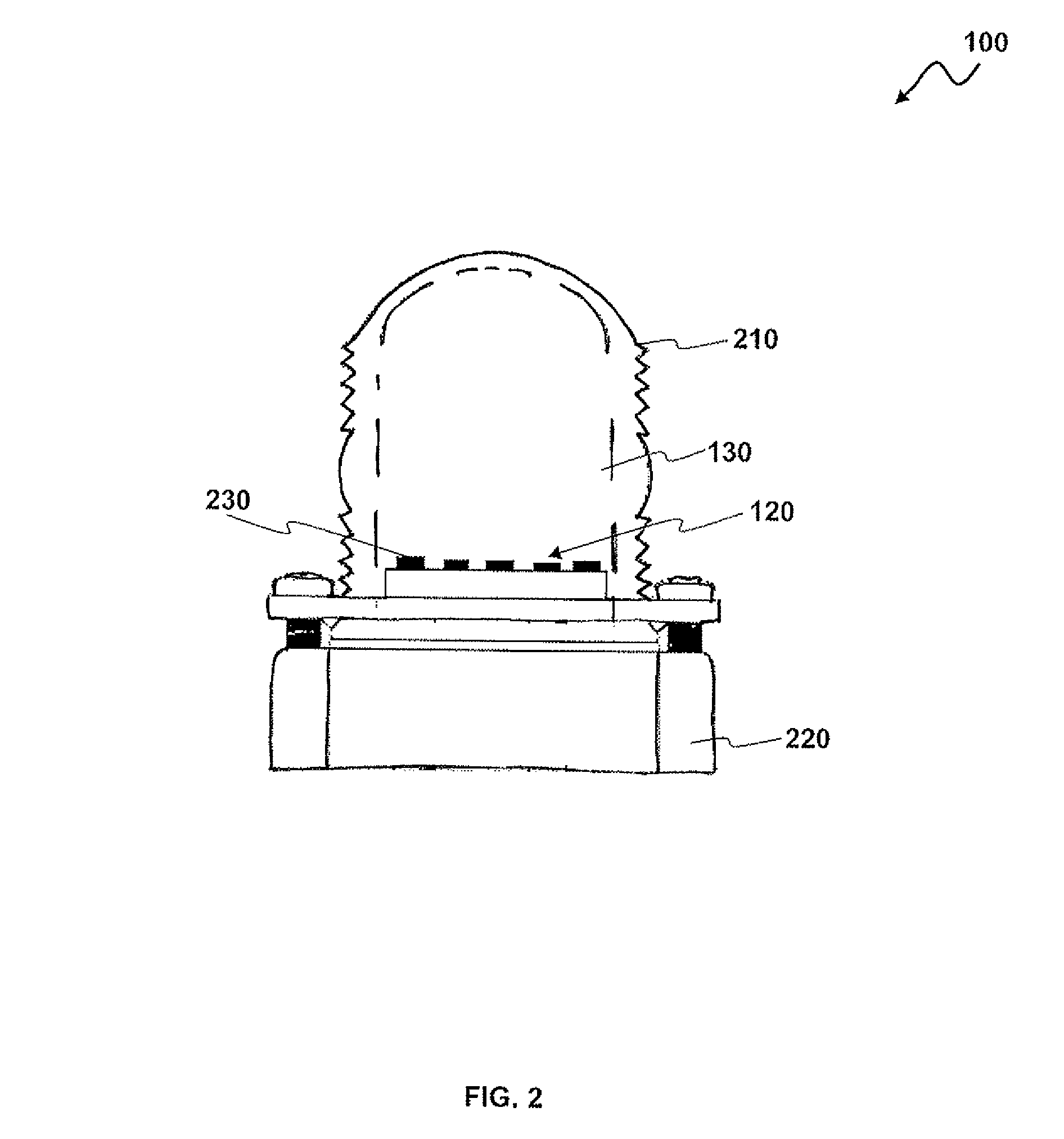

ActiveUS20130061873A1Rapid coolingElectrostatic cleaningSemiconductor/solid-state device manufacturingSpinsMechanical engineering

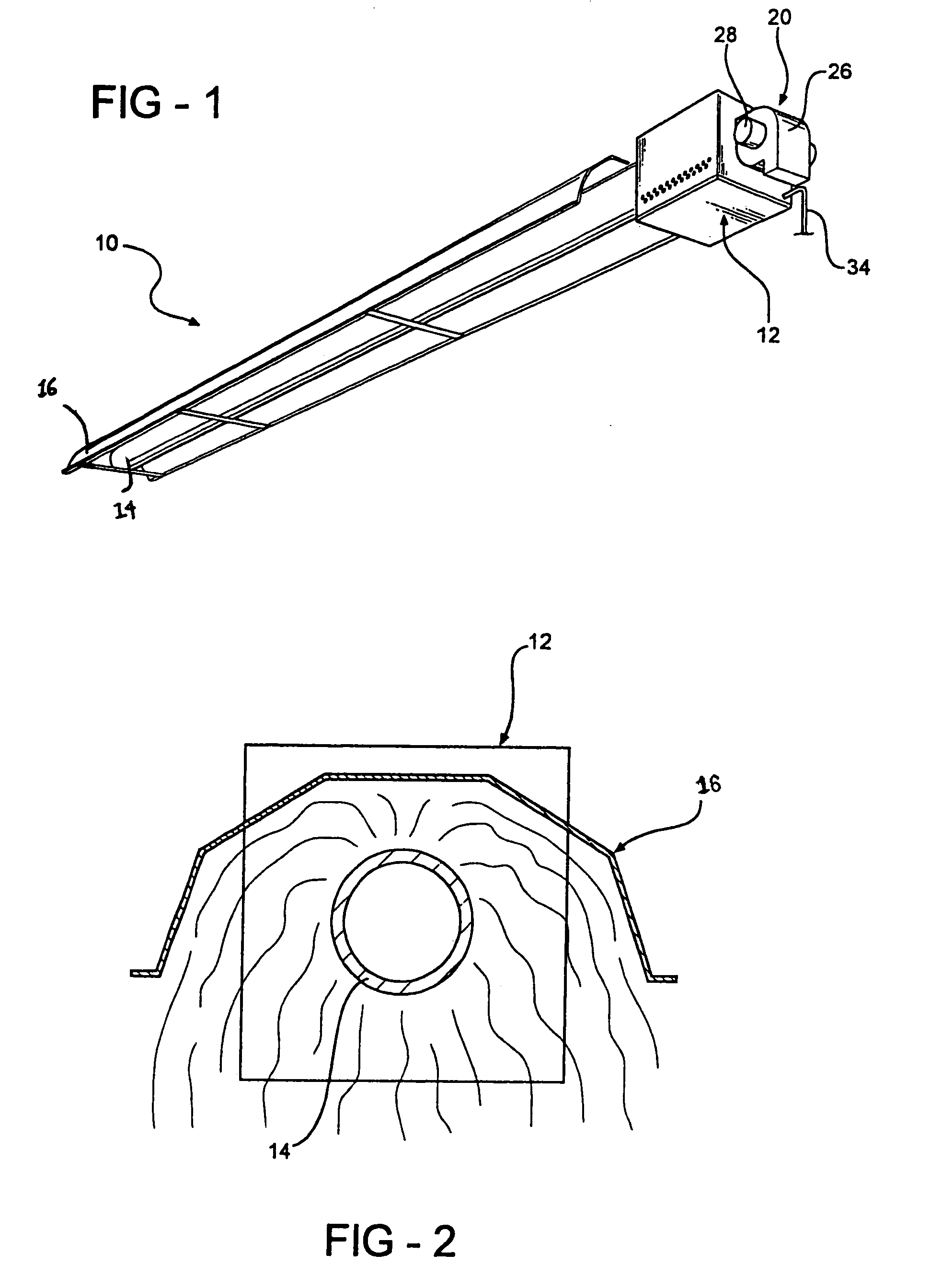

In an apparatus and method for treating a wafer-shaped article, a spin chuck is provided for holding a wafer-shaped article in a predetermined orientation wherein a lower surface of the wafer-shaped article is spaced a predetermined distance from an upper surface of the spin chuck. A heating assembly comprising at least one infrared heater is mounted above the upper surface of the spin chuck and below a wafer-shaped article when mounted on the spin chuck. The heating assembly is stationary in relation to rotation of the spin chuck.

Owner:LAM RES AG

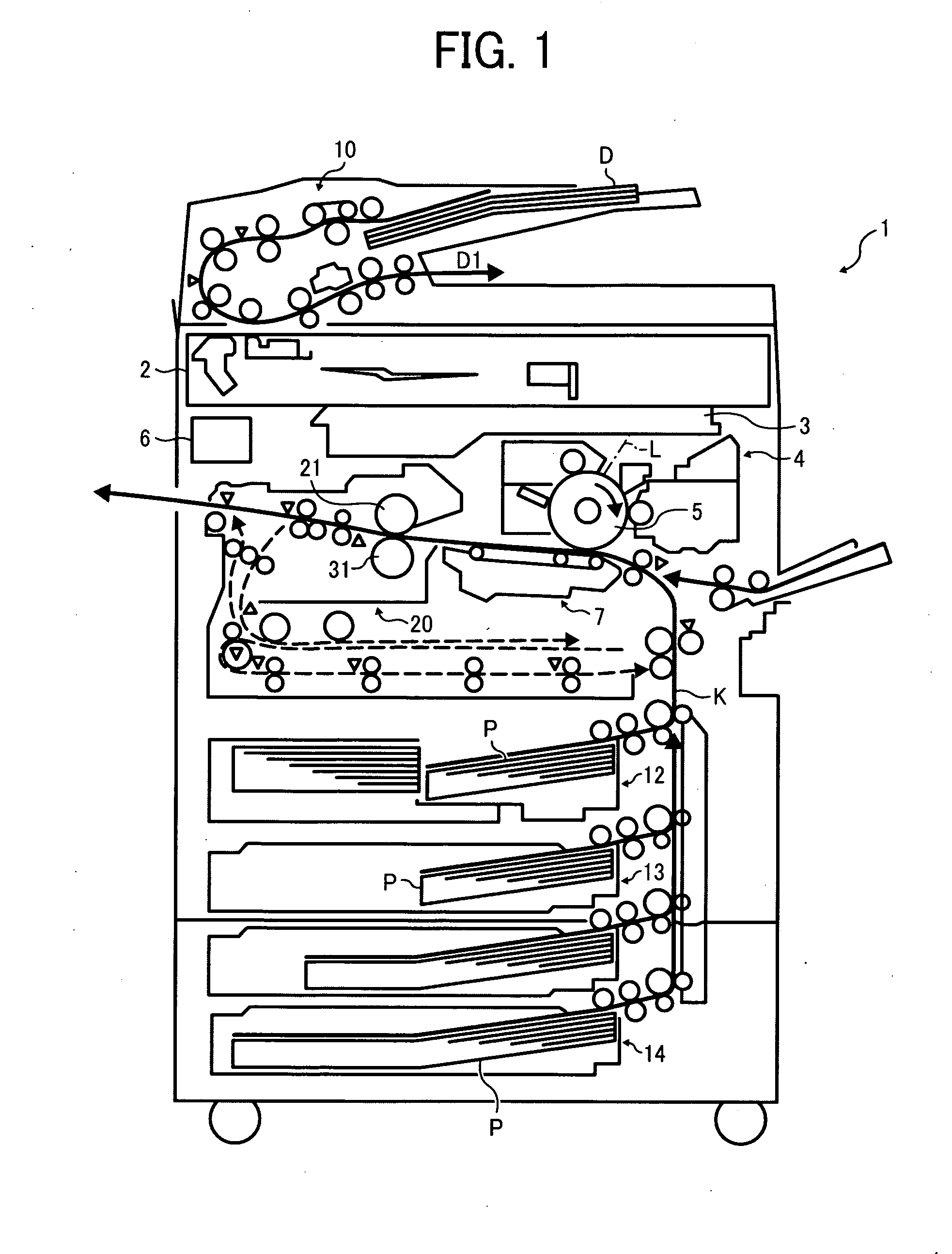

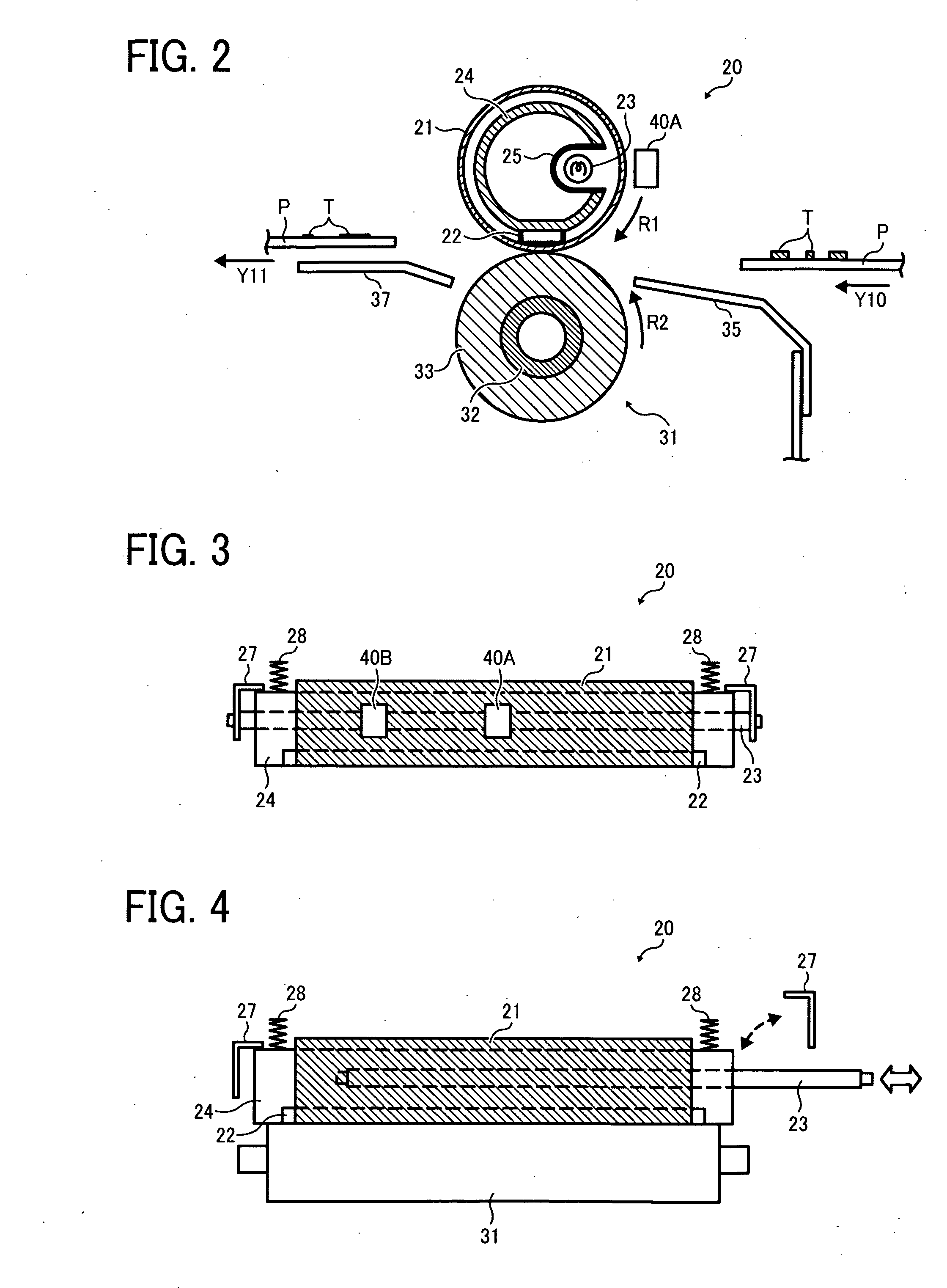

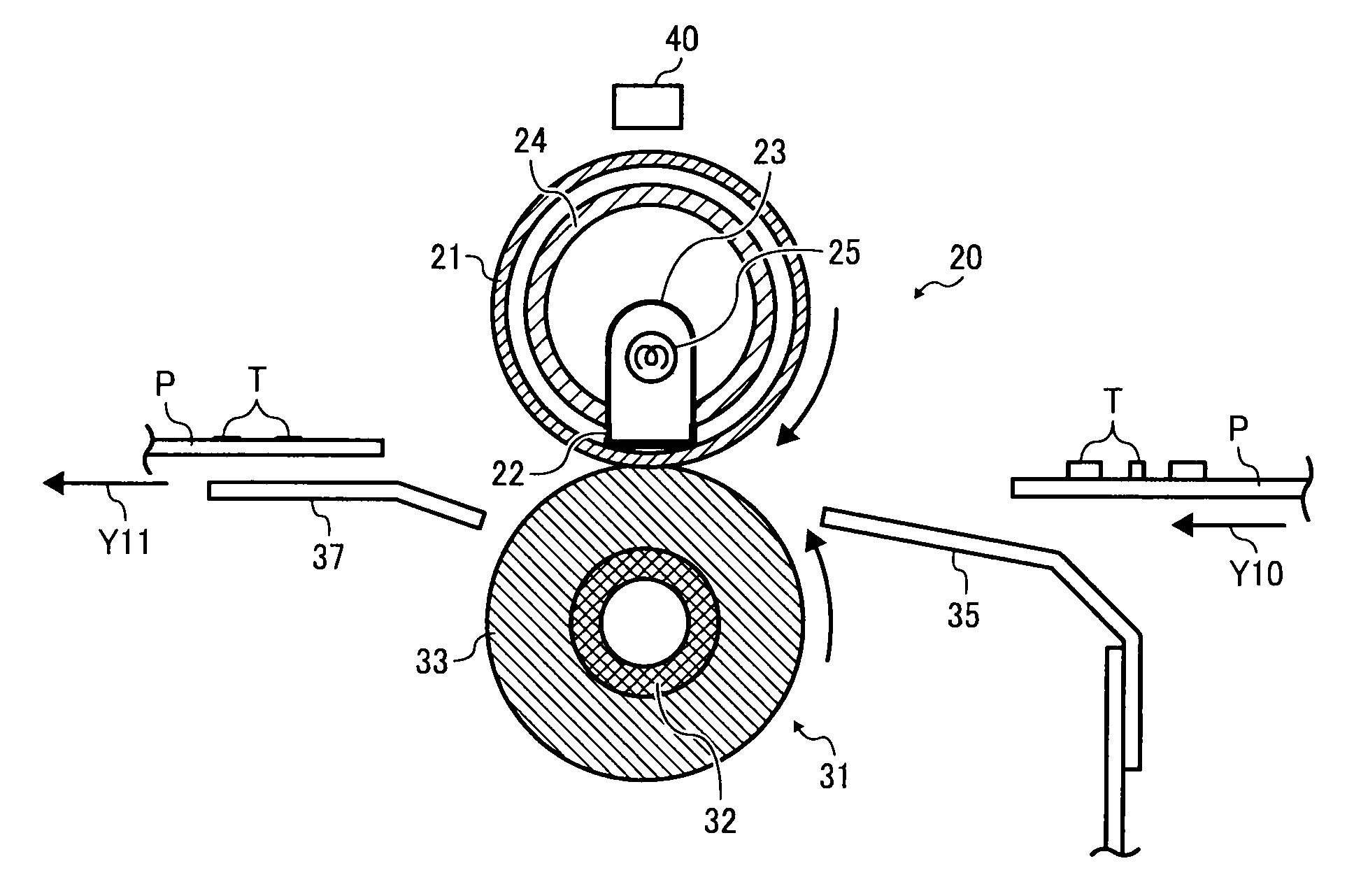

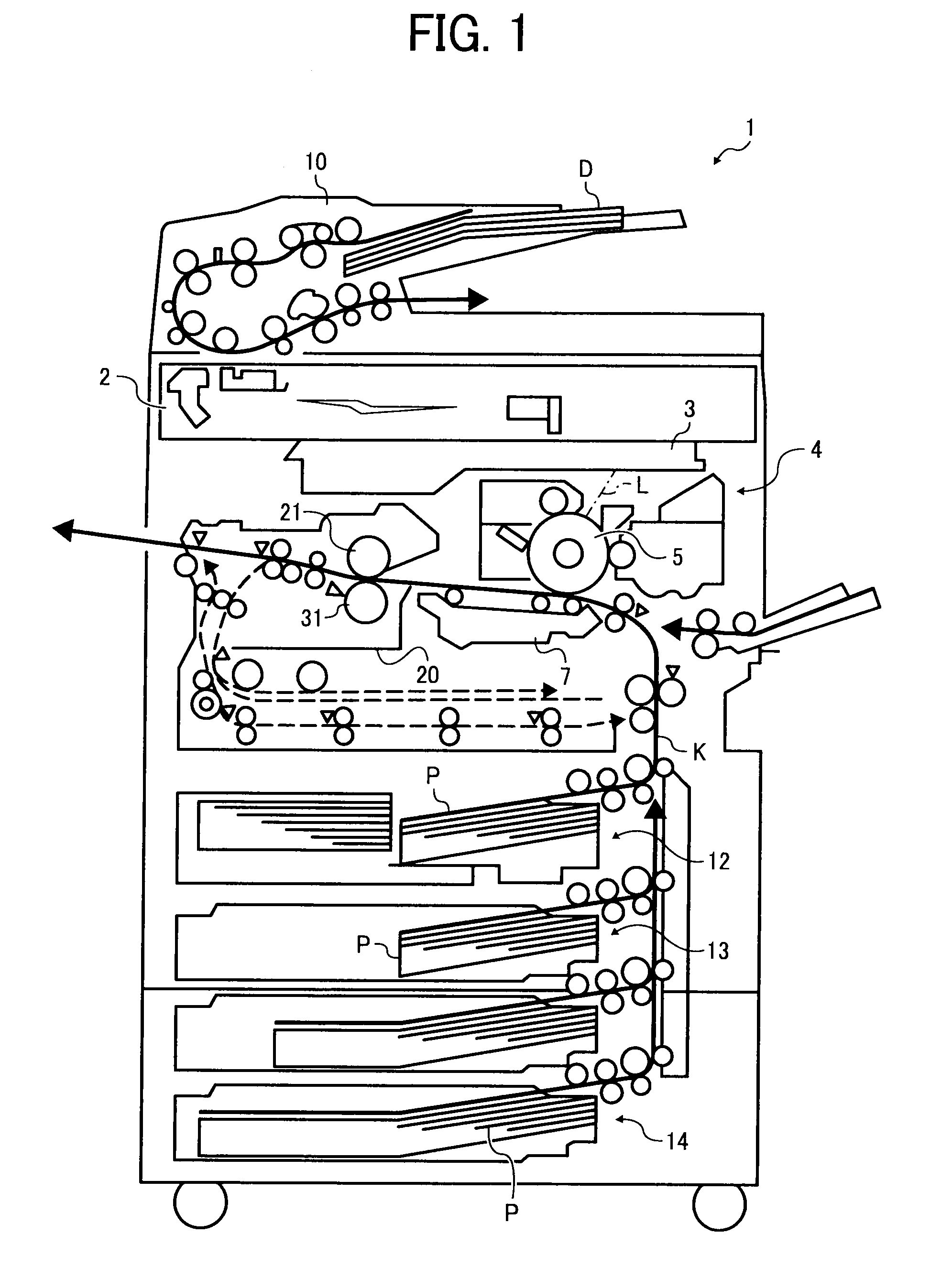

Fixing device and image forming apparatus incorporating same

In a fixing device, a first reflection plate covers a part of an outer circumferential surface of an infrared heater in a circumferential direction of the infrared heater along an axial direction of the infrared heater substantially perpendicular to the circumferential direction of the infrared heater. The first reflection plate reflects light emitted by the infrared heater toward a fixing member. At least one light control mirror is provided in at least one end of the first reflection plate in an axial direction of the first reflection plate. At least one second reflection plate opposes the infrared heater via the at least one light control mirror to reflect the light emitted by the infrared heater and passing through the at least one light control mirror toward a center portion of the fixing member in an axial direction of the fixing member.

Owner:RICOH KK

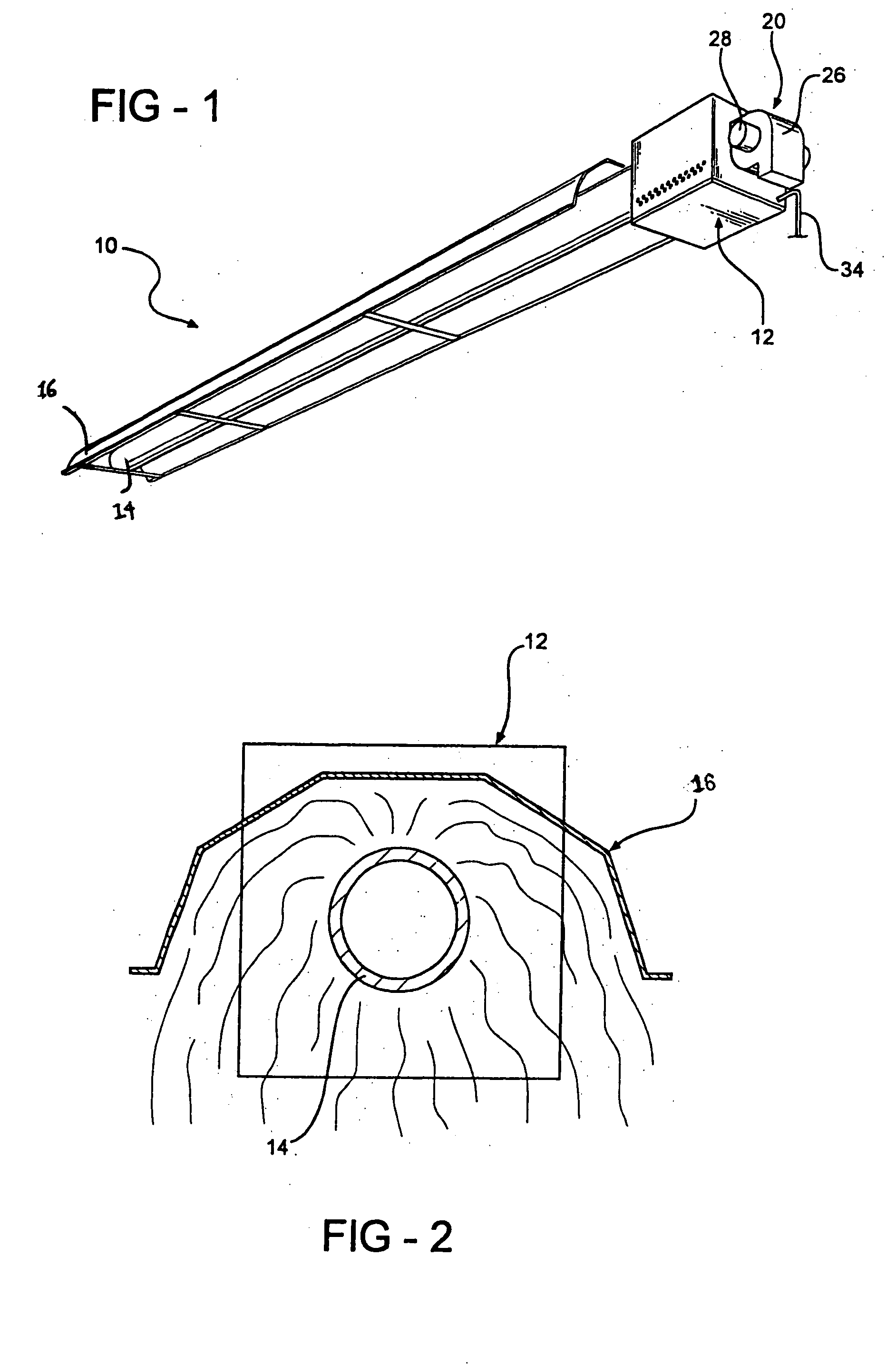

Variable low intensity infrared heater

ActiveUS20050175944A1Improve liquidityEasy to controlDomestic stoves or rangesPilot flame ignitersRadiant heaterCombustor

A radiant heater including a burner having an inlet for receiving an air and gas mixture and an exhaust for emitting exhaust gases generated by combustion of the air and gas mixture within the burner, an elongated radiant heating tube having an inlet for receiving the exhaust gases emitted by the burner, a gas flow control assembly for controlling the flow of gas to the burner, and a blower for controlling the flow of air to the burner. The blower comprises a two-stage blower including a motor having a low winding corresponding to a low blower speed and a high winding corresponding to a high blower speed. The gas flow control assembly comprises a two-stage regulator or two stage two-stage valve having a low setting for delivering a low gas flow to the burner and a high setting for delivering a high gas flow to the burner.

Owner:SOLARONICS

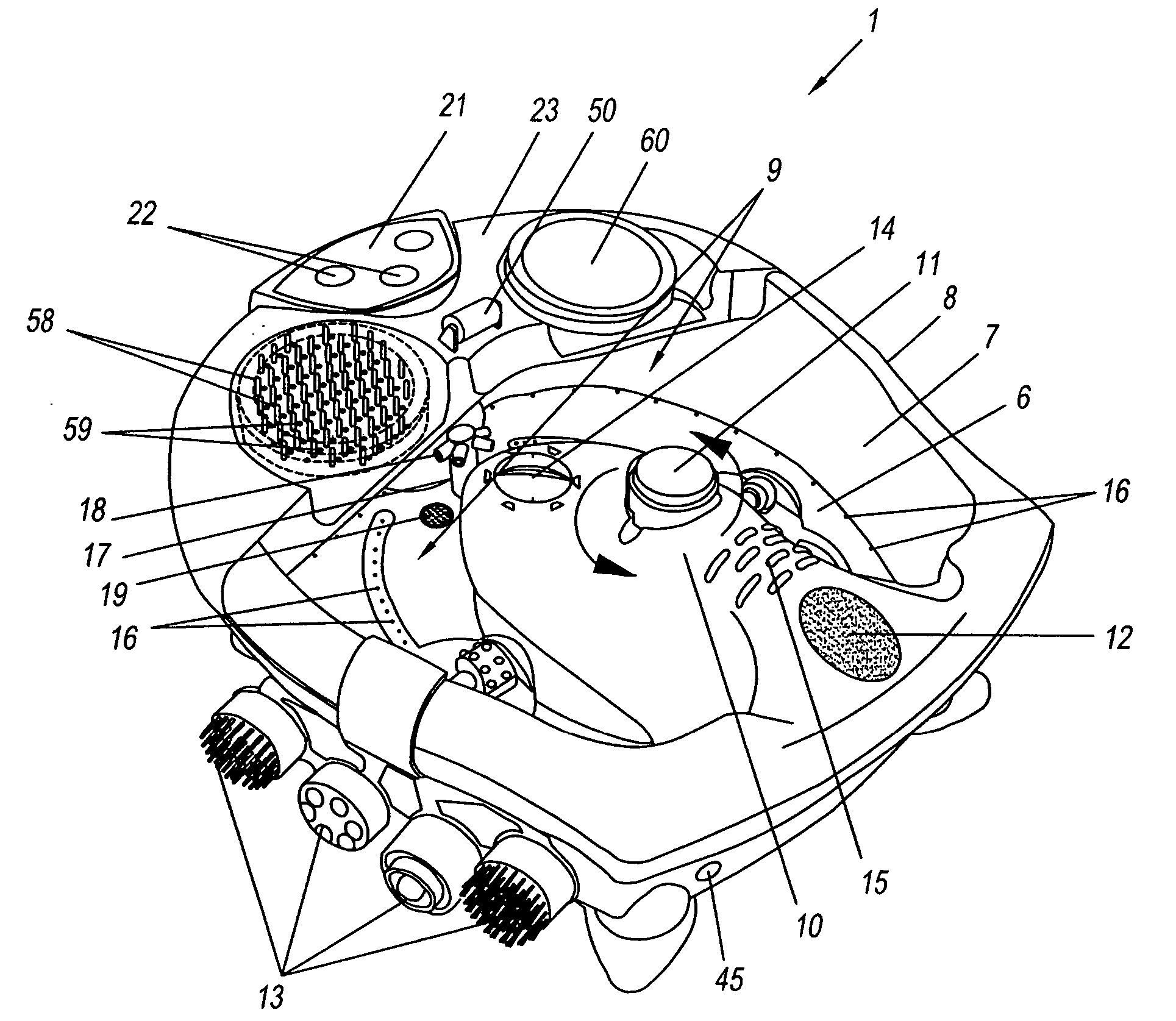

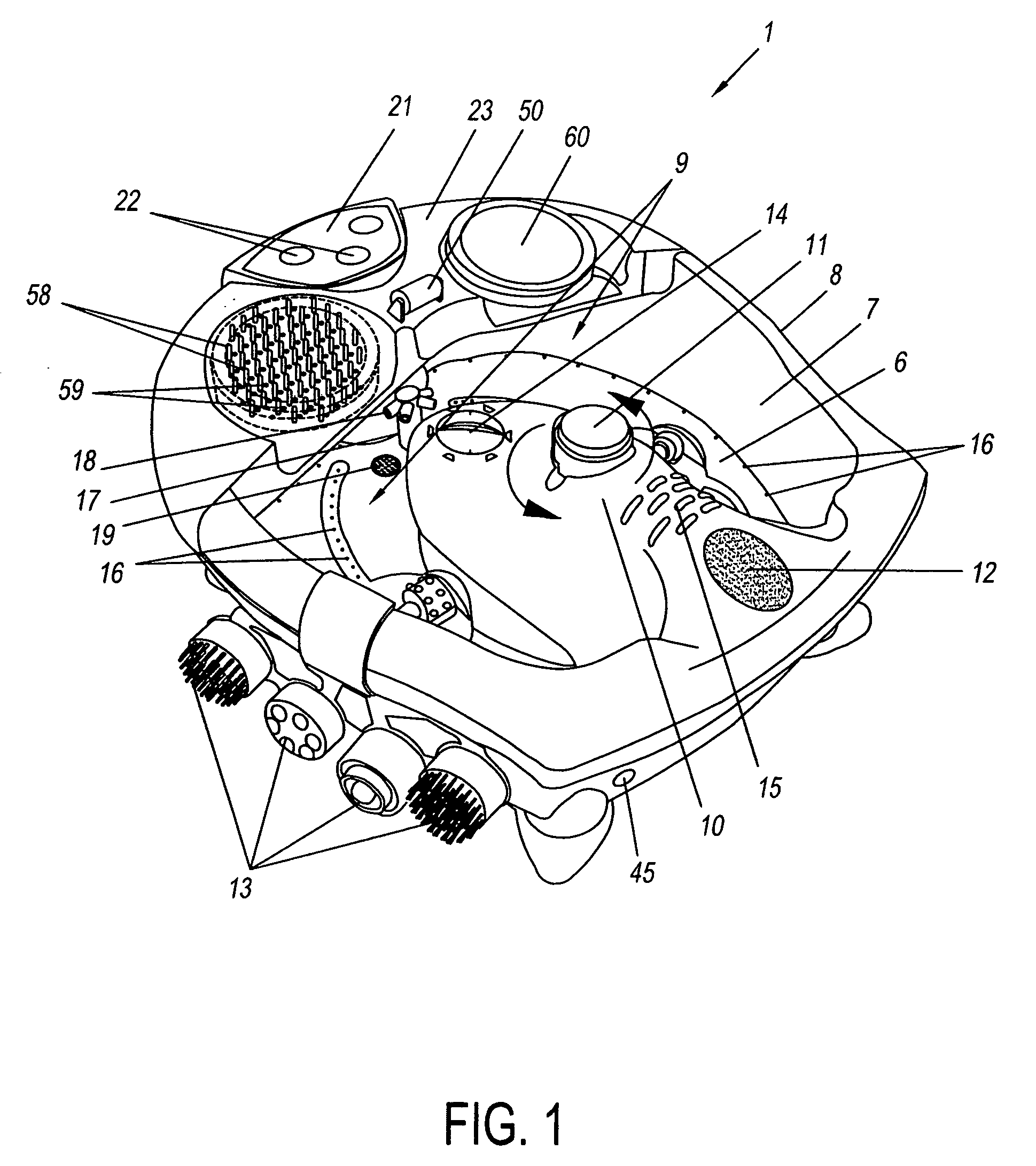

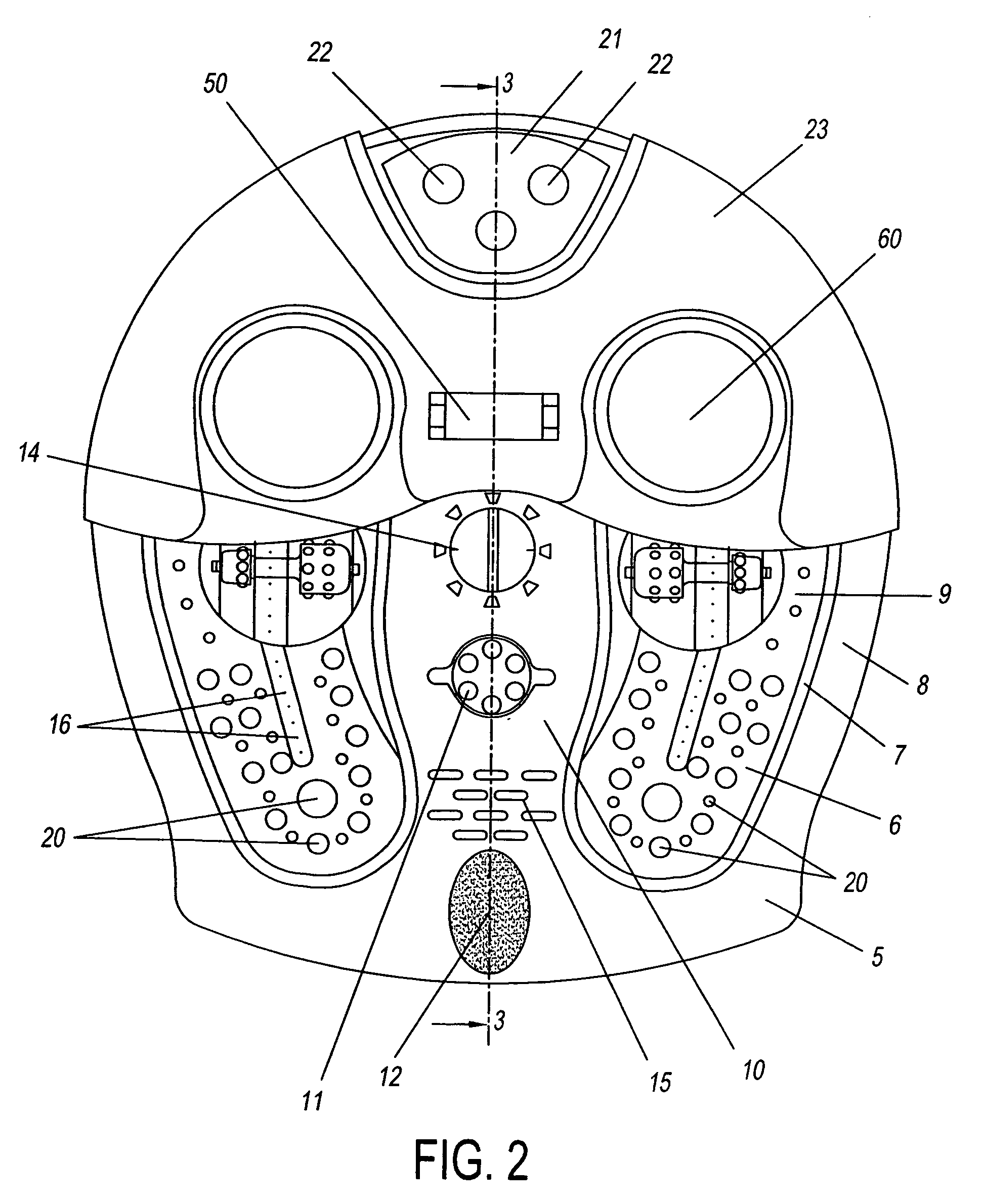

Multifeature foot spa

InactiveUS20050097669A1Easy to relaxAid in overall relaxation and well-beingBathsDouchesControl signalRemote control

A foot spa and a method for controlling the foot spa is provided. The foot spa has a housing defining a reservoir for retaining a volume of fluid, and a lid selectively covering a portion of the reservoir. The foot spa can have any combination of a remote control unit for generating a signal for controlling a plurality of functions of the foot spa, a receiver for receiving the control signal, a retractable cord, an infrared heater, an in-line fluid heater, adjustable fluid jets, a spinning massage attachment function, and a control assembly operable by the foot of the user.

Owner:CONAIR CORP

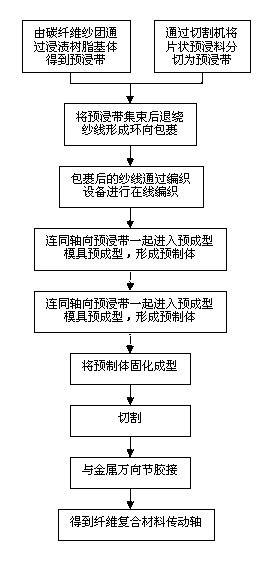

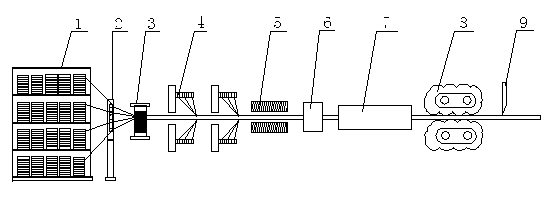

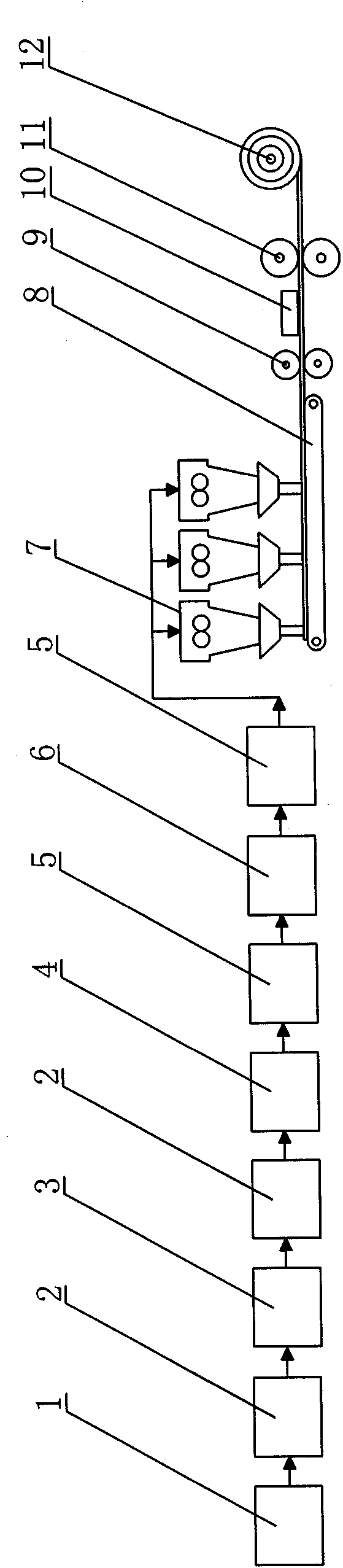

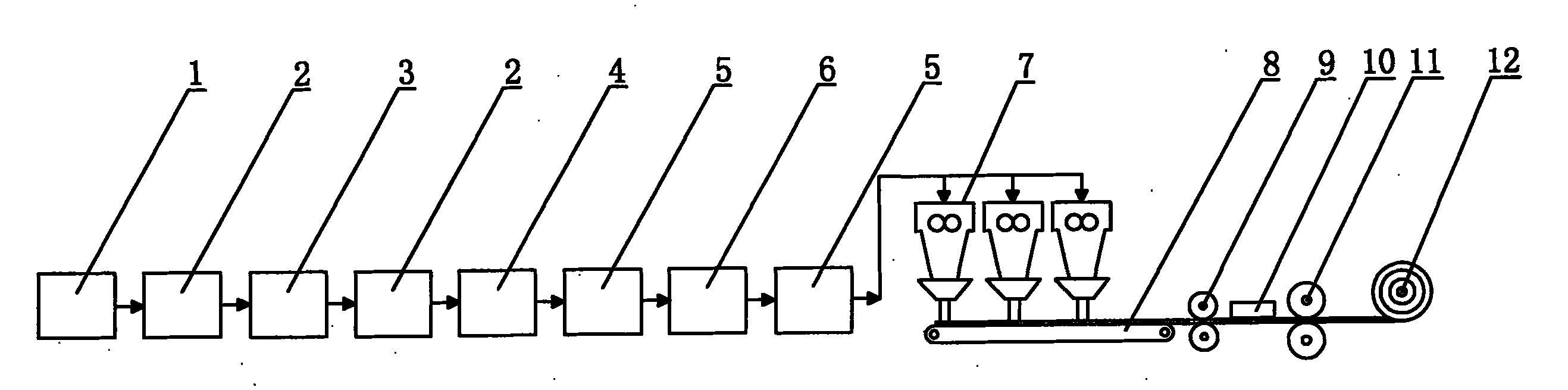

Continuous pultrusion manufacturing method and production device for fibrous composite drive shaft

The invention provides a continuous pultrusion manufacturing method for a fibrous composite drive shaft. The continuous pultrusion manufacturing method comprises the following steps: preparing a pre-dipping belt, pre-forming a mould, curing and forming, and mechanically processing. A production device for the fibrous composite drive shaft comprises a yarn creel, a pre-forming mould, a curing and forming mould, a traction mechanism and a cutting mechanism, wherein the yarn creel and the pre-forming mould are provided with a winding and braiding mechanism respectively; the winding and braiding mechanism comprises a yarn collecting plate, an annular winding disc and at least one braiding roller which are arranged in sequence; and an infrared heater is also arranged between the braiding roller and the pre-forming mould. According to the invention, a rod piece of a drive shaft can be directly subjected to pultrusion through a mould without the traditional gum dipping process and is cut and gummed so as to finish the production of the fibrous composite drive shaft, so that the production cost of the fibrous composite drive shaft is reduced, and meanwhile, the defects of difficultly controlled gum content and high gum waste in the traditional gum dipping process, easily damaged fibers and the like are avoided, and the production quality is improved.

Owner:HENGSHEN

Heat flow compensation method for ground simulation test on infrared heating cage of spacecraft

InactiveCN102092487AHigh precisionImprove accuracyCosmonautic condition simulationsStructural/machines measurementHeating timeHeat flow

The invention relates to a ground simulation test on a spacecraft, and discloses a heat flow compensation method for a ground simulation test on an infrared heating cage of a spacecraft. The method comprises the following steps of: arranging a radiation heat flowmeter on the surface of an experimental spacecraft; and supporting and connecting a plurality of heating loops through a frame to form the infrared heating cage. According to the invention, the method also comprises the following steps of: 1, sticking 20 layers of heat control multi-layer heat insulating components on the back of the radiation heat flowmeter; 2, arranging heating steel belts among the infrared heater loops; 3, tensioning the heating belts, and ensuring that the inner surfaces of the heating steel belts are parallel to the outer surface of the spacecraft; and 4, respectively arranging heat radiation power and heating time for each heating steel belt. The method solves the problems that low heat flow simulation is limited, heating areas are mutually interfered, the uniformity of heat flow is low and the like in the prior art, and has the advantages of improving the accuracy of applying external heat flow, improving the accuracy of simulating the spatial thermal environment and reducing simulation errors.

Owner:SHANGHAI SATELLITE ENG INST

Fixing device, image forming apparatus, and fixing method

InactiveUS20090010688A1Solve problemsOhmic-resistance heatingElectrographic process apparatusImage formationEngineering

Owner:RICOH KK

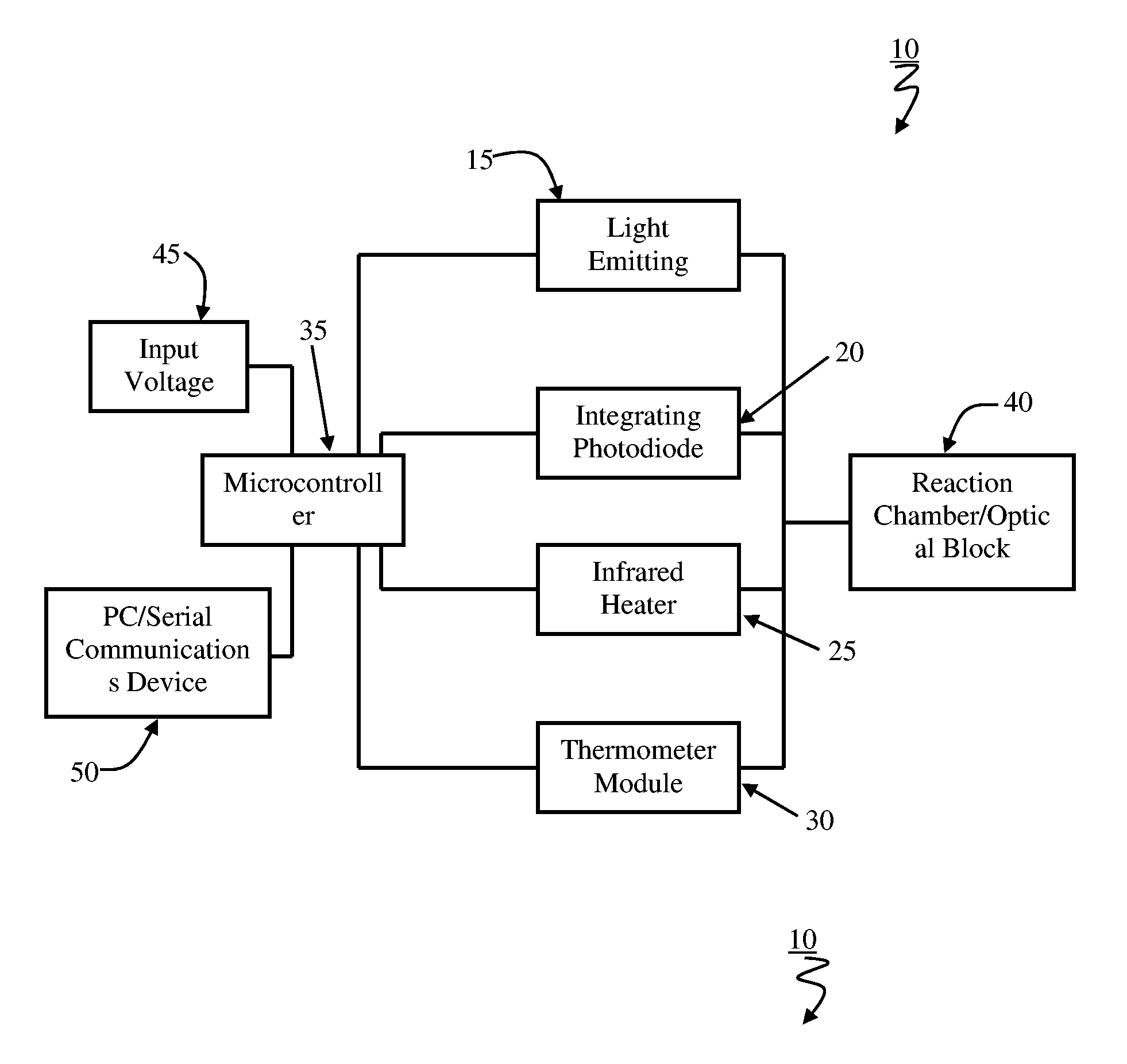

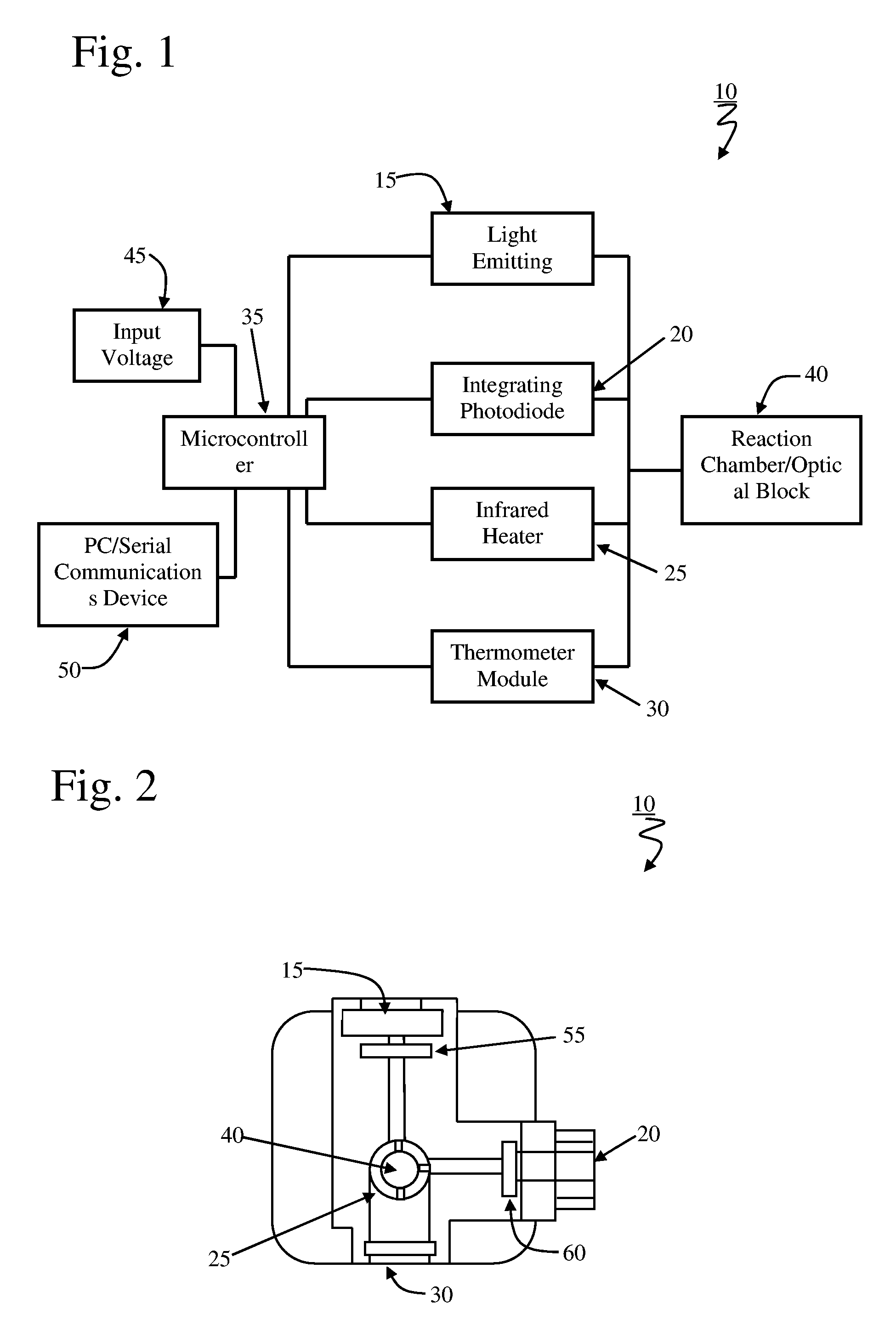

Low Thermal Mass Fluorometer

InactiveUS20050269522A1Low costImprove heat distributionPhotometryLuminescent dosimetersReal time analysisPhotodetector

The present invention provides core technologies necessary for a portable, low cost, thermal-regulating LED-based handheld fluorometer. The regulated fluorometer is based on a low thermal mass infrared heater, and an orthogonal geometry LED based filter fluorometer. Power is supplied through an external power supply and data is collected in real-time through standard serial interfaces of personal computers or personal digital assistants. Thermal regulation is automatically maintained using temperature sensor feedback control. Optical excitation relies on LED light source(s) and optical detection is through an adjustable integrating photodetector. Such a handheld system can allow applications requiring temperature sensitive photometric measurements for real time analyte detection to be performed in the field.

Owner:UNIV OF SOUTH FLORIDA

Cylinder head thermal shock test bench based on pre-tightening force, and method thereof

ActiveCN102735561AAccurately Study and Analyze Thermal FatigueAccurate research and analysis of thermal shock stateStrength propertiesThermostatEngineering

The present invention discloses a cylinder head thermal shock test bench based on pre-tightening force, and a method thereof. The test bench comprises a test apparatus and a control system, wherein the test apparatus comprises a cylinder head requiring detection, bolts, a valve mechanism, infrared heaters, an insulation pad, a cylinder gasket, a sense heating coil, a pseudo body, a fixing table stand, a sense heater control system, an infrared heater control system, a water pump, a water tank, a heater, a thermostat, and the like. The cylinder head requiring detection is additionally provided with the valve mechanism. The cylinder head requiring detection, the insulation pad, the cylinder gasket and the pseudo body are sequentially connected, and are fixed with the bolts. The front side and the rear side of the cylinder head requiring detection are provided with the infrared heaters. The sense heating coil is arranged inside the pseudo body. The cylinder head requiring detection is connected with the water tank through a water pipe and is driven by the water pump. Forced water cooling is performed on the cylinder head requiring detection. The test apparatus is controlled by the control system. With the present invention, the pre-tightening force is considered as the mechanical constraint, such that the actual working conditions can be simulated realistically, and the thermal fatigue state and the thermal shock state of the cylinder head can be accurately analyzed so as to improve the credibility of the test results.

Owner:ZHEJIANG UNIV

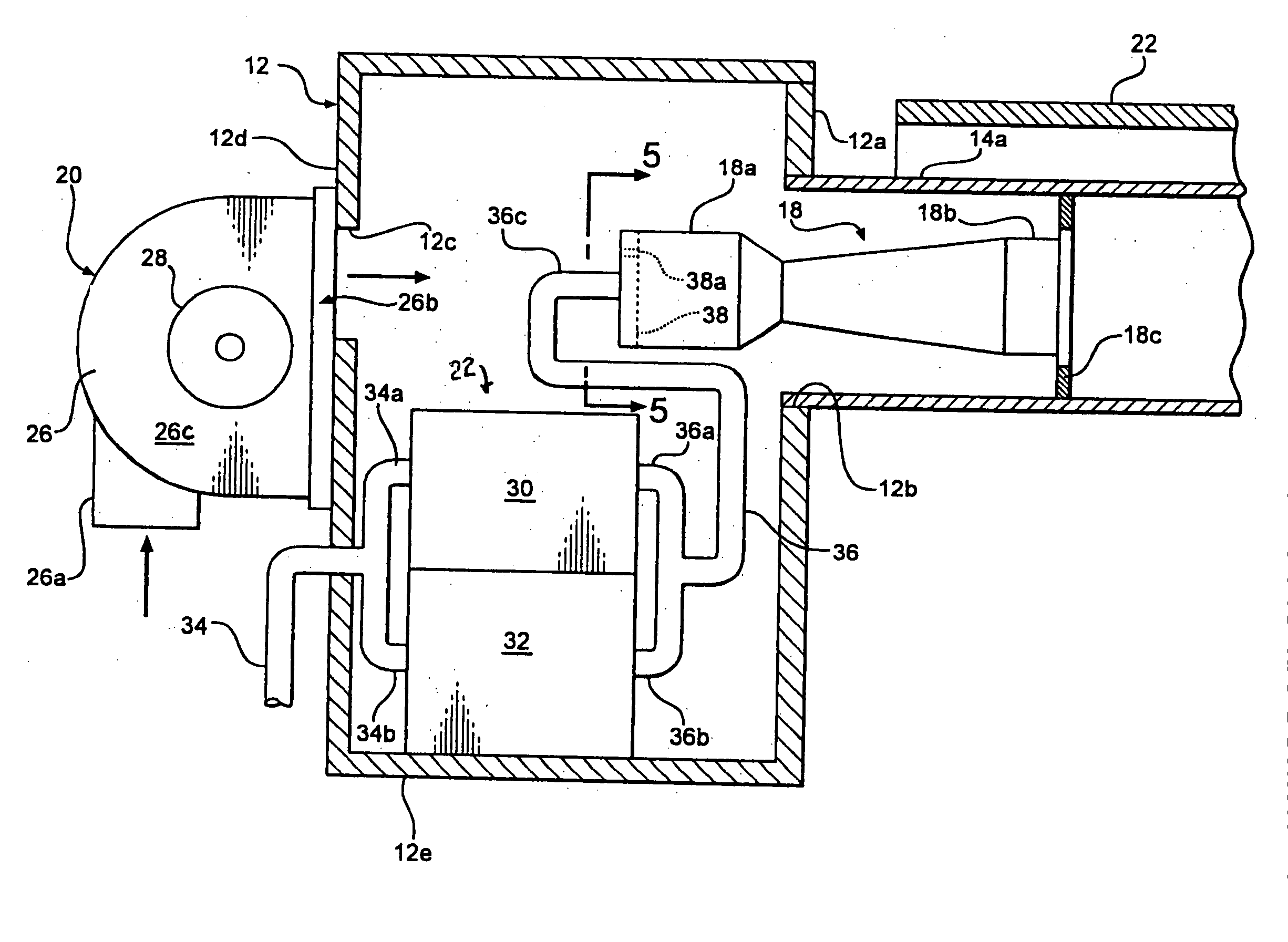

Variable low intensity infrared heater

ActiveUS6971871B2Reduce speedReduce airflowDomestic stoves or rangesPilot flame ignitersEngineeringConductor Coil

A radiant heater including a burner having an inlet for receiving an air and gas mixture and an exhaust for emitting exhaust gases generated by combustion of the air and gas mixture within the burner, an elongated radiant heating tube having an inlet for receiving the exhaust gases emitted by the burner, a gas flow control assembly for controlling the flow of gas to the burner, and a blower for controlling the flow of air to the burner. The blower comprises a two-stage blower including a motor having a low winding corresponding to a low blower speed and a high winding corresponding to a high blower speed. The gas flow control assembly comprises a two-stage regulator or two-stage valve having a low setting for delivering a low gas flow to the burner and a high setting for delivering a high gas flow to the burner.

Owner:SOLARONICS

Straw non-woven fabric and production method of straw non-woven fabric

The invention discloses a straw non-woven fabric and a production method of the straw non-woven fabric. Straws, a conveying mesh belt, a straw chopper, a primary fiber separator, a fan, a fine fiber separator, an air chamber, a polyester mesh, a pre-roller, an infrared heater, a hot roller and a non-woven fabric roll are adopted. The non-woven fabric is produced by effectively using the straws, the waste is changed into valuable, and the cost is low. The straw non-woven fabric manufactured by using the method has good use performance, soft handfeel and good water absorption, does not cause fiber drop, is particularly suitable for manufacturing industrial wiping cloth, is used for automobile heat insulation layers or building heat insulation layers and the like, and can also be used as moisture absorption cores in the middle of incontinence products such as paper diapers, sanitary towels and the like. A chemical processing method is not used for manufacturing the straw non-woven fabric, so the straw non-woven fabric has no secondary pollution, is totally biodegradable and is an environmentally-friendly product. The flow can be performed in fields, and the operation is simple, convenient and safe.

Owner:YANCHENG INST OF IND TECH

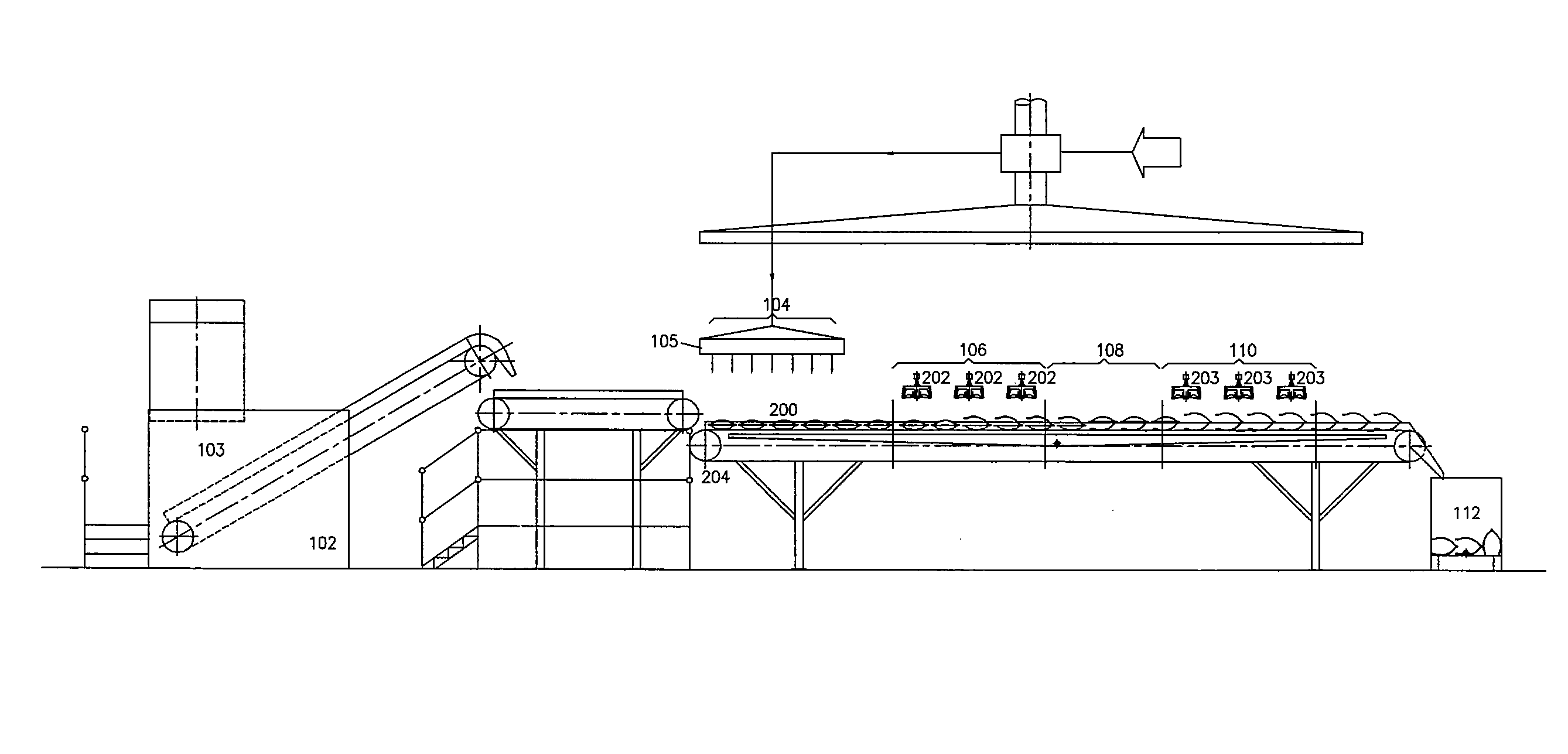

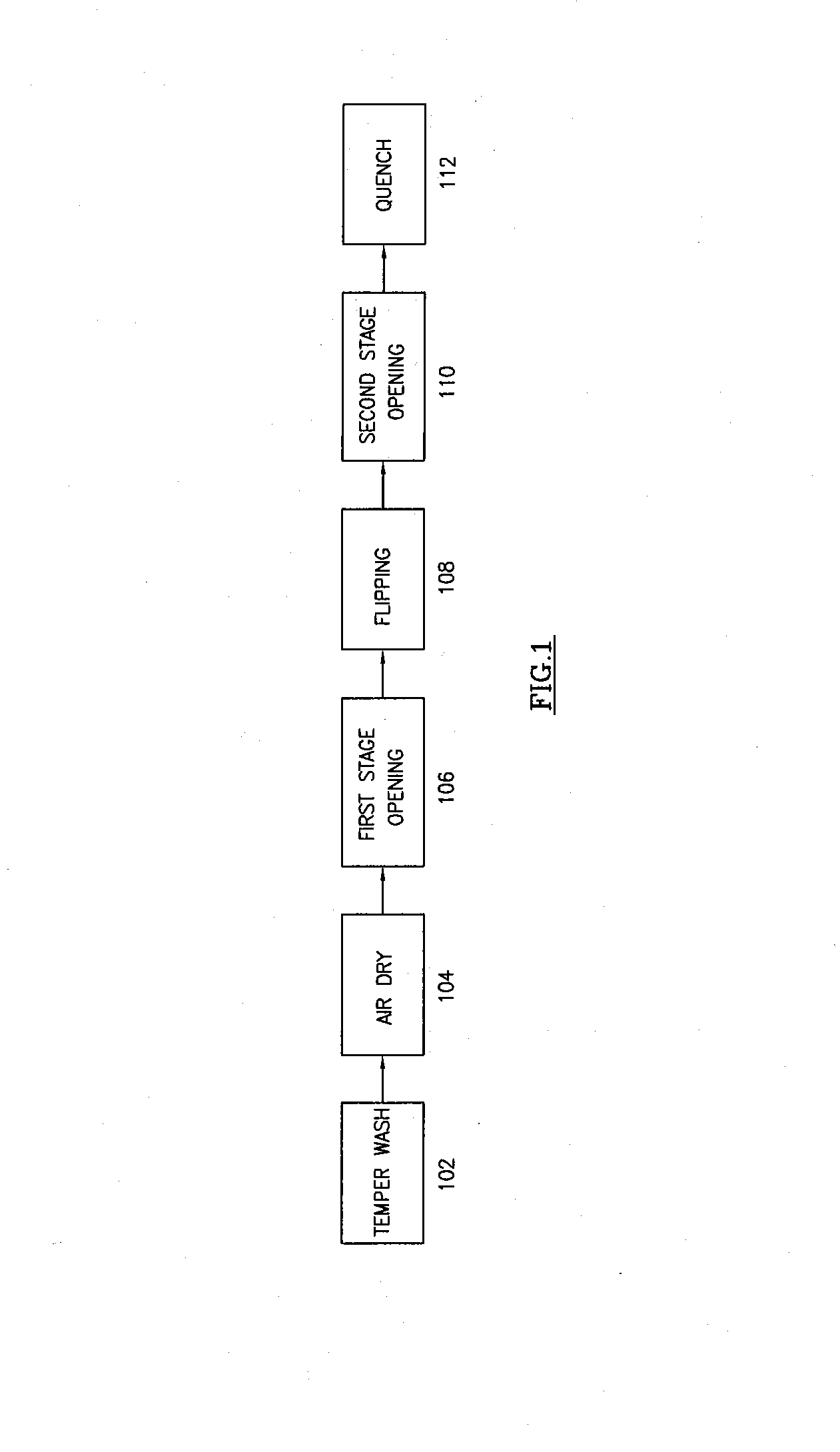

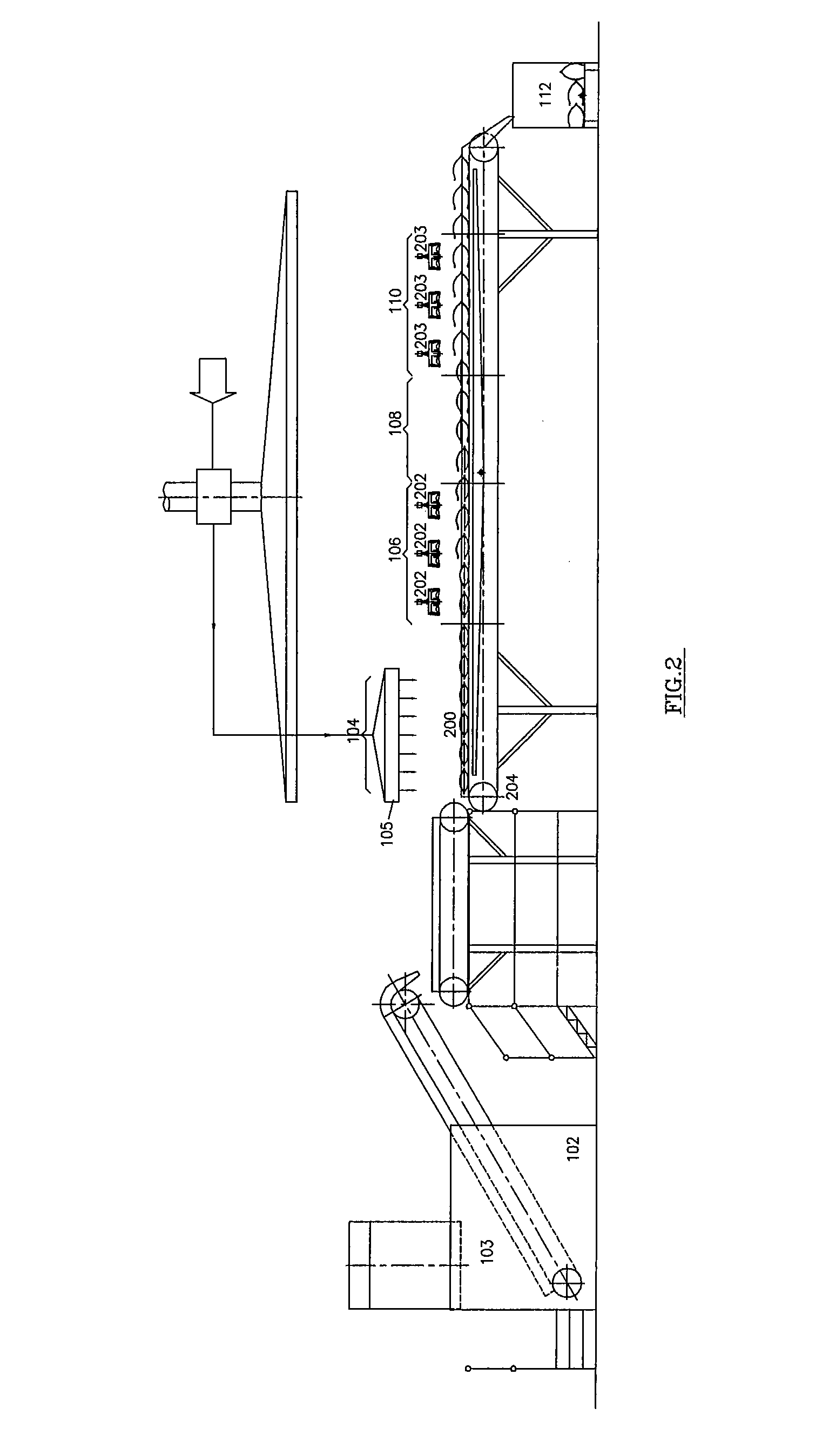

Method and system for opening shellfish using infrared energy

A method for shucking bi-valve shellfish, especially clams, includes imparting a wide array of infrared energy from at least one infrared heater from above to a first shell of the bi-valve shellfish sufficient to detach an adductor muscle from the first shell. The bi-valve shellfish are inverted to expose a second shell. Infrared energy is imparted again from above to a second shell of the bi-valve shellfish sufficient to release a shellfish meat from between the first and shell and the second shell. A system for carrying out this method includes a tank for washing the shellfish, a dryer, the infrared heaters, a device for inverting the shellfish, a tank for quenching the shellfish, and a conveyor for transporting the shellfish under the infrared heaters.

Owner:LAVECCHIA DANIEL P

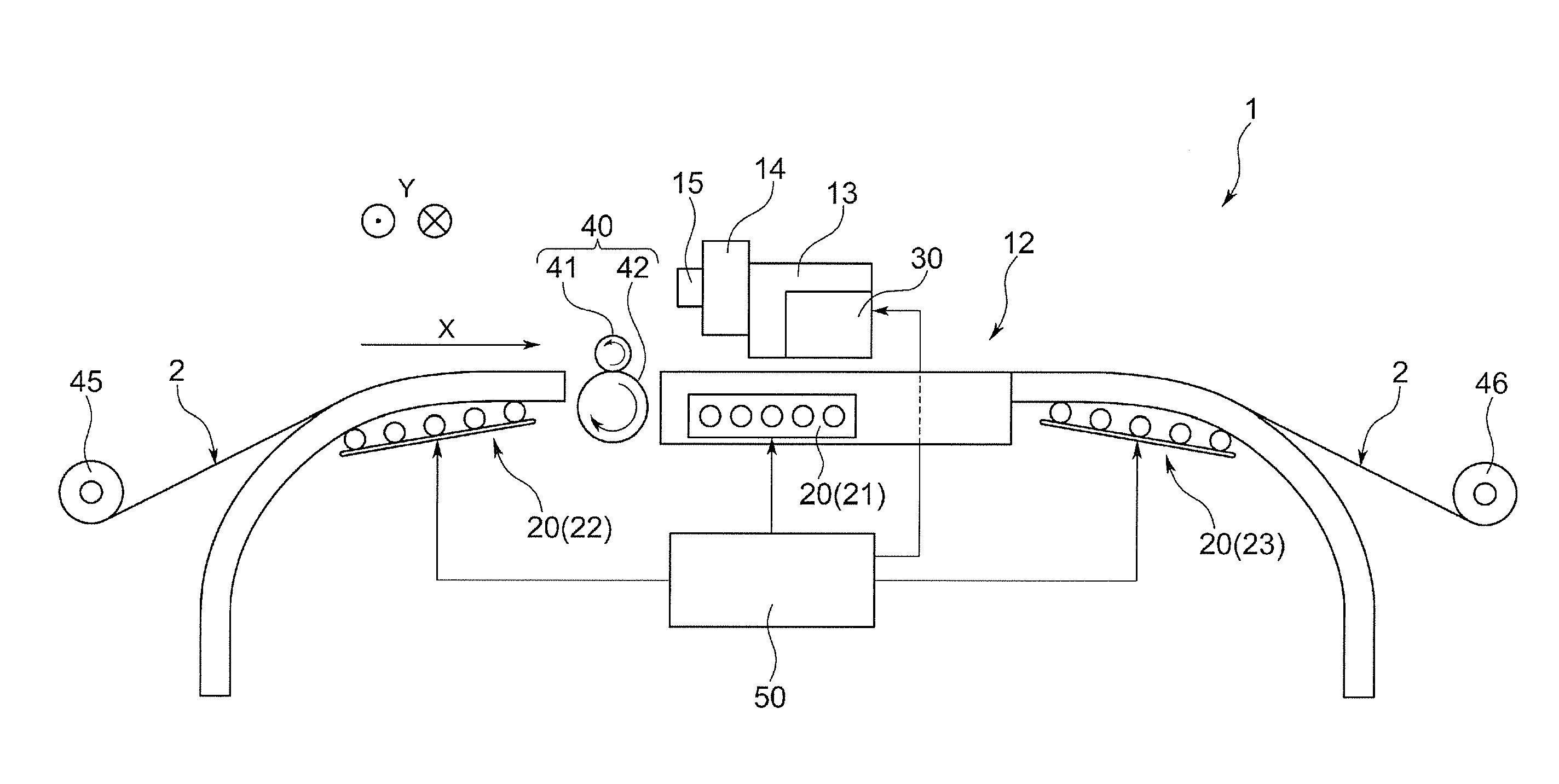

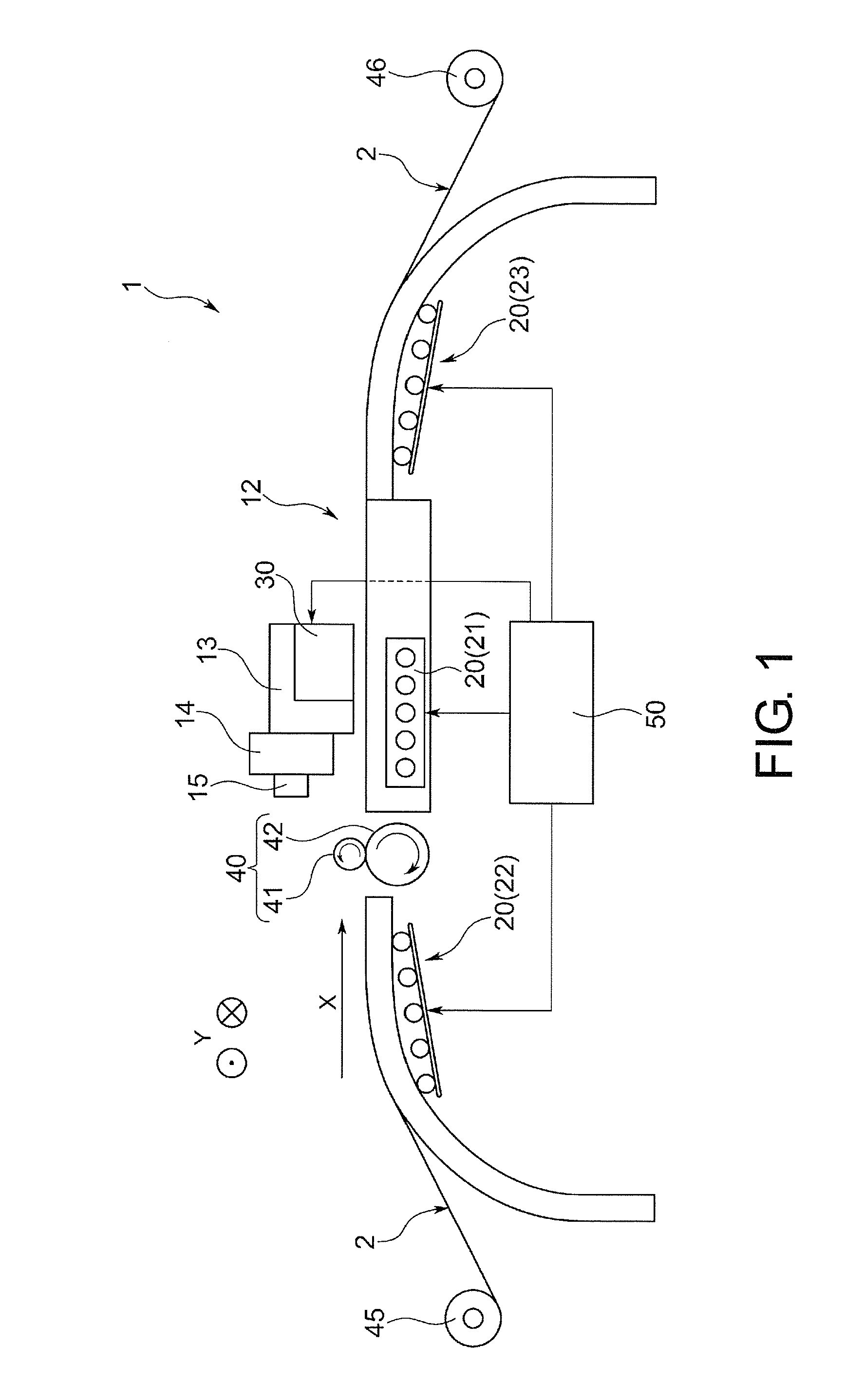

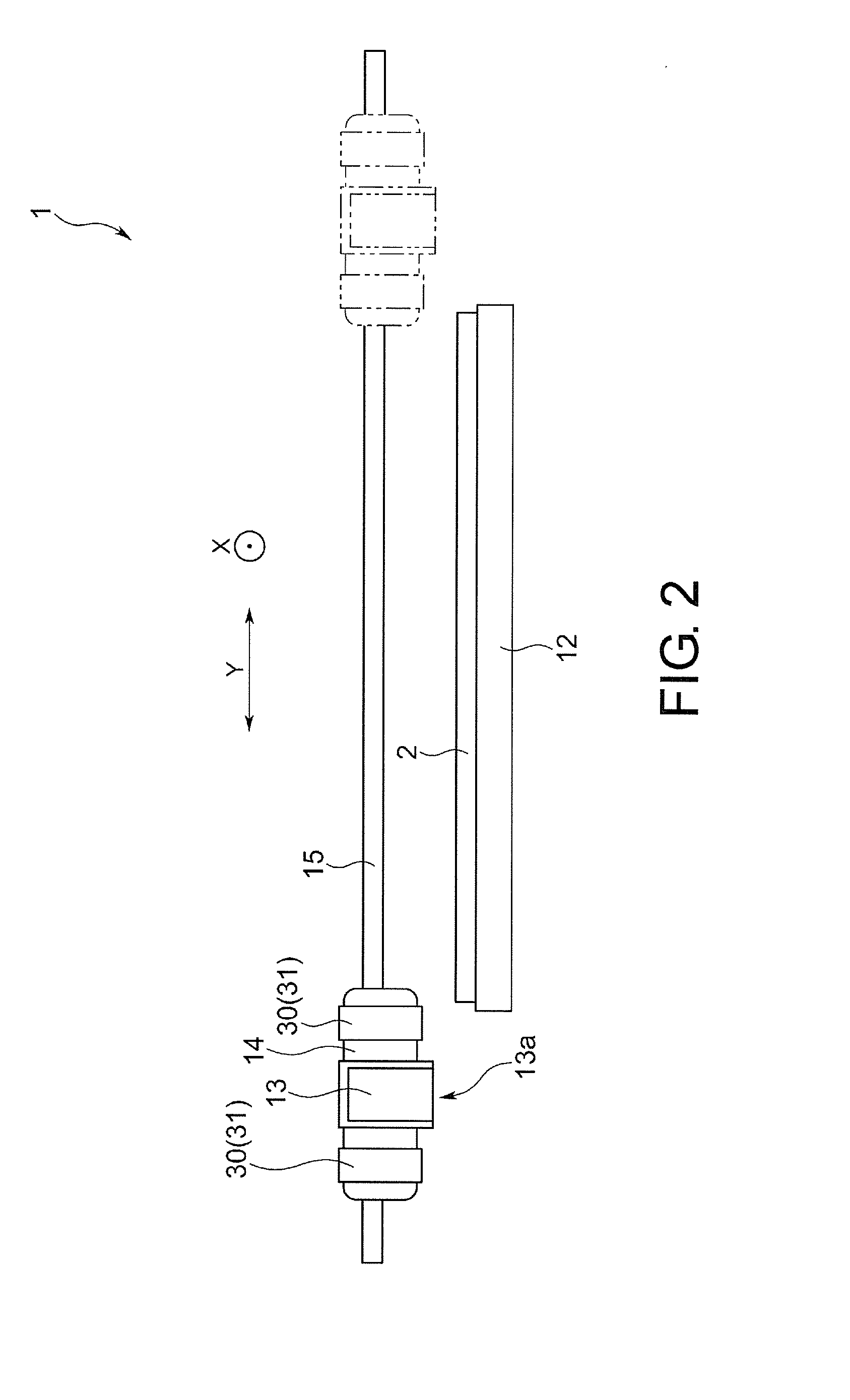

Ink jet recording apparatus

ActiveUS20150029255A1Avoid smearingNozzle become blockedOther printing apparatusEngineeringRecording media

Disclosed is an ink jet recording apparatus that prints an image onto a recording medium using an ink which is composed of an aqueous ink vehicle containing latex as a binder resin. The ink jet recording apparatus includes a carriage on which a recording head for discharging ink droplets onto the recording medium is mounted and that moves relative to the recording medium, in which an infrared heater that is disposed opposite to the recording medium and heats the recording medium is mounted on the carriage, and the infrared heater is disposed to be distant from the recording head in a moving direction (X direction) of the recording medium.

Owner:MIMAKI ENG

System and method for cleaning and sanitizing mattresses

The invention disclosed herein is a system and method for cleaning and sanitizing mattresses infested with insects and bacteria. Specifically, mattresses infested with bed bugs and / or dust mites may be cleaned and sanitized through a series of steps beginning with UV irradiation of the mattress. Next, the mattresses are subject to dry steam of a temperature of approximately 356° F. The mattress is then vacuumed to remove debris and waste. Next the mattress is heated with infrared heaters which produce a temperature of up to 265° F. Finally, the mattress is again vacuumed to remove any remaining debris. The system is mounted on an enclosed trailer so that the system may be transported to a home, hospital, hotel or dormitory to clean and sanitize the mattresses.

Owner:INGLE MICHAEL

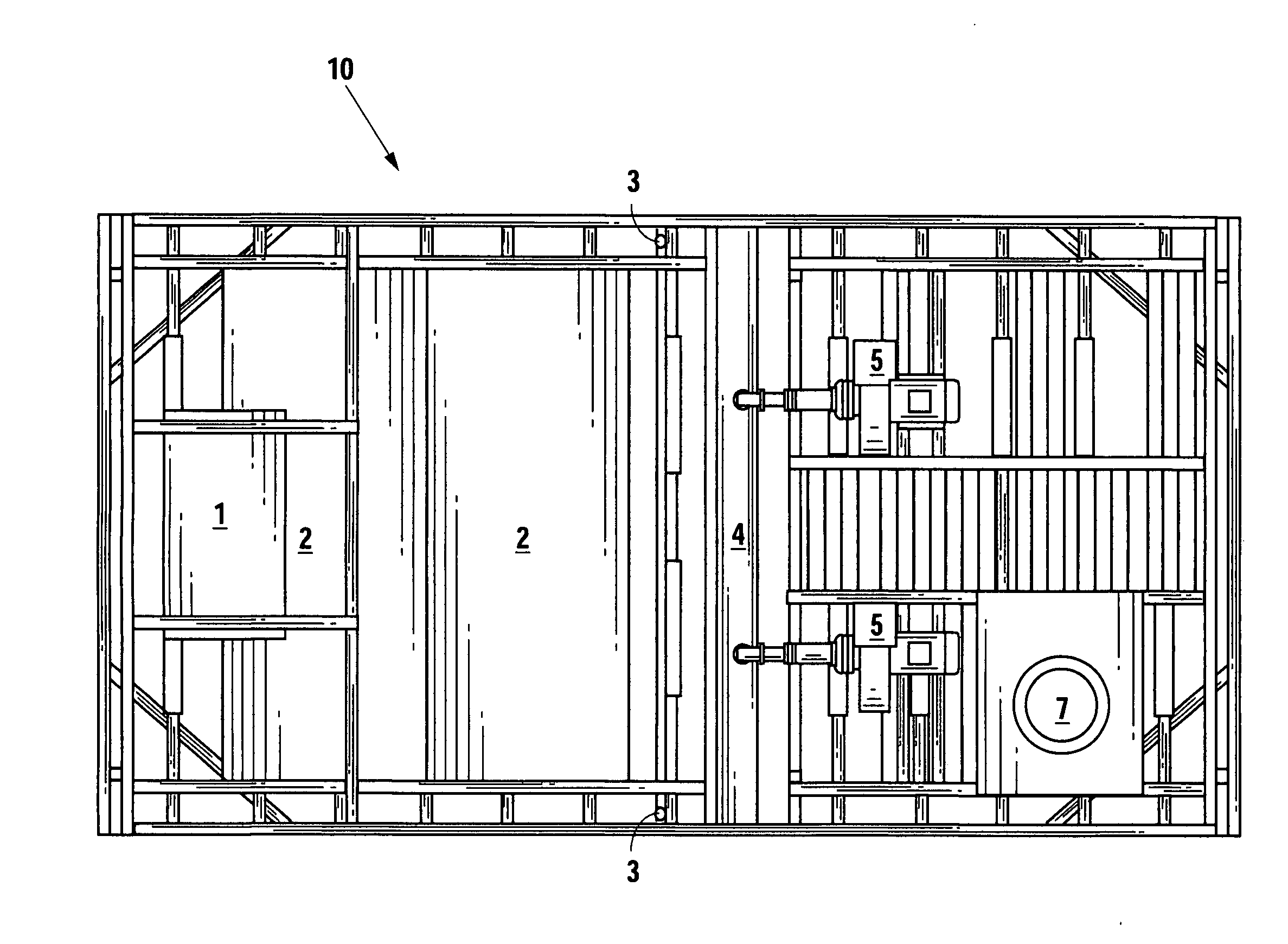

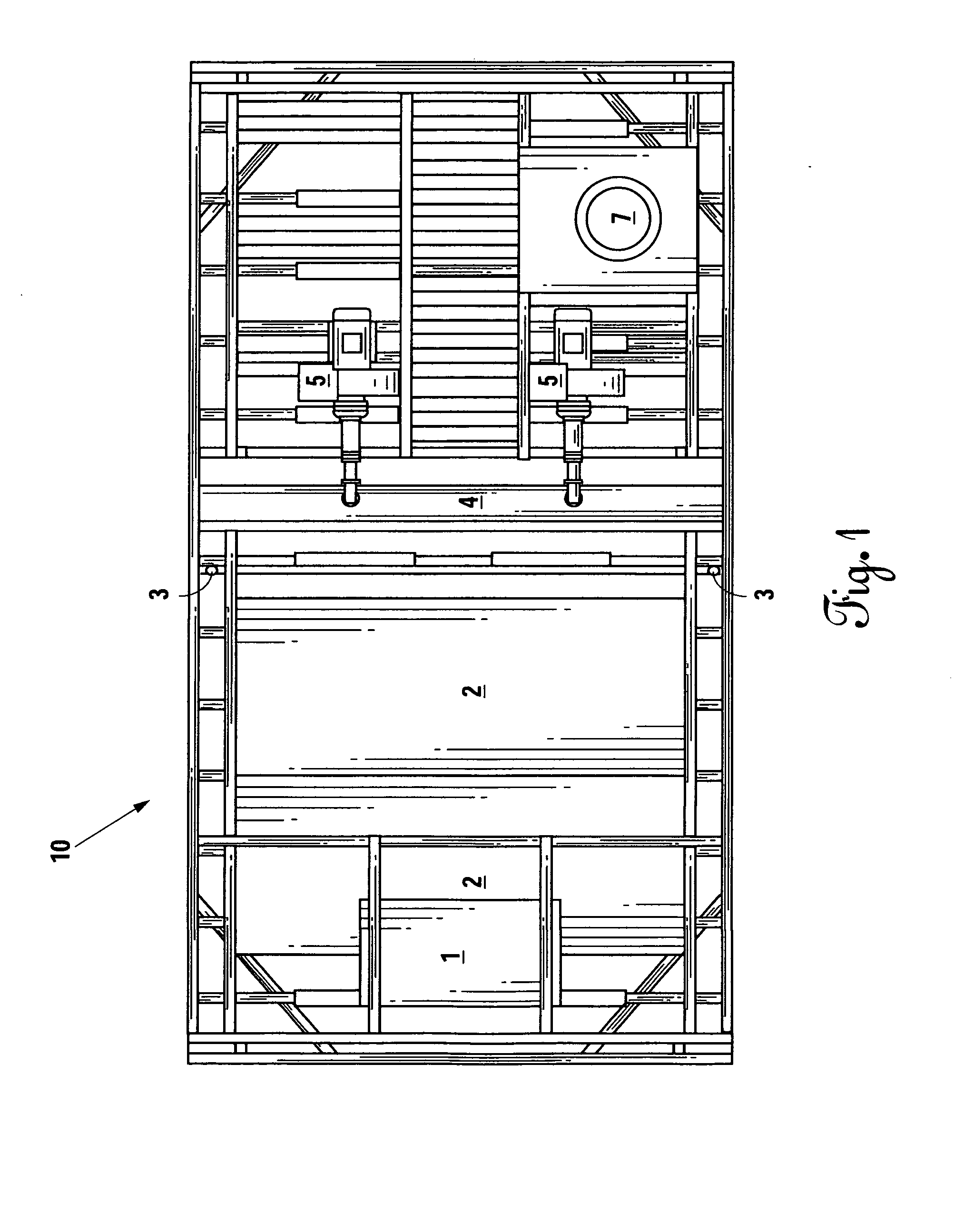

Lithium ion battery pole piece drying device

InactiveCN105486059AEasy to assembleEasy to moveDrying gas arrangementsDrying machines with progressive movementsElectrical batterySmall footprint

The invention relates to the technical field of lithium batteries and in particular to a lithium ion battery pole piece drying device. The lithium ion battery pole piece drying device comprises a cabinet. The cabinet is sequentially divided into a heating chamber I, a heating chamber II and a heating chamber III. Turning rolls I and infrared heaters are arranged in the heating chamber I. A first transmission port is formed in the upper end of the heating chamber I and formed in a heat insulation board I. Turning rolls II and fans are arranged in the heating chamber II. Turning rolls III are arranged in the heating chamber III and a vacuum pump and a vent valve are arranged at the upper end of the heating chamber III. A rotary roll is arranged at the lower end of the heating chamber III. The lithium ion battery pole piece drying device is safe, reliable, convenient to assemble and move, small in occupied area, high in drying speed and capable of solving the problem that bubbles, needle holes and chaps are generated and greatly improving production efficiency.

Owner:SHANDONG PEARSON POWER NEW ENERGY

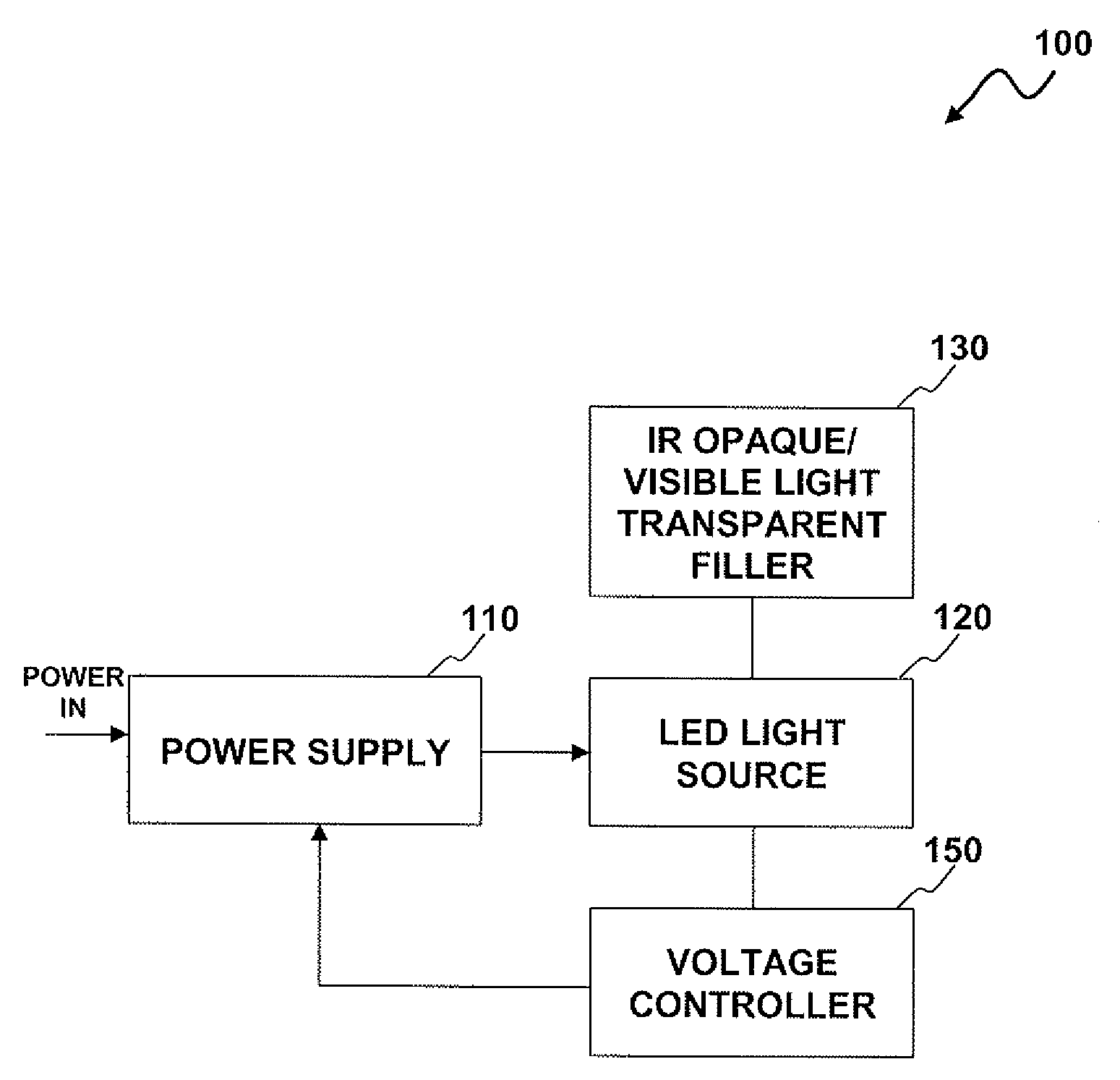

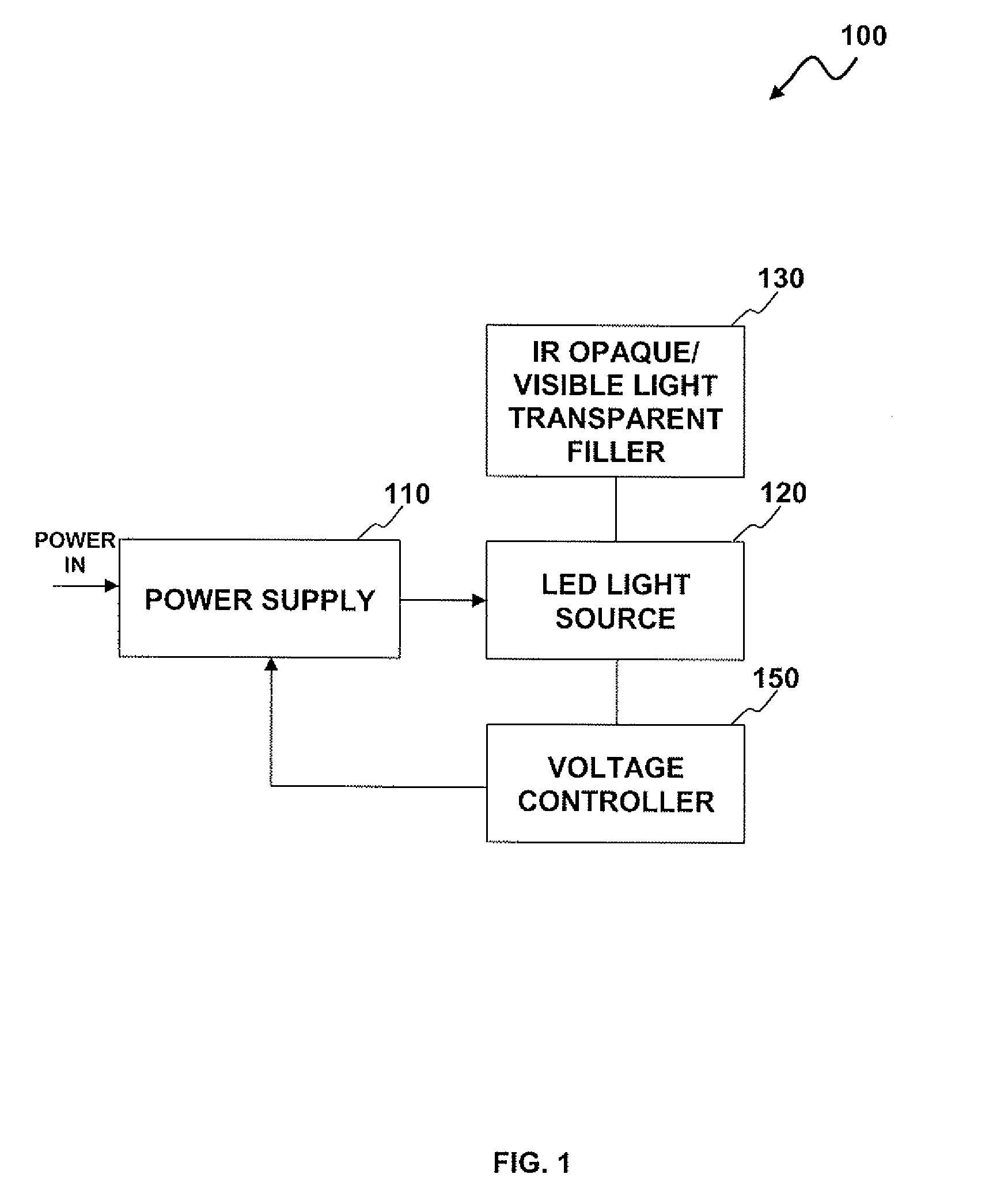

Infrared LED apparatus and surface heater

InactiveUS20100080542A1Fluid heatersSpace heating and ventilation detailsLength waveTransmitted light

An infrared LED apparatus and surface heater for heating complex surfaces that need to transmit light is disclosed. The infrared LED heater includes an infrared LED light source comprising a number of LEDs, which can be utilized to elevate the surface temperature of a lens utilizing less energy. The lens can be filled with an IR opaque and visible light transparent filler to elevate the lens surface temperature utilizing less energy. The filler is durable and opaque to infrared wavelengths and is transparent in the visible wavelengths. The infrared LED heaters can be utilized to heat complex surfaces that transmit light while consuming less energy than conventional resistive heaters.

Owner:HONEYWELL INT INC

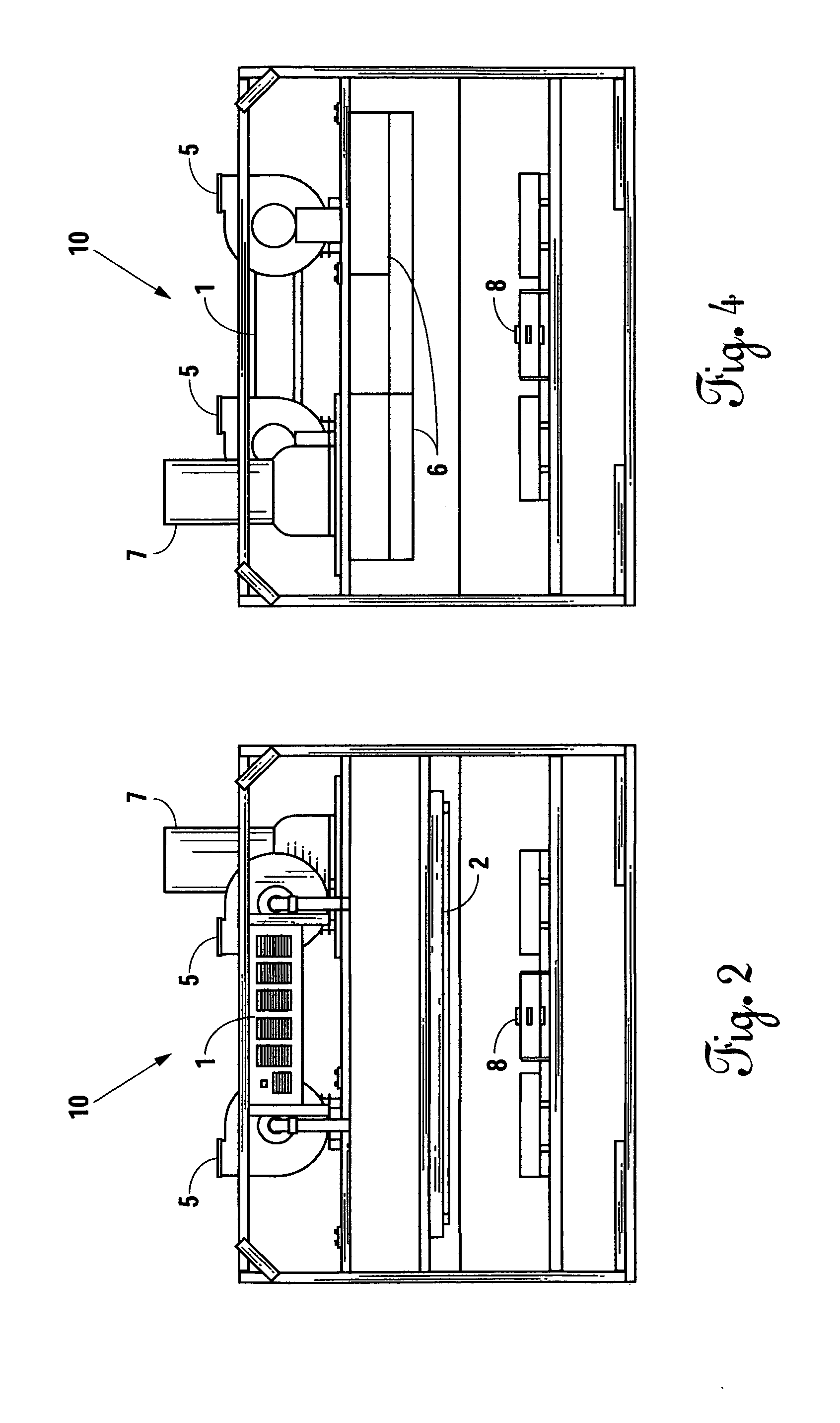

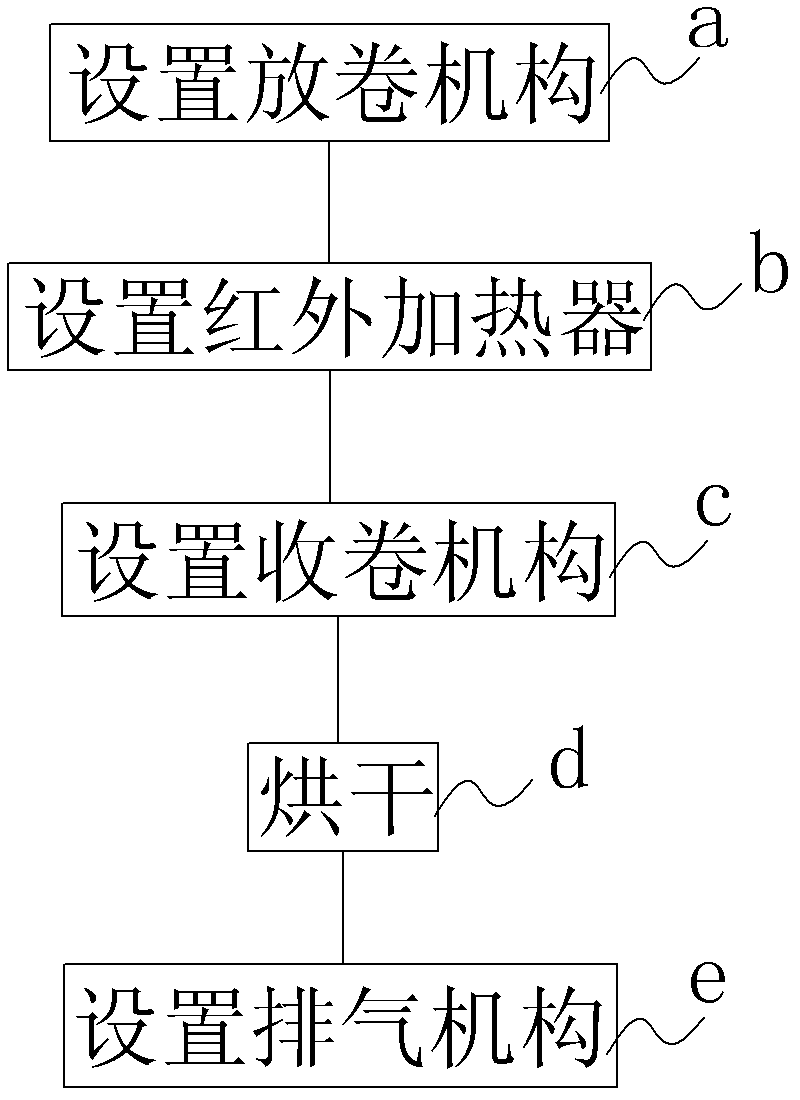

Drying device and method of lithium-ion power battery pole piece

InactiveCN103017496ASmooth dischargeAvoid differences in electrolyte consumptionDrying solid materials with heatCell electrodesLithiumPower battery

The invention provides a drying device and a drying method of a lithium-ion power battery pole piece. The drying device comprises a bracket, an unreeling mechanism, a rolling mechanism and an infrared heater; the unreeling mechanism, the rolling mechanism and the infrared heater are mounted on the bracket; the lithium-ion power battery pole piece is wound on the unreeling mechanism; one end of the lithium-ion power battery pole piece is fixedly arranged on the unreeling mechanism; the other end of the lithium-ion power battery pole piece is fixedly arranged on the rolling mechanism; and the lithium-ion power battery pole piece is dried by passing through the infrared heater at a uniform speed under the driving of the rolling mechanism. The drying method comprises an unreeling mechanism arranging step, an infrared heater arranging step, a rolling mechanism arranging step and a drying step. With the adoption of the drying method and the drying method provided by the invention, water is uniformly discharged by the pole piece, so that the difference of electrolyte consumption of a lithium-ion power battery can be avoided, the cycle life of the battery is prolonged, and the security in use can be improved.

Owner:BEIJING AOSIYUAN TECH & SCI

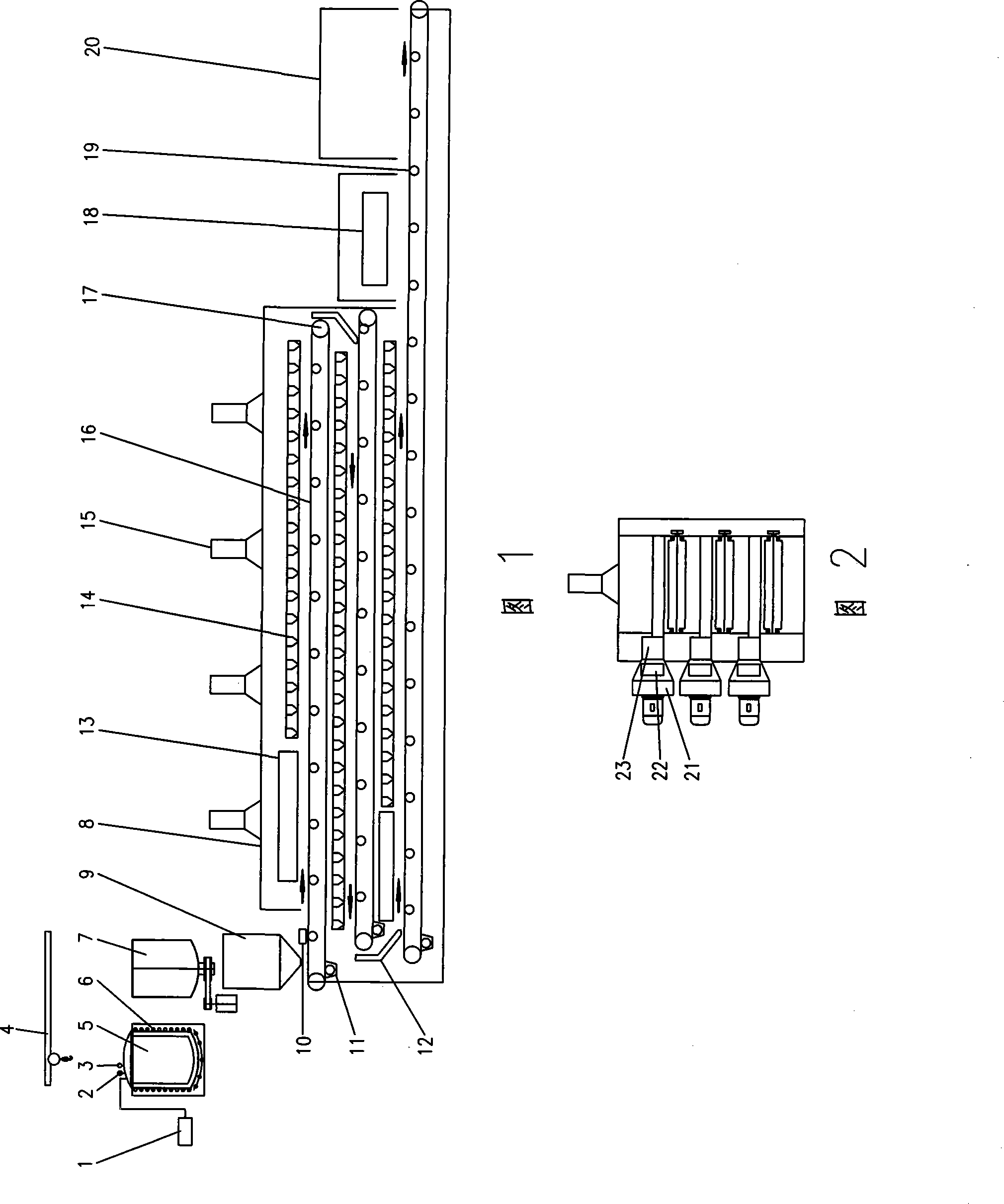

High-efficiency energy-saving automatic roasted seeds and nuts producing system

InactiveCN101238864AReduce energy consumptionShort energy consumptionFood preparationFood treatmentMaterial consumptionProcess engineering

The invention involves a high efficiency energy saving automatic system for producing roasted seeds and nuts, which includes cooking device, after being cooked by cooking device the product is lifted into dehydrator by lifting device, after dehydration the product is transferred into dryer through conveyor belt, entrance region of first layer conveyor belt in the dryer and last layer conveyor belt are equipped with infrared heater respectively, the top part of the dryer is equipped with humidity-discharging port, at least one layer of conveyor belt is installed in the dryer, the conveyor belt is driven by conveying roller and carrier roller belt, the upper part of the conveyor belt is installed with hot air injector, after being dried the product is cooled in cooler, after being cooled the product is separated in separator, at last the finished product is packed. The invention has merits of low energy consumption, low material consumption, high work efficiency, low producing cost and small occupation area.

Owner:邓元恺

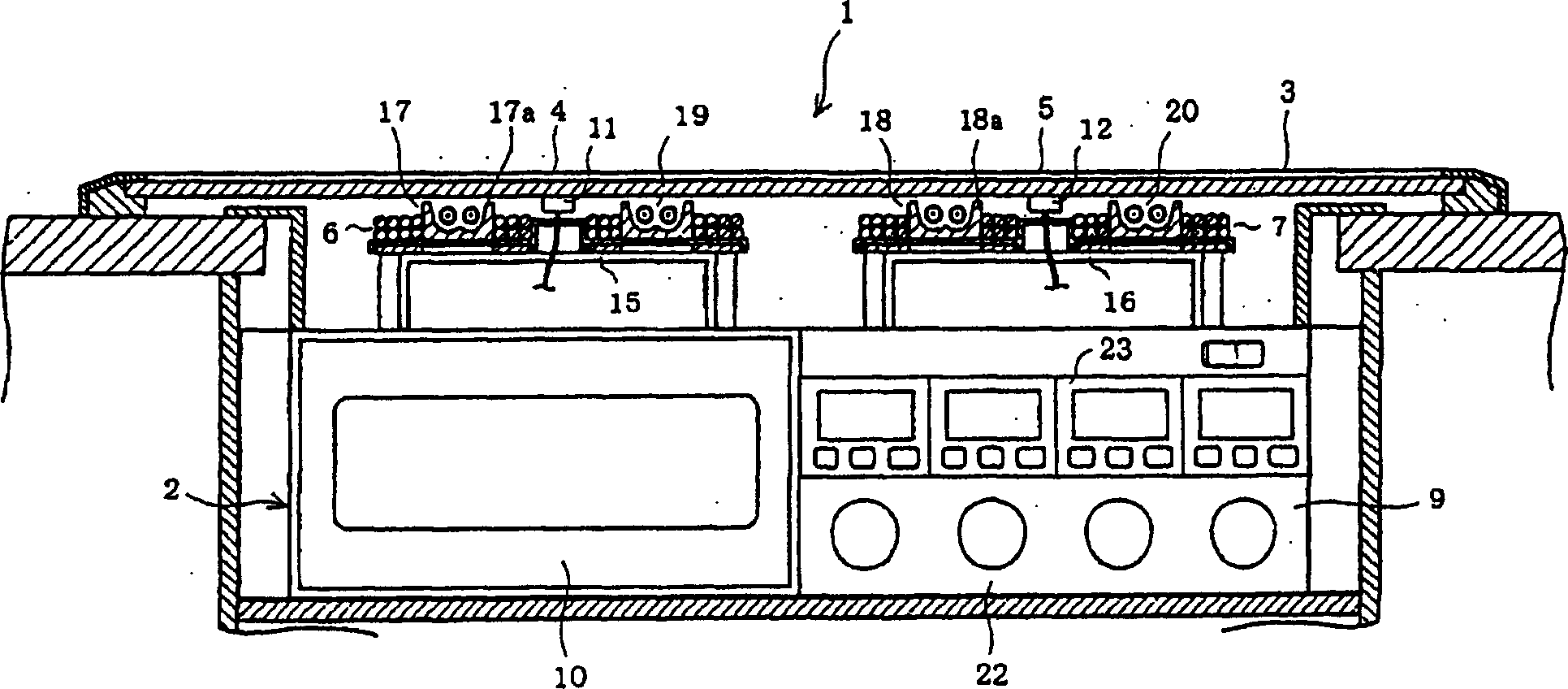

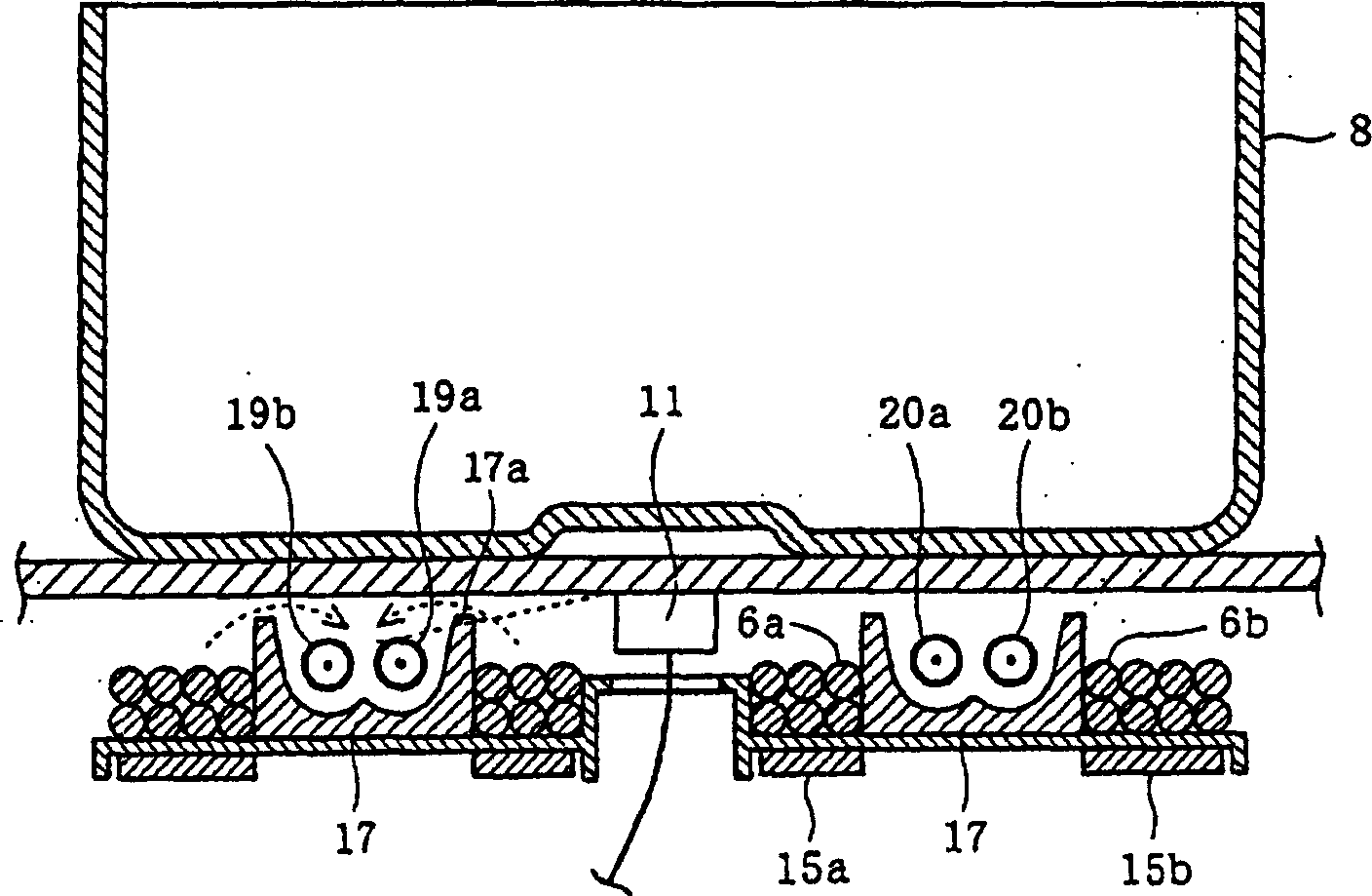

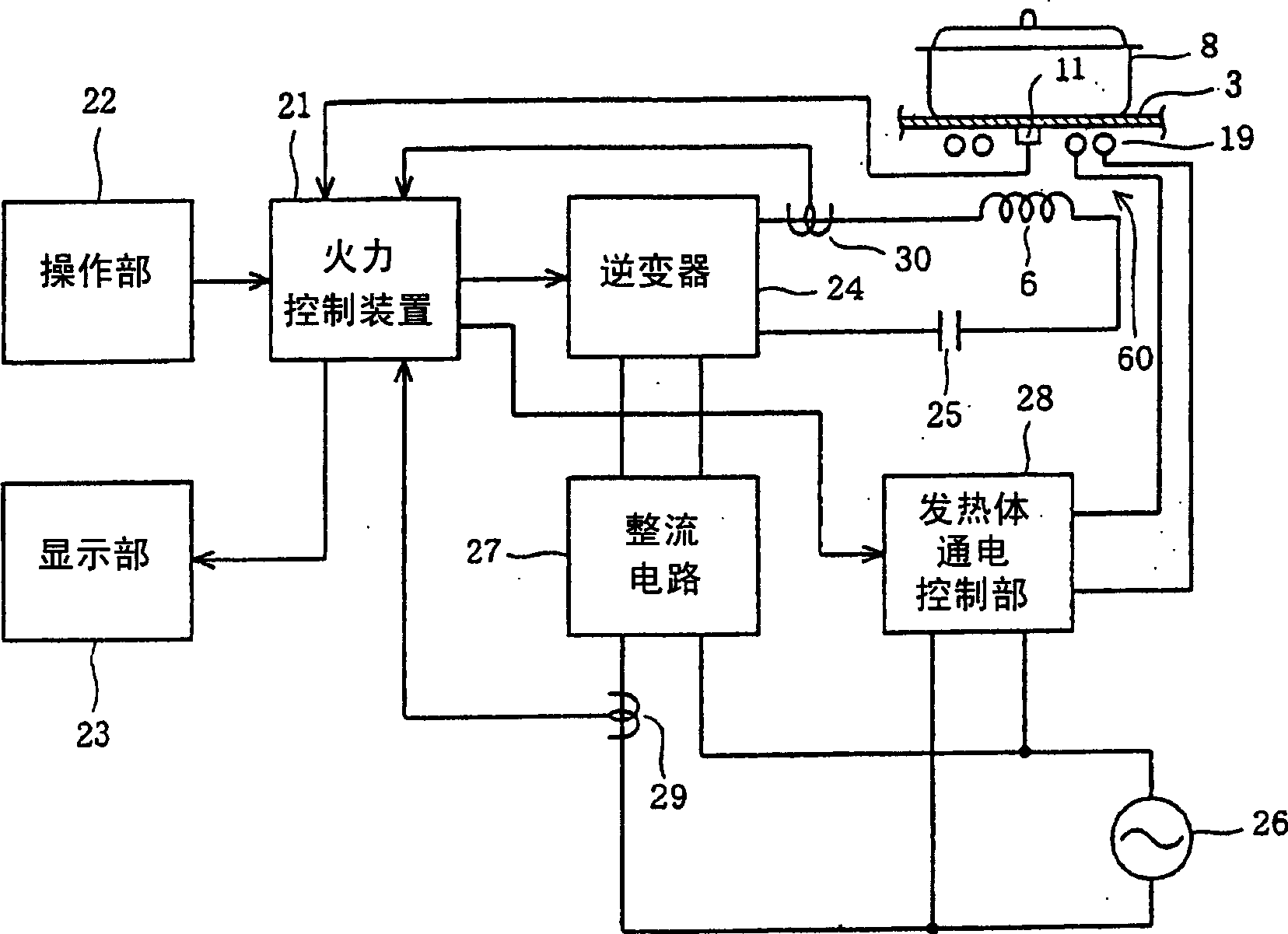

Heating cooker

InactiveCN1809229AReduce the number of turnsReduce the number of twisted wiresBuilding material handlingInduction heating apparatusEngineeringHeating power

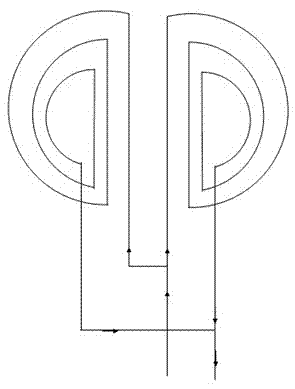

The present invention provides a heating cooker capable of further efficiently heating cookware to be heated that is made of a low-permeability material. This heating cooker comprises an induction heating coil 6 and an infrared heater 19 for heater heating. A heating power controller determines the material of the cookware 8 to be heated and controls an inverter and a heating element conducting section according to the material determined, thereby controlling the heating ratio between the induction heating coil 6 and the infrared heater 19. A temperature detection part 11 is disposed inside the infrared heater 19 forming a ring-like shape; and a heater installation member 17 is so structured that its side wall 17a prevents an infrared ray radiated from the infrared heater 19 from reaching the temperature detection part 11.

Owner:KK TOSHIBA +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com