Device for producing nonwoven fabric with fused mass and solution centrifugal spinning

A non-woven fabric and centrifugal spinning technology, which is applied in the direction of non-woven fabrics, melt spinning, textiles and papermaking, etc., can solve the problem of complex raw material handling in the electrospinning process, the inability to satisfy cells and blood vessel growth, and the inability to provide three-dimensional space and other problems, to achieve the effect of good mechanical strength, low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

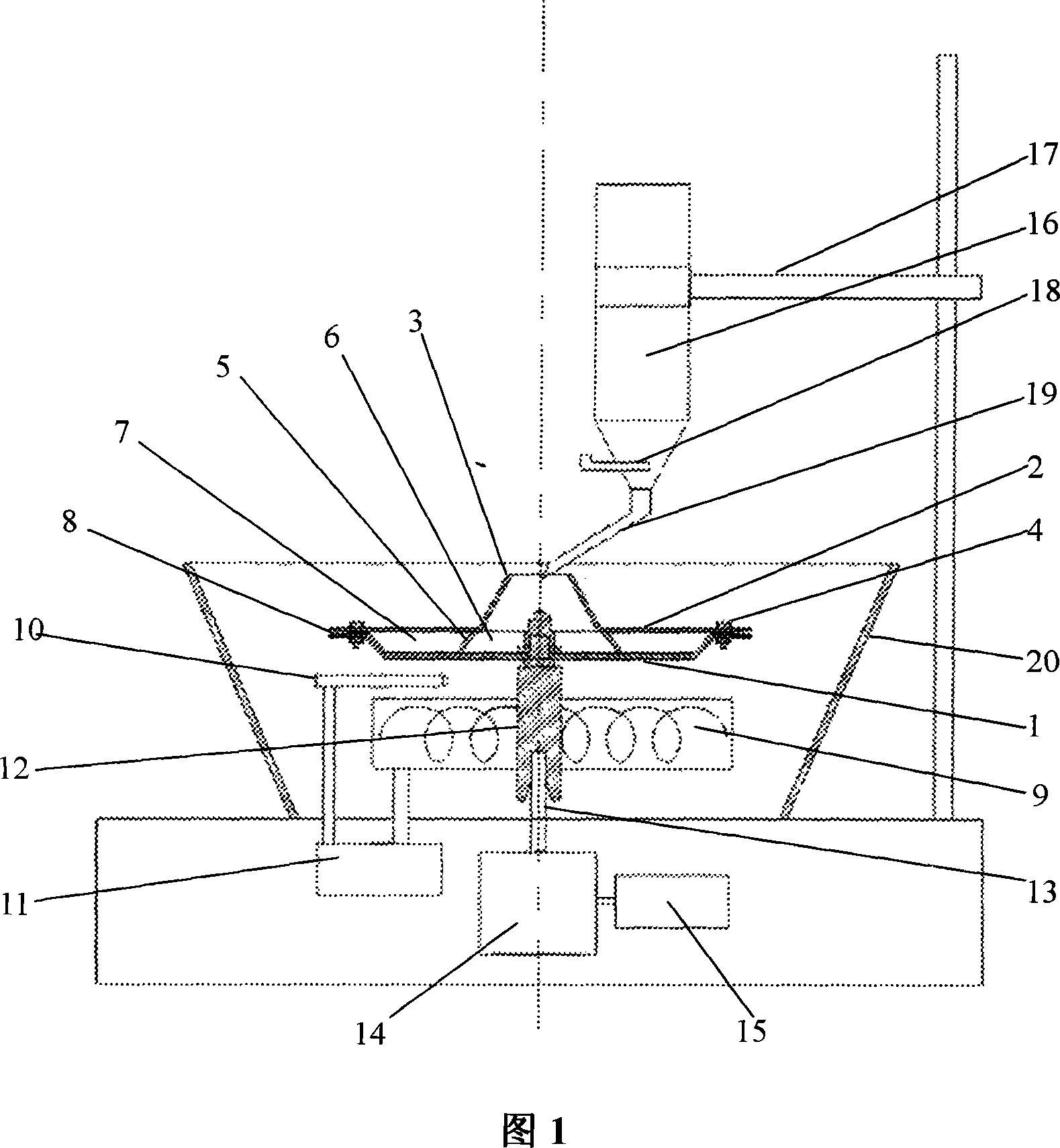

[0023] The melt and solution centrifugal spinning of the present invention prepare the device of nonwovens as follows:

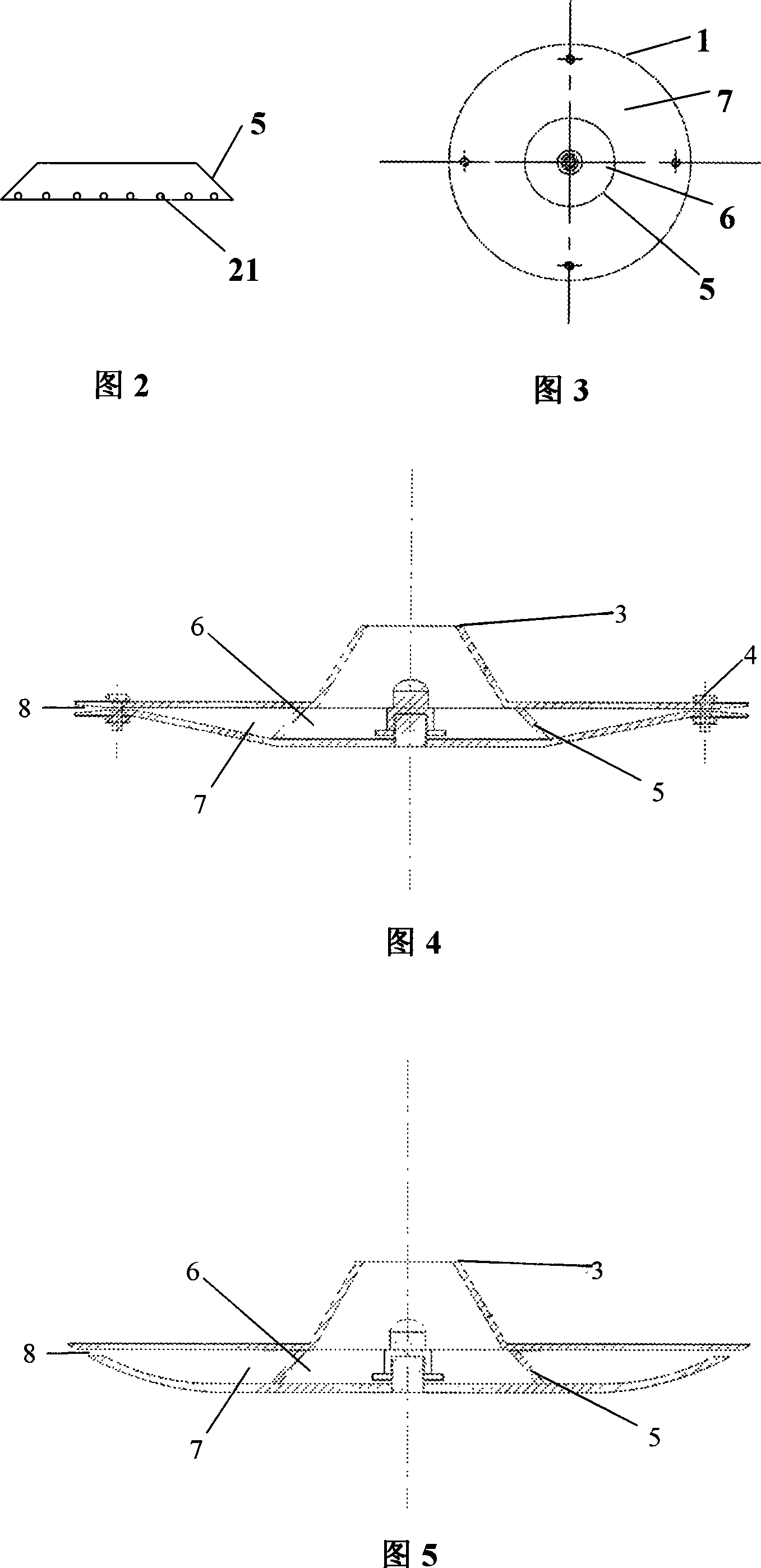

[0024] As shown in Fig. 1, the device has a rotating disk 1, and the shape of the side surface of the rotating disk 1 is rounded truncated. (See Figure 4). A rotating disk cover 2 is connected to the rotating disk 1, and there is a feed port 3 on the rotating disk cover 2. The rotating disk 1 and the rotating disk cover 2 are fixed by bolts 4, and the rotating disk 1 is divided into an inner cavity 6 and The outer cavity 7, the bottom of the annular spacer 5 has a small hole 21 (see Figure 2), the polymer melt or polymer solution flows out of the small hole 21, and the annular spacer 5 passes through both the rotating disk 1 and the rotating disk cover 2. Extrusion force is fixed, spinnerets 8 are distributed around the rotating disk 1, and the bottom surface of the rotating disk 1 is flat; there is a constant temperature infrared heater 9 under the rotating ...

Embodiment 3 and preparation ,1。( pic 5)。 Embodiment 2

[0028] Example 3 In the device for preparing nonwovens by centrifugal spinning of melt and solution according to the present invention, the shape of the side of the rotating disk 1 is a symmetrical surface of revolution. (See Figure 5). Example 2: Use of the device for the preparation of nonwovens by melt and solution centrifugal spinning

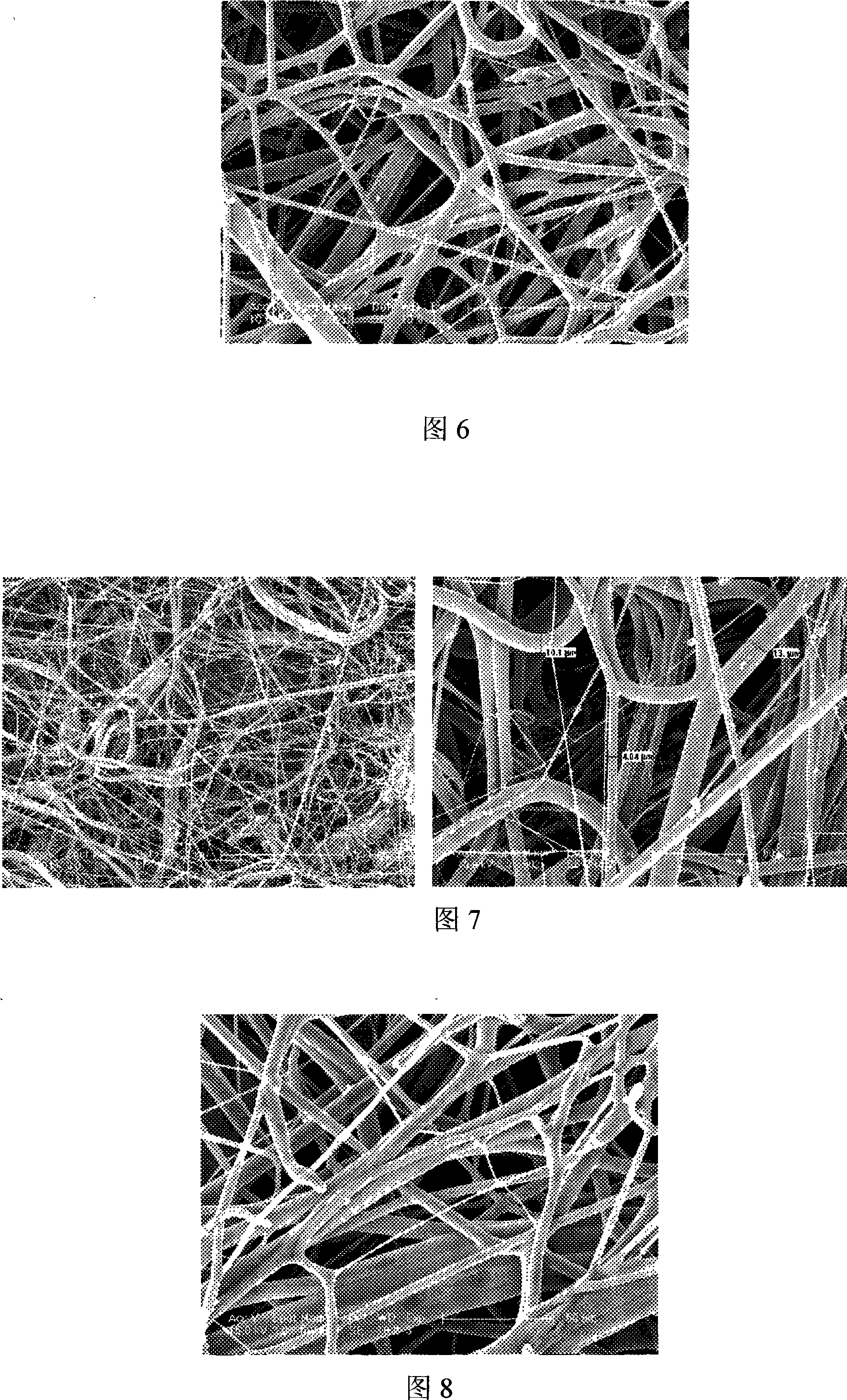

[0029] Melt spinning: 100 g of L-polylactic acid PLLA (viscosity average molecular weight: 100,000) is granulated into particles of about 0.5 cm by a twin-screw extruder. Before spinning, put PLLA particles into the feeder 16, start the main motor 14, adjust the speed of the main motor through the pressure regulating device 15 and keep it at 1500 rpm, and the main motor 14 is fixed by the motor transmission shaft 13 and the rotating disk 12 Make the rotating disk 1 rotate at a uniform speed. At the same time, turn on the power supply of the constant temperature infrared heater 9, and adjust the temperature of the rotating disk 1 to 220°C ...

Embodiment 3

[0031] Example 3: Use of the apparatus for the preparation of nonwovens by melt and solution centrifugal spinning

[0032] Solution spinning: Dissolve 7.5 g of the random copolymer PLGA of lactide and glycolide (wherein the mass composition is 80% lactide, 20% glycolide, viscosity average molecular weight is 160,000) in 100mL chloroform, ultrasonically Shake to fully dissolve. Turn off the constant temperature infrared heater 9 power supply before spinning, and the solution is transferred to the feeder 16. The upper surface of the rotating disk of the spinning device is a horizontal plane (see Figure 1), with a diameter of 50mm, and the speed of the rotating disk is adjusted to 5000 rpm. Open the shutter 18, so that the PLGA solution is delivered to the inner chamber 6 of the rotating disk 1 with a certain flow rate delivery pipe 19, and the PLGA solution flows out to the outer chamber 7 through the small hole passing through the annular partition Silk port 8 ejects fiber. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity average molecular weight | aaaaa | aaaaa |

| Viscosity average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com