Patents

Literature

455results about How to "Wide range of sizes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

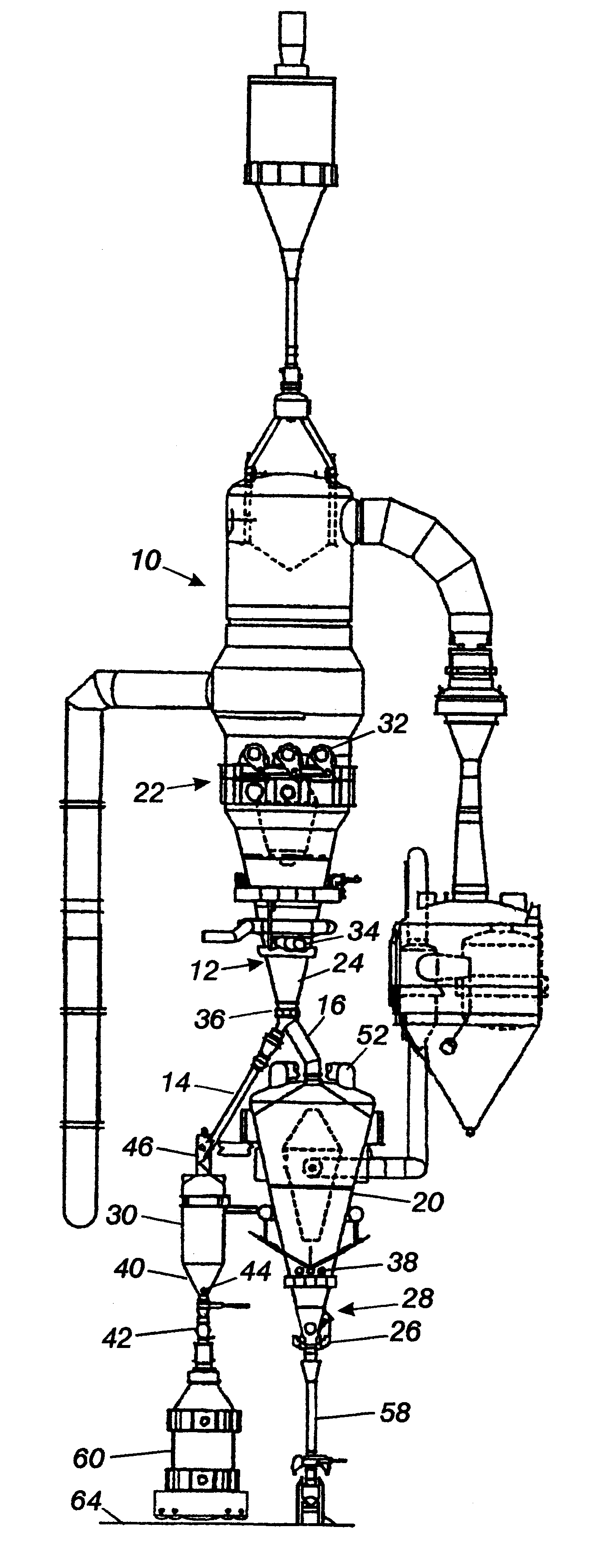

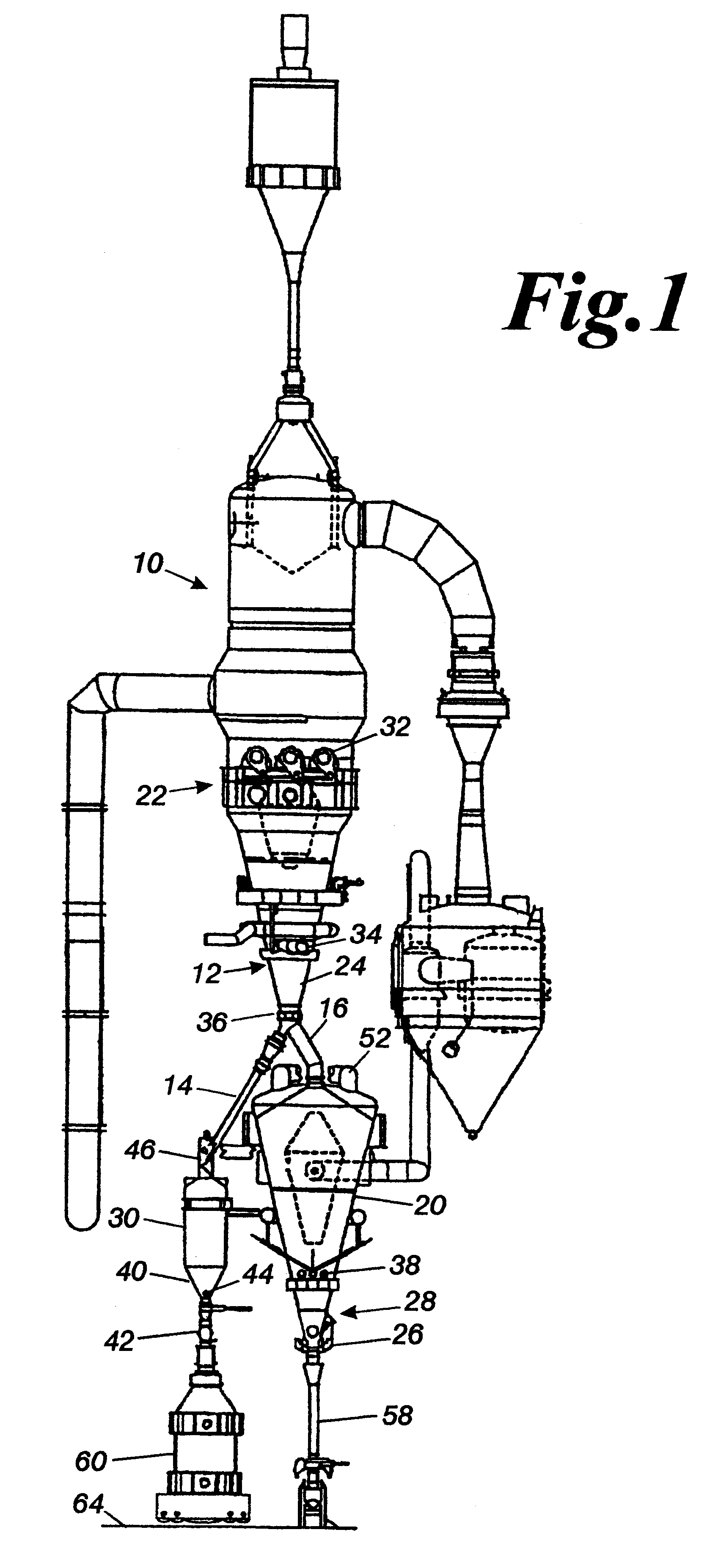

Direct reduced iron discharge system and method

InactiveUS6214086B1No loss in metallizationWide range of sizesMolten spray coatingNuclear energy generationEngineeringDirect reduced iron

A method and apparatus for simultaneously supplying varying proportions of hot and cold direct reduced iron(DRI) material from a source of hot DRI for melting, storage, briquetting, or transport. The system uses gravity to transport hot DRI material from a reduction furnace to a furnace discharge section, which transports desired amounts to a cooling receptacle and to a hot DRI vessel. The cooling section of the apparatus is connected to the furnace discharge section through a dynamic seal leg. The hot section is also connected to the furnace discharge section through separate a dynamic sealing leg and can feed a surge vessel, a briquetter, a storage vessel or a melting furnace. The method of operation is also disclosed.

Owner:IDREX INT BV ROTTERDAM ZURICH BRANCH

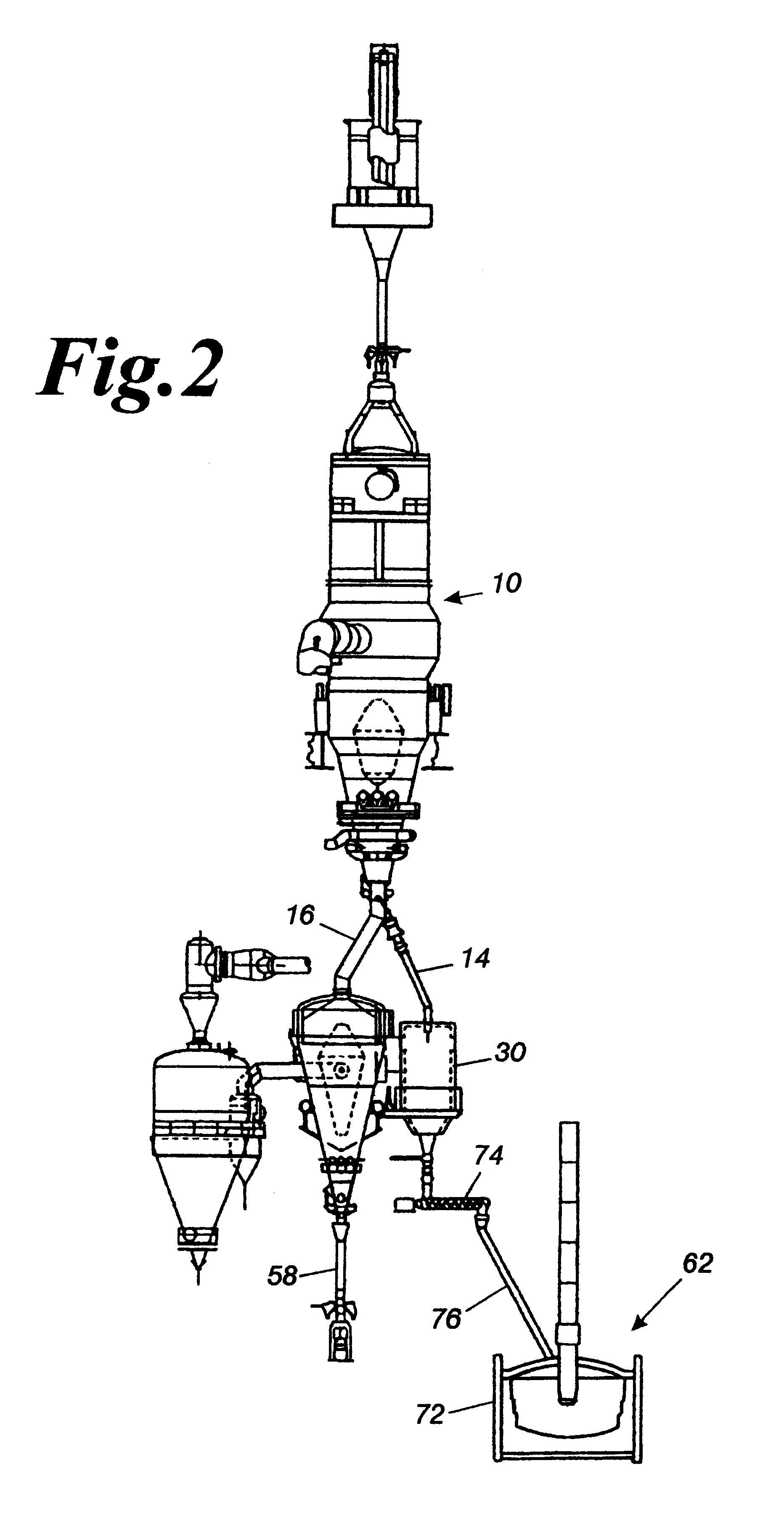

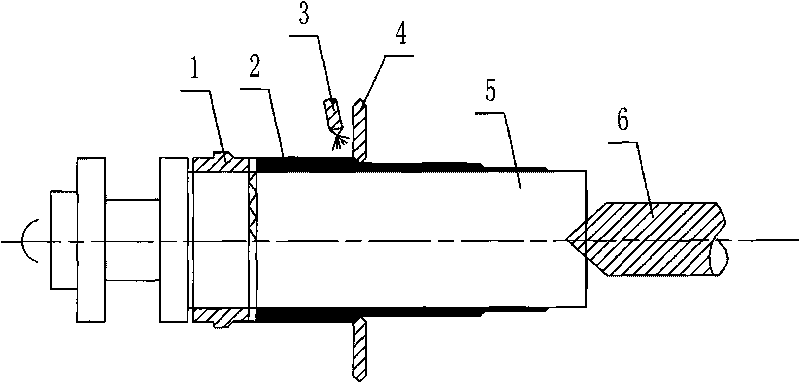

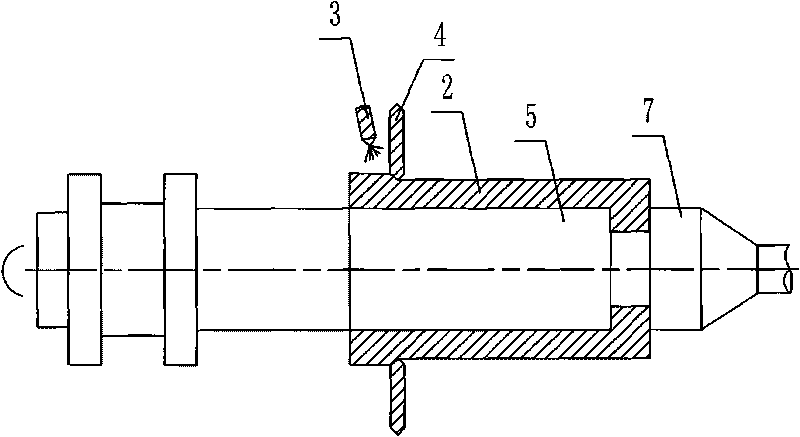

Manufacturing method of large-calibre seamless titanium alloy barrel body

InactiveCN101733641AWide range of sizesEasy to prepareOther manufacturing equipments/toolsTitanium alloyMachining

The invention discloses a manufacturing method of a large-calibre seamless titanium alloy barrel body, which comprises the steps of: 1, casting: casting titanium alloy raw materials into a large-calibre titanium alloy barrel blank by using a vacuum smelting furnace and through a vacuum smelting method; 2, hot isostatic pressing: performing the hot isostatic pressing for the large-bore titanium alloy barrel blank in an inert protective atmosphere by using a hot isostatic pressing device; 3, mechanical machining: processing a chamfer angle for spinning at the head of the large-bore titanium alloy barrel blank after the hot isostatic pressing by using mechanical processing equipment to obtain a spinning barrel blank; 4, spinning: thermally spinning the mechanically processed spinning barrel blank with the total deformation rate not less than 60% for many times by using spinning equipment to obtain a large-bore seamless titanium alloy thin-wall barrel body; and 5, subsequent treatment. The production process has short process flow, high yield, low cost, high utilization rate of materials and easy realization, and the defects of the large-bore seamless titanium alloy barrel body, such as complex process, high cost, low yield and the like of the traditional production process can be effectively solved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

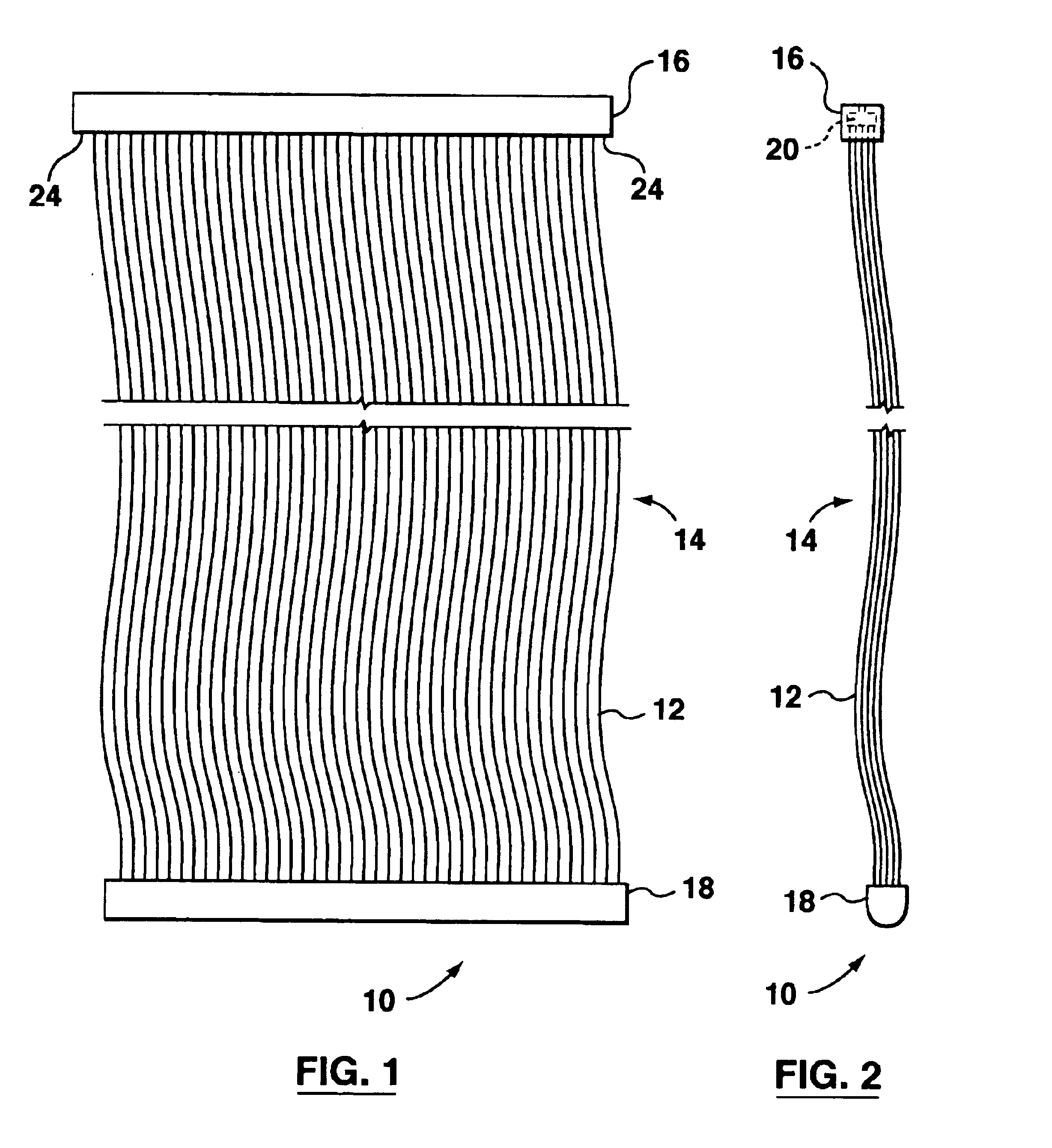

Stretchable absorbent article having lateral and longitudinal stretch properties

Absorbent articles with carefully controlled stretch properties are disclosed. In particular, the articles exhibit stretch not only in the lateral direction but also in the longitudinal direction. Specifically, the articles have a biaxial stretch ratio, which refers to a ratio of stretch along the hip circumference of the article to the amount of stretch in the longitudinal direction, that is from about 1.0 to about 2.5, and particularly from about 1.1 to about 1.5. Absorbent articles made in accordance with the present invention are capable of accommodating a relatively large size range of wearers. The articles also exhibit improved fit and prevent sagging or drooping of the crotch region, even after the crotch region has been wetted.

Owner:KIMBERLY-CLARK WORLDWIDE INC

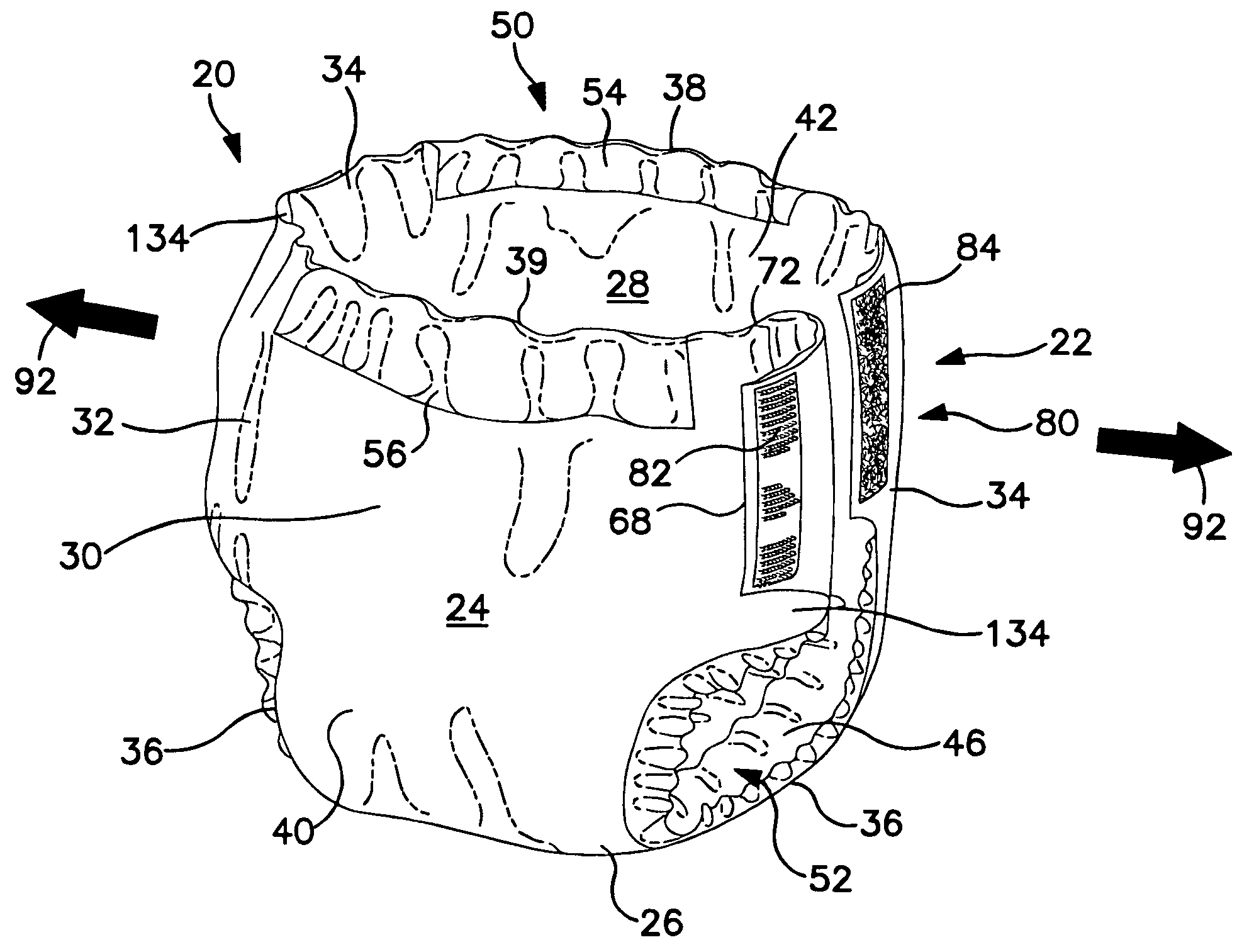

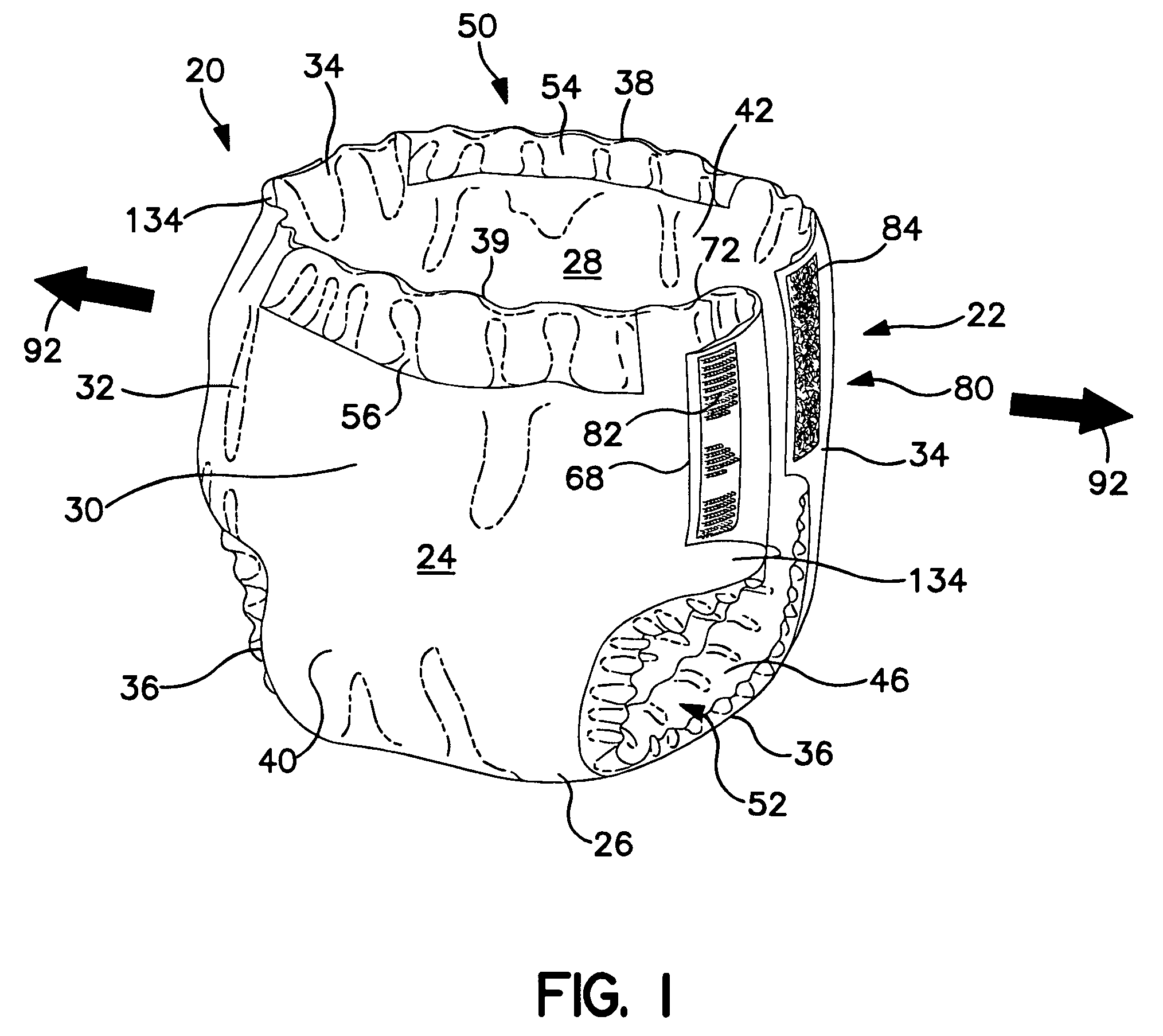

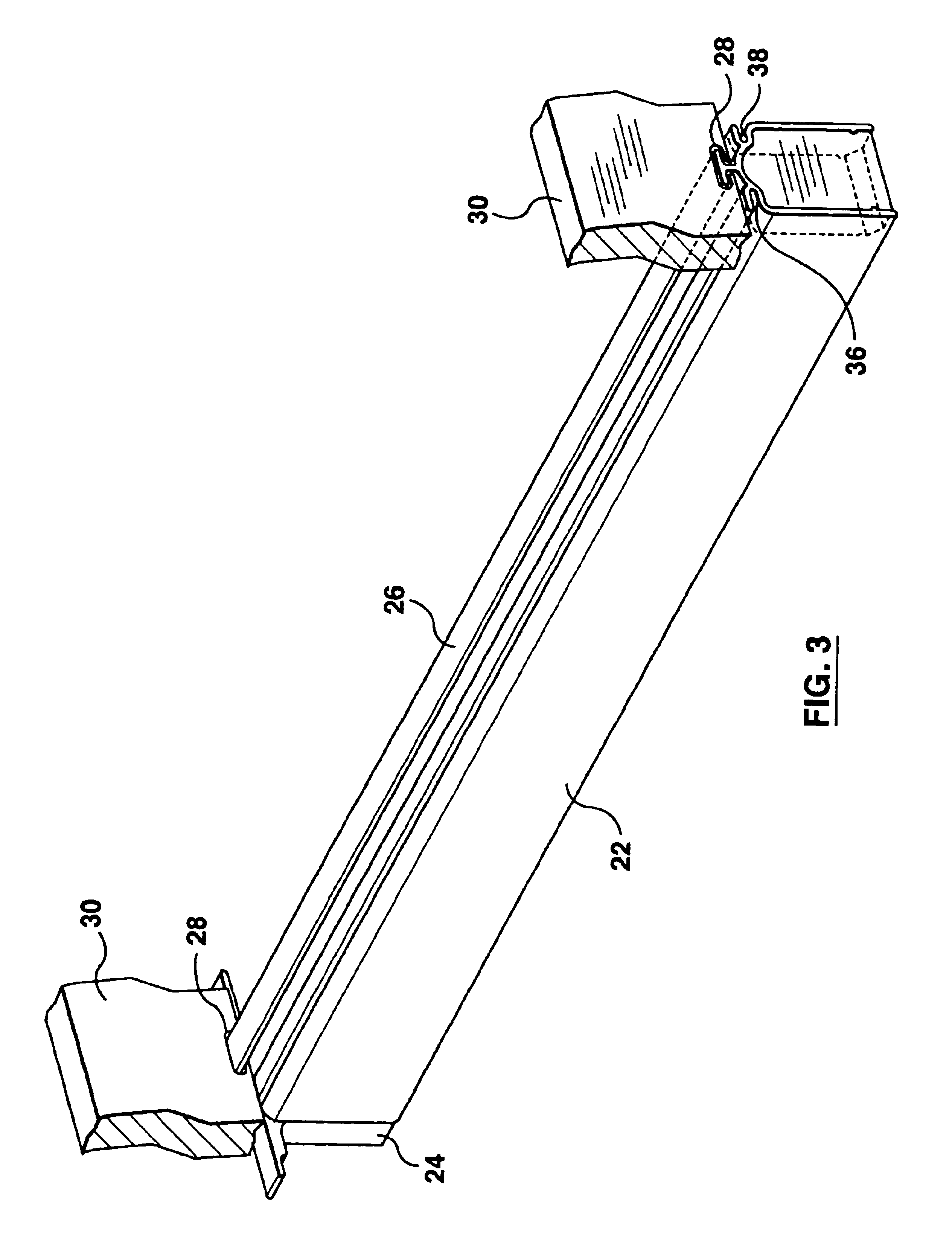

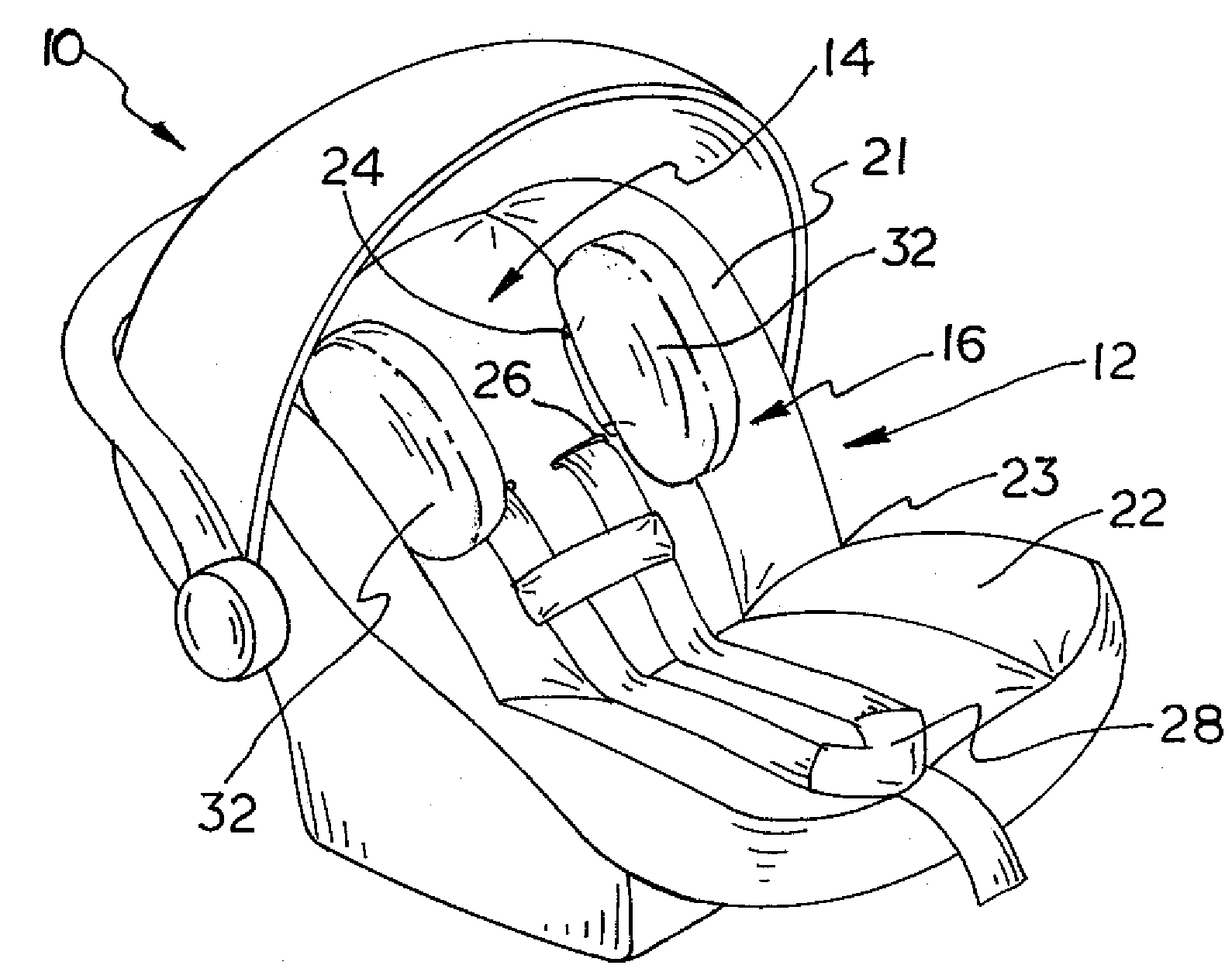

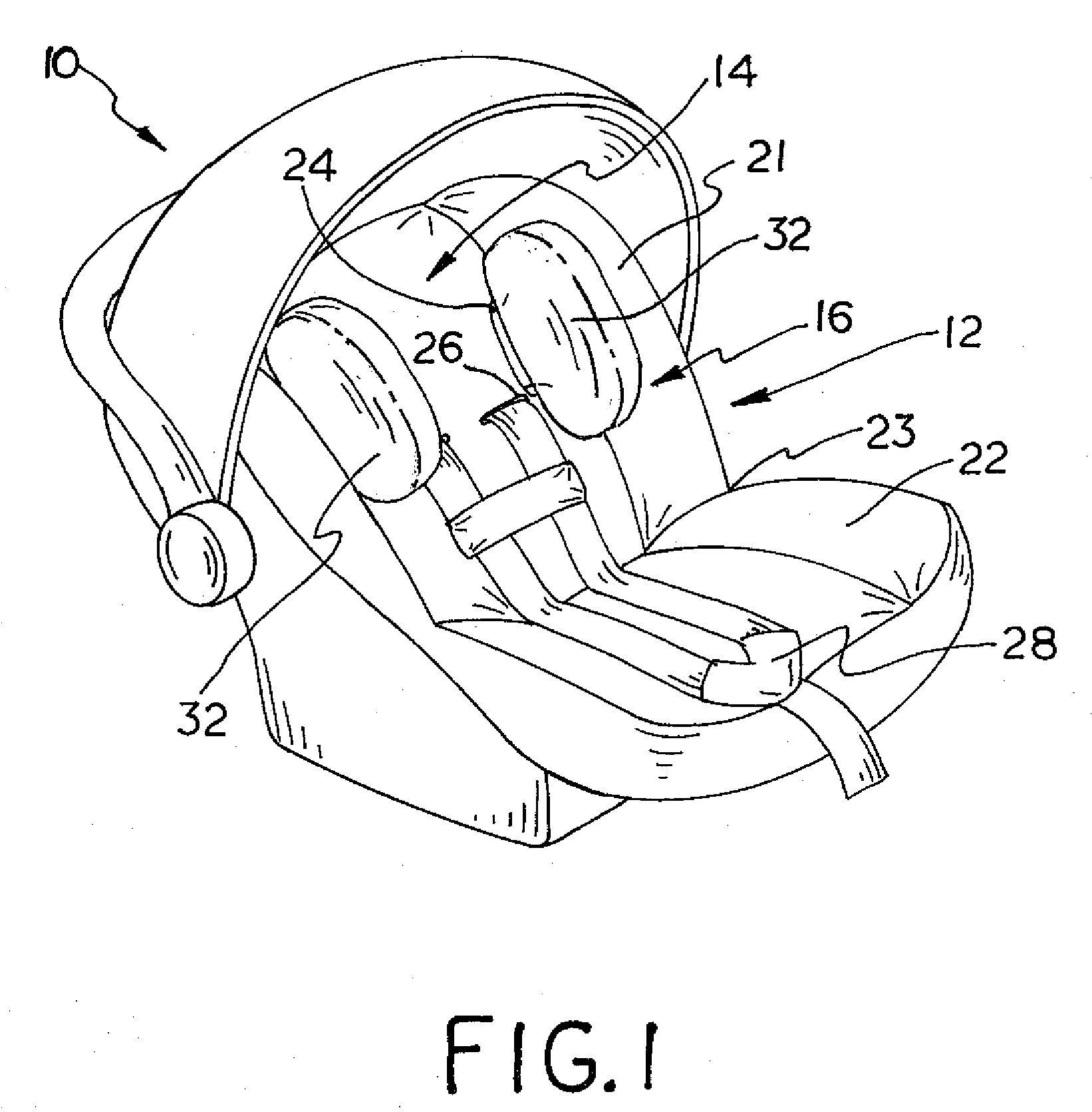

Head support and seat pad assembly for a child seat

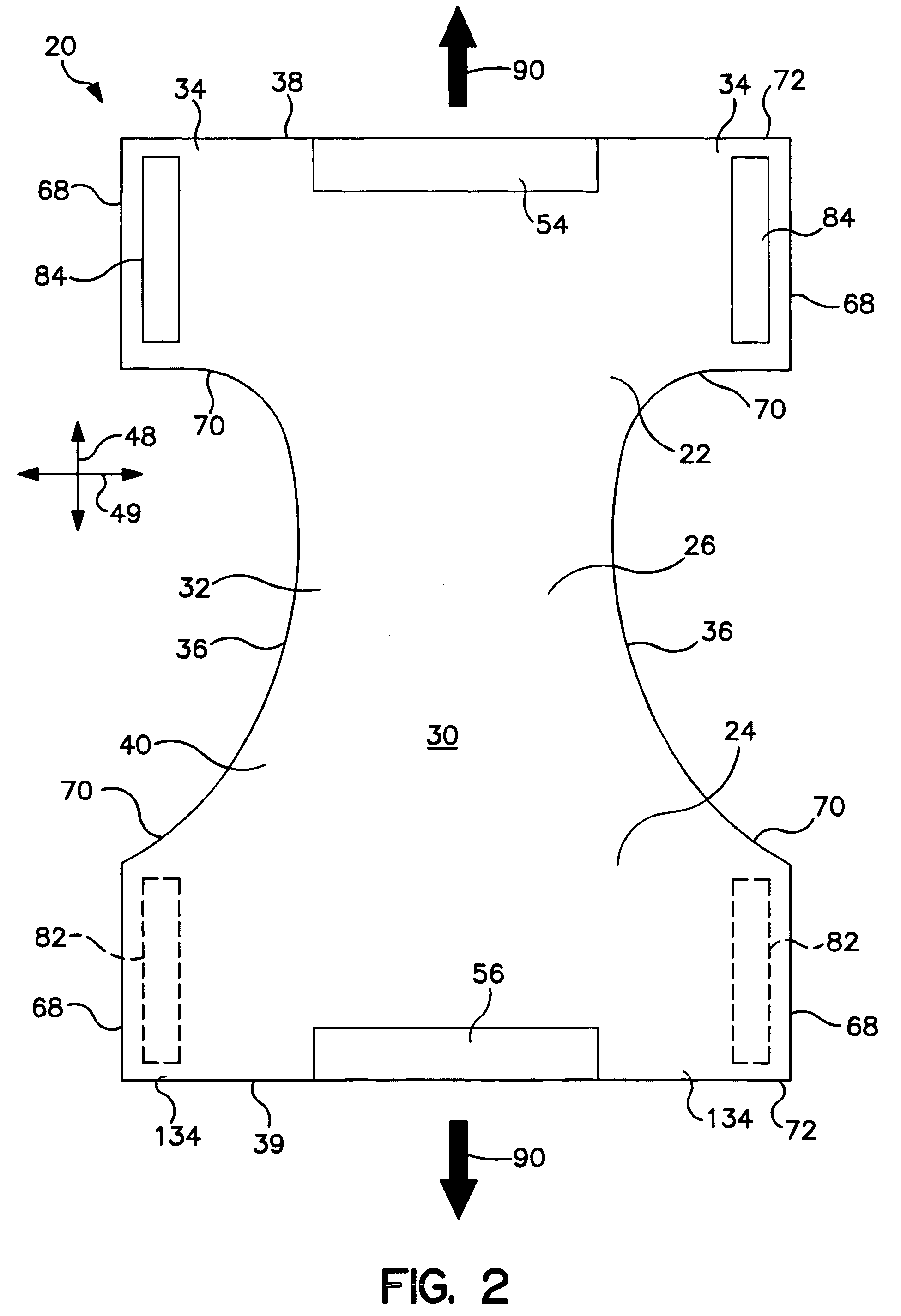

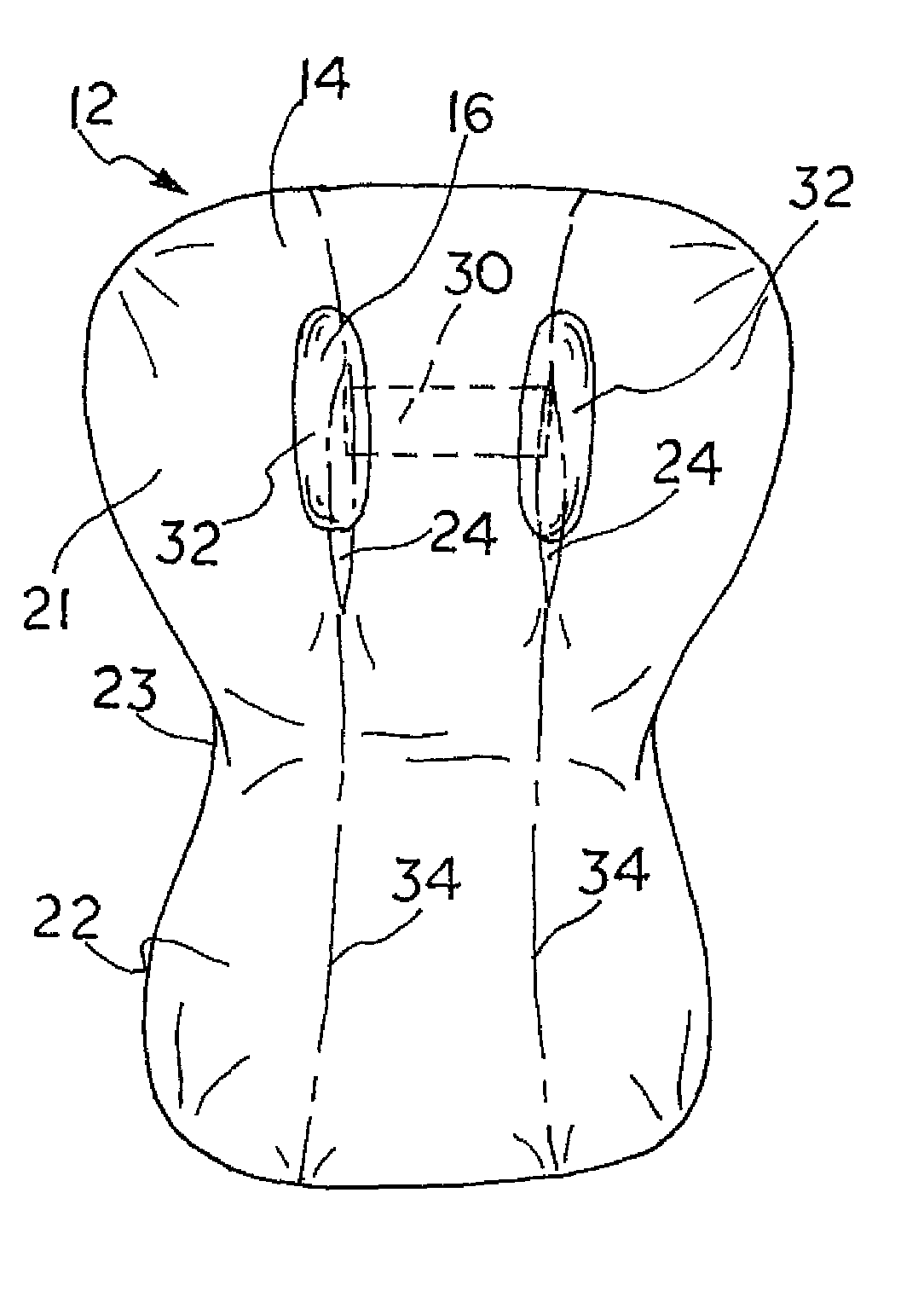

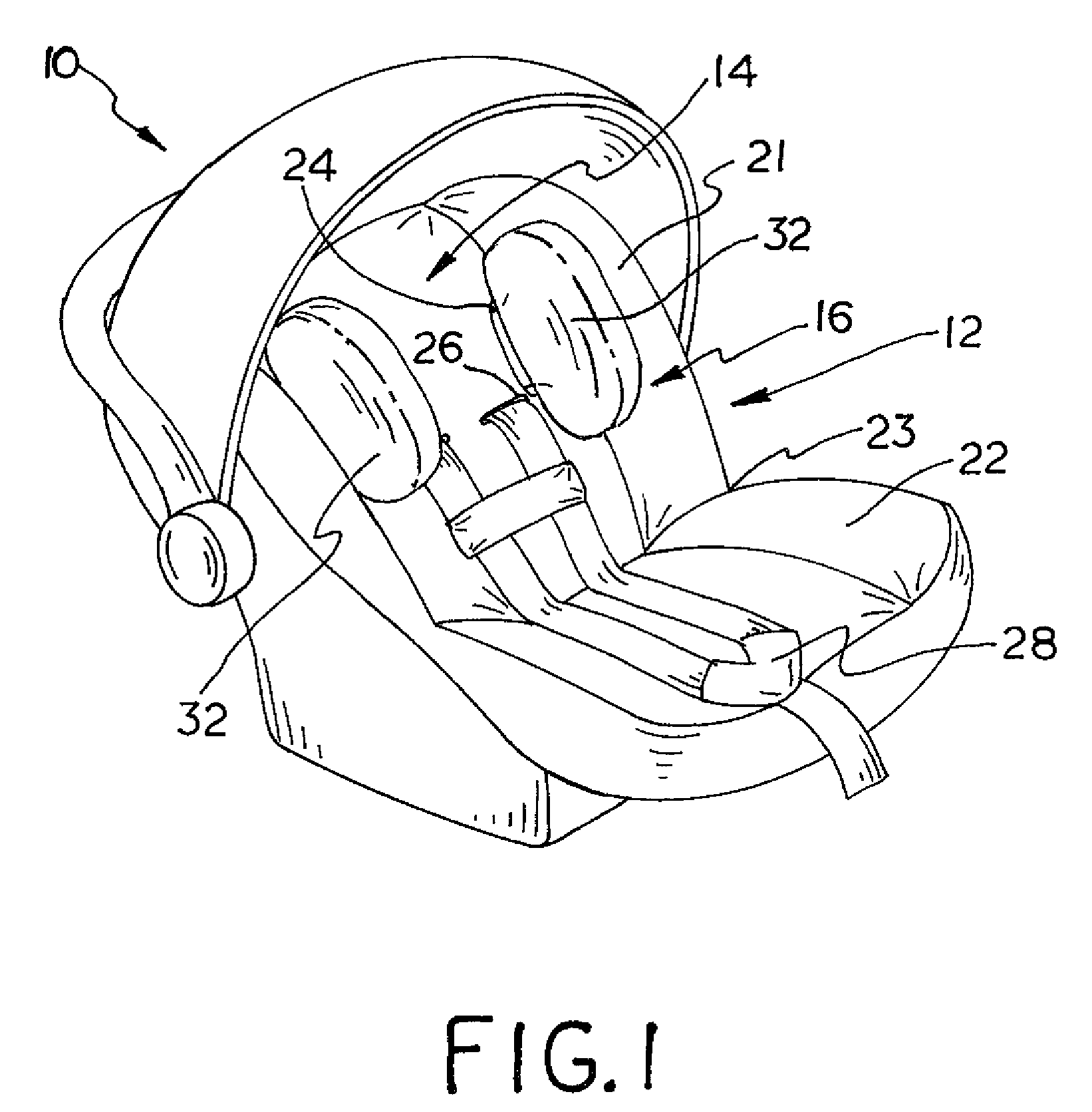

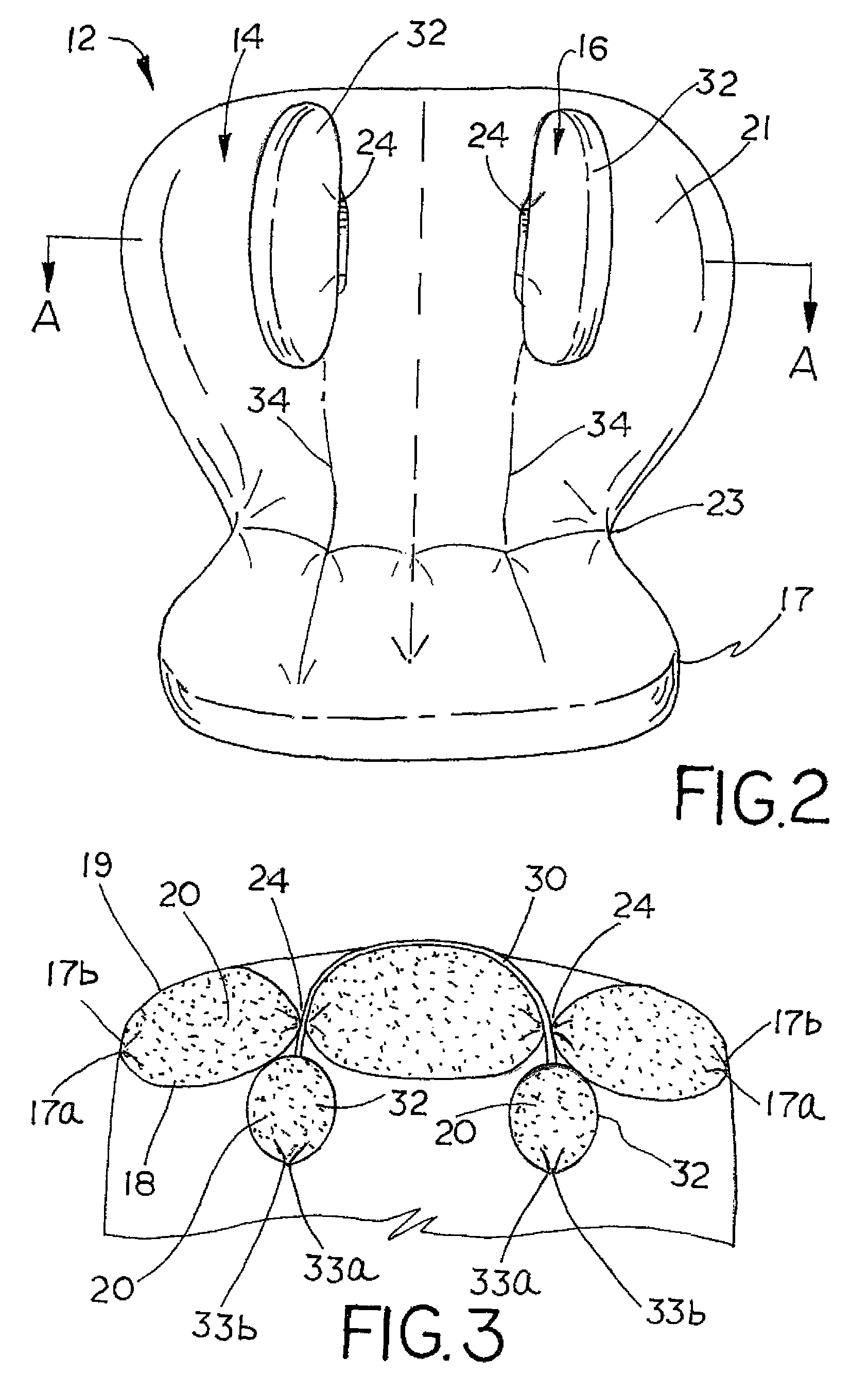

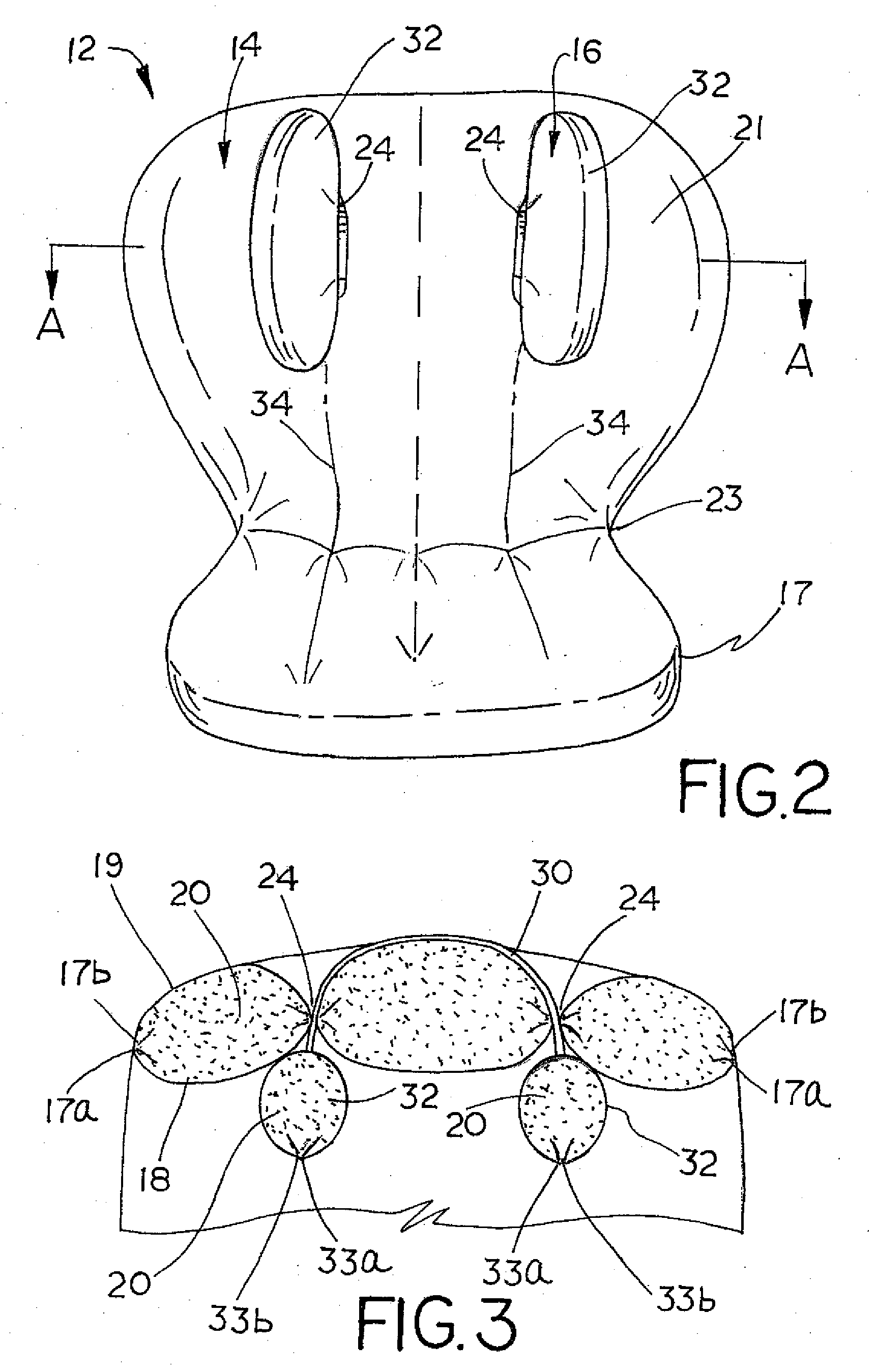

ActiveUS7806472B2Expanded size rangeWide range of sizesVehicle seatsStuffed mattressesCar seatEngineering

A seat pad assembly is disclosed including a body pad for placement on the seating surface of a child seating device. The body pad has a front side, a back side, and two spaced apart vertical slots through the pad. The seat pad assembly has a head support with a connecting strip extending between a pair of laterally spaced apart cushions. The head support is generally H-shaped and installed on the pad through the slots with the pair of cushions on one side of the pad and the connecting strip on the other side. The head support is slidable along the slots to adjust the vertical position of the cushions. The seat pad assembly can be used on a child seating device such as a children's car seat, an infant carrier, a stroller, an infant swing, or the like.

Owner:GRACO CHILDRENS PROD INC

A high-performance cooper-coated aluminum rectangle section compound conductive bus bar and its making technology

ActiveCN101241778AMeet the requirements of multiple specificationsGreat widthSingle bars/rods/wires/strips conductorsMeasuring devicesCopperAluminum composites

The present invention provides a high-performance copper-clad aluminum cross section composite conductive bus-bar and the preparing technique thereof, and the invention relates to a rectangle-cross section bimetal composite material and the preparation thereof. The copper-clad aluminum rectangular cross section composite conductive bus-bar is compounded by the core-part aluminum and the coating layer copper. The area proportion of the coating copper layer is 15to 50 The technique comprises the following procedures: Adopting horizontal continuous casting for directly compounding and forming the copper-clad aluminum composite blank. Commonly flat-roller rolling and finish drawing-pulling the copper-clad aluminum blank according to requirement or rolling with the flat roller provided with a vertical roller, the range of the rolling speed is 3-50m / min, and the single-pass relative reduction is between 15and 40 The speed range of finish drawing-pulling is 1-20m / min and the single-pass cross section scalage is 10%. When the multiple-pass relative reduction is up to 70%, the low-temperature intermediate annealing is executed to the copper-clad aluminum composite conductive bus-bar. The annealing temperature is between 250 and 450 DEG C and the annealing time is between 0.5 and 3h. The annealed composite conductive bus-bar is executed with hole-form rolling or drawing. The invention not only can produce the high-performance copper-clad aluminum cross section composite conductive bus-bar, but also has the advantages of short process flow and high efficiency of the producing method.

Owner:UNIV OF SCI & TECH BEIJING

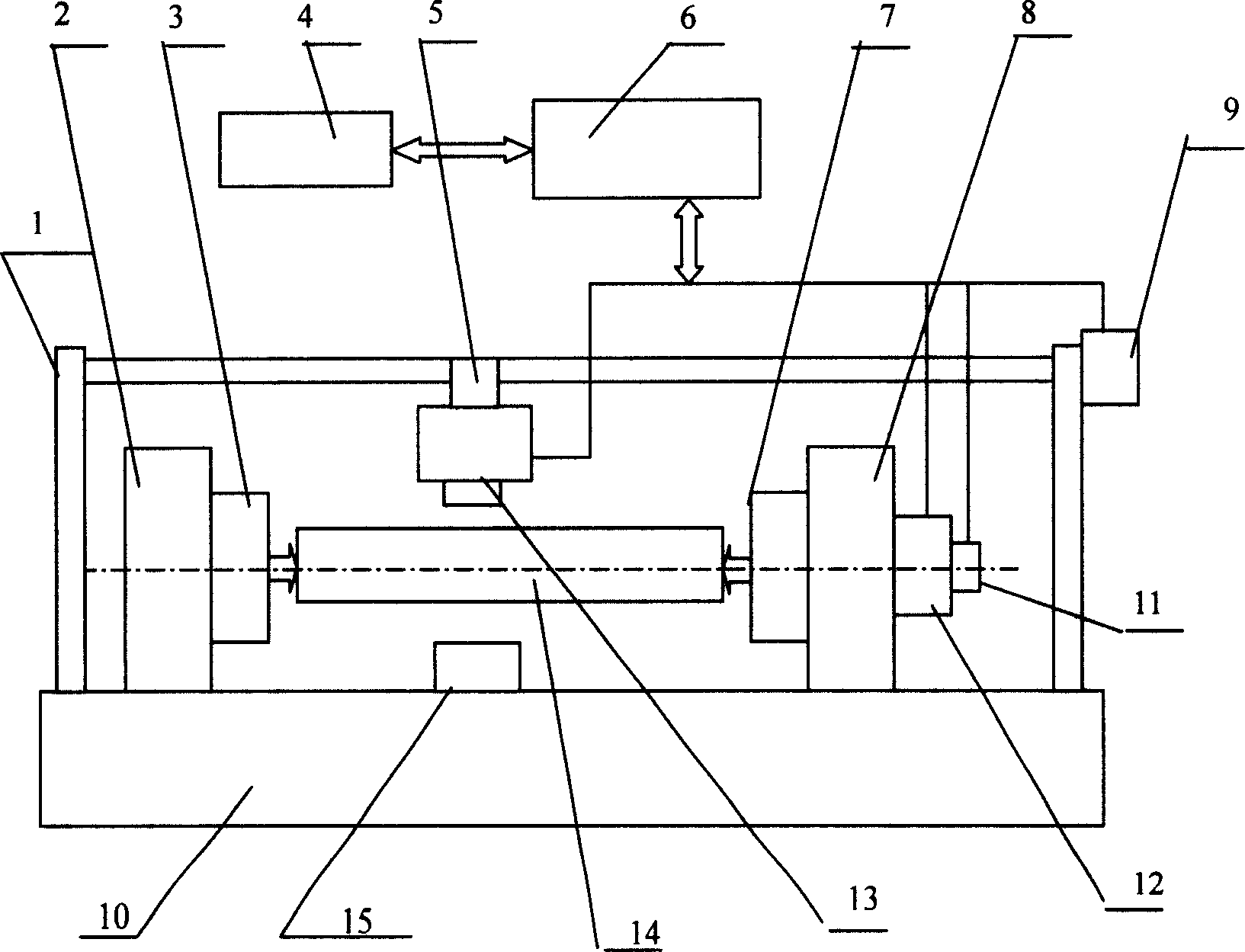

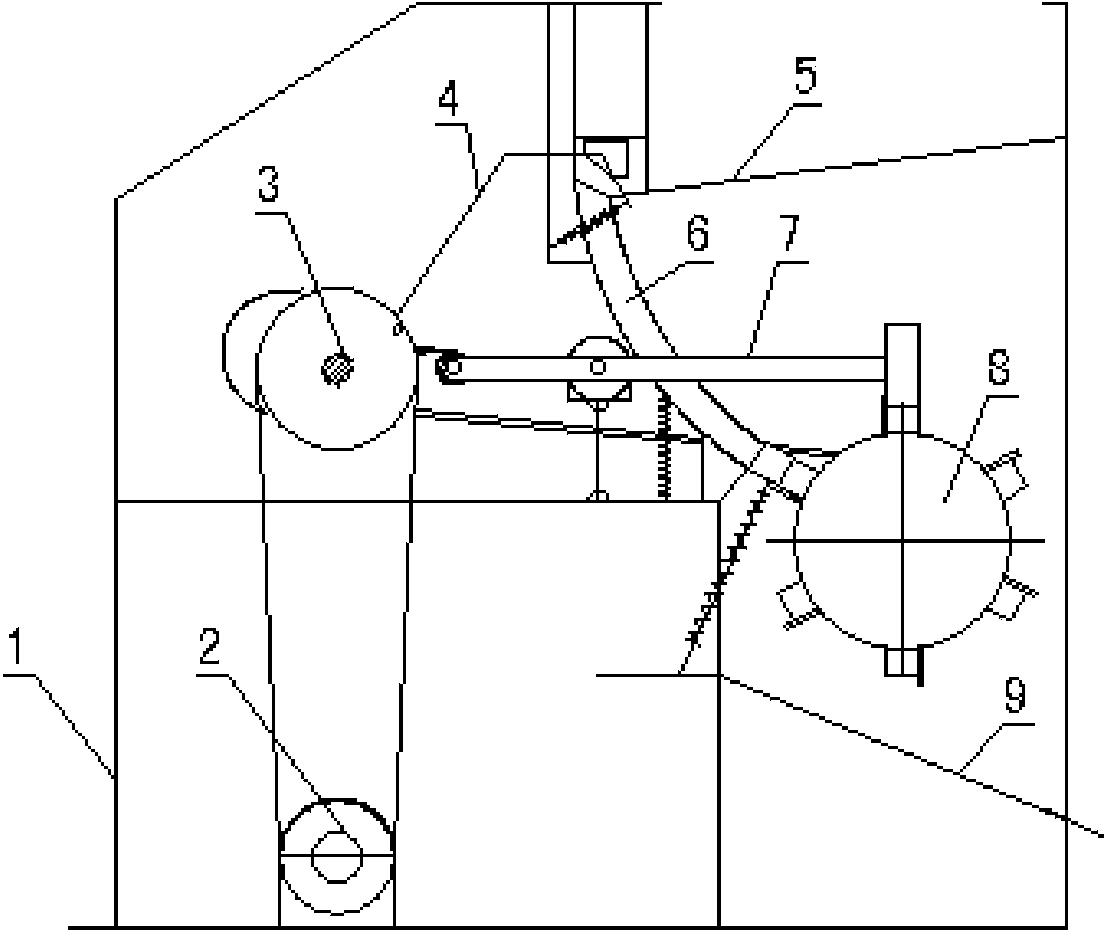

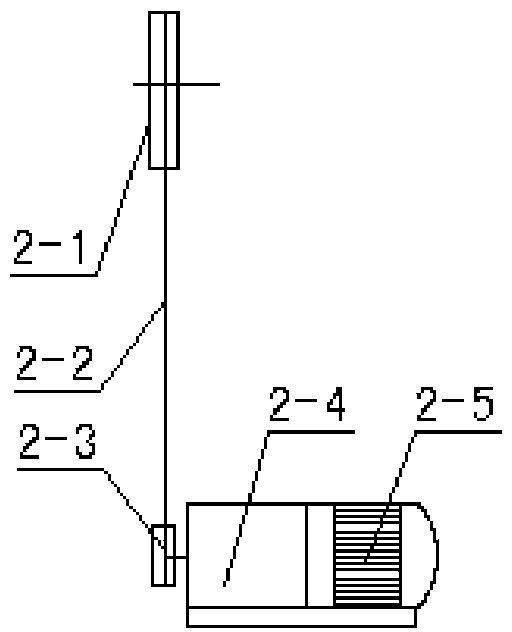

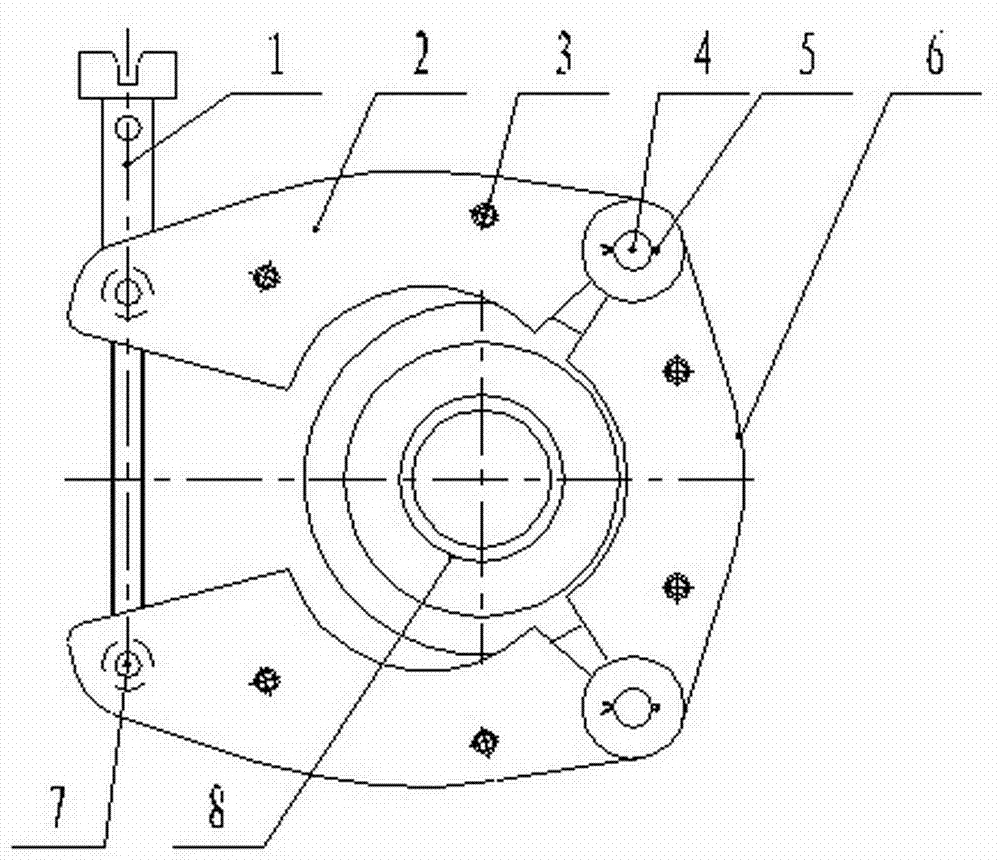

Axial workpiece bending deformed planar array CCD measuring method and apparatus

InactiveCN1645041AFast measurementWide range of sizesUsing optical meansProcess systemsControl system

A method for measuring the bending deflection of shaft parts includes using a planar array to collect image data of shaft parts, sending collected data to I / O card and then to process control computer for obtaining deflection parameter of the shaft parts after data is processed. The device for realizing the method consists of image collection and process system including planar array CCD, back light source, I / O card and process control computer as well as parts rotary control system including gear box, stepping motor and coder.

Owner:SOUTH CHINA UNIV OF TECH

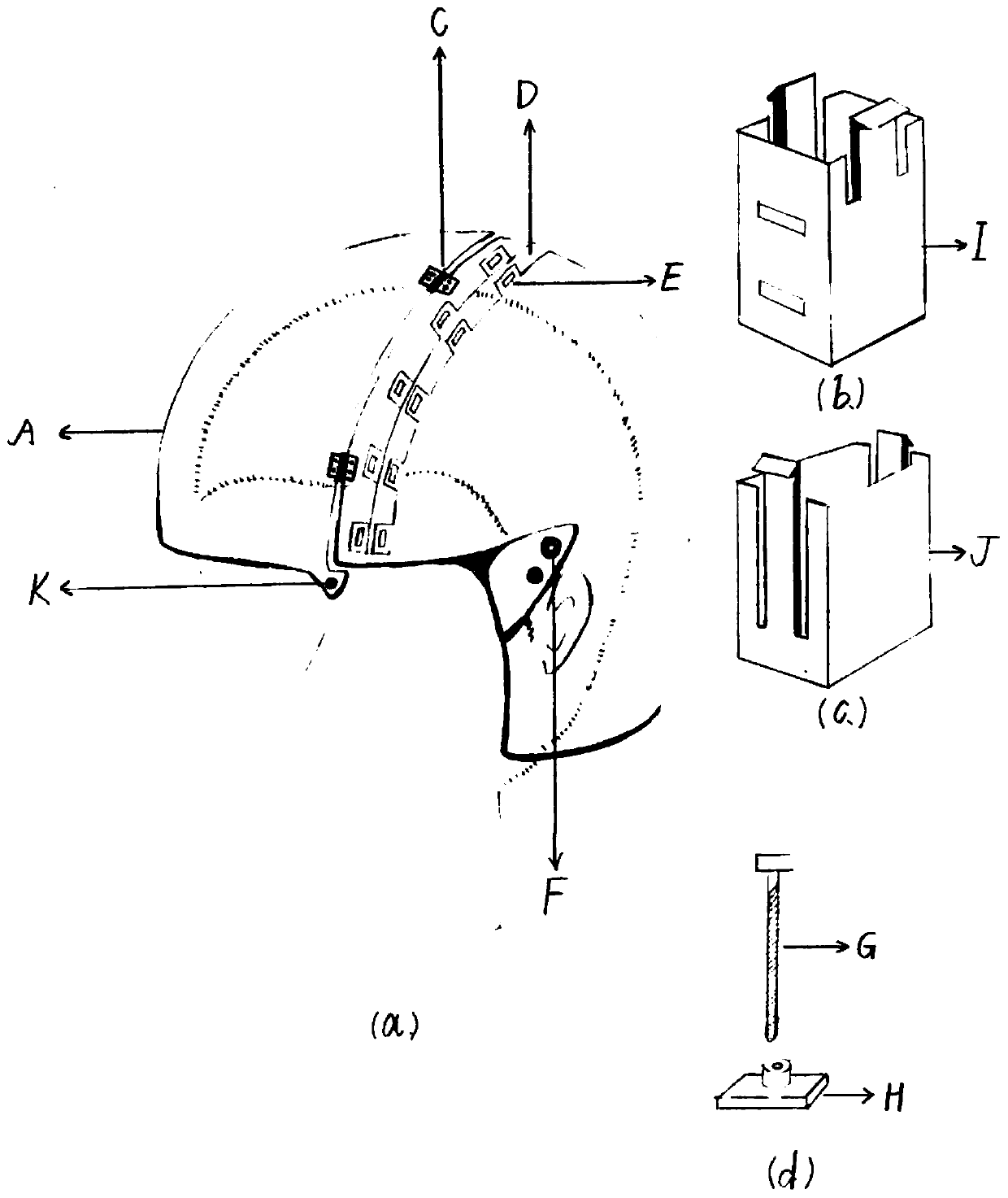

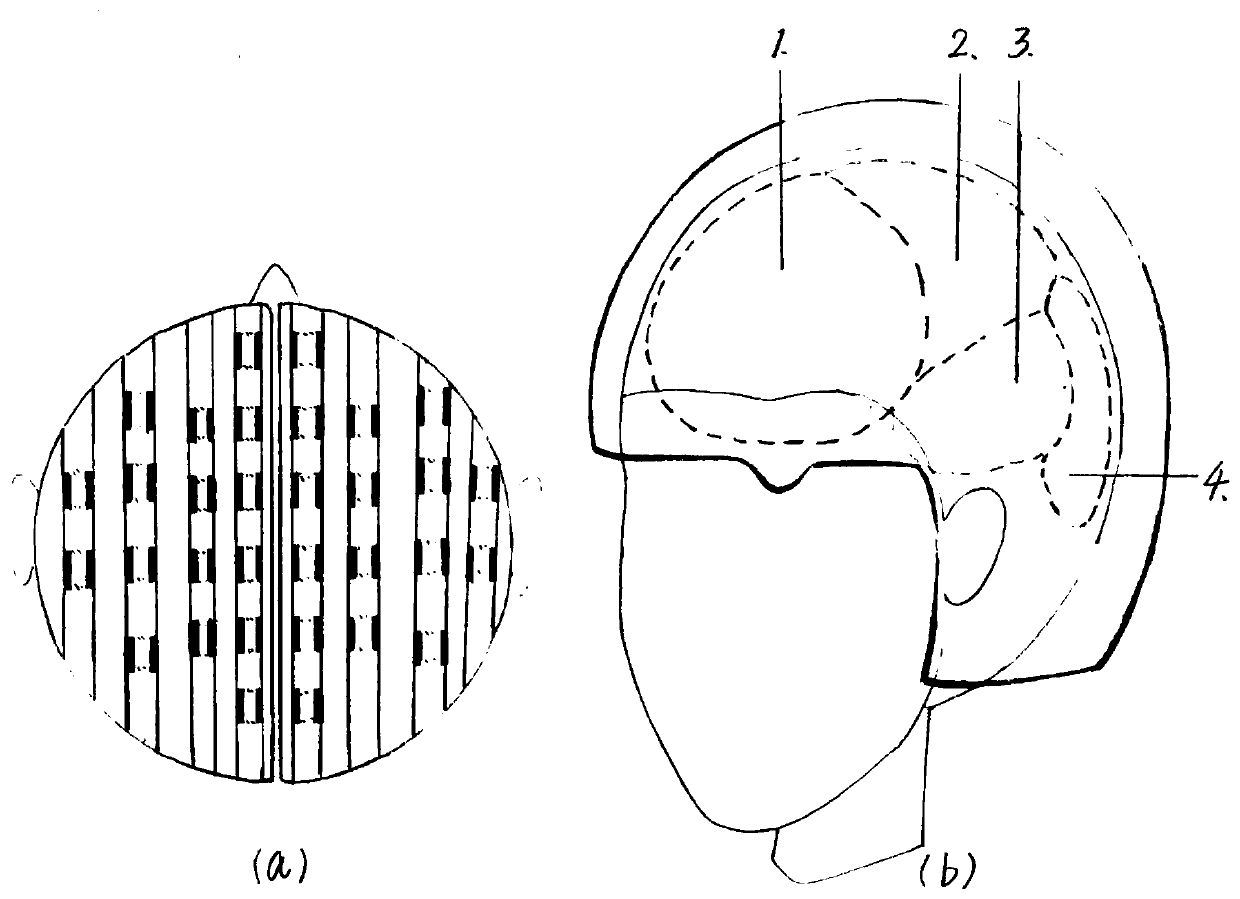

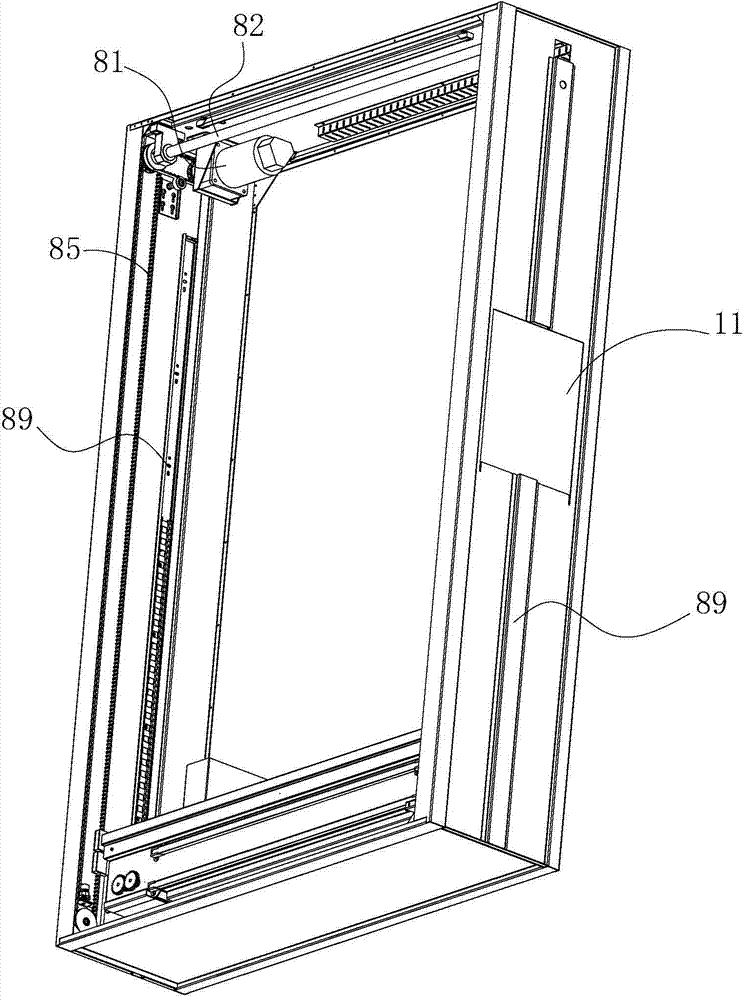

Slideway type wearable brain magnetic cap for measuring human brain magnetic field signals

The invention relates to a slideway type wearable brain magnetic cap for measuring human brain magnetic field signals, belongs to the field of biomedical engineering, and relates to a medical instrument. The slideway type wearable brain magnetic cap is composed of a slideway type brain magnetic cap body and a telescopic clamping groove; the left part and the right part of the cap body are connected through three arc-shaped hinges; a plurality of slideways are symmetrically distributed on the left and right parts of the cap body, and rectangular holes are designed in the slideways; cylindricalbases with threads inside are respectively arranged above the left ear side and the right ear side of a person; the telescopic clamping groove is composed of a fixed position clamping groove and a telescopic clamping groove body; distribution of the slideways and interval design of the rectangular holes are carried out by referring to an internationally universal 10-20 standard electroencephalogram acquisition lead system and physiological structures and functional partitions of human brains; and a reference coordinate system is established by taking three short cylinders on the nose root andthe left and right ear sides of a person as references, so that 3D data modeling is completed. The slideway type wearable brain magnetic cap is low in detection cost, high in practicability and capable of being used for efficiently measuring human brain magnetic field signals.

Owner:BEIHANG UNIV

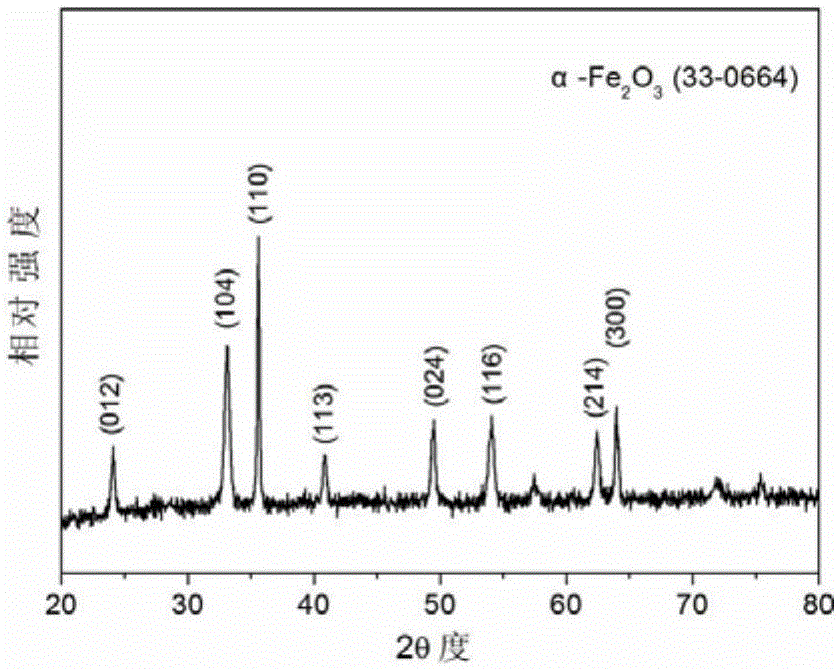

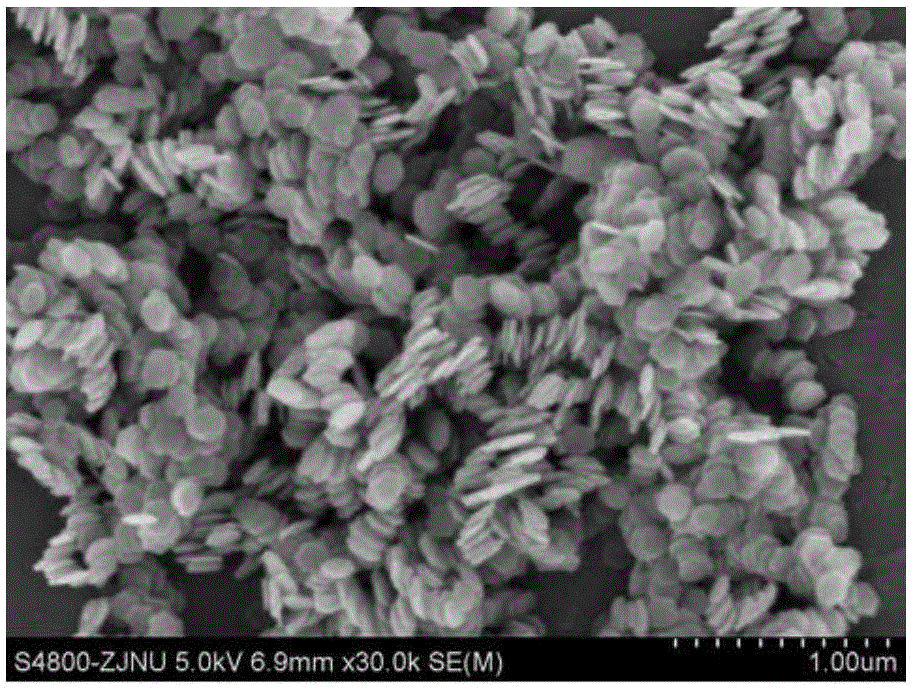

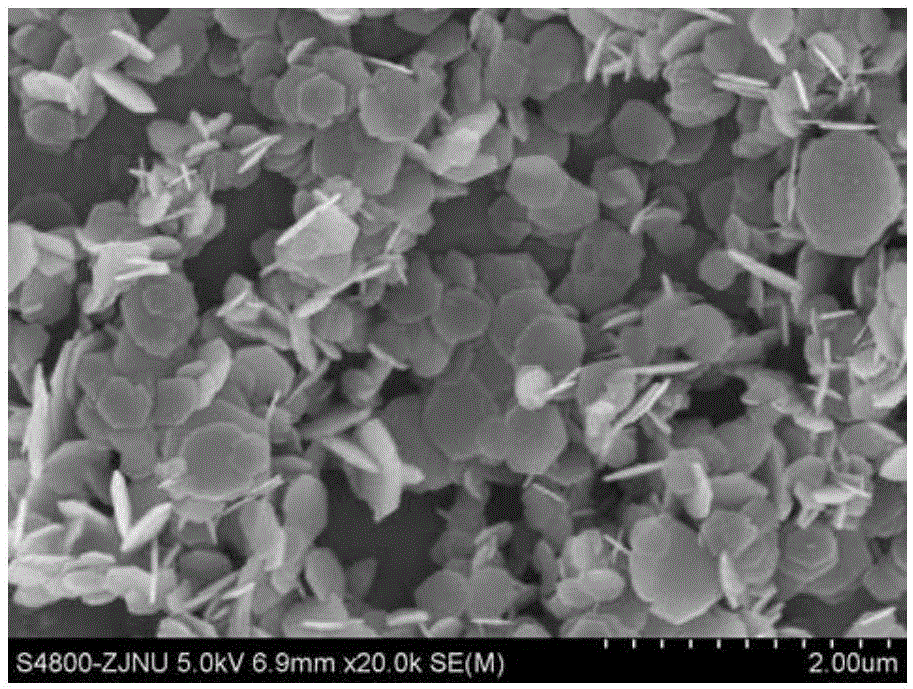

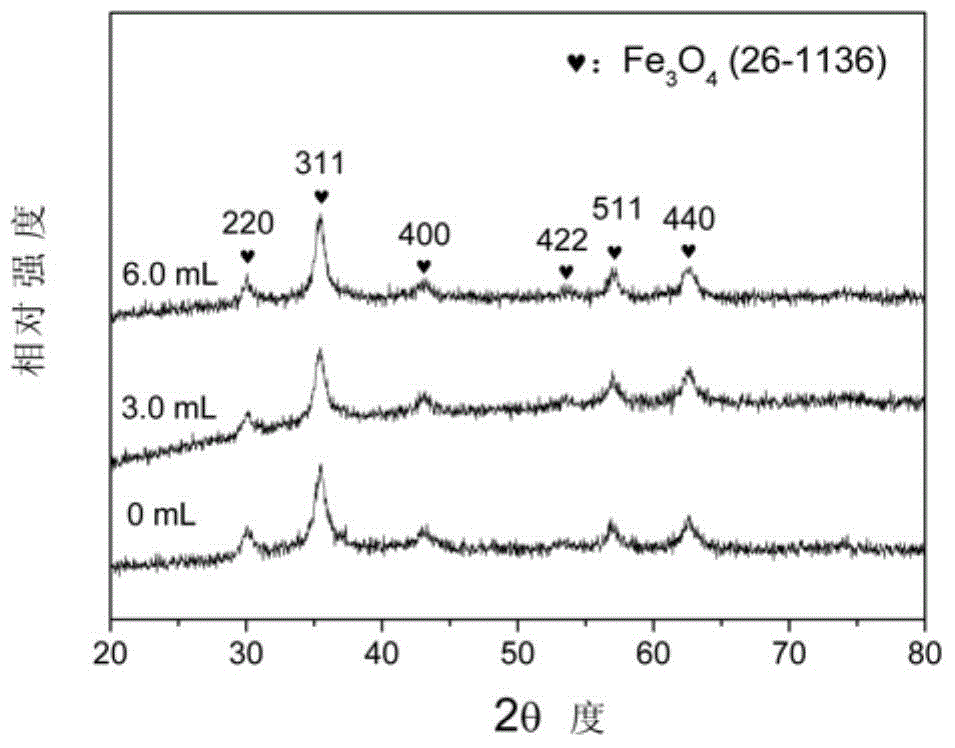

Magnetic micro-nano sheet, and preparation method and application thereof

ActiveCN105129865AGood dispersionImprove uniformityFerroso-ferric oxidesFerric oxidesMicrowaveSURFACTANT BLEND

The invention discloses a magnetic micro-nano sheet, and a preparation method and an application thereof. The magnetic micro-nano sheet is a dimension-adjustable alpha-Fe2O3 or Fe3O4 micro-nano sheet with good dispersion and homogeneity. The alpha-Fe2O3 micro-nano sheet is prepared through a mixed solvent thermal technology, and the dimension and the morphology of the micro-nano sheet are regulated through changing the volume of water, the reactant concentration, a molar ratio of an alkali to a metal salt and the type of the alkali (the diameter of a hexagonal or subround nano-sheet is 60-510nm, and the thickness of the hexagonal or subrotund nano-sheet is 8-30nm; and the diameter of an irregular micro-sheet is 2-16[mu]m, and the thickness of the irregular micro-sheet is 0.35-1[mu]m). The alpha-Fe2O3 is converted into the Fe3O4 micro-nano sheet with strong magnetism and excellent microwave absorption performance through a carbon thermal reduction process. The preparation method has the advantages of no need of a surfactant, simple preparation process, cheap and easily available raw materials, low cost, high output, and easy industrial application and popularization. The micro-nano sheet provided by the invention has application prospects in fields of photocatalysis, microwave absorption, electrode materials, magnetic record materials, sensors and biomedical engineering.

Owner:ZHEJIANG NORMAL UNIVERSITY

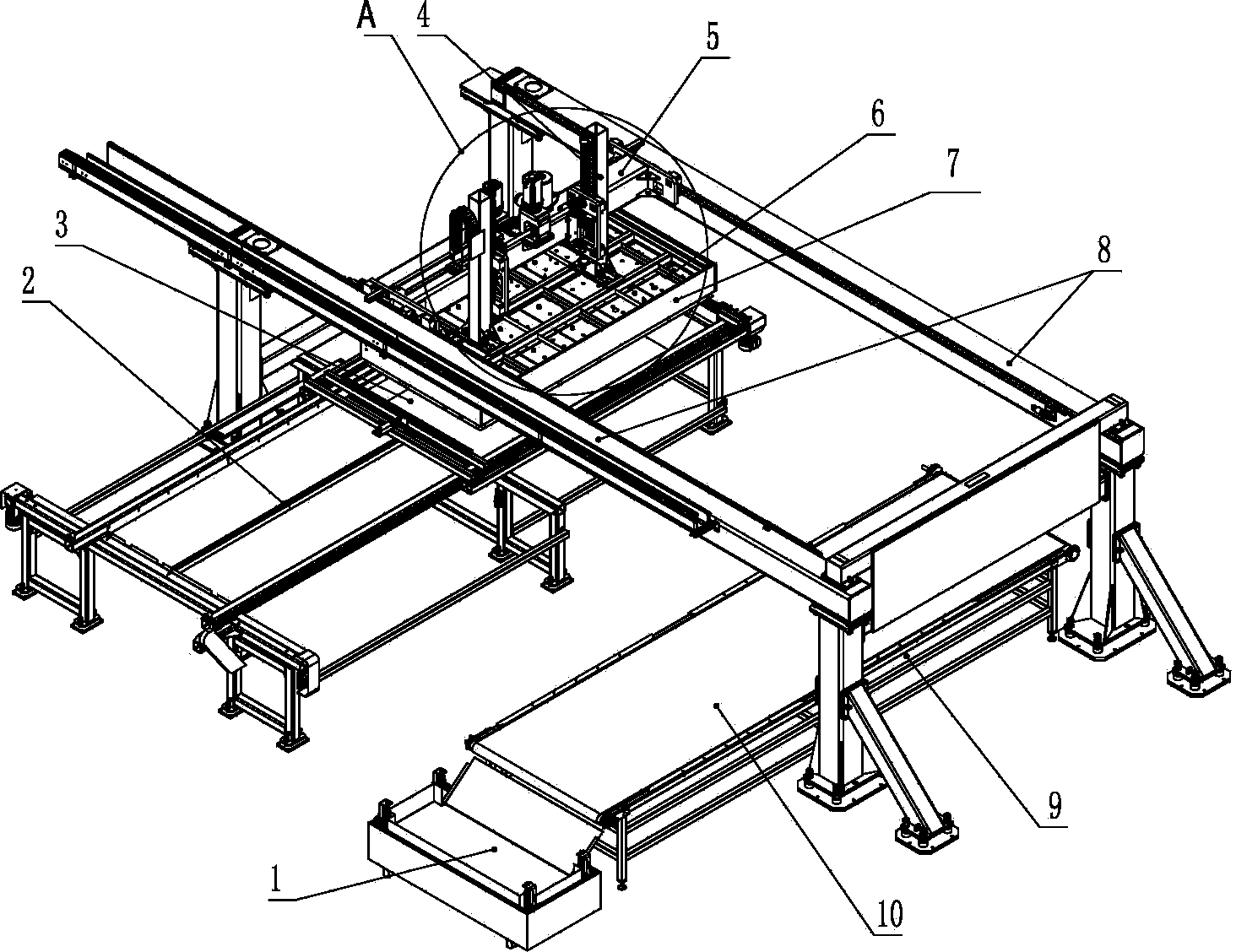

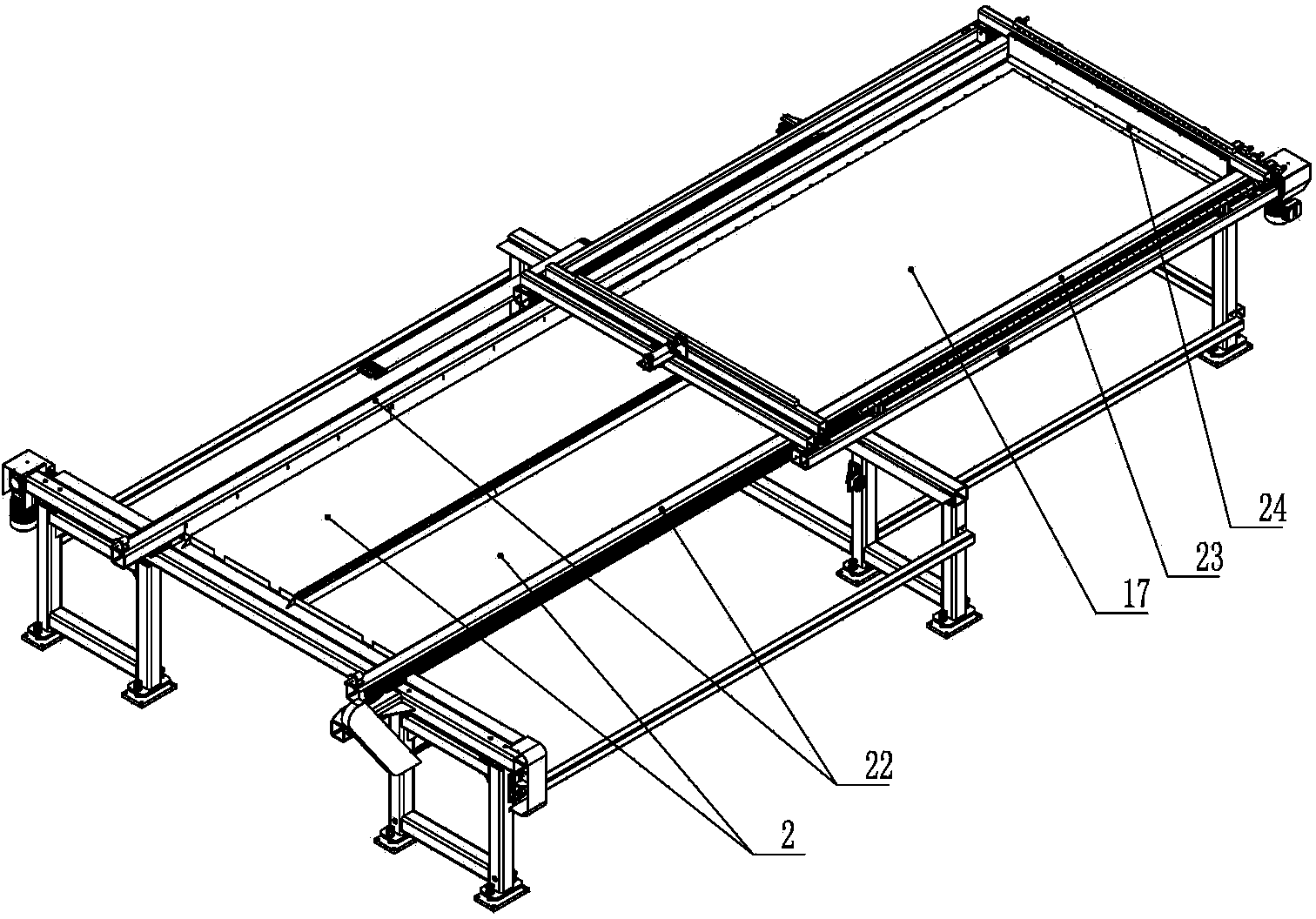

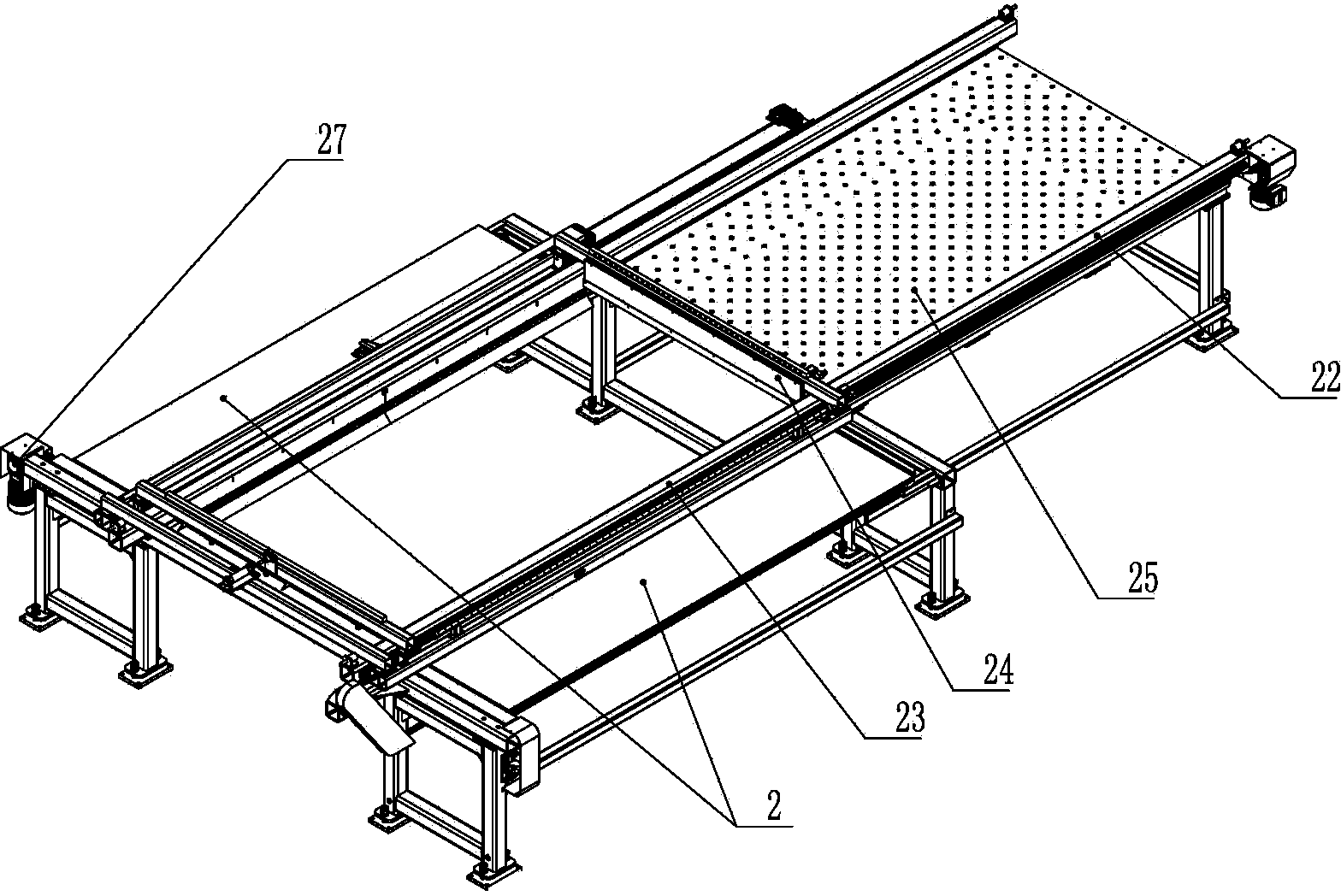

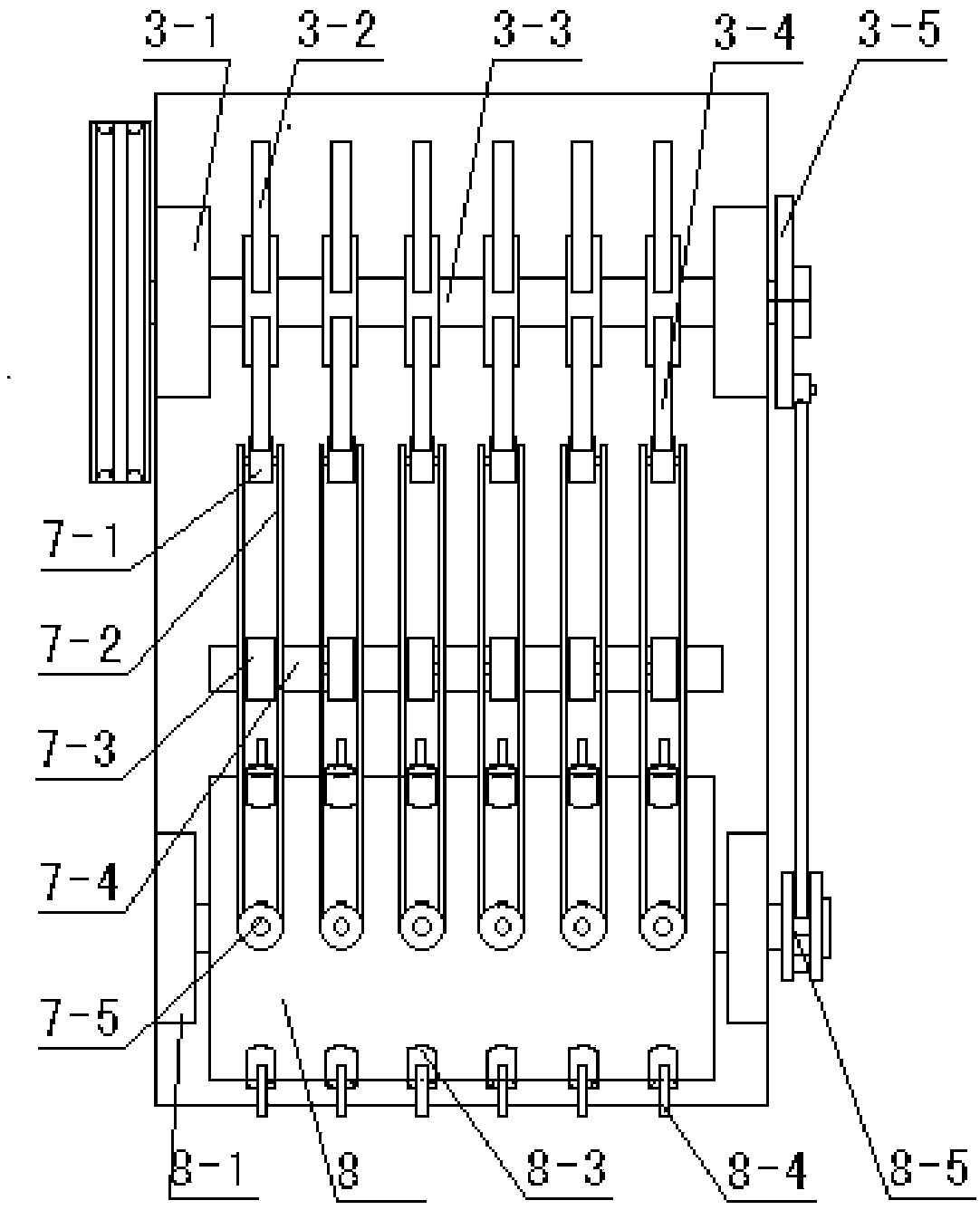

Laser cutting plate waste material separation part sorting system

ActiveCN103962736AEasy to separateReliable separationMagnetic separationMetal working apparatusLaser cuttingManipulator

The invention discloses a laser cutting plate waste material separation part sorting system in the field of laser cutting machines. The laser cutting plate waste material separation part sorting system comprises two parallelly arranged supporting beams. A beam capable of moving horizontally is movably connected between the two supporting beams. The beam is connected with a lifting column through a lifting transmission mechanism, the lower portion of the lifting column is connected with a blanking mechanical hand, a waste material separation table and a sorting working table are arranged below the supporting beams and correspond to the blanking mechanical hand, the blanking mechanical hand comprises a rectangular frame, a support is arranged in the frame, a mounting plate is arranged below the support, a plurality of liftable electric permanent magnets with suction surfaces downward are installed on the lower side of the mounting plate through an elastic mechanism, the waste material separation table is provided with a plurality of fixed electric permanent magnets with suction surfaces upward, and every liftable electric permanent magnet and every fixed electric permanent magnet can supply power independently. Parts and waste materials are separated more reliably, the parts are sorted conveniently, and the laser cutting plate waste material separation part sorting system is high in efficiency and suitable for laser cutting automation of carbon steel plates.

Owner:JIANGSU JINFANGYUAN CNC MACHINE CO LTD

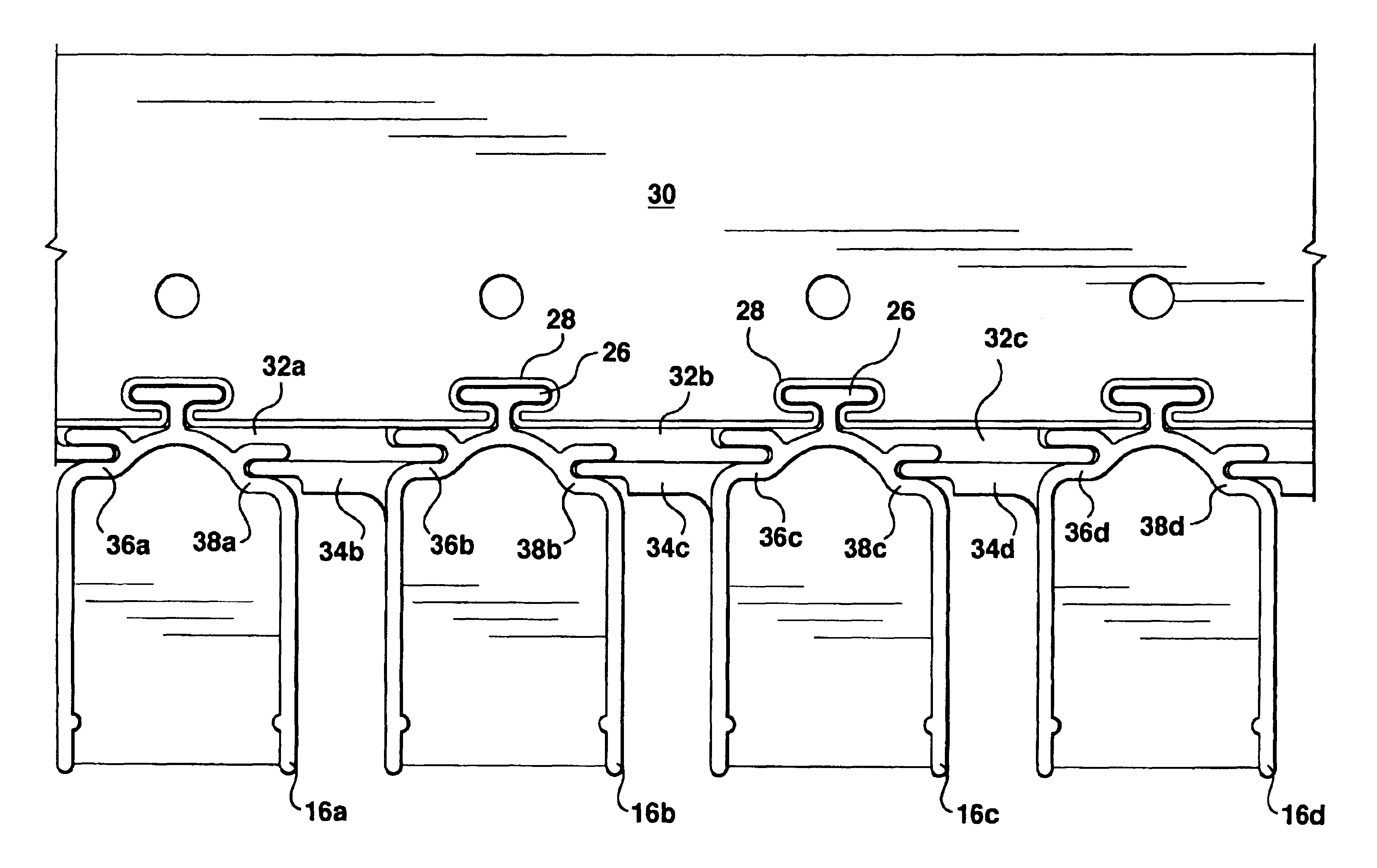

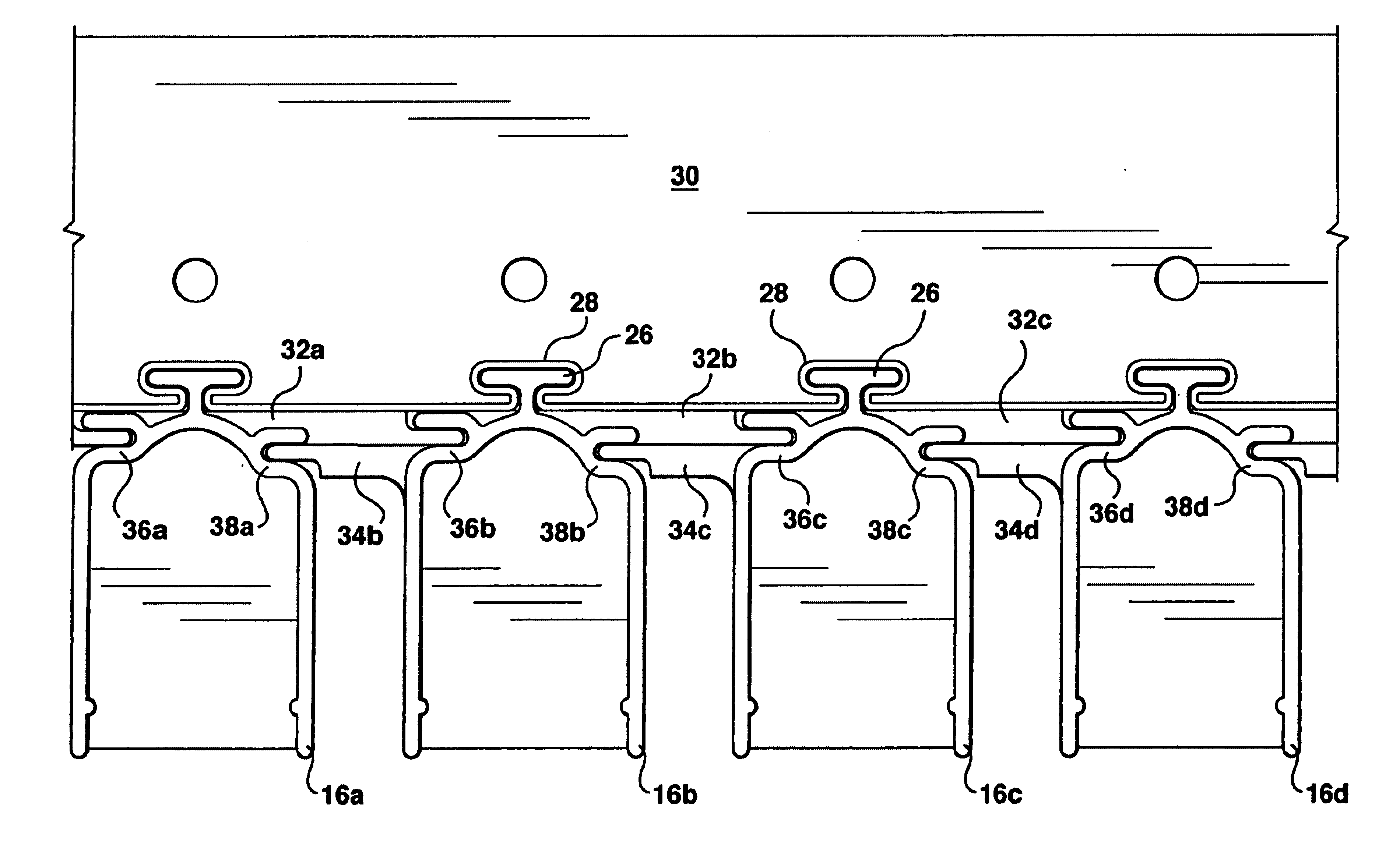

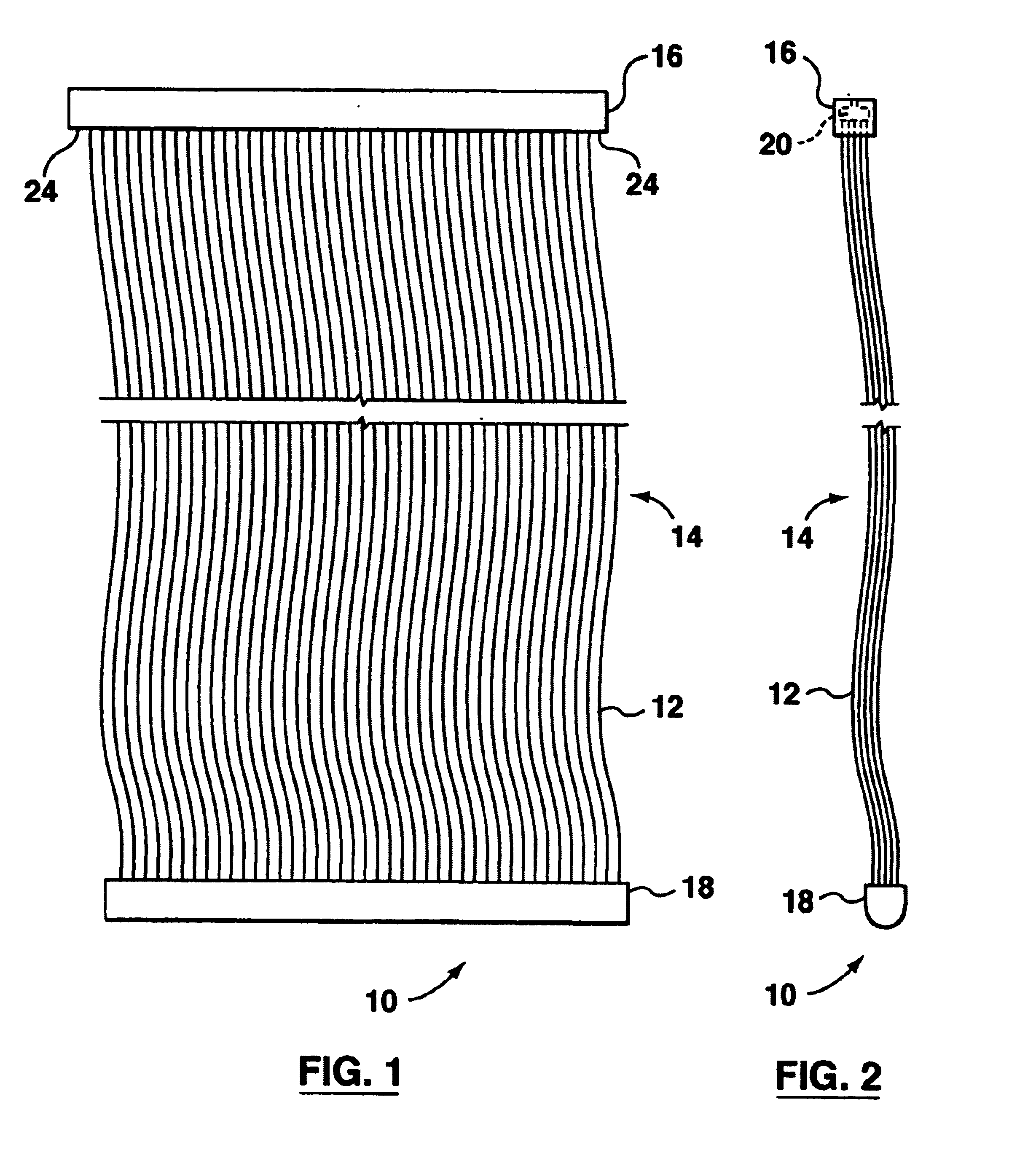

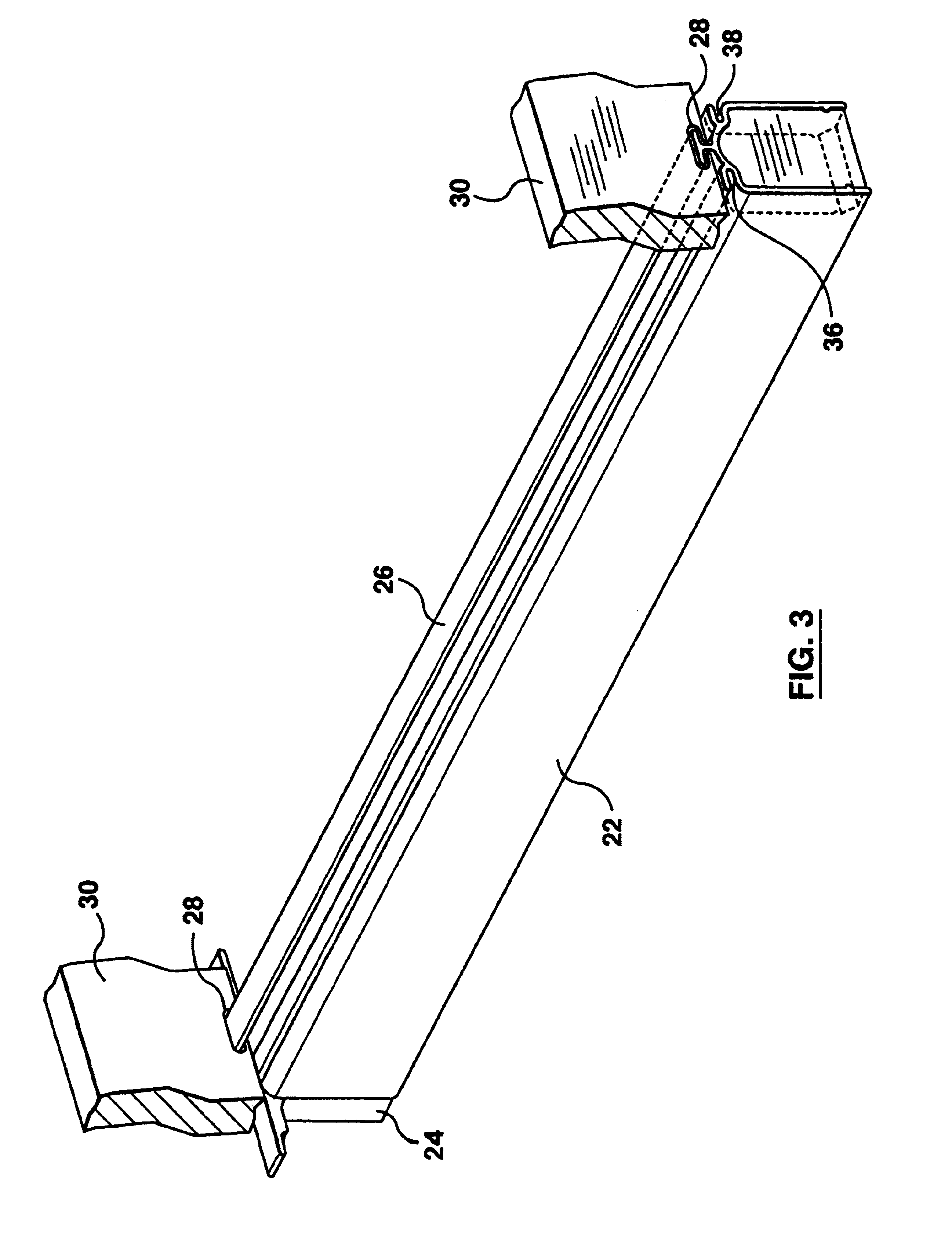

Immersed membrane apparatus

InactiveUS6899811B2Easily removeEasy to disassembleMembranesUltrafiltrationHollow fibre membraneEngineering

An apparatus for filtering a liquid in a tank has a plurality of elements and a frame for holding the elements while they are immersed in the liquid. The elements have a plurality of hollow fibre membranes attached to and suspended between an upper header and a lower header. The membranes are in fluid communication with one or more permeate channels in one or more of the headers. Releasable attachments between the headers and the frame allow the frame to releasably hold the elements by their headers. The size and configuration of the frame determines the positions of the upper and lower headers of each element relative to each other. Connections between the permeate channels and one or more permeate collection tubes attached to the frame are releasable and resealable connections which are made or broken automatically by the movements involved in inserting or removing an element into or out of the frame.

Owner:ZENON TECH PARTNERSHIP

Immersed membrane apparatus

InactiveUS7037426B2Easy to disassembleWide range of sizesMembranesUltrafiltrationFiberHollow fibre membrane

An apparatus for filtering a liquid in a tank has a plurality of elements and a frame for holding the elements while they are immersed in the liquid. The elements have a plurality of hollow fibre membranes attached to and suspended between an upper header and a lower header. The membranes are in fluid communication with one or more permeate channels in one or more of the headers. Releasable attachments between the headers and the frame allow the frame to releasably hold the elements by their headers. The size and configuration of the frame determines the positions of the upper and lower headers of each element relative to each other. Connections between the permeate channels and one or more permeate collection tubes attached to the frame are releasable and resealable connections which are made or broken automatically by the movements involved in inserting or removing an element into or out of the frame.

Owner:ZENON TECH PARTNERSHIP

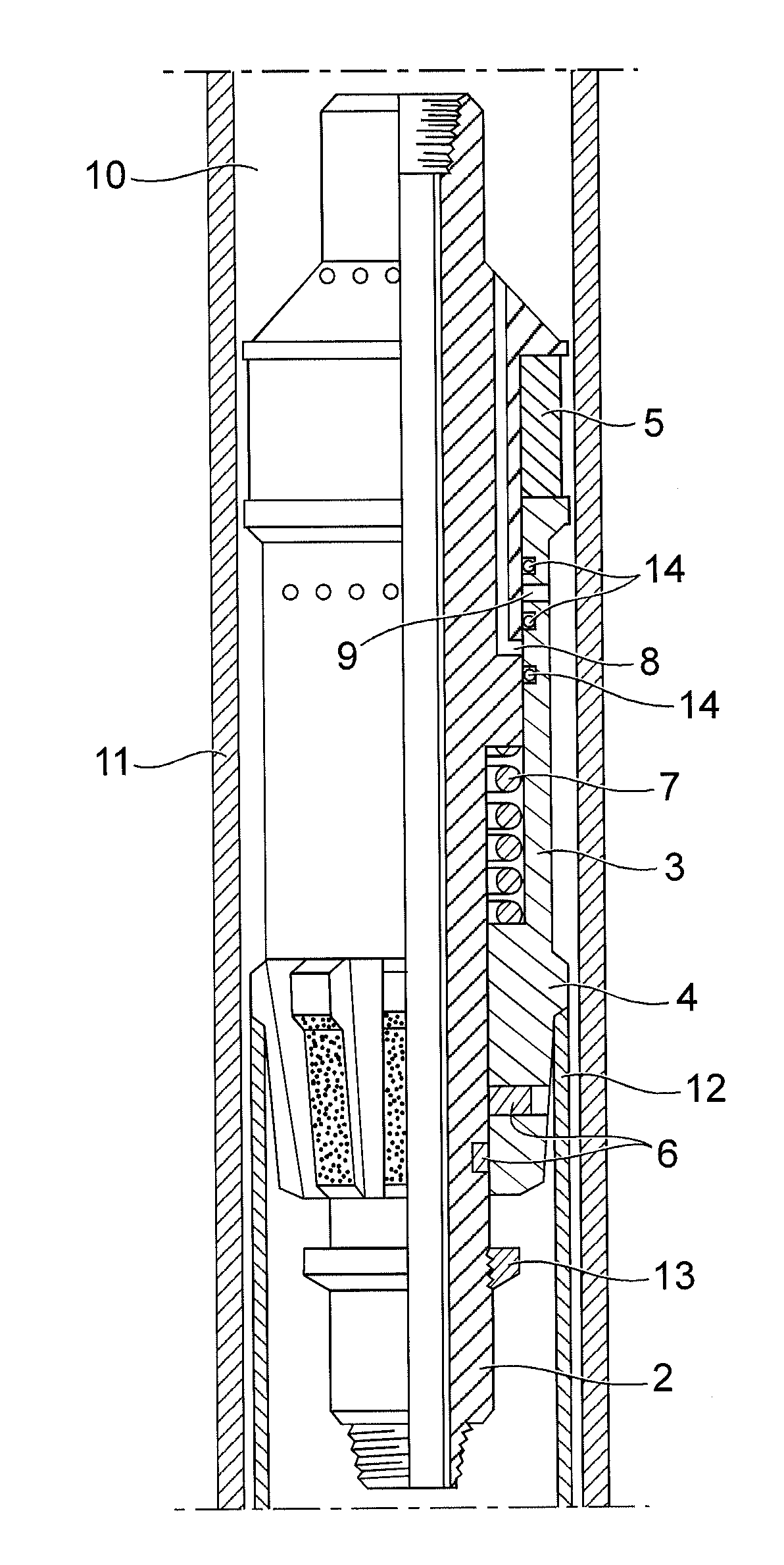

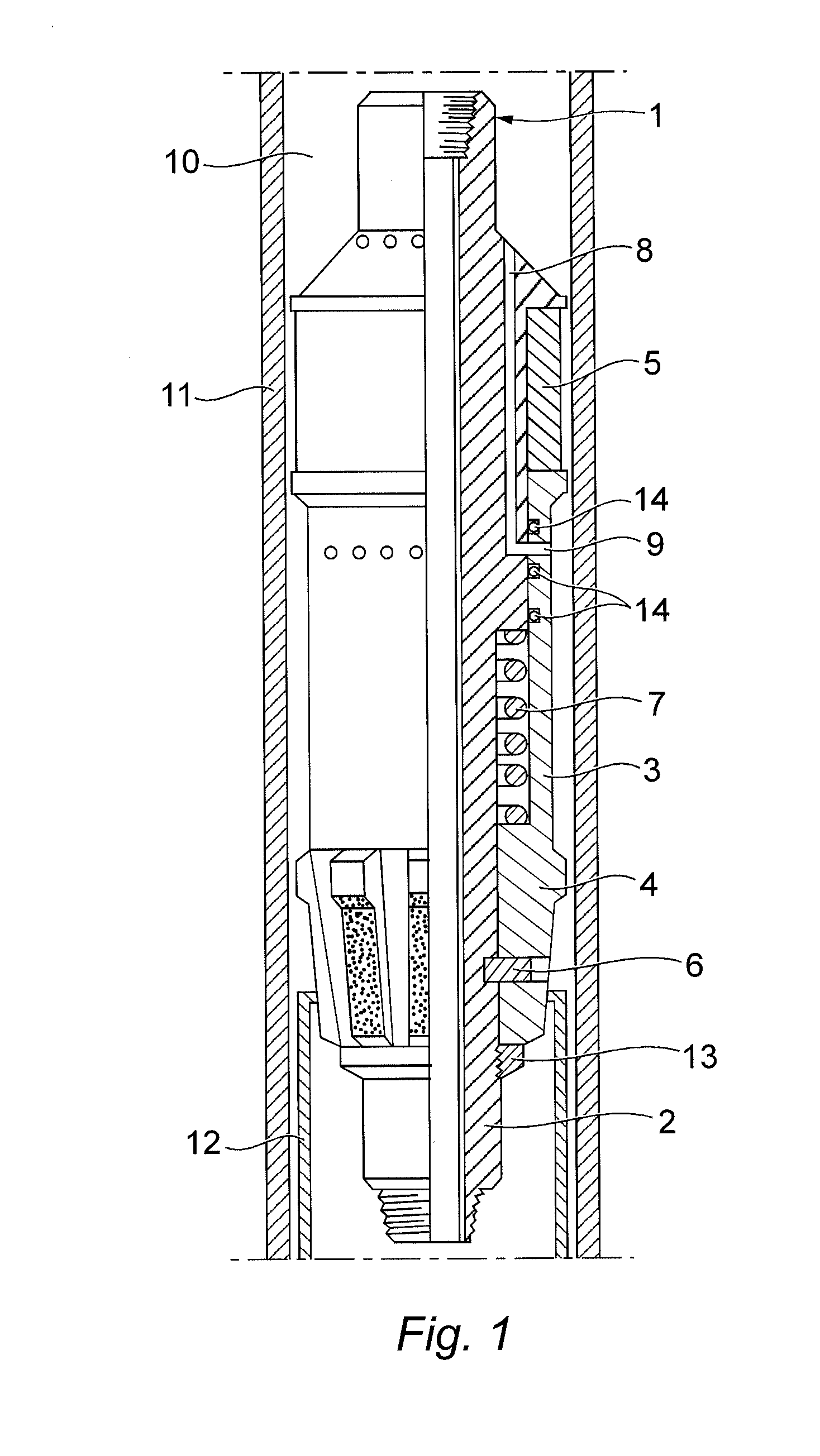

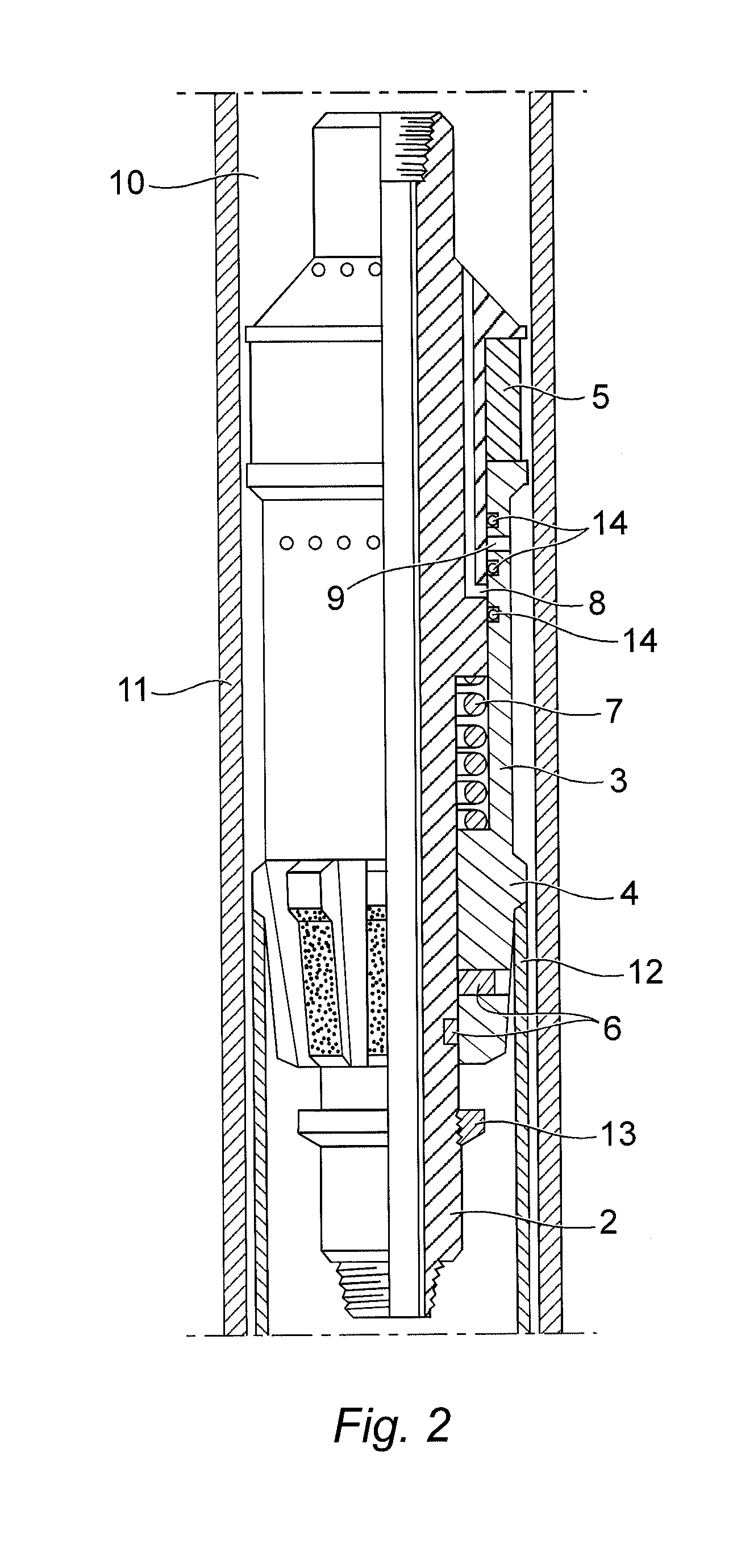

Downhole tool and method

ActiveUS20120132438A1Improved frictional engagementReduce riskConstructionsFluid removalEngineeringHigh pressure

A work string tool to be operably associated with a weight-set packer tool uses pressure applied by fluid circulated from the surface above the weight-set packer, to deploy a hydraulic hold-down anchor mechanism above the packer to reduce the risk of unsetting during a high pressure “positive” wellbore integrity test. An axial bore of a tool tubular body houses first and second inner sleeves, and is configured to accommodate independent axial movement of the sleeves to provide multiple fluid flowpath configurations through the tool which allow use of circulation fluid to pressure to circulate a ball obturator to a valve seat in a sleeve when a configuration change is required to deploy or release the anchor means.

Owner:M I DRILLING FLUIDS U K LTD

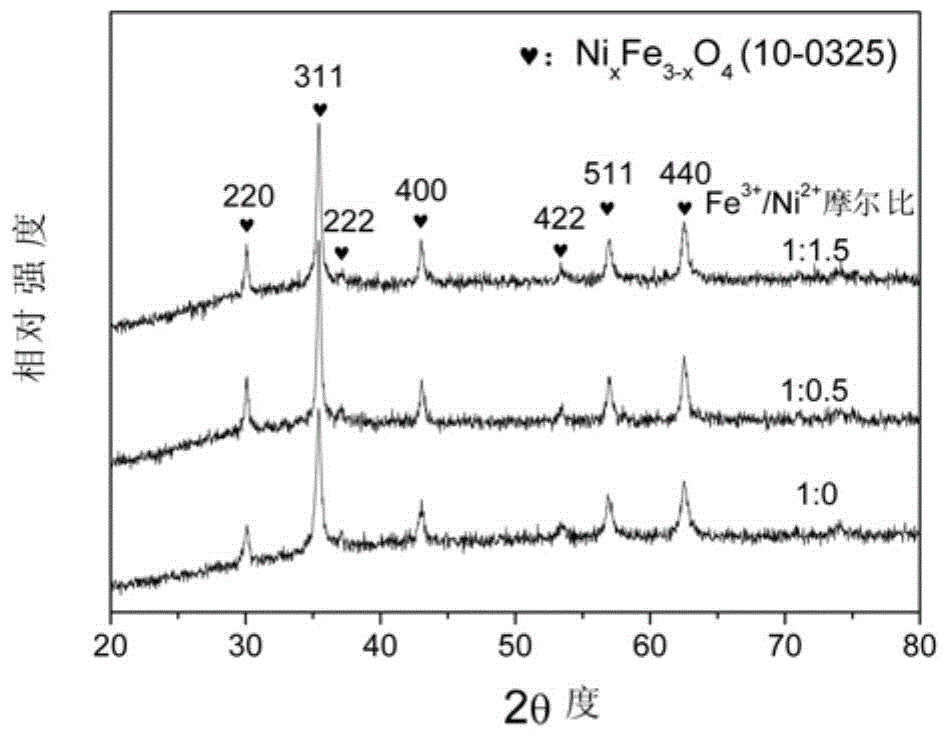

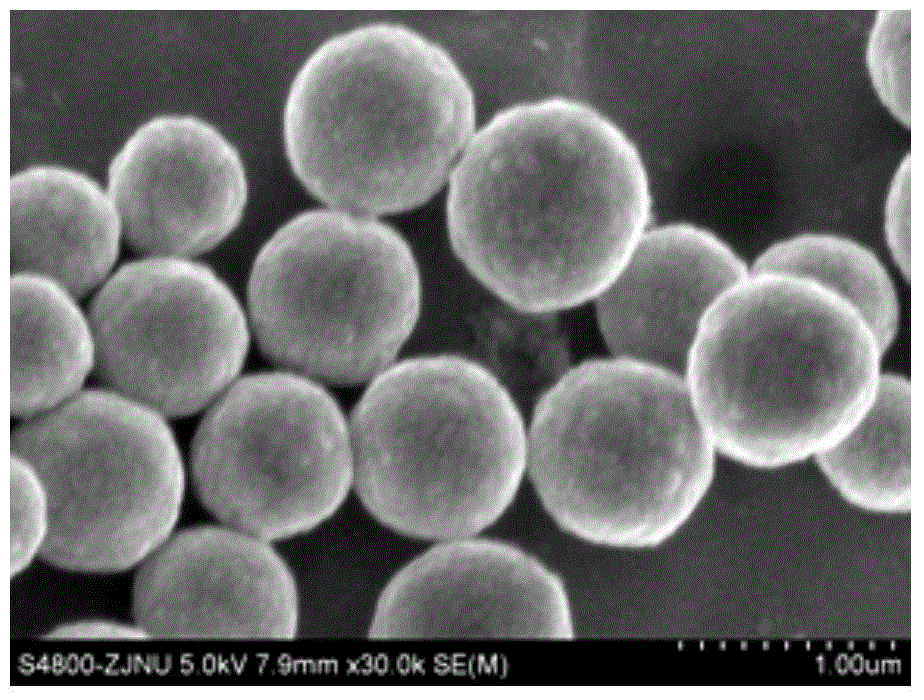

Multi-scale uniform and single-dispersion magnetic microsphere and preparation method thereof

ActiveCN104538145AEasy to prepareGood repeatabilityInorganic material magnetismMicroballoon preparationMicrometerMetal

The invention discloses a multi-scale uniform and single-dispersion magnetic microsphere and a preparation method of the multi-scale uniform and single-dispersion magnetic microsphere. The multi-scale uniform and single-dispersion magnetic microsphere comprises spinel structure ferrite doped with transition metal elements, the microsphere is a polycrystal micro-nano sphere which is formed by nanocrystalline in an aggregation mode, the diameter of the microsphere ranges from 20nm to 1.23 micrometers, the specific surface area of the microsphere ranges from 0.94 m<2>*g<-1> to 17.31 m<2>*g<-1>, and the size of the nanocrystalline ranges from 9.2nm to 25.8nm. A mixed solvothermal method is adopted, and the size and the composition of particles can be adjusted through adjustment of the volume fraction of water or the ratio of iron to other transition metal salt. According to the preparation method, raw materials are low in price, and can be easily obtained, the cost is low, the technology is simple, the requirement for equipment is low, efficiency is high, and popularization is easy; the multi-scale uniform and single-dispersion magnetic microsphere has the advantages that single dispersion and uniformity are good, and the size and the composition can be adjusted; the multi-scale uniform and single-dispersion magnetic microsphere can have the broad application prospect in the fields such as the magneto-rheological field, the magnetic separation field, the catalysis field, the electrode material field, the pigment field, the high-density magnetic recording material field and the medical diagnosis field.

Owner:ZHEJIANG NORMAL UNIVERSITY

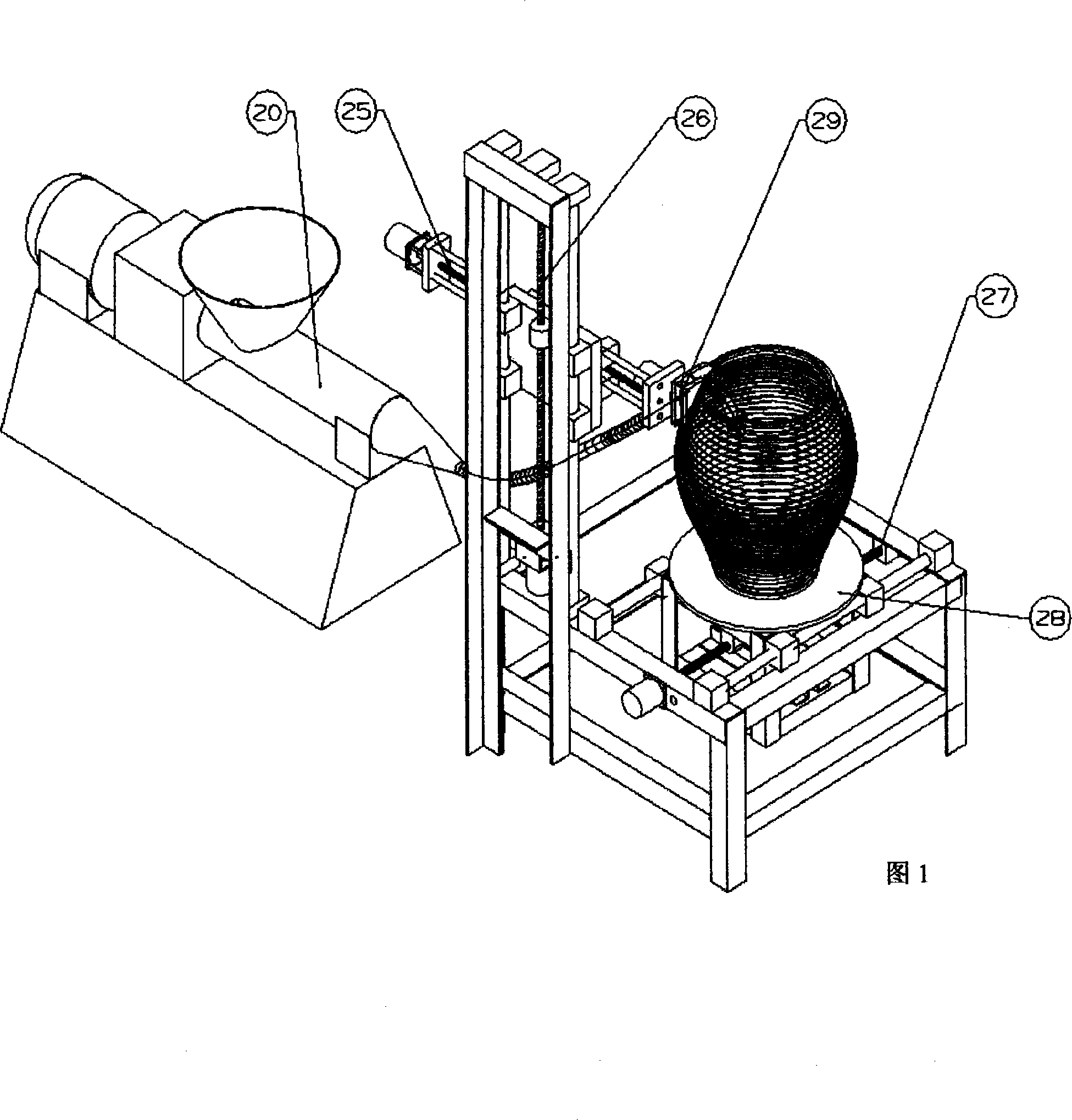

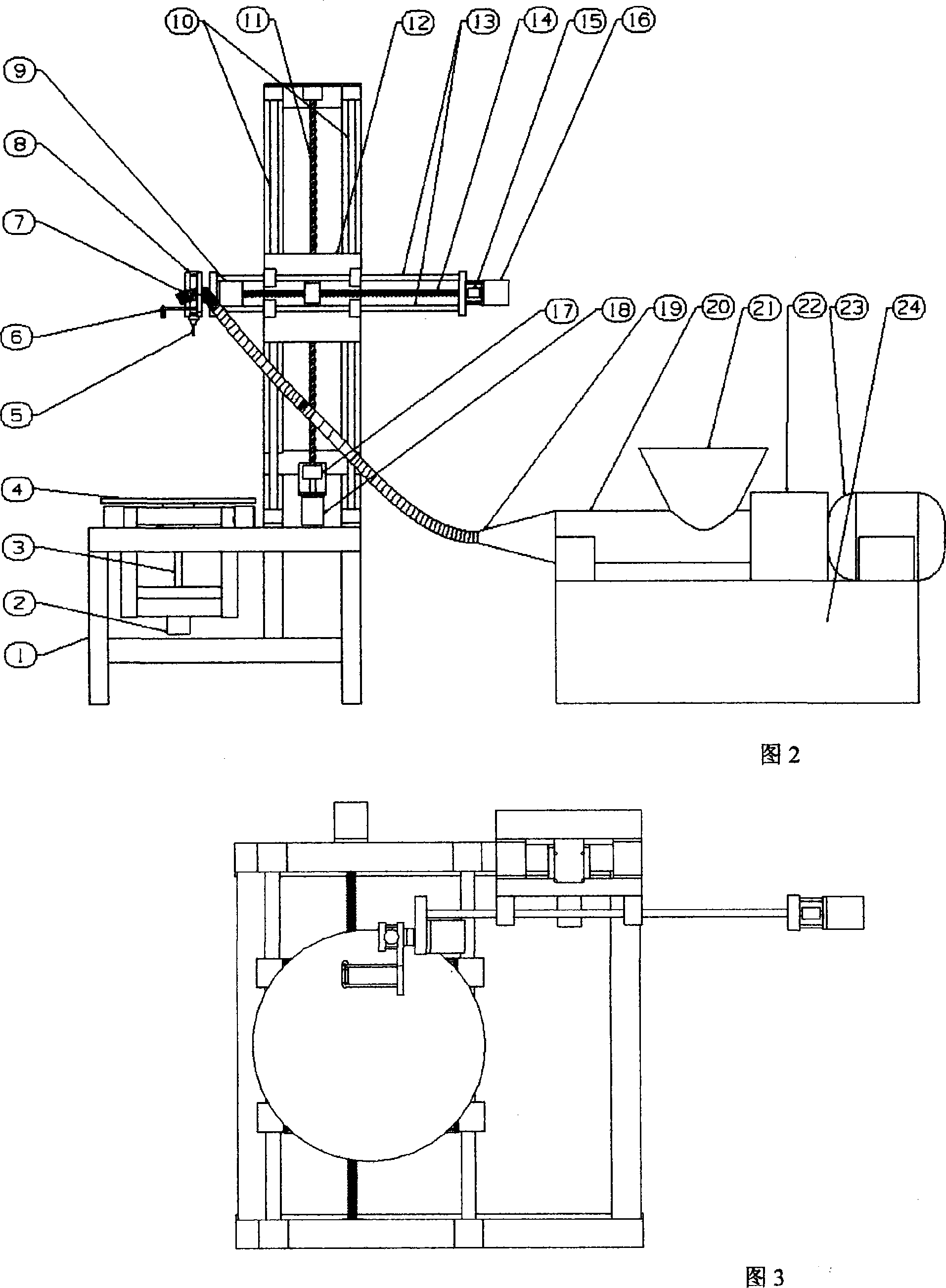

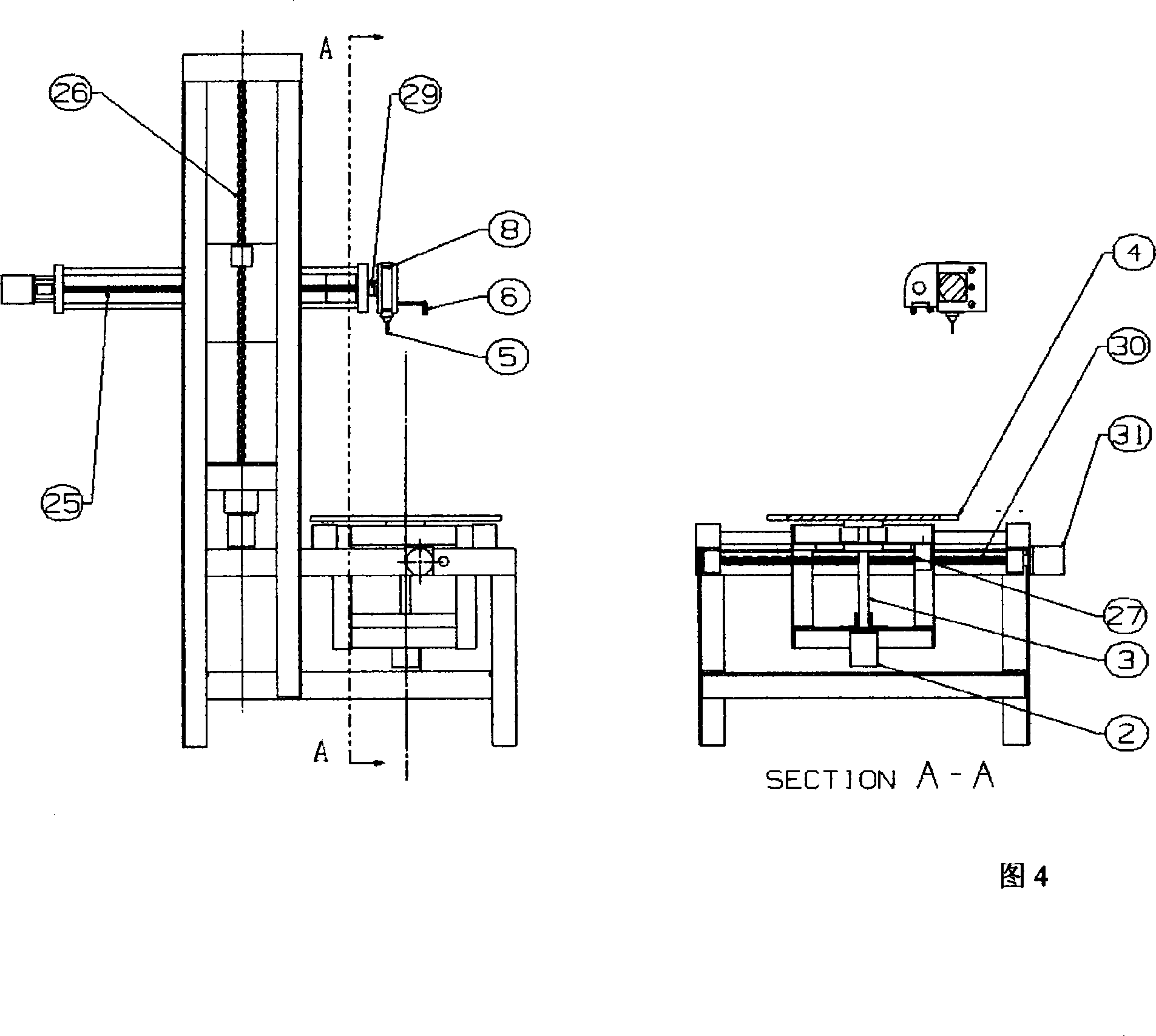

Digital controlled ceramic constructing forming machine

InactiveCN101143457AWide range of sizesImprove machining accuracyCeramic shaping apparatusManipulatorEngineering

A numerical control ceramic pile forming machine is automatic production equipment which integrates a plurality of functions of ceramic forming, basing and engraving. Three linear axles of X, Y and Z and two revolving axles of A (worktable revolving) and B (rolling manipulator and engraving joint swinging shaft) are movably composed. Five axles in all are composed and five-axle linkage is realized. Plugs are extruded out of a vacuum extruder (20). The machine can pile the pugs layer by layer for forming in any shape through a soft pipe (7) by the rolling manipulator (6) on the worktable (4) to replace a manual billet tension process. The pentahedron basing and the engraving process are implemented on the billets after being dried. Therefore, the automatic production of ceramic forming, basing and engraving is realized.

Owner:徐晗

Liquid discharge apparatus and image forming apparatus

InactiveUS20090147034A1Simple configurationQuality improvementOther printing apparatusControl signalEngineering

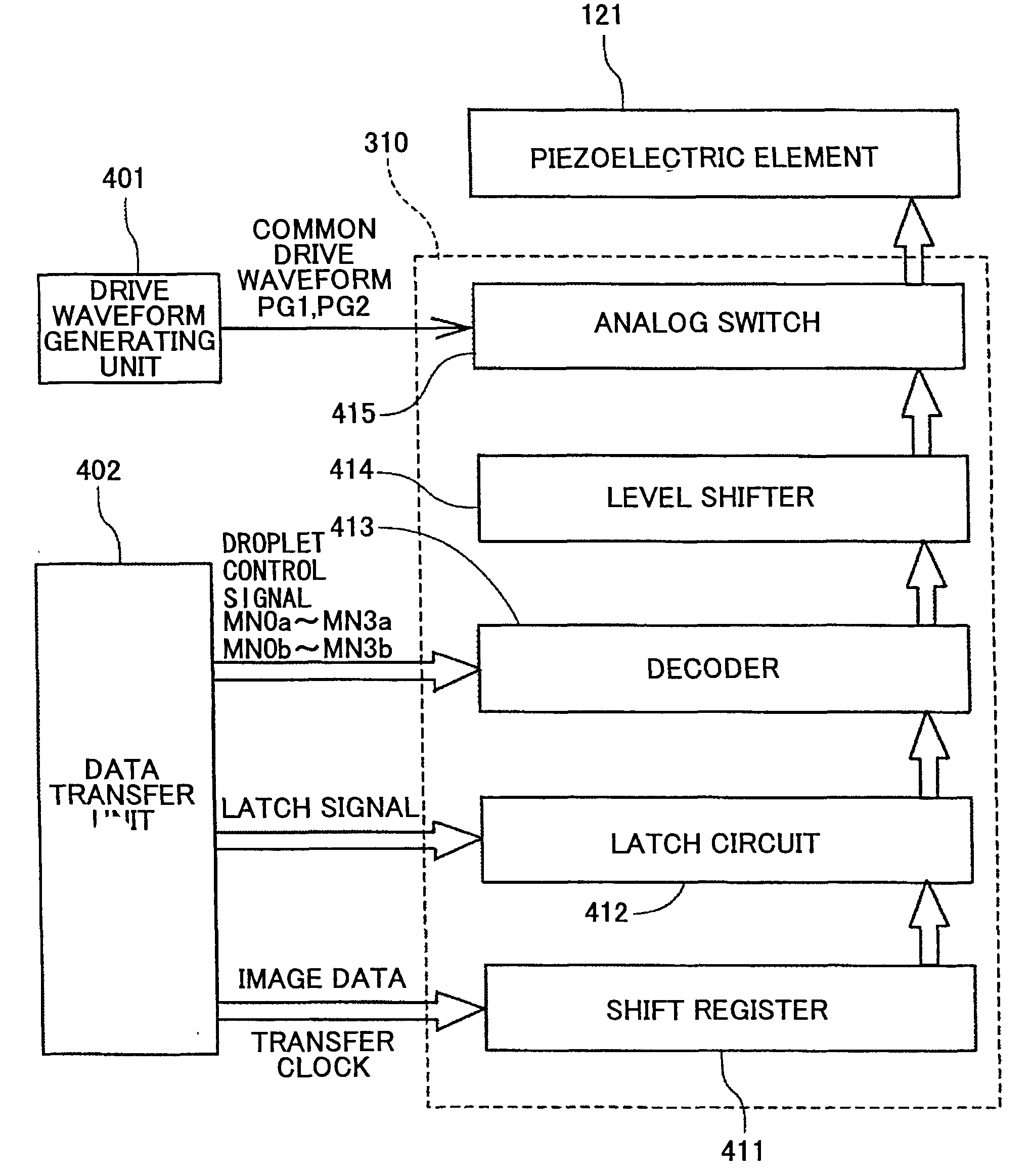

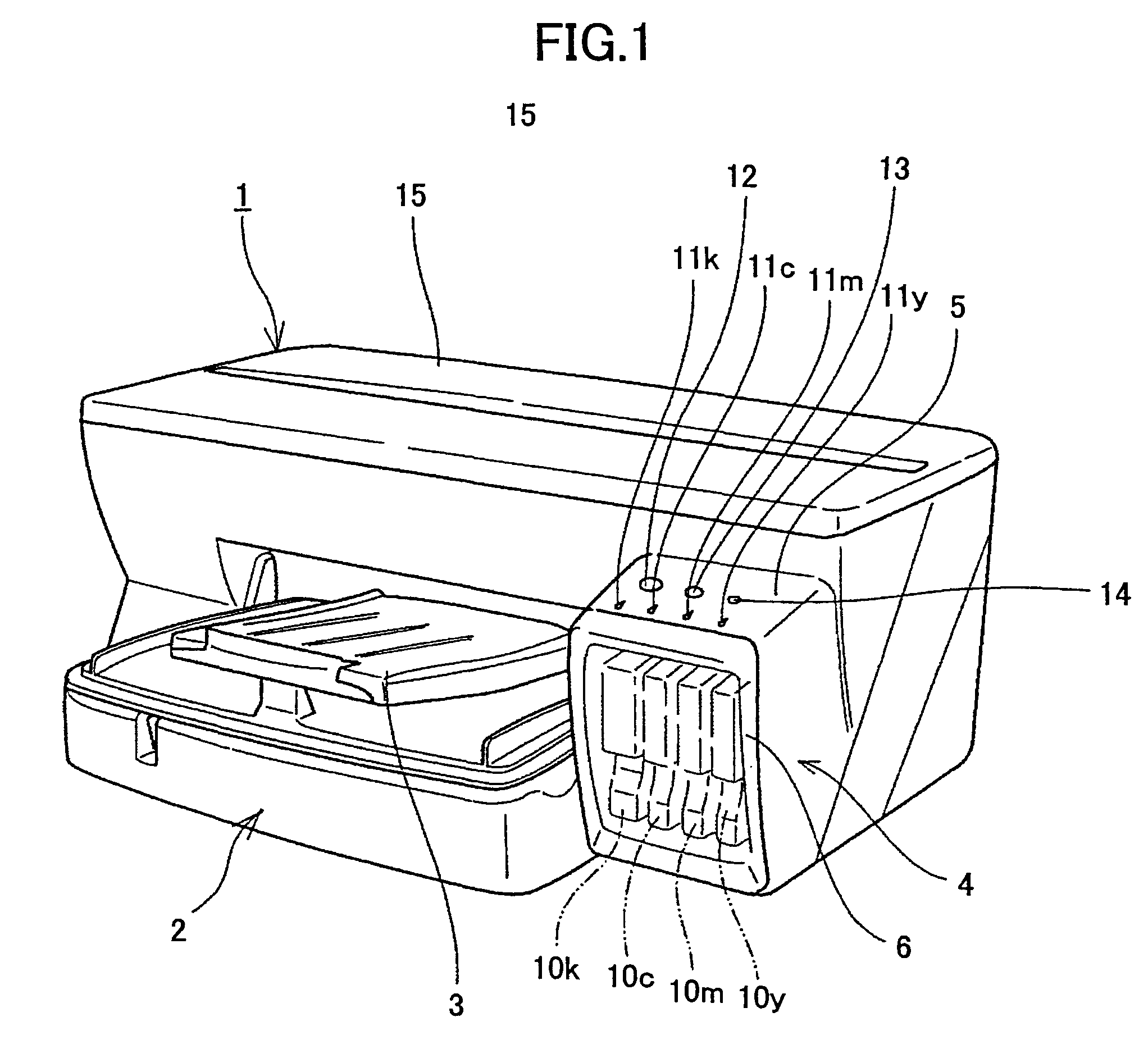

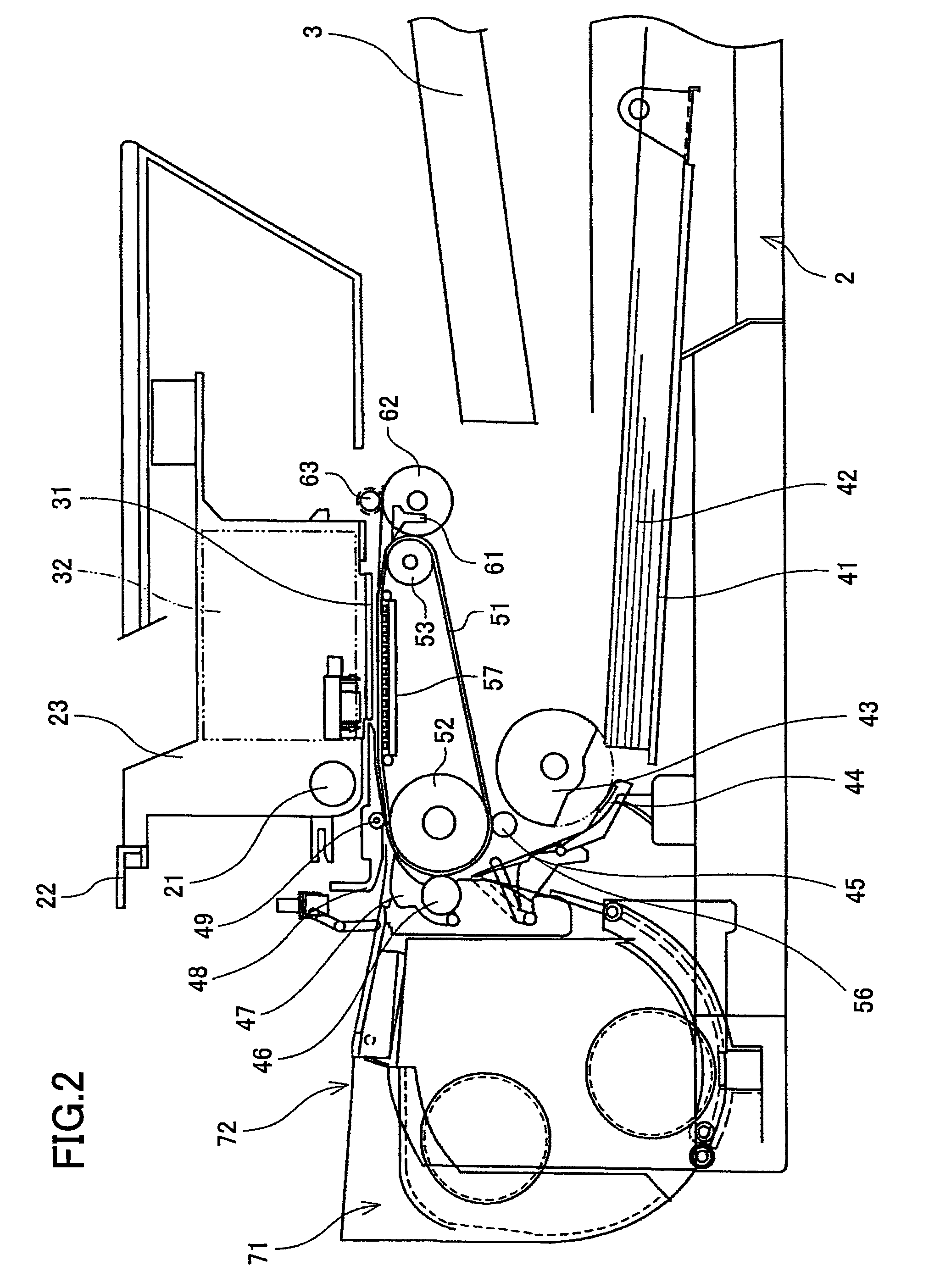

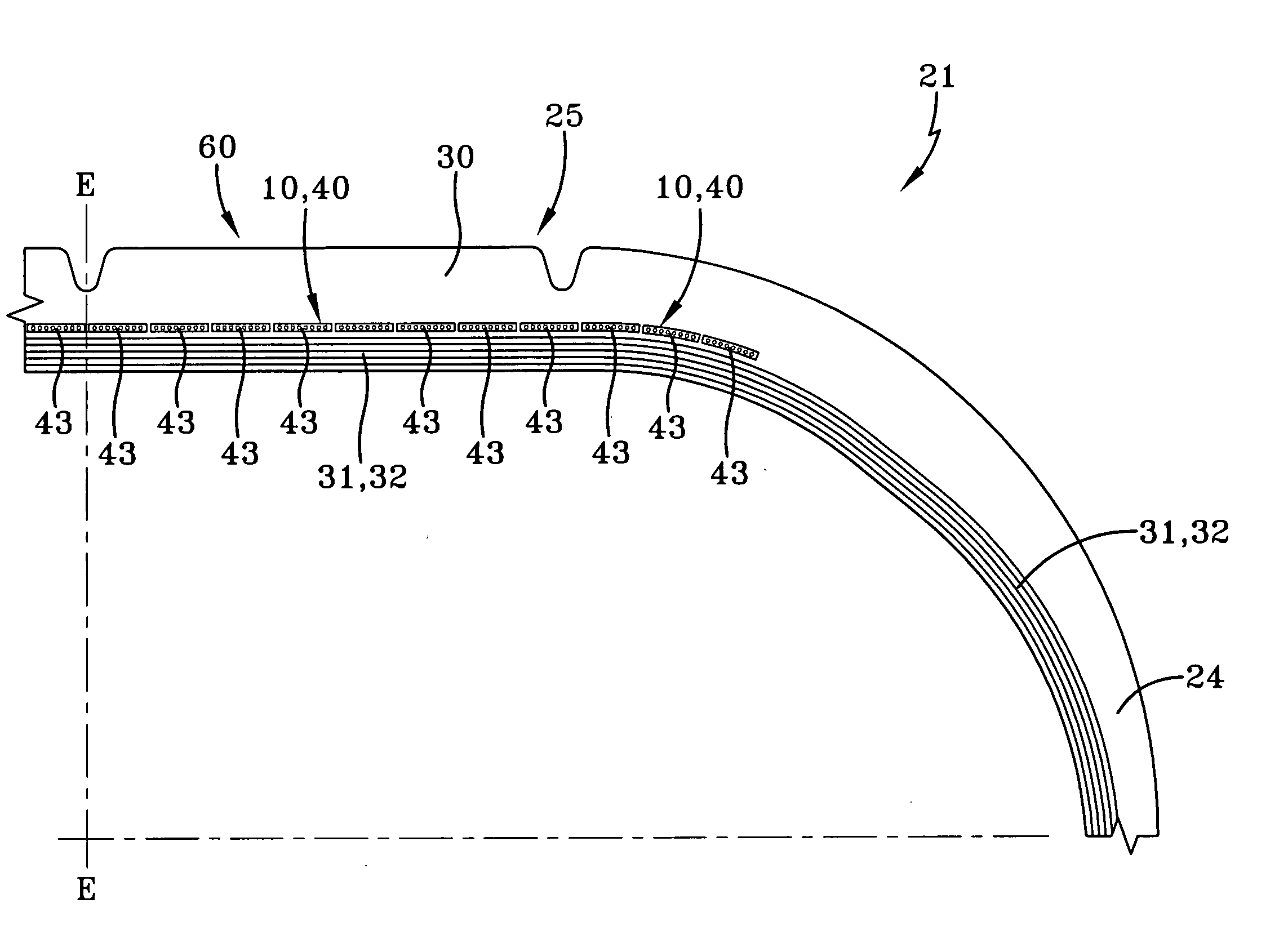

A liquid discharge apparatus is disclosed that includes a liquid discharge head that discharges plural types of liquid droplets; a drive waveform generating unit that generates and outputs a drive waveform including a first drive signal group made up of one or more drive signals and a second drive signal group made up of one or more drive signals within one drive period; a control signal output unit that outputs first control signals for controlling selection of the drive signals of the first drive signal group and second control signals for controlling selection of the drive signals of the second drive signal group; and a drive unit that inputs the drive waveform, the first control signals, and the second control signals, selects one or more drive signals from the drive signals of the first drive signal group and the second drive signal group using the first control signals and the second control signals, and supplies the selected drive signals to the liquid discharge head.

Owner:RICOH KK

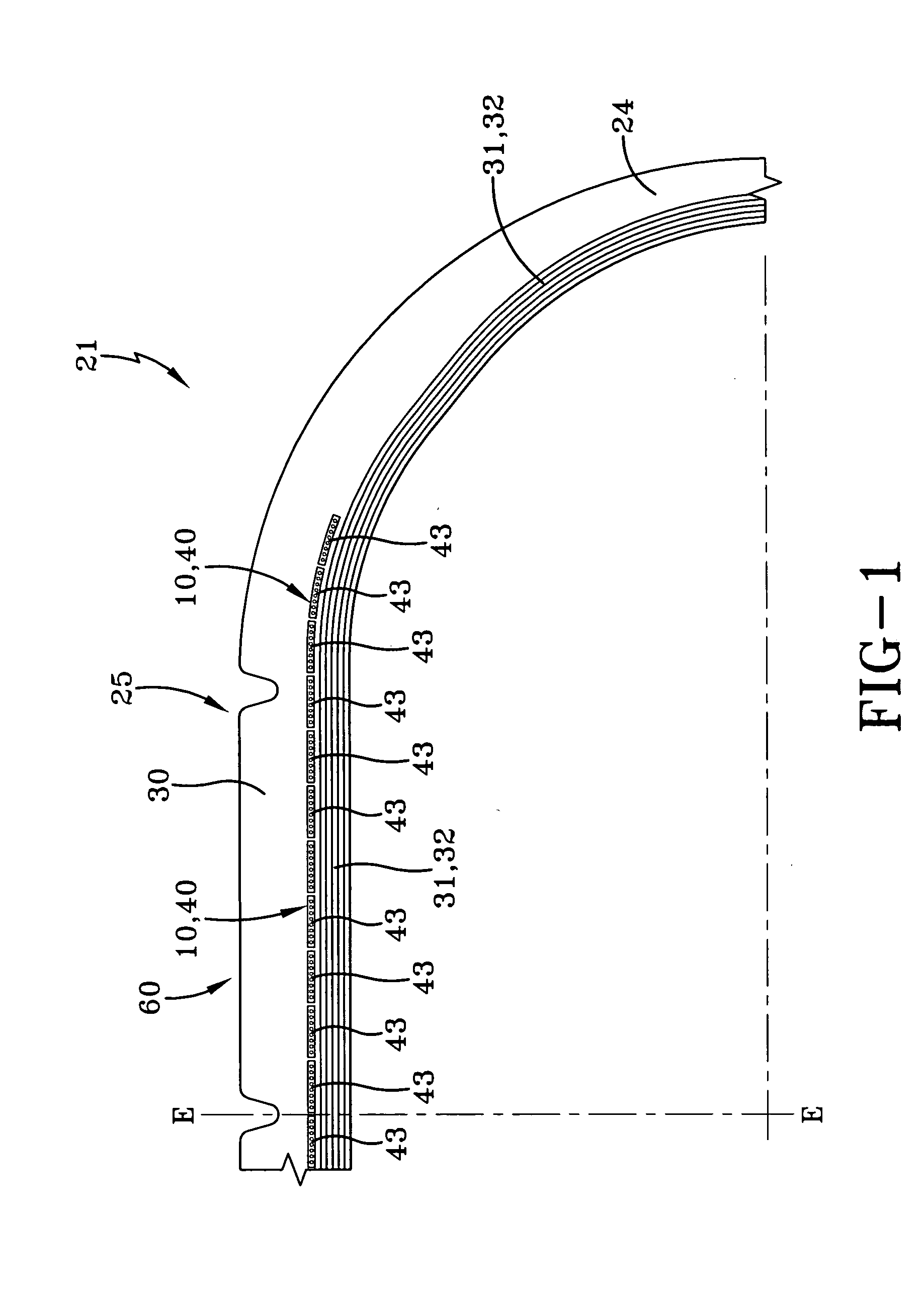

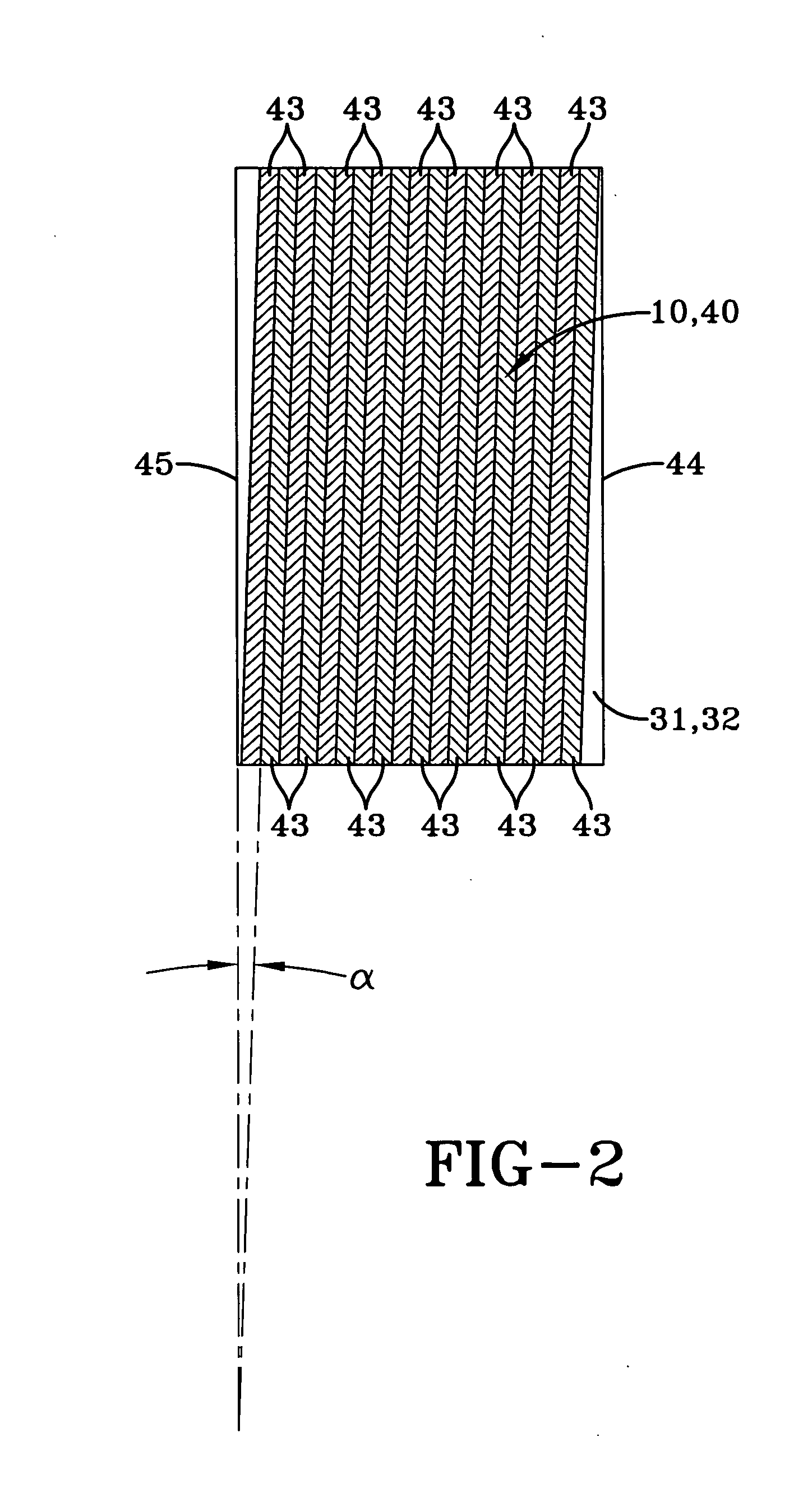

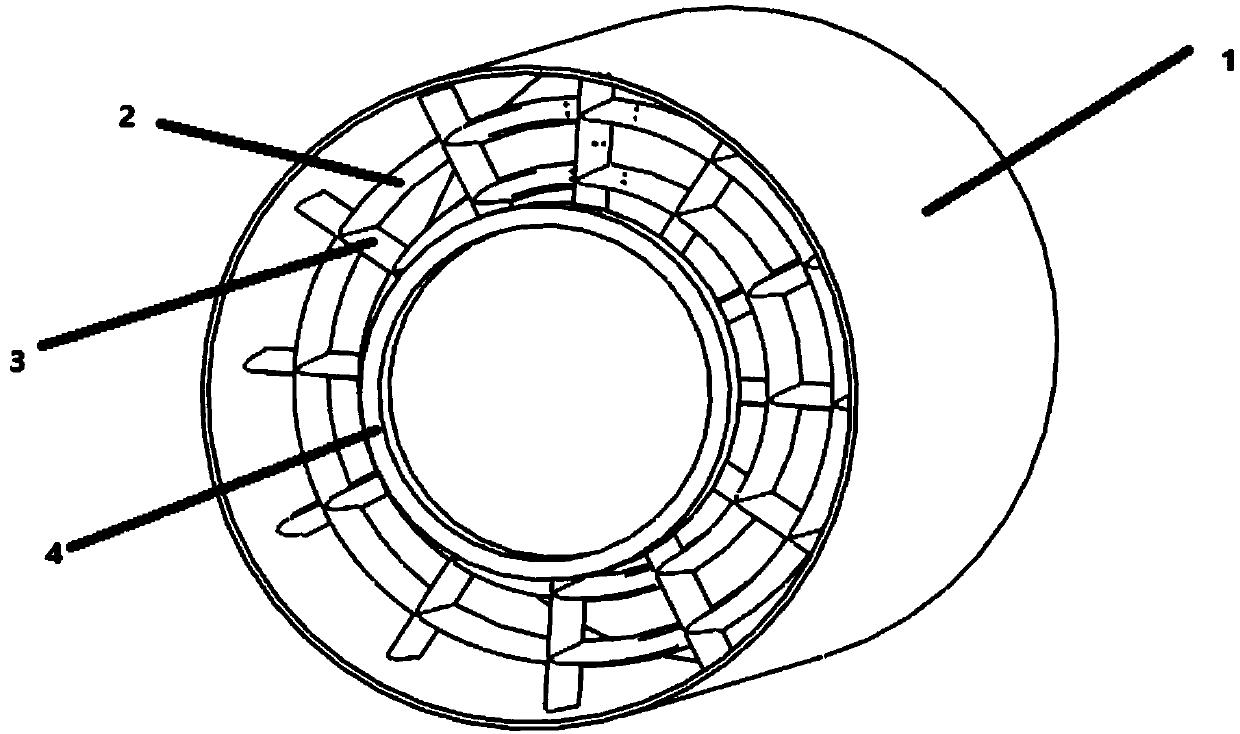

Pneumatic tire having a crown reinforcement structure with a plurality of adjacent cord reinforced strips and a process to manufacture or retread such a tire

InactiveUS20050194076A1Easily changed in sizeSimple structureSpecial tyresTyresStructural engineeringTread

A pneumatic tire having a carcass and a crown region is disclosed, the crown region comprising a crown reinforcement structure and a tread portion with a radially inner side and a tread on its radially outer side. The crown reinforcement structure is located between the tread portion and the carcass and comprises a plurality of adjacent cord reinforced strips. The cord reinforced strips are in direct contact either with the inner side of the tread portion or are separated from the tread portion only by a rubber cushion layer. A process to manufacture such a tire comprises the steps of: (1) preparing an assembly with a carcass, a green tread reinforcing rubberized ply layer applied radially upside of the carcass, and a green tread portion applied onto the green tread reinforcing rubberized ply layer, and (2) transferring the assembly into the pneumatic tire by curing. The green ply layer is formed by winding a continuous green rubberized cord comprising strip radially upside onto the carcass or an intermediate layer applied onto the carcass. The green tread portion is applied in such a way onto the green tread reinforcing rubberized ply layer that it is either in direct contact with the green tread reinforcing rubberized ply layer or that it is separated from the green tread reinforcing rubberized ply layer only by a rubber cushion layer. Slightly modified, this process can also be used to retread a pneumatic tire, in particular an aircraft tire.

Owner:THE GOODYEAR TIRE & RUBBER CO

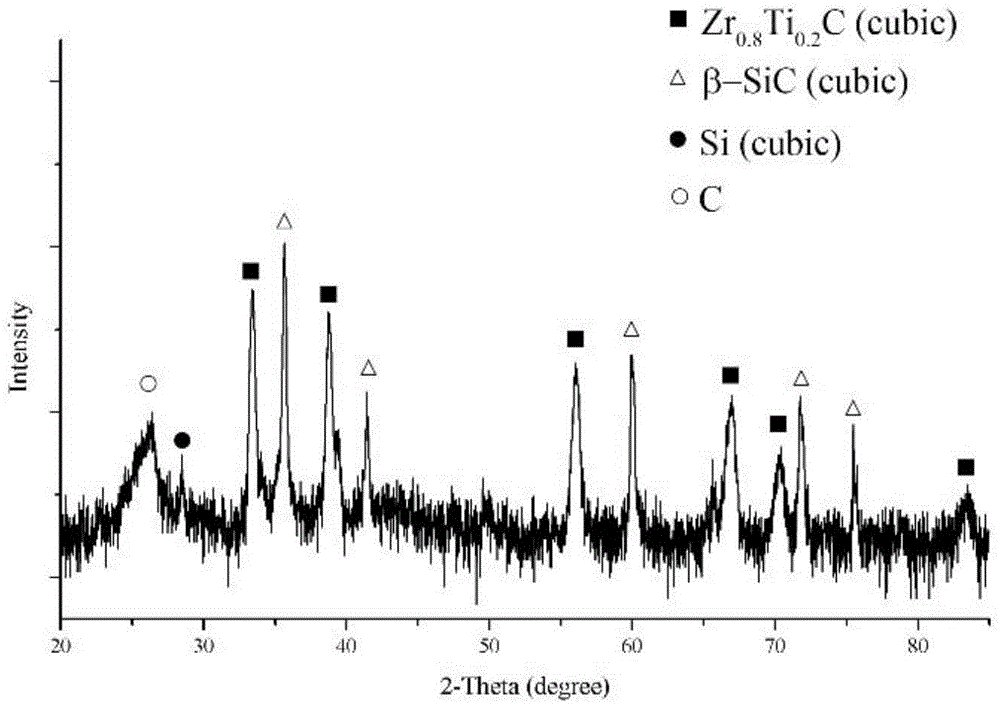

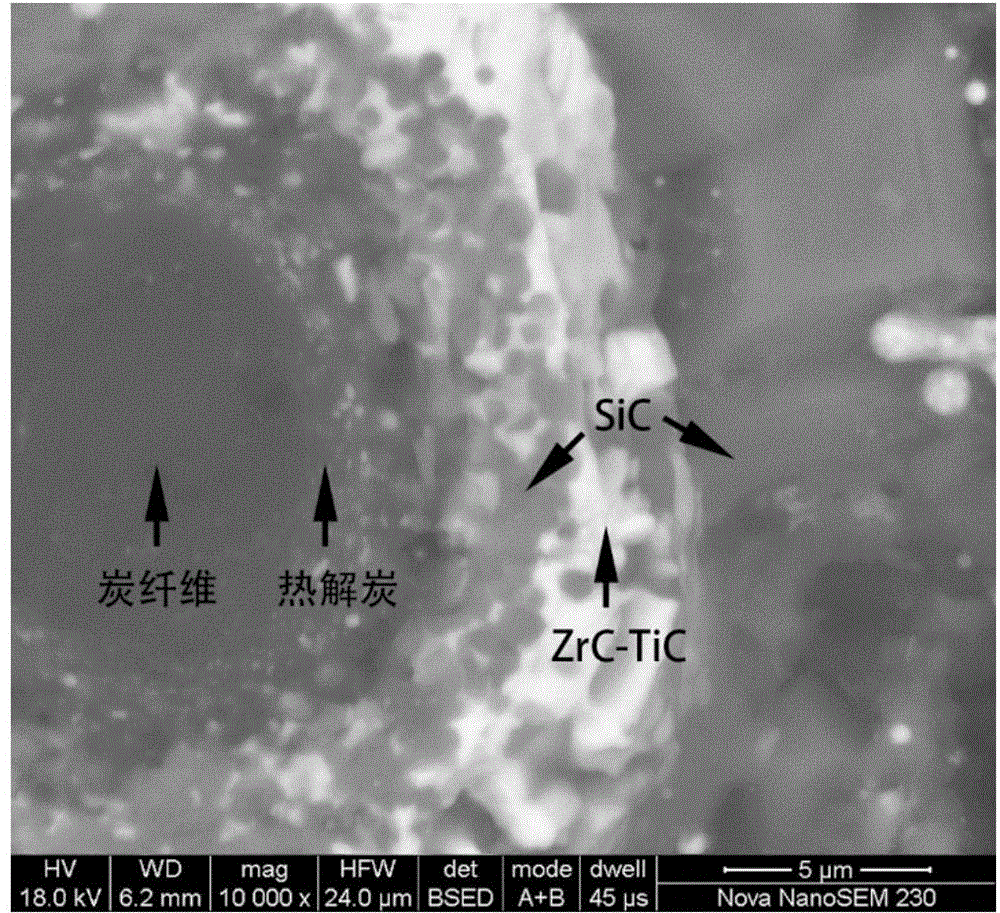

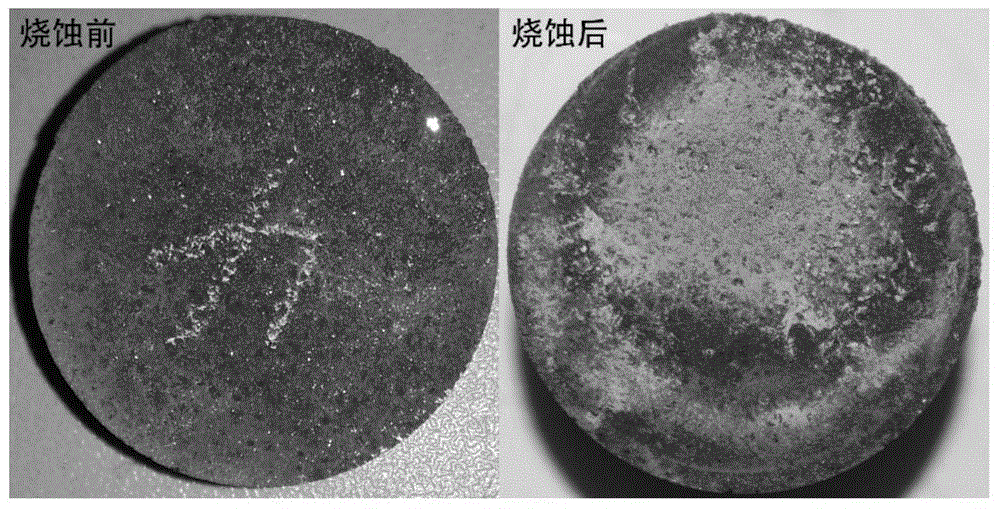

ZrC-TiC modified C/C-SiC composite material and preparation method thereof

The invention relates to a ZrC-TiC modified C / C-SiC composite material and a preparation method thereof, belonging to the technical field of preparation of composite materials. The composite material disclosed by the invention comprises carbon fibers, a pyrolytic carbon layer, SiC and ZrC-TiC, wherein the pyrolytic carbon layer coats the surface of the carbon fibers; SiC and ZrC-TiC coat the surface of the pyrolytic carbon layer; and ZrC-TiC is uniformly distributed in SiC. The preparation method comprises the following steps: preparing a low-density C / C composite material by adopting chemical vapor infiltration; melting Si, Zr and Ti powder, infiltrating the powder into the C / C composite material by virtue of a capillary action, and forming a ceramic phase in pores by virtue of a high-temperature in-situ reaction, thereby obtaining the ZrC-TiC modified C / C-SiC composite material. With the adoption of the process method which is low in cost, rapid and convenient, the service temperature of the C / C-SiC composite material is effectively improved, and the ultra-high temperature ablation resistance of the material is greatly enhanced.

Owner:深圳金羽先进材料有限公司

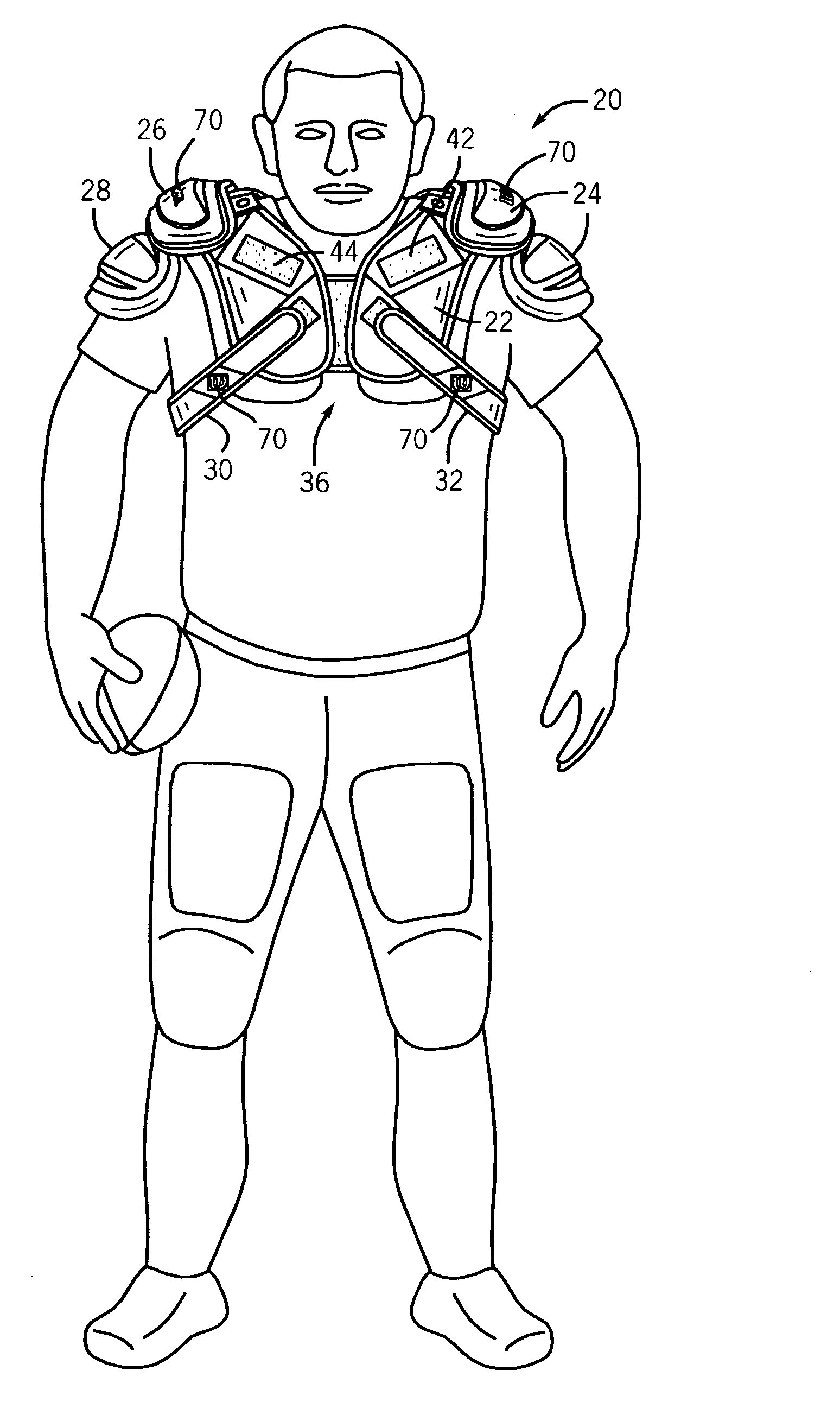

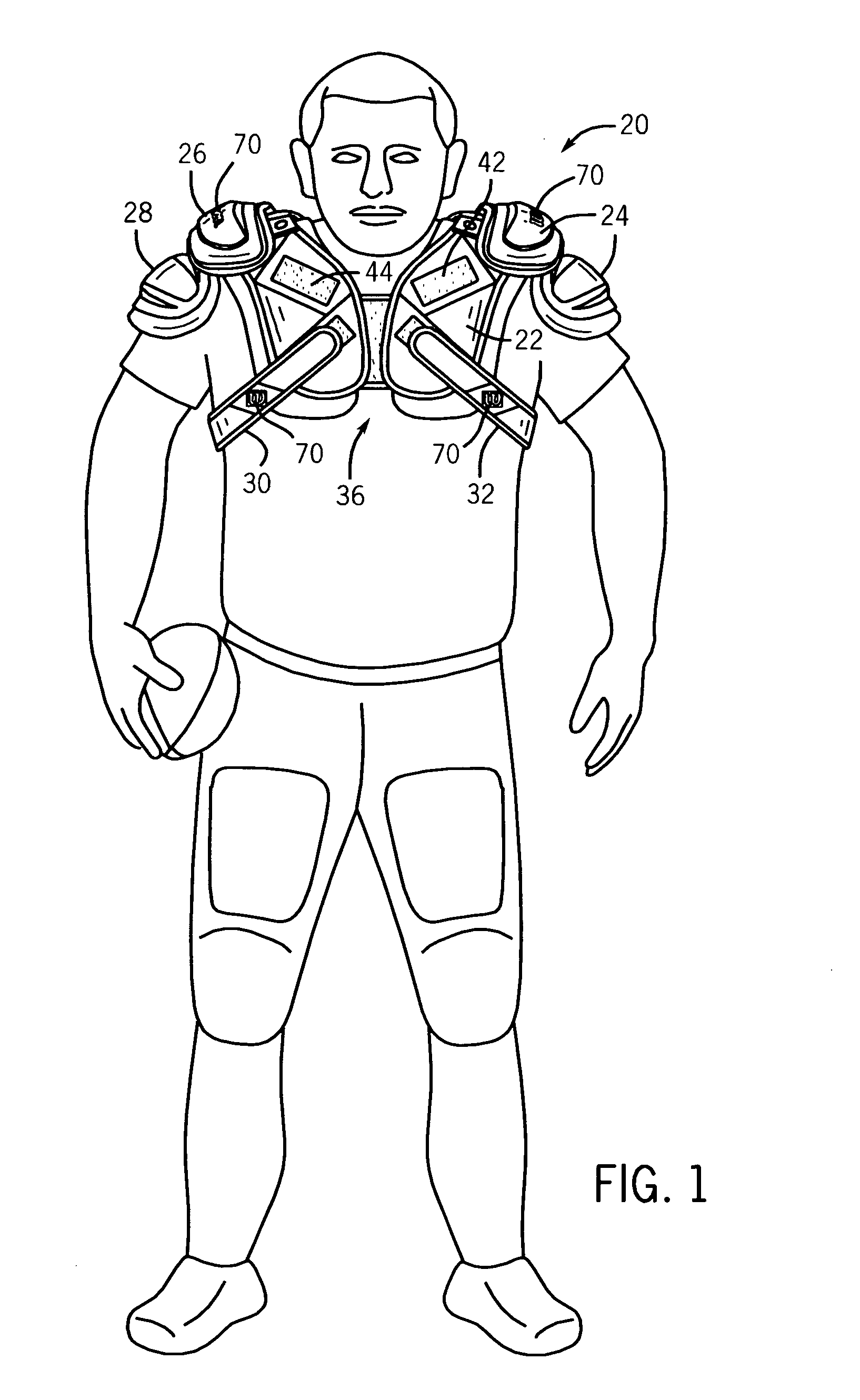

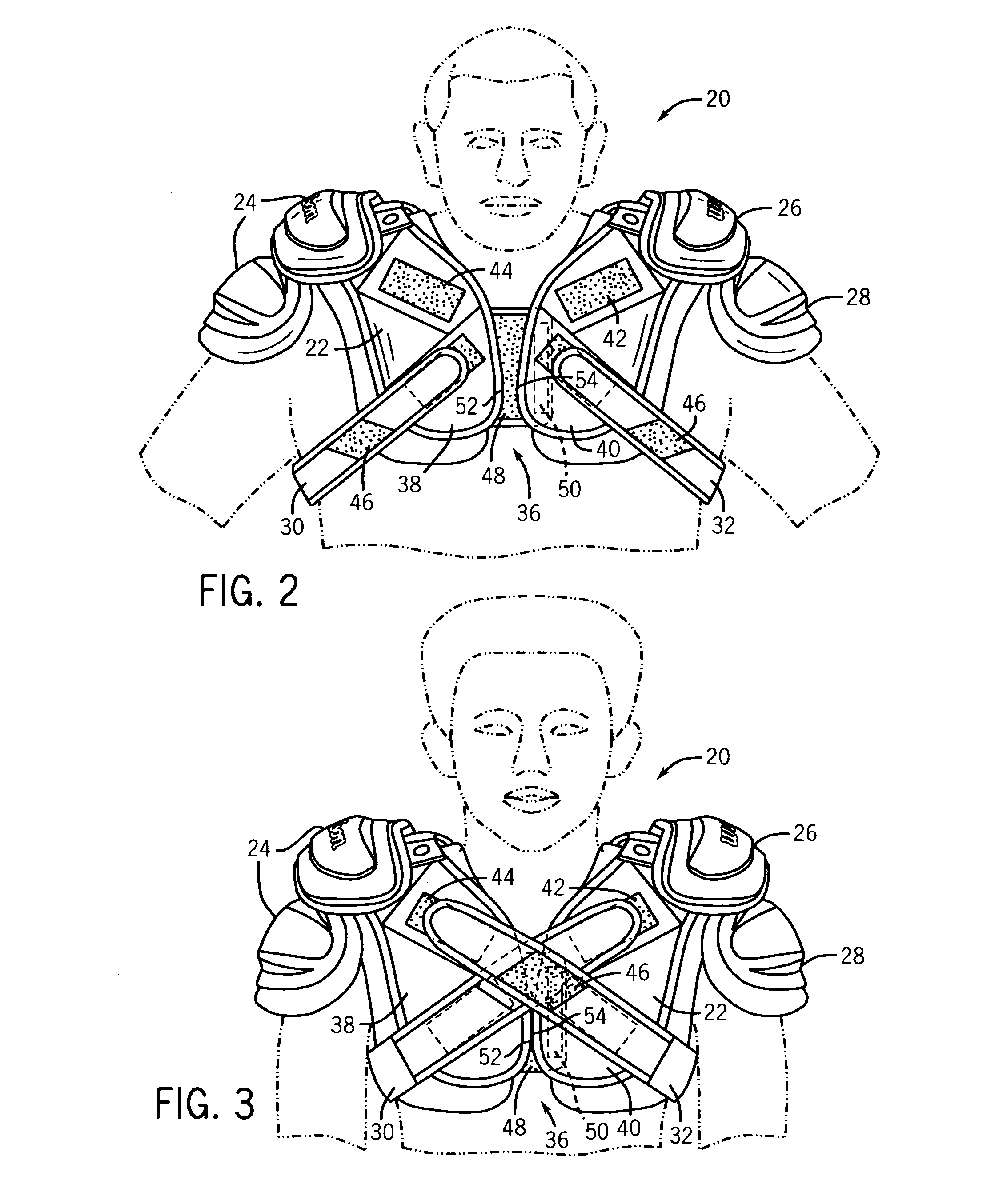

Protective shoulder pads

InactiveUS20090235440A1Protecting wearerRemoved and replacedGarmentsSport apparatusEngineeringCross over

A protective shoulder pad assembly for use in contact sports. The shoulder pad assembly includes a flexible vest, a pair of rigid shoulder pads attached to the vest, and a pair of straps extending from a back side of the vest. The straps can each be refastenably attached to a front side of the vest. In particular, the straps can be crossed over one another in an “X” configuration on the front side of the vest, thereby directly securing each strap to both a front right portion and a front left portion of the vest.

Owner:WILSON SPORTING GOODS

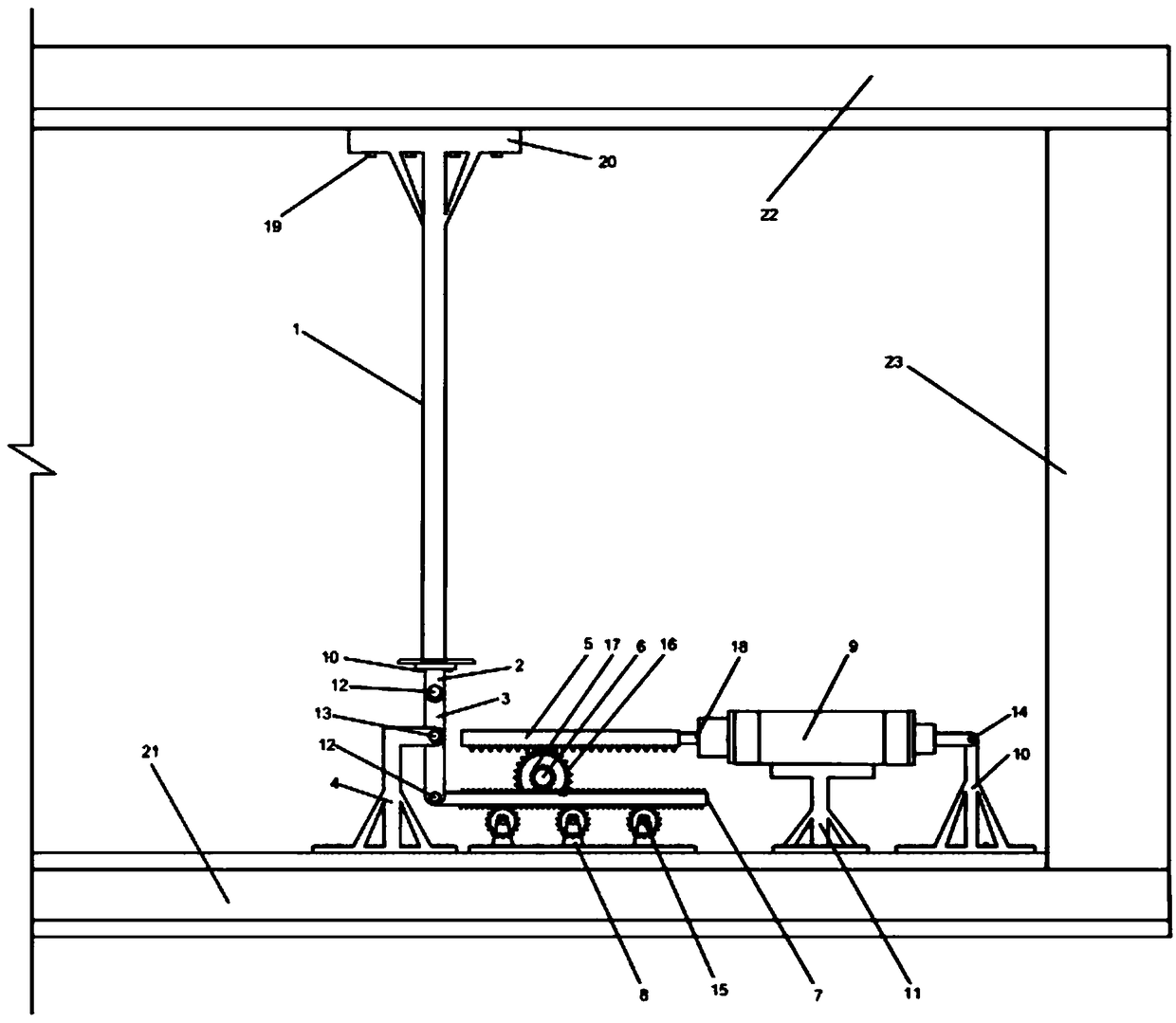

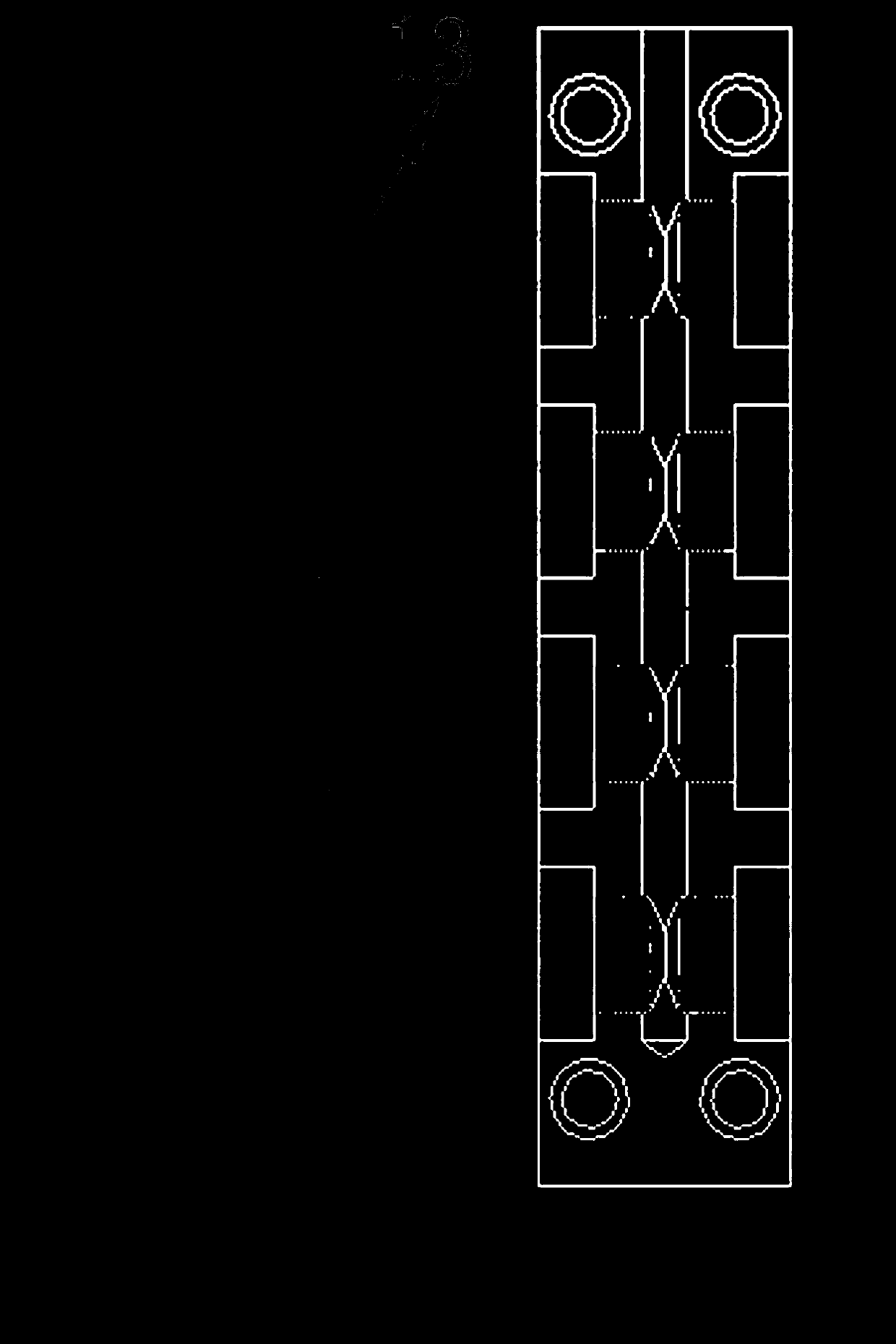

Efficient space-use type damper of end portion straight brace secondary displacement amplification device

ActiveCN108643666AImprove performanceEfficient use ofProtective buildings/sheltersShock proofingRelative displacementSnubber

The invention discloses an efficient space-use type damper of an end portion straight brace secondary displacement amplification device. The efficient space-use type damper of the end portion straightbrace secondary displacement amplification device comprises a vertical type moving displacement support, a T-shaped overhanging positioning bracket, a T-shaped connecting plate, a displacement amplification rod, an input rod with a rack, a duplicate gear, an output rod with a rack, a damper connecting piece, an input end guide gear, a damper device, a damper fixing support and the like. The efficient space-use type damper of the end portion straight brace secondary displacement amplification device performs first amplification on the relative displacement between layers of a building throughthe displacement amplification rod when the deformation of the building structure is small or slow, then the displacement of the first amplification is subjected to second amplification through the duplicate gear, two-time amplification is performed, so that the damper generates greater relative displacement, the damper generates greater damping force, and the better shock absorption effect is achieved. At the same time, the efficient space-use type damper has the characteristics of simple structure, considerable cost, convenient installation, convenient operation, flexible layout, firm and durable and the like, and has broad prospects of development and application.

Owner:山东清亿智能装备制造有限公司

Pecan hulling machine

The invention discloses a pecan hulling machine. The pecan hulling machine comprises a machine frame, wherein the machine frame is provided with a feed device, a hulling device, a discharge device and a power transmission device, wherein the feed device comprises a feed hopper and a feed pipe; the hulling device comprises a feed cylinder and a beating rod assembly; a plurality of outwards convex hammer bases are evenly arranged on the circumference of the feed cylinder; a plurality of small concave pits are formed in the inwards concave surfaces of the hammer bases; the beating rod assembly comprises a beating rod idler wheel, a beating rod, a beating rod bearing base, a beating rod hammer and a beating rod spring; the front end and the rear end of the beating rod are provided with the beating rod hammer and the beating rod idler wheel respectively; the middle of the beating rod is hinged to the beating rod bearing base to form a lever fulcrum; the upper end of the beating rod spring is connected to the beating rod; the lower end of the beating rod spring is fixed to the machine frame; the beating rod is driven through a cam mechanism to vertically swing; the cam mechanism comprises a cam and a flat board; the flat board is arranged at the opposite end of the convex surface of the cam. The pecan hulling machine has the advantages that granules of hulled pecans are full and low in degree of breakage, the level of integration and degree of automation are high, the hulling efficiency is high, and cost is low.

Owner:丁孝德

Head Support and Seat Pad Assembly for a Child Seat

ActiveUS20100148543A1Expanded size rangeGreat size rangeVehicle seatsStuffed mattressesCushionCar seat

A seat pad assembly is disclosed including a body pad for placement on the seating surface of a child seating device. The body pad has a front side, a back side, and two spaced apart vertical slots through the pad. The seat pad assembly has a head support with a connecting strip extending between a pair of laterally spaced apart cushions. The head support is generally H-shaped and installed on the pad through the slots with the pair of cushions on one side of the pad and the connecting strip on the other side. The head support is slidable along the slots to adjust the vertical position of the cushions. The seat pad assembly can be used on a child seating device such as a children's car seat, an infant carrier, a stroller, an infant swing, or the like.

Owner:GRACO CHILDRENS PROD INC

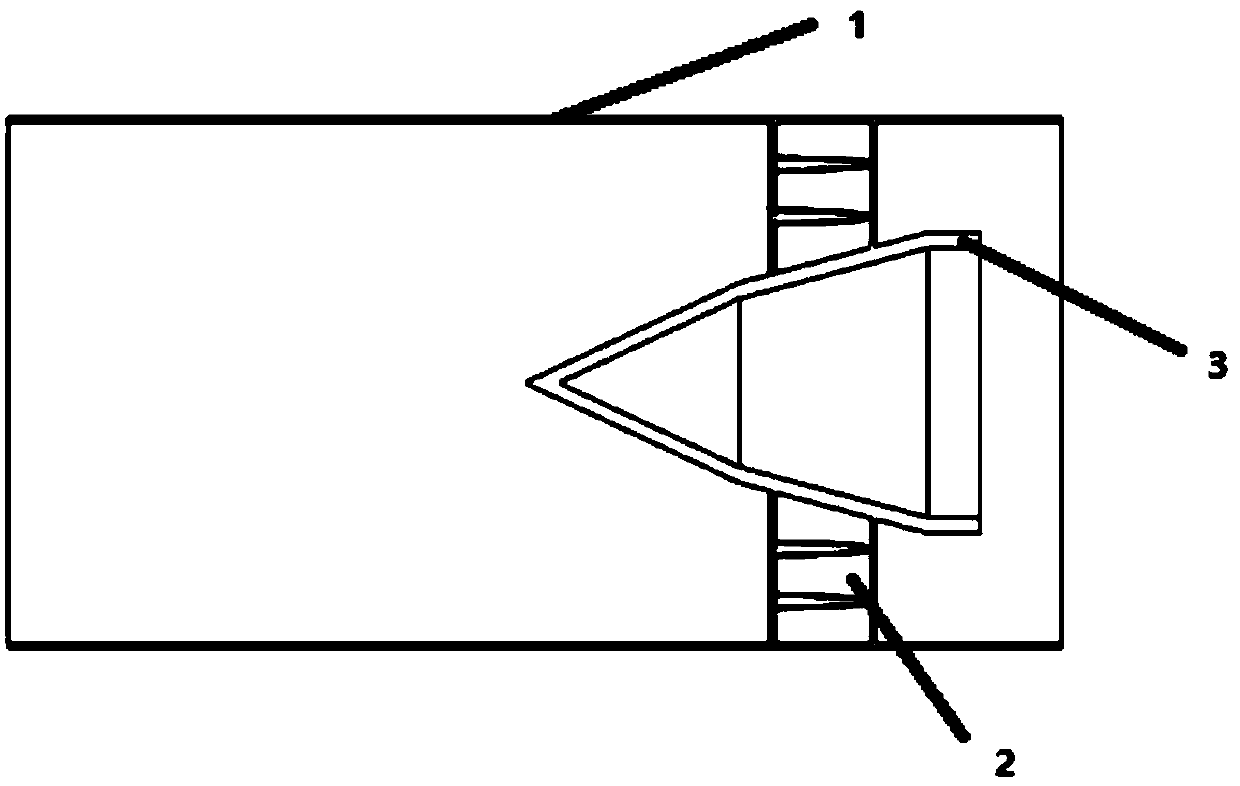

Integrated afterburner with grid-structure rectification supporting plate flame stabilizers

ActiveCN109595590AIncrease mixing intensityImprove combustion stability and combustion efficiencyContinuous combustion chamberSpray nozzleMesh grid

The invention provides an integrated afterburner with grid-structure rectification supporting plate flame stabilizers. The rectification supporting plate flame stabilizers in the radial direction areuniformly distributed on a thrust augmentation inner cone in the circumferential direction; the rectification supporting plate flame stabilizers in the circumferential direction perpendicularly intersect with the rectification supporting plate flame stabilizers in the radial direction and surround the thrust augmentation inner cone for one circle; the cross-sectional shape of the rectification supporting plate flame stabilizers in the radial direction is same as that of the rectification supporting plate flame stabilizers in the circumferential direction; and through the net-shaped structuraldesign of the rectification supporting plate flame stabilizers, a back flow area which is uniform and stable and has the certain fuel gas back flow amount and the appropriate size can be effectively formed on the downstream. Fuel oil enters the rectification supporting plate flame stabilizers through a fuel oil channel, is heated through high-temperature incoming gas and then is sprayed out through main fuel oil spray nozzles and standby fuel oil spray nozzles which are located on the two sides of the V shapes of the rear of the rectification supporting plate flame stabilizers, the fuel oil atomization degree and mixing of fuel oil and air can be effectively enhanced, and the burning stability and burning efficiency are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

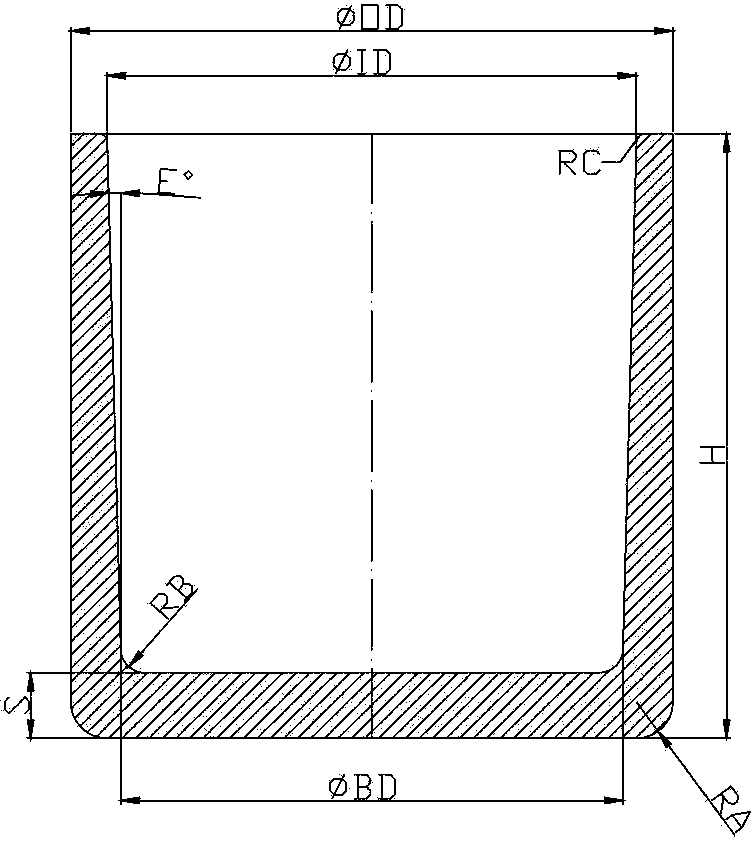

Large-size high-density tungsten crucible and preparation method thereof

The invention provides a large-size high-density tungsten crucible which is mainly used for sapphire crystal growth industry, and particularly provides a preparation method for the large-size high-density tungsten crucible. The method comprises the following steps: raw materials processing, mould core manufacturing, mould setting and forming, high-temperature sintering and mechanical processing. Compared with the prior art, the produced crucible is large in size range and suitable for mass production. Moreover, no binding agent is added in the production process, and impurity content of the product is low; the finished product has the advantages of being high in density, large in size (maximal external diameter of phi 650 mm and maximal height of 800 mm), good in size adaptability and consistency, and high in yield and surface finish, can bear 2000-2300 DEG C high temperature under the protective atmosphere, and can not react with sapphire raw materials under the high temperature.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

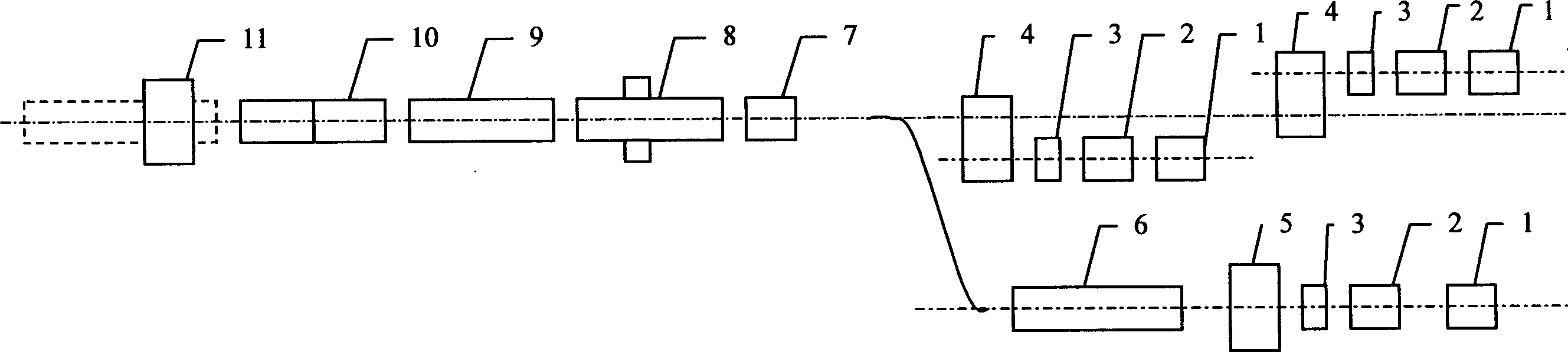

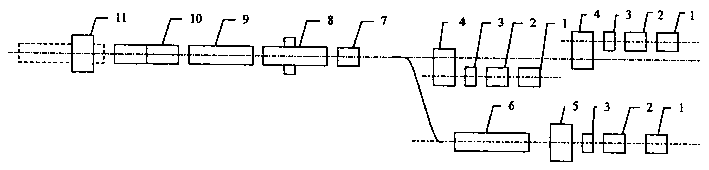

Continuous welding production method of light H-type steel

InactiveCN1411940AIncrease productivityRealize continuous productionWelding/cutting auxillary devicesAuxillary welding devicesStrip steelEngineering

The continuous welding production method of light H-type steel includes the following processes: decoiling band steel, flatening, shearing but-welding, loop stoage, web edge-upsetting, preassembling,high-frequency welding, quick-cooling, flatening drawing, length shearing. The parameters of every process are: edge-upsetting pressure is 500-8000 kgf, microtension of band steel before welding is 50-1000 Kgf, welding speed is 10-50 m / min., welding power is 100-1000 KW, and cooling speed is 1-30 deg.C / s.

Owner:CENT IRON & STEEL RES INST

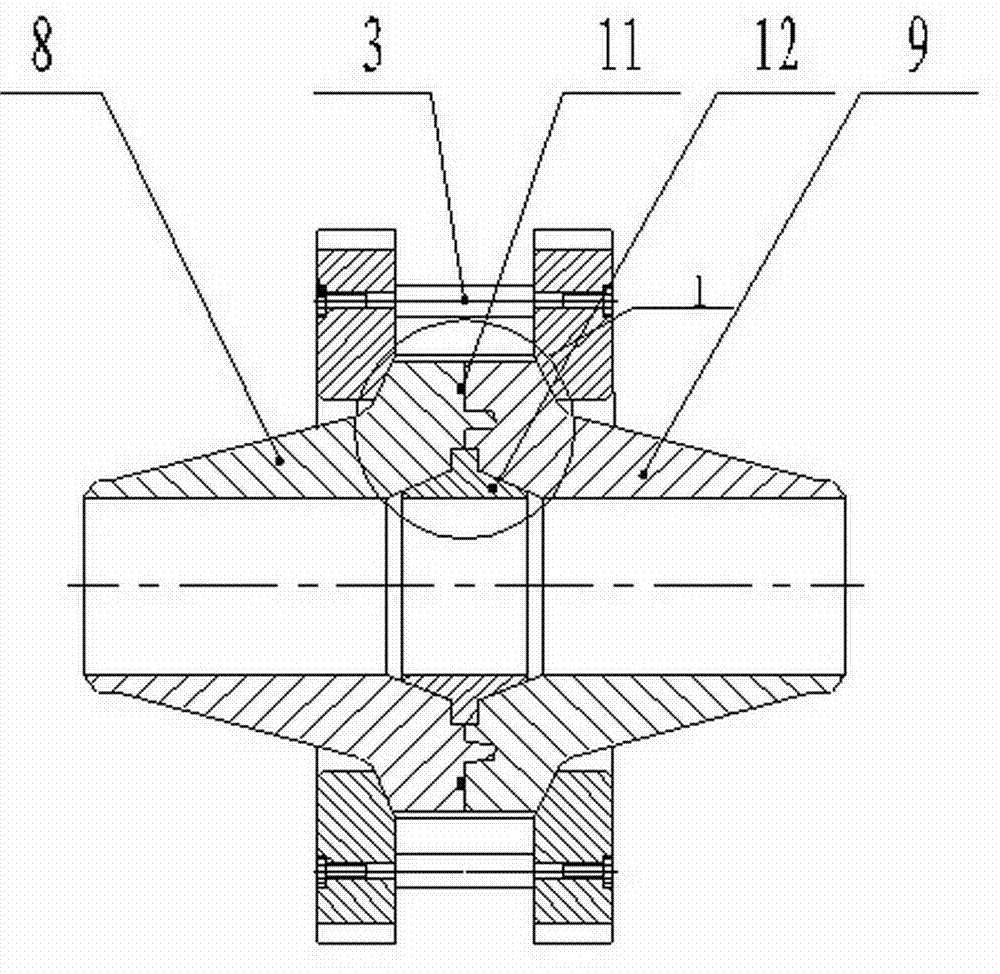

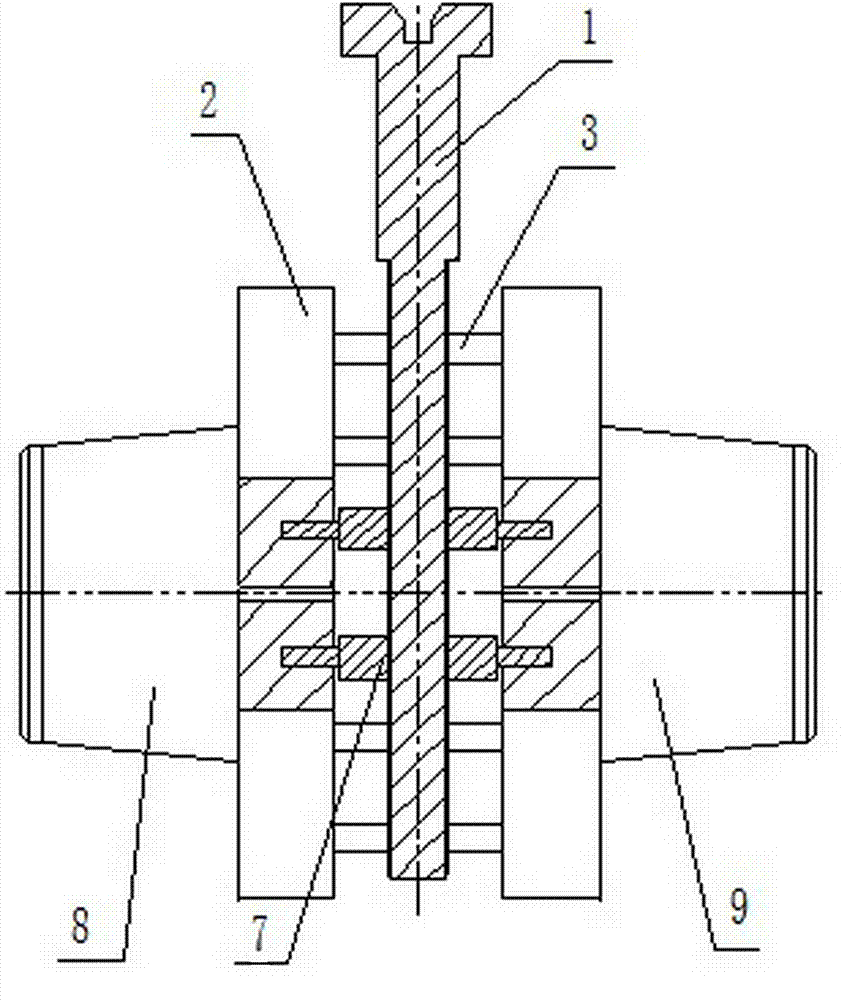

Clamping type ocean underwater pipeline connector

InactiveCN103363212AMeet the operating requirements of harsh working conditions such as ocean deep waterReduce manufacturing costFlanged jointsInterference fitLocking mechanism

The invention discloses a clamping type ocean underwater pipeline connector which comprises a left flange, a right flange and a flange locking mechanism. An auxiliary seal ring, ring-shaped grooves and a ring-shaped protruded edge are respectively arranged on the opposite end faces of the left flange and the right flange in a coaxial mode from outside to inside, wherein the ring-shaped grooves and the ring-shaped threads are in mutual interference fit in a sealing mode. The inner walls of end pipes of the left flange and the right flange are cone-shaped surfaces, ring-shaped concave steps are arranged on the outer edges of the cone-shaped surfaces, backing rings are arranged in the cone-shaped surface end pipes in an interference sealing fit mode, and the outer periphery walls of the backing rings respectively make contact with the ring-shaped concave steps and the cone-shaped surfaces. An upper locking arm and a lower locking arm are hinged to the upper end and the lower end of a locking base of the locking mechanism respectively. The locking arms are respectively composed of two pressing plates. Two connecting hinge pins are horizontally arranged between the free ends of the two pressing plates of the upper locking arm and between the two pressing plates of the lower locking arms respectively, wherein the connecting hinge pins are provided with center threaded holes. A vertically arranged threaded operating rod penetrates through the threaded holes in the two connecting hinge pins, and the cone-shaped back edges of the left flange and the right flange are located between the two pressing plates of the upper locking arm and between the two pressing plates of the lower locking arm respectively.

Owner:TARIM UNIV

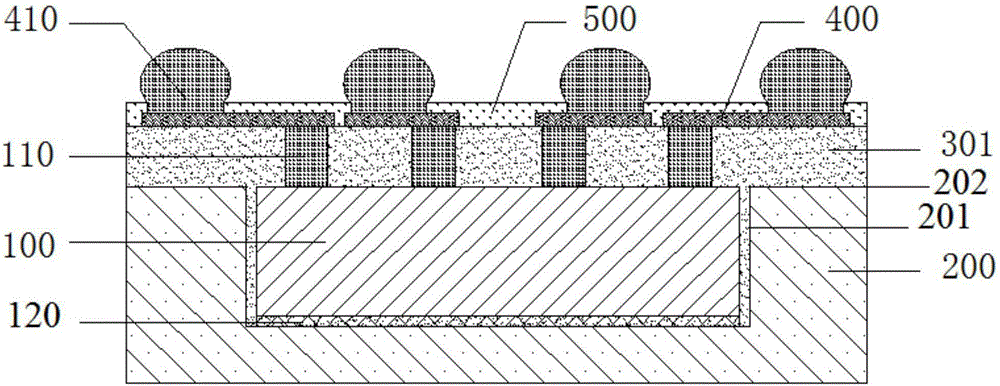

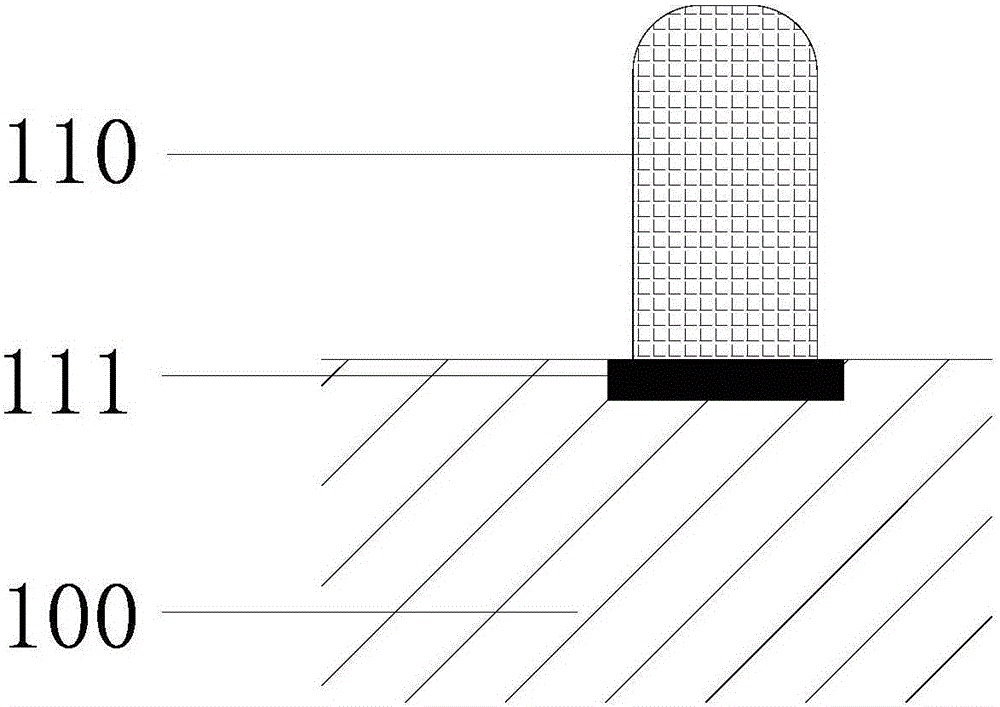

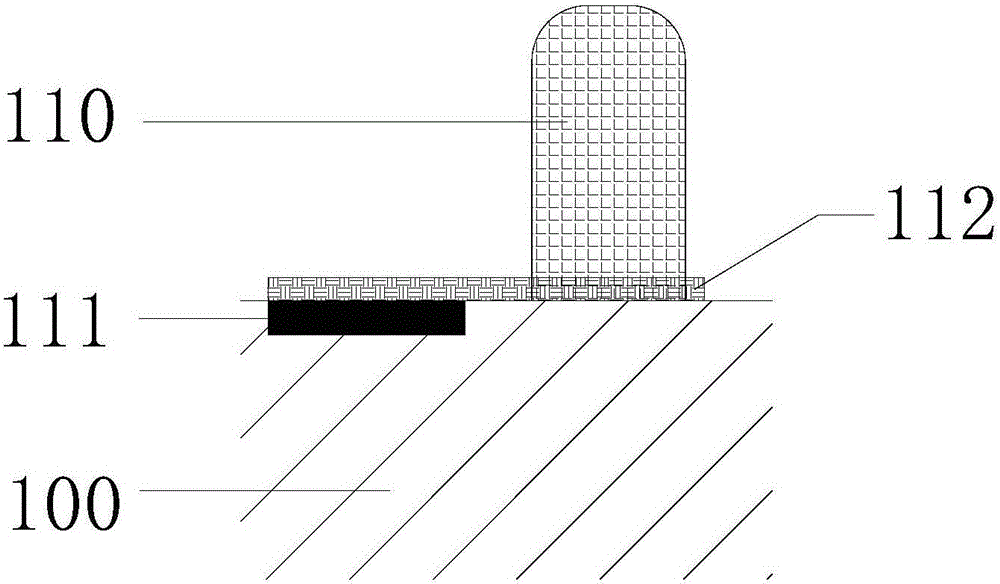

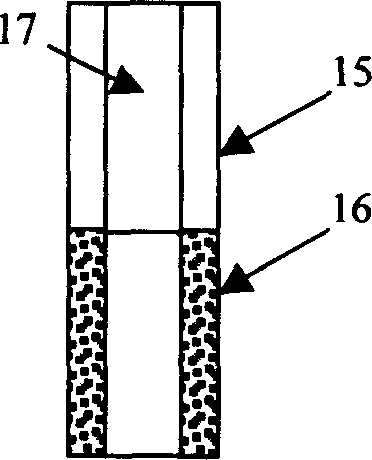

Embedded type semiconductor chip fan-out type packaging structure and manufacturing method therefor

InactiveCN106098664AGuaranteed flatnessWide range of sizesSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

The invention discloses an embedded semiconductor chip fan-out packaging structure and a manufacturing method thereof. The packaging structure includes a semiconductor substrate and a chip. A plurality of conductive pads are arranged on the front side of the chip, and the semiconductor substrate is provided with a receiving groove, and the chip is accommodated in the receiving groove with the front facing outward. A metal post is grown on each conductive pad, and the metal post is higher than the upper surface of the semiconductor substrate. The gap between the receiving groove and the chip, the upper surface and the surroundings of the metal post are filled or covered by an insulating layer. A metal rewiring is connected to the top surfaces of all the metal pillars, and at least one metal rewiring extends beyond the surface of the chip. In the present invention, metal pillars are long on the chip, and the chip and the metal pillars are covered with polymer materials, and then the metal pillars of the chip are exposed by using a planarization process, so as to ensure the flatness of the surface of the package; meanwhile, the size range of the groove can be expanded . The invention also discloses a manufacturing method of the embedded semiconductor chip fan-out packaging structure.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

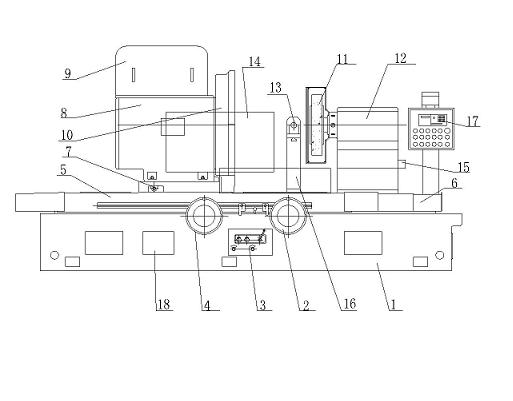

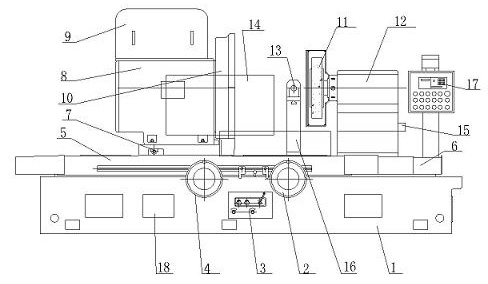

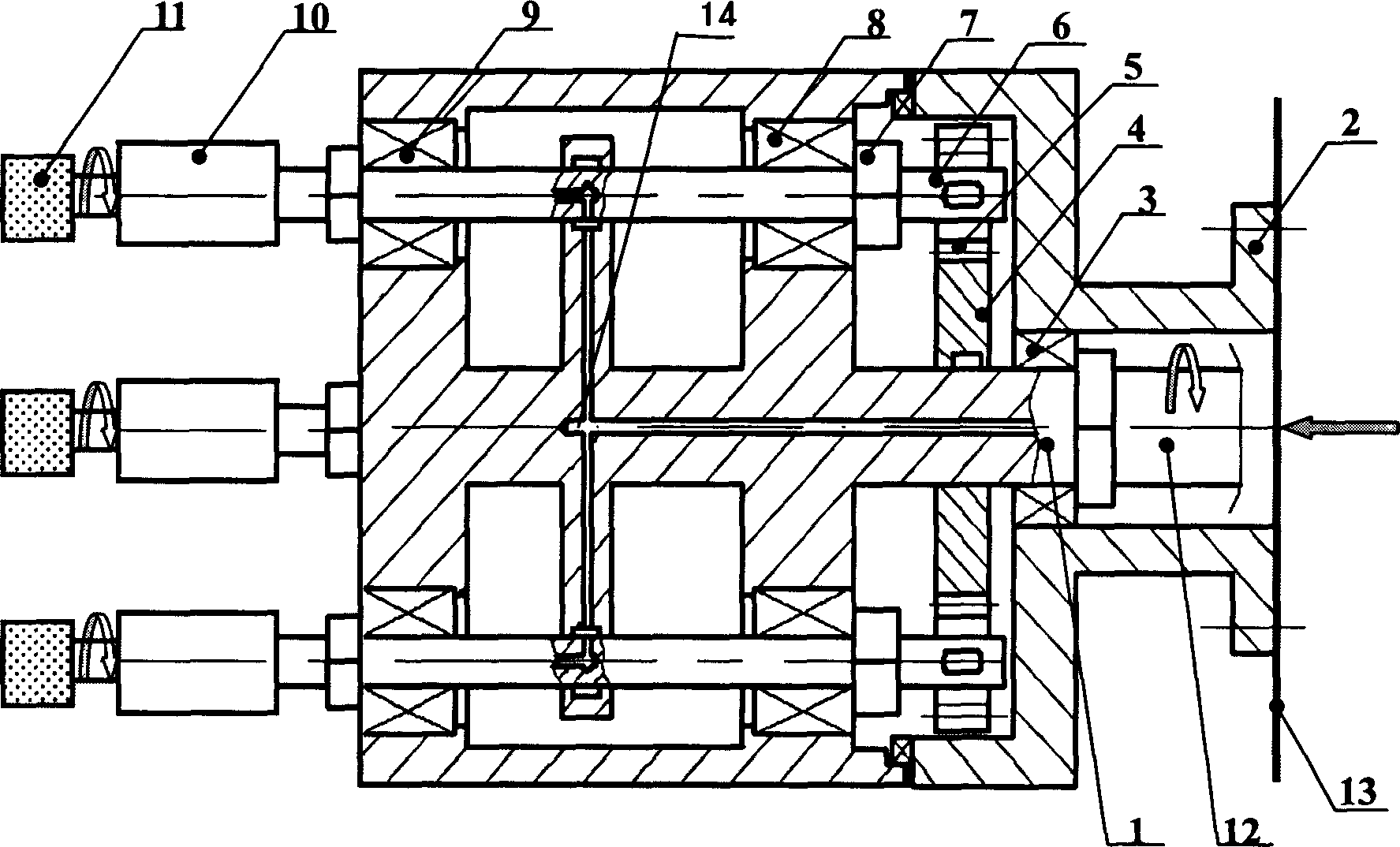

Cylindrical grinding machine for bearing ring

InactiveCN102179735ASimple structureStatic strongRevolution surface grinding machinesAbrasive surface conditioning devicesElectrical controlEngineering

The invention discloses a cylindrical grinding machine for a bearing ring. The cylindrical grinding machine comprises a machine body, a reciprocating operating platform, a grinding wheel shaft box, a workpiece shaft box, a longitudinal feed mechanism, a transverse feed mechanism, a grinding wheel dresser, a hydraulic system, a lubricating system, a cooling system and an electrical control system, wherein the reciprocating operating platform, the longitudinal feed mechanism and the transverse feed mechanism are arranged on the machine body; the grinding wheel shaft box is arranged on the machine body on the rear side of the reciprocating operating platform; a grinding wheel is arranged on the grinding wheel shaft box; the grinding wheel dresser is arranged on the reciprocating operating platform through a grinding wheel dresser seat; the workpiece shaft box is arranged on the reciprocating operating platform; the hydraulic system, the lubricating system and the electrical control system are arranged in the machine body; and the cooling system is arranged on the rear side of the machine body. The cylindrical grinding machine for the bearing ring has a simple structure, high static and dynamic rigidity, high vibration resistance, a high vibration reduction property, high precision retaining ability, a small number of faults, long service life and attractive appearance, is accurately positioned, lightly frictionally worn and easy to operate and maintain, saves energy, and is environment-friendly and safe.

Owner:大连沃飞亚装备制造有限公司

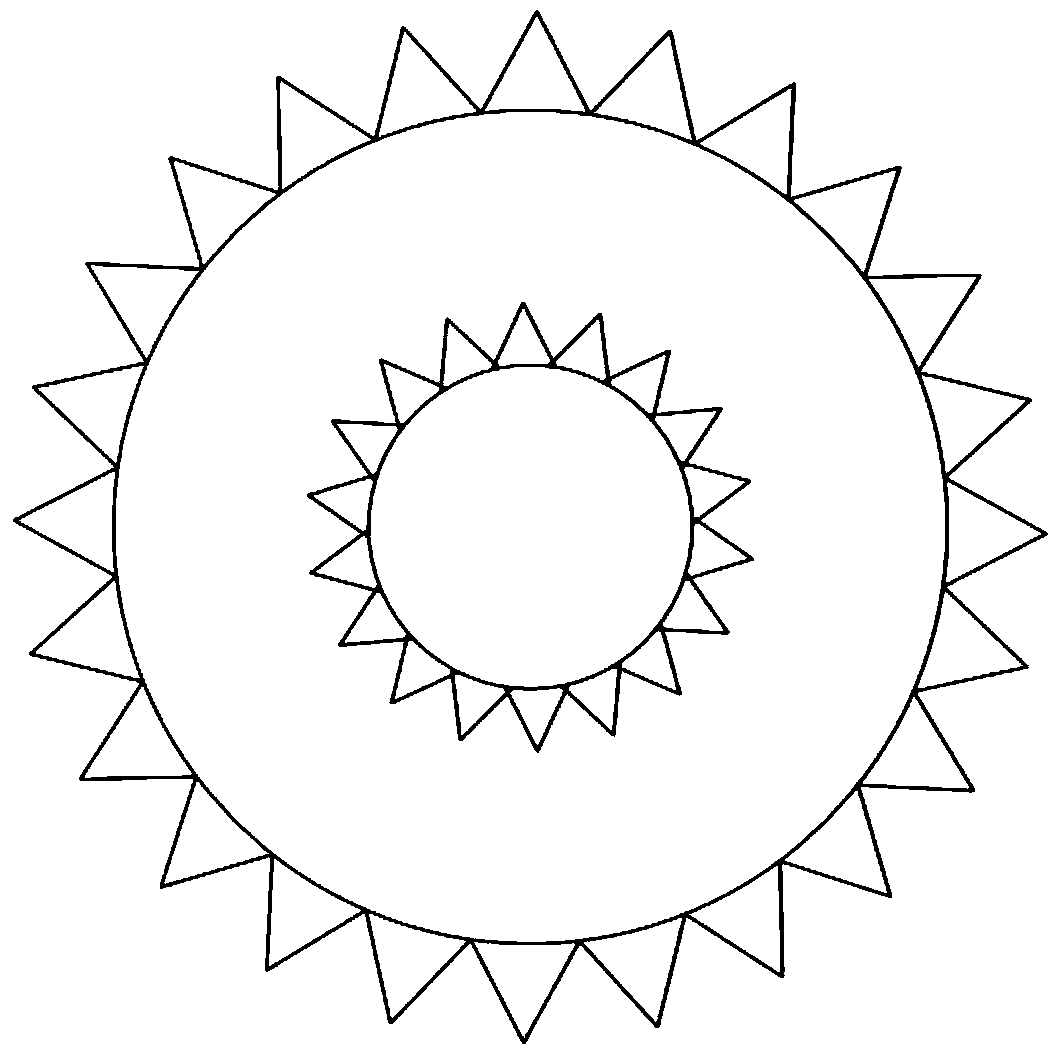

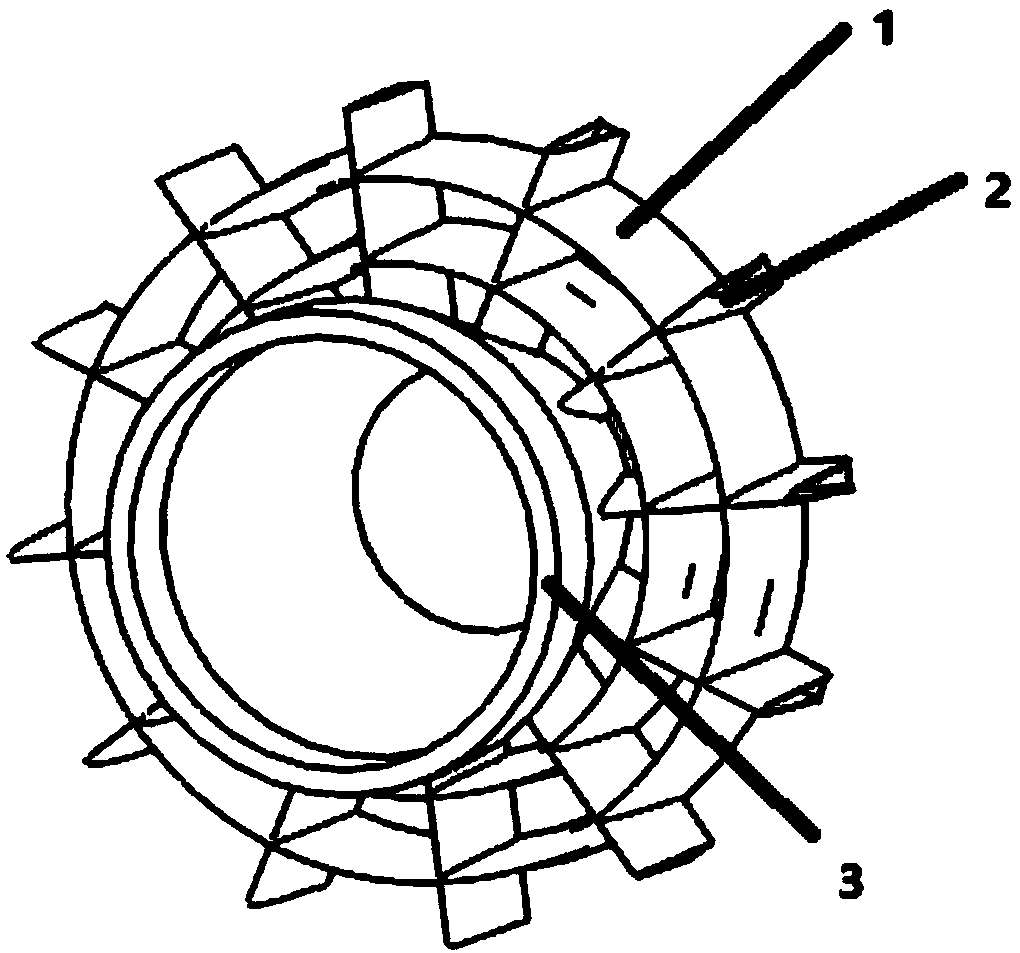

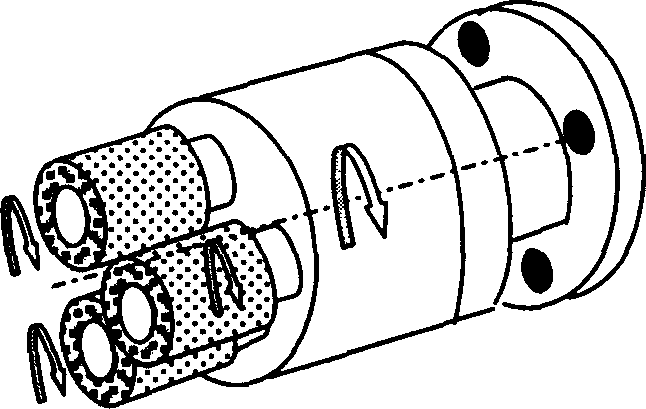

Planetary framework diamond abrasive tools

InactiveCN1836845AAvoid loweringMaintain sharpnessGrinding machinesMetal working apparatusDrive shaftGear wheel

The planetary mechanism diamond grinding tool is one workpiece grinding diamond grinding wheel apparatus with great grinding width, high efficiency, low cost and grinding wheel without needing trimming measure and tool. It has planetary gear mechanism, spring clamp sleeve, cooling pipeline, fixing and connecting casing and rotating casing. The planetary gear mechanism is provided with bearing, sun gear, planetary gear, nut, bearing and pressurized cooling liquid inflow pipeline. The rotating casing is connected to the driving shaft integrally, the bearing is set between the driving shaft and the fixing and connecting casing, the sun gear is set on the driving shaft for rotation, the planetary gear is connected to the sun gear, the spring clamp sleeve is set in the output end of the planetary shaft, the cooling liquid inflow pipeline is set in the axial center of the driving shaft and has one end connected to the built-in cooling pipeline inside the rotating casing.

Owner:XIAMEN UNIV

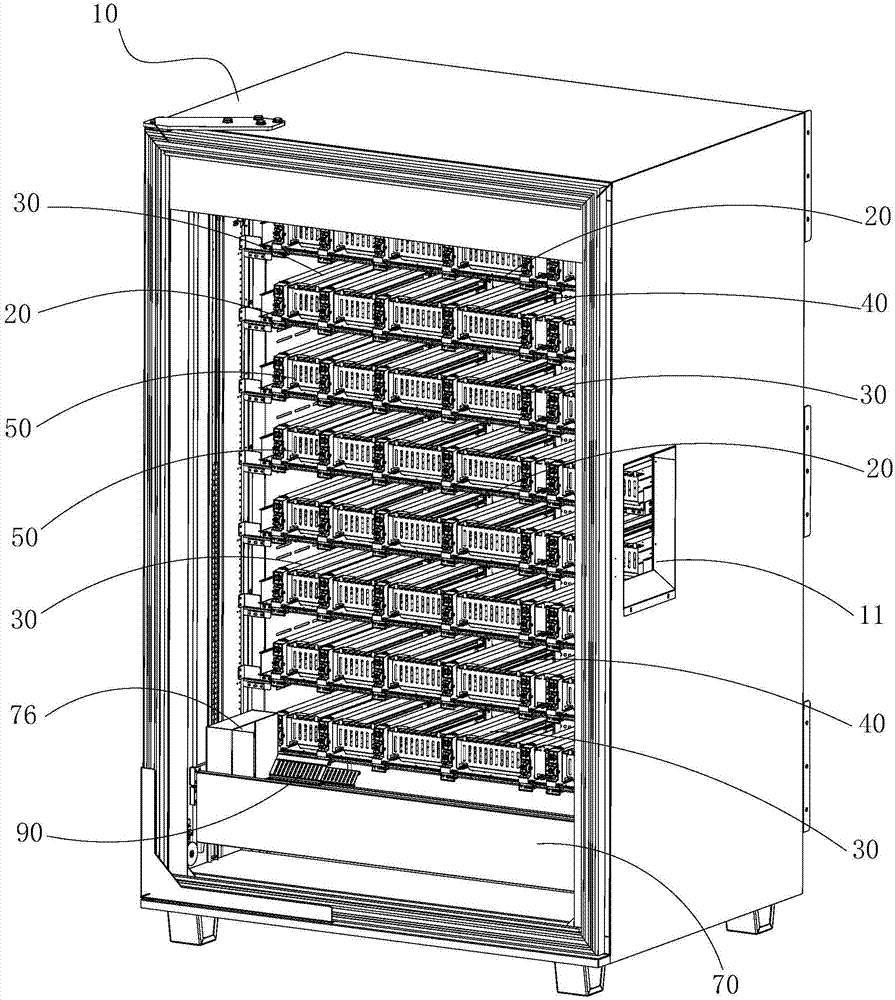

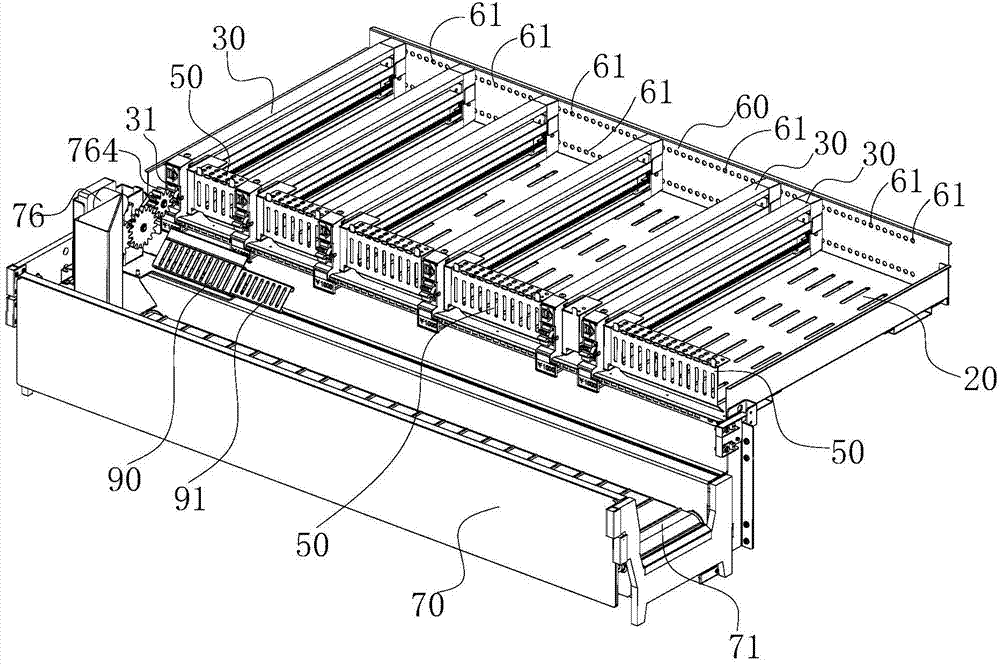

Vending machine

InactiveCN104778785AWide range of sizesEasy to assemble and disassembleCoin-freed apparatus detailsApparatus for dispensing discrete articlesOperations management

The invention discloses a vending machine. The vending machine comprises a cabinet body, goods shelves, partition pieces, first moving components and pushing plates. One or more rows of goods shelves are arranged inside the cabinet body. Installing plates are connected with the ends of each goods shelf, and each installing plate is provided with an installing groove or multiple installing holes. The one or more partition pieces are arranged in the goods shelves, each goods shelf is divided into one or more goods channels, and the end of each partition piece is detachably installed in the corresponding installing groove or the corresponding installing hole. The first moving components are in one-to-one correspondence to the partition pieces, and each first moving component is installed on the corresponding partition piece. The pushing plate are in one-to-one correspondence to the goods channels, and each pushing plate is arranged on the corresponding goods channel. Each first moving component is in transmission connection with the corresponding pushing plate so that each pushing plate can be moved from one end to other end of the corresponding goods channel. By means of the vending machine, the partition pieces can be detached and installed conveniently, the positions of the partition pieces on the installing plates can be adjusted, the width of each pushing plate can be changed correspondingly, and therefore the goods shelves of the vending machine can adapt to the goods dimensions in a wide range.

Owner:GUANGZHOU JOYI SMART TECH CO LTD

Hydraulic clamping device for special-shaped workpiece

InactiveCN104191289AWide range of sizesPositioning apparatusMetal-working holdersHydraulic cylinderEngineering

The invention provides a hydraulic clamping device for a special-shaped workpiece. The hydraulic clamping device is suitable for machine tools. The hydraulic clamping device is mainly composed of a base, a fixed matrix hydraulic cylinder and a movable matrix hydraulic cylinder. The movable matrix hydraulic cylinder is matched with the base through dovetail grooves, and longitudinally moves on the base through transmission of a lead screw. The matrix hydraulic cylinders are internally provided with single-action piston-type hydraulic rods resetting through springs, hydraulic oil with appropriate pressure is fed into the hydraulic cylinders, the pressure is transmitted to the hydraulic rods, and therefore the hydraulic rods position and clamp the workpiece. Due to the fact that the extension length of each hydraulic rod can be adjusted through hydraulic parts, the clamping range is not constant, and the hydraulic clamping device can clamp the irregular special-shaped workpiece. The process of reserving unnecessary technological structures on the clamped workpiece according to clamping requirements of the workpiece during machining and formulating the related technique is simplified, workpiece materials are saved, the machining technology is simplified, and the machining efficiency is improved.

Owner:任磊磊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com