Axial workpiece bending deformed planar array CCD measuring method and apparatus

A shaft part and bending deformation technology, which is applied in the field of bending deformation measurement of parts, can solve the problems of few detection points and low measurement accuracy, and achieve the effects of simple equipment, high measurement accuracy and fast measurement speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

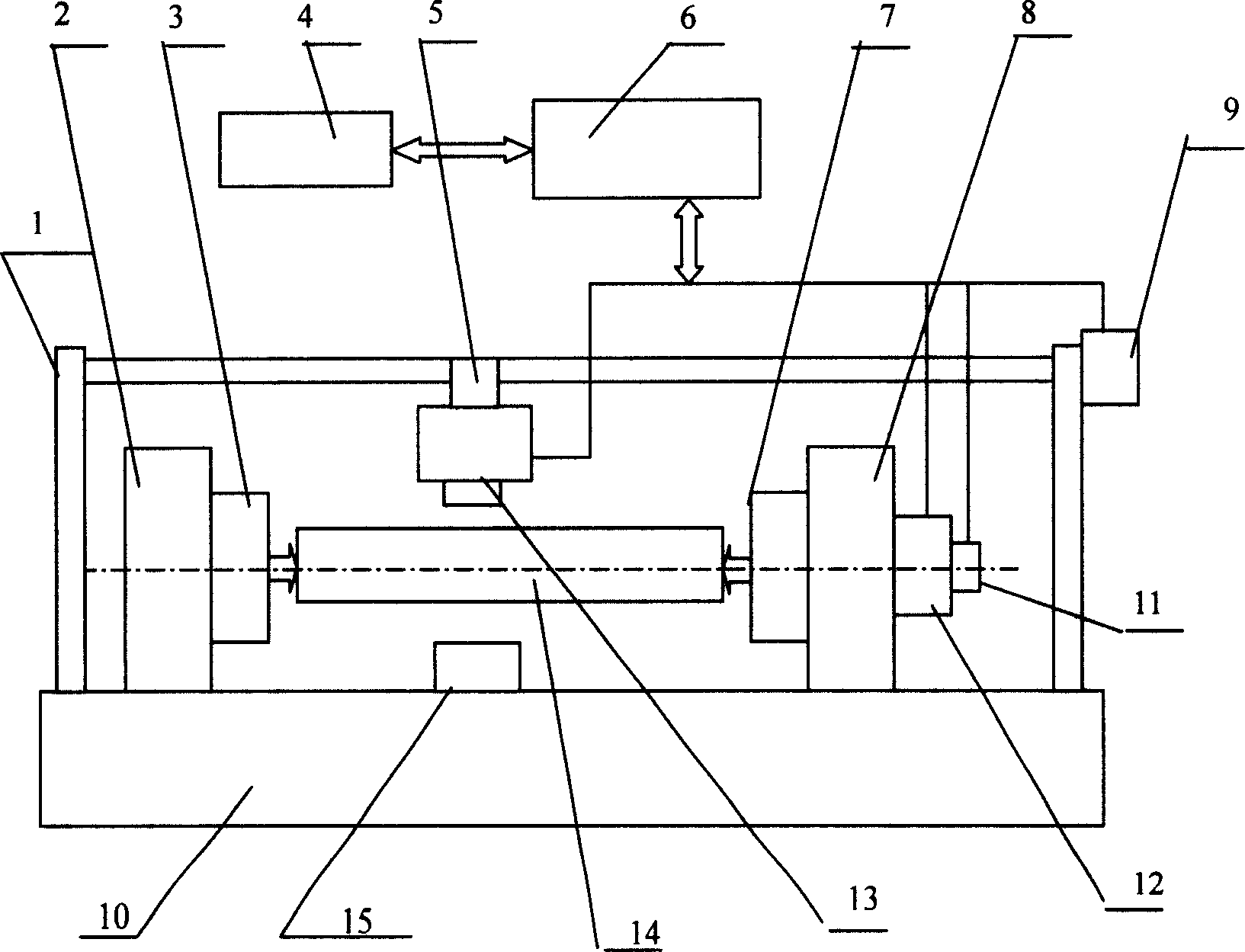

[0019] Such as figure 1 As shown, the shaft part to be measured is a long shaft, and the long-axis bending deformation area array CCD measuring device includes an image acquisition and processing system, and a rotation control system of the measured long shaft. The image acquisition and processing system and the rotation control system of the measured shaft parts are mounted on the frame 10 of the straightening machine. The image acquisition and processing system includes an area array CCD13, a backlight source 15, an I / O card 6, and an industrial computer 4. The measured long axis is supported by the top 3 and the top 7, the tailstock 2 and the gearbox 8 are fixed on the straightening machine frame 10, and the area array CCD 13 and the backlight 15 are respectively placed on both sides of the measured long step axis. The area array CCD13 is connected with the stepping motor 9 and located on the ball screw pair 5, and the stepping motor 9 drives the ball screw pair 5 to move ...

Embodiment 2

[0021] The shaft parts to be tested are three-step shaft parts. One area array CCD is used on each step, and a total of three area array CCDs are used to connect with the ball screw pairs respectively. The three ball screw pairs are connected with the support frame 1 and also connected with the stepping motor 9. The stepper motor 9 drives three area array CCDs 13 to move axially along the measured three-step shaft part, and continuously collects image data of different shaft diameters. Other devices are the same as Example 1, and the measurement method is also the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com