Digital controlled ceramic constructing forming machine

A molding machine and ceramic technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of large mold loss, high labor intensity, low precision, etc., and achieve the effect of high processing precision and large size range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

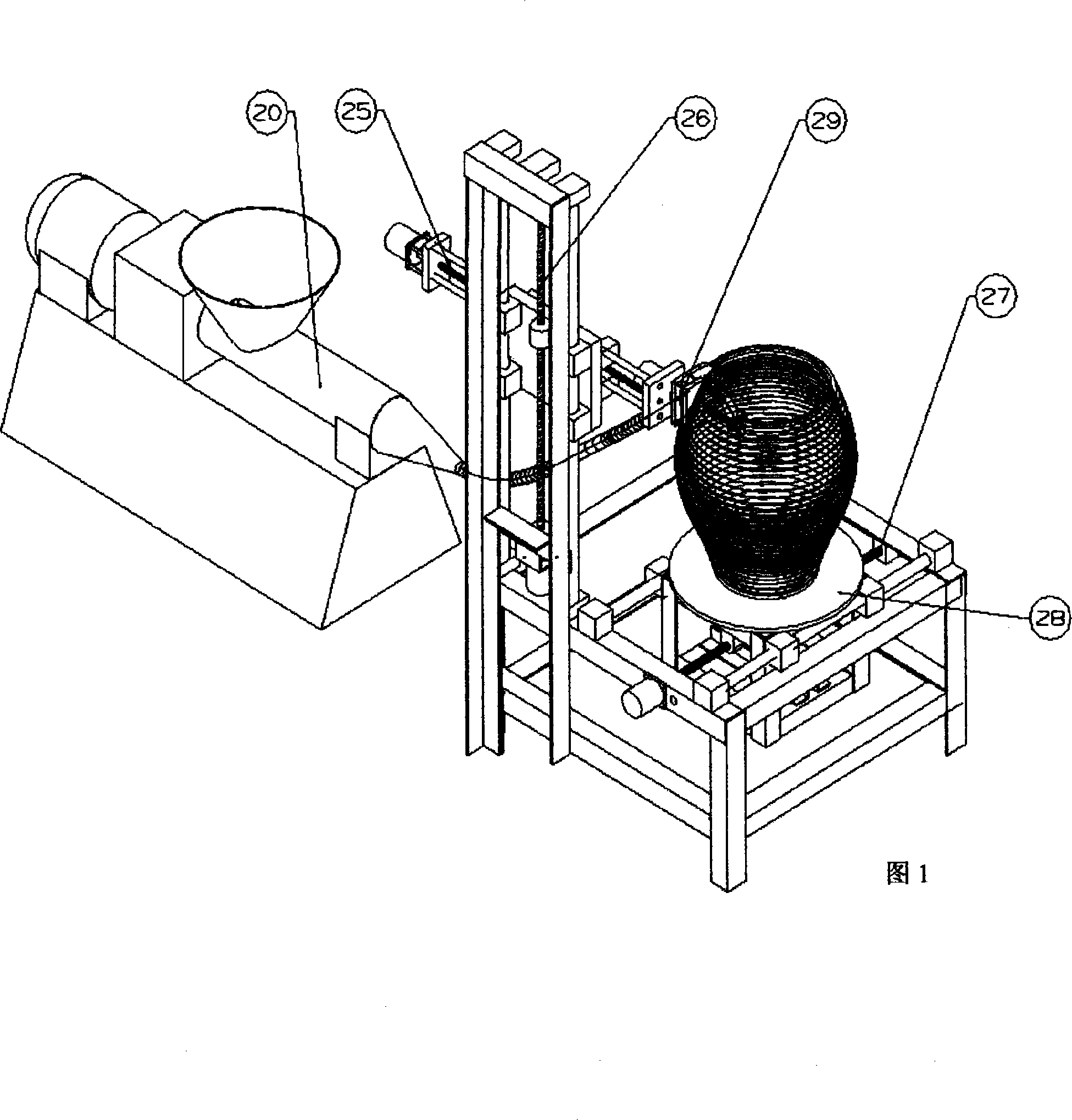

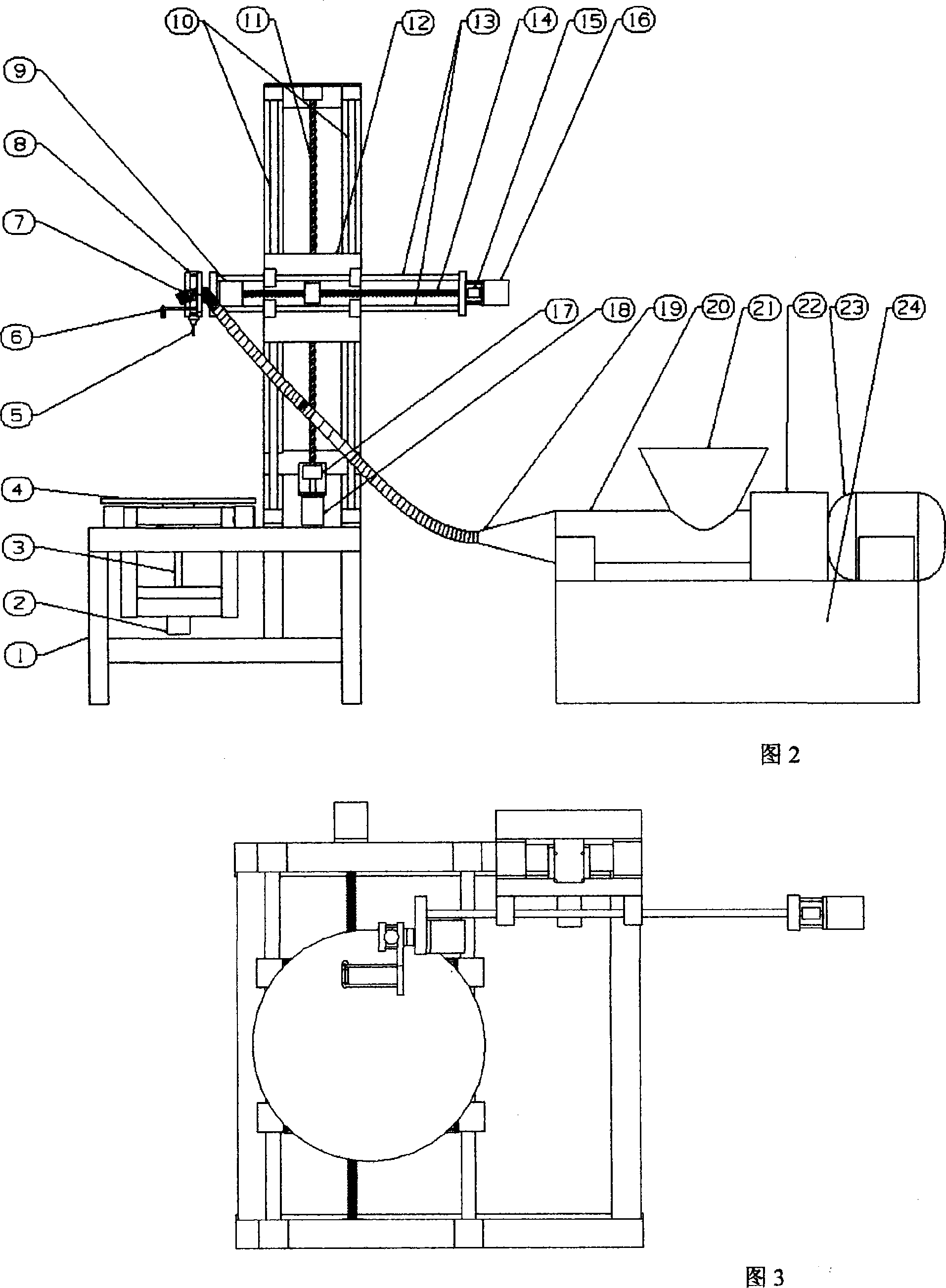

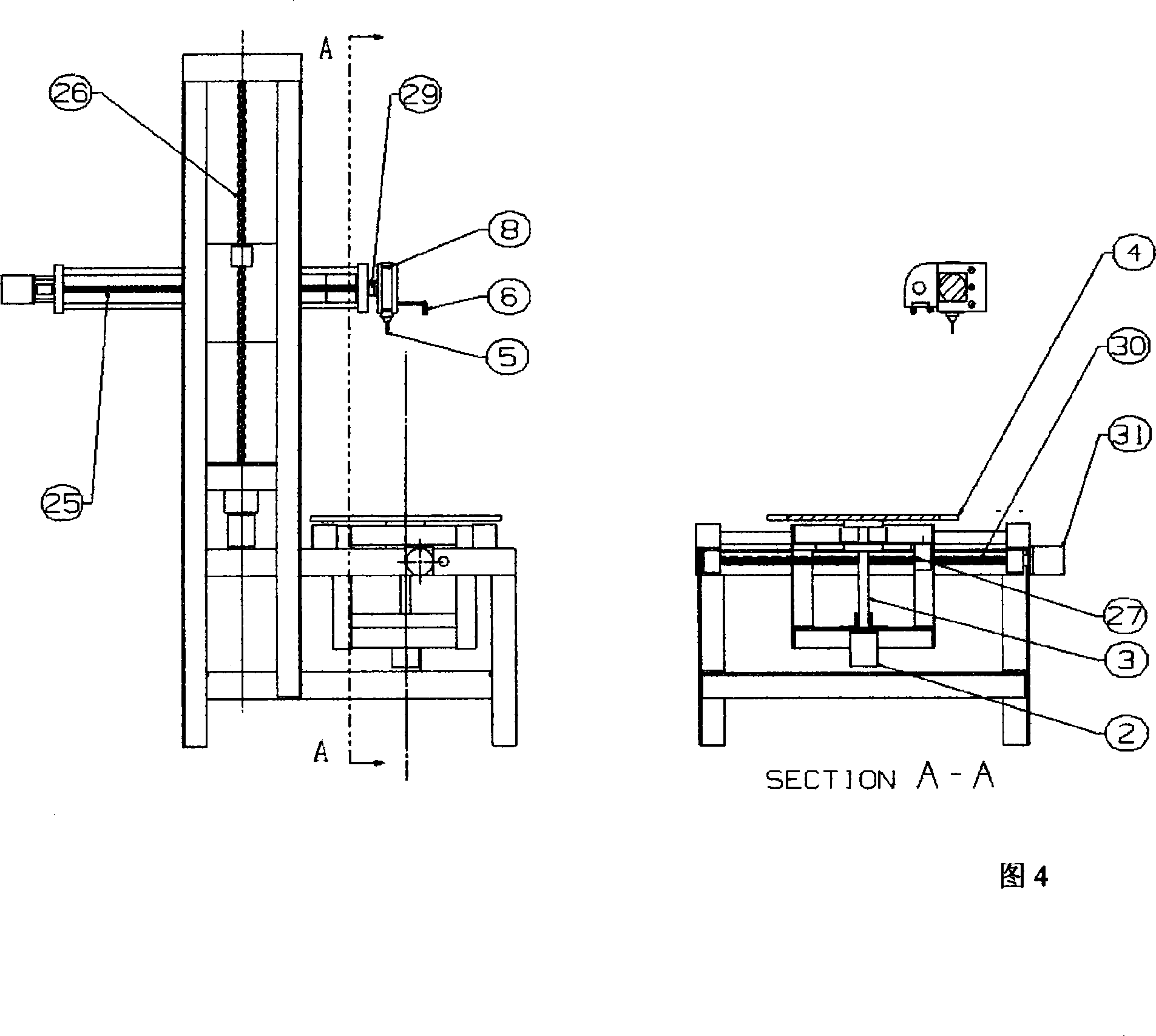

[0054] The CNC ceramic stacking molding machine of the present invention, as shown in the accompanying drawings, includes a computer control part, an X-axis feed part 25, a Y-axis feed part 26, a Z-axis feed part 27, an A-axis rotary part 28, and a B-axis swing part. 29, stacking manipulator 6, engraving head 8, vacuum extrusion part 20. According to the five-axis linkage control signal sent by the computer, it can drive the stepper motors of the three linear feed axes X, Y, and Z, and the two rotary axes A and B to realize stacking manipulator 6 and engraving. Five-axis linkage of any trajectory and posture of the head 8 in three-dimensional space. The high-quality ceramic mud extruded by the vacuum extruder 20 is transported to the stacking manipulator 6 through the hose 7, and stacked point by point and layer by layer on the rotary table 4. After waiting for the ceramic blank to dry, it can be put back on the rotary table for secondary processing, namely sharpening and eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com