Vending machine

A vending machine and shelf technology, applied in the field of vending machines, can solve the problems of high device cost, inconvenient maintenance, and many driving motors, and achieve the effects of low cost, avoiding damage from falling, and simple lifting structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention are described in detail below:

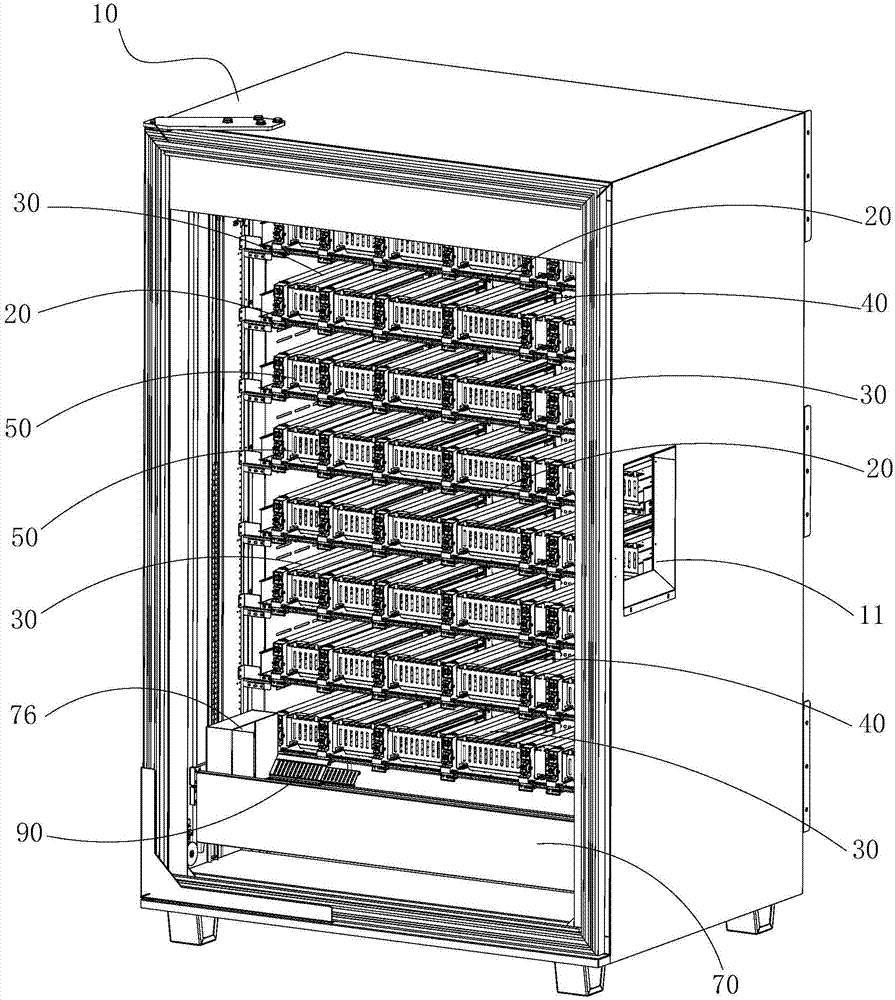

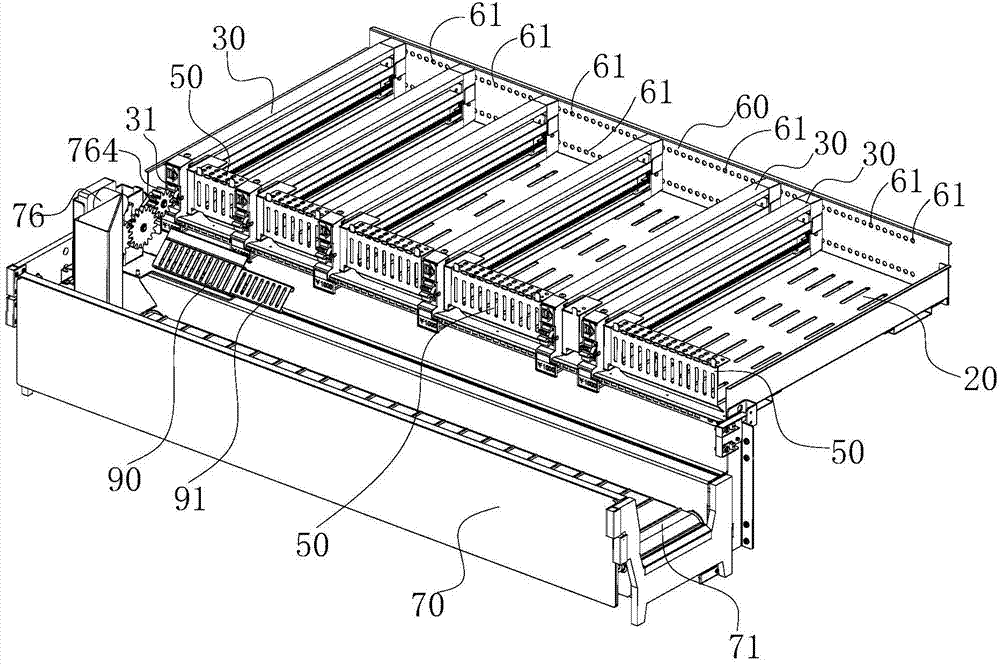

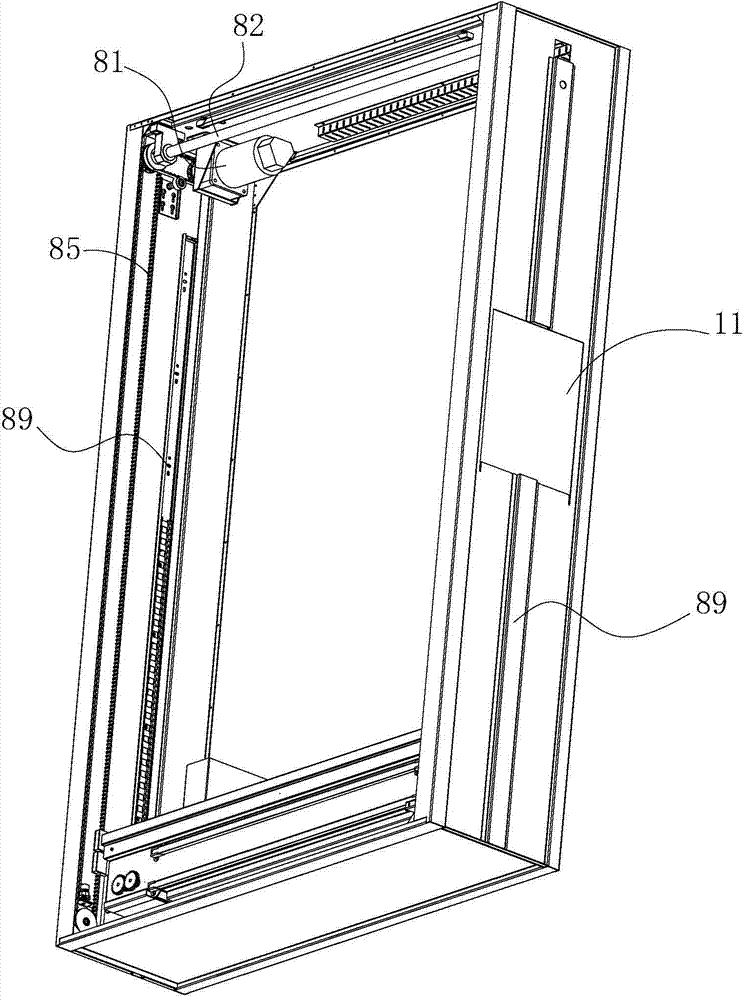

[0034] Such as figure 1 As shown, the vending machine of the present invention includes a box body 10 , a shelf 20 , a partition 30 , a first moving assembly 40 and a push plate 50 . The shelves 20 have one row or more than one row, and the shelves 20 are arranged in the box body 10 . see figure 2 , the end of the shelf 20 is connected with a mounting plate 60 , and the mounting plate 60 is provided with a mounting groove or a plurality of mounting holes 61 . The partition 30 has more than one and is arranged in the shelf 20, so as to divide the shelf 20 into more than one cargo lane (not shown in the figure), and the end of the partition 30 is detachably installed on the shelf. The above-mentioned mounting groove or mounting hole 61. More than one first moving assembly 40 is provided, the first moving assembly 40 corresponds to the partition 30 one by one, and the first moving assembly 40 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com