Clamping type ocean underwater pipeline connector

A connector and marine technology, applied in the direction of flange connections, pipes/pipe joints/fittings, passing components, etc., can solve the problems of unfavorable mass promotion and application, high production and installation costs, time-consuming and labor-intensive connections, etc., to achieve installation and disassembly Fast and convenient, low production and installation costs, reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

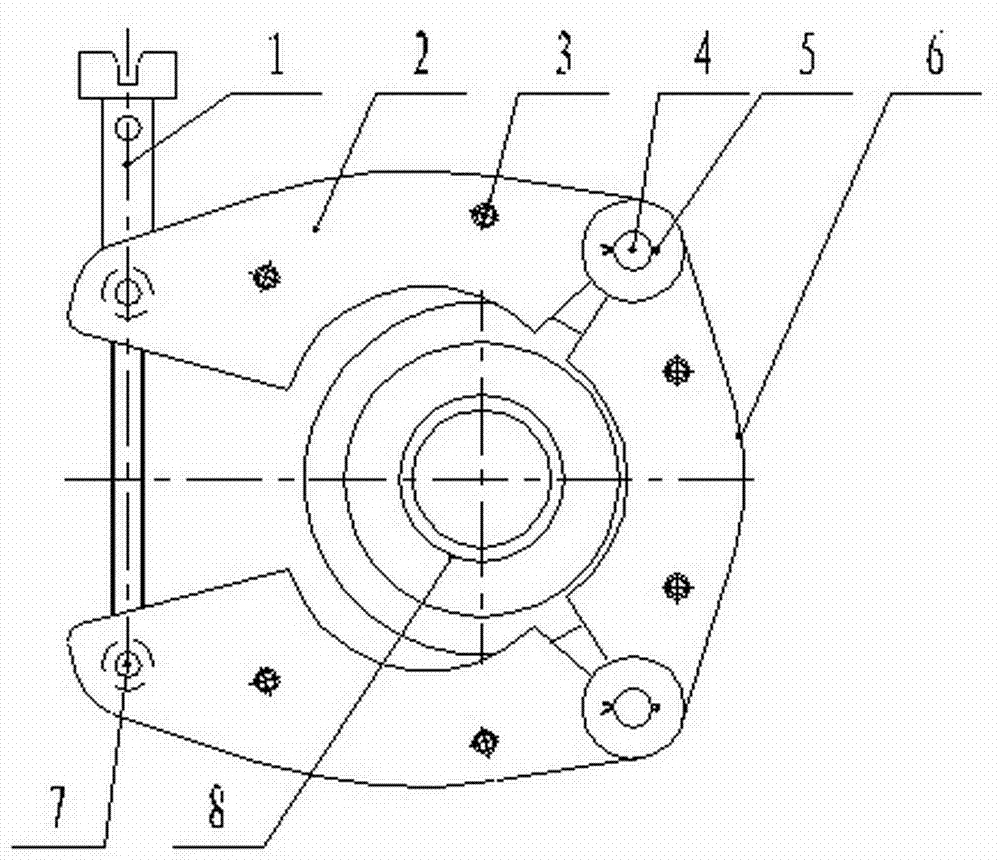

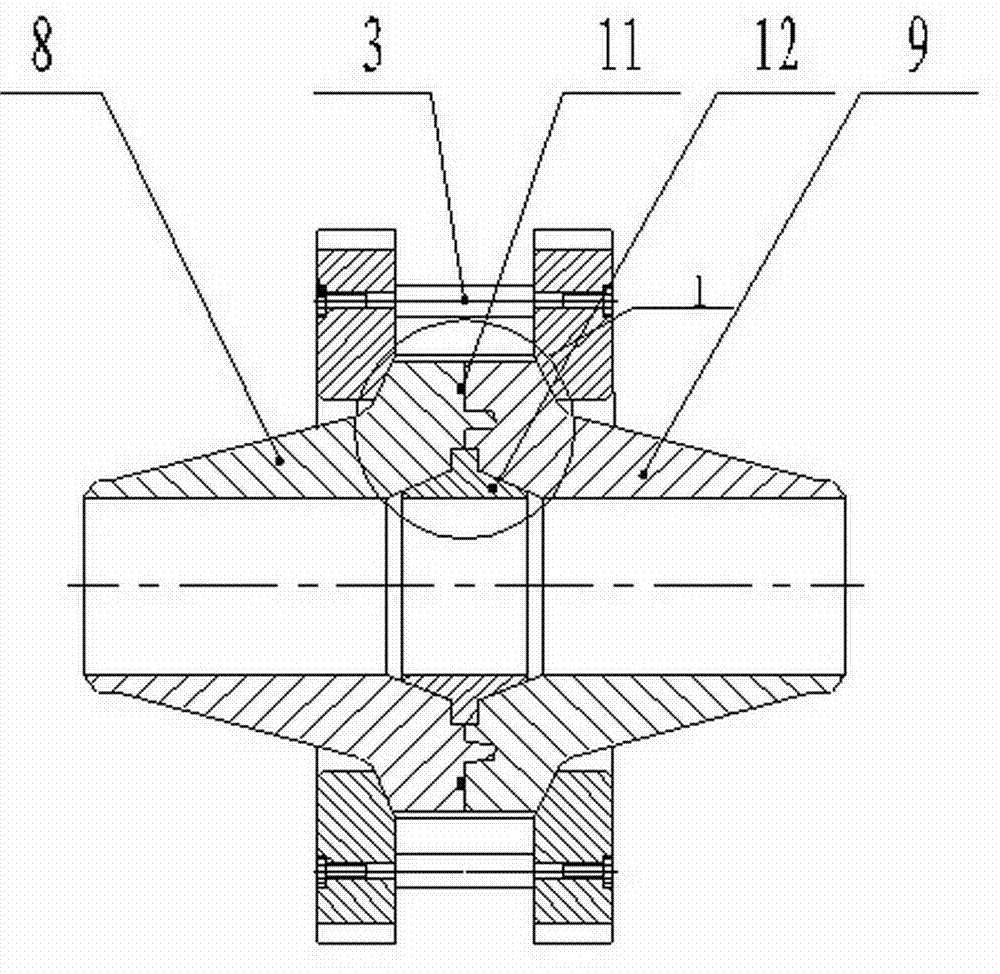

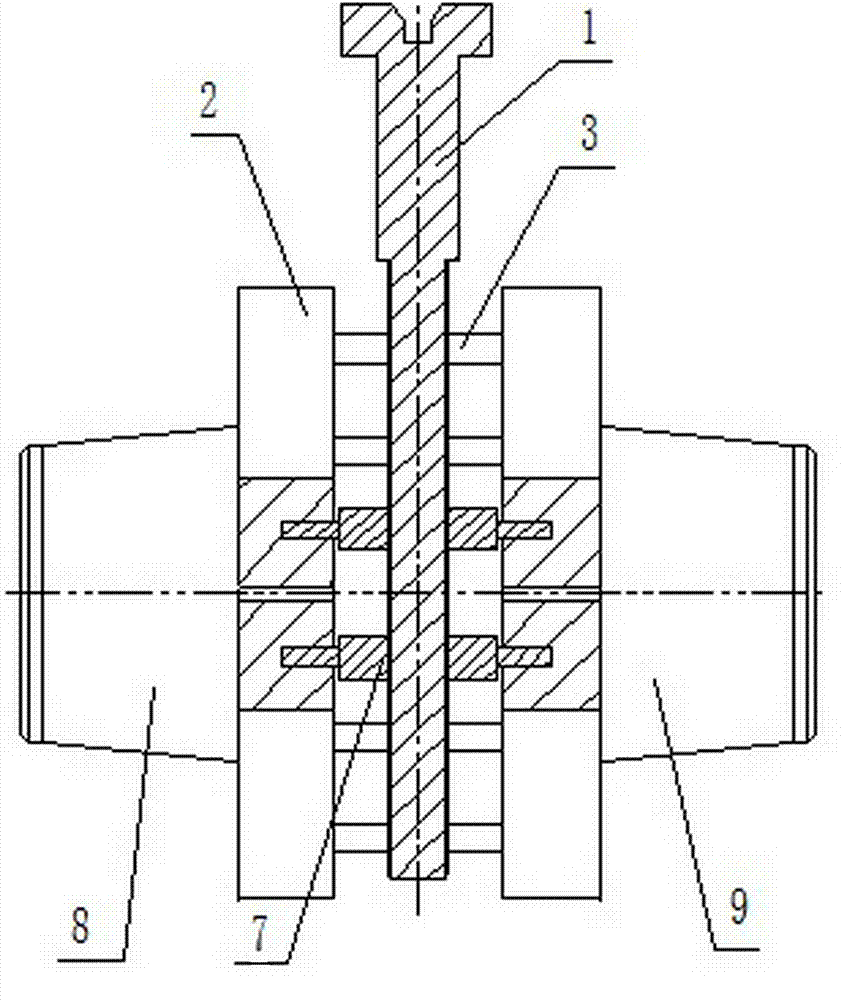

[0013] A clamp type marine underwater pipeline connector, such as figure 1 , figure 2 , image 3 As shown, it includes the left and right flanges 8, 9 welded on the ends of the connected pipes and the flange locking mechanism, and the opposite end faces of the left and right flanges 8, 9 are coaxially provided with secondary seals from the outside to the inside. The ring 11 and the annular grooves and ribs that are interference-sealed with each other. The three outer peripheral surfaces of the annular ribs are all conical surfaces, and the three contact surfaces of the corresponding annular grooves are also conical surfaces. Said annular grooves and ribs can be arranged in multiple shapes such as partial trapezoid, trapezoid, rectangle, etc. as required. The auxiliary sealing ring 11 is set as two, three or other multiple seals as required.

[0014] The inner walls of the end pipes of the left and right flanges are all conical surfaces, and an annular concave step is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com