Patents

Literature

180 results about "Plate waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

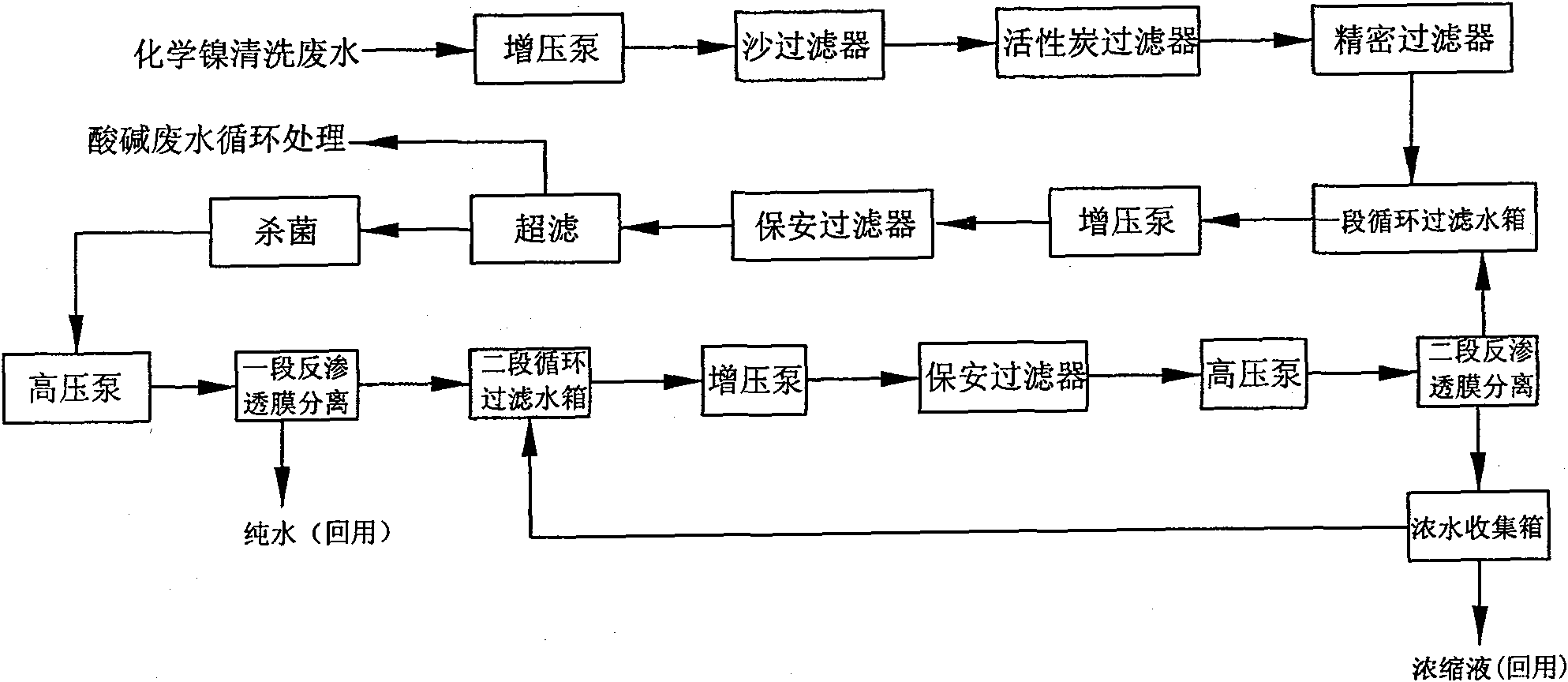

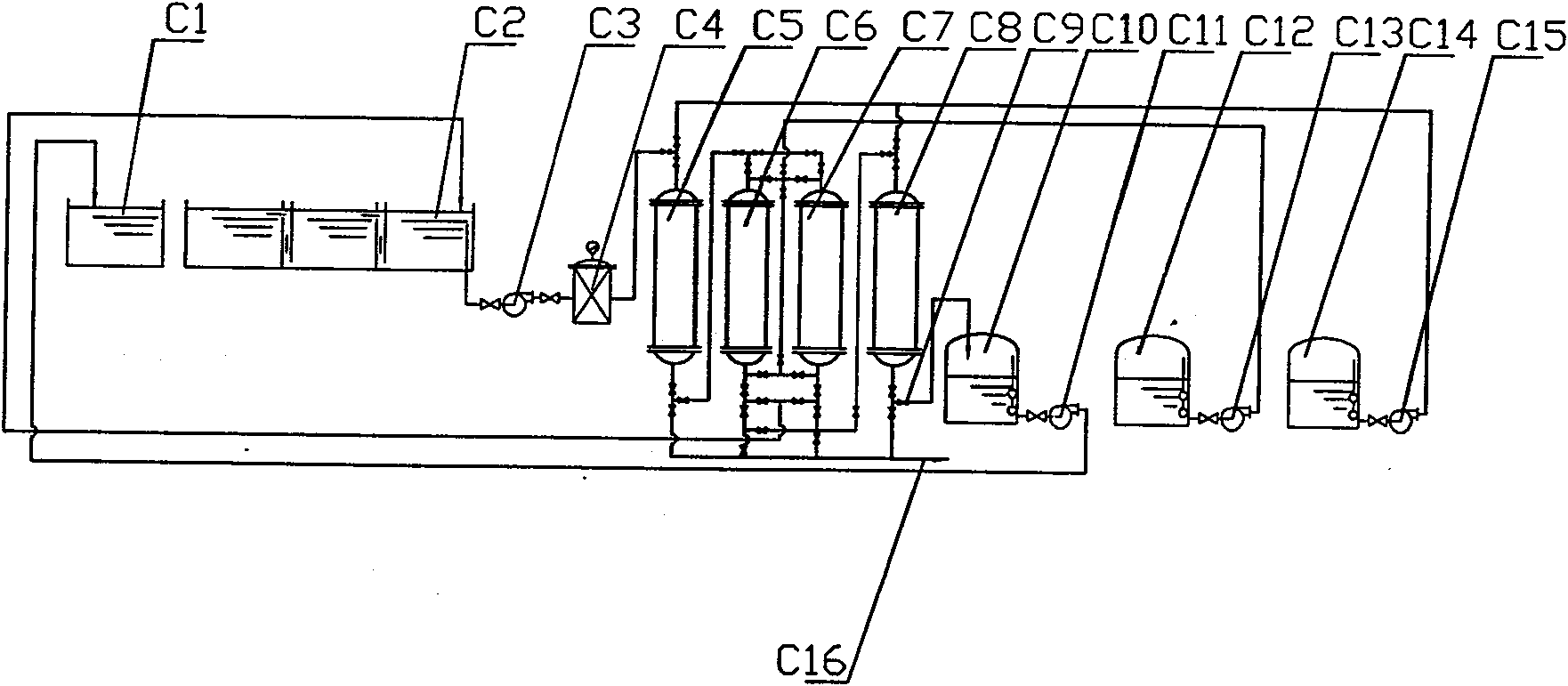

Method for classifying, treating and recycling plating washing water on line

ActiveCN101891323AAvoid cross contaminationStrong targetingWater contaminantsWater/sewage treatment by ion-exchangeCopper platingWater cycling

The invention discloses a method for classifying, treating and recycling plating washing water on line, which comprises the following steps of: removing oil, coarsening, reducing, activating, peptizing, chemically plating nickel, preplating nickel, plating copper, plating nickel and plating chromium in a plating process; and treating water and washing water during production and cleaning. The method specifically comprises the following steps of: preparing pure plating water, circularly processing acid and alkaline waste water, coarsening, circularly treating chromium-plating washing water, circularly treating chemically nickel-plating washing water, circularly treating copper-plating washing water and circularly treating nickel-plating washing water. Waste water in each procedure is directly used beside a tank edge in a closed cycle by an economical and effective means after being treated, no wastewater is discharged, and the cross contamination of different water qualities among the procedures is avoided. The method is a technological innovation for realizing zero emission of plating waste water and plating cleaner production.

Owner:NANJING YUANQUAN TECH CO LTD

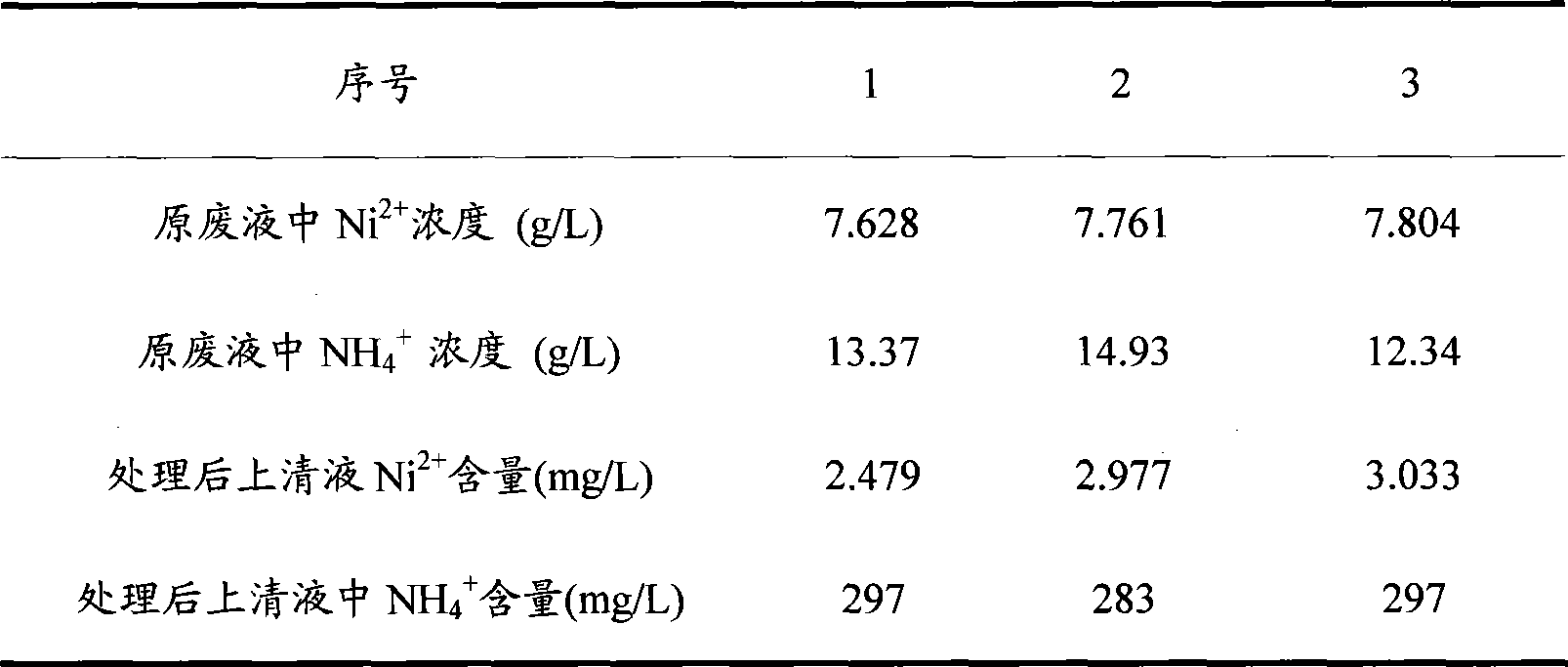

Processing method of chemical nickel phosphor plating

InactiveCN101434441AShort processEasy to handleWaste water treatment from metallurgical processWater/sewage treatmentLiquid wasteChemical plating

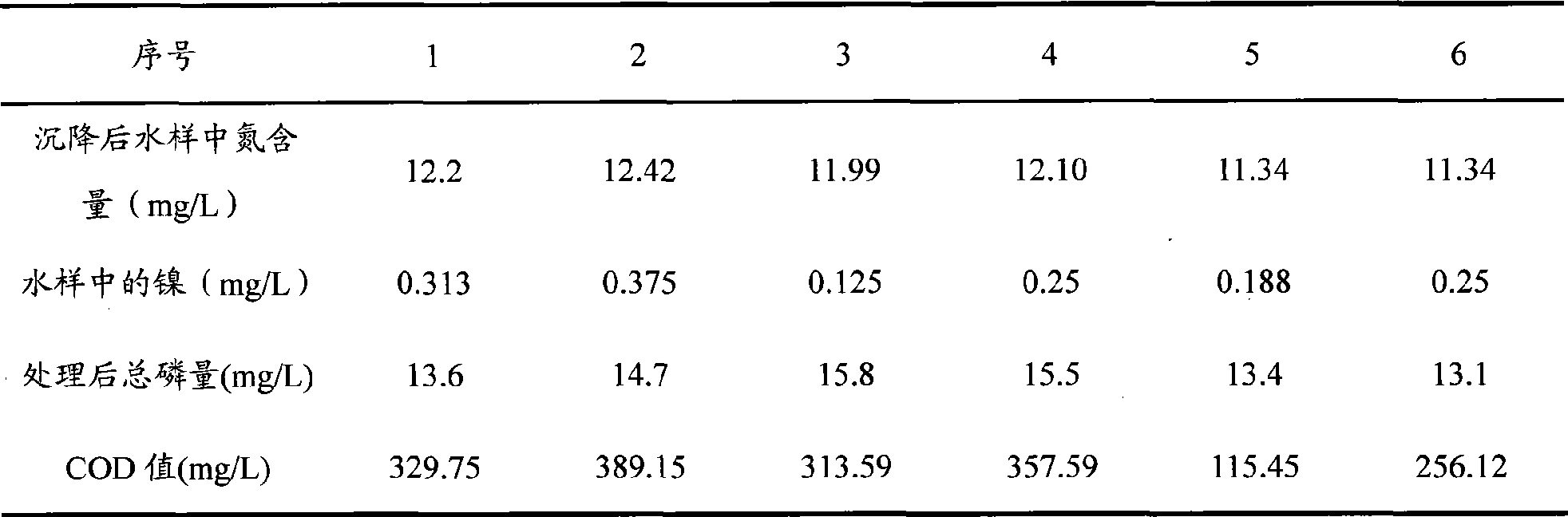

The invention discloses a treatment method of chemical nickel phosphor plating waste liquid, and relates to the comprehensive recovery and utilization field of chemical plating waste liquid. Under the condition of not adding any catalysts such as Pt salt and the like, and without external heating, the method utilizes sodium hydroxide dissolution, heat produced in the process of neutralization reaction and local high temperatures between liquid-solid interfaces, high pH value, and NaOH, and is induced by crystal nucleus provided by Ni2, therefore, the waste liquid is impelled to carry out self decomposition, and Ni-P alloy solid particles are generated. Under the action of the self decomposition of the Ni-P alloy solid particles, the waster liquid is decomposed quickly and completely, nickel is transformed into Ni-P alloy and then settled and separated out. More than 96 percent of nitrogen is transformed into ammonia, and phosphor, residual nitrogen, and majorities of organic acid are transformed into magnesium salt and calcium salt compound fertilizer. After the recycled nickel and phosphor resources are subjected to comprehensive recovery treatment, the nickel and the nitrogen contained in the waste liquid reach the national first-level discharge standard, and the phosphor and COD reach the national third-level discharge standard.

Owner:SHANDONG JIANZHU UNIV

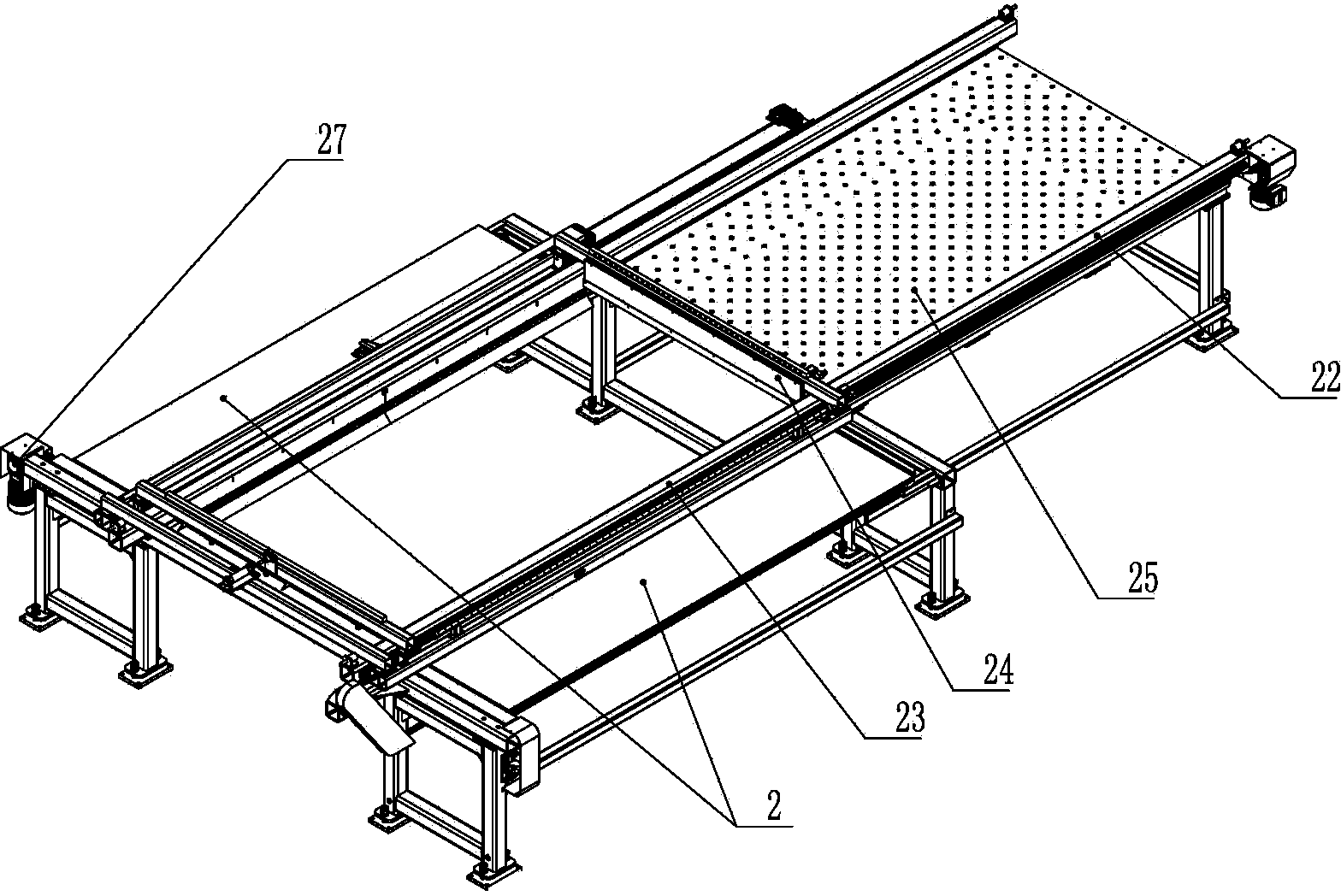

Laser cutting plate waste material separation part sorting system

ActiveCN103962736AEasy to separateReliable separationMagnetic separationMetal working apparatusLaser cuttingManipulator

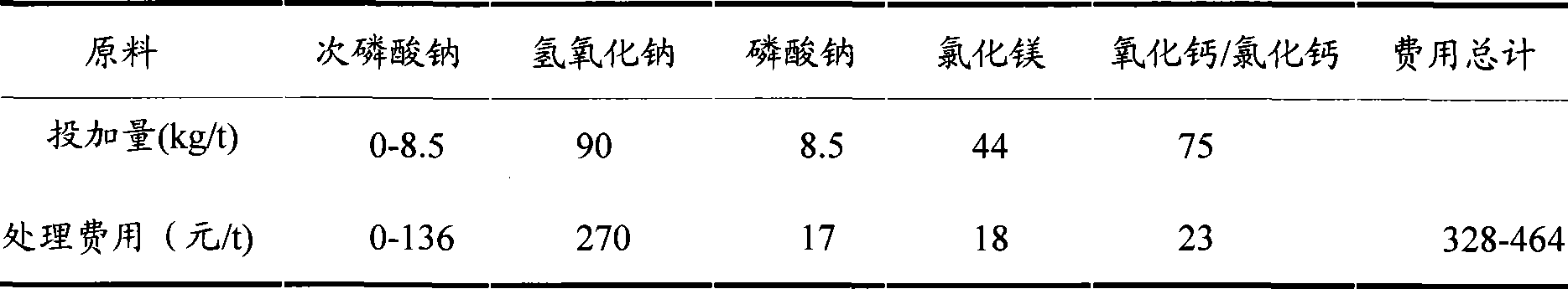

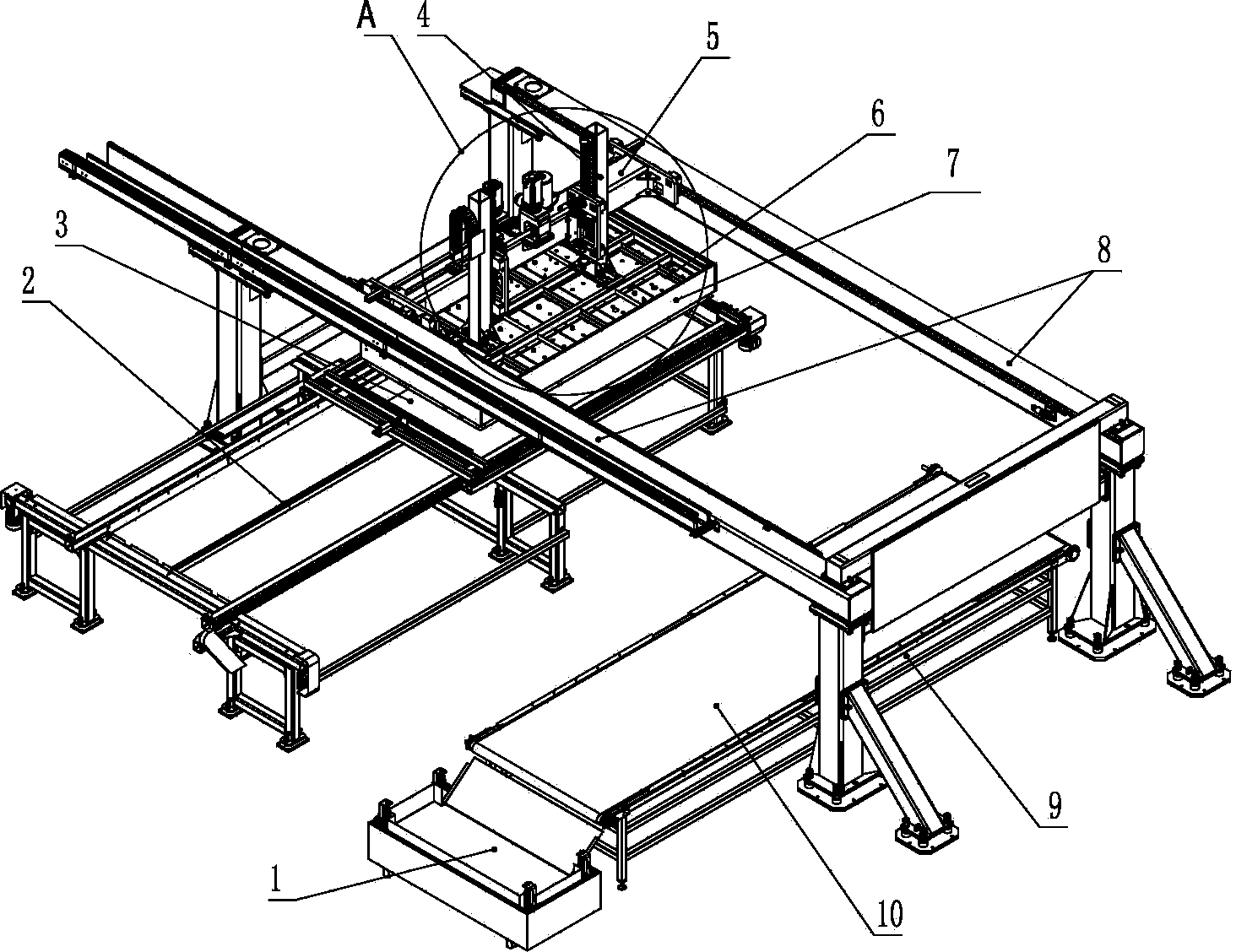

The invention discloses a laser cutting plate waste material separation part sorting system in the field of laser cutting machines. The laser cutting plate waste material separation part sorting system comprises two parallelly arranged supporting beams. A beam capable of moving horizontally is movably connected between the two supporting beams. The beam is connected with a lifting column through a lifting transmission mechanism, the lower portion of the lifting column is connected with a blanking mechanical hand, a waste material separation table and a sorting working table are arranged below the supporting beams and correspond to the blanking mechanical hand, the blanking mechanical hand comprises a rectangular frame, a support is arranged in the frame, a mounting plate is arranged below the support, a plurality of liftable electric permanent magnets with suction surfaces downward are installed on the lower side of the mounting plate through an elastic mechanism, the waste material separation table is provided with a plurality of fixed electric permanent magnets with suction surfaces upward, and every liftable electric permanent magnet and every fixed electric permanent magnet can supply power independently. Parts and waste materials are separated more reliably, the parts are sorted conveniently, and the laser cutting plate waste material separation part sorting system is high in efficiency and suitable for laser cutting automation of carbon steel plates.

Owner:JIANGSU JINFANGYUAN CNC MACHINE CO LTD

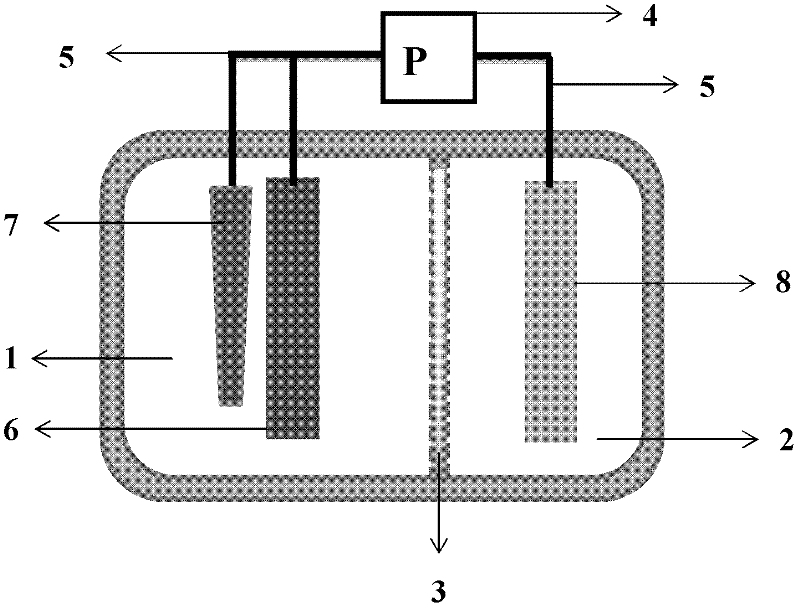

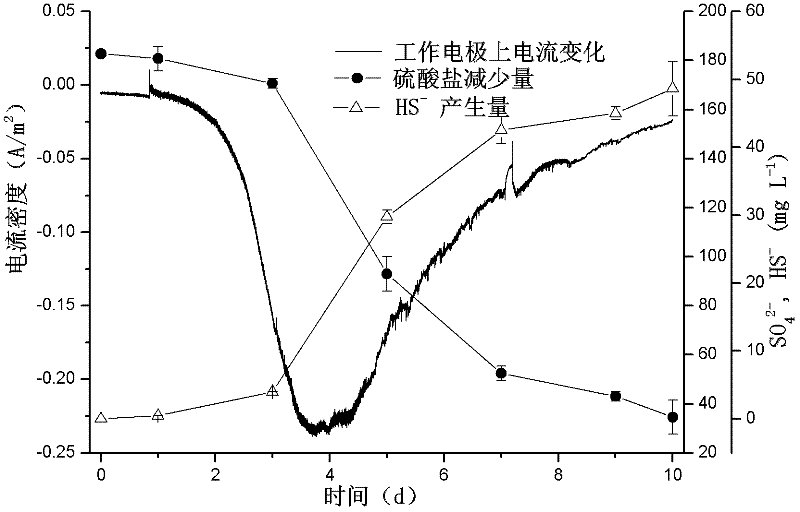

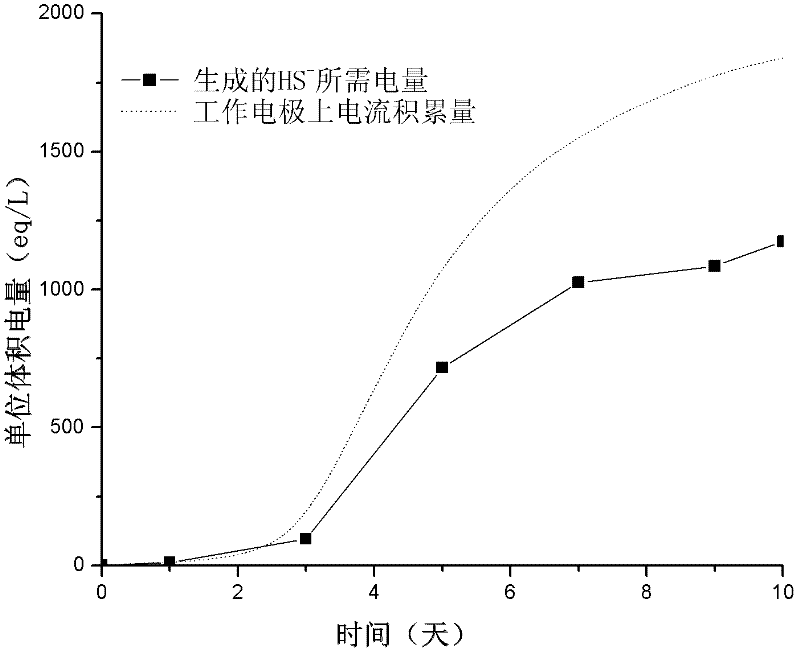

Method for treatment of metal waste water by sulfate reducing bacteria growing up with electric current

InactiveCN102642930AAvoid secondary pollutionEasy to operateWaste water treatment from quariesWater contaminantsSulfate-reducing bacteriaPollution

The invention belongs to the technical field of treatment of waste water, and particularly relates to a method for reduction of sulfate into sulfide and treatment of metal waste water by sulfate reducing bacteria growing up with electric current. The sulfate reducing bacteria provided by the invention is a mixing bacteria group, which comprises Desulfobulbus propinonicus, geobacter sulfurreducens. Under the condition of lacking organic carbon resource, an electrode is used as the only electronic donator for growing, sulfate is reduced into sulfide via bioelectrical chemistry, and the sulfide is applied to the treatment of metal waste water. According to the method provided by the invention, the defect that organic carbon resource is needed to be used as the electronic donator is overcome,the operation is simple, the secondary pollution is zero, the cost is low, and is particularly suitable for the treatment on organic carbon metal waste water of mine waste water, metal smelting wastewater, electric plating waste water and the like.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

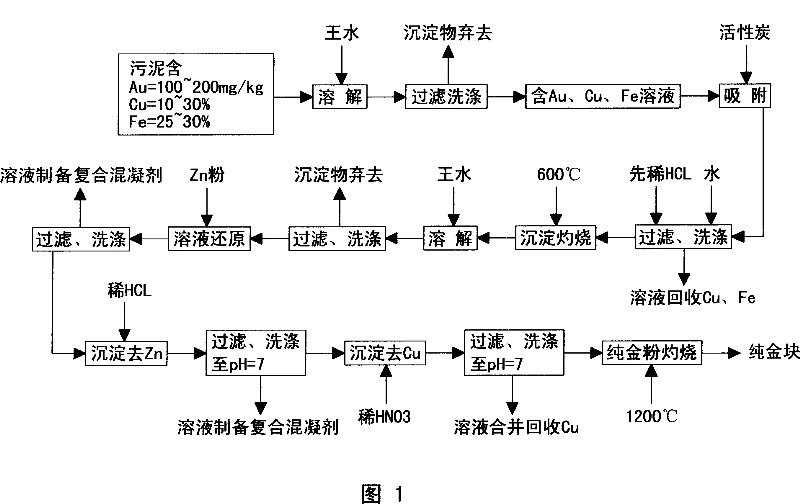

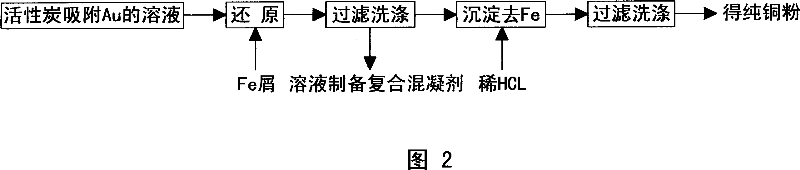

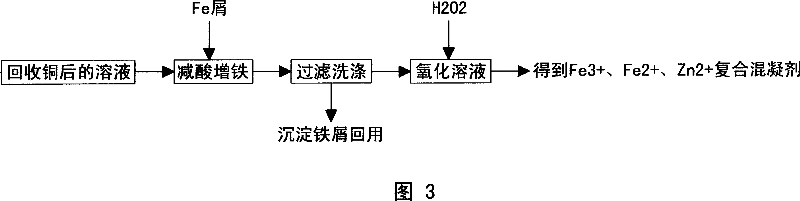

Integrative recovering and reusing of heavy metals in wire board plating wastewater treatment sludge

InactiveCN101037285AAchieve sustainable developmentHighlight substantive featuresSludge treatmentWater contaminantsSludgeCopper

The invention relates to a method of recovering gold and copper heavy metal from the sludge generated from plating waste water by dealing with circuit board and of producing waste water treating-agent. The method is provided with steps of: absorbing the gold in solution by active carbon; deoxidizing gold by zineum; substituting the scrap iron by the copper in filtrate; further treating the residual irons solution to get a good waste water treating-agent. The pureness of the achieved gold and copper is above 98%. The waste water treating-agent is used for treating printing and dyeing waste water and has an obvious decolorizing effects and a high COD removal rate. The invention invests few, takes effects quickly, wins more, handles simply, is with a percent products recovery and a good quality.

Owner:苏州市环境工程有限责任公司

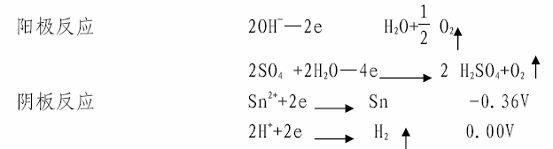

Method for recycling tin

InactiveCN102002594ASimple processLess investmentPhotography auxillary processesProcess efficiency improvementTinningElectrolysis

The invention relates to a method for recycling tin. Used tin recycling solution consists of 10 to 60 g / L of Cu<2+> and 40 to 100 g / L of H2SO4 serving as solutes and distilled water serving as a solvent. The method comprises the following steps of: soaking a waste tin-plated copper material into a replacement tank which is filled with tin recycling solution for 5 to 30 minutes for removing tin and keeping the working temperature of the tin recycling solution between 50 and 90 DEG C; taking the copper material from which tin is removed out and standing; and putting the tin-containing tin recycling solution into an electrolytic tank for electrolyzing so as to obtain electrolytic tin. The method for recycling the tin has a simple process, a small amount of equipment, small investment, good labor condition, low energy consumption, low cost and high metal recycling rate and is suitable for recycling tin in waste tin-plated copper materials and waste tin-plated copper wires in the electronic industry; the investment on tin-plated waste material equipment with the annual throughput of 5,000 tons is only about more than 0.3 million; and the recycling rates of copper and tin are 99.9 percent and 96 percent respectively.

Owner:赖小洪

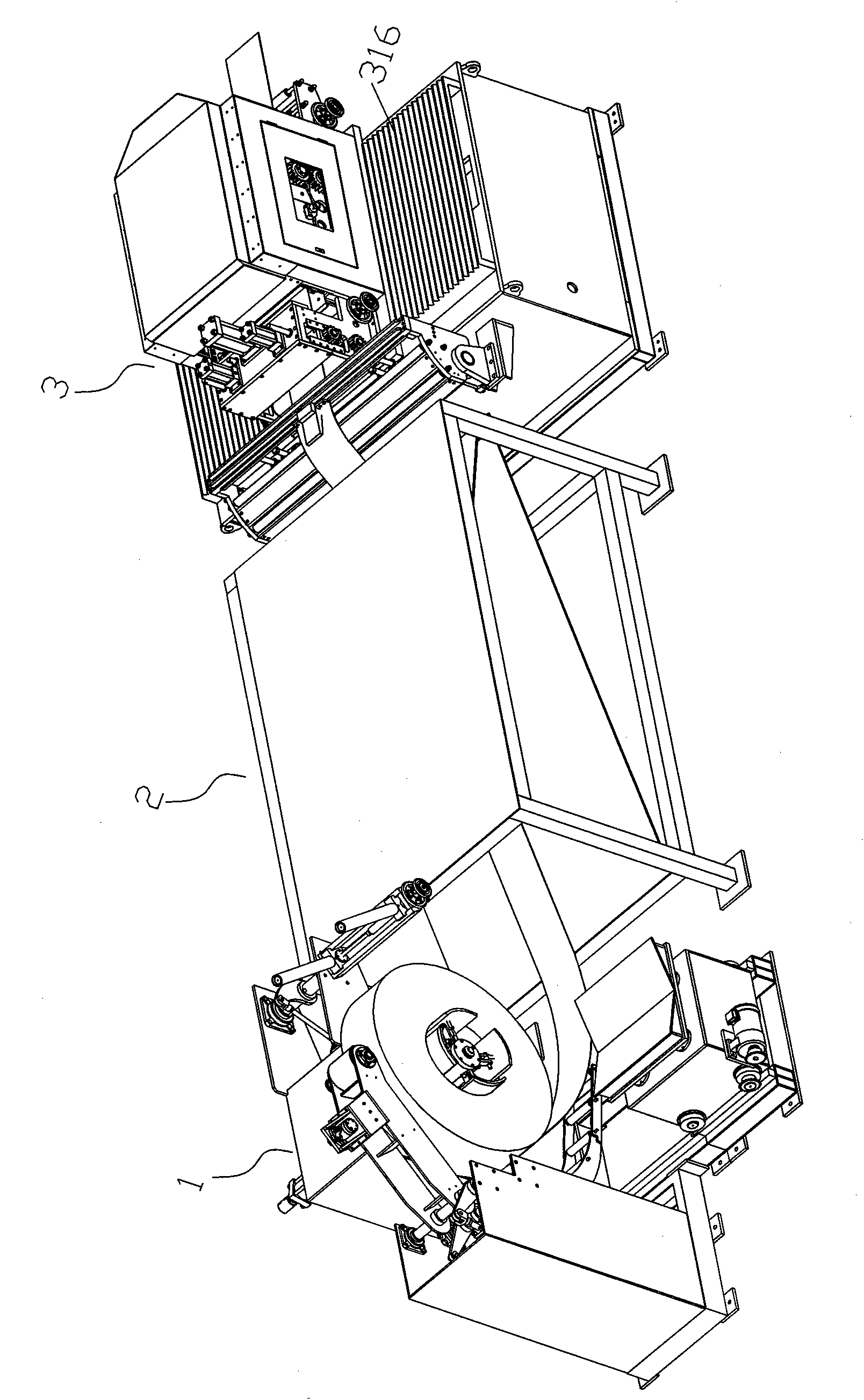

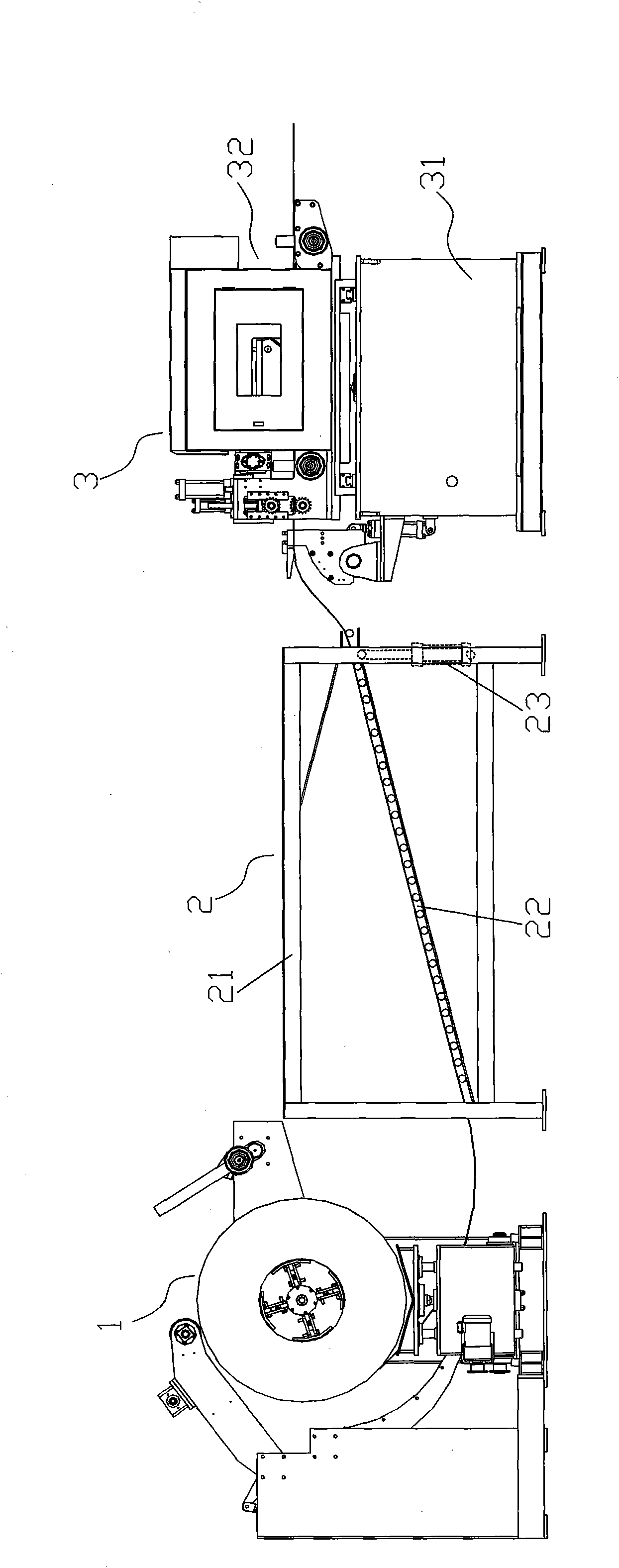

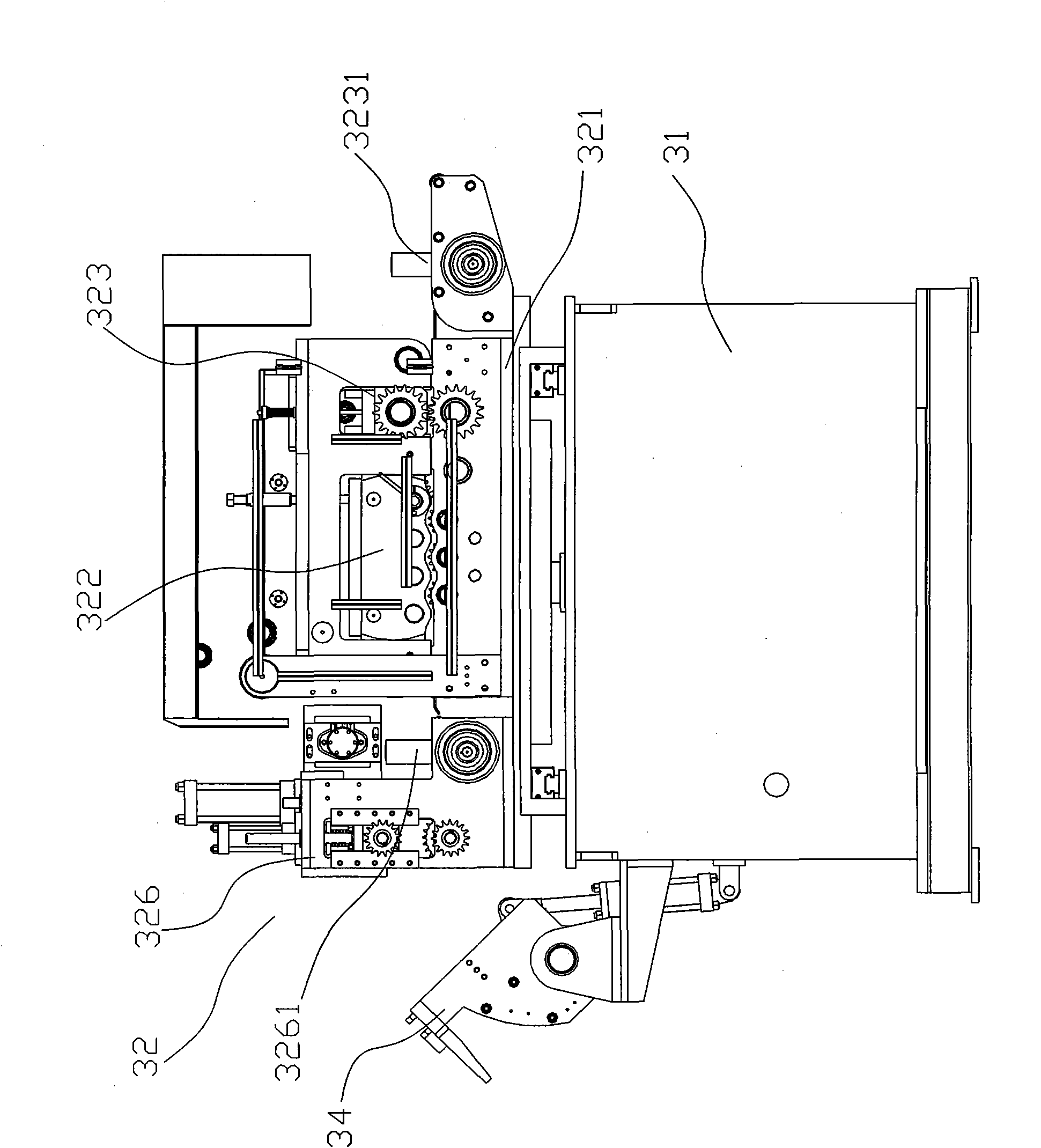

Deflection type servo feeding line

ActiveCN102069131AReduce wastePrevent springbackMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention relates to the technical field of peripheral equipment of a punch, in particular to a deflection type servo feeding line, which comprises an uncoiler, a transitional rack and a deflection type feeding host machine, wherein the deflection type feeding host machine comprises a main frame and an integral leveling and sizing host machine arranged on the main frame. A clamping feeding unit, a leveling unit and a sizing unit in the deflection type feeding host machine of the whole servo feeding line are integrated so as to reduce the occupied space, and the leveling and sizing operations of a plate are closely approached so as to improve the sizing accuracy and the acceptability of punched products. More significantly, the integral leveling and sizing host machine is integrally arranged on the deflectable deflection main frame, and the integral leveling and sizing host machine can be accurately controlled to deflect along the width direction of the plate according to the need so as to make the plate move in the width direction for a punch to stamp in the corresponding width direction, so the production efficiency is improved, the plate can be fully utilized, and plate waste is minimized.

Owner:东莞市金峥机械有限公司

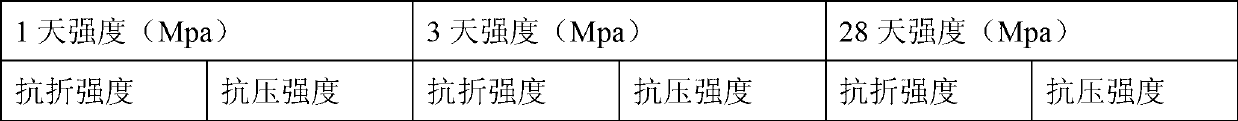

Cement clinker production method by utilization of artificial slabstone waste

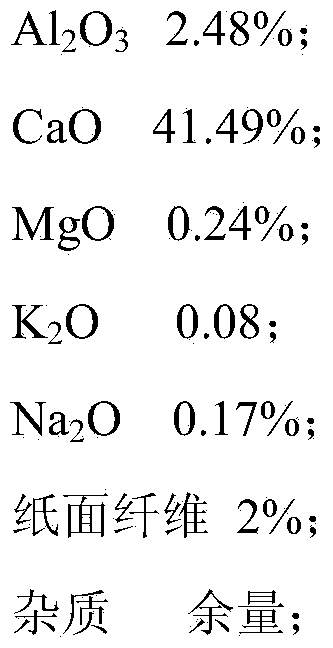

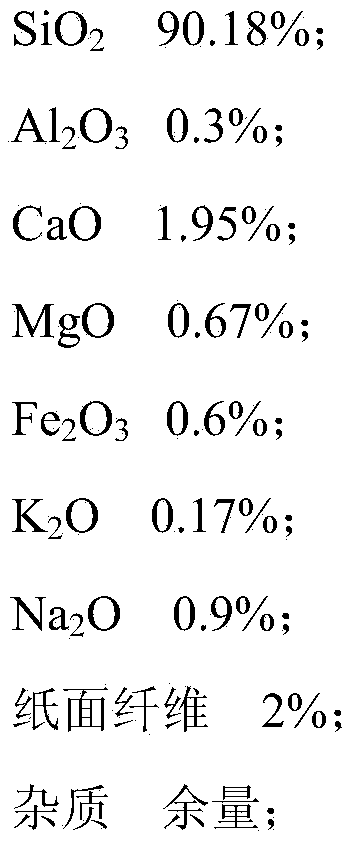

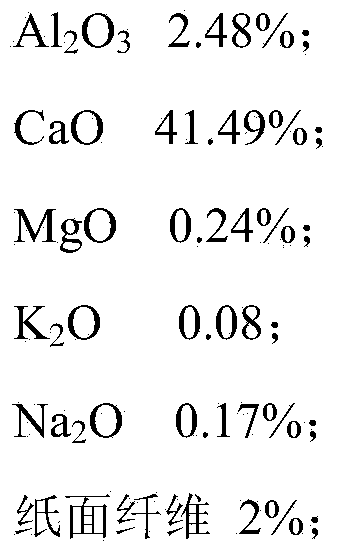

InactiveCN103130430AAchieve the purpose of usingWon't happenClinker productionCinker content reductionSlagMixed materials

The invention relates to a cement clinker production method by utilization of artificial slabstone waste. The artificial slabstone waste is used as raw materials, cement is fired through a drying method preheater, the artificial slabstone waste can be thoroughly processed, part of natural raw materials can be replaced, and energy-saving and emission-reducing purposes are achieved. The method includes the following steps: mixing artificial stone calcium aluminum plate waste, artificial quartz stone waste and steel slag according to a mixing ratio, drying, grinding, screening, and evenly mixing the mixed materials to obtain cement raw materials, and calcining the cement raw materials to obtain cement clinker by adopting a calcining process of an existing novel drying method kiln which is provided with a precalcining kiln. Cooled cement clinker is grinded through a mill, and the cement clinker meeting production requirements is obtained.

Owner:SHANDONG JIANZHU UNIV

Method for producing autoclaved bricks from artificial stone plate wastes

Owner:SHANDONG JIANZHU UNIV

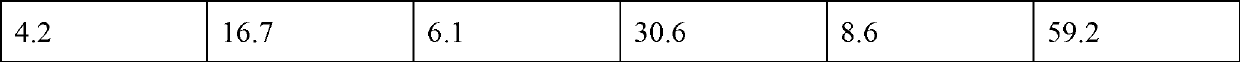

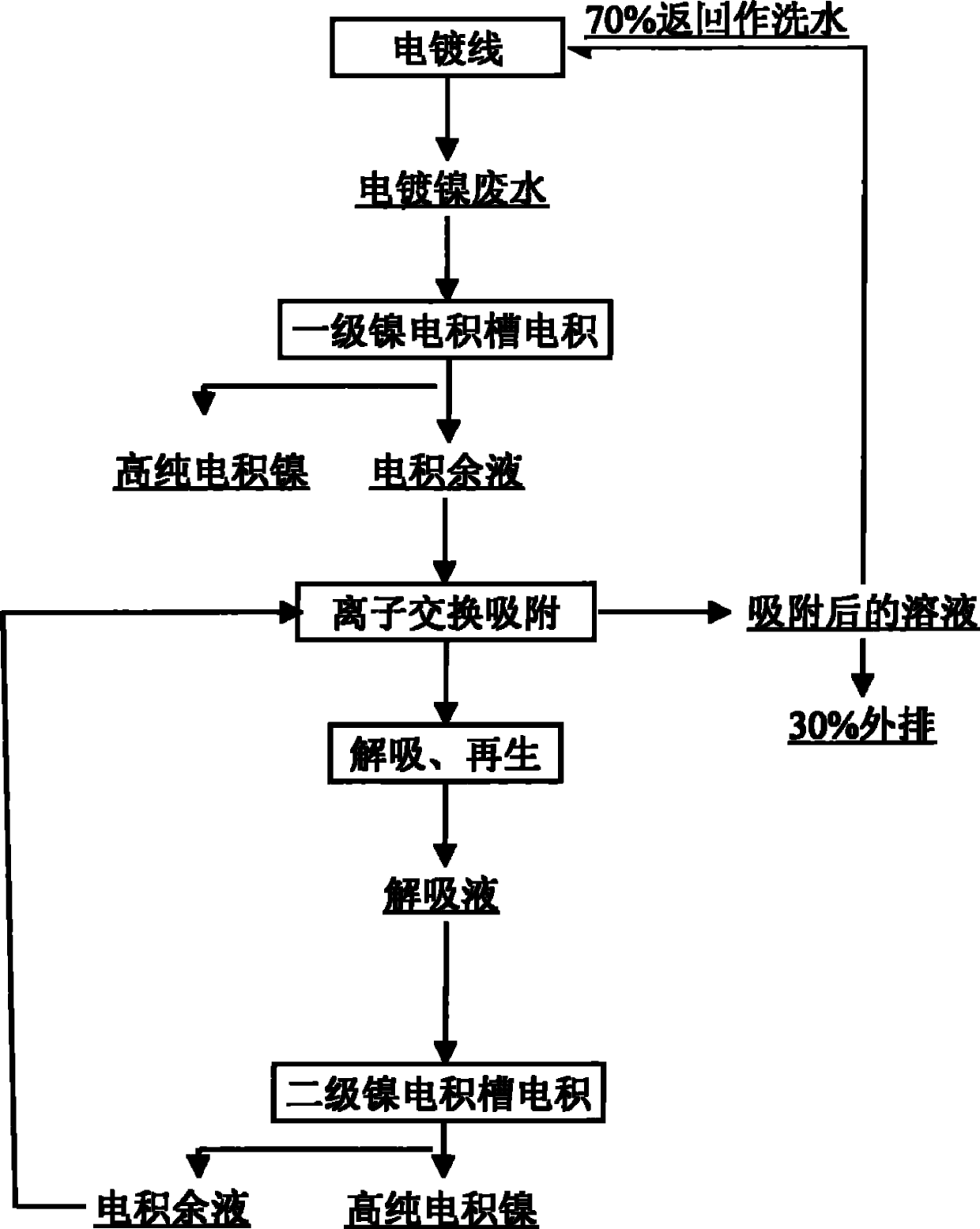

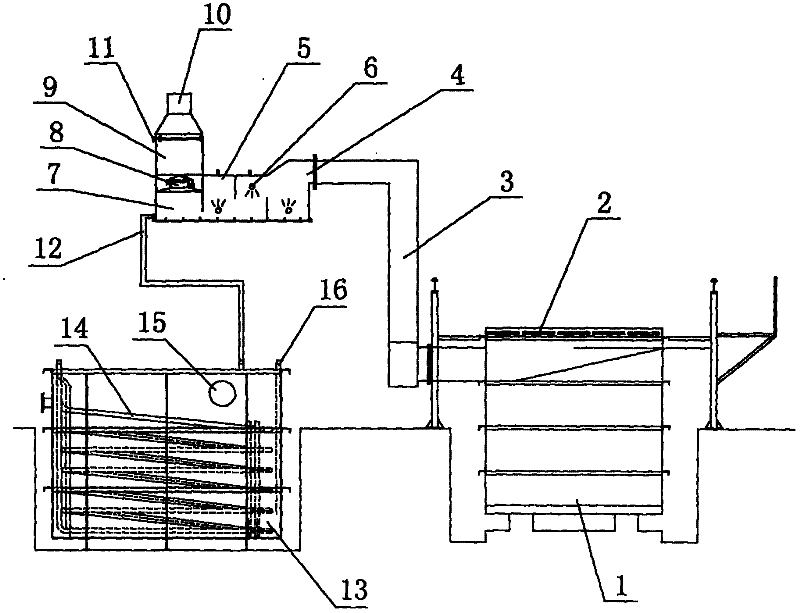

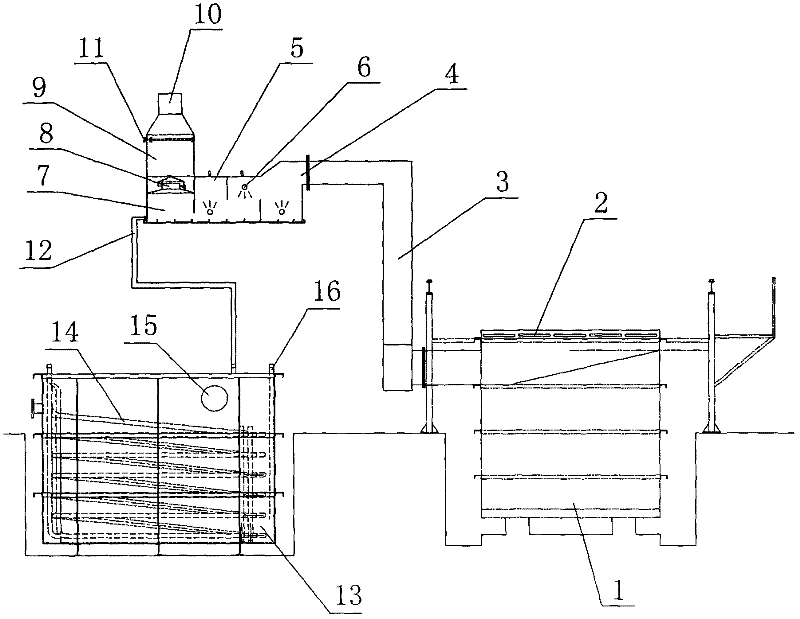

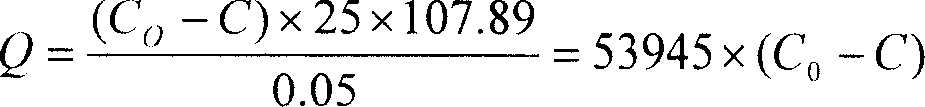

Recycling process of nickel in plating waste water

ActiveCN102583842AGuaranteed nickel contentLow nickel contentCellsPhotography auxillary processesLiquid wasteElectricity

The invention discloses a resource treatment process for nickel-contained plating waste water, which belongs to the waste water treatment of a plating industry. The recycling process is divided into three steps: electro-deposition, adsorption and secondary electro-deposition, wherein the plating waste liquid is conveyed to an electro-deposition trough to be electro-deposited after the pH value is adjusted to a given number, after nickel content in the solution is reduced to a designated value, the solution is conveyed to an adsorption column to be adsorbed, the nickel content of the plating waste water after being treated is less than 1ppm, and partial waste water is returned to a plating procedure to use. The nickel in the plating waste liquid is recycled in a metal state. After the adsorption column is saturated, backwashing and reproduction are carried out, and secondary electro-deposition is undertaken on the backwashed solution to obtain the metal nickel.

Owner:HUNAN VARY TECH

Method for recycling chemical copper plating waste liquid

ActiveCN108249649AHigh purityEnable recyclingWater treatment parameter controlWater/sewage treatment by irradiationSolubilityLiquid waste

The invention discloses a method for recycling a chemical copper plating waste liquid. The method comprises the following steps: (1) collecting the chemical copper plating waste liquid, and adjustingthe pH value of the waste liquid to 9.5-11; (2) performing oxidation complex-breaking treatment on the treated chemical copper plating waste liquid obtained in step (1), performing an oxidation complex-breaking reaction to change dissolved complexed copper into a copper-containing deposit, and keeping the pH value of the waste liquid in the oxidation complex-breaking reaction not less than 9; (3)performing solid-liquid separation to obtain the copper-containing deposit and a filtrate; and (4) adding isopyknic clear water to the copper-containing deposit, uniformly dispersing the deposit, adding an enriching agent, performing a reaction to obtain a copper-rich deposit, separating the copper-rich deposit and the clear water, and drying the copper-rich deposit. The highly pure copper depositis obtained through a simple enriching and purifying technology while performing the oxidation complex-breaking treatment on the dissolved complexed copper in the chemical copper plating waste liquid, so the method realizes recycling of precious metal copper and has significant environmental and economic benefits.

Owner:NANJING YUANQUAN TECH CO LTD

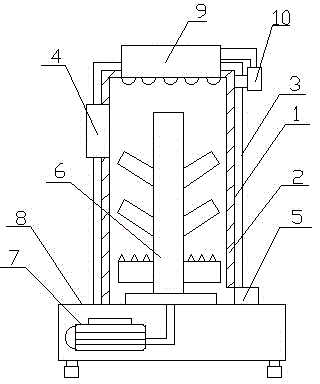

Plating waste gas treatment device

ActiveCN102330141AClosed loopSave raw materialsCellsUsing liquid separation agentTemperature controlEvaporation

The invention discloses a plating waste gas treatment device used for evaporation concentration of a solid-containing aqueous solution in the industries of plating, chemistry, chemical engineering and the like. The device comprises an air suction cover arranged on a plating tank, wherein the air suction cover is communicated with a spray compartment through an air suction pipe; the spray compartment is communicated with a gas-liquid separation tower, and a plurality of spray heads are arranged in the spray compartment; the bottom of the gas-liquid separation tower is provided with a reclaiming liquid collecting compartment communicated with the spray compartment; a collision cap is arranged above the reclaiming liquid collecting compartment; a filler layer is arranged above the collision cap; the upper part of the filler layer is connected with an air outlet pipe; the air outlet pipe is connected with a fan, and the bottom of the reclaiming liquid collecting compartment is connected with a reflux pipe; the reflux pipe is communicated with a temperature controlled evaporation tank; and the spray heads are communicated with a temperature controlled evaporation device through circulating cooling pumps. The plating waste gas treatment device has the advantages of small volume, convenience for maintenance, remarkable energy conservation, controllable concentration and long service life.

Owner:无锡出新环保设备有限公司

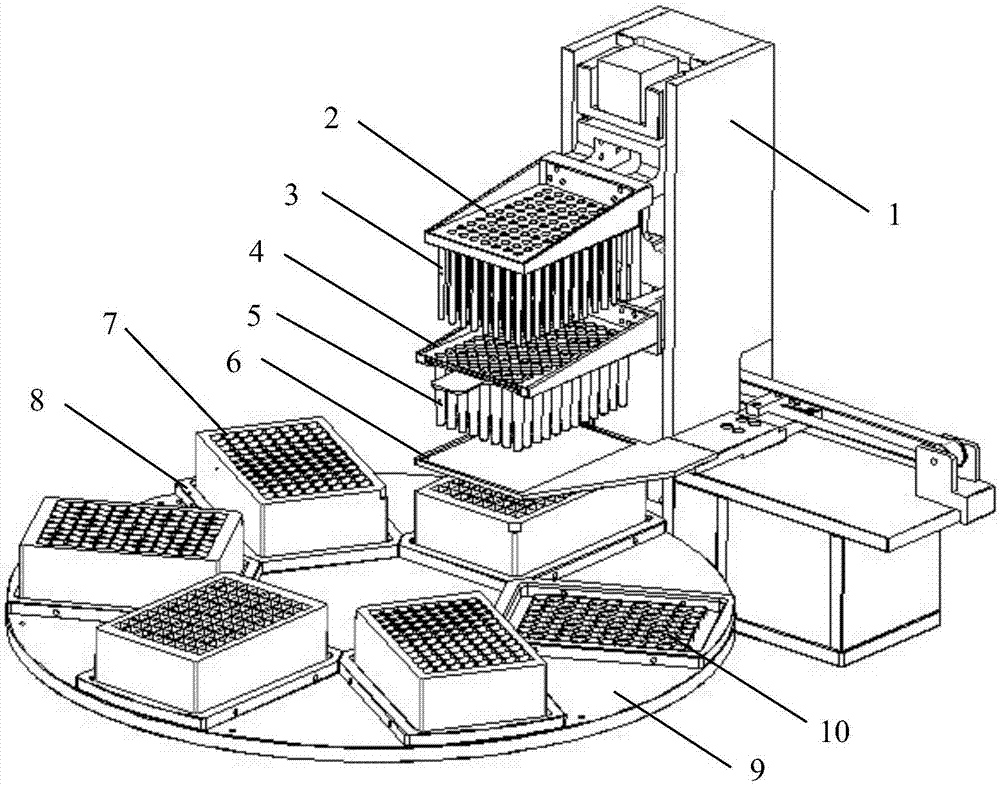

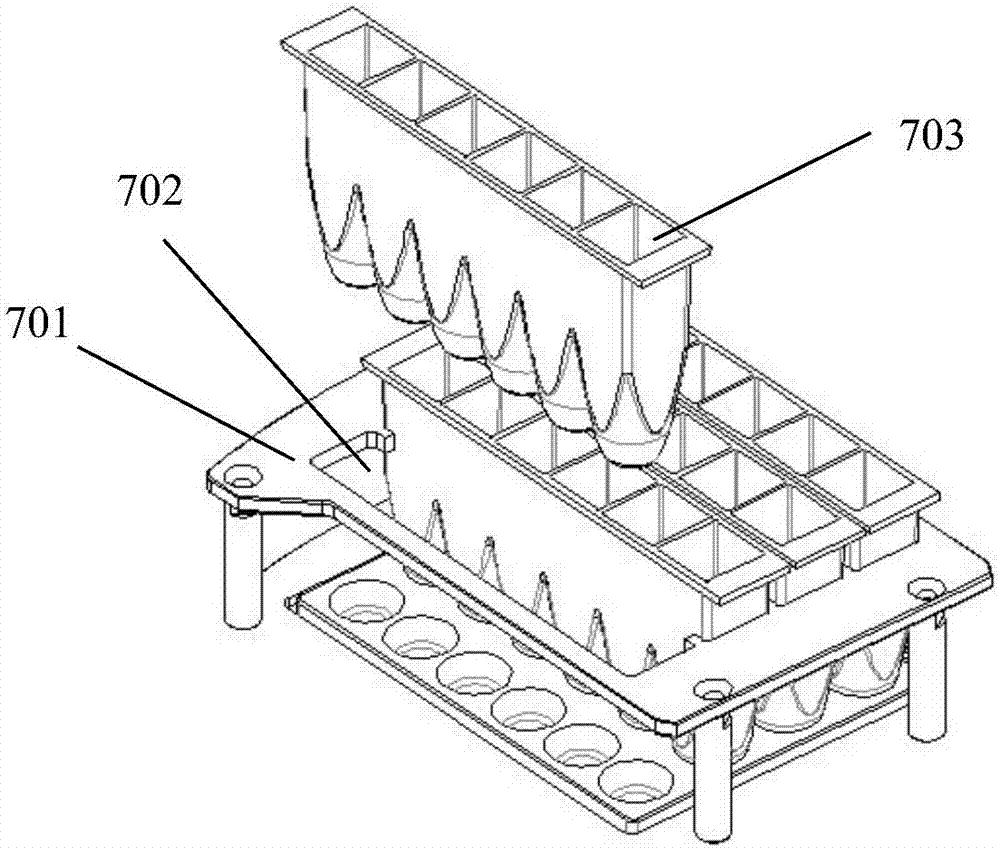

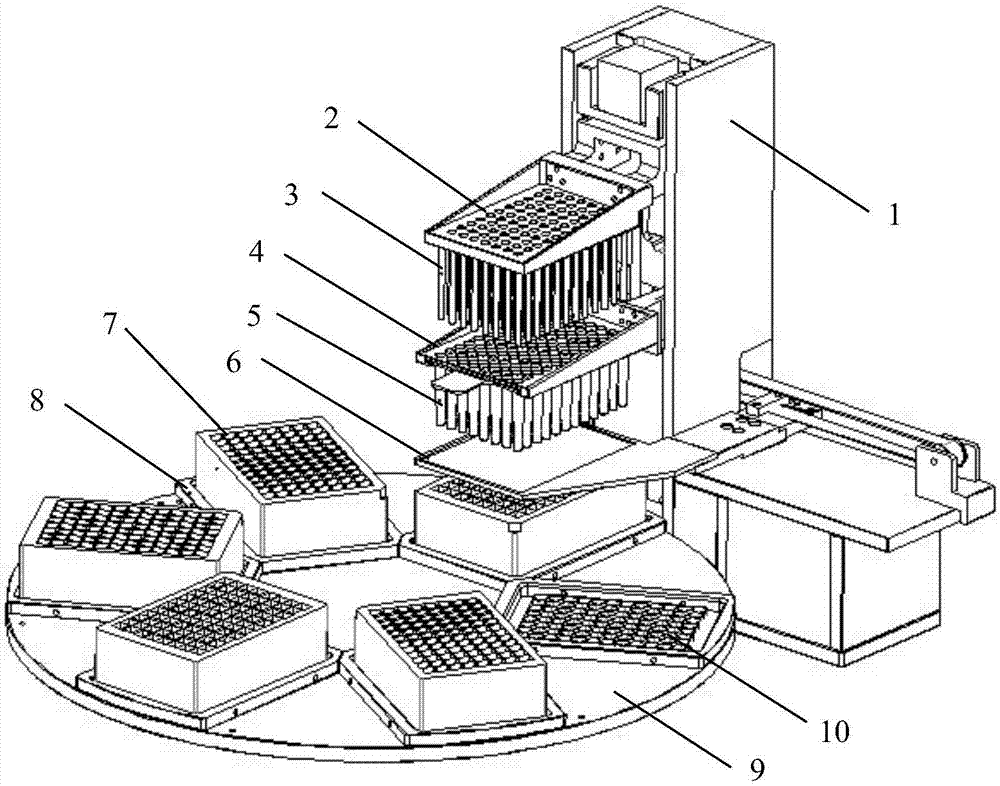

Nucleic acid isolation machine

PendingCN107974394AMove up and down steadilyNo shakingBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringDeep hole

The invention provides a nucleic acid isolation machine which comprises a machine body, a magnetic rack, a magnetic rod, a magnetic rod sleeve rack, a magnetic sleeve, a droplet baffle plate, a deep hole plate, a positioning base, a rotating disc and a control panel, wherein a guide track is arranged in the vertical direction of the machine body; the guide track comprises a first guide track and asecond guide track; and the first guide track and the second guide track are arranged in parallel on the machine body. Speeds of oscillation, mixing and magnetic sucking are adjusted in a stepless manner through the control panel, the magnetic rack and the magnetic rod sleeve rack are of double modes, and the deep hole plate is a common deep hole plate. By adopting the nucleic acid isolation machine, the problems in the prior art that a nucleic acid isolation machine is frequent in calibration, single in working mode and great in deep hole plate waste, the position of the magnetic rod is deviated, and the speeds of oscillation, uniform mixing and magnetic sucking cannot be precisely controlled, are solved.

Owner:BIOTEKE CORP (WUXI) CO LTD

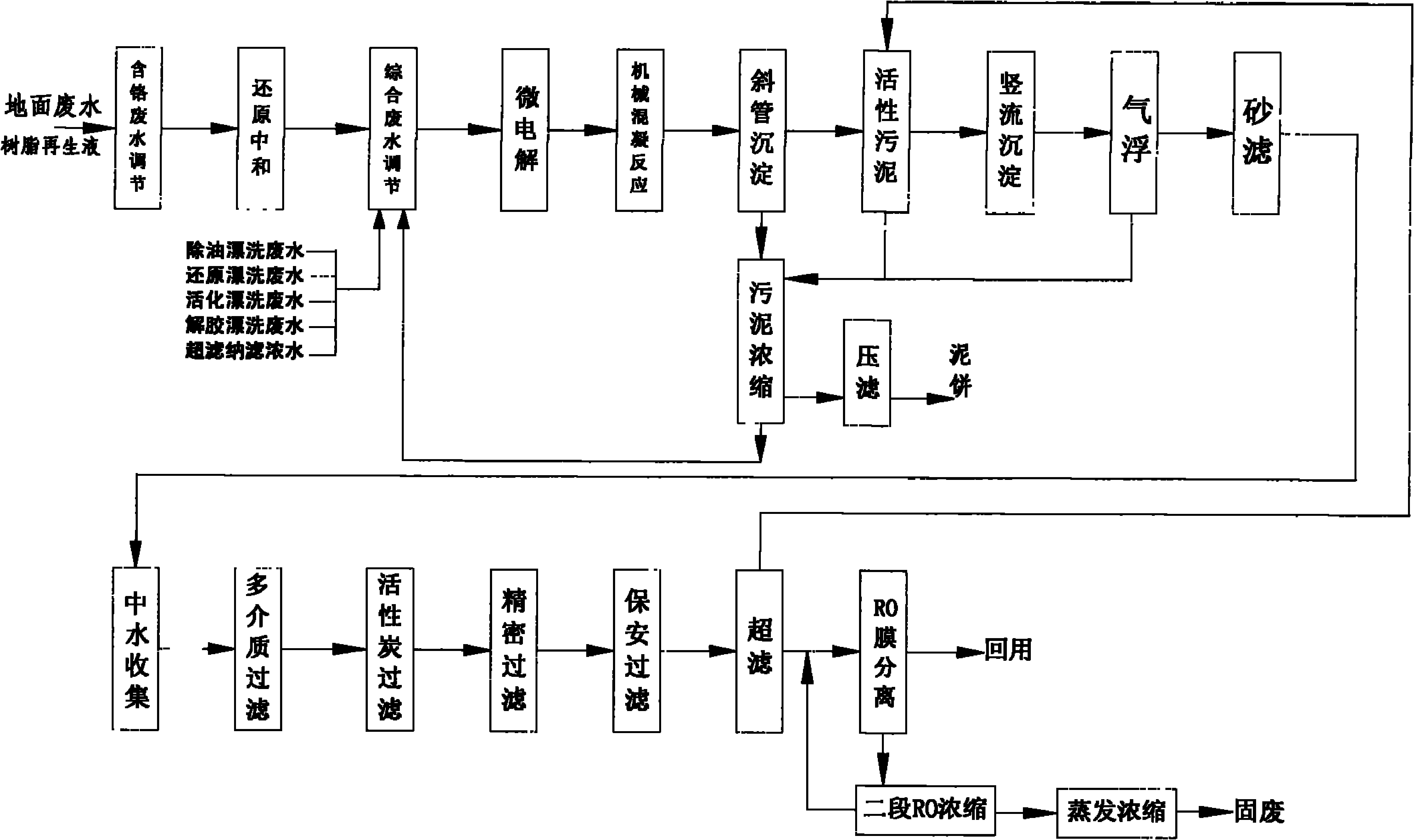

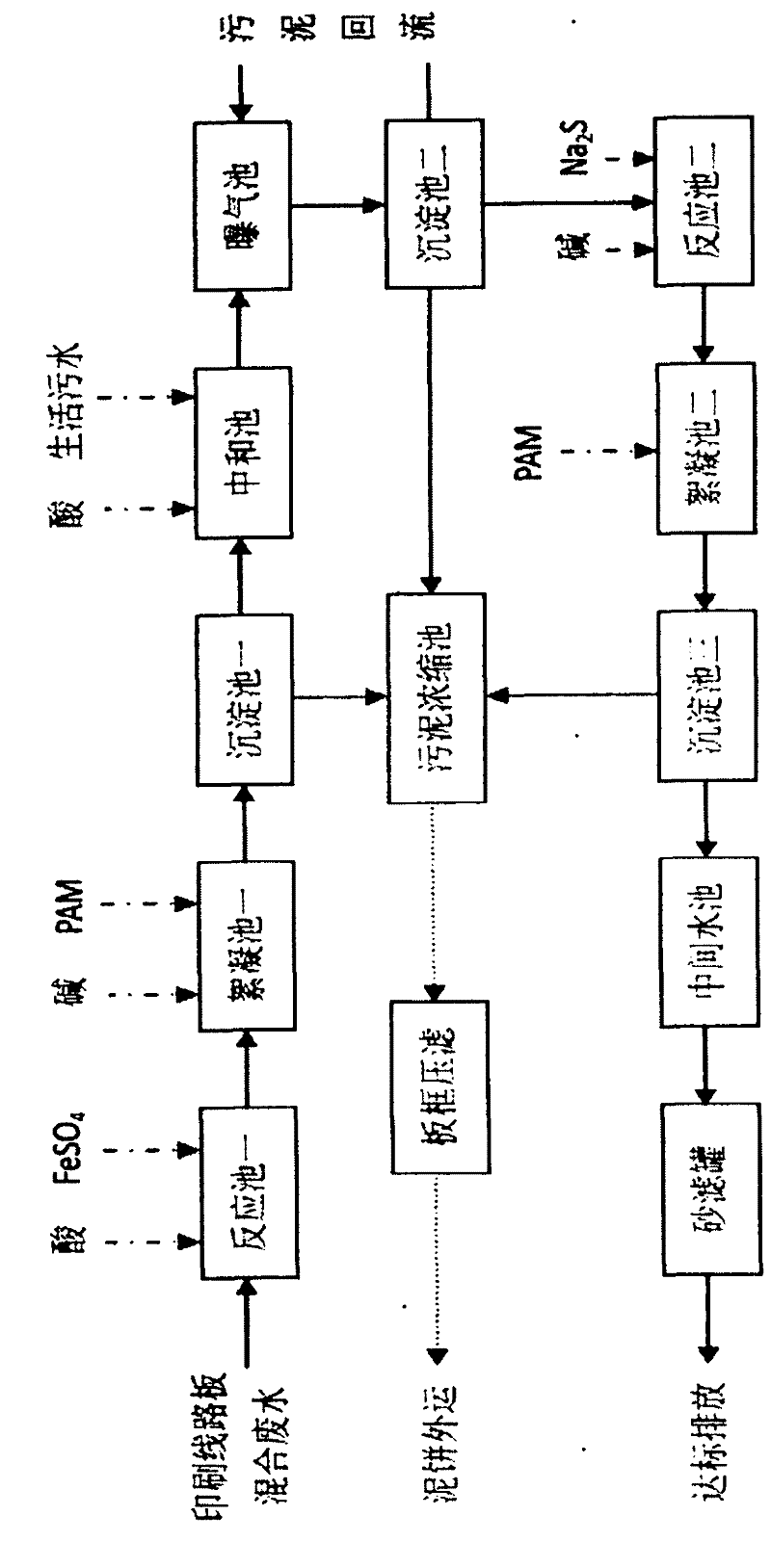

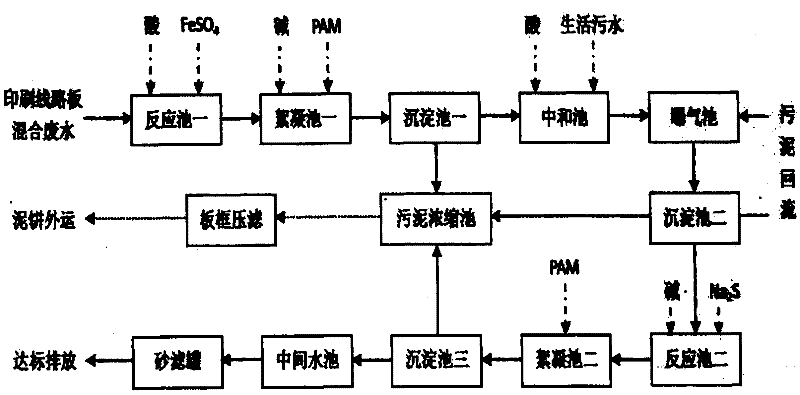

Three-stage biological comprehensive treatment method for printed circuit board waste water

ActiveCN102452764AImprove processing efficiencyLow costMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationPrinted circuit boardPlate waste

The present invention discloses a three-stage biological comprehensive treatment method for printed circuit board (PCB) waste water. The method comprises a three-stage biological treatment process, and is characterized in that: the method is performed by the following steps that: (1) PCB mixing waste water is poured into a reaction tank 1, the pH value is adjusted to 2.7-3.2 with sulfuric acid, ferrous sulfate is added, the waste water is transferred to a flocculation tank 1, the pH value is adjusted to more than 7 by an alkali solution, a flocculating agent is added to carry out precipitation, and the waste water and the resulting precipitation are transferred into a precipitation tank; (2) the waste water is poured into a neutralization tank, a nitrogen source is added, the pH value is adjusted to 6.8-7.2, the resulting waste water enters an aeration tank to carry out biodegradation, and flows through a precipitation tank 2; (3) the waste water is poured into a reaction tank 2, the pH value is adjusted to 8.8-9.2, the flocculating agent is added, the waste water is introduced to a precipitation tank 3, and then is discharged. With the present invention, the grinding plate waste water, the printing ink waste water, the copper-containing waste water and the electroplating waste water can be simultaneously treated, the treatment efficiency of the organic compound with high complex copper is high, and the cost is low.

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

Aluminum alloy ingot and production technology thereof

The invention provides an aluminum alloy ingot. The aluminum alloy ingot comprises an aluminum ingot and aluminum plate waste, wherein the mass ratio of the aluminum ingot to the aluminum plate wasteis 4:1-10:1. The invention further provides a production technology of the aluminum alloy ingot. The production technology comprises the following steps that (1) raw materials are smelted, wherein thealuminum ingot and the aluminum plate waste are placed into a smelting furnace for smelting; (2) primary refining and slagging-off are carried out in an upper furnace body; (3) the mixture is put into a lower furnace body for refining and slagging-off; (4) sampling is performed, the content of Si and Mg in molten aluminum is adjusted by adding magnesium ingots and silicon ingots, and step (3) andstep (4) are repeated until the content of each chemical element in the molten aluminum reaches a target value; (5) gas and slag are removed, and the molten aluminum is purified; (6) the molten aluminum is cast into an aluminum bar, and Al-Ti5-B0.2 wires are added in the casting process; (7) high-temperature annealing is carried out; and (8), the head and tail portions of the aluminum bar are cutoff after being discharged from the furnace and cooled. According to the aluminum alloy ingot, the defects of coarse grains and feather-shaped crystals on the edge of the ingot are reduced.

Owner:苏州铭恒金属材料科技有限公司

Bast fiber plate waste recycling-based short fiber-reinforced composite material for automotive interiors and preparation method of bast fiber plate waste recycling-based short fiber-reinforced composite material

InactiveCN105504504ASolve the difficulty of blankingReduce reprocessingAntioxidantFiber-reinforced composite

The invention discloses a bast fiber plate waste recycling-based short fiber-reinforced composite material for automotive interiors. The bast fiber plate waste recycling-based short fiber-reinforced composite material is prepared from the following raw materials in parts by weight: 20-60 parts of crushed bast fiber plate materials, 100 parts of thermoplastic resin, 2-5 parts of an antioxidant, 1-3 parts of a light stabilizer, 2-5 parts of a lubricant and 0-10 parts of a flexibilizer. The bast fiber plate waste recycling-based short fiber-reinforced composite material has the beneficial effects that compared with the prior art, the bast fiber plate waste is recycled and changed into treasures; and the cost is reduced. The bast fiber plate is crushed and pelletized as a processing raw material for the short fiber-reinforced composite material, so that the problem that a bast fiber is difficult to feed is solved; the reprocessing technology of the bast fiber is reduced; the short fiber-reinforced composite material can be applied to the automotive interiors through an injection molding process; relatively complicated part injection molding manufacturing in the automobile industry can be further achieved; and the application situation that only the bast fiber plate is marketized in the field of the automotive interiors is also changed.

Owner:SHANGHAI PRET COMPOSITES

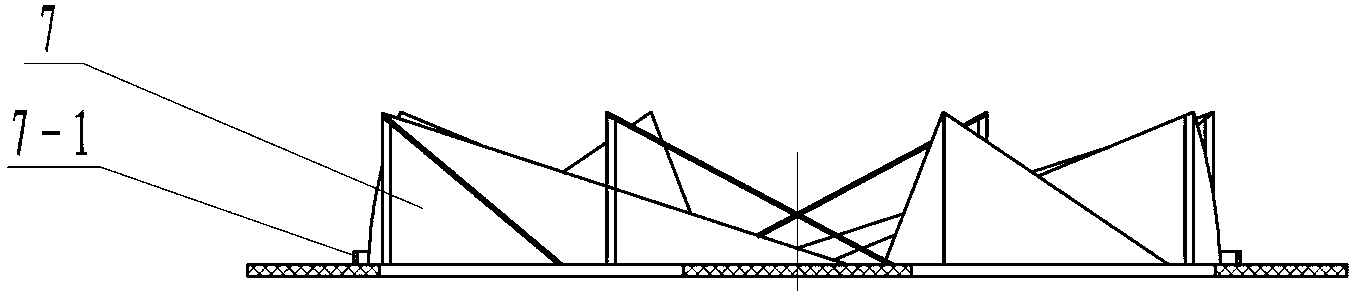

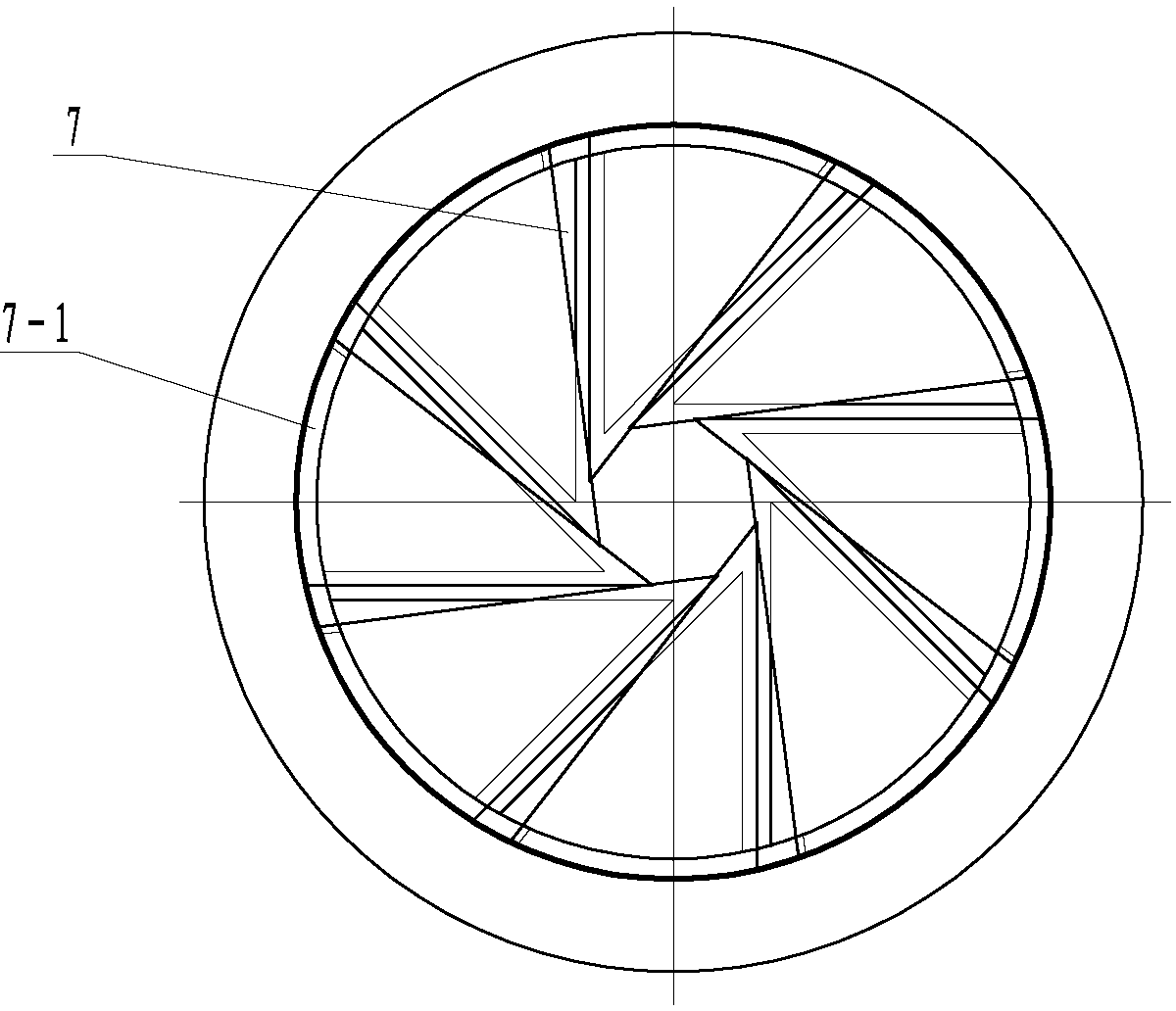

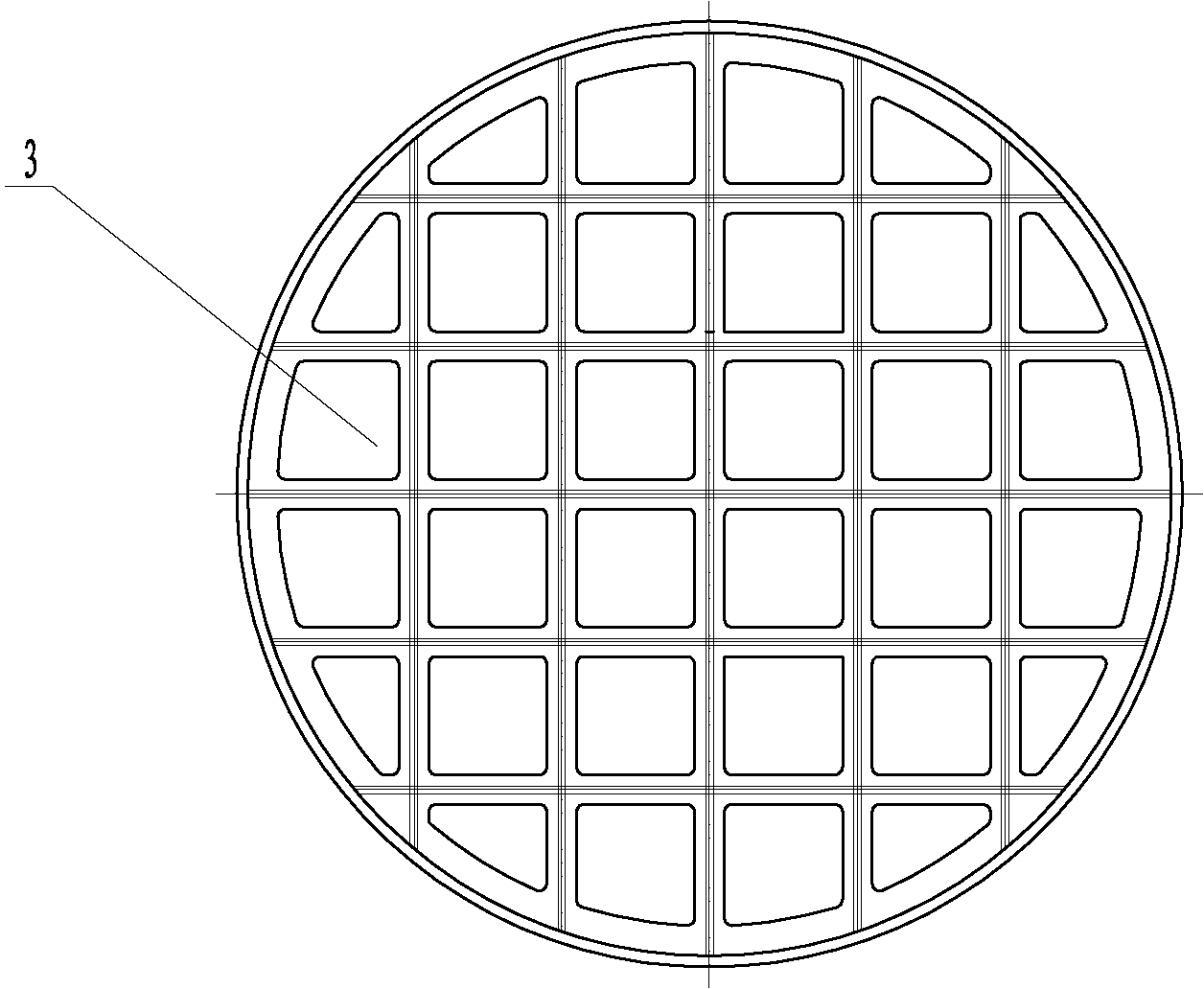

Method for producing calcium silicate board from artificial stone plate wastes and quartz stone plate wastes

InactiveCN103964785APlay a role in tougheningImprove flexural performanceSolid waste managementCalcium silicateFiber

Owner:SHANDONG JIANZHU UNIV

Plastic waste gas washing tower

InactiveCN103230736AExtended service lifeImprove corrosion resistanceDispersed particle separationLiquid wastePlastic waste

The invention belongs to the technical field of waste gas purification equipment, and in particular relates to a plastic waste gas washing tower. The plastic waste gas washing tower comprises a tower body, a waste gas inlet, a waste gas outlet, more than one tower plate, a filler spraying device and observation holes, and is characterized in that overall corrugated fillers are respectively arranged on the tower plate; a swirl plate is arranged on the top tower plate of the tower body; an annular catch tray is arranged at the lower part of the swirl plate; a swirl plate waste liquid outlet is formed in the side surface of the tower body; a lower tower plate waste liquid outlet is formed in the center at the bottom of the tower body; and the spraying device consists of long spraying pipes with nozzles and short spraying pipes with nozzles, which are uniformly and alternately arranged in the circumferential direction of the tower body. The plastic waste gas washing tower has the advantages of high corrosion resistance, ageing resistance, reasonable structure, stable performance, large processing capacity, small system resistance, convenience for mounting, no maintenance, long service life and the like.

Owner:ALIBEI PLASTIC STORAGE TANK ANSHAN

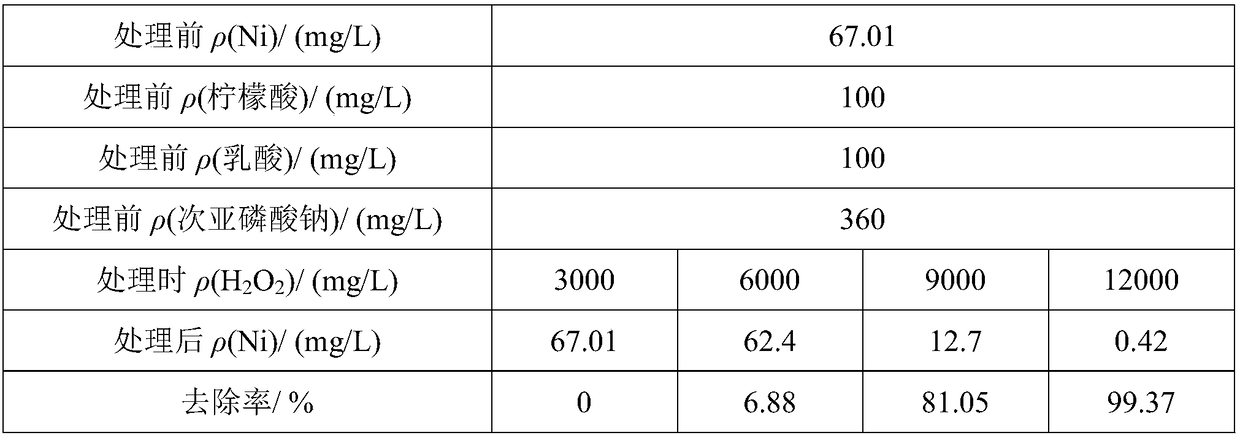

Treatment method of chemical nickle-plating waste water

ActiveCN108218129AAvoid difficultiesEasy to handleWaste water treatment from metallurgical processMultistage water/sewage treatmentSodium carbamatePrecipitation

Owner:GUANGZHOU ULTRA UNION CHEM LTD

Method for precipitating gold from cyanogen-containing gold-plated waste liquid

InactiveCN102978414AReduce pollutionImprove resource utilizationProcess efficiency improvementLiquid wasteResource utilization

The invention provides a method for precipitating gold from a cyanogen-containing gold-plated waste liquid. The method comprises the following steps of: (1) adding the cyanogen-containing gold-plated waste liquid containing 1-500mg / L gold ions into a container, adjusting the pH to 12 with 10wt% NaOH, adding NaClO to adjust the redox potential to 350mv, and reacting for 30 minutes; adding 10wt% H2SO4 to adjust the pH to 7.5, adding NaClO to adjust the redox potential to 650mv, and reacting for 30 minutes so that the cyanogen concentration in the waste liquid is damaged to less than 1mg / L; and (2) adding a gold precipitator into the cyanogen-containing gold-plated waste liquid with damaged cyanogen, stirring for reaction and filtering. The method provided by the invention can be used for protecting environment, precipitating gold and improving the utilization rate of resources.

Owner:DALIAN DONGTAI INDAL WASTE TREATMENT

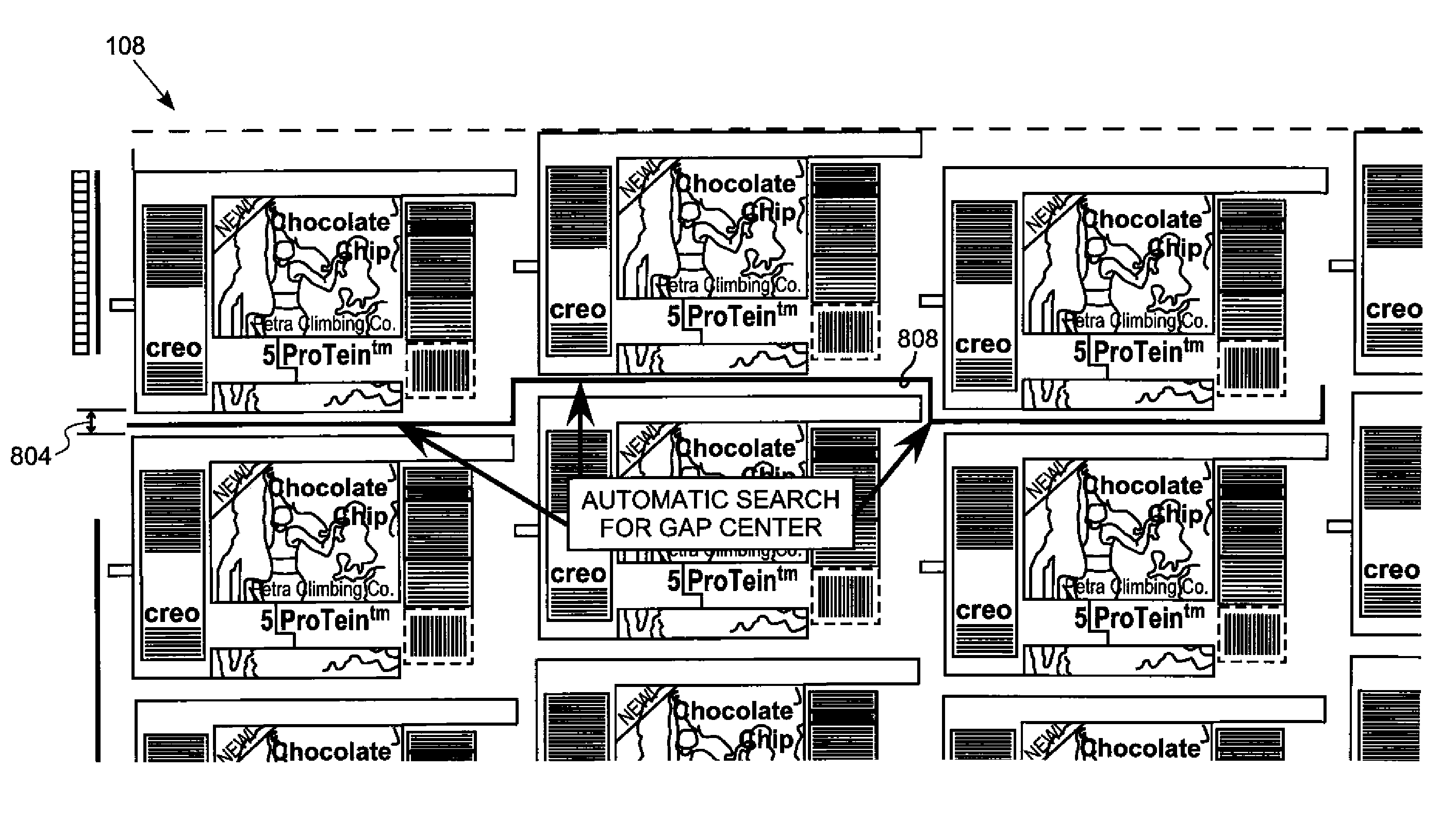

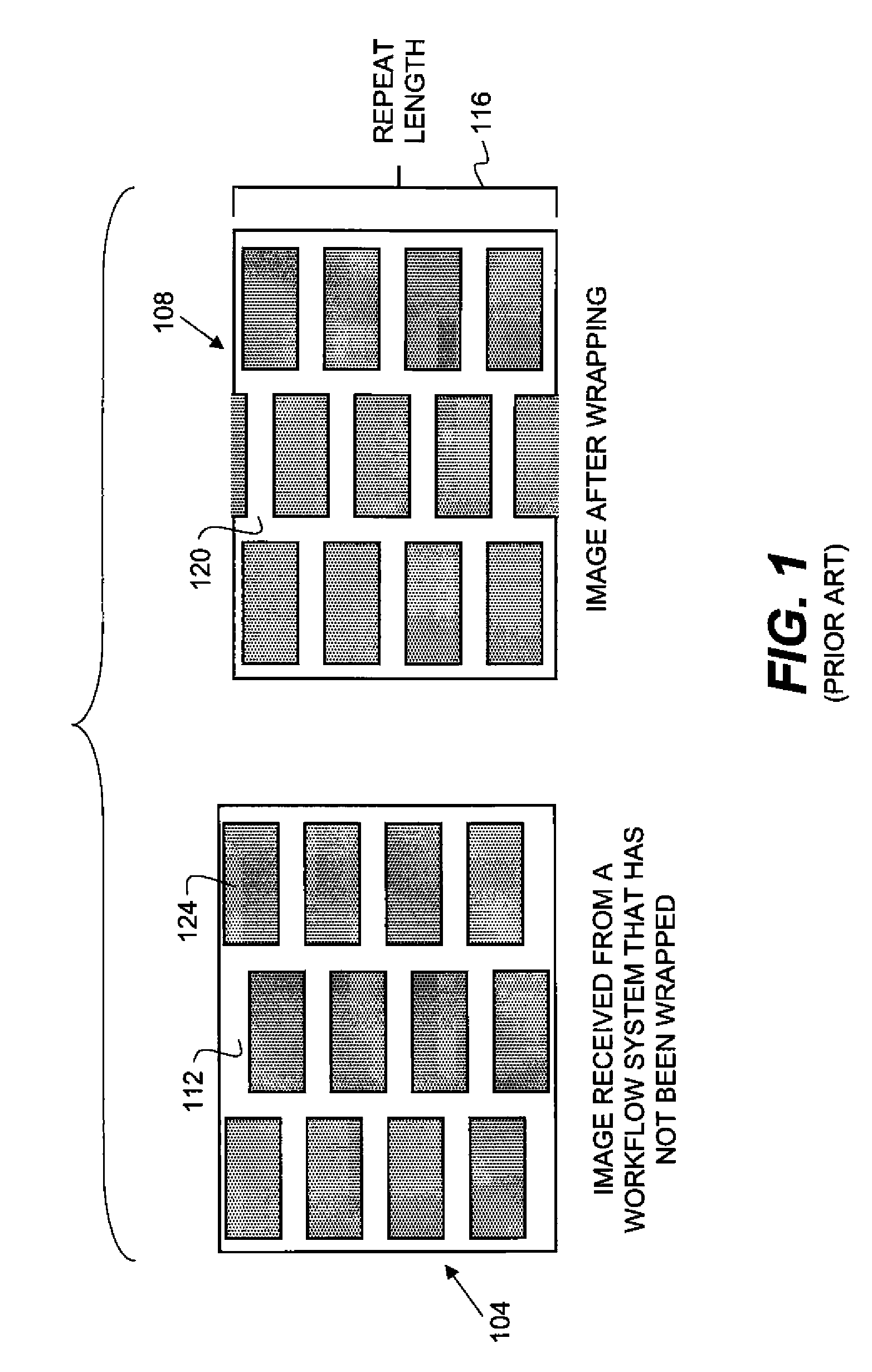

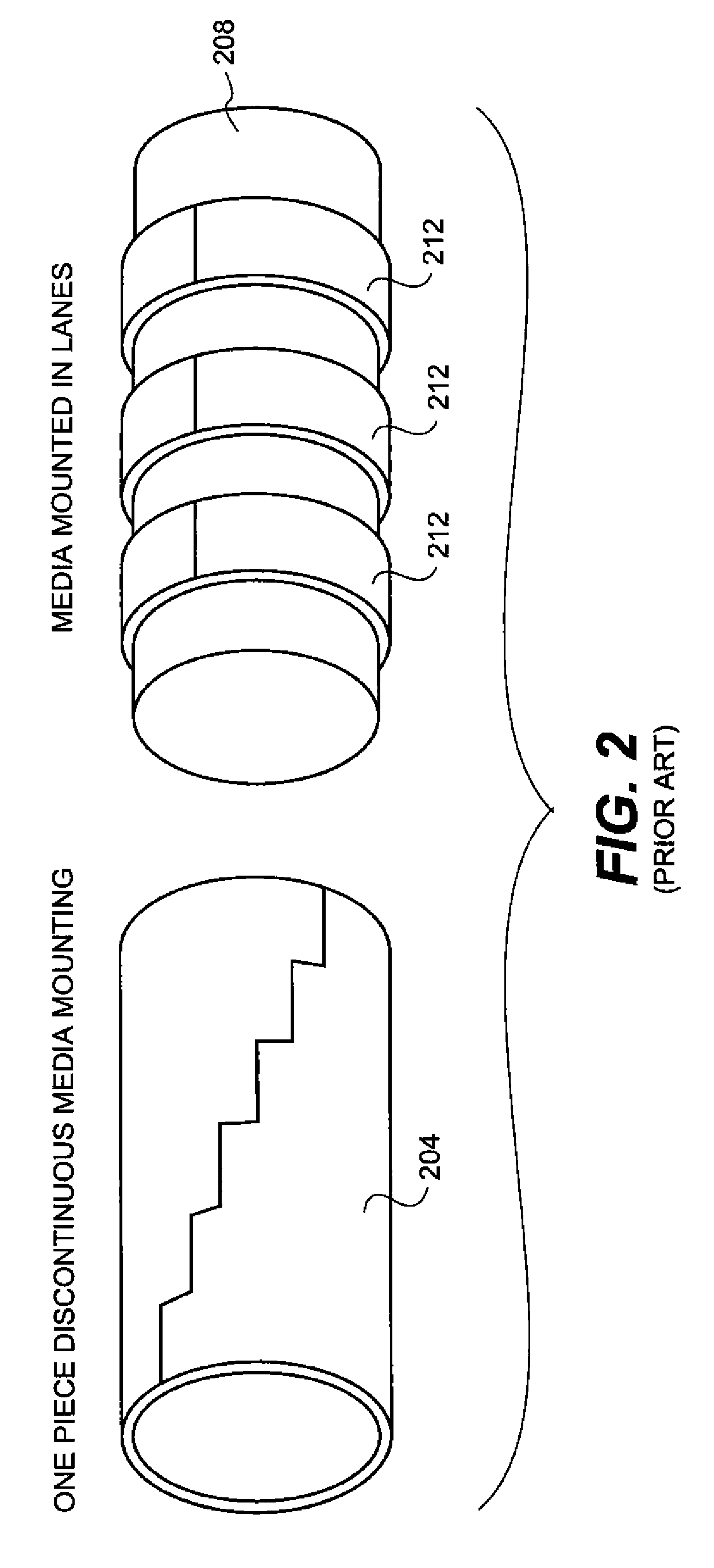

Optimizing a seam for a print job

A method for seam for a layout of a packaging printing job (908). The method is adapted to create minimal plate waste (1312) and includes the following steps; providing a wrapped layout (120) comprised of plurality of step and repeat element elements, and analyzing the wrapped layout to produce seam cut line design (1204) for the packaging printing job. The cut line is produced by searching for an non imaged areas inside the images and the borders of the step and repeat elements.

Owner:EASTMAN KODAK CO

Laboratory cyanide copper plating waste liquor recycling method

The invention relates to a laboratory cyanide copper plating waste liquor recycling method, which belongs to the field of waste liquor comprehensive utilization in an electroplating field. The method comprises the following steps of: firstly adding activated carbon into waste liquor to remove organic impurities, reducing the temperature of the waste liquor with refrigeration tablets so as to form sediments and remove carbonate, heating to melt sodium carbonate obtained through condensation, recrystallizing to obtain sodium carbonate, adding sodium sulphide into the waste liquor, sedimenting the contained metal elements of Pb<2+> and Zn<2+> through chemical reaction, arranging the waste liquor in an air-tight container, adding alkali, heating, and pressurizing to hydrolyze cyanide to produce nontoxic sodium formate and ammonia, distillating a treated solution, burning and harmlessly burying the rest solid substances. The invention provides a simple and feasible method for treating cyanide copper plating waste liquor in a laboratory, resources can be effectively recycled, and pollution is reduced.

Owner:SHANDONG JIANZHU UNIV

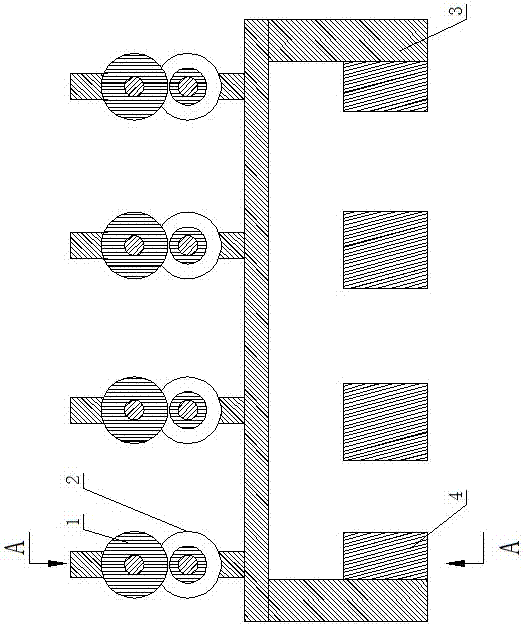

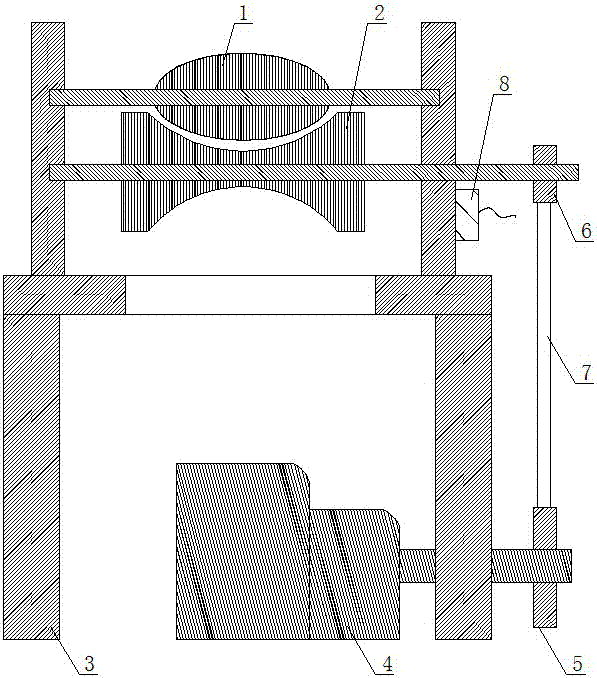

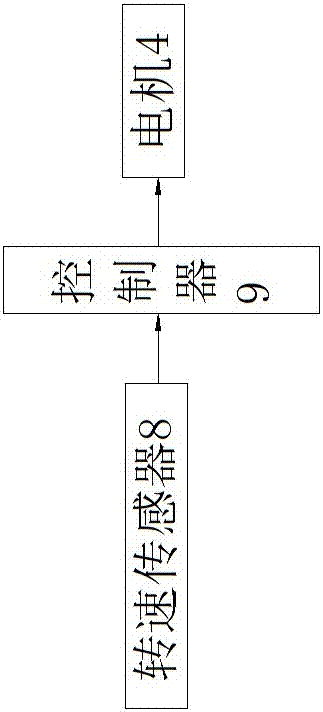

Extruding roller level difference control device and method

The invention discloses an extruding roller level difference control device and method, belongs to the field of reel pipe manufacturing devices and aims to solve the technical problem that tail ends of plates are abandoned to cause plate waste. The extruding roller level difference control device structurally comprises a rack, multiple extruding rollers and multiple driving devices, wherein the extruding rollers comprise concave wheels and convex wheels which are arranged oppositely, a gap for plates to pass through is formed between each concave wheel and the corresponding convex wheel, the driving devices are connected with the extruding rollers and drive the concave wheels and the convex wheels to synchronously rotate in different-direction mode, the multiple extruding rollers are arranged on the rack and are sequentially arranged in the conveying direction of the plates to form a forming mechanism, each driving device is connected with the corresponding concave wheel and the corresponding convex wheel and can drive the corresponding concave wheel and the corresponding convex wheel to synchronously rotate in different-direction mode, the rotation speeds of the multiple extruding rollers are progressively increased in the conveying direction of the plates, and each driving device is connected to a controller. By adopting the method, plates are coiled through the extruding roller level difference control device.

Owner:SHANDONG XINHEYUAN HEAT TRANSFERRING TECH

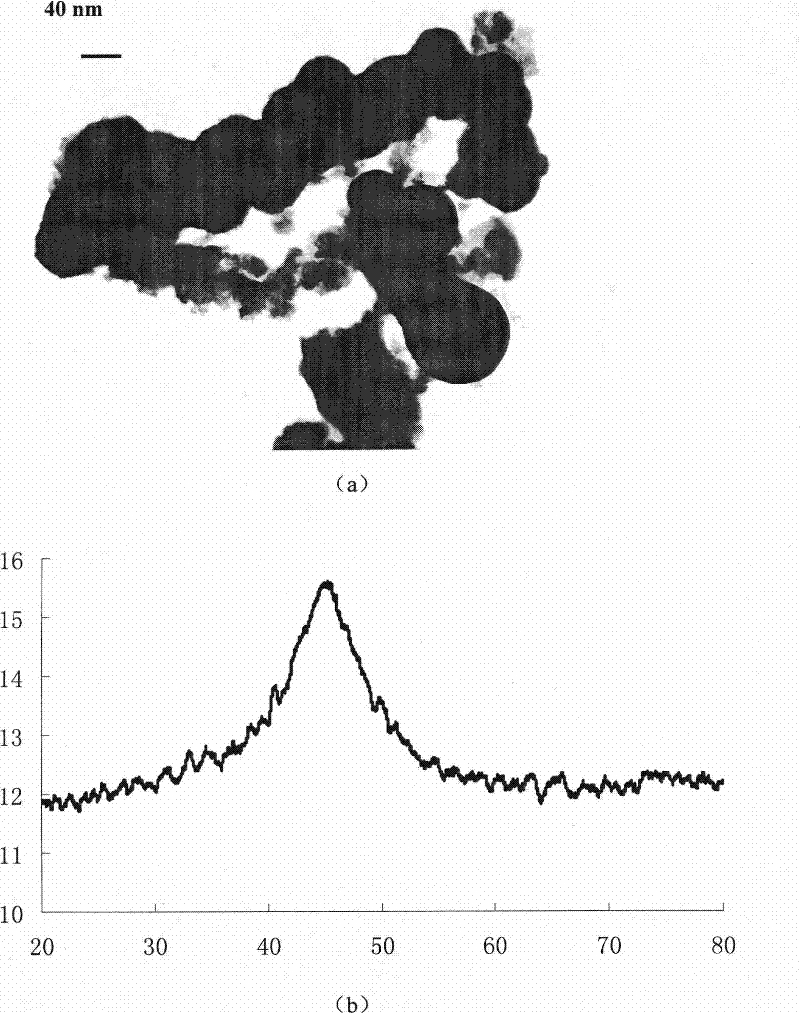

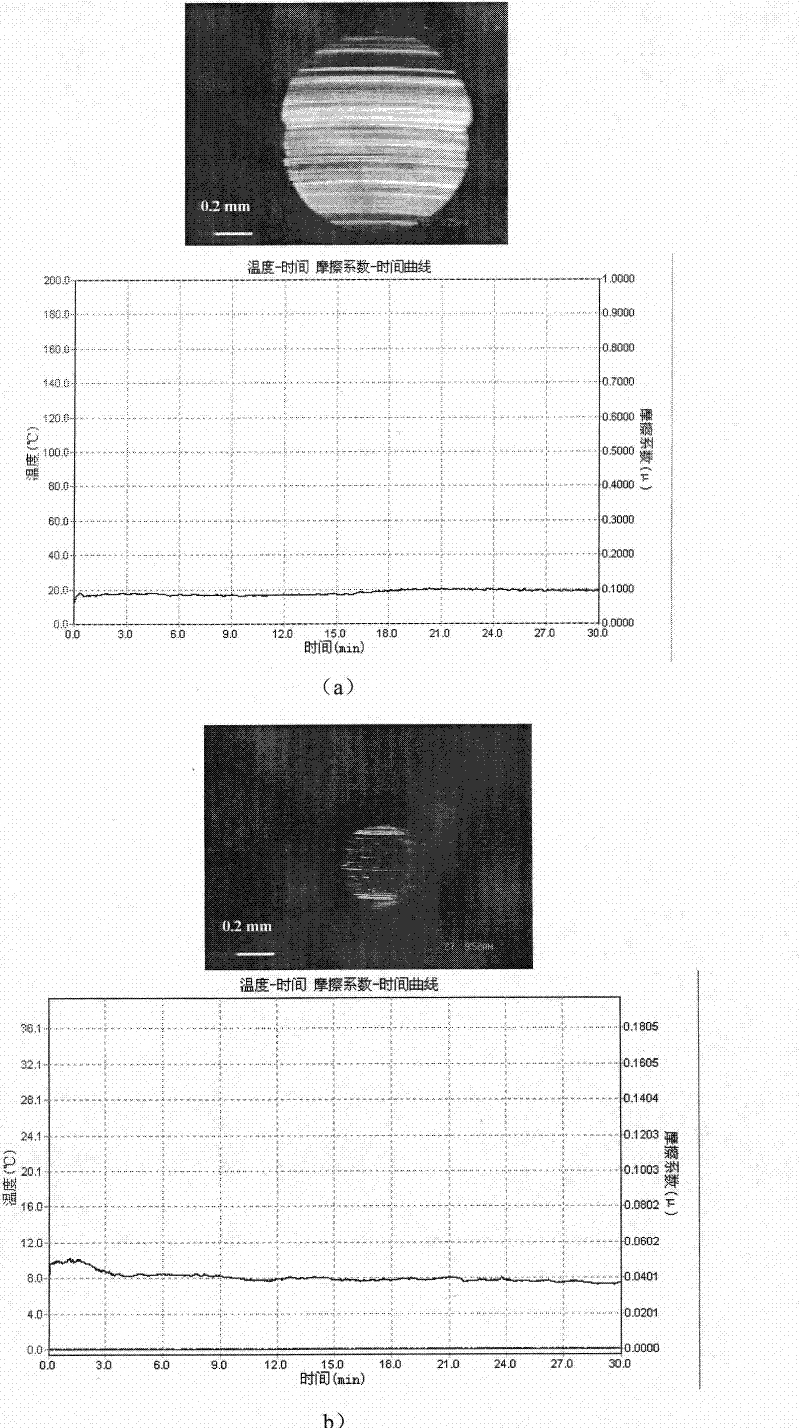

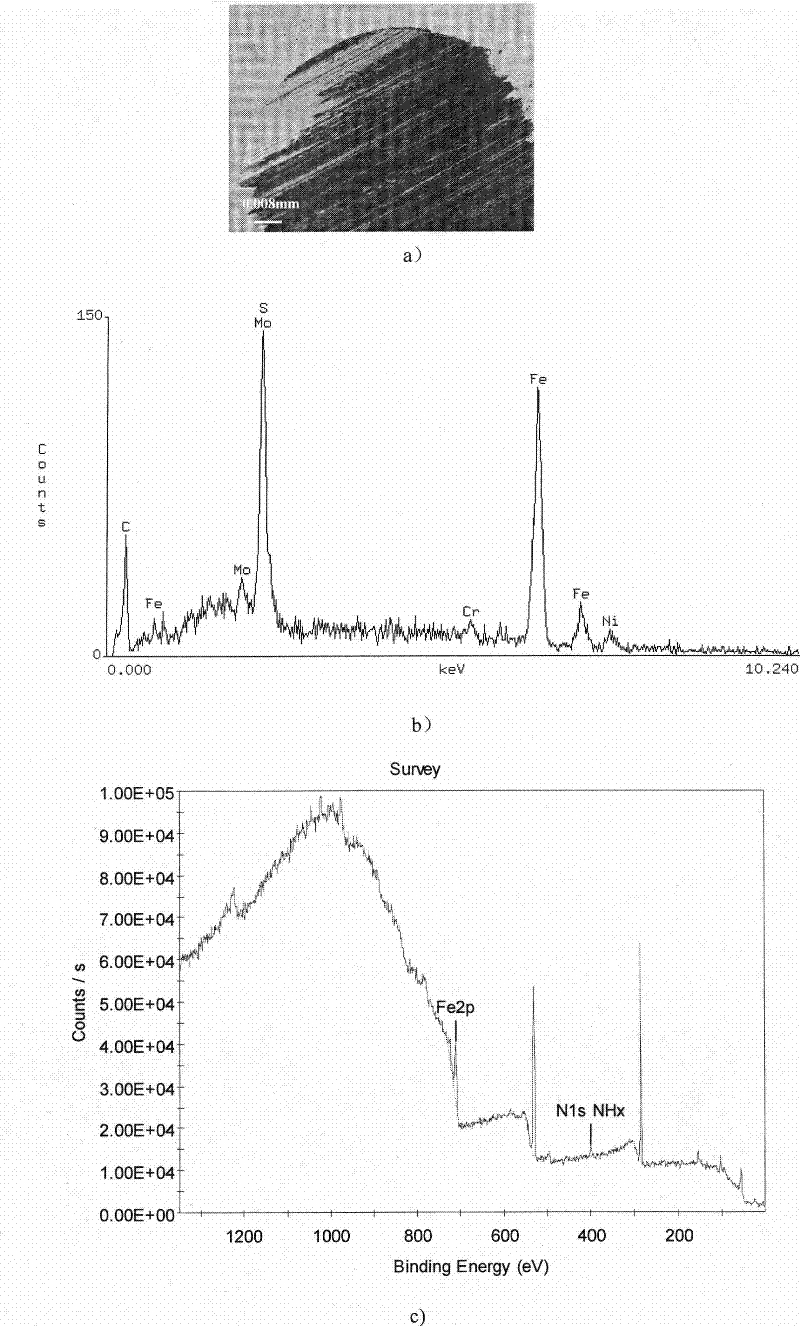

Lubricant additive containing Ni-P powder recycled from electroless plating waste liquid, preparation and application thereof

InactiveCN101747985AExtend oil change intervalsIncrease pressureAdditivesElectroless nickelLiquid waste

The invention discloses a Ni-P alloy nano-powder lubricant additive prepared from nickel and phosphorus recycled from electroless nickel plating waste liquid, and a using method thereof in different friction occasions, wherein Ni-P powder is subjected to in-situ dispersion and recovered from electroless nickel plating waste liquid, dispersed again and then prepared into the lubricant additive through certain steps, together with metal chemical friction modifiers, detergent-dispersant, oxygen corrosion-resistant agents, auxiliary performance regulator, stabilizer and base oil. The lubricant additive has the advantages of good suspension stability, capability of greatly reducing equipment friction and wear, greatly reducing the frequency of equipment maintenance and parts replacement and prolonging equipment lifespan and overhaul time limit, as well as good effect of saving energy and protecting environment. The lubricant additive can be widely used in gasoline / diesel internal combustion engines, general fluid machinery, mechanical chemical sealing pieces, transmission gearboxes and other occasions, can realize the recycling of nickel and phosphorus in the electroless nickel plating waste liquid with high added value in order to change pollutants into useful things, and realizes the coordination and unification of economic, environmental and social benefits.

Owner:NANJING UNIV OF TECH

Low-noise and easy-maintenance honeycomb plate waste crushing decomposer

InactiveCN106582993AEasy to cleanAvoid influenceDirt cleaningGrain treatmentsLow noiseWorking environment

The invention provides a low-noise and easy-maintenance honeycomb plate waste crushing decomposer. The low-noise and easy-maintenance honeycomb plate waste crushing decomposer comprises a crusher body, a feed port and the like, and is characterized by further comprising a wear resisting layer, a silent protective cover, a silent box, a dust sucking device and a dust collecting box; the wear resisting layer is mounted on the inner wall of the crusher body; the external of the crusher body is coated with the silent protective cover; and the feed port is formed in one side of the crusher body. The low-noise and easy-maintenance honeycomb plate waste crushing decomposer is provided with the silent protective cover; on the one hand, the difficult cleaning of the production area caused by waste splashing and falling in the crushing decomposition process can be prevented; and on the other hand, the noise can be effectively lowered; the wear resisting layer is arranged in the crusher body to effectively prolong the service life and improve the practicability and the safety; and the dust sucking device is provided for absorbing floating dust generated in the crushing decomposition process and discharging into the dust collecting box, so that the influence on the working environment by the floating dust generated in the production process can be reduced, the environmental protecting performance is improved, and the equipment is easy to maintain.

Owner:天津富松汽车零部件有限公司

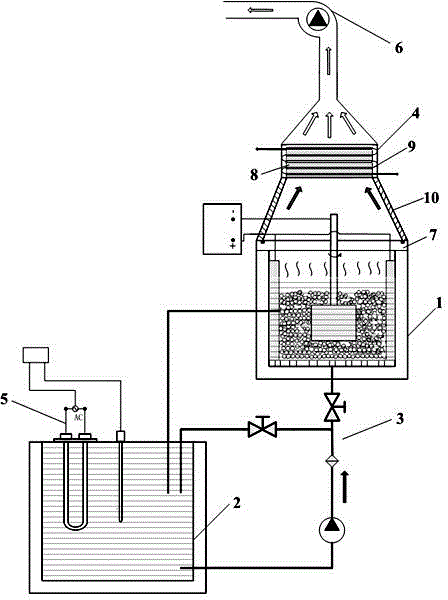

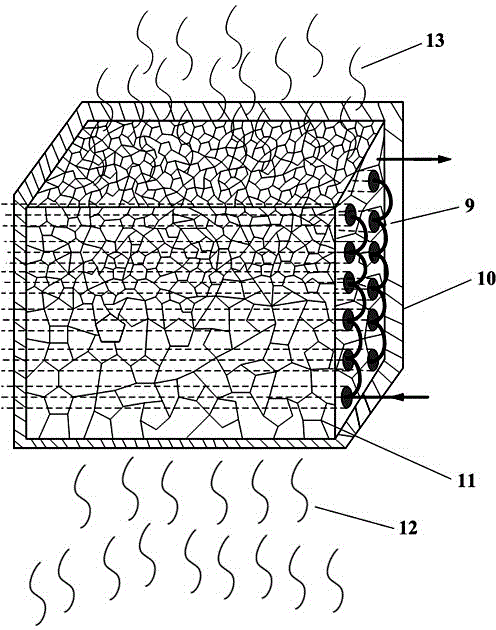

Electric chromium plating waste gas purification system and method

The invention relates to an electric chromium plating waste gas purification system and a method and belongs to the technical field of electroplating. The system comprises a condensation cover (4) mounted above an electroplating unit (1) via a coupling flange (7) and forming a sealed channel, wherein the condensation cover (4) is internally equipped with a plurality of layers of foam metals (8) and a condensation tube (9); the foam metals are distributed in a layered manner sequentially according to a gap size; a gap diameter of a lower layer is greater than that of an upper layer; the condensation tube (9) is arranged in the foam metals (8); and the system further comprises a gas collecting system connected with the upper end of the condensation cover (4). The system can effectively purify and recover volatile chromic acid generated in an electric chromium plating process and discharges waste gas containing electric chromium plating acid after purification.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

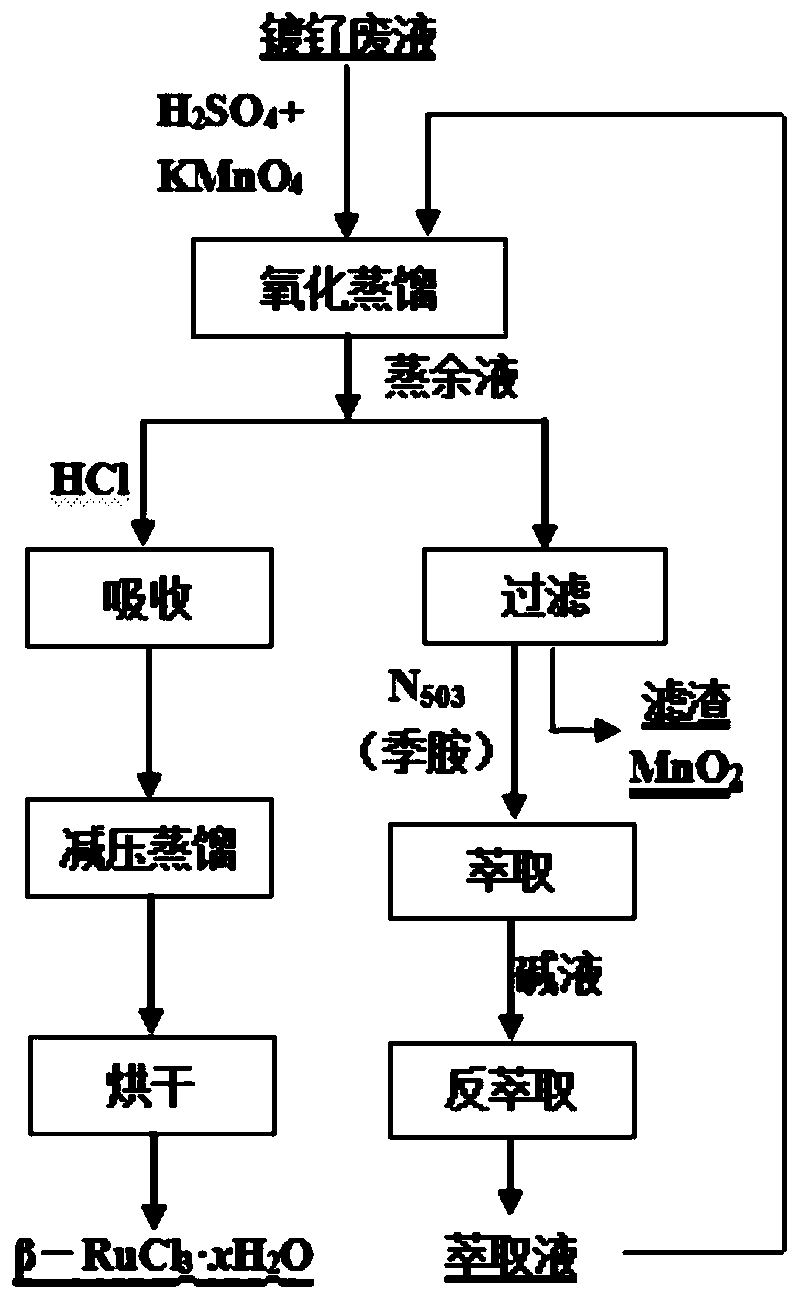

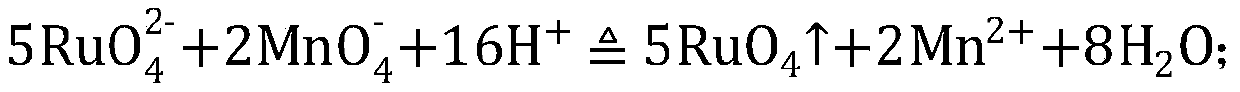

Method for recovering ruthenium trichloride from ruthenium plating waste liquid

ActiveCN110423896AHigh recovery rateEmission reductionProcess efficiency improvementDistillationEconomic benefits

The invention provides a method for recovering ruthenium trichloride from ruthenium plating waste liquid, and relates to the technical field of noble metal recovery. The method comprises the followingstepsofS1, performing oxidative distillation on the ruthenium plating waste liquid in an acidic medium to obtain the ruthenium trichloride and distilled residual liquid; S2, extracting and back-extracting the distilled residual liquid to obtain a water phase; and S3, performing oxidative distillation on the water phase. According to the method for recovering the ruthenium trichloride from the ruthenium plating waste liquid, the distillation process and the extraction process are combined to further recover the residual ruthenium element in the distilled residual liquid, so that on one hand, the recovery rate of ruthenium trichloride is increased; and on the other hand, discharge of the waste liquid is reduced, secondary pollution to the environment is reduced, and thus, social and economic benefits and environmental benefits are increased.

Owner:JIANGSU UNIV OF TECH

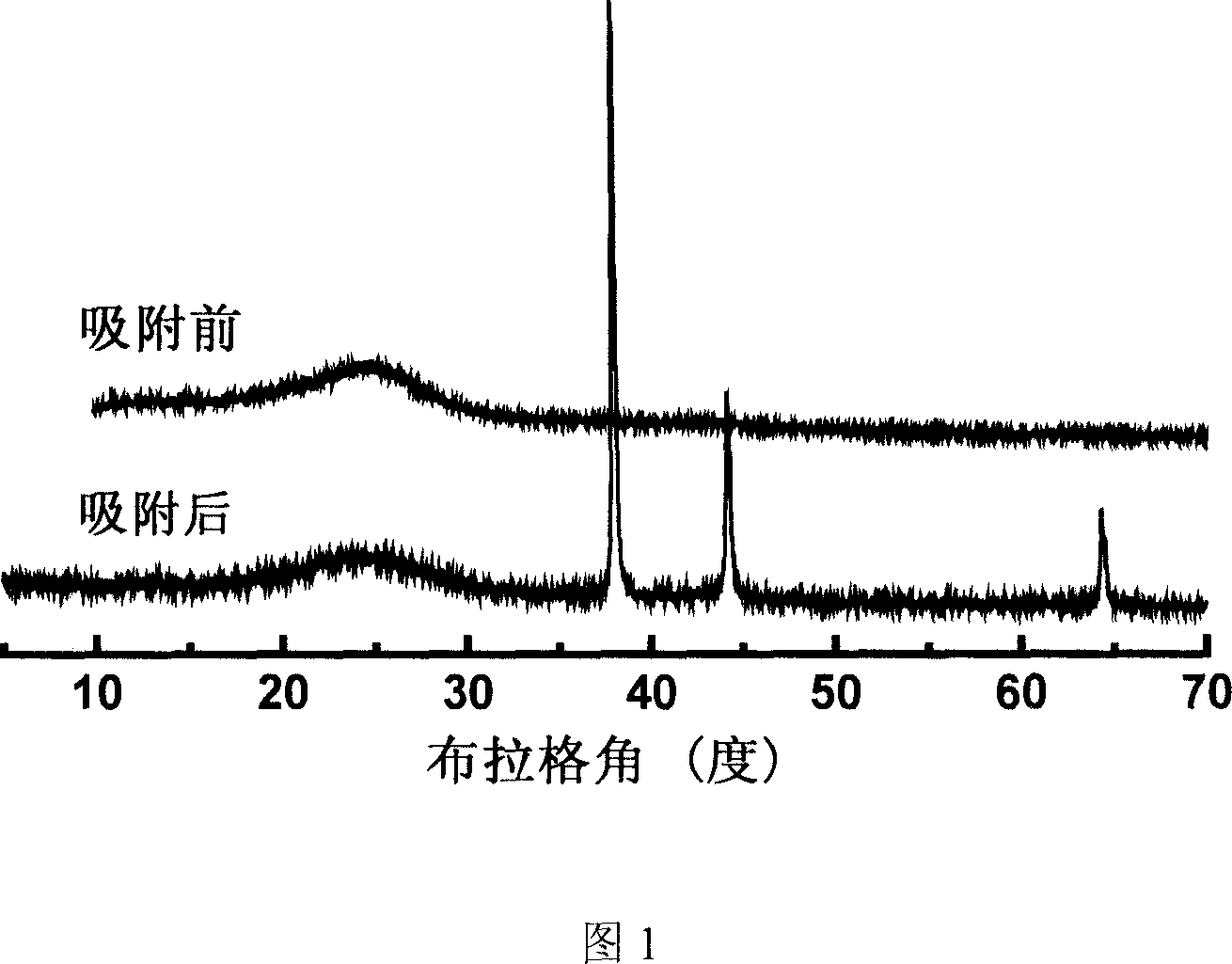

Method of reclaiming silver from silver ion containing solution by polydiaminoanthraquinone as adsorbent

InactiveCN101016585AAchieve recyclingWeak ability to absorb silverProcess efficiency improvementLiquid wasteMicrometer

Owner:TONGJI UNIV

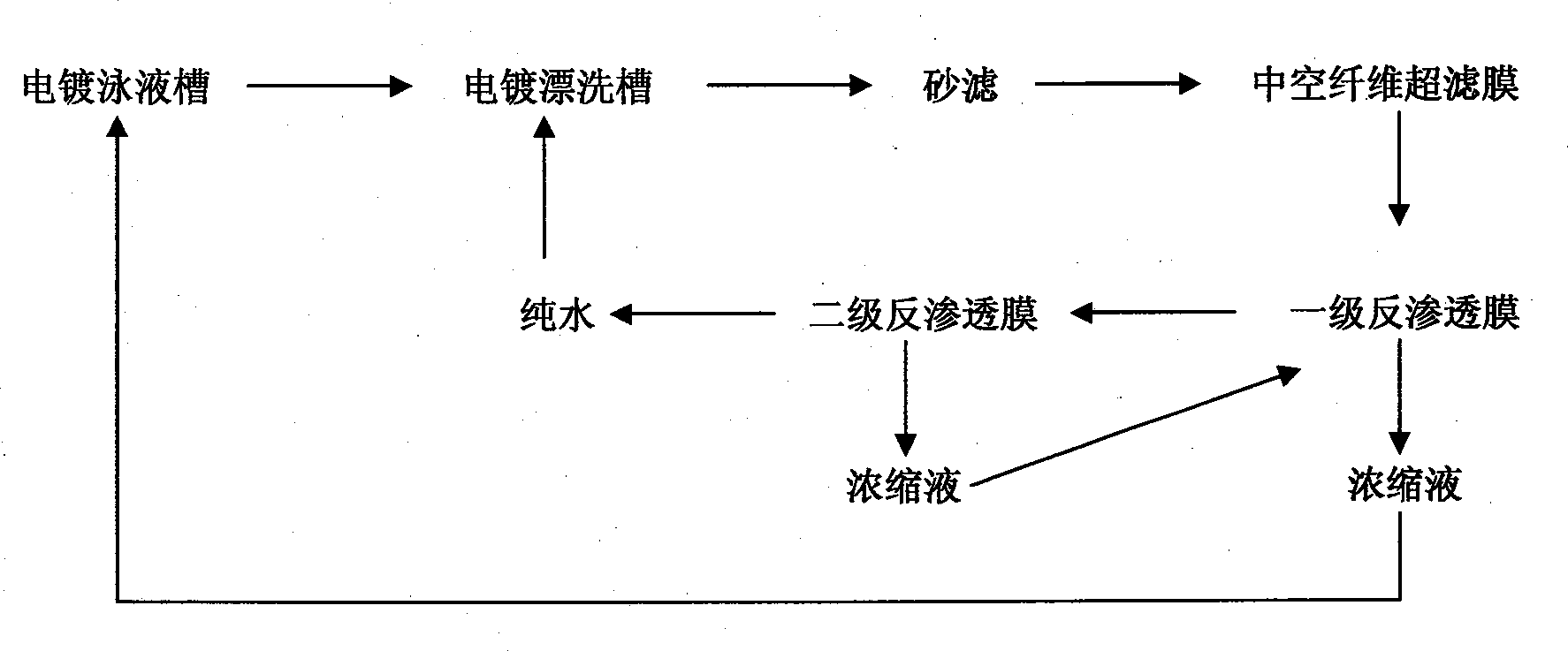

Whole membrane treatment method of electroplating chromeplating waste water

ActiveCN103130348ASolve the problem of membrane oxidation degradationSolve problems such as secondary pollutionWaste water treatment from metallurgical processWater/sewage treatment bu osmosis/dialysisFiberUltrafiltration

A whole membrane treatment method of electroplating chrome plating waste water comprises the following treatment steps of: 1) rinsing: rinsing electroplating chromeplated parts with clear water in a rinsing tank after being electroplated through a chromeplating electrophoresis liquid tank to obtain rinsed liquid; (2) sand filtration: treating the rinsed liquid in the rinsing tank by a sand filtration tank to remove suspension, colloid, flocculate, mud sand, rust, and the like to obtain sand-filtered liquid; (3) hollow fiber ultrafiltration membrane treatment; (4) reverse osmosis treatment: performing reverse osmosis concentration treatment of the clear liquid by a reverse osmosis device; (5) cyclic operation of the above steps. The method has the advantages that the problem of secondary pollution caused by traditional chemical precipitation methods is solved; the problem of membrane oxidation and degradation due to hexavalent chromium ions is solved; the method meets the new discharge national standard; the whole process flow operation is simple and convenient; waste water in the whole process is in a recycle state, and is not discharged to the outside at all; and the whole process reaches the standard of zero discharge.

Owner:深圳市立威塑胶五金制品有限公司

Method for preparing LFT-D (long fiber reinforced thermoplastic composite) dung draining plate by utilizing production leftovers

The invention discloses a method for preparing an LFT-D (long fiber reinforced thermoplastic composite) dung draining plate by utilizing production leftovers. The method comprises the steps of crushing the recovered LFT-D production leftovers into particles in a size of 5mm to 8mm, adding a new material according to a weight ratio of (1:3) to (1:4), adding glass fibers according to a weight ratio of the glass fibers to wastes of (1:1.8) to (1:2.1), finally uniformly mixing and heating, and extruding the mixture to a dung draining plate mold to obtain a product. Various mechanical properties of each product processed in the method can reach relevant inspection standards of the dung draining plate, and the recycling of raw materials of the LFT-D dung draining plate wastes is realized, and an important significance on environmental protection can be realized.

Owner:陕西新智汇科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com