Extruding roller level difference control device and method

A control device and roller technology, which is applied in the field of squeeze roller level difference control device, can solve the problems of abandoned plates and waste, and achieve the effects of energy saving, easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

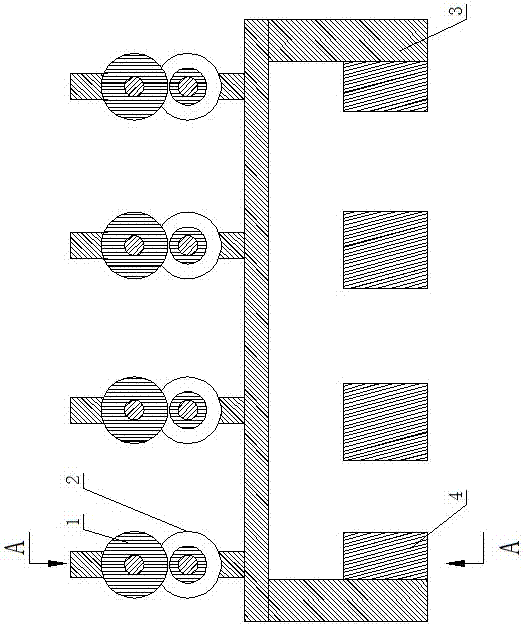

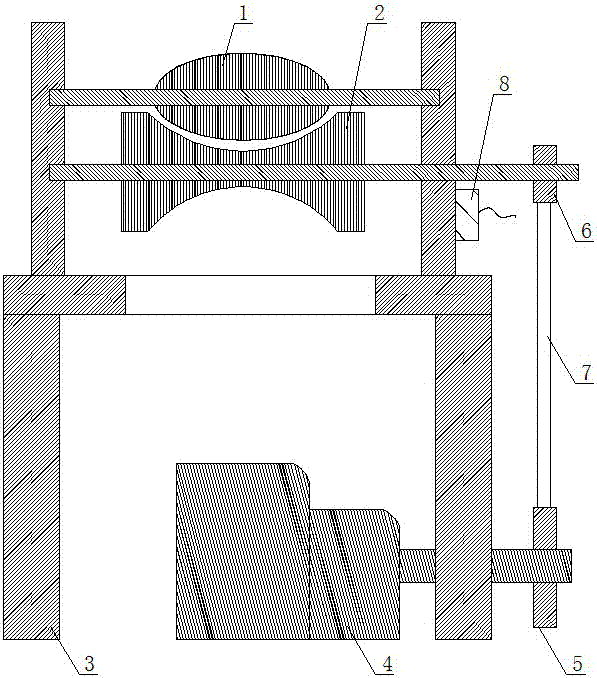

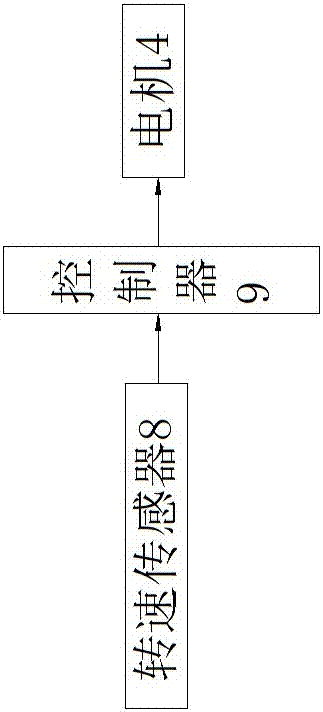

[0023] as attached figure 1 , attached figure 2 And attached image 3 As shown, the extrusion roller differential control device includes a frame 3, an extrusion roller and a driving device, and the extrusion roller includes a concave wheel 2 and a cam 1 which are arranged up and down oppositely, and the cam 1 is located above the concave wheel 2, and the concave wheel 2 There is a gap between the wheel 2 and the cam 1 for the plate to pass through, and the cam 1 and the concave wheel 2 cooperate to squeeze the plate, and the driving device is connected with the extrusion roller and drives the concave wheel 2 and the cam 1 to rotate synchronously in different directions; the above There are a plurality of extrusion rollers and driving devices. The plurality of extrusion rollers are arranged on the frame 3 and arranged in sequence along the conveying direction of the plate to form a forming mechanism. Each extrusion roller corresponds to a driving device, and each driving Th...

Embodiment 2

[0028] In the extrusion roller differential control method of the present invention, the plate is bent through the extrusion roller differential control device disclosed in Embodiment 1, and the rotational speeds of the multiple extrusion rollers in the forming mechanism are set to be along the conveying direction Incrementing successively to form a differential control forming mechanism, through which the plate is bent and deformed step by step to obtain a coiled tube. Including the following steps:

[0029] (1) Set the rotation speed of the extrusion rollers through the driving device, so that the concave wheel 2 and the cam 1 in each extrusion roller rotate in different directions synchronously, and make all the extrusion rollers in the forming mechanism meet the following conditions: The rotation speed of each extrusion roller increases sequentially along the conveying direction of the plate, forming a differential control forming mechanism;

[0030] (2) Send the flat pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com