Method for producing calcium silicate board from artificial stone plate wastes and quartz stone plate wastes

A technology for quartz slate and artificial slate, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of environmental pollution, high energy consumption of calcium-silicon plates, waste of waste and other problems, so as to reduce environmental load and save energy. Construction materials, the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for producing silicon slab calcium with artificial slate and quartz slate waste, comprising steps as follows:

[0030] (1) With artificial stone aluminum plate waste and quartz stone waste, take raw material according to following ratio:

[0031] 40 parts of artificial stone calcium aluminum plate waste, 35 parts of quartz slate waste, 10 parts of cement, 10 parts of artificial stone or quartz stone particles with a particle size of 0.2-0.5 mm, 5 parts of high-strength alumina fiber with a length of 4-8 mm, 0.3 parts of water reducing agent and 15 parts of water;

[0032] (2) The above materials are mixed and molded, the molding pressure is 50-60Mpa, demoulding, and natural curing for 28 days.

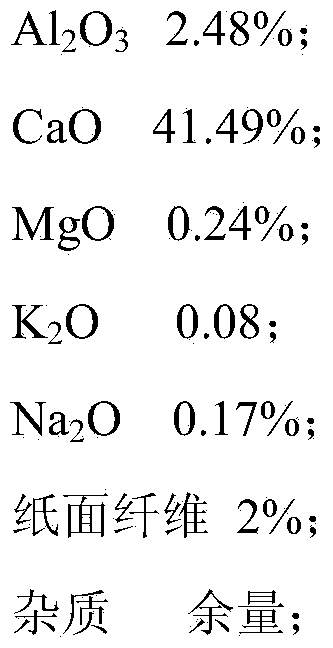

[0033] In the described step (1), the artificial stone calcium-aluminum plate waste, its component content percentage is as follows:

[0034]

[0035]

[0036] Among them, impurities are resin and moisture contained in calcium aluminum plate waste.

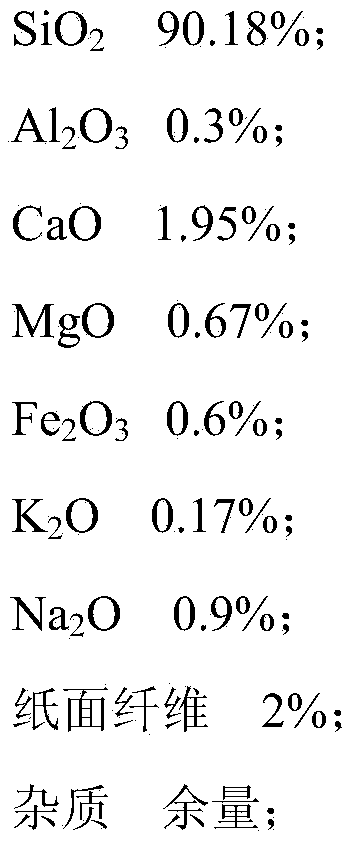

[0037] In ...

Embodiment 2

[0047] A method for producing silicon slab calcium with artificial slate and quartz slate waste, comprising steps as follows:

[0048] (1) With artificial stone aluminum plate waste and quartz stone waste, take raw material according to following ratio:

[0049] 42 parts of artificial stone calcium aluminum plate waste, 37 parts of quartz slate waste, 15 parts of cement, 12 parts of artificial stone or quartz stone particles with a particle size of 0.2-0.5 mm, 7 parts of high-strength alumina fiber with a length of 4-8 mm, 0.4 parts of water-reducing and anti-water agent, 17 parts of water;

[0050] (2) The above materials are mixed and molded, the molding pressure is 50-60Mpa, demoulding, and natural curing for 28 days.

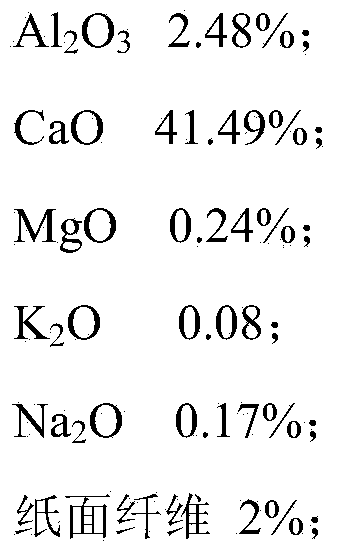

[0051] In the described step (1), the artificial stone calcium-aluminum plate waste, its component content percentage is as follows:

[0052]

[0053] Among them, impurities are resin and moisture contained in calcium aluminum plate waste.

[0054] In ...

Embodiment 3

[0065] A method for producing silicon slab calcium with artificial slate and quartz slate waste, comprising steps as follows:

[0066] (1) With artificial stone aluminum plate waste and quartz stone waste, take raw material according to following ratio:

[0067] 45 parts of artificial stone calcium aluminum plate waste, 34 parts of quartz slate waste, 20 parts of cement, 15 parts of artificial stone or quartz stone particles with a particle size of 0.2-0.5 mm, 8 parts of high-strength alumina fiber with a length of 4-8 mm, 0.5 parts of water-reducing and anti-water agent, 20 parts of water;

[0068] (2) The above materials are mixed and molded, the molding pressure is 50-60Mpa, demoulding, and natural curing for 28 days.

[0069] In the described step (1), the artificial stone calcium-aluminum plate waste, its component content percentage is as follows:

[0070]

[0071] Among them, impurities are resin and moisture contained in calcium aluminum plate waste.

[0072] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com