Powder coating for building materials and preparation method thereof

A technology for powder coatings and building materials, used in powder coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of powder coating permeability and poor corrosion resistance, and achieve improved corrosion resistance, good adhesion, and improved processing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

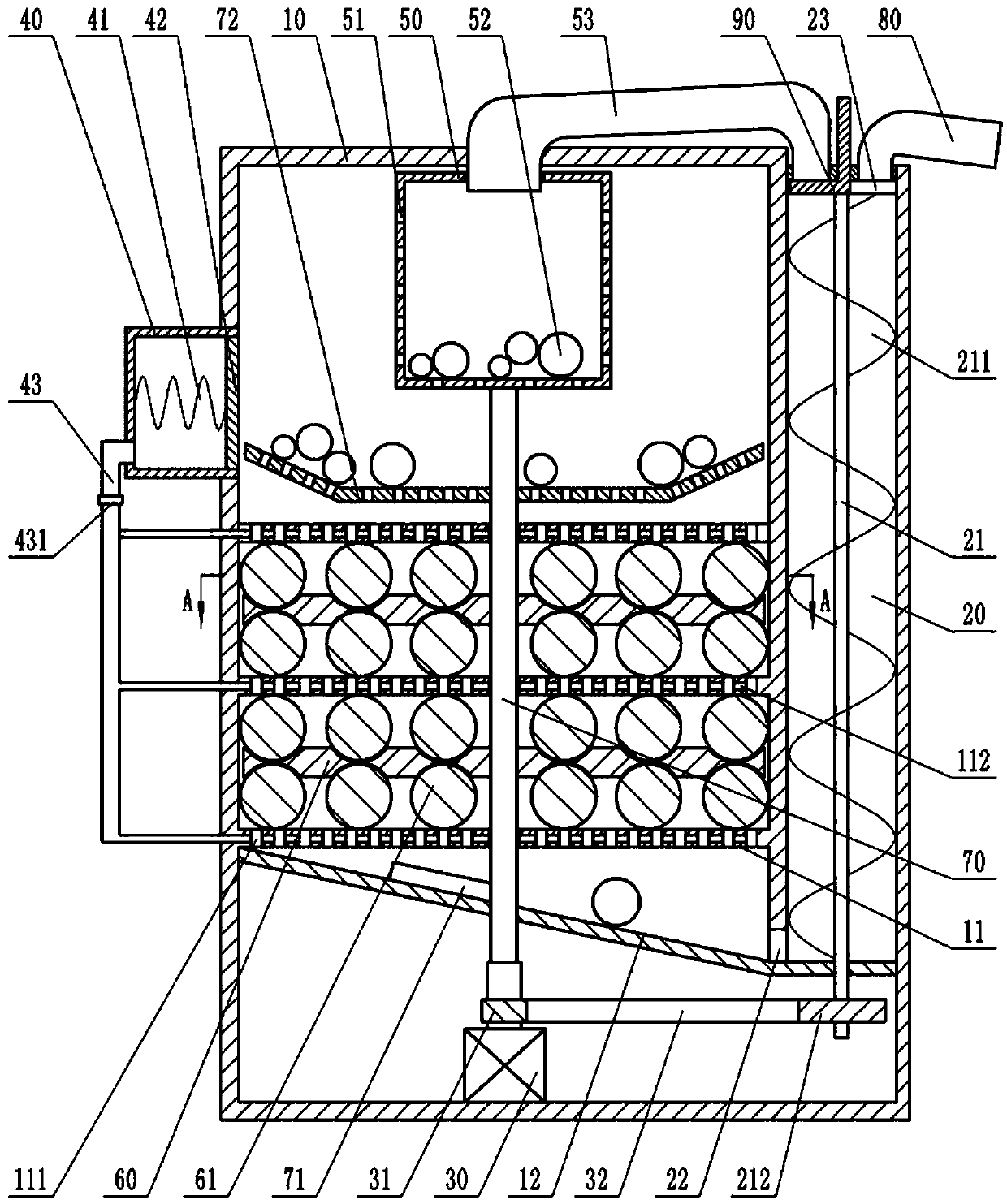

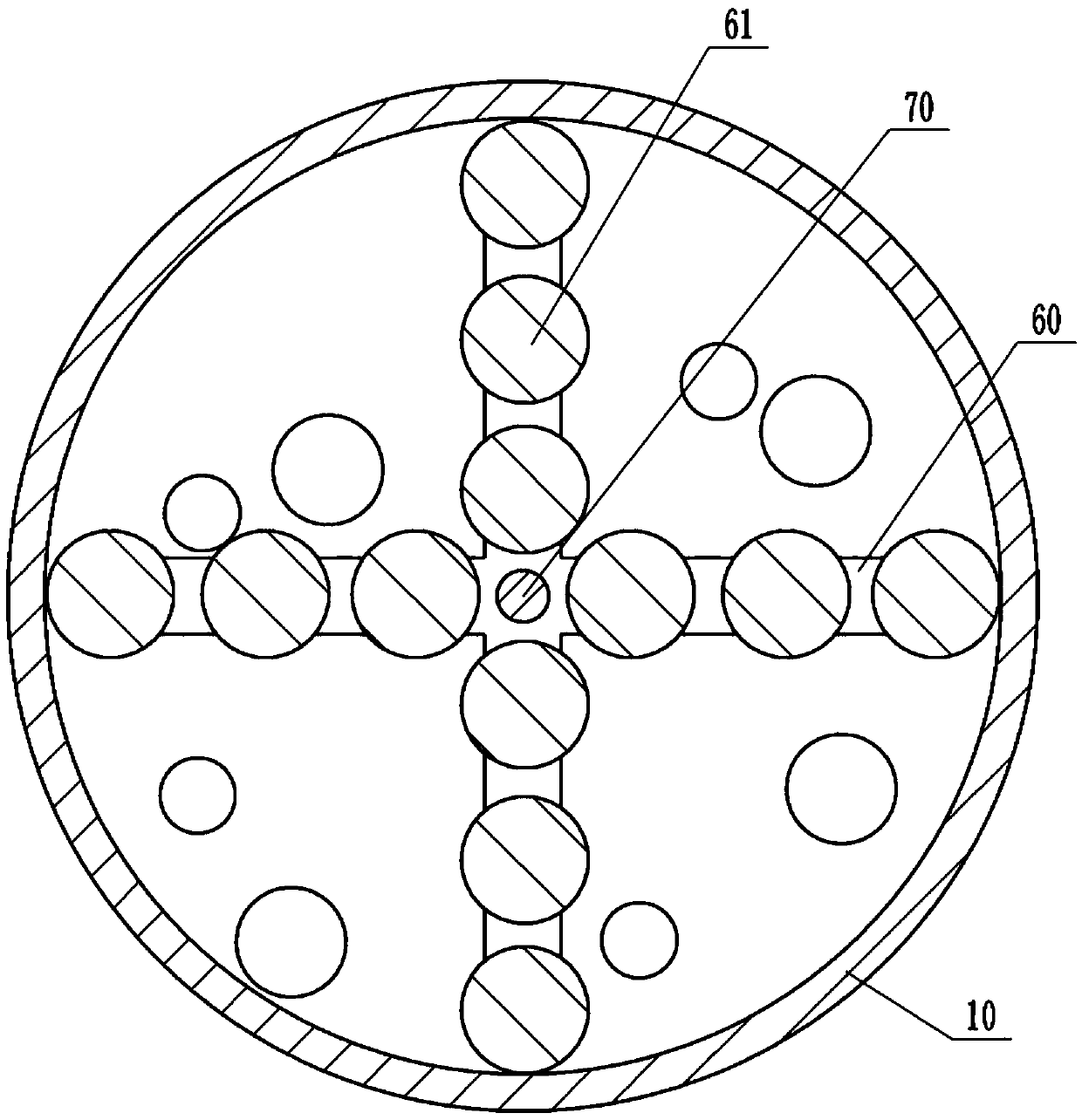

Image

Examples

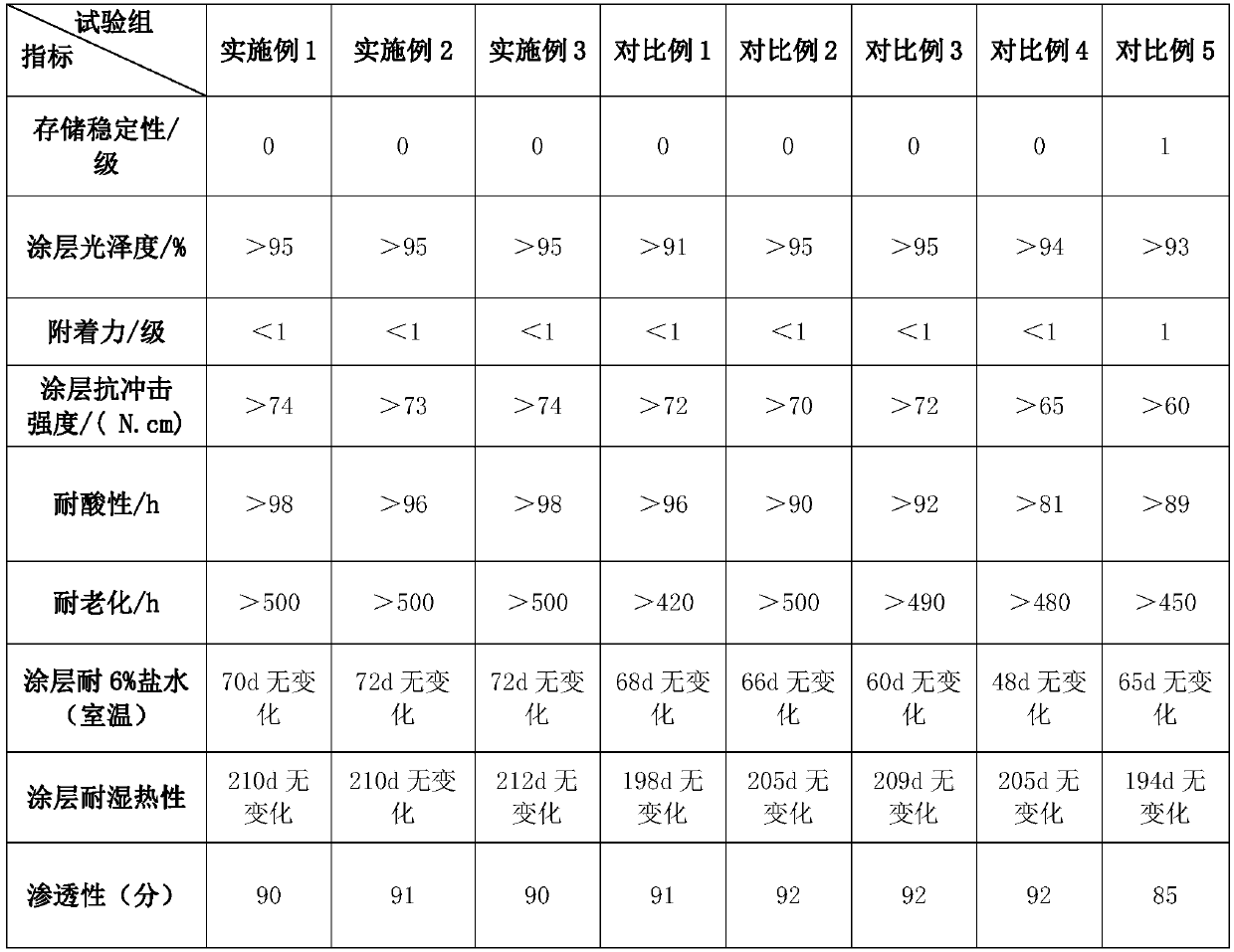

Embodiment 1

[0029] This embodiment discloses a powder coating for building materials, including the following raw materials in parts by mass: 56 parts of epoxy resin, 38 parts of polyester resin, 22 parts of polyethersulfone resin, 20 parts of pigment, 18 parts of filler, leveling agent 0.6 parts, 10 parts of curing agent. The filler includes the following raw materials in parts by mass: 8 parts of nanoclay, 15 parts of graphene, 4 parts of cermet particles, 10 parts of nano silicon dioxide and 3 parts of carbon black.

[0030] The preparation method of above-mentioned a kind of powder coating for building material, comprises the following steps:

[0031] (1) Ingredients: prepare the following raw materials in parts by mass, 56 parts of epoxy resin, 38 parts of polyester resin, 22 parts of polyethersulfone resin, 20 parts of pigment, 18 parts of filler, 0.6 part of leveling agent, and 10 parts of curing agent . The filler includes the following raw materials in parts by mass: 8 parts of...

Embodiment 2

[0045] This embodiment discloses a powder coating for building materials, including the following raw materials in parts by mass: 54 parts of epoxy resin, 35 parts of polyester resin, 20 parts of polyethersulfone resin, 20 parts of pigment, 18 parts of filler, leveling agent 0.8 parts, 10 parts of curing agent. The filler includes the following raw materials in parts by mass: 10 parts of nanoclay, 15 parts of graphene, 5 parts of cermet particles, 10 parts of nano silicon dioxide and 4 parts of carbon black. Wherein the pigments include organic pigments and inorganic pigments, the organic pigments are selected from bright red, and the inorganic pigments are selected from iron oxide red.

[0046] The preparation method of above-mentioned a kind of powder coating for building material, comprises the following steps:

[0047] (1) Ingredients: Prepare the following raw materials in parts by mass, 54 parts of epoxy resin, 35 parts of polyester resin, 20 parts of polyethersulfone r...

Embodiment 3

[0053] This embodiment discloses a powder coating for building materials, including the following raw materials in parts by mass: 52 parts of epoxy resin, 35 parts of polyester resin, 25 parts of polyethersulfone resin, 22 parts of pigment, 16 parts of filler, and leveling agent 0.6 parts, 12 parts of curing agent. The filler includes the following raw materials in parts by mass: 8 parts of nanoclay, 16 parts of graphene, 6 parts of cermet particles, 12 parts of nano silicon dioxide and 4 parts of carbon black. The pigments include organic pigments and inorganic pigments, the organic pigments are phthalocyanine blue and phthalocyanine green, and the inorganic pigments are iron oxide yellow.

[0054] The preparation method of above-mentioned a kind of powder coating for building material, comprises the following steps:

[0055] (1) Ingredients: prepare the following raw materials in parts by mass, 52 parts of epoxy resin, 35 parts of polyester resin, 25 parts of polyethersulfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com