Patents

Literature

104results about How to "Play a role in toughening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyphenylene oxide composition used for photovoltaic junction box

ActiveCN102399433AImprove liquidityGuaranteed toughnessHazardous substanceComparative Tracking Index

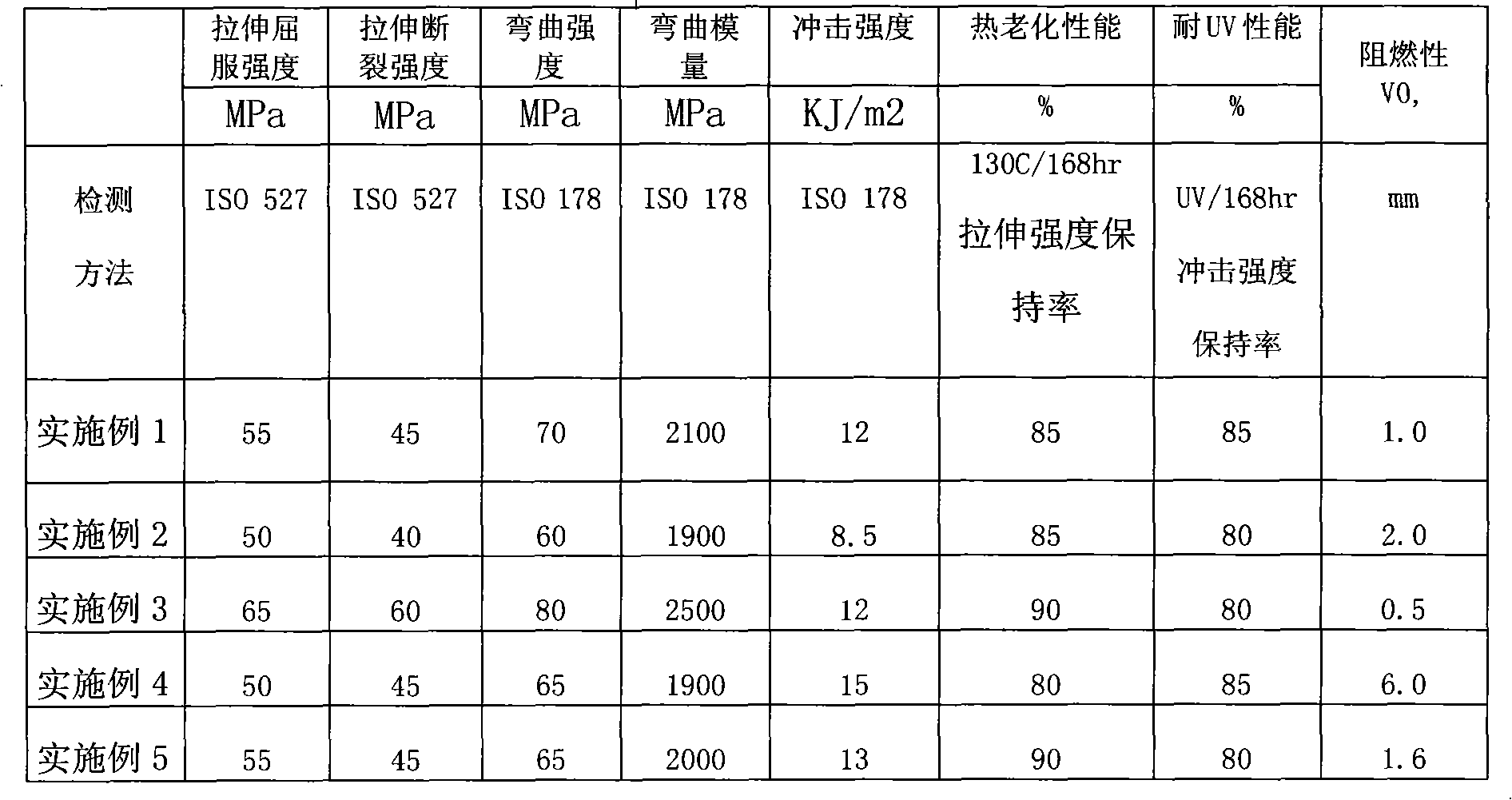

The invention provides a polyphenylene oxide composition used for a photovoltaic junction box. The composition comprises the following components by weight: 55-95 parts of polyphenylene oxide, 45-5 parts of styrene resin, 2-10 parts of a flexibilizer, 5-20 parts of a phosphate fire retardant, 0.5-2.5 parts of an acid absorbent, 0.2-0.6 part of a hindered phenol main antioxidant, 0.2-0.6 part of a phosphite auxiliary antioxidant, 0.3-1.5 parts of an ultraviolet absorbent, 0.3-1.5 parts of a hindered amine light stabilizer, 0.1-0.5 part of a lubricating agent, and 0.1-1.0 part of toner. With the characteristics of good flame resistance, thermo-oxidative aging resistance, UV (ultraviolet) resistance, excellent electrical performances, the composition of the invention has flame retardancy up to grade UL945VA, RTI (relative temperature index)=110DEG C, CTI (comparative tracking index) PLC ( programmable logic controller)=2, and GWIT (glow wire ignition temperature)=750DEG C, thus satisfying the requirements in ROHS (restriction of hazardous substances) standard. Thus, the composition provided in the invention can be used for electronic and electrical component production of solar photovoltaic junction boxes, etc.

Owner:广东瑞能新材料有限公司

Paper making material, preparation method and paper making method of environment-friendly synthetic paper

ActiveCN101760990AImprove stabilityImprove heat resistanceNon-fibrous pulp additionSpecial paperFiberBlow molding

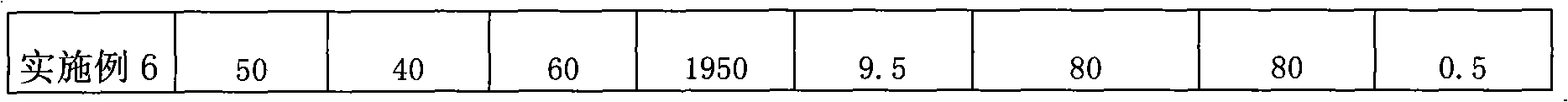

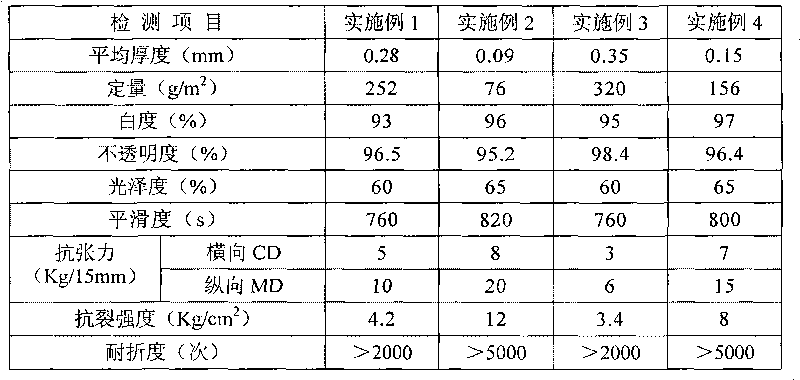

The invention relates to a paper making material, a preparation method and a paper making method of environment-friendly synthetic paper. The material comprises modified mineral fiber, thermoplastic starch, cellulose derivative, compatilizer, auxiliary components and the like, wherein the average particle diameter of the modified mineral fiber is 5-10 micrometers, the ratio of the length of the modified mineral fiber to the diameter of the modified mineral fiber is 8-15:1, and the modified mineral fiber is treated by fibrosis ultrafine grinding and surface recombination modification; the thermoplastic starch is formed by performing micronization and plasticization modification on norm starch; and the auxiliary components comprise lubricant and colorant. The paper making material is prepared by sequentially mixing the raw material components fully and then extruding and granulating the mixture by a screw extruder at 60-180 DEG C. According to the plastic process mode, the material can be treated by blow molding through a calender or a paper film machine for carrying out two-way stretch to prepare corresponding paper products. The paper making material can overcome the defects of the current synthetic paper and can be widely applied to the fields of commercial printing, publications, office paper, packing and the like, and the processing procedure of making paper by using plastic processing equipment has environmental protection and low cost.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

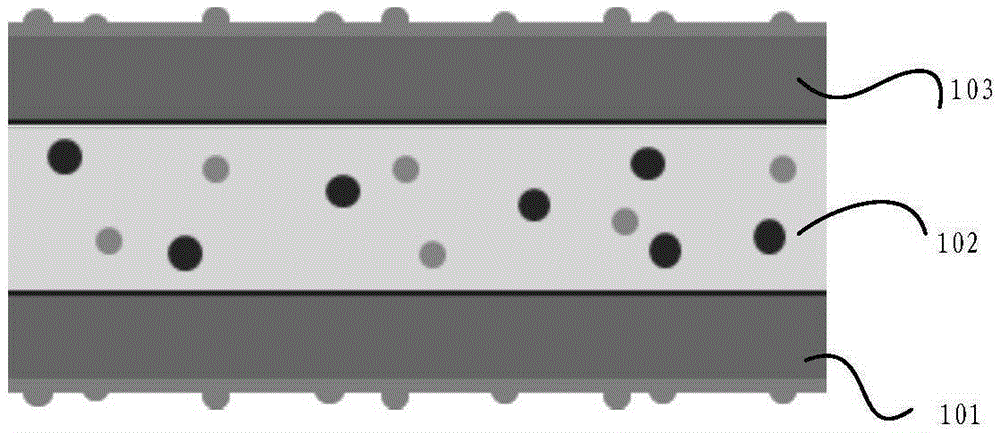

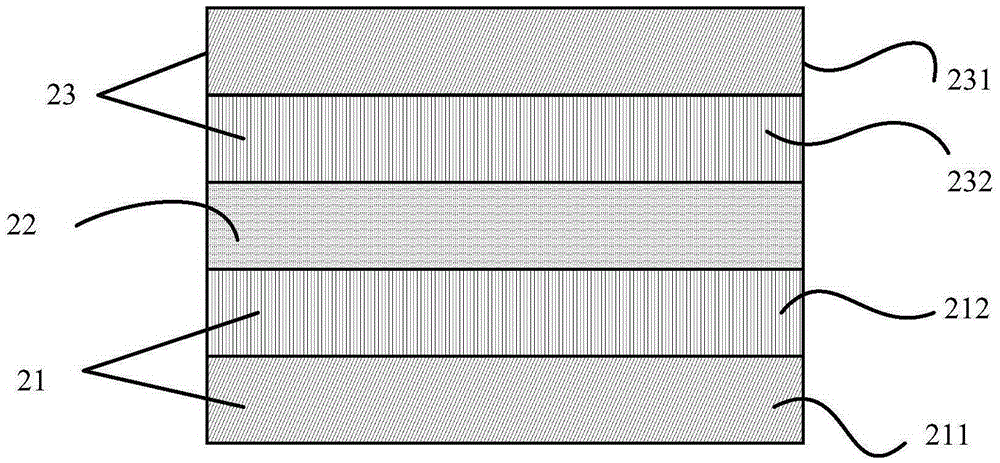

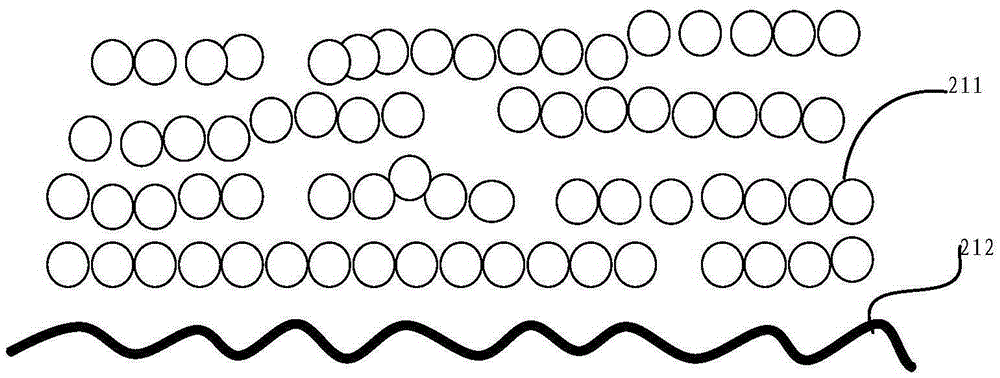

Display device, backlight module, quantum dot optical diaphragm and preparation method thereof

InactiveCN105425463ARepair scratchesEliminate failure areasNon-linear opticsPolyethylene terephthalateDisplay device

The invention discloses a display device, a backlight module, a quantum dot optical diaphragm and a preparation method thereof. The quantum dot optical diaphragm comprises a quantum dot layer, a first composite water oxygen barrier layer which covers the surface of the light inlet side of the quantum dot layer and a second composite water oxygen barrier layer which covers the surface of the light outlet side of the quantum dot layer; the first composite water oxygen barrier layer and the second composite water oxygen barrier layer are each selected from one or a combination of any two of a first film structure, a second film structure and a third film structure, wherein the first film structure is the composite water oxygen barrier layer which is composed of polyethylene terephthalate (PET) and graphene, the second film structure is a graphene layer, and the third film structure is the water oxygen barrier layer which is composed of PET and aluminum oxide. Compared with the prior art, the water oxygen barrier property, the photopermeability and the structural stability of the quantum dot optical diaphragm are obviously improved.

Owner:HISENSE VISUAL TECH CO LTD

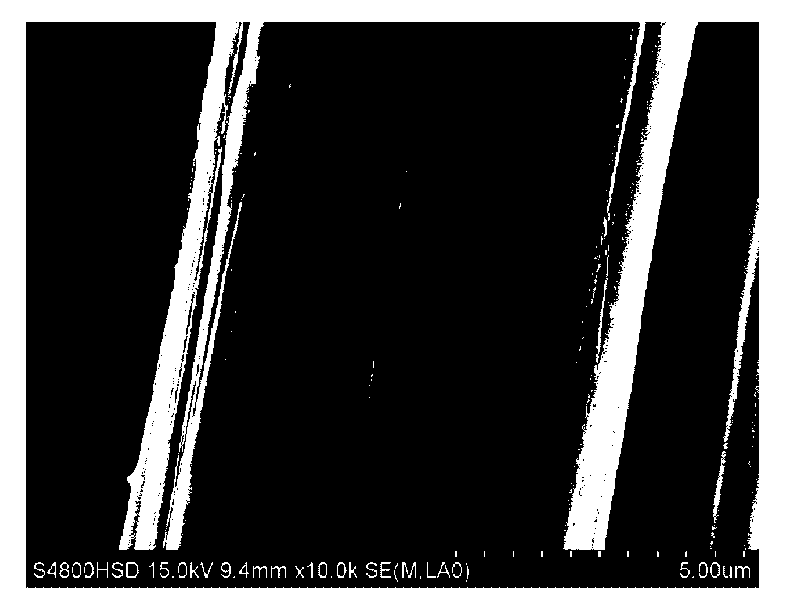

Method for modifying carbon fibers by dendritic macromoleculars

InactiveCN101709542AUnique rheological propertiesGood groomingPhysical treatmentCarbon fibresFiberEpoxy

The invention provides a method for modifying carbon fibers by dendritic macromoleculars, relating to a method for modifying the carbon fibers and aiming at solving the problem of poor stability due to that only one functional group of organic silicon compound can react with the fiber modified surface so as to limit a membrane in a bidimensional surface. The method comprises the following steps: adding carbon fibers in a strong oxidizing acid, utilizing ultrasonic for processing, heating and refluxing, drying, adding into dendritic macromolecular solution for ultrasonic processing once again, reacting under the temperature of 20-100 DEG C, washing and drying to obtain the carbon fibers modified by the dendritic macromoleculars. The dendritic macromoleculars used in the invention have the advantages of tri-dimensional structure, evenly-distributed and thick outer functional groups, lower viscosity, unique flowing deformation property, good film forming property and favorable modified effect. The epoxy resin composite material prepared by using the carbon fibers modified by the dendritic macromoleculars obtained in the invention has 53.2-55.8MPa of interface shearing strength.

Owner:HARBIN INST OF TECH

Friction material for brake block of heavy-duty automobile

InactiveCN106147124AImprove stress resistanceImprove impact resistanceOther chemical processesFriction liningAcrylic rubberHeat stability

The invention discloses a friction material for a brake block of a heavy-duty automobile. The friction material is prepared from, by weight, 20-35 parts of phenolic resin, 2-5 parts of acrylic rubber, 3-8 parts of amph-POSS, 2-8 parts of quartz fibers, 10-20 parts of high silica fibers, 3-10 parts of silica fibers, 3-12 parts of aluminum borate whiskers, 3-10 parts of basic magnesium sulfate whiskers, 20-35 parts of nano-palygorskite, 15-35 parts of barium carbonate, 3-10 parts of aluminum powder, 3-10 parts of nano powdered carbon, 5-15 parts of boron nitride, 3-12 parts of emery powder, 2-6 parts of vermiculite, 0.5-5 parts of mica, 3-5 parts of molybdenum trioxide, 2-6 parts of natural graphite, 2-10 parts of micron zirconia balls and 2-8 parts of graphene oxide. The friction material for the brake block of the heavy-duty automobile has excellent high temperature resistance, wear resistance and heat stability and is used for the brake block of the heavy-duty automobile, and is good in braking performance and long in service life.

Owner:WUHU DONGZHENG AUTOMOTIVE IND

Wear-proof brake pad

ActiveCN106015411AImprove toughnessImprove wear performanceOther chemical processesFriction liningSodium titanateAramid

The invention discloses a wear-proof brake pad. The wear-proof brake pad comprises a steel plate, a thermal-insulating layer and a friction block. The friction block is fixed to the steel plate through the thermal-insulating layer. The raw materials of the friction block comprise, by weight, 10-20 parts of phenolic resin, 3-12 parts of nitrile rubber, 2-10 parts of butadiene rubber, 5-10 parts of carbon fiber, 3-8 parts of aramid fiber, 2-5 parts of glass fiber, 10-30 parts of potassium titanate lamella crystals, 5-20 parts of iron sodium titanate lamella crystals, 20-40 parts of barium sulfate, 2-5 parts of nano-silica, 2-5 parts of sepiolite, 2-8 parts of alumina powder, 0.2-1.5 parts of accelerant D, 0.1-0.5 part of zinc oxide, 1-4 parts of vermiculite powder, 2-5 parts of petroleum coke, 1-5 parts of synthetic graphite and 3-10 parts of bamboo charcoal. The wear-proof brake pad is excellent in wear resistance and impact resistance, good in heat resistance and small in curing shrinkage.

Owner:WUHU DONGZHENG AUTOMOTIVE IND

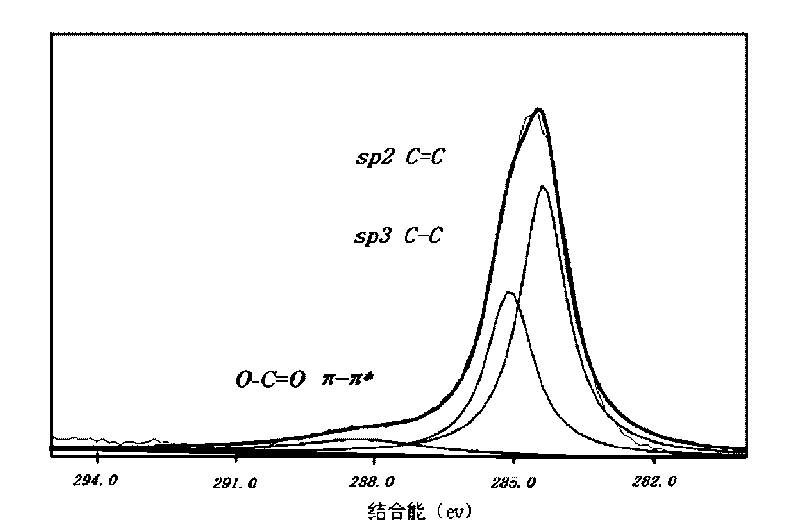

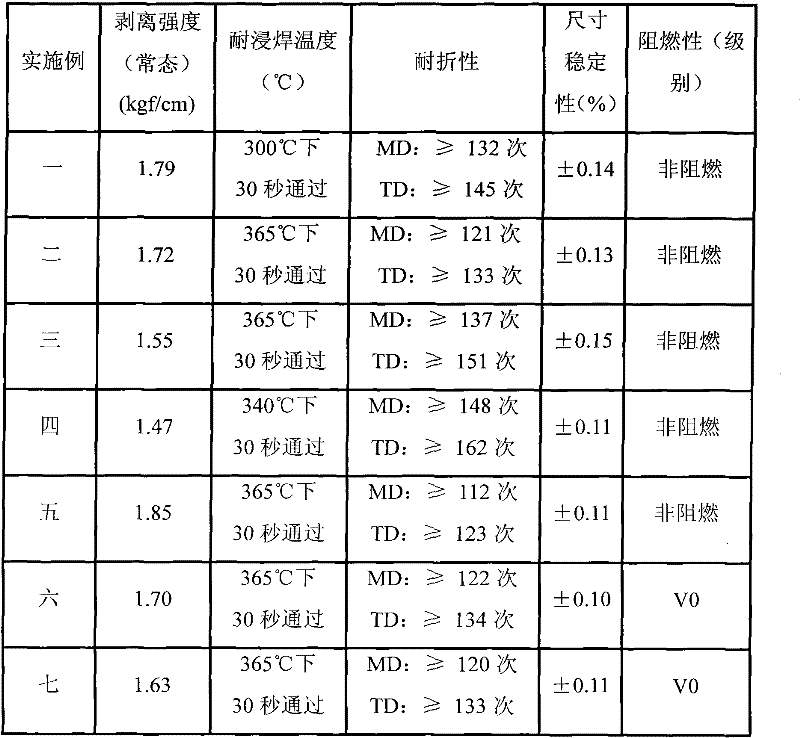

Modified epoxy resin adhesive used for polyimide flexible copper-clad plate

InactiveCN102199413APlay a role in tougheningImprove heat resistanceEpoxynovolac adhesivesMetal layered productsEpoxyOrganic solvent

The invention relates to an epoxy resin adhesive modified by bismaleimide and liquid butadiene nitrile rubber, and a method for manufacturing a polyimide flexible copper-clad plate using the adhesive. The adhesive is composed of a bismaleimide copolymer, liquid rubber-modified epoxy resin, unmodified epoxy resin, filler, a curing agent and an organic solvent. The adhesive can be used for manufacturing a three-layer flexible copper-clad plate composed of a polyimide thin film, the adhesive and a copper foil, and the dip-soldering resisting temperature of the obtained copper-clad plate can reach 365 DEG C.

Owner:ZHOUSHAN WEITE NEW MATERIAL TECH

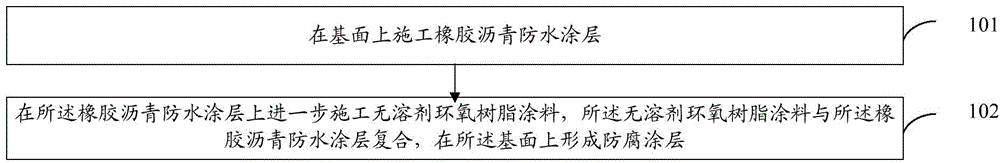

Construction method of novel anticorrosive coating layer

ActiveCN104945991AIncrease shear forceDoes not cause swellingUnspecified rubber coatingsAnti-corrosive paintsSolvent freeResin coating

The invention provides a construction method of a novel anticorrosive coating layer. The method comprises the following steps: constructing a rubber asphalt waterproof coating layer on a base surface; and further constructing a solvent-free epoxy resin coating on the rubber asphalt waterproof coating layer, and compounding the solvent-free epoxy resin coating with the rubber asphalt waterproof coating layer in order to form the anticorrosive coating layer on the base surface. The solvent-free epoxy resin coating comprises a component A and a component B; the component A comprises epoxy resin, an epoxy active diluent, an additive, a filler and a pigment; the component B comprises modified polyamine; the epoxy active diluent is at least one of dodecyl glycidyl ether, 1,4-butanediol diglycidyl ether and ethylene glycol diglycidyl ether; the additive comprises at least one of a leveling agent, a rheological assistant, a dispersant, a substrate wetting agent, an antifoaming agent and an ultraviolet ray absorber; and the filler comprises titanium dioxide, talcum powder, wet sericite powder, wollastonite powder and ceramic powder.

Owner:YUGREAT (BEIJING) INTERNATIONAL TECHNOLOGY CO LTD

Short glass fiber reinforced polyphenylene sulfide resin material and preparation method thereof

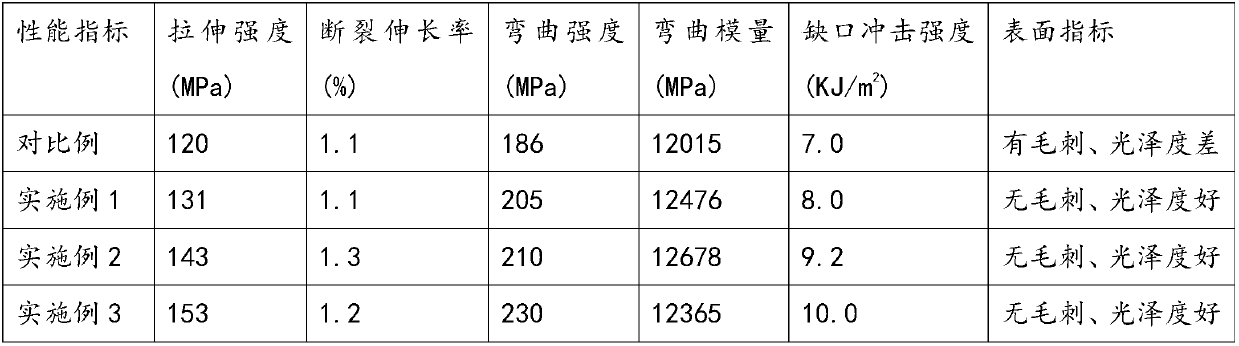

The invention discloses a short glass fiber reinforced polyphenylene sulfide resin material and a preparation method thereof. The short glass fiber reinforced polyphenylene sulfide resin material comprises the following raw materials in percentage by weight: 45-66.2% of polyphenylene sulfide, 30-45% of short glass fibers, 0.3-0.5% of an antioxidant, 0.5-1.5% of a lubricating agent and 3-8% of a compatilizer. According to a synergistic effect of the compatilizer and the lubricating agent, the short glass fibers are prevented from floating out of the surface during processing, and the problems that burrs easily appear on the polyphenylene sulfide surface and the glossiness is poor are effectively solved. Meanwhile, the mechanical property of the polyphenylene sulfide is improved, and the prepared short glass fiber reinforced polyphenylene sulfide resin material is high in appearance quality.

Owner:姜希猛

MPP power cable protecting tube

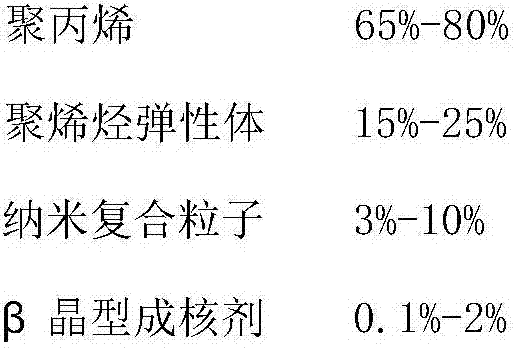

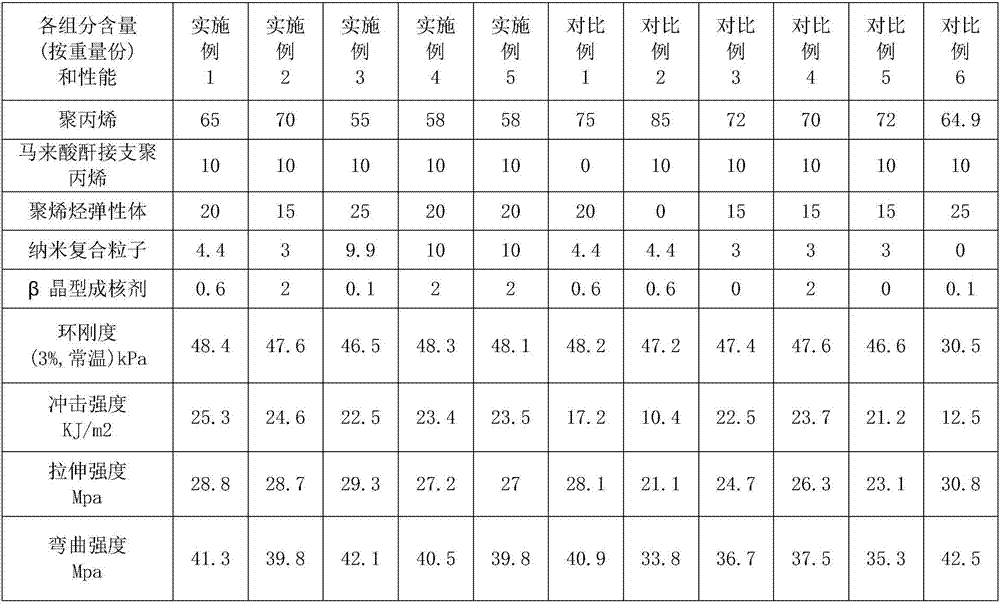

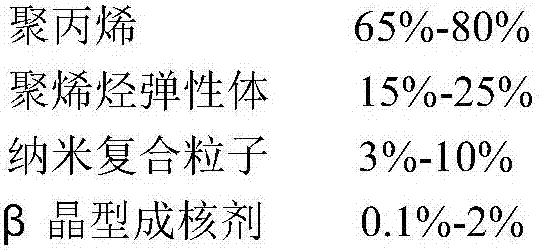

InactiveCN107540930APlay a role in tougheningImprove mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

The invention discloses an MPP power cable protecting tube. The MPP power cable protecting tube is prepared from modified polypropylene, wherein the modified polypropylene comprises the following components in percentage by mass: 65-80% of polypropylene, 15-25% of polyolefin elastomer, 3-10% of nano composite particle and 0.1-2% of beta crystal nucleating agent, wherein the nano composite particleis a calcium carbonate particle of which the surface a silicon dioxide particle adheres to. The MPP power cable protecting tube has the following advantages and effects: by using a multielement blended system formed by the polypropylene, the polyolefin elastomer and the nano composite particle, the polyolefin elastomer has a toughening effect on the polypropylene; the nano composite particle combines the effects of the silicon dioxide particle and the calcium carbonate particle, thereby improving the tensile strength, impact strength and ring stiffness of the modified polypropylene, and achieving a further toughening effect; and after the beta crystal nucleating agent is added, the beta crystal nucleating agent and the calcium carbonate particle achieve a synergistic effect, so that the polypropylene changes from the alpha crystal form to the beta crystal form, and the impact property of the modified polypropylene is further improved, thereby improving the comprehensive properties ofthe MPP power cable protecting tube prepared from the modified polypropylene.

Owner:SHAOXING RENTONG PLASTIC CO LTD

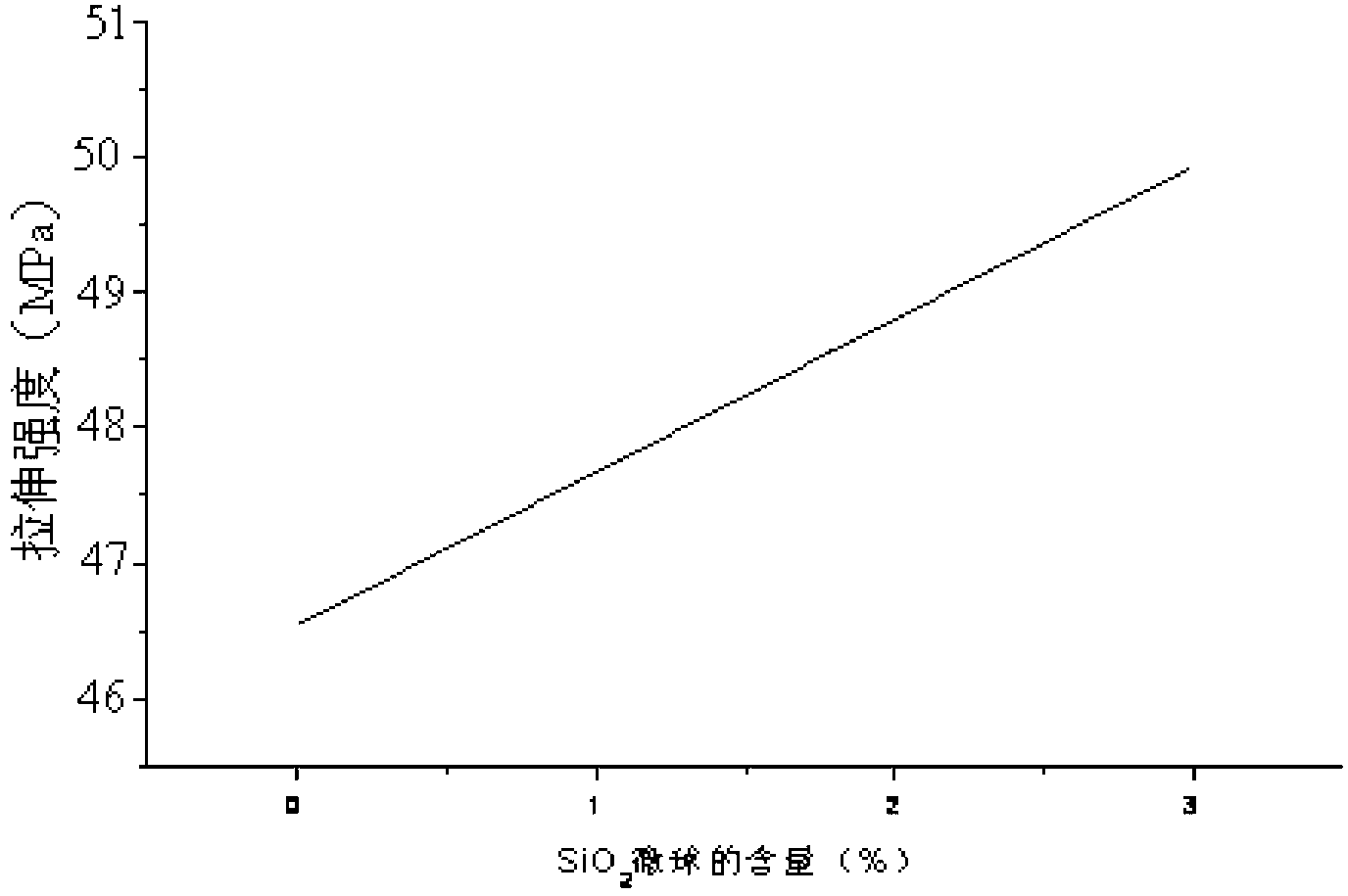

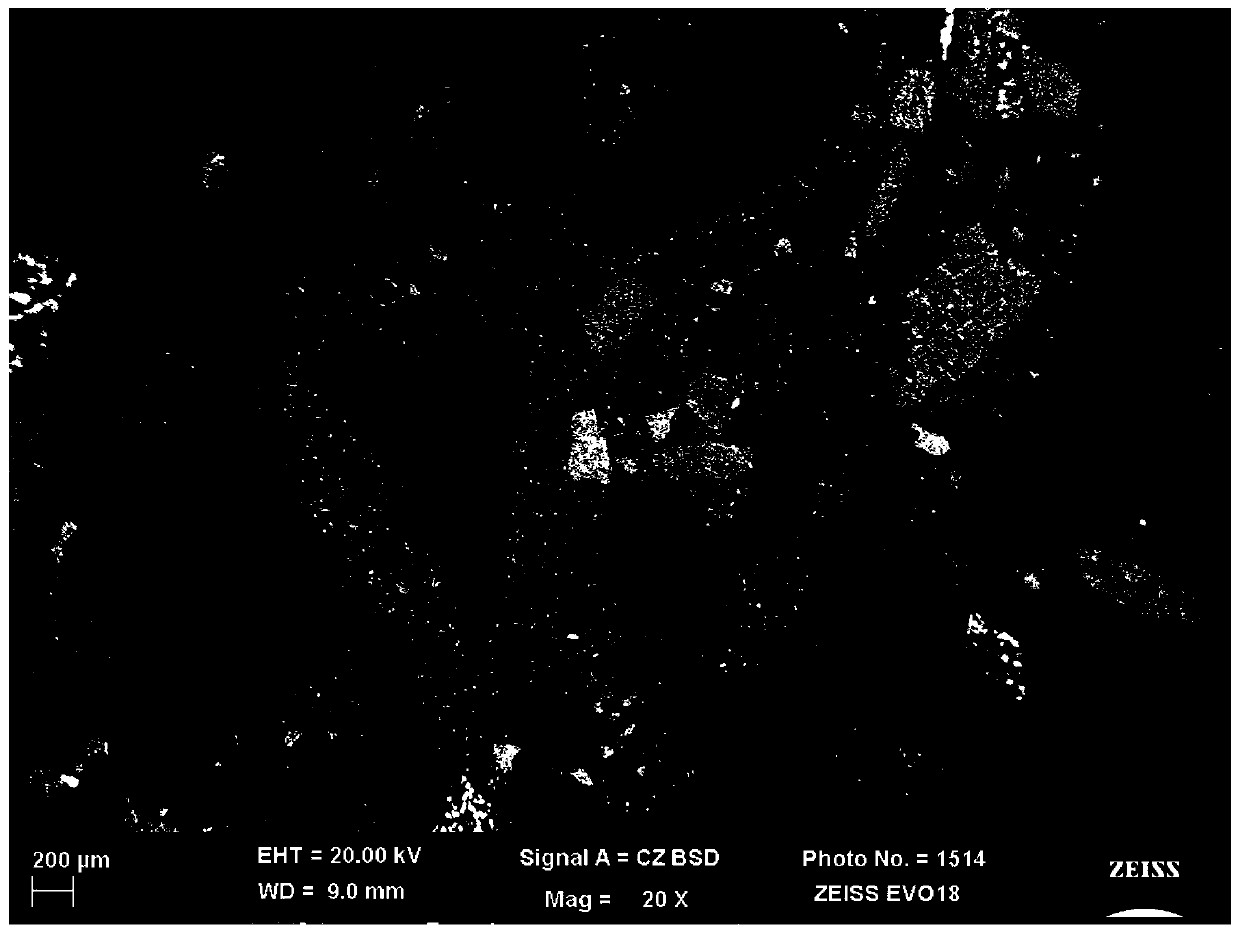

Preparation method of SiO2/ABS (acrylonitrile-butadiene-styrene) composite material

The invention relates to a preparation method of a SiO2 / ABS (acrylonitrile-butadiene-styrene) composite material. The invention aims to solve the technical problems of unfavorable effects of reinforcement, toughening and comprehensive property improvement on the ABS resin in the existing modified ABS resin. The method comprises the following steps: 1. preparing an SiO2 seed solution; 2. preparing a SiO2 colloid microsphere sol solution; 3. preparing sedimentary SiO2 colloid microspheres; 4. preparing dry SiO2 colloid microspheres; 5. preparing a blend; and 6. preparing the SiO2 / ABS composite material. The SiO2 microspheres in the SiO2 / ABS composite material have favorable dispersion effect, can achieve the goal of reinforcement and have the action of toughening, and obviously enhance the mechanical properties of the composite material; and the SiO2 / ABS composite material has high thermal weight loss and favorable heat stability. The invention is applied to the field of preparation of composite materials.

Owner:HEILONGJIANG UNIV

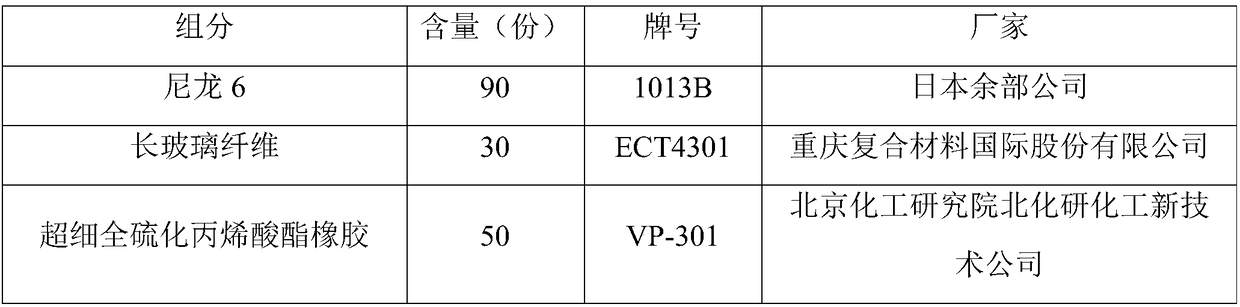

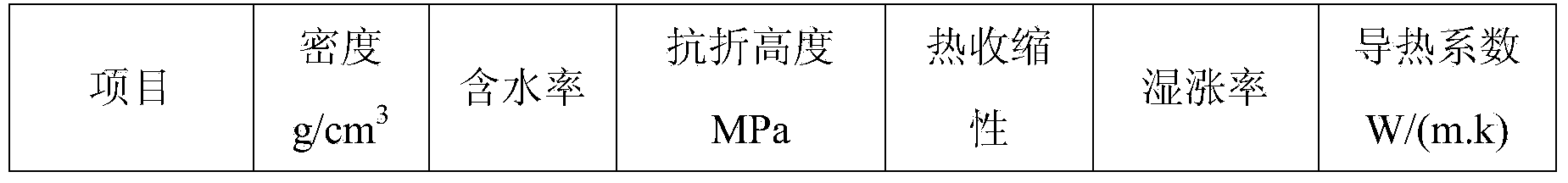

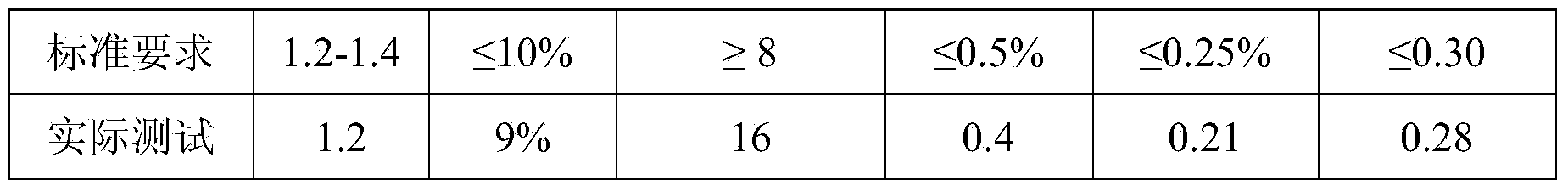

Heat-resistant long glass fiber enhanced nylon composite material and preparation method thereof

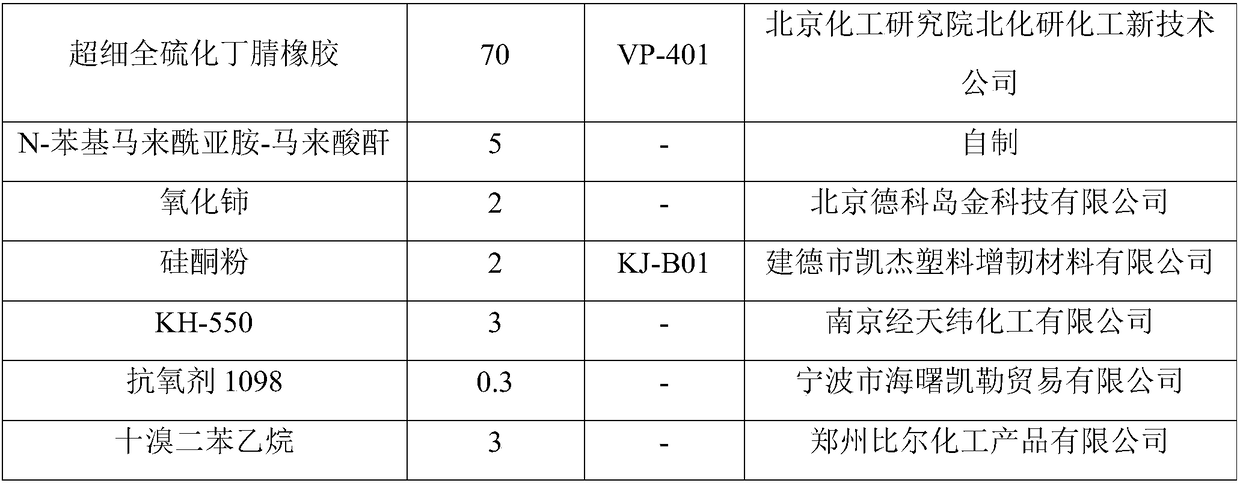

The invention provides a heat-resistant long glass fiber enhanced nylon composite material and a preparation method thereof. The heat-resistant long glass fiber enhanced nylon composite material is prepared from the following components of nylon 6, long glass fiber, superfine fully-vulcanized powdered rubber, N-phenylmaleimide-maleic anhydride, rare earth oxide, a lubricant, a coupling agent, an antioxidant and a flame-retardant agent through melting blending and double-screw extruding. The heat-resistant long glass fiber enhanced nylon composite material has the advantage that under the synergistic action of the superfine fully-vulcanized powdered rubber, the N-phenylmaleimide-maleic anhydride and the rare earth oxide, the heat-resistant property of the nylon composite material is obviously improved, so that the nylon composite material can be well applied to the preparation of automobile components and parts, instrument and meter parts, electromechanical components and parts, and electronic elements.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

High-temperature-resistant brake pad

InactiveCN106117965AImprove toughnessImprove heat resistanceOther chemical processesFriction liningCarbon fibersTalc

The invention discloses a high-temperature-resistant brake pad. The high-temperature-resistant brake pad comprises a steel plate, a thermal insulation layer and a friction block, wherein the friction block is prepared from a phenol-formaldehyde resin composite, the phenol-formaldehyde resin composite is prepared from raw materials in parts by weight as follows: 15-30 parts of phenol-formaldehyde resin, 3-10 parts of epoxy resin, 3-10 parts of organic silicon resin, 5-10 parts of carbon fibers, 3-10 parts of aramid fibers, 2-8 parts of quartz fibers, 12-30 parts of potassium magnesium titanate lamellas, 5-15 parts of sodium iron titanate lamellas, 15-30 parts of ferrotitanium powder, 2-10 parts of corundum powder, 3-10 parts of barite powder, 2-8 parts of aluminum powder, 1-3 parts of talc powder, 1-5 parts of iron oxide, 2-8 parts of zirconium dioxide, 2-8 parts of petroleum coke, 1-3 parts of natural graphite, 2-5 parts of bamboo charcoal and 2-5 parts of graphene. The provided high-temperature-resistant brake pad has excellent high-temperature resistance, good impact resistance and heat stability, high wear resistance, small thermal expansivity and long service life.

Owner:WUHU DONGZHENG AUTOMOTIVE IND

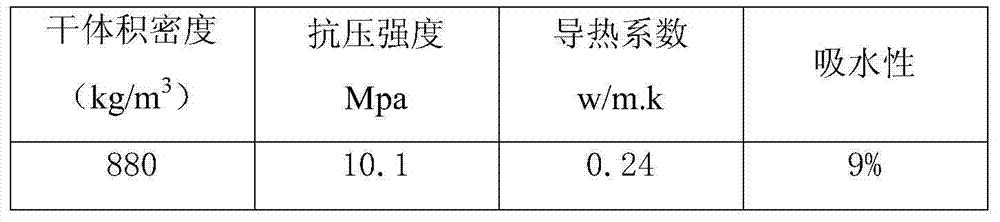

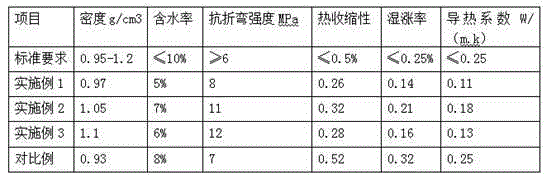

Method for producing calcium silicate board by utilizing papermaking white clay and quartz stone wastes

The invention discloses a method for producing a calcium silicate board by utilizing papermaking white clay and quartz stone wastes. The method comprises the following steps: taking out the quartz stone wastes, sieving and filter-pressing to obtain quartz stone waste powder; mixing and forming the papermaking white clay, the quartz stone wastes, high-early-strength silicate cement, high-strength alumina fiber, a water reducing waterproof agent and water, demoulding and naturally curing to obtain the calcium silicate board. The method has the benefits that by utilizing a large quantity of industrial wastes, the environmental load and the manufacturing cost of wall materials are reduced, a large quantity of building materials are saved, the cultivated land is protected, the double effects of controlling the environmental pollution and comprehensively and efficiently utilizing the wastes are achieved, so that the sustainable development of the papermaking industry and the wall material industry is promoted; the wall materials prepared by the method have better rupture strength, good heat insulation property, small density and light self-weight.

Owner:SHANDONG JIANZHU UNIV

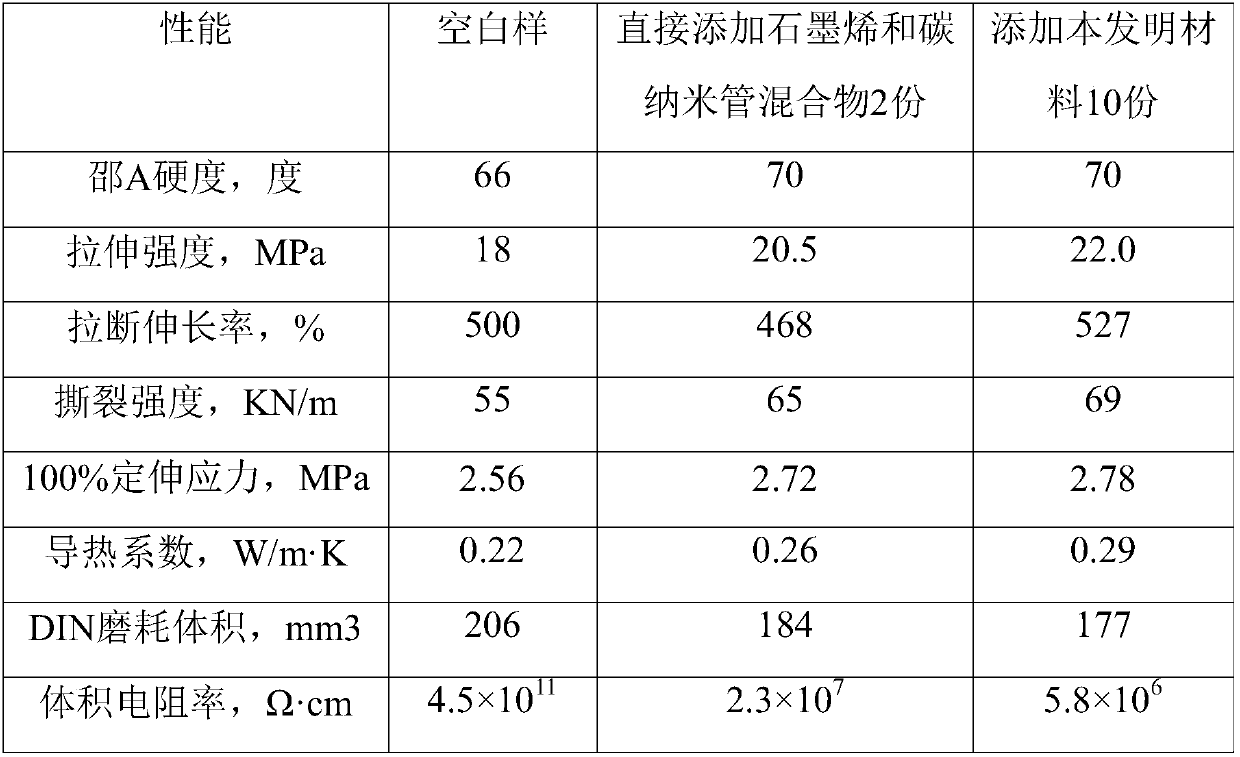

Modified composite material using carbon nanotubes and graphene and preparation method thereof

The invention discloses a modified composite material using carbon nanotubes and graphene and a preparation method thereof, and belongs to the technical field of a rubber product. In the formula, methacrylic acid is firstly added into the graphene and the carbon nanotubes for acidification modification; then, zinc oxide is added for ionization reaction; the in-situ generation of zinc methacrylateis realized; then, liquid rubber and peroxide initiating agents are added; the zinc methacrylate is initiated for performing co-crosslinking with the liquid rubber after the copolymerization; the surface adsorption wrapping modification and the surface chemical modification on the graphene and the carbon nanotubes are realized, so that the carbon nanomaterial surface has high chemical activity; good bonding force between a carbon nanomaterial and a polymer base body is ensured; the dispersion degree of the carbon nanomaterial in the polymer base body is improved; further, after the composite material is formed, the load can be smoothly transferred onto the carbon nanomaterial; the carbon nanomaterial achieves the enhancing and toughening effects; the heat conduction and electric conductionperformance of the modified composite material are obviously improved.

Owner:青岛泰歌新材料科技有限公司

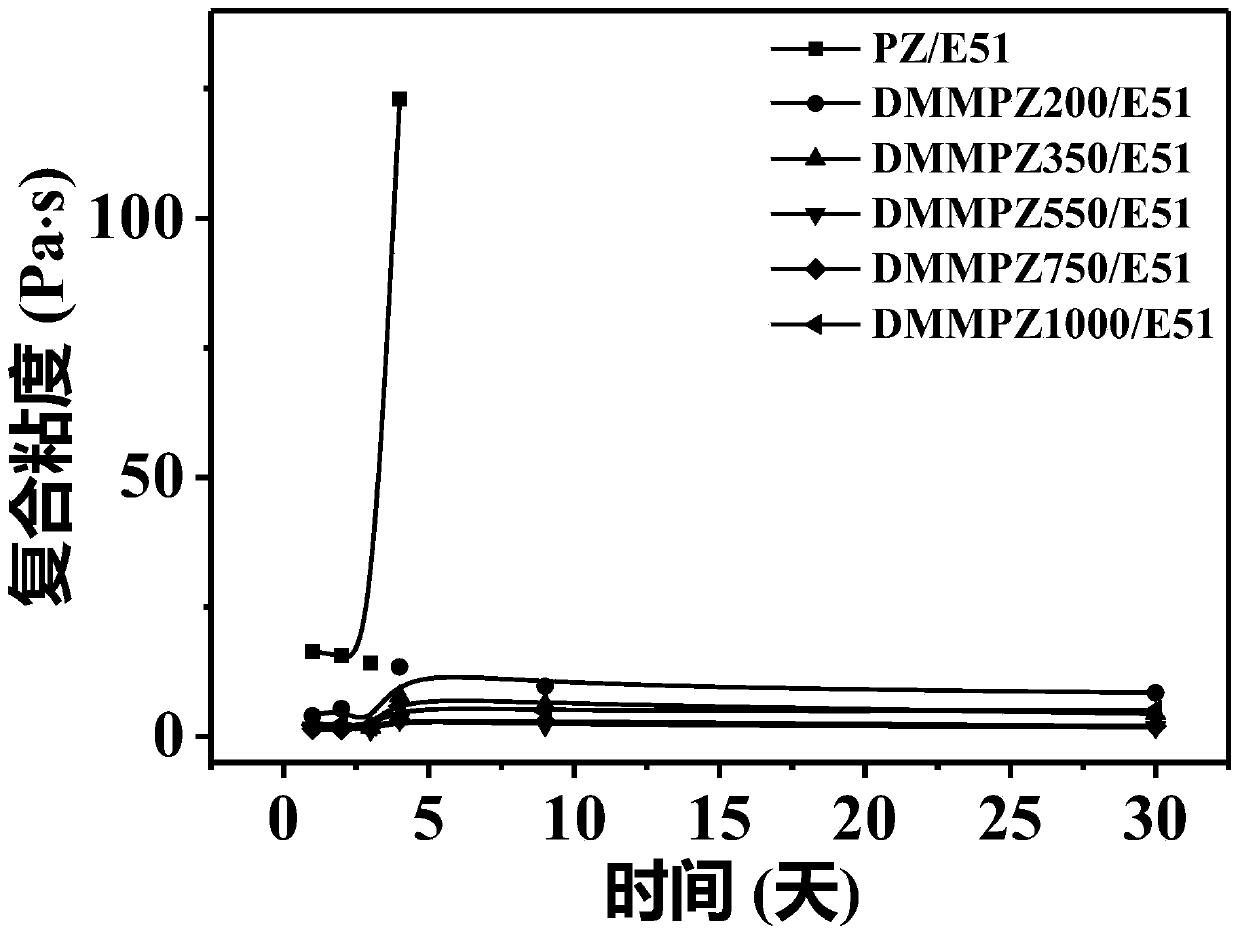

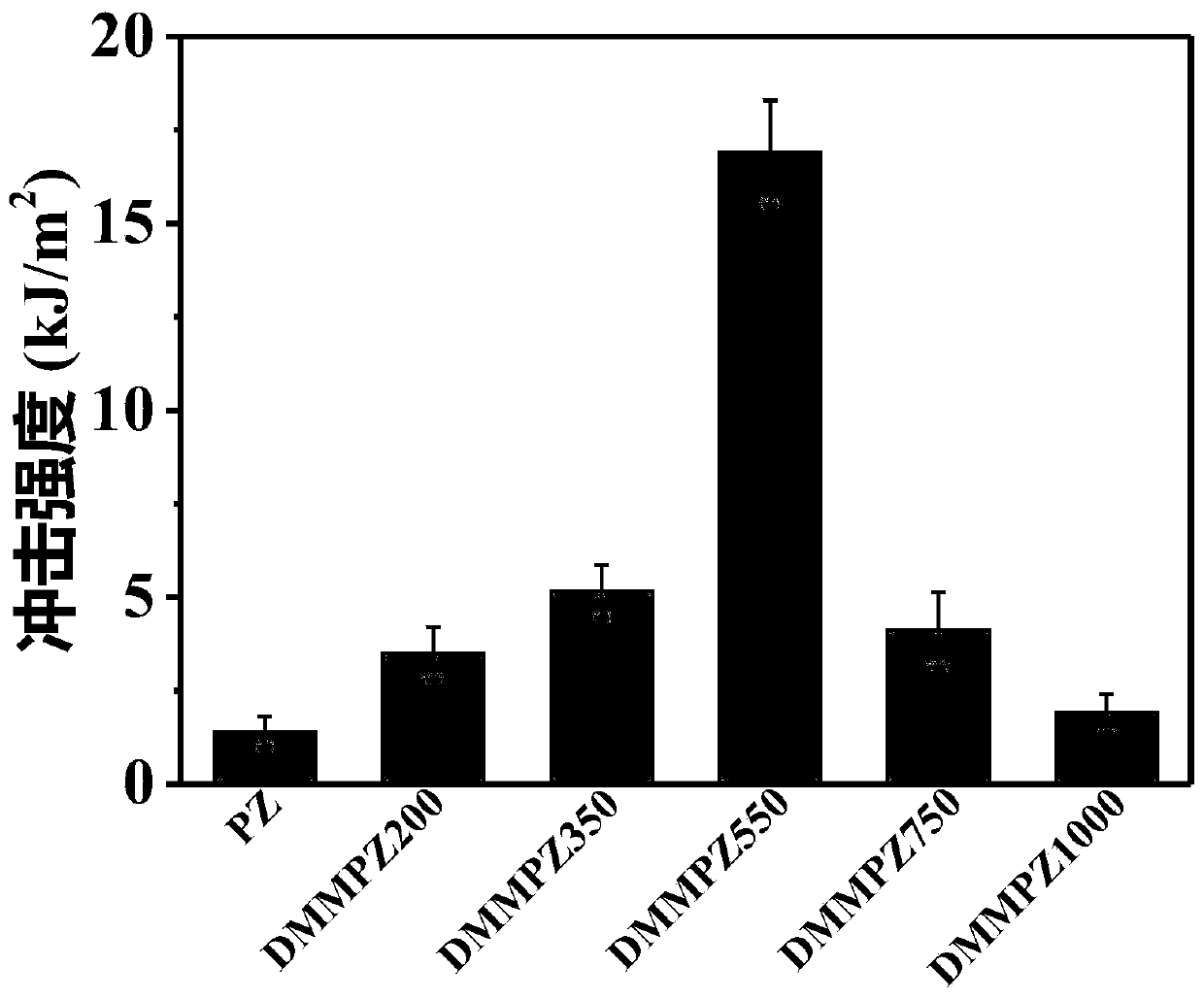

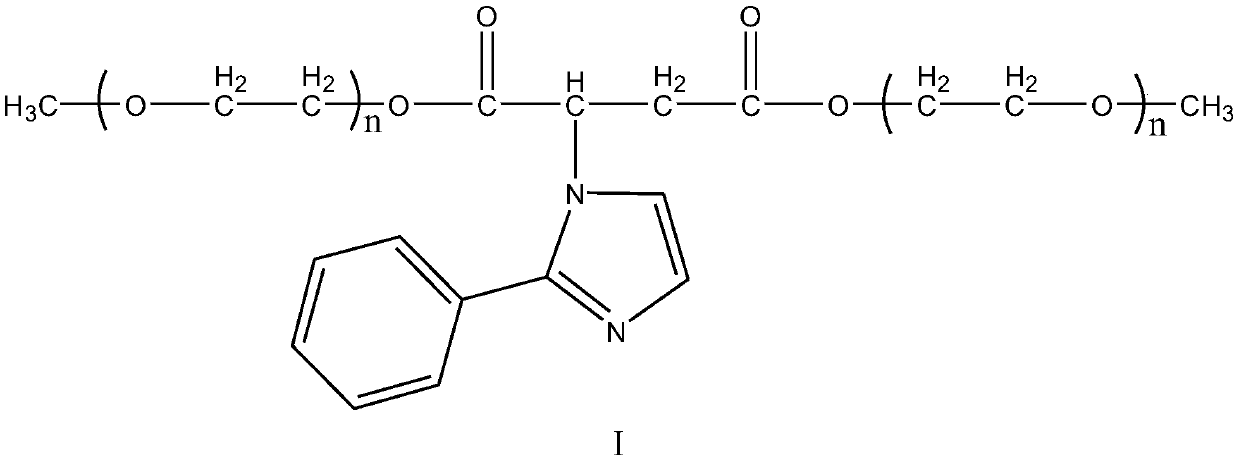

Latent curing agent capable of toughening imidazole epoxy resin, and preparation method thereof

The invention discloses a latent curing agent capable of toughening imidazole epoxy resin. The curing agent has the advantages of long working life, good latent stability at a low temperature, long storage period at room temperature, high curing rate a high temperature, and realization of toughening of epoxy cured products. The structure of the latent curing agent capable of toughening imidazole epoxy resin is represented by formula I; and n in the formula I is 4-22.

Owner:NANJING TECH UNIV +1

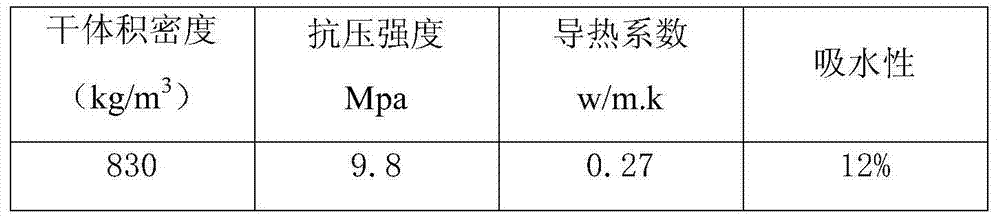

Method for producing light-weight wall material by using papermaking white clay

The invention relates to a method for producing a light-weight wall material by using papermaking white clay. The method comprises the steps of preparing the following components in percentage by mass: 60-70% of papermaking white clay, 5-10% of zirconium-silicate slag, 20-30% of Portland cement and 1-5% of an enhanced water-releasing agent and mixing uniformly, preparing into concrete slurry having a required flowability, curing and molding, wherein the enhanced water-releasing agent is a mixed solution prepared by dissolving 4-5 parts of sodium sulfate, 7-8 parts of triethanolamine, 15-18 parts of saccharide sodium, 25-30 parts of sodium methyl sulfonate and 40-45 parts of calcium lignin sulfonate in water. The wall material prepared by the method disclosed by the invention has the advantages of good compressive strength, good heat insulation property, low density and light self-weight.

Owner:SHANDONG JIANZHU UNIV +1

Converter slag-stopping sliding plate brick added with titanium nitride composite powder and preparation method of converter slag-stopping sliding plate brick

InactiveCN110922173ASimple compositionImprove wear resistanceManufacturing convertersSteelmakingBreaking strength

The invention discloses a converter slag-stopping sliding plate brick added with titanium nitride composite powder and a preparation method of the converter slag-stopping sliding plate brick, and belongs to the technical field of refractory materials. The converter slag stopping sliding plate brick comprises a granular material, composite powder and an additive, wherein the granular material comprises high-hardness materials with various particle sizes, the composite powder comprises titanium nitride powder and other antioxidant powder materials, the additive comprises a high-melting-point material, and the addition amount of the additive is 1.5-4.5% of the total mass of the granular material and the composite powder. The titanium nitride composite powder converter slag-stopping sliding plate brick is prepared through the processes of mixing, forming, drying, grinding and the like. The converter slag-stopping sliding plate brick prepared by the invention is short and simple in production process period, is free of firing and oil soaking, energy-saving and environment-friendly, has good high-temperature strength and breaking strength in use, also has good thermal shock resistance and wear resistance, has relatively high chemical erosion resistance in a high-temperature tapping process, and can meet efficient production and safe use of converter steelmaking.

Owner:MAANSHAN LIER KAIYUAN NEW MATERIAL

Zirconium-containing alumina hollow sphere insulating brick and preparation method thereof

The invention relates to a zirconium-containing alumina hollow sphere insulating brick. The insulating brick comprises the following components in percentage by mass: 40-69% of alumina hollow spheres,21-46% of alumina micro powder and 5-14% of zirconium-containing powder, wherein the sum is 100%. Extra components in percentage by weight are added, and a calculation basis of the addition amount isa ratio of the sum of the weight of the previous components to a binding agent of 8.5-12%. The condition that the traditional zirconium-containing alumina hollow sphere insulating brick is single inmain composition is improved, the matrix toughness is increased, and the characteristics of the material such as strength, thermal shock resistance and the like are improved, so that the service lifeof the insulating brick is prolonged.

Owner:LUOYANG LIER REFRACTORY MATERIAL

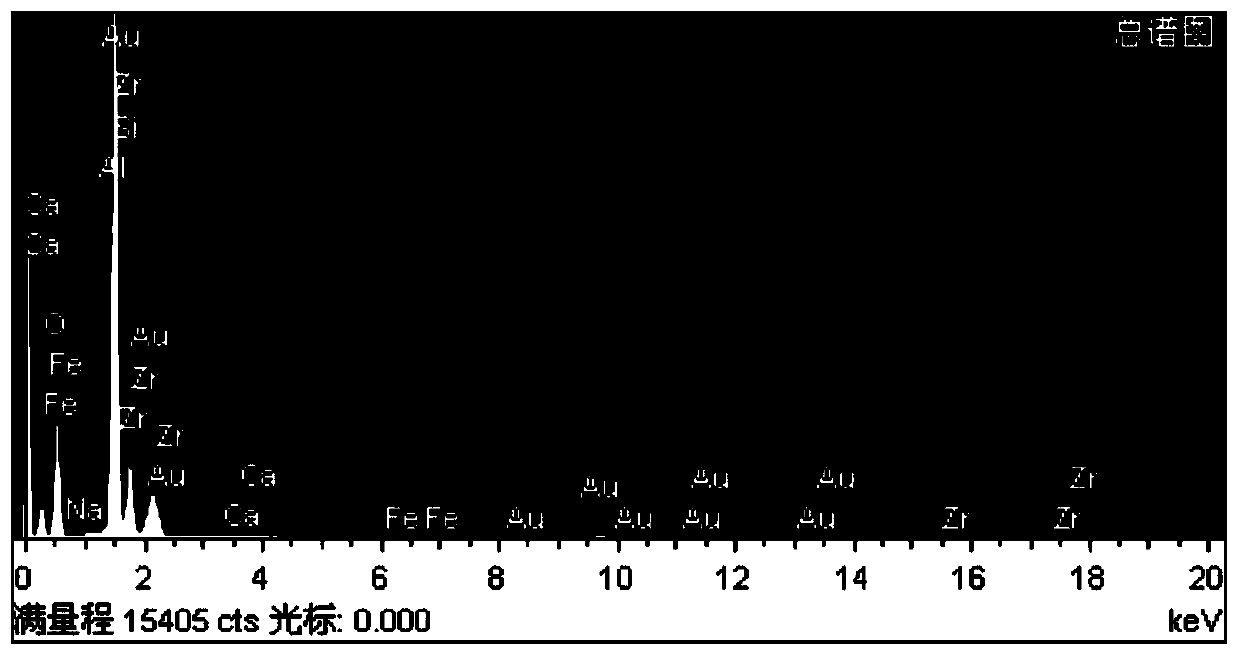

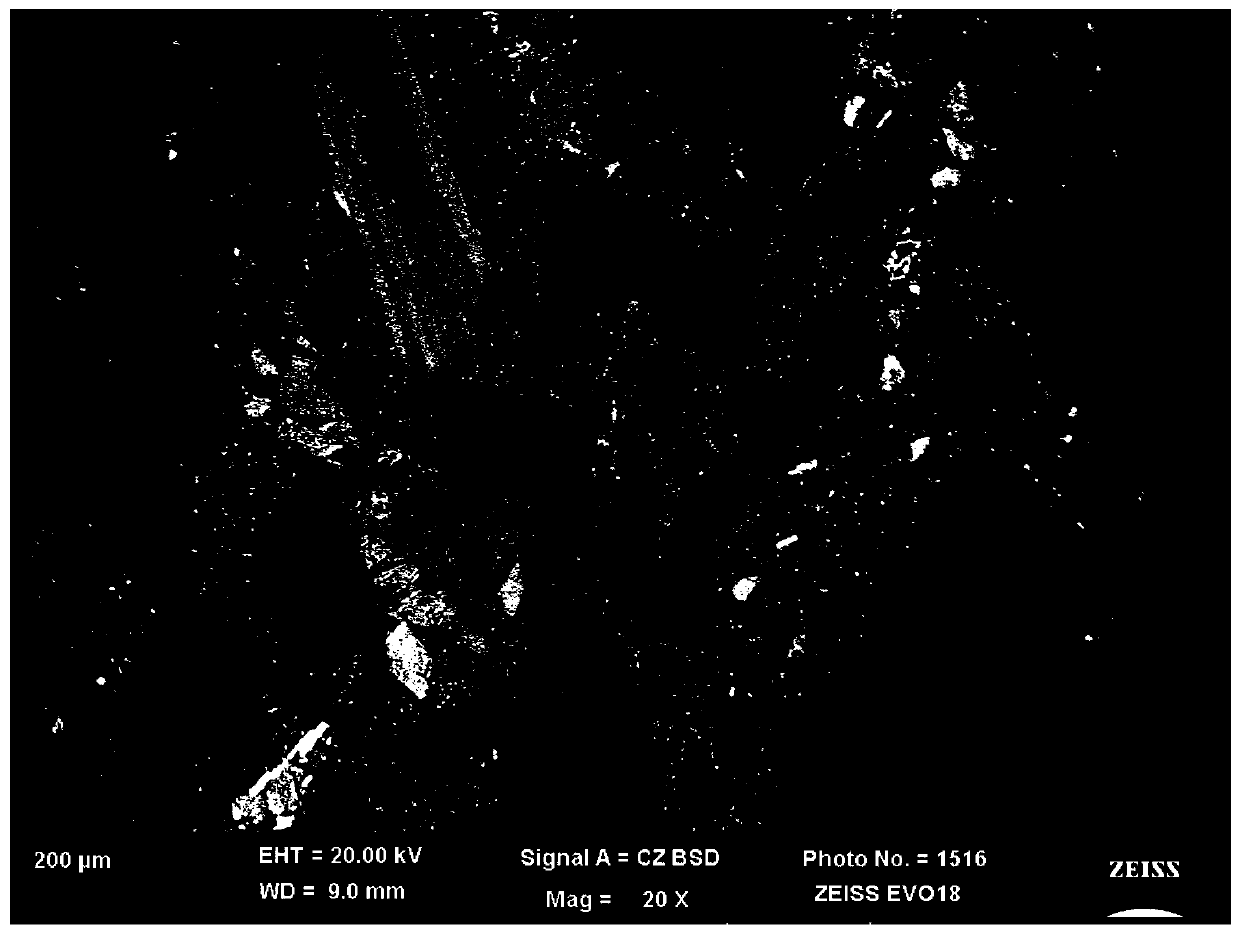

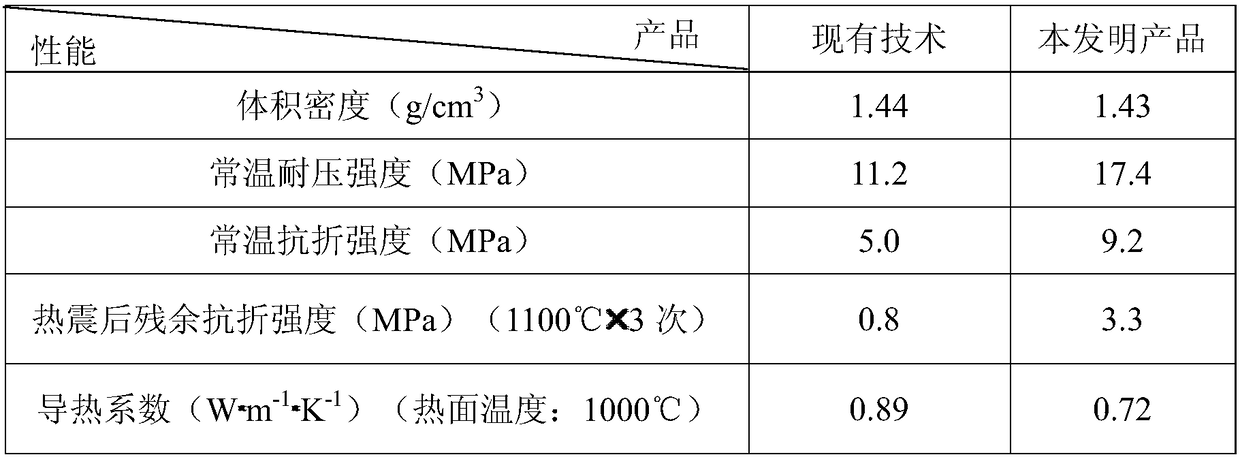

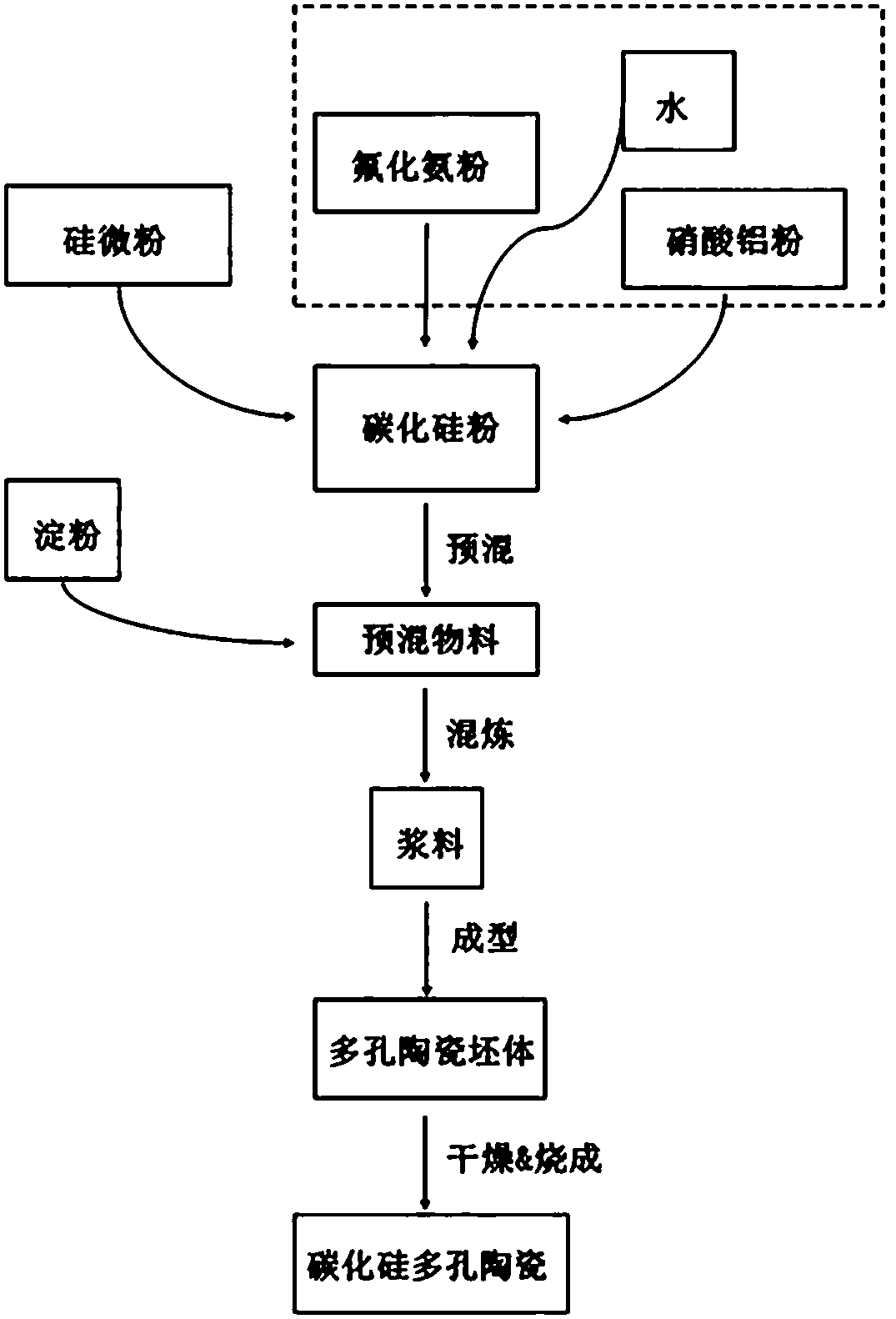

Preparation method of mullite whisker enhanced silicon carbide porous ceramic

InactiveCN110452008AImprove high temperature resistanceImprove corrosion resistanceCeramicwareMullitePorous ceramics

The invention relates to a preparation method of a mullite whisker enhanced silicon carbide porous ceramic. Silicon carbide powder and silicon powder are taken as the raw materials, aluminum nitrate is taken as the aluminum source, ammonium fluoride is used as a catalyst, starch is taken as a bonding agent and a pore forming agent, and the raw materials are pre-mixed, dissolved, mixed, moulded, dried, and sintered to obtain the porous ceramic. The sintering is carried out at a low temperature, mullite whiskers are formed among silicon carbide particles, the breaking toughness of the porous ceramic is enhanced; the rupture strength of the porous ceramic is strengthened, and high strength silicon carbide porous ceramic is obtained.

Owner:UNIV OF SCI & TECH LIAONING

Preparation method of carbon nanotube modified foamed ceramics

The invention provides a preparation method of carbon nanotube modified foamed ceramics. The preparation method comprises the following steps: adding inorganic ceramic particles and cationic surface active agent into deionized water, stirring at a high speed, enabling the cationic surface active agent to cover the surface of the inorganic ceramic particle, and then filtering and drying to obtain inorganic ceramic particles with positive charge; adding the inorganic ceramic particles and carbon nanotube into deionized water, enabling the inorganic ceramic particles with the positive charge to have electrostatic adsorption with carbon nanotube, and then filtering and drying to obtain composite powder; grinding the composite powder together with organic resin, performing hot pressing and sintering under the protection of nitrogen to obtain the carbon nanotube modified foamed ceramics. The carbon nanotube modified foamed ceramics are used as a reinforcing phase, so that on one hand, an effect of flexibilizing a foamed ceramic substrate can be achieved; on the other hand, the sound wave can be bounced for multiple times in a hollow structure of the carbon nanotube, so that a denoising effect can be realized. The preparation method is high in practicability.

Owner:STATE GRID CORP OF CHINA +2

Novel epoxy-polyacrylate core-shell emulsion and preparation method thereof

The invention discloses a novel epoxy-polyacrylate core-shell emulsion and a preparation method thereof. Aqueous epoxy resin is generally an emulsion, a water dispersing body or an aqueous solution formed by dispersing micro particles, liquid drops or colloid into a water phase; the emulsion, the water dispersing body and the aqueous solution are different in particle sizes of epoxy resin dispersing phases. The preparation method for the novel epoxy-polyacrylate core-shell emulsion comprises the steps of (1) emulsifying the epoxy resin emulsion prepared by a phase inversion method and 1 / 3 of acrylate mixed monomers under the temperature of 20-40 DEG C for 0.5 hour; (2) adding an initiator into a reaction system, adding the residual acrylate mixed monomers drop by drop under the temperature of 80-90 DEG C for 3-4 hours, and preserving the heat for 1-5 hours; and (3) cooling the mixture to be below 50 DEG C, and discharging. The novel epoxy-polyacrylate core-shell emulsion disclosed by the invention is used as paint or a paint base material.

Owner:HARBIN UNIV OF SCI & TECH

Titanium-silicon-carbon metal composite converter slag-stopping sliding plate brick and preparation method thereof

PendingCN112876265AHigh melting pointImprove wear resistanceManufacturing convertersSteelmakingAl powder

The invention discloses a titanium-silicon-carbon metal composite converter slag-stopping sliding plate brick and a preparation method thereof. The titanium-silicon-carbon metal composite converter slag-stopping sliding plate brick comprises fused zirconia corundum, fused zirconia mullite, sintered tabular corundum and fused magnesia-alumina spinel particles, fused magnesia-alumina spinel powder, metal silicon powder, metal aluminum powder, alpha calcined alumina powder, boron carbide, titanium silicon carbon and carbon black, organic silicon resin and thermosetting phenolic resin. The preparation method comprises the following steps: uniformly mixing the raw materials, molding, drying, sintering, hooping, grinding, coating and carrying out finish machining to obtain a finished product. The titanium-silicon-carbon metal composite converter slag-stopping sliding plate brick disclosed by the invention has strong corrosion resistance and oxidation resistance, and is not easy to react with molten steel and steel slag to generate a low melt; and meanwhile, relatively high wear resistance and relatively low wettability can ensure relatively long service life and relatively high use stability of the product, and particularly the titanium-silicon-carbon metal composite converter slag-stopping sliding plate brick has obvious advantages in complex steelmaking processes such as smelting of high-grade steel.

Owner:MAANSHAN LIER KAIYUAN NEW MATERIAL

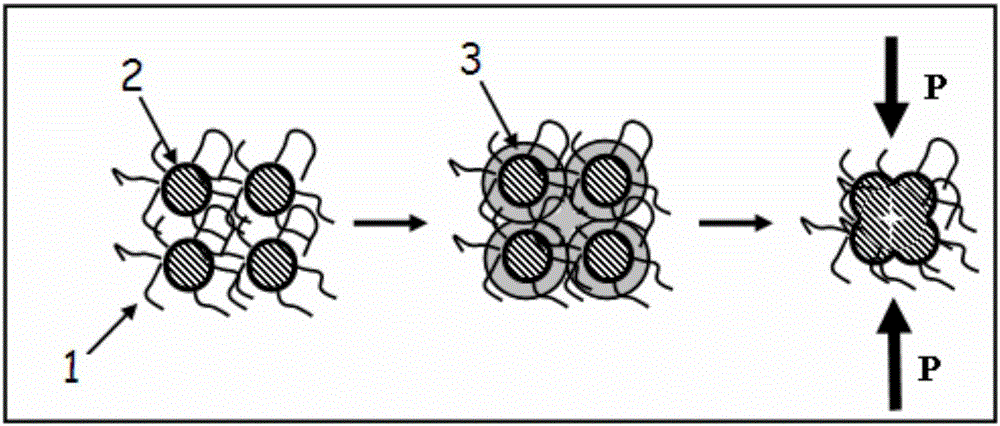

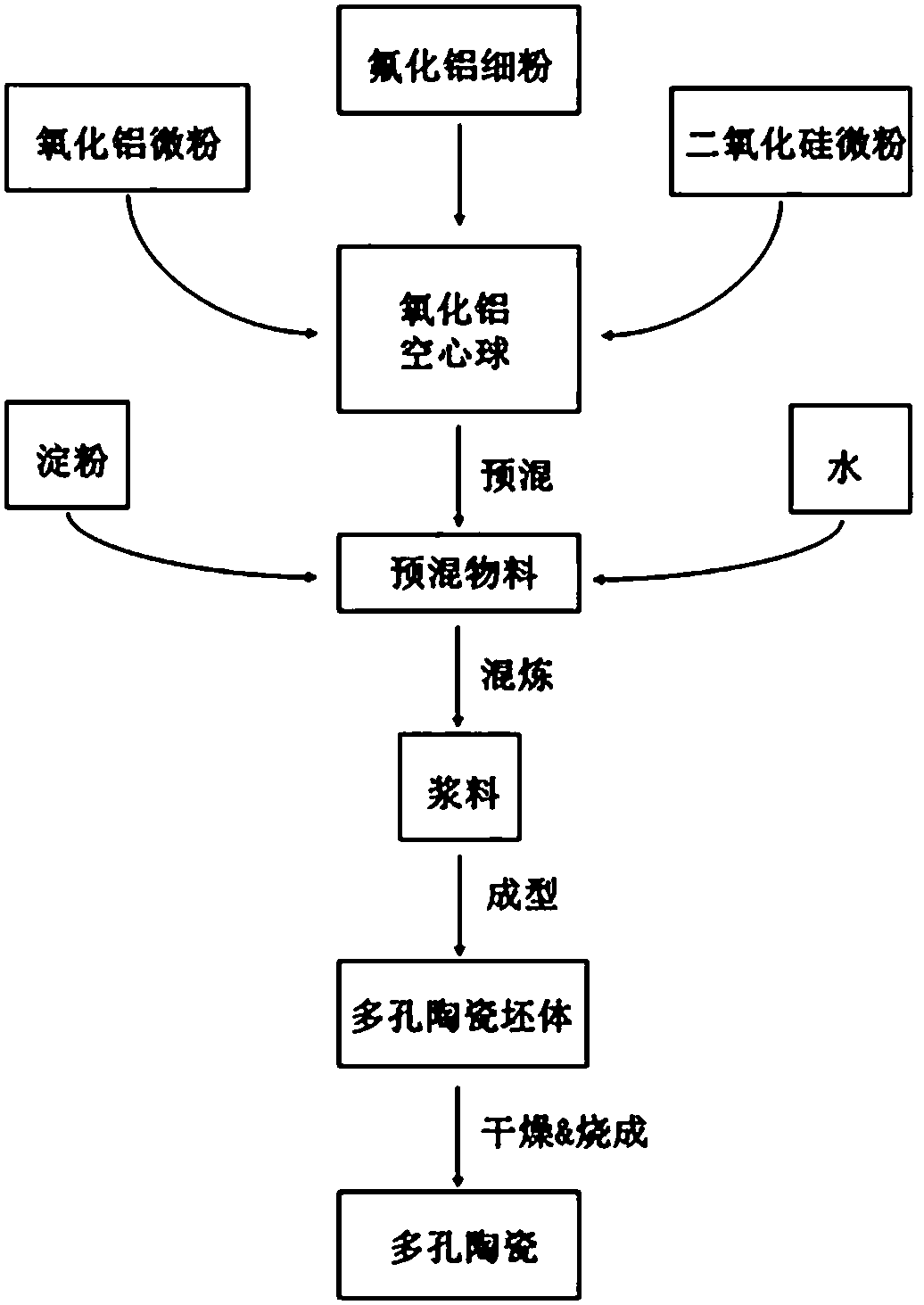

Method for preparing mullite whisker-reinforced alumina hollow sphere porous ceramic

The invention relates to a method for preparing mullite whisker-reinforced alumina hollow sphere porous ceramic. The method includes the following steps: putting alumina hollow spheres, alumina fine powder, silica fine powder, aluminum fluoride, starch and water in a mixer for mixing so as to obtain mixed pug, putting the uniformly-mixed pug into a mold, performing molding and pouring, curing a sample in the mold, releasing the mold so as to form an alumina hollow sphere porous ceramic green body, drying the porous ceramic green body obtained after mold release, calcining the dried porous ceramic green body at a high temperature for 2-6 hours, performing natural cooling in the furnace, and taking out the cooled porous ceramic green body so as to obtain the mullite whisker-reinforced alumina hollow sphere porous ceramic. The mullite whisker-reinforced alumina hollow sphere porous ceramic is prepared from Al2O3 and Si02 raw materials with abundant resources, the cost is low, and the toughness and impact strength of the material can be improved through introduction of mullite whisker into the porous ceramic material, so that improvement of the service life of the material is facilitated.

Owner:UNIV OF SCI & TECH LIAONING

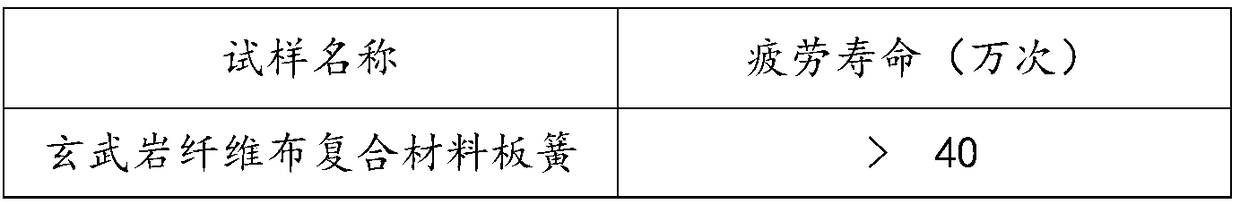

Basalt fiber fabric composite automobile plate spring and preparation method thereof

InactiveCN109486113AAvoid the shortcoming of easy crackingImprove performanceDomestic articlesEpoxyUltraviolet

The invention relates to the field of lightweight of automobiles, and relates to an elastic plate, in particular to a basalt fiber fabric composite automobile plate spring and a preparation method thereof. The basalt fiber fabric composite automobile plate spring consists of the following components in percentages by weight: 30-40% of polyurethane modified epoxy resin and 60-70% of a basalt fiberfabric. The provided basalt fiber fabric elastic composite automobile plate spring has the characteristics of high mechanical strength, no cracking, wide used temperature range, flame retardance, no smoke, ultraviolet resistance, weather resistance, chemical corrosion resistance and good moisture resistance, and meanwhile has the advantages of reasonable structure and low density. Compared with atraditional steel automobile plate spring, the basalt fiber fabric composite automobile plate spring has the advantages that the weight can be reduced by 60-70%, and the basalt fiber fabric compositeautomobile plate spring is suitable for a lightweight arc-shaped automotive composite plate spring.

Owner:四川自胜机电设备有限责任公司

Preparation method for colored-stone foamed thermal-insulation decorative plate and product thereof

The invention relates to a preparation method for a colored-stone foamed thermal-insulation decorative plate. The preparation method comprises the following steps: step 1, preparation of a green body: mixing raw materials consisting of perlite, bentonite, zeolite, kaolin, travertine, black clay, green ceramic silicon powder, fluorite tailings, combustible carbon powder, gangue, short-cut basalt fiber and polypropylene short-cut fiber, then successively carrying out crushing, wet ball milling, uniform ageing, spray drying, granulation and pulverization, carrying out compacting and molding so as to obtain a biscuit and drying the biscuit so as to obtain the green body; step 2, preparation of a glaze and glazing: subjecting the raw materials for the green body, albite and potash feldspar to ball milling so as to obtain the glaze and glazing the green body with the glaze; and step 3, carrying out high-temperature sintering on the glazed green body so as to form the colored-stone foamed thermal-insulation decorative plate with the glaze and with closed pores uniformly and densely distributed in the green body. The colored-stone foamed thermal-insulation decorative plate provided by the invention has the technical effects of lightweight, thermal insulation performance, fire resistance, water resistance, high strength, aging resistance and wearing of a decorative surface.

Owner:浙江孚瓯科技有限公司

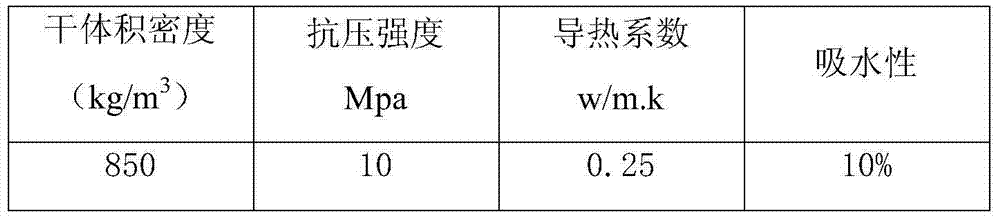

Special calcium silicate cement board for green-fabricated building walls and production method of special calcium silicate cement board

ActiveCN104926232ASimple production methodPlay a role in tougheningSolid waste managementCalcium silicateSlag

The invention provides a special calcium silicate cement board for green-fabricated building walls and a production method of the special calcium silicate cement board. The calcium silicate cement board is prepared from the following raw materials in parts by weight: paper mill sludge, Zr-containing silica residues, coal ash, slag powder, portland cement, straw fibers, ceramic fibers, a PC water reducer, an SM water reducer, water, alumina powder, talc powder, zinc oxide, antimony oxide, sodium silicate and silicon nitride, wherein the paper mill sludge comprises the following components by weight: 30-40 kg of plant fibers, 1.4 kg of aluminum oxide, 7.95 kg of silicon dioxide, 1.15 kg of ferric oxide, 45.6 kg of calcium oxide and 2.5 kg of magnesium oxide; the mass fraction of silicon dioxide in Zr-containing silica residues is 85.3%; slag powder comprises the following components by weight: 15.6 kg of silicon oxide, 6.58 kg of aluminum oxide, 32.8 kg of calcium oxide and 4.68 kg of magnesium oxide.

Owner:SHANDONG LUTAI BUILDING MATERIAL SCI & TECH GRP CO LTD

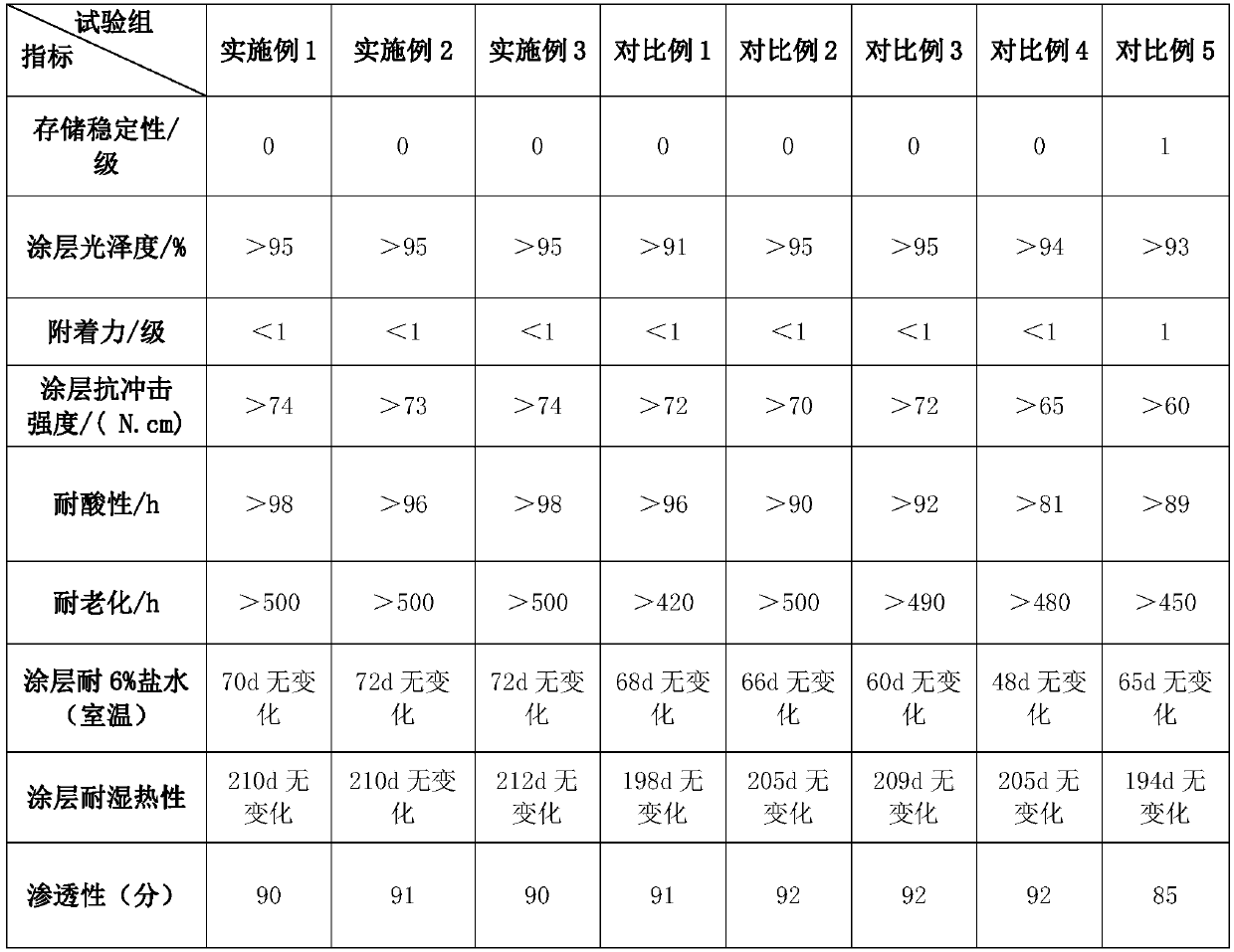

Powder coating for building materials and preparation method thereof

InactiveCN109608992AImprove mechanical propertiesImprove toughnessAnti-corrosive paintsPowdery paintsEpoxySilicon dioxide

The invention belongs to the technical field of epoxy resin-based coating compositions, and particularly discloses a powder coating for building materials and a preparation method thereof, the powdercoating comprises the following raw materials in parts by mass: 40-62 parts of epoxy resin, 30-48 parts of polyester resin, 15-28 parts of polyether sulfone resin, 16-30 parts of a pigment, 8-18 partsof a filler, 0.5-1 part of a flatting agent and 4-12 parts of a curing agent, and the filler comprises nano clay, graphene, metal ceramic particles, nano silicon dioxide and carbon black. The powdercoating prepared by using the technical scheme is high in permeability and good in adhesive force, a continuous coating layer can be quickly formed during use, and the damage of the external corrosionmedium to the building materials can be effectively isolated. The formed coating layer can replace water on the surface of the building materials, and only cleaning of the water on the surface of thebuilding materials is needed when coating the coating, the humidity of the building materials does not need to be strictly controlled, the drying step before use is omitted, and the processing efficiency is improved.

Owner:CHONGQING QICAIHONG CHEM

High-strength and oil-resistant electric power cable

InactiveCN105566699AImprove the defects of unsatisfactory impact resistanceIncrease elasticityRubber insulatorsInsulated cablesEpoxyInsulation layer

The invention discloses a high-strength and oil-resistant electric power cable, which comprises a conductor, wherein the conductor is clad with an insulation layer; the insulation layer is clad with a protecting jacket; the protecting jacket is prepared from a modified nitrile rubber composite material; the modified nitrile rubber composite material is prepared from the following raw materials: nitrile rubber, polypropylene, polyurethane, modified black carbon sepiolite powder, bentonite, attapulgite, a zinc oxide, a stearic acid, dicumyl peroxide, sulfur, turpentine, an anti-ageing agent, an accelerating agent, a silane coupling agent, epoxy butyl tallate, epoxy butyl stearate and stannous octoate. The high-strength and oil-resistant electric power cable which is provided by the invention is high in strength, good in oil resistance and excellent in abrasion resistance and ageing resistance.

Owner:ANHUI HAIYUAN SPECIAL CABLE

Weather-proof and flame-retardant PVC (polyvinyl chloride)-sheathed cable

InactiveCN105255044AIncrease crosslink densityImprove brittlenessPlastic/resin/waxes insulatorsInsulated cablesMethacrylateModified carbon

The invention discloses a weather-proof and flame-retardant PVC (polyvinyl chloride)-sheathed cable. Raw materials of a sheath comprise PVC, chlorinated polyethylene, styrene-butadiene block copolymers, hydroxyl-terminated polybutadiene, dodecafluoroheptyl methacrylate, beta-(3,5-diterbutyl-4-hydroxyphenyl) propionate octadecanol ester, modified montmorillonite, expansible graphite, zinc borate, nano ZnSn(OH)6, a heat stabilizer, butyl stearate, cerium stearate, ethylene glycol dimethacrylate, dioctyl adipate, hexaphenoxycyclotriphosphazene, modified carbon nano tubes, isobutyl triethoxysilane and 4,4'-thio-bis(6-t-butyl-3-methyl phenol). According to the weather-proof and flame-retardant PVC-sheathed cable, the shock resistance of the sheath is good, the flame retardance and weathering resistance are excellent, and the service life is long.

Owner:ANHUI LAND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com