Method for preparing mullite whisker-reinforced alumina hollow sphere porous ceramic

A technology of alumina hollow balls and mullite whiskers, which is applied in ceramic products, applications, household appliances, etc., can solve the problems of reducing the weight of the kiln, energy saving and consumption reduction, and high bulk density, achieving low cost and improving use. Long life, excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

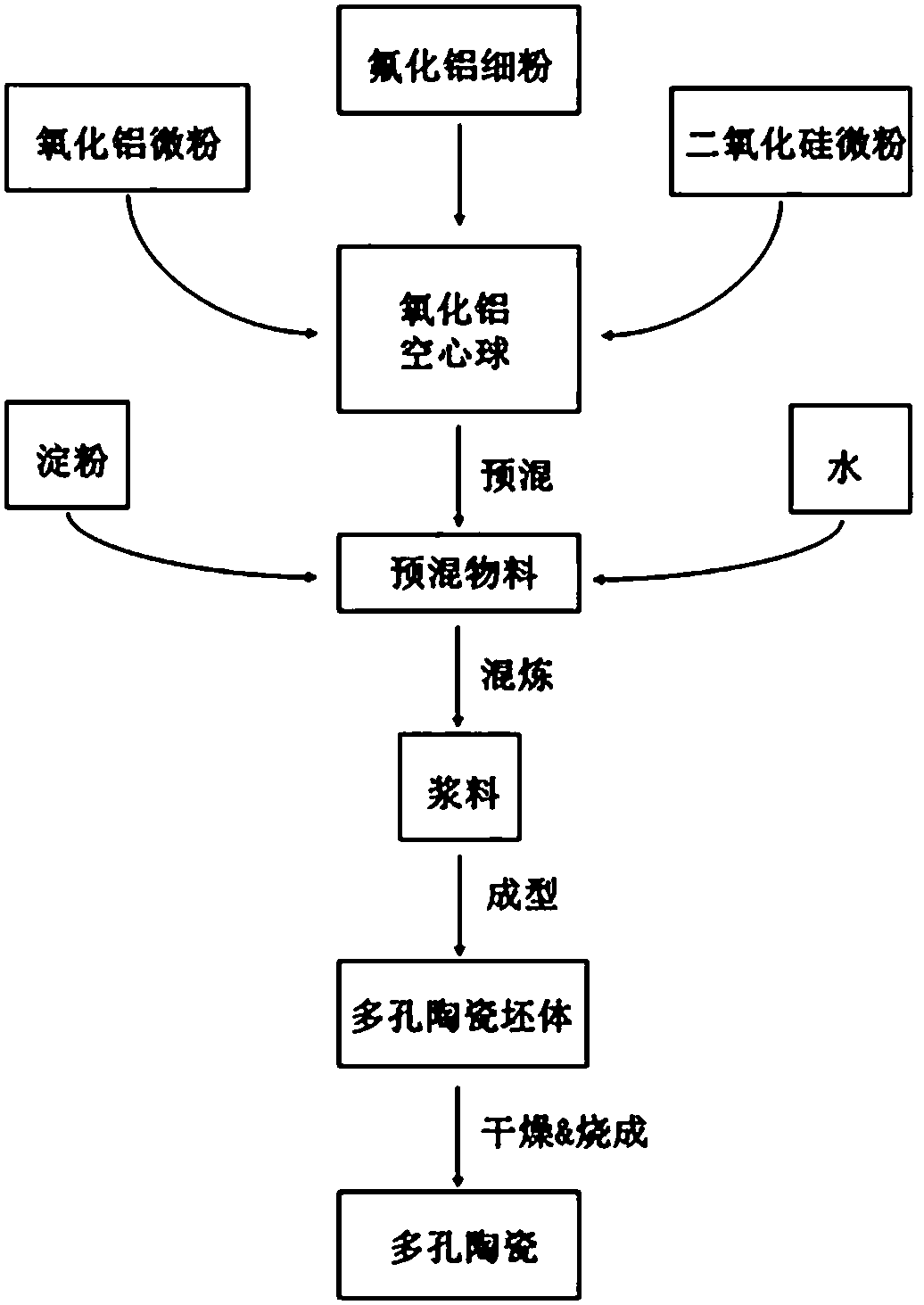

[0016] The mullite whisker-reinforced aluminum oxide hollow sphere porous ceramics given in this example is composed of materials: 70 kg of aluminum oxide hollow spheres with a particle size of 3-0.1 mm, 19 kg of alumina fine powder with a particle size of less than 0.074 mm, 9.2 kg of fine silica powder with a particle size of less than 0.045 mm, and 1.8 kg of fine aluminum fluoride powder with a particle size of less than 0.074 mm. Using starch as a binder and pore-forming agent, through kneading, molding, drying and sintering, the alumina hollow sphere porous ceramics reinforced with mullite whiskers are obtained. The specific operation steps are as follows:

[0017] Step 1: Put the aluminum oxide hollow spheres above in a mixer, add 5kg of water and 6kg of starch, and mix for 15 minutes at a speed of 160r / min; Fine powder, continue to knead with 160r / min rotating speed for 15 minutes, obtain the castable after kneading;

[0018] Step 2, molding, putting the mixed castable...

Embodiment 2

[0023] The mullite whisker-reinforced aluminum oxide hollow sphere porous ceramics given in this example consists of the following: 68 kg of alumina hollow spheres with a particle size of 3-0.1 mm, 21 kg of alumina fine powder with a particle size of less than 0.074 mm, 9kg of fine silica powder with a particle size of less than 0.045mm, and 2kg of fine aluminum fluoride powder with a particle size of less than 0.074mm. Using starch as a binder and pore-forming agent, through kneading, molding, drying and sintering, the alumina hollow sphere porous ceramics reinforced with mullite whiskers are obtained. The specific operation steps are as follows:

[0024] Step 1: Put the aluminum oxide hollow spheres above in a mixer, add 6kg of water and 10kg of starch, and knead for 15 minutes at a speed of 160r / min; Fine powder, continue to knead with 160r / min rotating speed for 15 minutes, obtain the castable after kneading;

[0025] Step 2, forming, putting the mixed castable into a mol...

Embodiment 3

[0030] The mullite whisker-reinforced alumina hollow sphere porous ceramics given in this example is composed of the following: 65kg of alumina hollow spheres with a particle diameter of 3-0.1mm, 22kg of alumina fine powder with a particle diameter of less than 0.074mm, 10.6 kg of fine silica powder with a particle size of less than 0.045 mm, and 2.4 kg of fine aluminum fluoride powder with a particle size of less than 0.074 mm. Using starch as a binder and pore-forming agent, through kneading, molding, drying and sintering, the alumina hollow sphere porous ceramics reinforced with mullite whiskers are obtained. The specific operation steps are as follows:

[0031] Step 1, put the above alumina hollow spheres in a mixer, add 7kg of water and 8kg of starch, and knead for 15 minutes at a speed of 160r / min; then add the above alumina fine powder, silica micropowder, aluminum fluoride Fine powder, continue to knead with 160r / min rotating speed for 15 minutes, obtain the castable a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| High temperature flexural strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| High temperature flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com