Method for producing light-weight wall material by using papermaking white clay

A paper-making white mud and lightweight wall technology, which is applied in the field of waste utilization and building materials, can solve the problems of environmental pollution, high production cost of lightweight concrete, etc., and achieve the effects of controlling environmental pollution, promoting sustainable development, and protecting cultivated land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

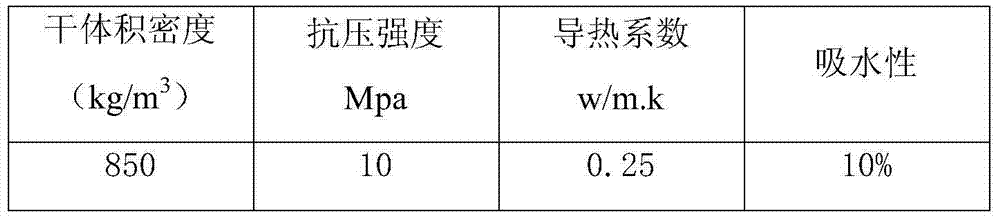

[0030] Take and mix the materials, take 65% papermaking white mud, 10% zirconium silica slag, 22% ordinary Portland cement, 3% enhanced water release agent, and the enhanced water release agent is 5 parts by weight Sodium sulfate, 7 parts of triethanolamine, 18 parts of sodium sugar, 30 parts of sodium methanesulfonate and 40 parts of calcium lignosulfonate are mixed and dissolved in 900 parts of water to obtain a mixed solution. It is prepared by preparing concrete slurry that meets the requirements of fluidity, natural curing, and its strength and performance are tested for 28 days. The strength grade, water absorption, thermal conductivity, etc. meet the requirements of national standards GB / T15229-2002 and JC / T422-2007.

[0031]

Embodiment 2

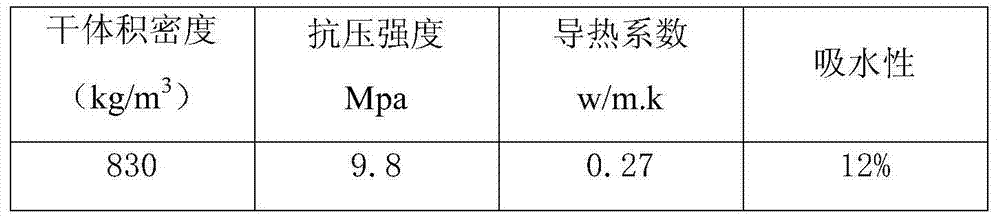

[0033] Take and mix the materials, take 68% papermaking white mud, 7% zirconium silica slag, 20% ordinary Portland cement, 5% enhanced water release agent, and the enhanced water release agent is 4 parts by weight Sodium sulfate, 8 parts of triethanolamine, 15 parts of sodium sugar, 25 parts of sodium methanesulfonate and 42 parts of calcium lignosulfonate are mixed and dissolved in 900 parts of water to obtain a mixed solution. It is prepared by preparing concrete slurry that meets the requirements of fluidity, natural curing, and its strength and performance are tested for 28 days. The strength grade, water absorption, thermal conductivity, etc. meet the requirements of national standards GB / T15229-2002 and JC / T422-2007.

[0034]

Embodiment 3

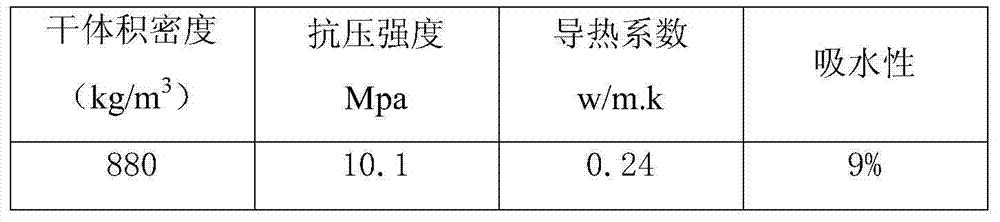

[0036] Take and mix the materials, take 60% papermaking white mud, 7% zirconium silica slag, 30% ordinary Portland cement, and 3% enhanced water-releasing agent, and the enhanced water-releasing agent is 5 parts by weight Sodium sulfate, 7 parts of triethanolamine, 17 parts of sodium sugar, 28 parts of sodium methanesulfonate and 45 parts of calcium lignosulfonate are mixed and dissolved in 900 parts of water to obtain a mixed solution. It is prepared by preparing concrete slurry that meets the requirements of fluidity, natural curing, and its strength and performance are tested for 28 days. The strength grade, water absorption, thermal conductivity, etc. meet the requirements of national standards GB / T15229-2002 and JC / T422-2007.

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com