Patents

Literature

103 results about "Calcium lignin sulfonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lubricating Greases Containing Lignosulfonate, The Production Thereof, and the Uses Thereof

InactiveUS20120302472A1Lend them mechanical stabilityReadily available, renewable raw material for industrial productsAdditivesAlkaline earth metalBoiling point

The object of the invention are lubricating greases that contain calcium lignin sulfonates, and which consist of a base oil, calcium soaps, calcium lignin sulfonate having average molecular weights (weight average) greater than 10,000 g / mol as well as other, optional alkaline earth lignin sulfonates, producible by heating to temperatures above 120° C. converting and driving out components with low boiling point in order to produce a base grease, and cooling and addition of base oil and possibly other additives with mixing, a corresponding process, and use of the lubricating greases containing calcium lignin sulfonate.

Owner:FUCHS PETROLUB SE

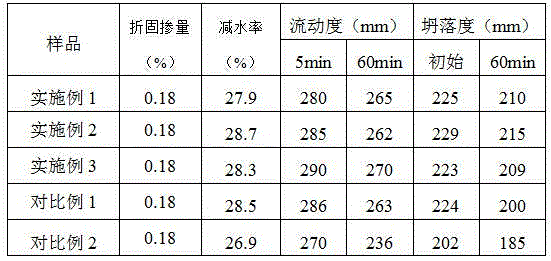

Modified polycarboxylate superplasticizer and preparation method thereof

The invention relates to the technical field of construction material additives, in particular to a modified polycarboxylate superplasticizer and a preparation method thereof. The preparation method comprises the following steps: conducting condensation reaction on calcium lignosulphonate and acrylic acid to prepare modified calcium lignosulphonate; utilizing monomer methyl allyl polyoxyethylene ether, the modified calcium lignosulphonate and acrylic acid to prepare the modified polycarboxylate superplasticizer through free radical copolymerization synthesis under the action of chain transfer agent sodium methallyl sulfonate and initiator ammonium persulfate. According to the invention, the sulfonic acid group in the introduced calcium lignosulphonate has high dispersity; water-reducing rate is improved; manufacturing cost is reduced; the polycarboxylate superplasticizer is environment-friendly and economic; the preparation technology is simple; the synthesized modified polycarboxylate superplasticizer is high in water-reducing rate, fluidity and slump maintaining capability.

Owner:ANHUI XIN SOLID ENVIRONMENTAL CO LTD

Cassava dreg composite heavy metal curing agent and preparation method thereof

InactiveCN104773932AGood curing effectReduce leaching concentrationSludge treatment by thermal conditioningSpecific water treatment objectivesManufacturing technologyPhosphogypsum

The invention discloses a cassava dreg composite heavy metal curing agent, which is composed of the following raw materials in parts by weight: 20 to 30 parts of cassava dreg, 20 to 30 parts of phosphogypsum, 10 to 15 parts of fly ash, 5 to 10 parts of attapulgite, 3 to 5 parts of glutinous rice flour, 0.3 to 0.5 part of chitosan, 4 to 8 parts of gelatin, 0.5 to 1 part of borax, and 1 to 2 parts of calcium lignin sulfonate. The provided curing agent is mainly composed of industrial and agricultural wastes, has a good curing effect on a plurality of heavy metals, is capable of reducing the leaching concentration of heavy metals to prevent separation-out, and has the advantages of low price, energy saving, waste utilization, simple manufacturing technology, and high social and economical benefits.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

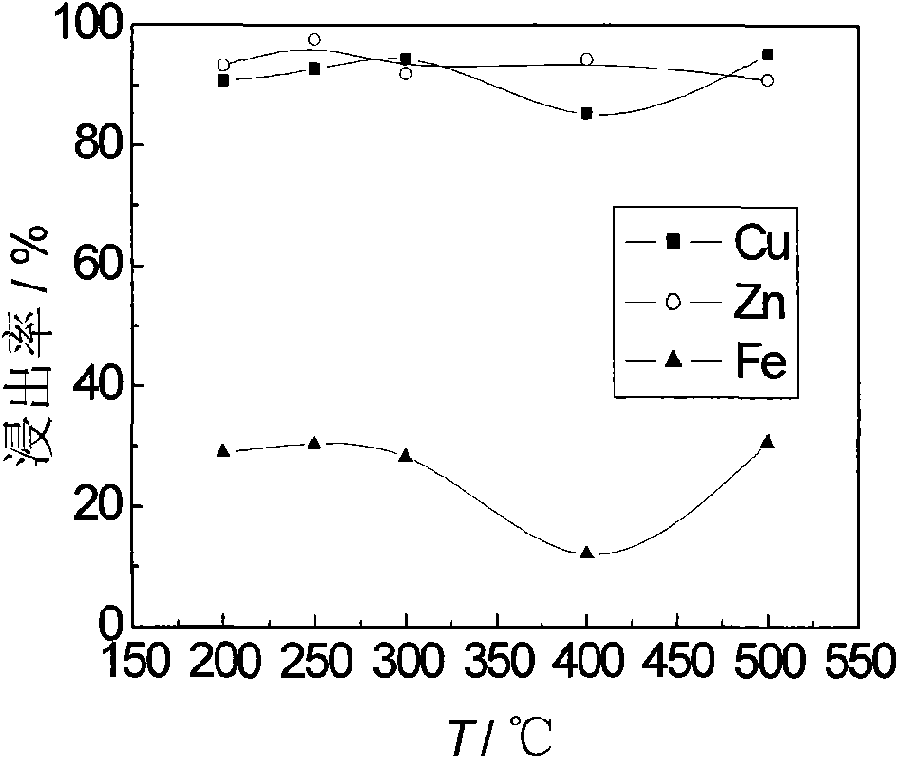

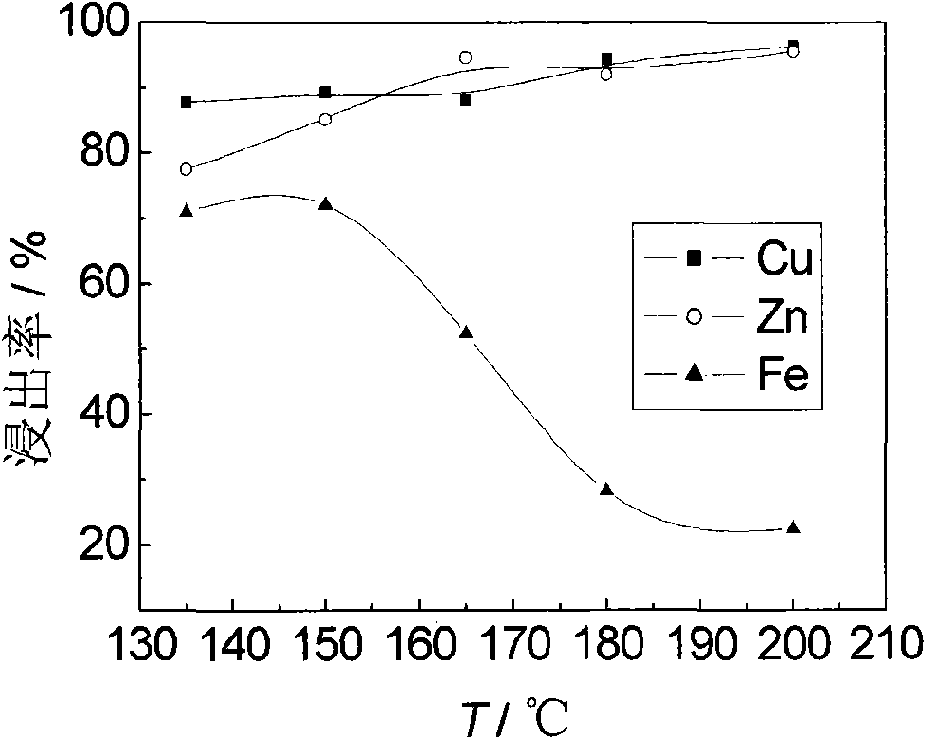

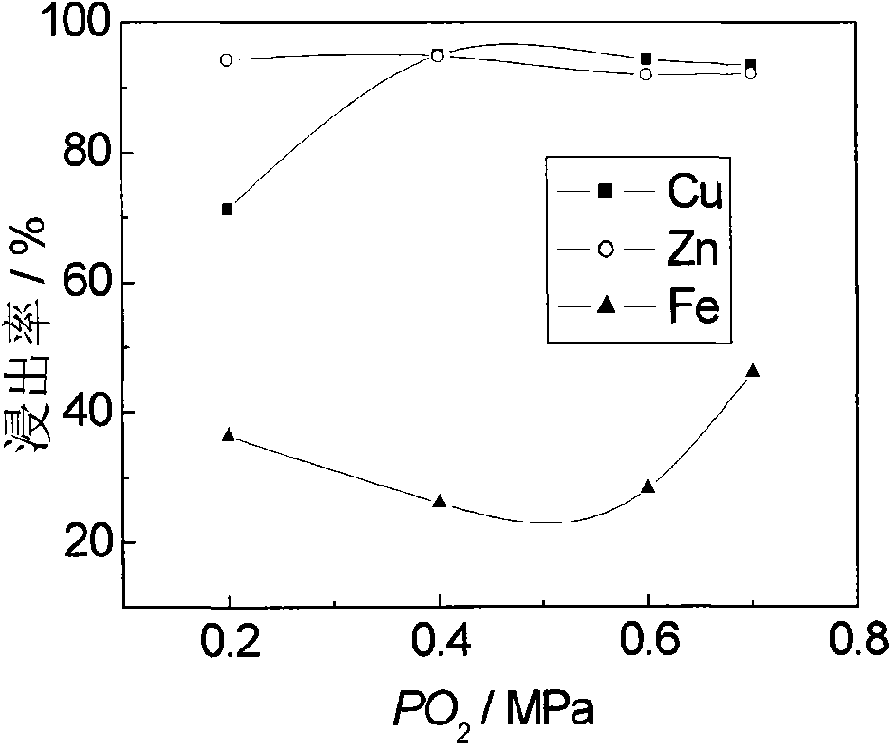

Complex copper sulphide ore thermal activating-pressure leaching technology

ActiveCN101643846ANo low-altitude pollution problemsEfficient leachingProcess efficiency improvementLiquid ratioCalcium lignin sulfonate

The invention relates to a wet metallurgy technology of complex copper sulphide ore, in particular to a complex copper sulphide ore thermal activating-pressure leaching technology. The technical scheme of the technology is as follows: activating time is 2.0 hours under the temperature of 300 DEG C; leaching temperature is 180 DEG C; oxygen partial pressure is 0.6 MPa; initial sulfuric acid concentration is 1.23 mol / L; solid-to-liquid ratio mL / g is 5:1; surface active agent selects calcium lignin sulfonate, wherein usage amount thereof is 1.25% of the weight of fine ore; stirring speed is 500 r / min; and leaching time is 2.0 hours. The technology can not generate toxic compounds such as SO2, and the like, to cause low-air pollution, is cleaning and environmentally friendly, improves the copper leaching ratio from original less than 70% to more than 90%, smoothly solves the difficulties of easy passivation in the process of leaching yellow copper ore and tetrahedrite, improves metal use ratio, and reduces resource waste.

Owner:JIANGXI UNIV OF SCI & TECH

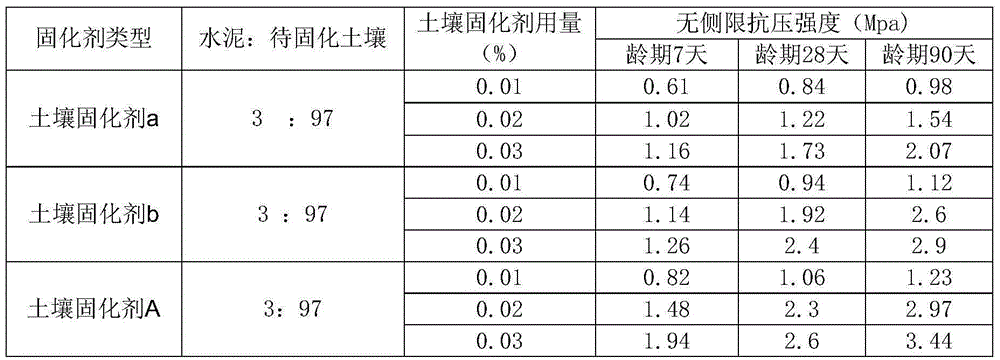

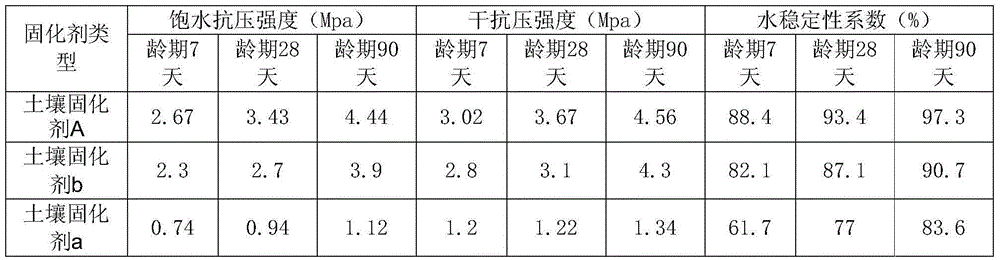

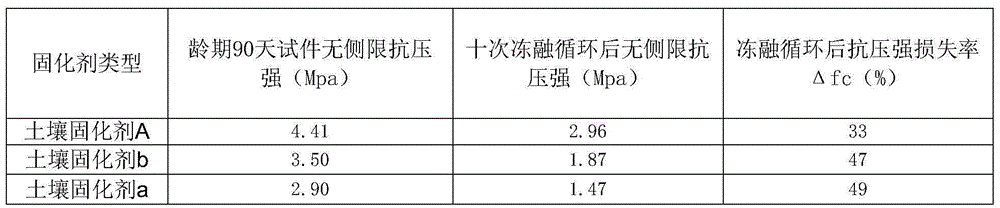

Soil solidifying agent, and preparation method and use method thereof

ActiveCN105018103APH adjustableImprove the safety of useBuilding constructionsOrganic fertilisersLithium hydroxidePhosphate

The invention discloses a soil solidifying agent, and a preparation method and a use method thereof. The soil solidifying agent is prepared from, by weight, 0.4 parts of calcium lignin sulfonate, 0.9 parts of sodium polycarboxylate, 1.7 parts of lithium hydroxide, liquid aluminum dihydrogen phosphate, illegally recycled waste cooking oil, sulfamic acid and distilled water, the pH value of the soil solidifying agent is 5-9, a weight ratio of the illegally recycled waste cooking oil to the liquid aluminum dihydrogen phosphate is 1.5:1, and the use amount of sulfamic acid is 1 / 2 of the total weight of the illegally recycled waste cooking oil and the liquid aluminum dihydrogen phosphate. The preparation method of the soil solidifying agent comprises the following steps: preparing an alkaline neutralization solution, preparing acidic fatty alcohol sulfide, mixing the alkaline neutralization solution with the acidic fatty alcohol sulfide, layering and extracting, and filtering to prepare the finished soil solidifying agent. The soil solidifying agent provided by the invention is not strong acidic or alkaline, and has the advantages of high safety, no pollution to environment, strong compression resistance, high water stability, high freeze stability and realization of waste utilization of the illegally recycled waste cooking oil; and the preparation method of the soil solidifying agent has the advantages of low energy consumption, no pollutants, safety and environmental protection.

Owner:BEIJING HUAXIA PIONEERING NEW MATERIAL

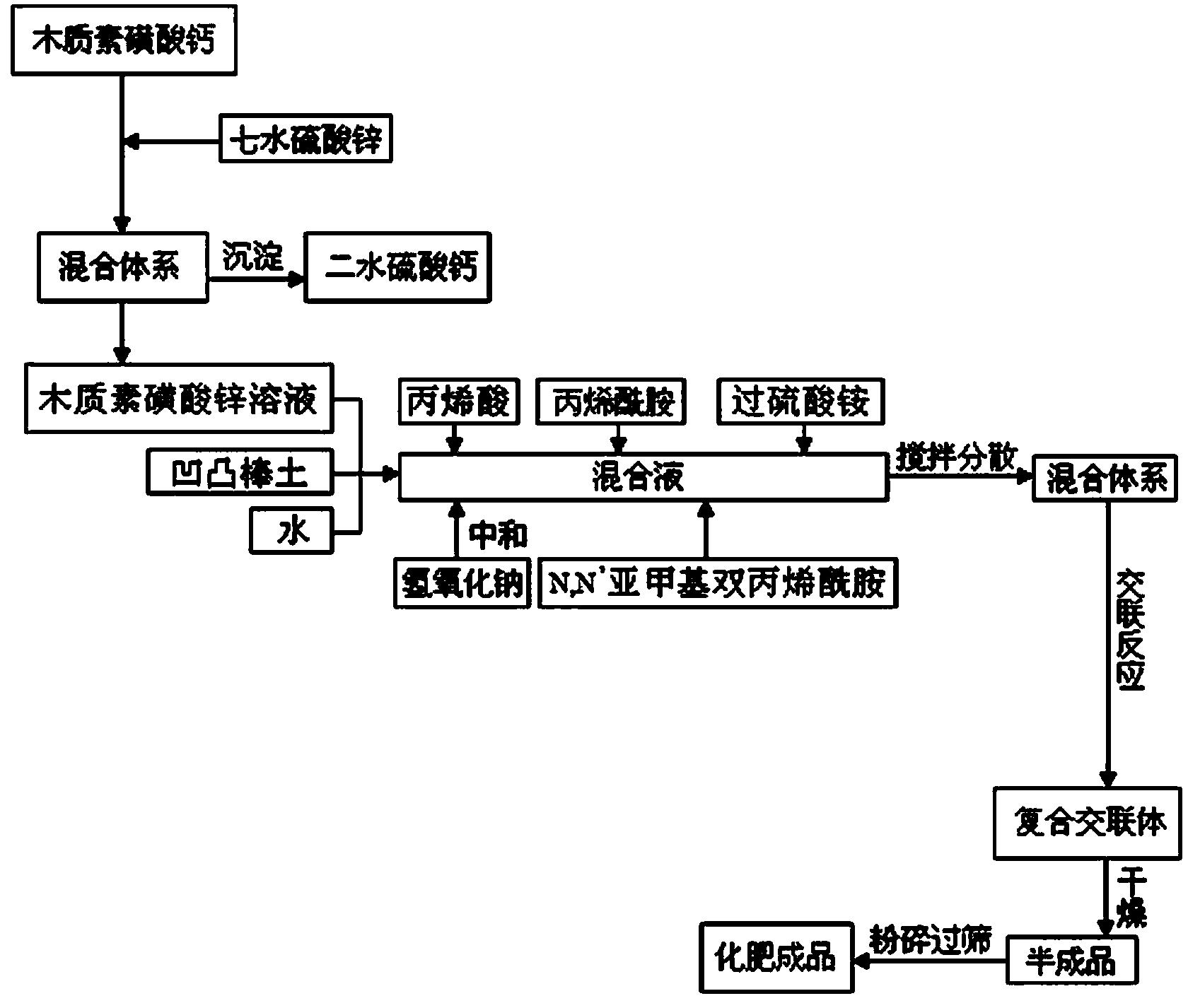

Attapulgite and zinc lignosulphonate-based interpenetrating network-type water-retention and slow-release zinc fertilizer

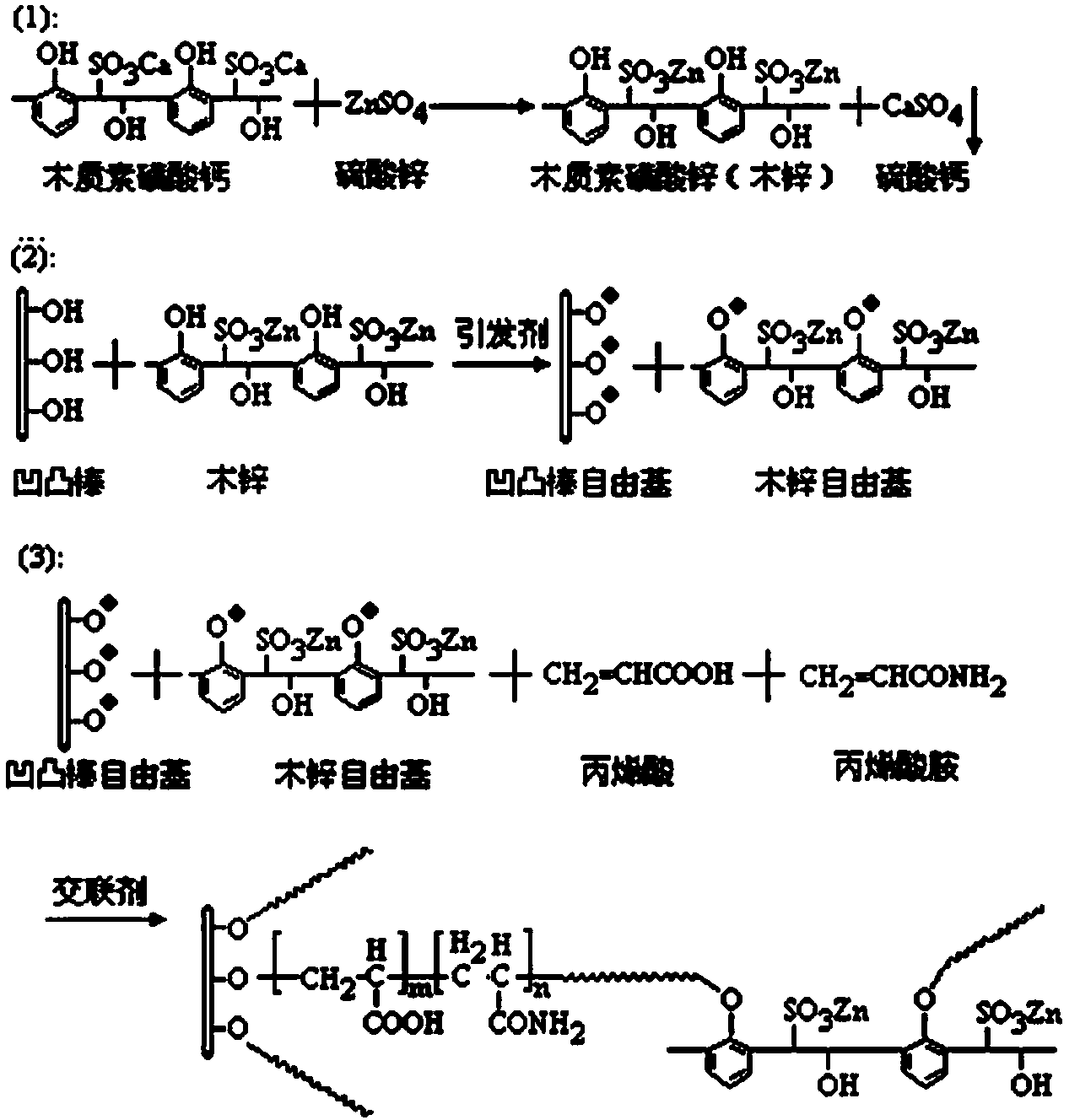

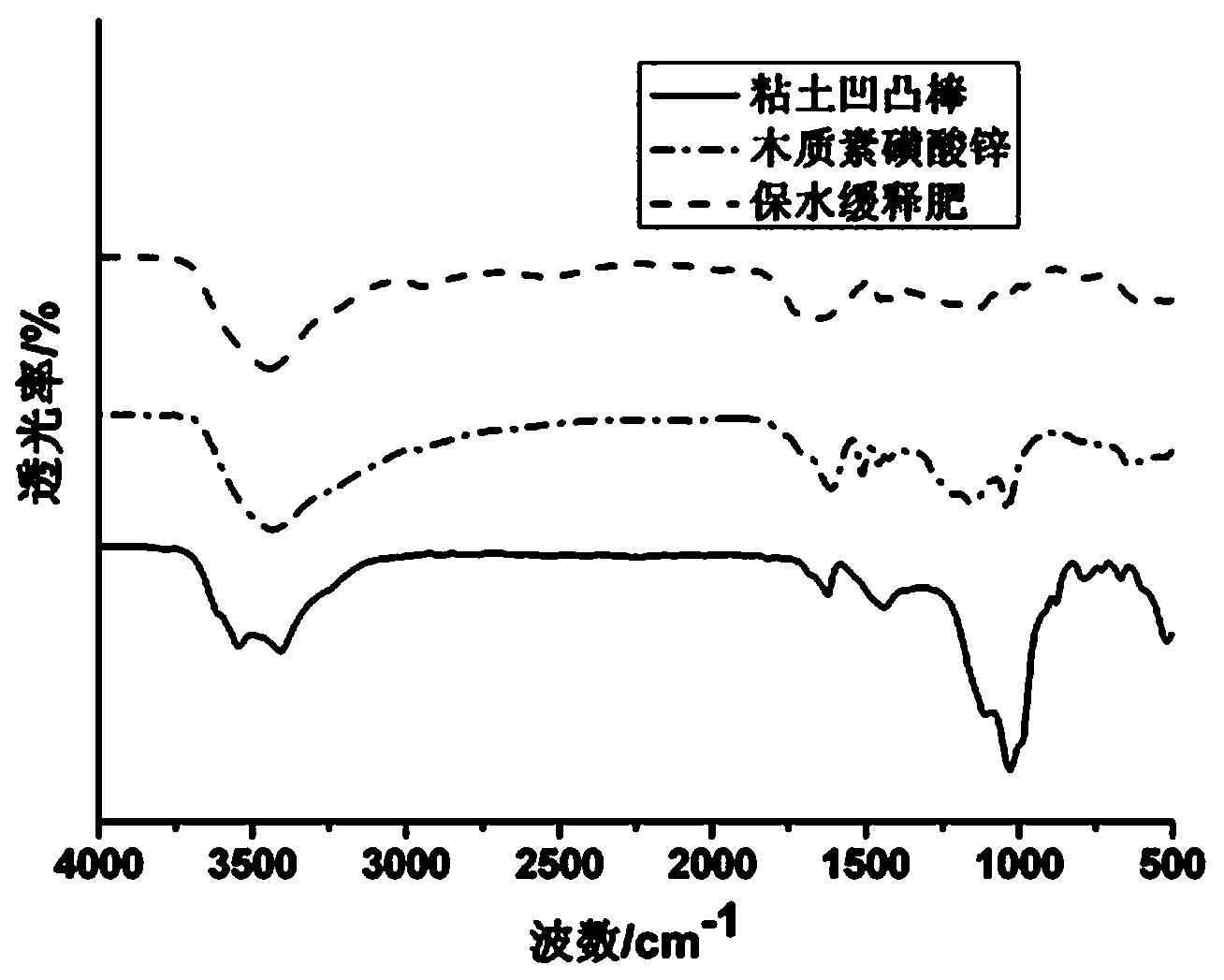

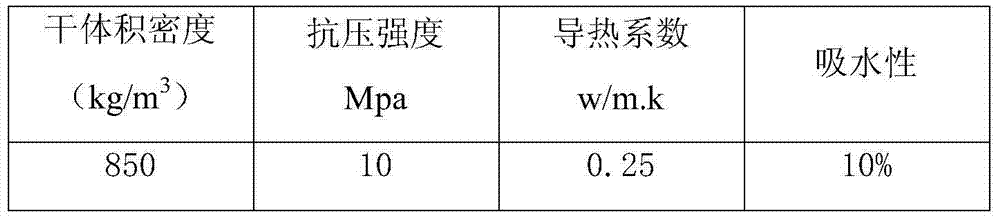

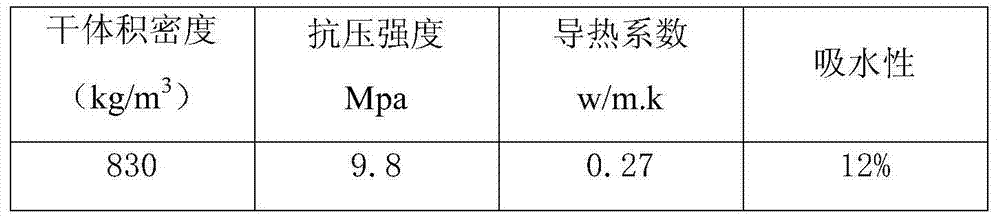

InactiveCN103408379AReduce contentAchieve reuseFertilizer mixturesCalcium lignin sulfonateCross linker

The invention provides an attapulgite and zinc lignosulphonate-based interpenetrating network-type water-retention and slow-release zinc fertilizer. The attapulgite and zinc lignosulphonate-based interpenetrating network-type water-retention and slow-release zinc fertilizer is prepared by taking natural clay attapulgite, calcium lignosulphonate, acrylic acid, acrylamide, an initiator and a cross-linking agent in a percentage by mass respectively, wherein the total of the percentages of the constituents is 100%; preparing a calcium lignosulphonate aqueous solution from calcium lignosulphonate, then adding zinc heptahydrate to obtain a zinc lignosulphonate solution; combining natural clay attapulgite and the zinc lignosulphonate solution, and dispersing in water, adding acrylic acid and acrylamide, then adjusting the pH value, adding N,N'-methylene bisacrylamide and ammonium persulfate to perform a cross-linking reaction, so as to generate a compound cross-linked body; and performing vacuum drying and crushing. Relative to the traditional absorbing-fixing zinc fertilizers and physically-blended zinc fertilizers, the slow-release zinc fertilizer has the advantages of being stable in structure, high in water absorption rate, good in slow-release effect and the like.

Owner:NORTHWEST RES INST CO LTD OF C R E C

High toughness construction material

The invention discloses a high toughness construction material. The high toughness construction material comprises the following raw materials in parts by weight: 40 to 60 parts of silicate cement, 20 to 40 parts of composite carbon fiber, 30 to 55 parts of admixture, 3 to 5 parts of dispersant, 1 to 3 parts of water reducer, 1 to 3 parts of thickening agent, 0.5 to 3 parts of flexibilizer, 0.3 to 0.8 part of antifoaming agent, 1 to 5 parts of fire retardant, 3 to 8 parts of mica powder, 10 to 15 parts of calcium carbonate, 5 to 10 parts of fly ash, 3 to 8 parts of silicon powder, 2 to 6 parts of talcum powder, and 3 to 10 parts of calcium lignin sulfonate. A composite fiber material and a dispersant are added, the composite fiber material is evenly dispersed under the effect of the dispersant, the reinforcing and crack-resistant effects of fiber can be better exerted, the toughness and crack resistant property of material are enhanced; the mechanical properties are changed, the performance of the material on resisting deformation is prominently reinforced, the possibility of cracking and breaking of concrete is reduced, the using effect is good, the construction material has high completeness when being applied to buildings, and the cost of buildings is largely reduced.

Owner:ZHENGZHOU UNIV OF IND TECH

Cement paste for prestress engineering and manufacturing method thereof

The invention which provides a cement paste for prestress engineering and a manufacturing method thereof belongs to the technical field of the prestress engineering. The manufacturing method comprises the following steps: 1, preparing a material which comprises 300 parts of Portland cement, 4-8 parts of a naphthalene water reducer, 1-2 parts of a calcium lignin sulphonate retarder, 88-100 parts of water and 2-7 parts of a paste thixotropic agent; 2, pouring water into a paste stirring tank, and pouring the naphthalene water reducer; 3, adding the Portland cement under stirring, and costarring for 4-6min to obtain a cement paste; 4, transferring the cement paste to a paste storage tank, allowing it to stand for 45min, adding the calcium lignin sulphonate retarder, and stirring for 4-6min to obtain a retardation paste; 5, allowing the retardation paste to continuously stand for 1h; and 6, adding the paste thixotropic agent while starting a stirrer to stir, and continuously stirring for 15-30s to obtain a thixotropic paste (the cement paste of the invention). The grouting of largely-bent pipelines can be once completed with the thixotropic paste, so the work efficiency and the construction quality are substantially improved.

Owner:CHINA NUCLEAR IND HUAXING CONSTR +1

Multi-component composite metal antirust paint and its preparation method

The invention discloses a multi-component composite metal antirust paint and its preparation method. The metal antirust paint is composed of the following raw materials, by weight, 32-35 parts of a polypropylene resin, 28-32 parts of a bisphenol A epoxy resin, 10-15 parts of a phenolic resin, 17-25 parts of modified meerschaum powder, 1.4-1.6 parts of 8-hydroxyquinoline, 20-25 parts of dibutyl phthalate, 0.6-0.8 parts of calcium lignin sulphonate, 0.4-0.8 parts of polybutylene terephthalate, 0.3-0.5 parts of poly-4-methyl-1-pentene, 1.1-1.3 parts of 4,4-methylene-bis(2,6-di-t-butylphenol), 2-5 parts of a modified styrene-acrylate emulsion, 1.5-1.7 parts of carboxymethyl cellulose sodium, 0.4-1.0 part of vinyltrisilane, 0.4-0.7 parts of sodium stearate and 1.0-1.5 parts of sodium dodecyl benzene sulfonate. The film of the metal antirust paint has the advantages of good adhesion, fast drying, good heat resistance, environmental protection and no pollution, and the modified meerschaum powder and the modified styrene-acrylate emulsion which are added to the raw materials improve the excellent performances of high-polymer materials in the raw materials and simultaneously increase the corrosion and heat resistances of the metal antirust paint; and the preparation method of the metal antirust paint has the advantages of simplicity, low cost and suitableness for large-scale production.

Owner:佛山市顺德区姿彩塑料粉末实业有限公司

Steel slag grinding aid and preparation method thereof

The invention discloses a steel slag grinding aid. The grinding aid comprises the following raw material component in parts by weight: 8-12 parts of acrylamide, 8-12 parts of benzamide, 15-20 parts of alkanolamine, 5-10 parts of ethylene diamine phosphate, 10-15 parts of calcium lignin sulfonate, 8-12 parts of sodium lignin sulfonate, 0.1-0.5 part of tributyl phosphate and 20-80 parts of water. The preparation method comprises the steps of adding acrylamide, benzamide, alkanolamines in water in a certain ratio, dissolving, then sequentially adding ethylenediamine phosphate, calcium lignin sulfonate and sodium lignin sulfonate, mixing and finally adding tributyl phosphate, stirring to obtain steel slag grinding aid. The process is simple and the activity index of steel slag can be regulated.

Owner:JIANGSU RONGDA NEW MATERIAL

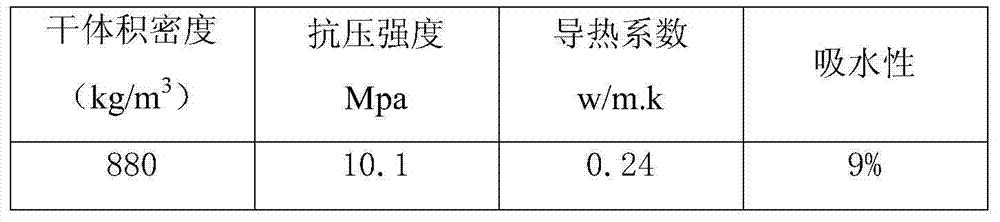

Method for producing light-weight wall material by using papermaking white clay

The invention relates to a method for producing a light-weight wall material by using papermaking white clay. The method comprises the steps of preparing the following components in percentage by mass: 60-70% of papermaking white clay, 5-10% of zirconium-silicate slag, 20-30% of Portland cement and 1-5% of an enhanced water-releasing agent and mixing uniformly, preparing into concrete slurry having a required flowability, curing and molding, wherein the enhanced water-releasing agent is a mixed solution prepared by dissolving 4-5 parts of sodium sulfate, 7-8 parts of triethanolamine, 15-18 parts of saccharide sodium, 25-30 parts of sodium methyl sulfonate and 40-45 parts of calcium lignin sulfonate in water. The wall material prepared by the method disclosed by the invention has the advantages of good compressive strength, good heat insulation property, low density and light self-weight.

Owner:SHANDONG JIANZHU UNIV +1

PS [PAM-Ca-LS (polyacrylamide-calcium lignin sulfonate)] lignin gel type profile control agent and method for preparing same

InactiveCN106811185ALow viscosityGel time controllableDrilling compositionCross-linkCalcium lignin sulfonate

The invention relates to a PS [PAM-Ca-LS (polyacrylamide-calcium lignin sulfonate)] lignin gel type profile control agent. By the aid of the PS lignin gel type profile control agent, the problem of poor profile control effects due to high initial viscosity, short profile control valid periods and low plugging efficiency of existing profile control agents mainly can be solved. The PS lignin gel type profile control agent is characterized by comprising, by weight, 0.5-1.5% of macromolecular polymers, 1-10% of gel, 0.2-2.0% of colloid stabilizers, 0.2-2.0% of reducing agents, 0.2-0.6% of chelating agents, 0-1.0% of retarders, 0.5-1.5% of cross-linking agents and the balance water. A method for preparing the PS lignin gel type profile control agent includes adding the corresponding water into a container, then sequentially adding the gel, the colloid stabilizers, the reducing agents and the chelating agents into the container, circularly stirring the corresponding water, the gel, the colloid stabilizers, the reducing agents and the chelating agents at the normal temperature under the normal pressure for half an hour to obtain first mixtures, then spreading the macromolecular polymers into the first mixtures, stirring the macromolecular polymers and the first mixtures for 2 hours to obtain second mixtures and allowing the second mixtures to stand still for 8 hours to obtain agents A; completely dissolving the cross-linking agents and the corresponding water according to a proportion of 1:1 to obtain agents B; adding the retarders into the agents A before the agents B are injected, adding the agents B into the agents A and uniformly stirring the agents A, the retarders and the agents B to obtain the PS lignin gel type profile control agent. The PS lignin gel type profile control agent and the method have the advantages of long profile control valid period, high plugging efficiency and good profile control effect.

Owner:大庆市杰森钻采助剂厂

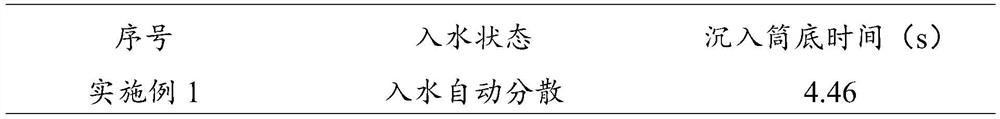

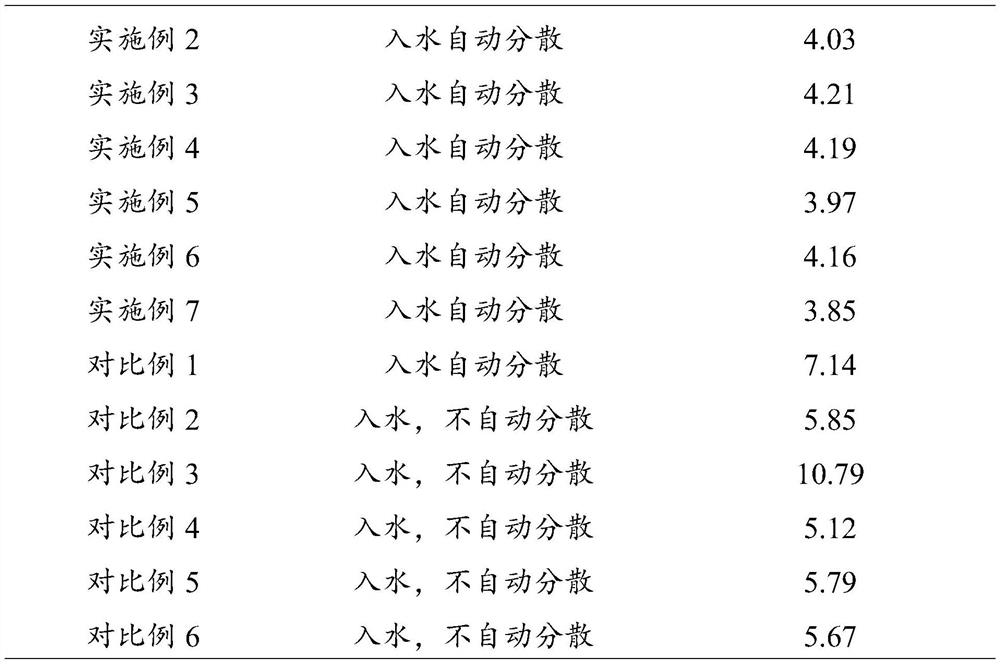

Pymetrozine-dinotefuran dry suspending agent and preparation method thereof

ActiveCN113424832AWell dispersed in waterGood suspensionBiocideAnimal repellantsPhosphoric acidCalcium lignin sulfonate

The invention relates to a pymetrozine-dinotefuran dry suspending agent and a preparation method thereof, and belongs to the technical field of pesticides. The dry suspending agent is prepared from the following components in percentage by mass: 40 to 60 percent of pymetrozine raw medicine, 5 to 30 percent of dinotefuran raw medicine, 1 to 5 percent of anionic dispersing agent, 5 to 10 percent of liquid wetting agent, 5 to 20 percent of lignin and the balance of filler up to 100%, wherein the lignin is sodium lignin sulfonate and / or calcium lignin sulfonate; the anionic dispersing agent comprises ethoxylated tristyryl phenol potassium phosphate salt. The lignin, the anionic dispersant and the liquid wetting agent can generate a synergistic effect with pymetrozine and dinotefuran raw medicines; therefore, the dispersity and suspension performance of the pymetrozine-dinotefuran dry suspending agent are improved, and the preparation is not prone to precipitation and layering and easy to disintegrate.

Owner:中化化工科学技术研究总院有限公司 +1

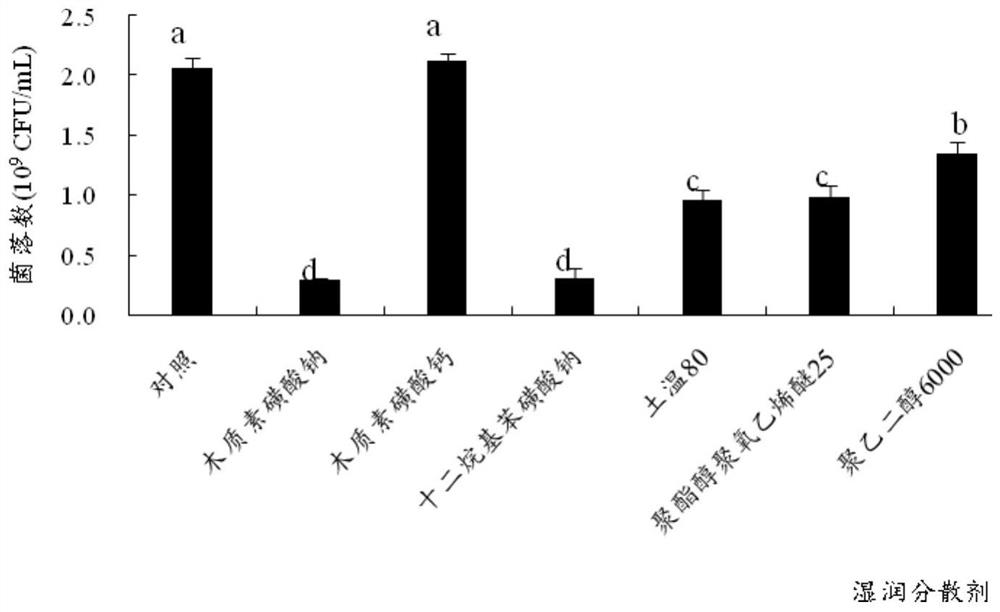

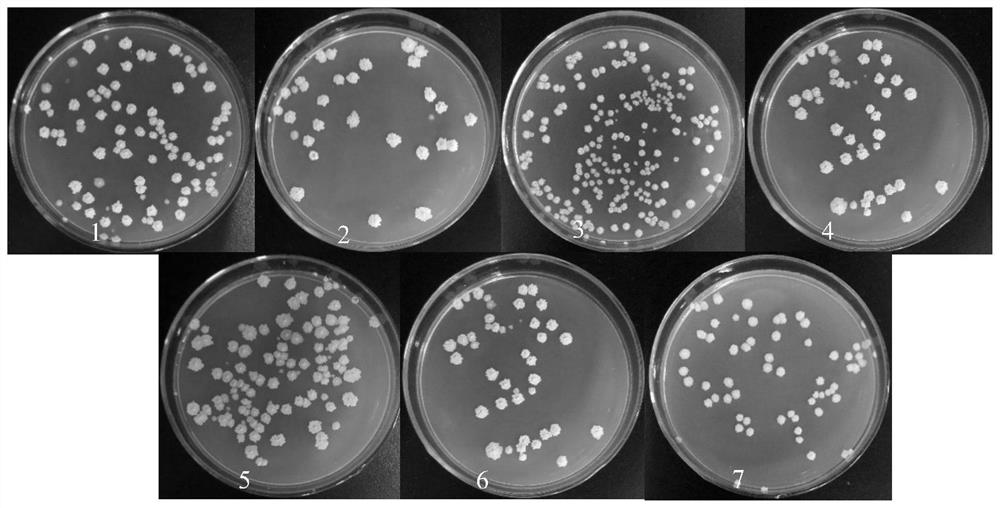

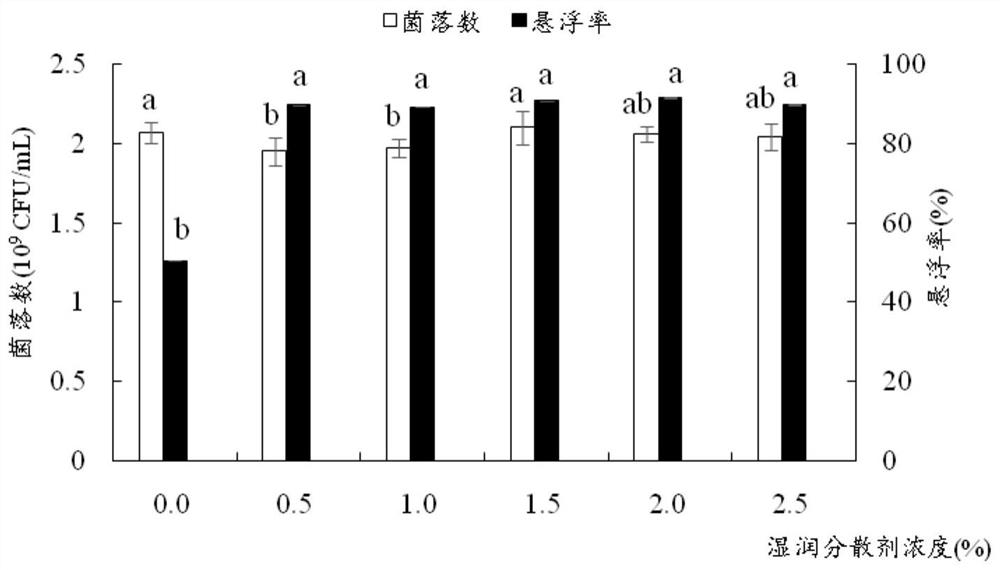

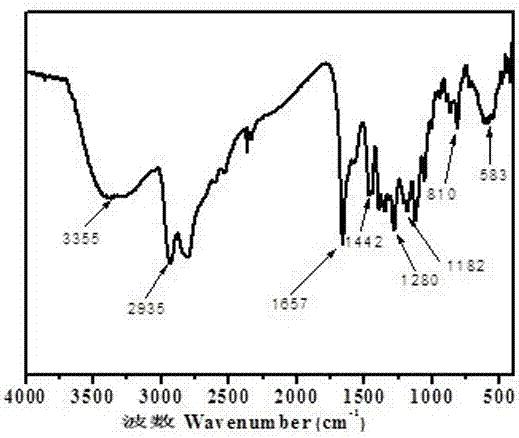

Bacillus velezensis BMF 03 water suspending agent as well as preparation method and application thereof

ActiveCN112493253AGood control effectImprove the effect of prevention and controlBiocideFungicidesBiotechnologySuspending Agents

The invention relates to a bacillus velezensis BMF03 water suspending agent, which is composed of bacillus velezensis BMF03 fermentation broth and an auxiliary agent, and the auxiliary agent comprisesthe following components in percentage by weight: 1.5% of wetting dispersant calcium lignosulphonate, 0.25% of a viscosity modifier xanthan gum; 0.6% of an antifoaming agent soybean oil; 0.8% of preservative sodium chloride; and 0.2% of an ultraviolet protective agent dextrin. The thallus density of the water suspending agent is not lower than 2*10<9>CFU / mL. The invention further discloses a preparation method of the bacillus velezensis BMF03 water suspending agent. The bacillus velezensis BMF03 water suspending agent can be used for preparing a medicine for treating pear ring rot, the BMF 03strain fermentation liquor and the water suspending agent have good prevention and treatment effects on the pear ring rot, the prevention and treatment effects are 63.94% and 69.14% respectively, andthe prevention and treatment effect of the preparation is higher than that of the fermentation liquor.

Owner:JIANGSU OCEAN UNIV

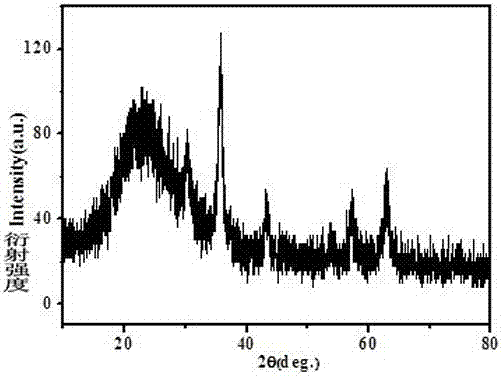

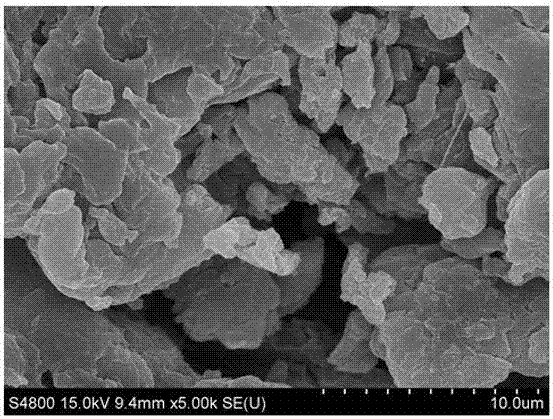

Preparation method of magnetic lignin-based adsorbent and application thereof

InactiveCN107262054AImprove adsorption capacitySimple processOther chemical processesAlkali metal oxides/hydroxidesWater bathsSorbent

The invention belongs to the technical field of composite material synthesis, and relates to a preparation method of a magnetic lignin-based adsorbent, and especially relates to the preparation method of the magnetic lignin-based adsorbent and an application thereof. The method comprises the following steps: a solvothermal method is used for preparing magnetic Fe3O4, the magnetic Fe3O4 is coated by glucose to prepare Fe3O4 / C, through water-bath backflow, calcium lignin sulphonate is taken as a main raw material for compositing the Fe3O4 / C, triethylene tetramine is used for performing aminating modification on the composite material, so that the magnetic lignin-based adsorbent is prepared, which can be used for adsorption treatment for waste water pollution. The lignosulfonate structure has many active functional groups, has certain ion exchange and adsorption performances, and can prepare the magnetic lignin-based adsorption materials with various function through magnetic composition. The method has the advantages of simple process flow, easy operation, easily available raw material, and low cost of raw material, realizes greenization of a synthesis technology and high-efficiency utilization of the waste calcium lignin sulphonate, can reuse papermaking waste, and reduces environment pressure; and the magnetic lignin-based adsorbent has good adsorptive property, and is suitable for industrial production.

Owner:JIANGSU UNIV

Domestic sewage treatment agent and preparation method thereof

InactiveCN107840397AStickyEasy to handleWater treatment parameter controlWater/sewage treatment by flocculation/precipitationSodium acetateActivated sludge

The invention discloses a domestic sewage treatment agent and a preparation method thereof, belonging to the field of sewage treatment. The method includes the following steps: (1) drying and dehydrating the activated sludge; (2) mixing the dried and dehydrated activated sludge, boronite calcium carbonate, and sodium bentonite, putting them into a low-temperature pulverizer for pulverization, and 150 (3) Soak chitin-modified plant fiber and cellulase in bamboo vinegar solution for 1-2 hours, freeze-dry to constant weight, and set aside; (4) Mix the mixed powder, polysilicic acid Add aluminum, calcium chloride, calcium lignosulfonate, aluminum chloride, ferric chloride, sodium acetate, acetyl lanolin, glyceryl monostearate, and potato powder into water and mix well; (5) add sodium alginate , Dry at 130-150°C, grind again, and cool. Each component in the domestic sewage treatment agent of the invention interacts and cooperates with each other, so that the effect of sewage treatment is greatly improved.

Owner:曾世容

Addition for concrete of road for enhacing anti-bending strength

InactiveCN1326795CReduce dosageReduce the water-binder ratioSolid waste managementCalcium lignin sulfonateRebar

The invention relates to a road concrete additive of improving folding strength, prepared of benzene solfonic acid formaldehyde condensation compound, lignin calcium sulfonate, sugar calcium, sodium calcium sulphate, ferrous sulphate, calcium nitrite and powder coal ashes. It can reduce the water dosage of concrete by above 18%, enhances the early strength of concrete by a large margin and increase the 28 d pressive strength, obviously enhance the folding strength of concrete, thus on condition of less dosage of cement, able to make the folding strength of concrete up to the requirements for above secondary roads (folding strength above 4.5 MPa), and simultaneously able to improve the durability of concrete. It can be widely applied to road concrete and simultaneously applied to the constructions (structures) of reinforced concrete, precast concrete, steam cured concrete, etc.

Owner:TONGJI UNIV

Heat-resisting ageing resistant material and preparation method thereof

The invention discloses a heat-resisting ageing resistant material and a preparation method thereof. The material comprises following components in parts by weight: 80-100 parts of polyvinyl chloride (PVC), 10-20 parts of bisphenol A epoxy resin, 5-10 parts of toluene diisocynate, 0.8-2 parts of lignin calcium sulfonate, 8-15 parts of polyethylene glycol 600, 6-15 parts of styrene, 5-10 parts of stabilizer, 1-5 parts of lubricant, 2-6 parts of acrylamide, and 0.5-3 parts of antioxidant. The preparation method comprises the steps of adding the PVC, bisphenol A epoxy resin, styrene, stabilizer and antioxidant into a mixing blender, mixing at certain conditions, then adding the lignin calcium sulfonate and acrylamide, heating up, then adding the left components, stirring for 10-20 minutes at 80-90DEG C, rising the temperature and reacting, so as to obtain the mixture, and finally, extruding the mixture by a twin-screw extruder so as to obtain the heat-resisting ageing resistant plastic.

Owner:佛山市埃森塑胶电器有限公司

Floatable FeS-lignin hydrogel nano composite material, preparation method and application thereof

ActiveCN112774584AEasy to prepareAchieve cross-linkingOther chemical processesWater contaminantsNetwork structureCalcium lignin sulfonate

The invention provides a floatable FeS-lignin hydrogel nano composite material, a preparation method and application thereof. According to the invention, a lignin hydrogel with high strength, light weight and weak water absorption is prepared by interpenetrating network cross-linking of calcium lignosulphonate and sodium alginate, and uniformly distributed nano FeS is loaded on the lignin hydrogel through an in-situ synthesis method, so that the preparation method is simple and convenient, and the raw materials are cheap and easy to obtain and environment-friendly; in the prepared floatable FeS-lignin hydrogel nano composite material, an interpenetrating network structure prevents aggregation and falling of nano FeS, so that the problems that FeS is easy to agglomerate and is difficult to apply and the adsorption effect is reduced due to agglomeration are solved, and the composite material for removing heavy metals has an obvious adsorption removal effect; and the light and weak-water-absorption hydrogel composite material can float, so that later recovery is effectively realized, the purpose of thoroughly removing heavy metals is achieved, and the hydrogel composite material has a wide application prospect.

Owner:SOUTH CHINA AGRI UNIV

Organosilicone waterproof agent for multifunctional high-performance concrete

PendingCN105753365AProlong initial and final setting timeSmall slump lossLiquid stateSodium lignosulfonate

The invention discloses an organosilicone waterproof agent for multifunctional high-performance concrete.The organosilicone waterproof agent is composed of organosilicone, naphthalene sulfonated formaldehyde condensate sodium salt, triethanolamine, sodium lignin sulfonate or calcium lignin sulfonate, citric acid, sodium thiosulfate and water.The organosilicone waterproof agent is a multifunctional liquid-state waterproof agent integrating efficient waterproofness, water reduction and pumping and having slight expansion effect and can meet the technical requirements on pumping construction of large-flow waterproof concrete.The organosilicone waterproof agent can remarkably improve early strength of mortar and concrete, flowability and plasticity maintaining capability and is suitable for waterproof mortar, waterproof concrete and pumping concrete of underground engineering, dykes and dams, building engineering and traffic engineering.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

Waterproof additive for cement

InactiveCN104860570AStrong anti-seepage and anti-leakage performanceImprove waterproof performanceCarboxylic saltCalcium lignin sulfonate

The invention relates to a waterproof additive for cement, wherein components comprise calcium lignin sulfonate, a FDN water reducer, stearic acid, fly ash, lime, calcium sulfate, aluminum sulfate, polyethylene amide, hydroxy carboxylate, and sodium fluorosilicate. According to the waterproof additive prepared by using the formula of the present invention, permeation resistance and leakage resistance are strong, such that the outer surface and the internal of the cement wall or ground becomes oil-based so as to significantly improve water resistance, permeation resistance and leakage resistance of the cement; and the waterproof additive has characteristics of low cost, convenient construction, aging resistance, and long service life, and can be widely used in roofs, kitchens, bathrooms, basements, outdoor walls, water reservoirs, tunnels, culverts, and other moisture-proof and waterproof projects of industrial and civil building.

Owner:RUGAO BINJIANG URBAN CONSTR INVESTMENT

Wastewater processing and purifying agent developed based on agriculture and agricultural technologies

InactiveCN108516596AFast purificationGood effectRunoff/storm water treatmentWater/sewage treatment by flocculation/precipitationIron sulphatePolyethylene glycol

The invention discloses a wastewater processing and purifying agent developed based on agriculture and agricultural technologies. The wastewater processing and purifying agent is composed of followingraw materials in parts by weight: 0.2 to 0.7 part of polyacrylamide, 0.2 to 0.6 part of sodium tripolyphosphate, 3 to 9 parts of modified diatomite, 0.3 to 0.7 part of inorganic flocculant, 4 to 7 parts of polyacrylamide, 2 to 6 parts of diatomite, 0.3 to 0.7 part of light calcium carbonate, 3 to 8 parts of builder, 2 to 7 parts of inorganic flocculant, 0.2 to 0.5 part of polyethylene glycol, 0.3to 0.7 part of graphene, 0.3 to 0.9 part of calcium lignin sulfonate, 3 to 8 parts of active carbon, 2 to 7 parts of alumina powder, 0.3 to 0.6 part of calcium oxide, 0.5 to 1 part of sericite powder, 0.3 to 0.7 part of fly ash, 0.3 to 0.7 part of sodium alginate, 0.3 to 0.8 part of biological fertilizer, 0.4 to 0.7 part of calcium peroxide, 0.3 to 0.6 part of polymeric ferric sulfate, and 2 to 6parts of biological nutrients. The provided wastewater processing and purifying agent has the advantages of quick purifying speed, good effect, environmental friendliness, short purifying time, rapidness, and high efficiency. A sewage purifying agent prepared according to provided formula is convenient to use. The treatment time is short, and the water quality can be maintained for a long term.

Owner:王奔

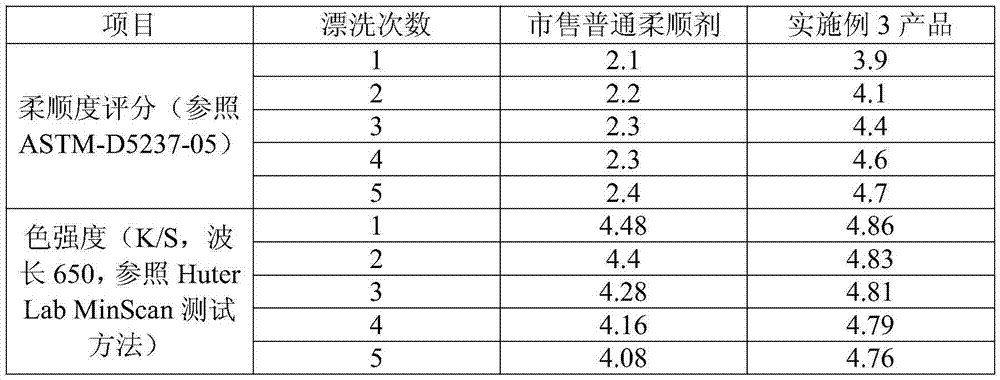

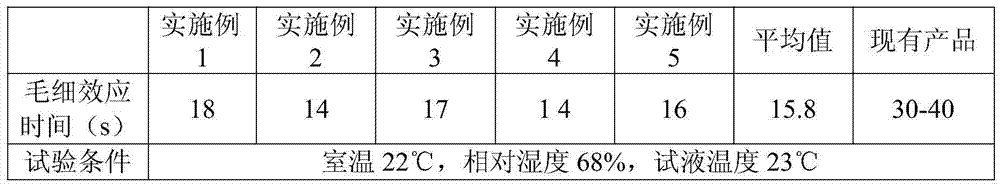

Novel silk softening agent and preparation method thereof

InactiveCN105442315APromote degradationEasy to prepareGrip property fibresAnimal fibresCarrageenanSilanes

The invention discloses a novel silk softening agent and a preparation method thereof, and belongs to the technical field of softening agent processing. The novel silk softening agent comprises the follow raw materials: ester group quaternary ammonium salt, silane modified polyurethane, polyether modified silane, sodium lignosulfonate, sodium alkyl benzene sulfonate, starch grafted sodium acrylate, sodium polyacrylate, sodium N-lauroyl glutamate, calcium lignin sulfonate, citronellal, malic acid, carrageenan, locust bean gum, triadimefon, and deionized water. The novel silk softening agent is prepared by steps of ester group quaternary ammonium salt dissolution, microwave reactions, antifoaming, and pH value adjustment. The provided novel silk has a strong biodegradable performance, and is green and environment-friendly. The preparation method is simple, convenient, and feasible. The preparation cost is low, and thus the popularization and application are easy to promote.

Owner:张莘蔓

Efficient coal combustion-supporting additive and preparation method thereof

The invention relates to an efficient coal combustion-supporting additive and a preparation method thereof. The composition is prepared from the following raw materials in parts by weight: 3-6 parts of dolomite, 2-5 parts of carbide slag, 1-4 parts of calcium lignosulphonate, 2-5 parts of olivine powder, 1-3 parts of magnesium carbonate mineral powder, 1-3 parts of zirconium powder, 1-3 parts of nano shell powder, 0.5-1.5 parts of strontium carbonate, 0.5-2 parts of anhydrous borax, 1-2 parts of potassium chromate and 1-3 parts of a cyclohexane methyl acrylate-polyethylene glycol monoallyl ether-lecithin-vinyl glucopyranoside copolymer. The invention further discloses a preparation method of the efficient coal combustion-supporting additive. The efficient coal combustion-supporting additive disclosed by the invention is remarkable in combustion-supporting effect, and can reduce sulfur dioxide, nitric oxide and smoke dust generated during coal combustion at the same time, so that the purpose of protecting the environment is achieved; in addition, the combustion efficiency can be improved, and the service life of equipment such as a boiler can be prolonged.

Owner:ANHUI ZHENGJIE HIGH TECH MATERIALS CO LTD BY SHARE

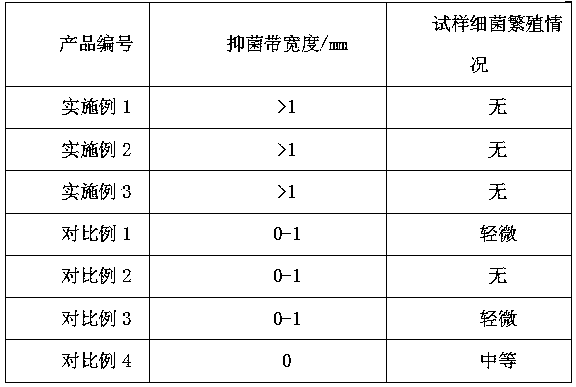

Preparation method of chitosan leather mildew-proof novel material

InactiveCN107801719AImprove the bactericidal effectEvenly dispersedBiocideDisinfectantsBenzoyl peroxideCalcium lignin sulfonate

The invention relates to a preparation method of a chitosan leather mildew-proof novel material. The preparation method of the chitosan leather mildew-proof novel material comprises the following steps: adding the following components in a reaction kettle in parts by weight: carboxymethyl chitosan, ethylene bis(oxy-ethylene) adipic esters, 1,3-adamantane glycol diacrylate, yttrium mesosilicate, N-butylpyridine sulfonate p-toluene sulfonate ionic liquid, calcium lignosulphonate, ethanol, benzoyl peroxide and gelatin; and heating and stirring to obtain the chitosan leather mildew-proof novel material.

Owner:孝感市锐思新材科技有限公司

Water reducer

The invention discloses a water reducer comprising the following components in parts by weight: 35-50 parts of epoxyethane compound, 10-15 parts of urea, 20-40 parts of calcium lignosulphonate, 55-75 parts of sodium hydroxide water solution with the concentration of 30% and 35-55 parts of formaldehyde. The water reducer is prepared by stirring and heating the components. The water reducer disclosed by the invention has a better water reducing property than that of a high-efficiency naphthalene sulfonate formaldehyde condensate water reducer and simultaneously substitutes for the expensive melamine monomer, so that a new water reducer with excellent properties and low price without containing cyanogen, naphthalene and other harmful substances to human bodies, animals and plants is synthesized.

Owner:王琴

Composite fertilizer additive and preparation method thereof

InactiveCN104774073AHigh viscosityHigh particle strengthFertilizer mixturesPolyvinyl alcoholCalcium lignin sulfonate

The invention discloses a composite fertilizer additive and a preparation method thereof. The composite fertilizer additive is prepared by mixing the following raw materials, by weight, 50-55 parts of calcium chloride, 8-15 parts of barium sulfate, 1-3 parts of polyacrylamide, 10-12 parts of carboxymethylcellulose sodium, 2-5 parts of calcium hydrogen phosphate, 2-4 parts of low molecular weight polyacrylic acid, 4-6 parts of ferric chomium calcium lignin sulfonate, 1-2 parts of sodium hyposulfite, 2-4 parts of zinc naphthenate, 3-5 parts of gelatin and 8-10 parts of polyvinyl alcohol. The additive is added to fertilizers in order to improve the pelletizing rate of the fertilizers and reduce the production cost.

Owner:HUBEI GUANGDA CHEM IND CO LTD

Construction composite material with strong stability

InactiveCN104628310AChange the original activityImpermeableCement productionPhenylhydrazine hydrochloridePolyvinyl chloride

The invention discloses a construction composite material with a strong stability. The material is characterized by being composed of the following components in parts by weight: 25 to 30 parts of polyvinyl chloride, 8 to 15 parts of fly ash, 10 to 15 parts of cement clinker, 3 to 4 parts of protective colloid, 10 to 13 parts of hydroxymethyl cellulose, 3 to 5 parts of vinyl acetate, 3 to 4 parts of ethylene, 0.6 to 0.7 part of processing aid ACR401, 0.8 to 1 part of lubricating property modifier LS-303, 0.2 to 0.3 part of polyethylene wax, 0.3 to 0.4 part of paraffin, 0.12 to 0.15 part of stearic acid, 3 to 4 parts of calcium lignin sulfonate, 0.5 to 0.7 part of sodium methyl phenylhydrazine hydrochloride, and 0.5 to 0.8 part of foaming agent. The obtained construction composite material has the characteristics of penetration resistant property, freeze-resistant performance, environment-friendliness, no pollutant discharge, and long service life. The toughness of the construction material is high, during the using process, the adhesive force is strong, the falling ash is reduced, no precipitation is generated, the operation is simple and labor-saving, and the construction material is nontoxic, odorless, and pollution-free and is an environment-friendly construction material.

Owner:青岛诚运建筑工程有限公司

High efficiency water purification composite material and preparation method thereof

ActiveCN106006798AImprove water purification abilitySimple preparation processWater contaminantsWater/sewage treatmentPolyacrylamidePolymer

The invention discloses a high efficiency water purification composite material and a preparation method thereof. The high efficiency water purification composite material is prepared from 85-95 parts by weight of an aluminum ferric chloride polymer, 55-65 parts by weight of polyacrylamide, 10-20 parts by weight of bentonite powder, 5-15 parts by weight of calcium lignin sulphonate, 6-10 parts by weight of basic aluminum chloride and 5-7 parts by weight of polyethylene glycol 400 and benzotriazole. A weight part ratio of polyethylene glycol 400 to benzotriazole is 4-6: 1. The high efficiency water purification composite material has excellent water purification performances and can effectively remove heavy metals in sewage. The preparation method of the high efficiency water purification composite material has simple processes and is suitable for large scale production.

Owner:东莞市天纵企业管理咨询有限公司

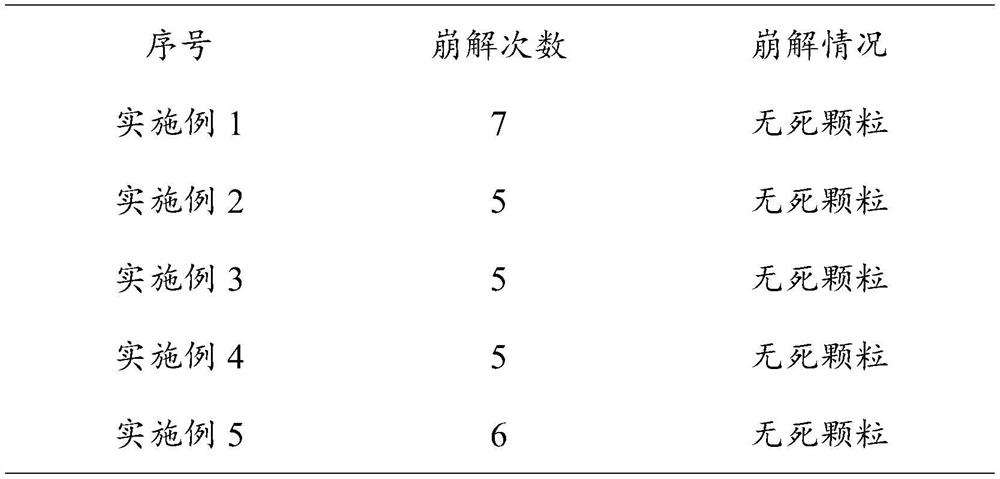

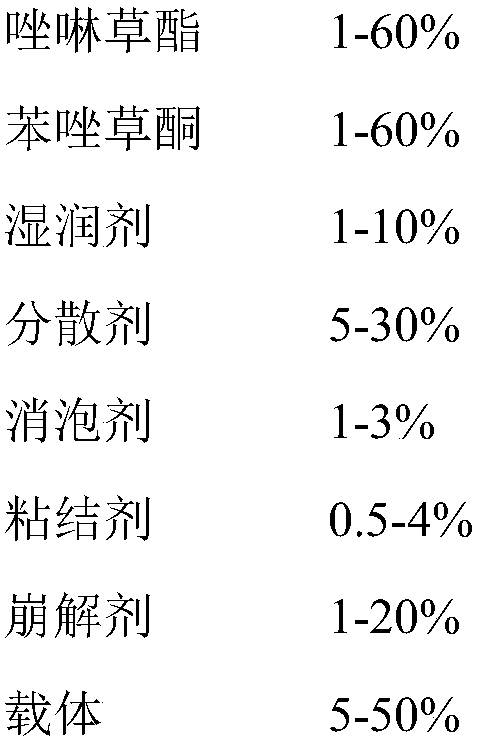

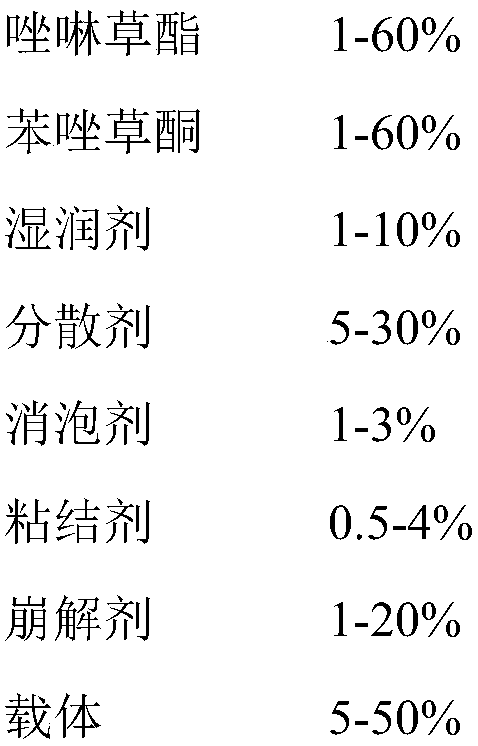

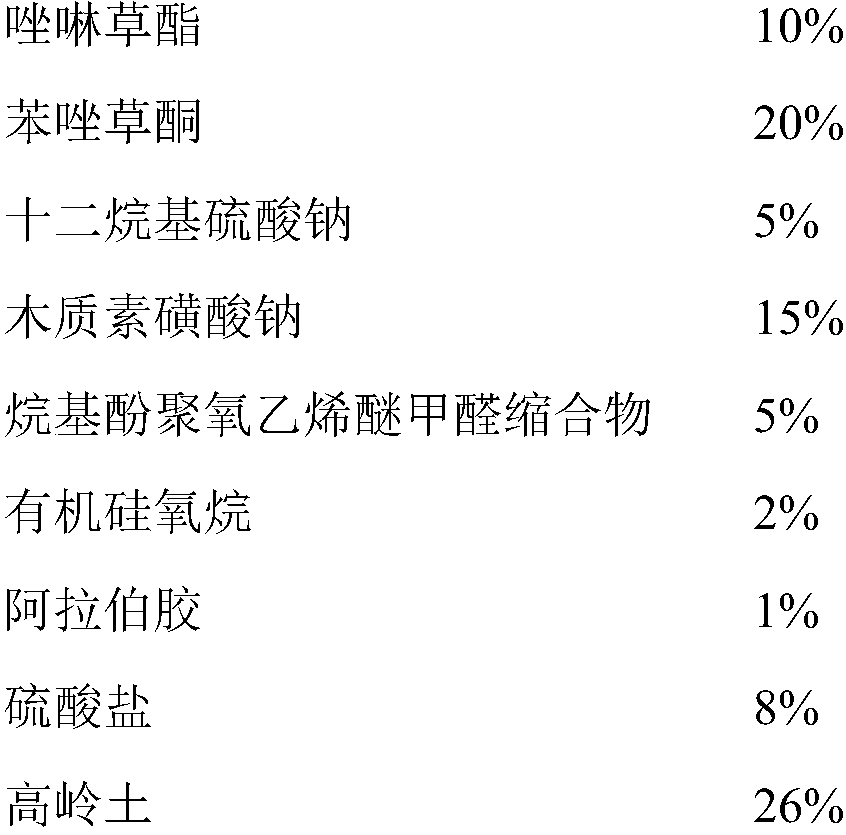

Dry flowable containing pinoxaden and topramezone

The invention relates to a dry flowable containing pinoxaden and topramezone. A dispersant in the dry flowable is a composite dispersant of a lignosulfonate and one selected from an alkylphenol polyoxyethylene ether formaldehyde condensate and a fatty alcohol polyoxyethylene ether sulfate, wherein the weight ratio of the lignosulfonate to the alkylphenol polyoxyethylene ether formaldehyde condensate or the fatty alcohol polyoxyethylene ether sulfate is 5:1-2:1. The lignosulfonate is sodium lignosulfonate or calcium lignosulfonate. The dry flowable of pinoxaden and topramezone has good dispersing and suspending properties in performance, can form a homogeneous suspension system during use, and can save labor and time when being used to spray post-emergence stems and leaves for weeding. Especially, the dry flowable is excellent in stability, especially heat storage stability, due to the selection of a specific composite dispersant.

Owner:NANJING GAOZHENG AGROCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com