Modified polycarboxylate superplasticizer and preparation method thereof

A technology of polycarboxylic acid and water reducing agent, applied in the field of modified polycarboxylic acid water reducing agent and its preparation, can solve the problems of insignificant effect, cumbersome process, restricting development, etc. Simple process and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

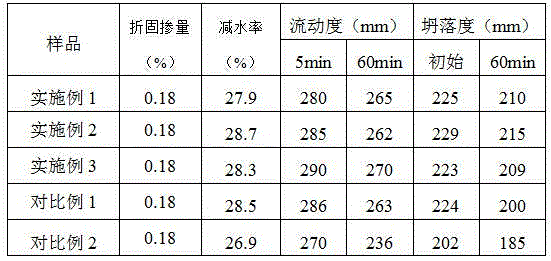

Examples

Embodiment 1

[0030] A modified polycarboxylate water reducer is produced by radical polymerization of the following raw materials in parts by weight:

[0031] Bottom liquid: methallyl polyoxyethylene ether: 300, modified calcium lignosulfonate: 31, sodium methacryl sulfonate: 5, deionized water: 70;

[0032] Solution A: acrylic acid: 35, deionized water: 135;

[0033] Solution B: ammonium persulfate: 2.5, deionized water: 210.

[0034] The preparation method of the modified polycarboxylate water reducer comprises the following steps: when the temperature of the bottom liquid is 80°C, drop solution A into the bottom liquid for 1 hour, and simultaneously add solution B dropwise into the bottom liquid , the dropping time was 1.5 hours; after the dropping was completed, the insulation reaction was carried out for 30 minutes, and then 32% mass concentration of sodium hydroxide aqueous solution was added to adjust the pH value to 6.5, and the temperature was stirred for 20 minutes to obtain the...

Embodiment 2

[0036] A modified polycarboxylate water reducer is produced by radical polymerization of the following raw materials in parts by weight:

[0037] Bottom liquid: methallyl polyoxyethylene ether: 325, modified calcium lignosulfonate: 46, sodium methacrylate: 7, deionized water: 310;

[0038] Solution A: acrylic acid: 41, deionized water: 144;

[0039] Solution B: ammonium persulfate: 3.2, deionized water: 230;

[0040] The preparation method of the modified polycarboxylate water reducer comprises the following steps: when the temperature of the bottom liquid is 85°C, drop solution A into the bottom liquid for 1 hour, and simultaneously add solution B dropwise into the bottom liquid , the dropping time is 1.5 hours; after the dropping is completed, keep the temperature for 30 minutes, then add 32% mass concentration of sodium hydroxide aqueous solution to adjust the pH value to 6.8, and keep stirring for 20 minutes to obtain the modified polycarboxylate water-reduced agent.

Embodiment 3

[0042] A modified polycarboxylate water reducer is produced by radical polymerization of the following raw materials in parts by weight:

[0043] Bottom liquid: methallyl polyoxyethylene ether: 340, modified calcium lignosulfonate: 50, sodium methacryl sulfonate: 9, deionized water: 380;

[0044] Solution A: acrylic acid: 46, deionized water: 160;

[0045] Solution B: ammonium persulfate: 3.9, deionized water: 260.

[0046] The preparation method of the modified polycarboxylate water reducer comprises the following steps: when the temperature of the bottom liquid is 90°C, drop solution A into the bottom liquid for 1 hour, and simultaneously add solution B dropwise into the bottom liquid , the dropping time was 1.5 hours; after the dropping was completed, the insulation reaction was carried out for 30 minutes, and then 32% mass concentration of sodium hydroxide aqueous solution was added to adjust the pH value to 6.1, and the temperature was stirred for 20 minutes to obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com