Soil solidifying agent, and preparation method and use method thereof

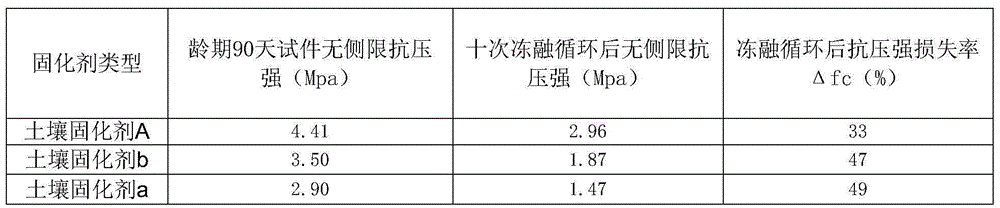

A technology of soil stabilizer and lithium hydroxide, which is applied in the field of building materials, can solve the problems of operator danger, ecological environment damage, high energy consumption, etc., and achieve improved water stability and freezing stability, high use safety, and pressure resistance powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

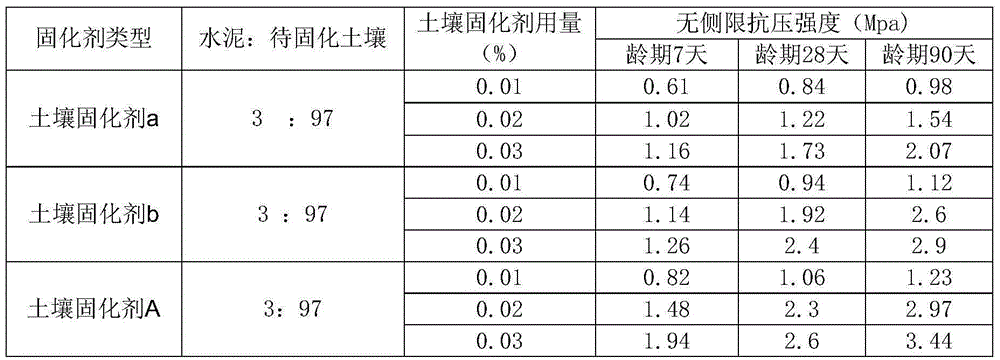

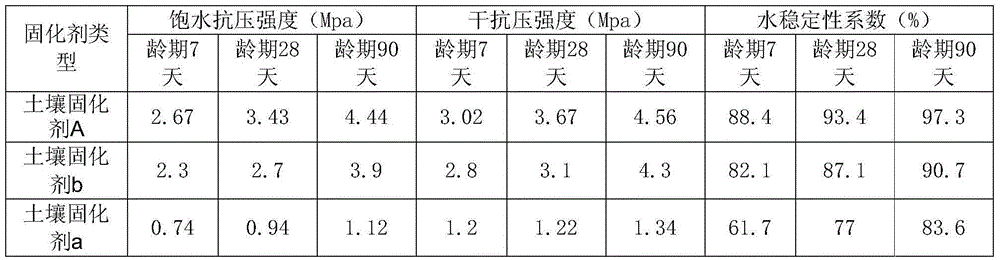

Examples

preparation example Construction

[0025] (2) Preparation method of soil stabilizer

[0026] A kind of preparation method of soil solidifying agent, specifically can comprise following operation:

[0027] Step 1, in parts by weight, heat 7 parts of distilled water to at least 60°C, add 0.4 parts of calcium lignosulfonate, 0.9 parts of sodium polycarboxylate, and 1.7 parts of lithium hydroxide to the distilled water, stir and mix until each group (namely, the three components of calcium lignosulfonate, sodium polycarboxylate and lithium hydroxide) were completely dissolved, and then kept at a constant temperature of 60°C for at least 24 hours to prepare an alkaline neutralizing solution.

[0028] Specifically, after adding calcium lignosulfonate, sodium polycarboxylate, and lithium hydroxide into distilled water, usually stirring for 1 to 2 hours, the calcium lignosulfonate, sodium polycarboxylate, and lithium hydroxide three components are completely dissolved. This process is mainly to prepare alkaline neutr...

Embodiment 1

[0045] A kind of soil solidifying agent A is prepared by adopting the preparation method of the soil stabilizing agent described in the above-mentioned technical scheme; its special feature is: in the process four, the alkaline neutralization solution and the acidic fatty alcohol sulfide The mixing ratio is 1:1 by weight; thus the soil stabilizer A with a pH value of 6.5 is finally prepared.

Embodiment 2

[0047] A kind of soil solidifying agent B is prepared by adopting the preparation method of the soil stabilizing agent described in the above-mentioned technical scheme; its special feature is: in the process four, the alkaline neutralization solution and the acidic fatty alcohol sulfide The mixing ratio is 0.85:1 by weight; thus the soil stabilizer B with a pH value of 5.5 is finally prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com