Method of preparing nano Bi2S3 film

A thin-film and nanotechnology, applied in the field of preparation of nano-Bi2S3 thin films, to achieve excellent photocatalytic activity and enhance redox ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

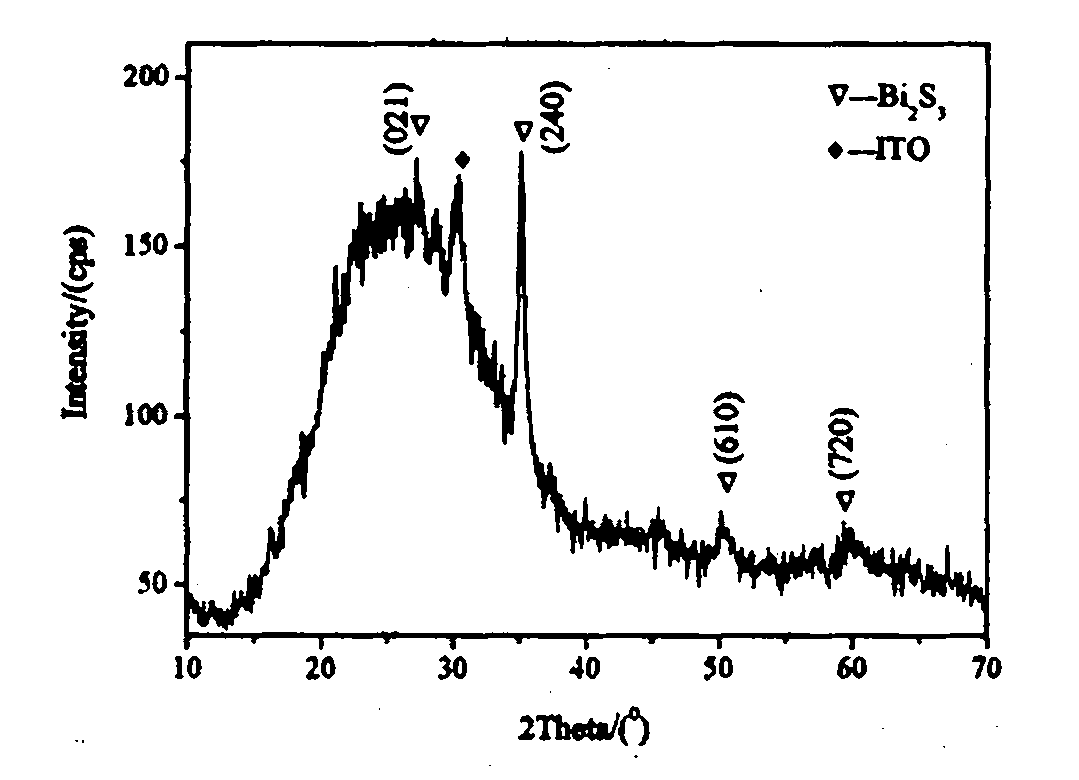

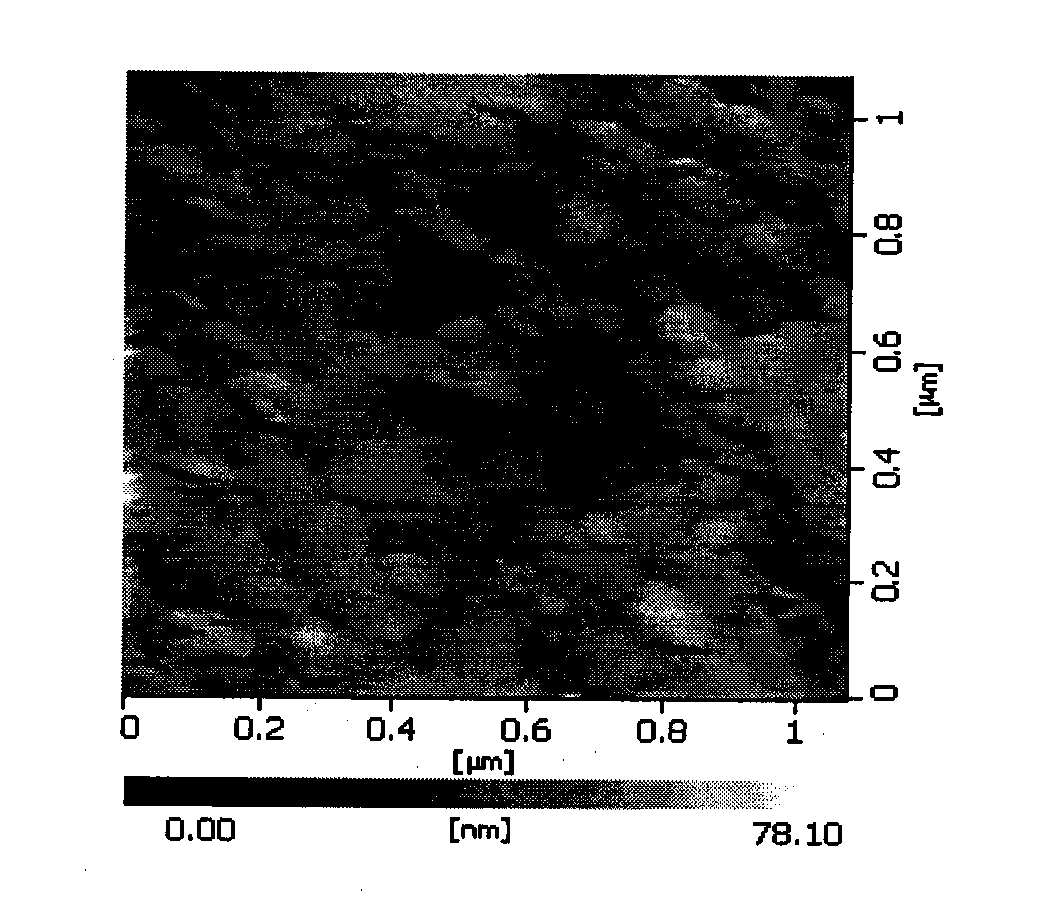

[0013] Embodiment 1: at first will analyze pure Bi(NO 3 ) 3 ·5H 2 O was added to distilled water, and placed in an ultrasonic generator with a power of 100W for ultrasonic dispersion to prepare Bi 3+ Concentration is the transparent solution of 0.0125mol / L, and the gained solution is recorded as A; Then, add analytically pure Na in A solution 2 S 2 o 3 and trisodium citrate, making the mixed solution [Bi 3+ ]:[S 2 o 3 2- ]:[C 6 h 5 o 7 3- ]=1:5:1 molar ratio, under stirring, the pH value was adjusted to 4.5 to form a precursor solution, and the resulting solution was denoted as B; the B solution was placed in an electrodeposition device, and the ITO glass substrate was ultrasonically cleaned in ethanol as As the cathode, graphite is used as the anode, and Bi is prepared on the ITO glass substrate by cathode constant voltage deposition. 2 S 3 Thin film; the deposition voltage is 1V, the deposition time is 20min, and after the deposition, the prepared film is natur...

Embodiment 2

[0015] Embodiment 2: at first will analyze pure Bi(NO 3 ) 3 ·5H 2 O was added to distilled water, and placed in an ultrasonic generator with a power of 100W for ultrasonic dispersion to prepare Bi 3+ Concentration is the transparent solution of 0.2mol / L, and the gained solution is recorded as A; Then, add analytically pure Na in A solution 2 S 2 o 3 and trisodium citrate, making the mixed solution [Bi 3+ ]:[S 2 o 3 2- ]:[C 6 h 5 o 7 3- ]=1:7:1 molar ratio, under stirring, the pH value was adjusted to 5.5 to form a precursor solution, and the resulting solution was denoted as B; the B solution was placed in an electrodeposition device, and the ITO glass substrate was ultrasonically cleaned in ethanol as As the cathode, graphite is used as the anode, and Bi is prepared on the ITO glass substrate by cathode constant voltage deposition. 2 S 3 thin film; the deposition voltage is 3V, and the deposition time is 17min. After the deposition, the prepared film is naturall...

Embodiment 3

[0016] Embodiment 3: first will analyze pure Bi(NO 3 ) 3 ·5H 2 O was added to distilled water, and placed in an ultrasonic generator with a power of 100W for ultrasonic dispersion to prepare Bi 3+ Concentration is the transparent solution of 0.3mol / L, and the obtained solution is recorded as A; Then, add analytically pure Na in A solution 2 S 2 o 3 and trisodium citrate, making the mixed solution [Bi 3+ ]:[S 2 o 3 2- ]:[C 6 h 5 o 7 3- ]=1:4:1 molar ratio, under stirring, the pH value was adjusted to 4.3 to form a precursor solution, and the resulting solution was denoted as B; the B solution was placed in an electrodeposition device, and the ITO glass substrate was ultrasonically cleaned in ethanol as As the cathode, graphite is used as the anode, and Bi is prepared on the ITO glass substrate by cathode constant voltage deposition. 2 S3 film; the deposition voltage is 8V, and the deposition time is 13min. After the deposition, the prepared film is naturally dried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com