Patents

Literature

120 results about "Sodium polycarboxylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polycarboxylates are linear polymers with a high molecular mass (Mᵣ ≤ 100 000) and with many carboxylate groups. They are polymers of acrylic acid or copolymers of acrylic acid and maleic acid. The polymer is used as the sodium salt (see: sodium polyacrylate).

High-elasticity external wall paint and its preparation method

The preparation method of high-elasticity external wall paint includes the following steps: adding 7-12 portions of water, 0.2-0.4 portions of sodium polycarboxylate, 0.2-0.3 portions of mildew-proof agent deconil M, in-tank-preservative chloromethyl-methyl isothiazolinone and oxirene alkyl acid ether into dispersing tank; slowly adding hydroxyethyl cellulose, at the same time mechanically stirring and adding alcohol ester 12, propanediol, defoaming agent SN345-organic silicon and inorganic silicon mixture, rutile titanium pigment and calcium carbonate (800 meshes); transferring the above-mentioned materials, liquid into mixing tank, and adding 34-39 portions of elastic polyacrylic emulsion, 8-10 portions of pure polyacrylic emulsion, 5.6-10 portions of OP-62B covering polymer and other.

Owner:崔玉国

Sound-absorbing radiation protective paint and preparation method thereof

ActiveCN101831211AImprove sound absorptionGood radiation protectionRadiation-absorbing paintsLow speedHydroxyethyl cellulose

The invention relates to a sound-absorbing radiation protective paint, which comprises the following components in percentage by weight: 30 to 38 percent of porous modified starch, 5.0 to 9.5 percent of styrene-acrylic latex emulsion, 33 to 41 percent of barite, 0.5 to 1 percent of iron oxide, 0.25 to 1 percent of sodium polycarboxylate dispersant, 0.01 to 1 percent of brightening agent, 1.0 to 6 percent of titanium white, 0.5 to 1 percent of defoamer, 0.01 to 1 percent of mildew preventive, 13 to 18 percent of water, 0.4 to 1 percent of ethylene glycol, 0.3 to 1 percent of film-forming auxiliary agent, 0.005 to 1 percent of anti-freeze agent, 0.5 to 1 percent of graphite, 1 to 3 percent of hydroxyethyl cellulose and 0.20 to 1 percent of thickening agent. A preparation method of the sound-absorbing radiation protective paint comprises the steps of: (a) premixing, namely stirring 1 / 2 water, the sodium polycarboxylate dispersant, 1 / 2 defoamer, the mildew preventive, the thickening agent, the hydroxyethyl cellulose and the brightening agent at low speed to form colloidal solution; (b) dispersing and grinding, namely adding the titanium white, the barite, the graphite and the iron oxide into the colloidal solution and stirring the solution at high speed to prepare uniform sizing agent; (c) paint mixing, namely adding crylic acid emulsion, the film-forming auxiliary agent and the anti-freeze agent into the sizing agent, uniformly stirring the sizing agent, then dividing the porous modified starch into 1 to 5 parts, and adding the porous modified starch by 1 to 5 times into the mixture for low-speed and uniformly stirring the mixture; and (d) packaging the resulting product.

Owner:谢绍何

Coating Liquid and Gas Barrier Laminate

ActiveUS20110217561A1Good dispersionExcellent gas barrier propertiesSynthetic resin layered productsPolyurea/polyurethane coatingsPolyester resinCarboxylic acid

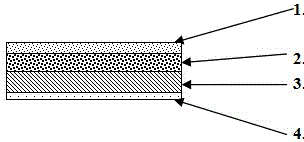

Provided are aqueous coating liquids that contain ultrafine inorganic compound particles with good dispersibility, and gas barrier laminates of excellent transparency and gas barrier properties that have a layer formed from the coating liquid. The coating liquid includes ultrafine inorganic compound particles, a polyester resin, a sodium polycarboxylate and water. The gas barrier laminate includes a substrate and a gas barrier layer formed on the substrate, wherein the gas barrier layer has a layer (A) formed from the coating liquid and a layer (B) containing a polycarboxylic acid polymer.

Owner:TOPPAN PRINTING CO LTD

Polymer cement RG waterproof coating and preparation method therefor

The present invention provides a polymer cement RG waterproof coating. The coating comprises a liquid material and a powder material, wherein the liquid material comprises an emulsion, an NXZ defoamer, an A10 defoamer, a dispersant, a thickener, a preservative, and water; the powder material comprises white cement and heavy calcium. The present invention also provides a polymer cement RG waterproof coating. The coating comprises a liquid material and a powder material. The feedstock of the liquid material is as follows in parts of weight: 90 parts of a modified polyacrylic elastic emulsion, 10 parts of a VAE emulsion, 50 parts of an SD-5281 nanometre silicone-acrylic emulsion, 60 parts of an SD-628 tertiary fluoro emulsion, 8 parts of a sodium polycarboxylic acid dispersing agent, 10 parts of a DR-7010 thickener, 5 parts of the A10 defoamer, 5 parts of a compound preservative, and 20 parts of water. The invention has the advantages of good impermeability, high tensile strength, high breaking elongation, and high bond strength.

Owner:凯鑫防水材料股份有限公司

Titanium dioxide production method

ActiveCN104098136AIncrease hydrolysis rateHydrolyzed evenly and fullyTitanium dioxideBoiling pointSodium silicate

The invention relates to a titanium dioxide production method and belongs to the field of titanium dioxide. The titanium dioxide production method produces titanium dioxide through a sulfuric acid method. A hydrolysis method comprises the following steps of a, adding dispersant, wherein the dispersant is at least one of sodium polycarboxylate, sodium silicate and sodium hexametaphosphate, wherein the mass ratio between the dispersant and TiO2 in titaniferous solution is 0.2-2%; b, performing heating and curing including heating the hydrolysis system obtained in the step a to a first boiling point, when the hydrolysis system is steel grey, namely, is at a graying point, stopping heating and mixing and performing first curing for 0-40 minutes; c, performing second curing including, after finishing the first curing, heating the hydrolysis system to a second boiling point and maintaining a micro-boiling state; d, supplementing desalted water into the hydrolysis system and maintain the micro-boiling state of the system until hydrolysis reaction is completed. The titanium dioxide production method can improve the hydrolysis rate and meanwhile improve the washing efficiency of metatitanic acid, thereby reducing the cost of sulfuric acid method titanium dioxide production.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Dual-fluid grouting material for sand and gravel stratum and application method thereof

The invention discloses a dual-fluid grouting material for a sand and gravel stratum, which comprises a fluid I and a fluid II, wherein the fluid I comprises the following components in parts by weight: 40-60 parts of water, 40-60 parts of cement and 0.2-1.5 parts of sodium-polycarboxylate dispersing agent; and the fluid II comprises the following components in parts by weight: 40-60 parts of water and 40-60 parts of water glass. The invention also discloses an application method of the dual-fluid grouting material for a sand and gravel stratum. Since the sodium-polycarboxylate dispersing agent can be adsorbed to the solid particle surface, the condensed solid particle surface can be easily wetted, thereby preparing the grout for a sand and gravel stratum. Compared with the traditional cement-water glass grout, the grout disclosed by the invention has higher flowability, uniformity and injectability, so that the dual-fluid grout has wide injection range and more uniform dispersion in the sand and gravel stratum.

Owner:BEIJING MUNICIPAL CONSTR +2

Nanometer anti-radon antibacterial latex paint

The invention provides nanometer anti-radon antibacterial latex paint, which comprises the following components in portion by weight: 95.0 to 115.0 portions of nanometer polyacrylate emulsion, 7.5 to9.5 portions of film-forming additives, 4.5 to 5.5 portions of sodium polycarboxylate serving as dispersant, 2.0 to 2.4 portions of anti-mildew anti-algae agent, 70.0 to 90.0 portions of nanometer titanium dioxide serving as antimicrobial agent, 125.0 to 145.0 portions of nanometer calcium carbonate serving as filler, 50.0 to 150.0 portions of nanometer barium metaborate serving as radioactive absorbent, 4.5 to 5.5 portions of associative thickener, 0.6 to 1.0 portions of pH regulator, 1.5 to 2.5 portions of leveling modifier, and 31.5 to 151.5 portions of water. The latex paint forms water-proof shielding film with bad air permeability in the coating process, has the advantages of high indoor anti-radon efficiency, good decorative effect, easy construction and the like, and can be used asanti-radon material for modern families, high-radioactivity buildings and underground buildings.

Owner:珠海展辰新材料股份有限公司

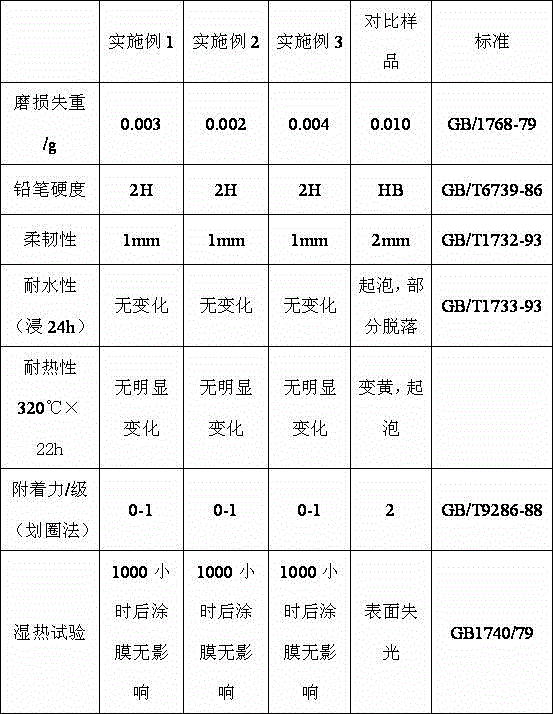

Abrasion-resistant coating for automobile spring steel plate and preparation method of abrasion-resistant coating

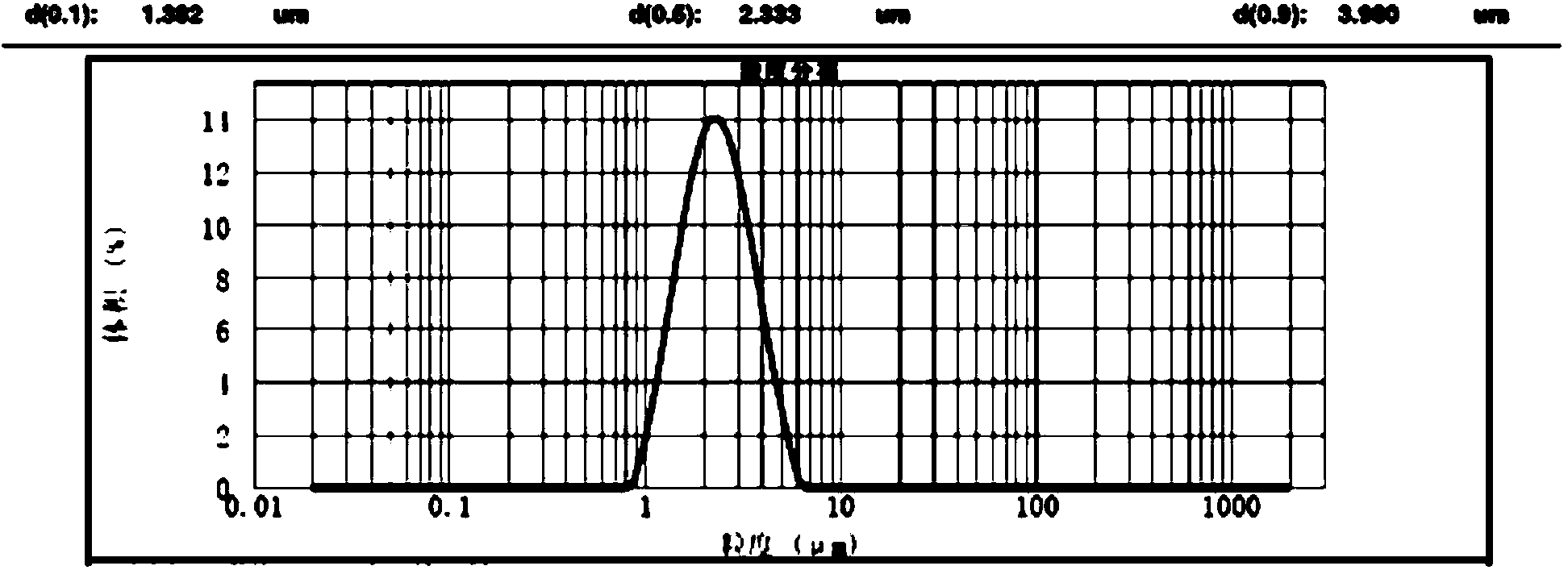

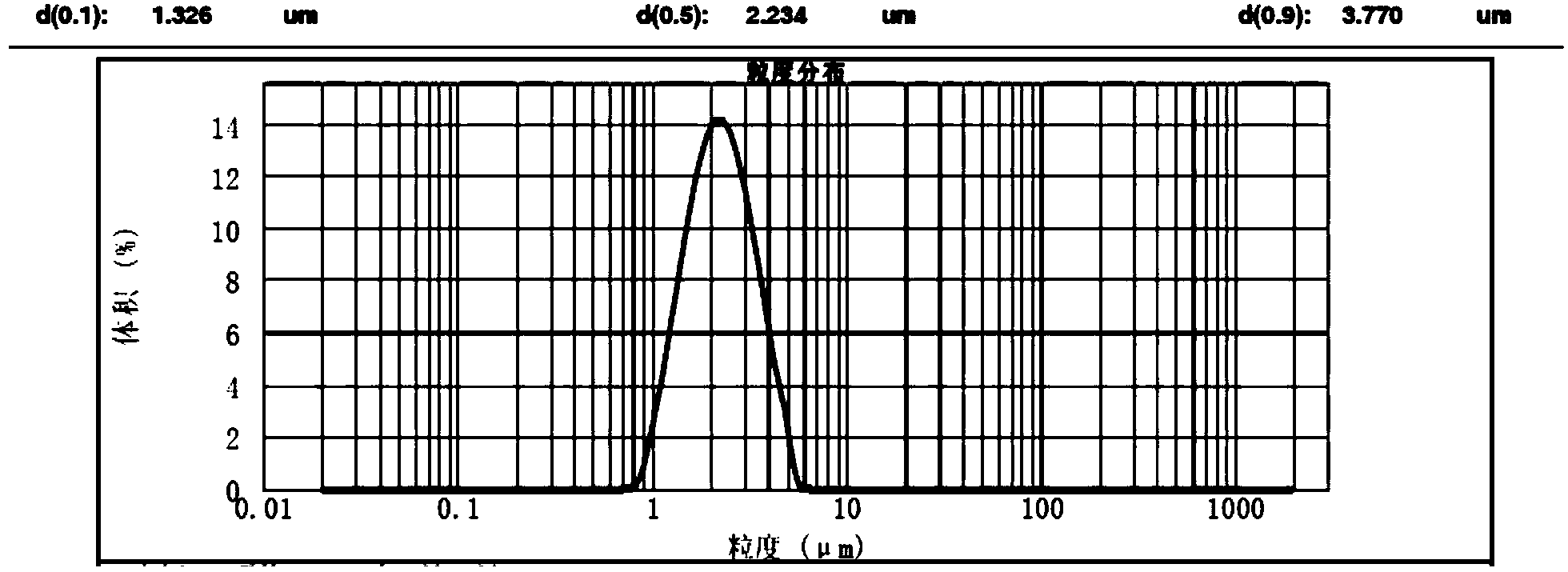

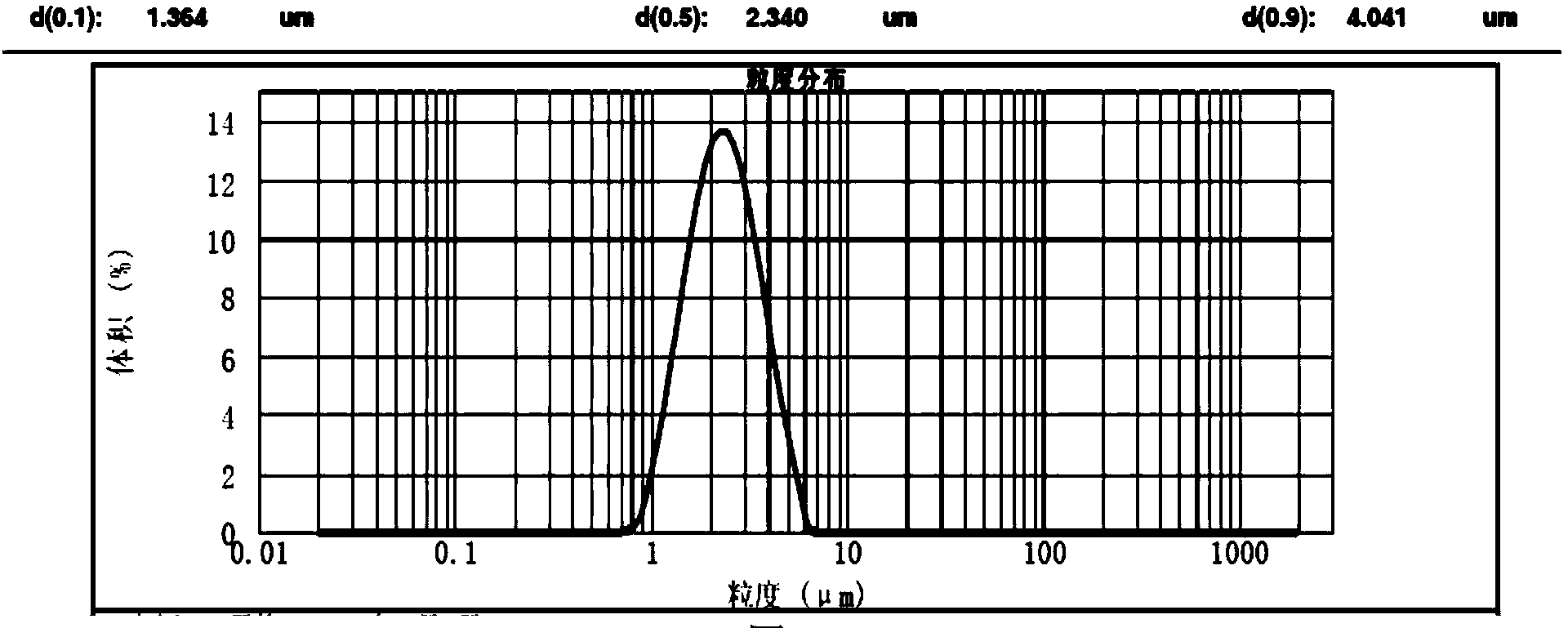

ActiveCN104356870ASmall particle sizeGood dispersionAnti-corrosive paintsEpoxy resin coatingsPolymer adhesiveSodium phosphates

The invention relates to an abrasion-resistant coating for an automobile spring steel plate and a preparation method of abrasion-resistant coating and belongs to the field of abrasion-resistant coating. According to the abrasion-resistant coating, tetrafluoroethylene latex is synthesized by virtue of a micro-emulsion method, the synthesized tetrafluoroethylene latex has the advantages of small grain size, good dispersibility, good stability and the like and is conductive to applying the coating; by adding a nanometer powder material, the corrosion resistance and abrasion resistance of the epoxy resin coating can be increased; sodium polyacrylate and sodium polycarboxylate used in a dispersant have good nanometer powder dispersing effects; by adding sodium tripolyphosphate, the stable dispersion of the polymer latex is facilitated; the stability and dispersibility of the coating are increased through the synergistic effect of sodium polyacrylate, sodium polycarboxylate and sodium tripolyphosphate; components of a curing agent have the advantage of room temperature curing so that the curing process is simple; the abrasion-resistant coating for the automobile spring steel plate disclosed by the invention is simple in process and convenient to operate and is conducive to large-scale industrial production.

Owner:陕西雷帕得悬架系统有限公司

Heavy corrosion-resistant paint for industry and preparation method thereof

InactiveCN104212324AImprove corrosion resistanceStrong anti-salt spray performanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolyamideFirming agent

The invention discloses heavy corrosion-resistant paint for industry. The heavy corrosion-resistant paint comprises the following components in parts by weight: 10-30 parts of epoxy resin, 25-45 parts of polyurethane, 2-15 parts of solvent, 2-4 parts of modified amino silicon oil, 1-5 parts of polysiloxane, 1-3 parts of chlorinated paraffin, 1-3 parts of sodium polycarboxylate, 5-10 parts of polyamide, 8-15 parts of D9050 modified aromatic resin epoxy curing agent and 13-17 parts of additive; the additive comprises the following components in parts by mass: 10-15 parts of dispersing agent, 5-10 parts of thickening agent, 5-10 parts of film-forming additive, 1-5 parts of PH adjusting agent, 5-10 parts of silane coupling agent, 2-6 parts of delustering agent and 1-6 parts of defoaming agent. The heavy corrosion-resistant paint disclosed by the invention has strong corrosion-resistant property and anti-salt-mist property and can be firmly adsorbed on the surface of metal so as to have good corrosion-resistant and anti-rusting property; and the heavy corrosion-resistant paint has the advantages that the corrosion-resistant time is long, the raw materials are easily obtained, the production process is simple, the construction is convenient, the operation is easy, the drying speed is high, the construction period is short and the demolding is not needed in the following processing procedure. The invention also discloses a method for preparing the heavy corrosion-resistant paint for industry.

Owner:JIANGSU MARINE VICTORY COATING

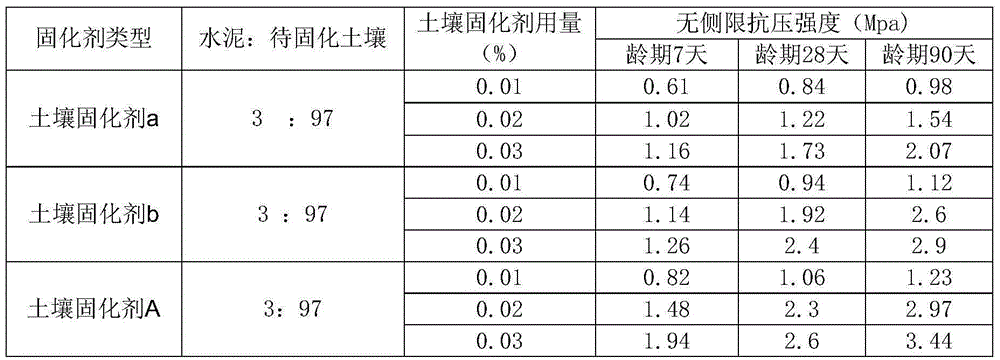

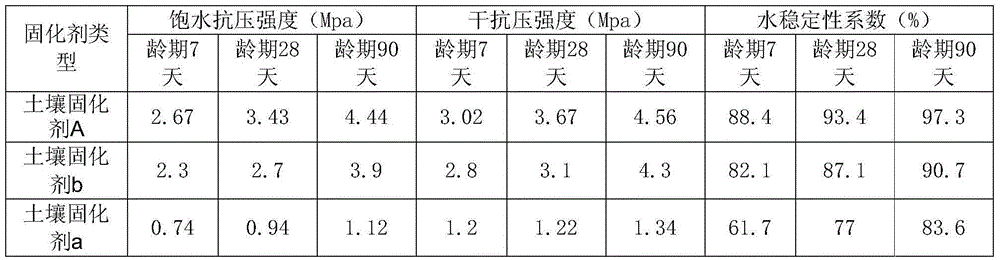

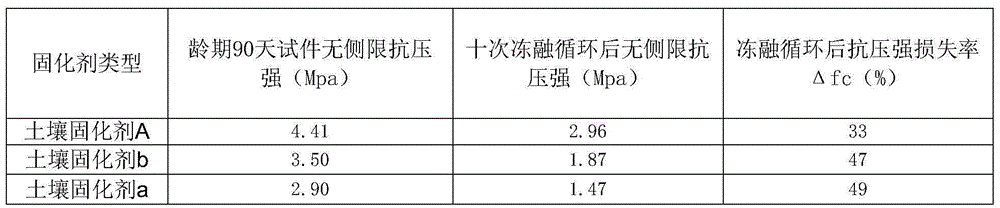

Soil solidifying agent, and preparation method and use method thereof

ActiveCN105018103APH adjustableImprove the safety of useBuilding constructionsOrganic fertilisersLithium hydroxidePhosphate

The invention discloses a soil solidifying agent, and a preparation method and a use method thereof. The soil solidifying agent is prepared from, by weight, 0.4 parts of calcium lignin sulfonate, 0.9 parts of sodium polycarboxylate, 1.7 parts of lithium hydroxide, liquid aluminum dihydrogen phosphate, illegally recycled waste cooking oil, sulfamic acid and distilled water, the pH value of the soil solidifying agent is 5-9, a weight ratio of the illegally recycled waste cooking oil to the liquid aluminum dihydrogen phosphate is 1.5:1, and the use amount of sulfamic acid is 1 / 2 of the total weight of the illegally recycled waste cooking oil and the liquid aluminum dihydrogen phosphate. The preparation method of the soil solidifying agent comprises the following steps: preparing an alkaline neutralization solution, preparing acidic fatty alcohol sulfide, mixing the alkaline neutralization solution with the acidic fatty alcohol sulfide, layering and extracting, and filtering to prepare the finished soil solidifying agent. The soil solidifying agent provided by the invention is not strong acidic or alkaline, and has the advantages of high safety, no pollution to environment, strong compression resistance, high water stability, high freeze stability and realization of waste utilization of the illegally recycled waste cooking oil; and the preparation method of the soil solidifying agent has the advantages of low energy consumption, no pollutants, safety and environmental protection.

Owner:BEIJING HUAXIA PIONEERING NEW MATERIAL

Nano self-cleaning external wall paint

The invention discloses a nano self-cleaning external wall paint and a production method thereof, relating to the technical field of chemical industry. The nano self-cleaning external wall paint comprises the following components in percentage by weight: 50-55% of nano silicon resin, 15-18% of titanium white, 13-16% of ultrafine coarse whiting powder, 2-2.5% of C12 alcohol ester, 0.3-1% of sodium polycarboxylate, 0.3-1% of polyether modified siloxane, 0.6-0.8% of 2-(2-hydroxy-3,5-ditert-butyl)-5-benzotriazole chloride, 0.2-0.3% of polyoxyethylene fatty acid ester, 0.5-1% of polyacrylate, 0.1-0.2% of 1,2-benzothiazolinyl-3-one, 0.8-1% of 2-(4-thiazolyl)benzimidazole and the balance of water. The invention can solve the problems of poor pollution resistance, high pollution tendency and dissatisfactory heat insulation effect in the coating.

Owner:DRAGON FISH PAINT

Flame-retardant insulating paint

InactiveCN103756506AStrong adhesionHigh mechanical strengthFireproof paintsEpoxy resin coatingsElectrical conductorFirming agent

The invention relates to a flame-retardant insulating paint, belonging to the technical field of paint. The flame-retardant insulating paint comprises the following components in parts by weight: component A: 100-120 parts of epoxy resin, 7-10% of magnesium hydroxide whisker, 6-12 parts of Tetraphenyl resorcinol bis(diphenylphosphate), 10-25% of silica micropowder, 4-8 parts of 2,4-dihydroxybenzophenone, 0-5 parts of pigments, 0.5-2 parts of polycarboxylic acid sodium salt, 0.2-0.5% of defoaming agent, 5-10 parts of acetone, and 8-15 parts of ethyl acetate; component B: 2-10 parts of curing agent. The paint not only has the advantages of being strong in adhesion force, high in mechanical strength, good in high temperature resistance property, excellent in anti-corrosion and humidity resistance properties, fast in low-temperature drying speed, and good in storage stability, but also has excellent flame-retardant property, electric insulating property and anti-ultraviolet property, and can be used for flame-retardant insulating paint for surfaces of conductors in various electrical devices.

Owner:吴江市东泰电力特种开关有限公司

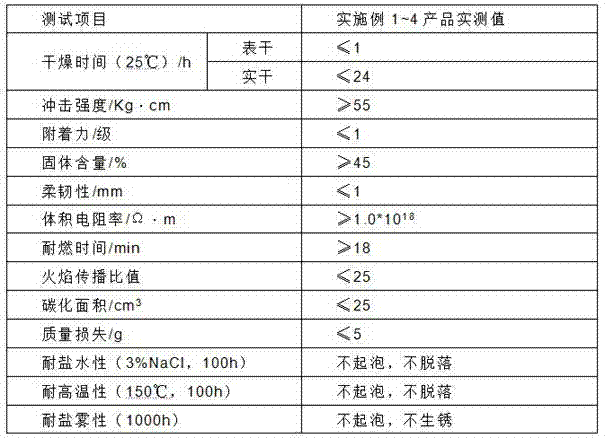

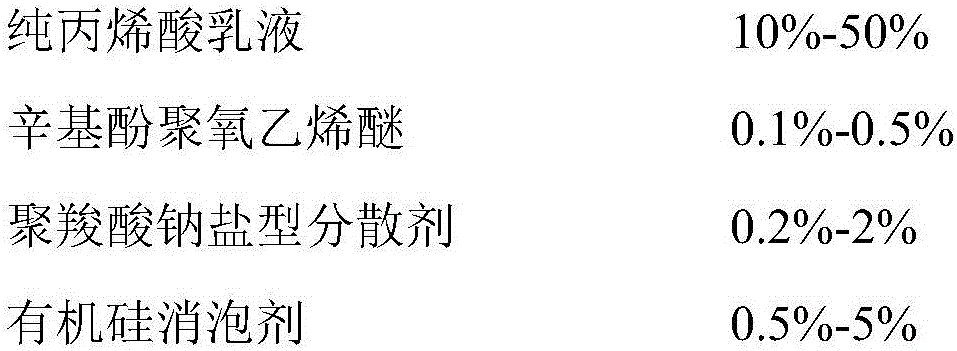

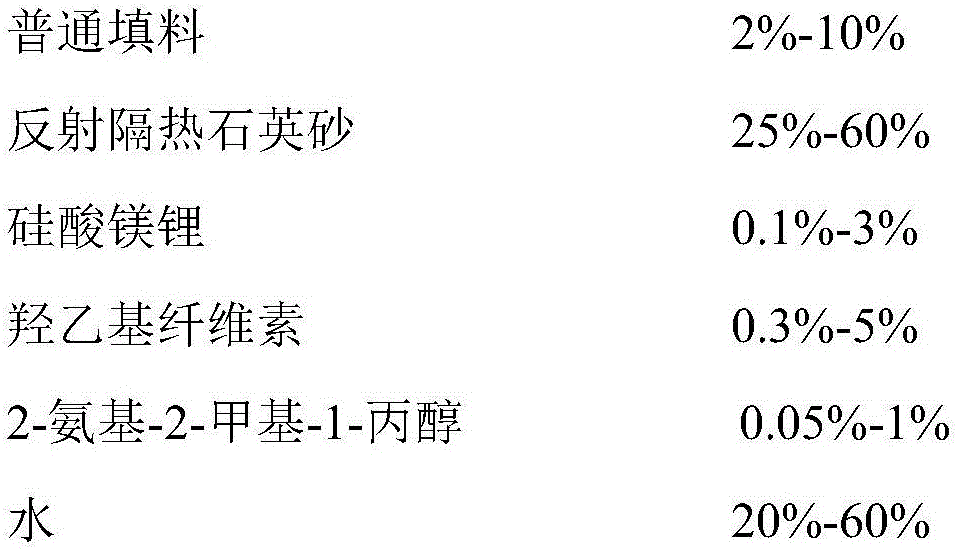

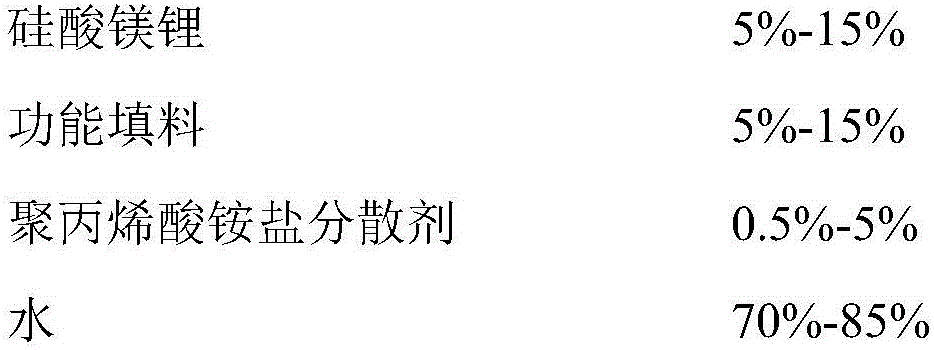

Reflective-insulation quality-sense colorful coating and a preparing method thereof

ActiveCN106497284AImprove functionalityReduce the temperatureReflecting/signal paintsMulticolor effect coatingsHydroxyethyl cellulose2-methyl-1-propanol

Reflective-insulation quality-sense colorful coating is disclosed. The coating comprises a base quality-sense component A, a functionalization component B and a light-covered oil-coated component C. The base quality-sense component A comprises a pure acrylic acid emulsion, octylphenol polyoxyethylene ether, a sodium polycarboxylate type dispersant, a silicone defoamer, a common filler, reflective-insulation quartz sand, magnesium lithium silicate, hydroxyethyl cellulose, 2-amino-2-methyl-1-propanol and water. The functionalization component B comprises magnesium lithium silicate, a functional filler, an ammonium polyacrylate dispersant and water. The light-covered oil-coated component C comprises a coating emulsion, Texanol ester alcohol, water and a thickening agent. A preparing method of the coating is disclosed. The coating can imitate marble decorative effects with high quality, has a coarse rock sense better than that of common colorful coating, has a certain reflective insulation property and is more energy saving and environment friendly.

Owner:宁波新安涂料有限公司 +1

Alloy material liquid forging release agent and preparing method thereof

ActiveCN104226897ASmall coefficient of thermal expansionLow gas productionFoundry mouldsFoundry coresPhosphatePotassium

The invention relates to an alloy material liquid forging release agent. The alloy material liquid forging release agent is prepared from the following ingredients: 6-18% of mullite, 1-5% of talcum powder, 0.5-5% of light silicon oxide, 1-5% of diatomite, 0.5-1% of sodium polycarboxylate, 0.1-1.5% of iso-tridecanol polyoxyethylene ether, 0.05-0.1% of sodium polyacrylate, 0.05-1.5% of n-octanoic acid, 0.05-1.5% of n-capric acid, 0.02-0.6% of magnesium hydrogen phosphate trihydrate, 0.5-1.5% of arabic gum, 0.05-0.8% of potassium polyoxyethylene ether phosphate, 0.5-1.5% of polyether organic silicone, 0.01-0.3% of dialkyl sulfosuccinate and the rest of deionized water. The invention further provides a preparing method of the release agent. The alloy material liquid forging release agent can avoid die attaching, cold shut and air vent phenomena in the liquid forging process, and the technology of the preparing method is easy to operate and low in cost.

Owner:GUANGDONG DONGGUAN TEAMRUN ELECTRONICS MATERIAL

Antifouling coating material for ship surfaces and preparation method of material

PendingCN109749580ALower surface energyIncrease contact angleAntifouling/underwater paintsPaints with biocidesEpoxyPolyamide

The invention relates to the technical field of antifouling coating materials for marine ships, and discloses an antifouling coating material for ship surfaces. The coating material comprises the following raw materials in parts by weight: 45-60 parts of organic silicon modified epoxy resin, 5-20 parts of polytetrafluoroethylene, 5-15 parts of paraffin oil, 5-10 parts of ethanol, 3-6 parts of nanotitanium dioxide, 2-5 parts of magnesium oxide, 0.5-0.8 parts of talcum powder, 0.5-2 parts of dodecyl alcohol, 3-8 parts of chitin / chitosan, 0.8-1.5 parts of sodium polycarboxylate dispersants, 3-10parts of polyamide, 1-3 parts of acetone and 1-3 parts of N-methylpyrrolidone. The invention further discloses a preparation method of the antifouling coating material for the ship surfaces. The technical problem that the antifouling coating material can not effectively improve the adhesion performance and impact resistance while effectively improving the antifouling performance.

Owner:许飞

Liquid soil solidifying agent and preparation method, using method and application thereof

InactiveCN108715764AShort curing timeControllable pollutionBuilding constructionsOrganic fertilisersSulfonateSludge

The invention discloses a liquid soil solidifying agent and a preparation method, a using method and the application thereof. The liquid soil solidifying agent is prepared by adding water to dilute the following raw materials in percent by weight: 45-55% of diethanol monoisopropanolamine, 20-30% of sodium polycarboxylate, 10-20% of lignosulfonate, 5-10% of polyethylene OP-10 and 2-5% of sodium alpha-alkenyl sulfonate. The liquid soil solidifying agent is simple in production technology, can control dust pollution after addition into cement, effectively shortens the solidifying time of sludge solidification, and is small in addition amount, high in strength, low in cost and good in curing stability effect.

Owner:天津市三川恒泰科技有限公司

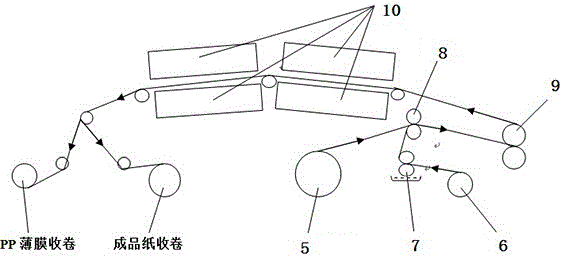

Transfer coating ink-jet printing high-gloss photographic paper

ActiveCN105970724AGood ink absorptionGood color fixing effectWater-repelling agents additionDuplicating/marking methodsEmulsionPolyvinyl acetate

The invention relates to a paper and especially relates to a transfer coating ink-jet printing high-gloss photographic paper. The paper comprises a surface coating, a base coating, a raw paper layer and a back coating. The surface coating is an ink absorption water-resistant gloss coating. The base coating is an ink absorption fixation coating. The back coating is a water-resistant coating for balancing two surface tensions of a photographic paper. The base coating comprises light calcium carbonate, a sodium polycarboxylate dispersant, a polyvinyl acetate emulsion adhesive, a polyvinyl alcohol glue solution and a fixer. The surface coating comprises aqueous silica sol and a polyvinyl alcohol glue solution. The back coating comprises polyvinyl alcohol. The photographic paper surface is a high-gloss mirror surface, images obtained by color ink-jet printing have plump colors and realizes real restoration and ink absorption and fixing performances are good.

Owner:ZHEJIANG JUNMA DIGITAL TECH

Sulphate-attack-resistant concrete admixture and preparation method thereof

ActiveCN109650769AAvoid adverse effects on mechanical propertiesImproves resistance to sulfate attackAdhesivePrice ratio

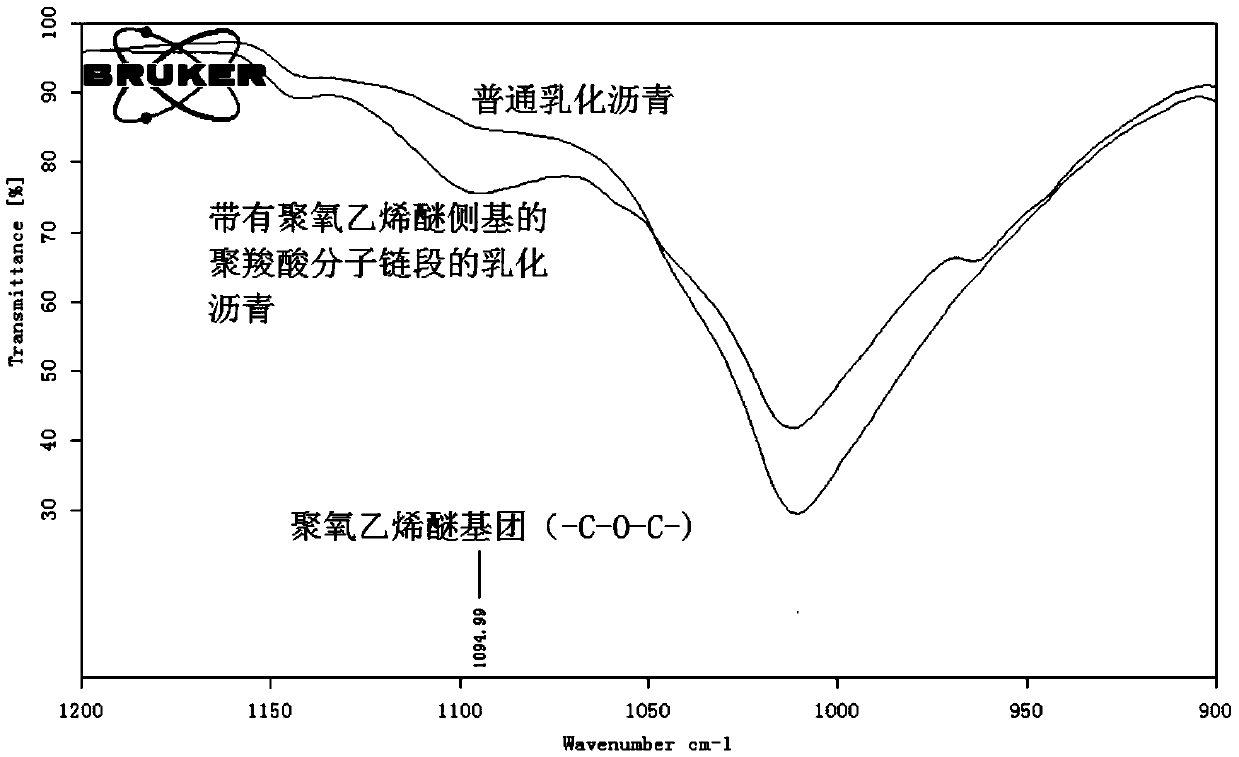

The invention provides a sulphate-attack-resistant concrete admixture and a preparation method thereof. The concrete admixture is prepared from, by mass, 100 parts of asphalt, 5-8 parts of a macromolecule emulsifier, 0-1 part of a stabilizer, 0-1 part of a protective adhesive, 5-10 parts of an excipient, 5-10 parts of a modifier, and 100-120 parts of water, wherein the macromolecule emulsifier refers to sodium polycarboxylate salt containing a polyoxyethylene ether lateral group, and the molecular weight range is from 10000 to 22000. The macromolecule emulsifier, the modifier, the excipient and other reagents are adopted, emulsified asphalt is prepared and modified, through the modification effect of all the components, emulsified asphalt has a good sulphate-attack-resistant effect when used in a cement system, the original mechanical properties of concrete are maintained, and modified sulphate-attack-resistant emulsified asphalt which has good corrosion resistance and is easy to apply and high in performance-price ratio is prepared.

Owner:TIANJIN BUILDING MATERIALS SCI RES INST

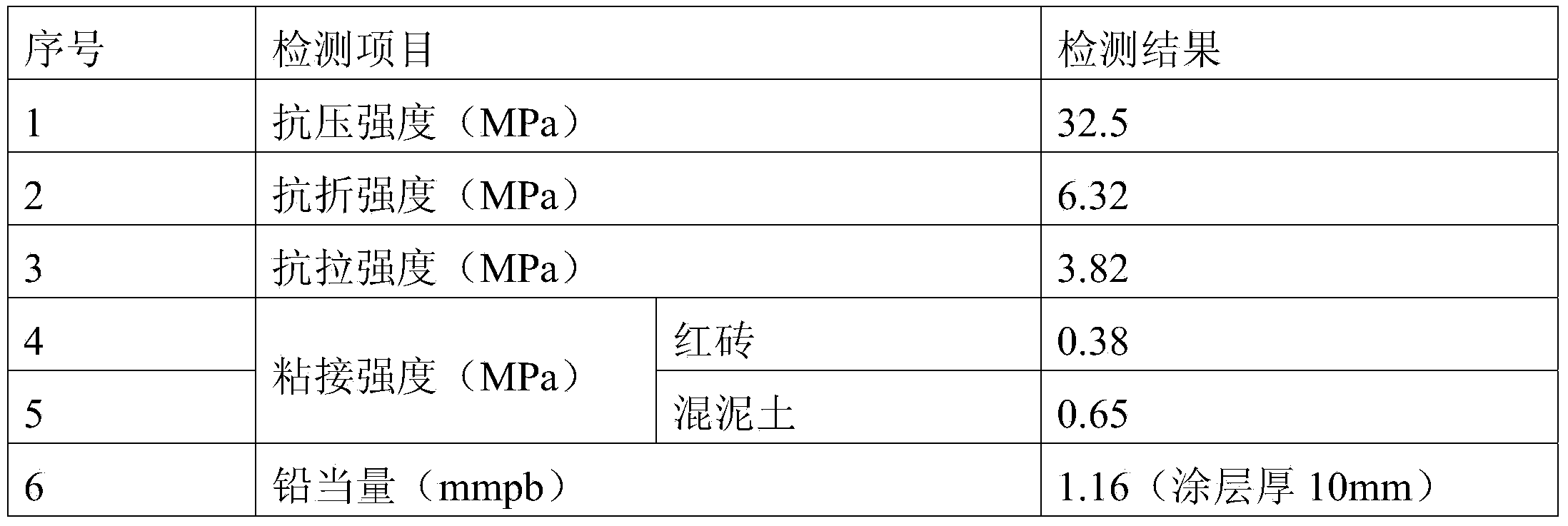

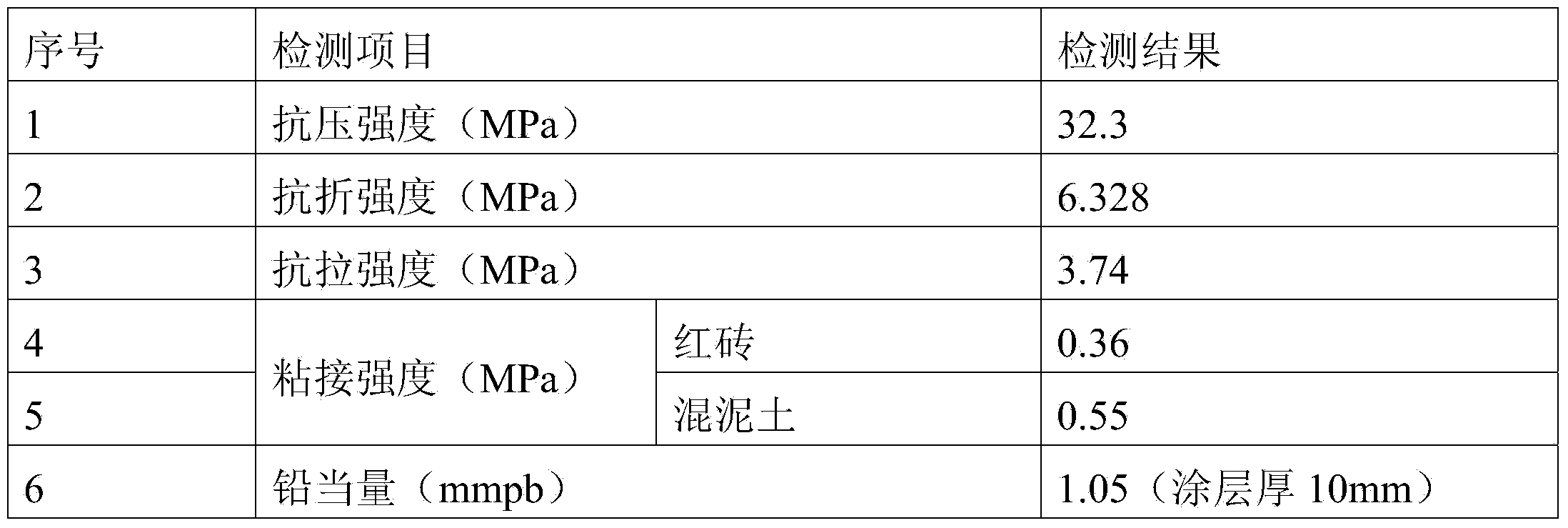

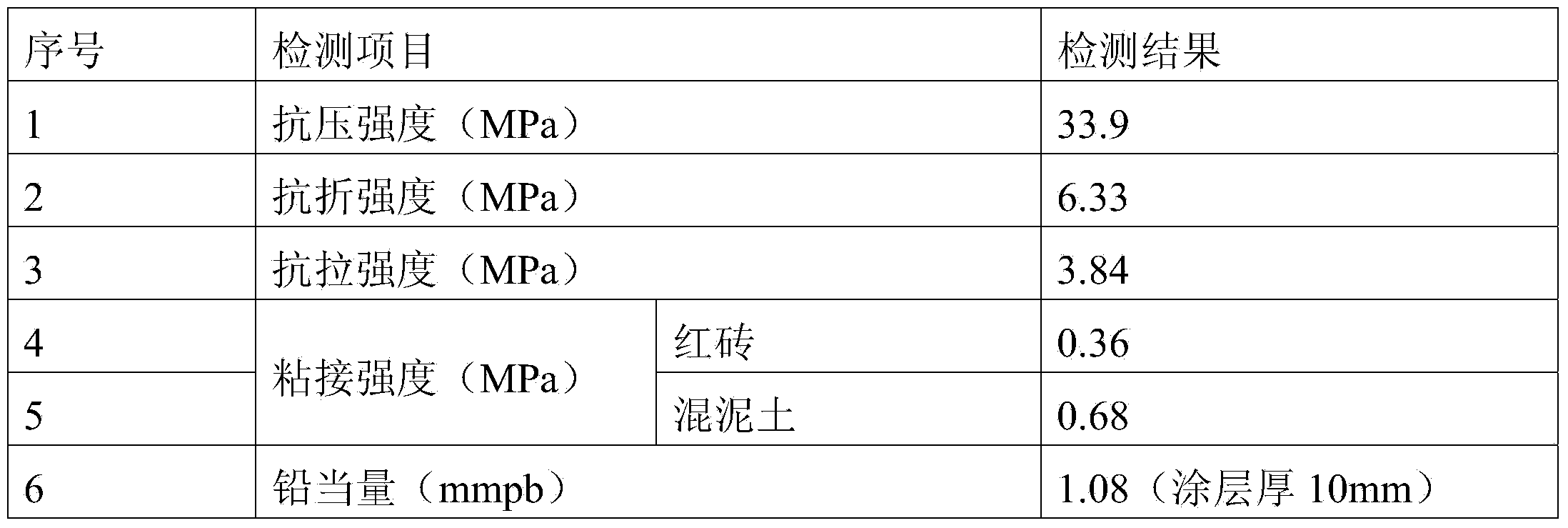

Radiation-proof coating and preparation method thereof

InactiveCN103555071AImprove performanceEasy to transportStarch coatingsRadiation-absorbing paintsEpoxyGamma ray

The invention proposes a radiation-proof coating and a preparation method thereof. The radiation-proof coating is prepared from the following raw materials in parts by weight: 8-12 parts of talcum powder, 8-12 parts of lime powder, 40-50 parts of porous starch, 8-12 parts of titanium dioxide, 8-12 parts of quartz powder, 35-45 parts of barium carbonate, 8-20 parts of epoxy modified silicone resin powder, 8-12 parts of styrene-acrylic emulsion, 0.8-1.5 parts of sodium polycarboxylate dispersant, 0.3-0.9 part of thickener, 0.1-0.5 part of defoamer, 0.8-1.2 parts of coupling agent and 40-70 parts of water. Compared with the prior art, the radiation-proof coating disclosed by the invention has the beneficial effects that the radiation-proof coating is safe and non-toxic, stable in performance, and easy to transport and store; the lead equivalent is 1.05 mmpb at least when the thickness of the coating achieves 10mm; the radiation-proof coating has strong absorbing ability on X and gamma rays, and is simple in preparation technology, and low in preparation cost; no secondary refraction is generated.

Owner:张洪男

Environment-friendly and sound-insulation building paint and preparation method thereof

InactiveCN106752582AAchieve removalAchieve long-term effectFireproof paintsAntifouling/underwater paintsFiberEpoxy

The invention discloses environment-friendly and sound-insulation building paint and a preparation method thereof. The environment-friendly and sound-insulation building paint is prepared from the following raw materials in parts by weight: 25 to 35 parts of quartz sand, 20 to 30 parts of aqueous silicone acrylic emulsion, 18 to 25 parts of lightweight calcium carbonate, 10 to 15 parts of lignosulfonates, 15 to 20 parts of diatomite, 10 to 15 parts of sodium polycarboxylate, 15 to 25 parts of montmorillonite clay, 2 to 4 parts of organic silicon modified epoxy resin, 5 to 8 parts of nanometer aluminum silicate and 6 to 9 parts of talcum powder. The environment-friendly and sound-insulation building paint has a good sound-adsorption effect and is safe and environmentally friendly; the indoor space is saved; a coating has a good sound-adsorption effect and the coating has no seams and is stuck with a wall body to form a whole body, so that an indoor space is hardly occupied; meanwhile, the environment-friendly and sound-insulation building paint disclosed by the invention also has the effects of purifying air and adjusting the humidity; a coating film contains a plurality of pores and the inner area is large; toxic and harmful gas in the air can be adsorbed; and meanwhile, the humidity of the indoor air can be adjusted, and a pore wall, especially wood fibers, can adsorb certain moisture when the air humidity is relatively great.

Owner:芜湖浩权建筑工程有限公司

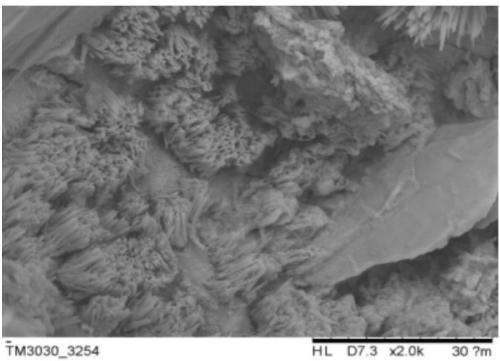

Preparation method of superfine boron carbide spray granulation powder

The invention belongs to the field of nano material processing and discloses a preparation method of superfine boron carbide spray granulation powder. The preparation method includes: using compressed air to well mix boron carbide powder not larger than 500um, deionized water and sodium polycarboxylate, and grinding paste to 0.4-0.5um in granularity; enabling obtained paste to pass a 500-mesh sieve, using 'tu-4 cup' to measure and strip-pasting to 100S, sequentially adding polyethylene glycol 6000 water solution and hydrogen peroxide, and feeding compressed air for well mixing; pumping obtained paste into a centrifugal spray granulator which is already preheated through a peristaltic pump for granulation drying to obtain spray granulation powder; detecting and aging for 48h, and subjecting to boron carbide ceramic sintering to obtain the superfine boron carbide spray granulation powder. Other grading processes do not need to be adopted, one drying process is omitted, production period is short, and energy consumption is low; the superfine boron carbide spray granulation powder creates a condition for non-pressure sintering of boron carbide ceramic.

Owner:大连正兴磨料有限公司

Self-cleaning flame-retardant exterior wall coating and preparation method thereof

InactiveCN104277637ASmall contaminationImprove adhesionFireproof paintsAntifouling/underwater paintsEpoxyPolymer science

The invention discloses a self-cleaning flame-retardant exterior wall coating. The self-cleaning flame-retardant exterior wall coating is characterized by being prepared from the following raw materials in parts by weight: 36-42 parts of an acrylic resin emulsion, 30-35 parts of a vinyl epoxy resin emulsion, 3-4 parts of aluminum silver powder, 2-3 parts of polyisobutylene, 3-4 parts of rutile-type nanometer titanium dioxide powder, 2-4 parts of propylene glycol monomethyl ether, 0.3-0.5 part of sodium polycarboxylate, 2-3 parts of silica sol, 0.3-0.6 part of triethanolamine oleate, 2-3 parts of titanium phosphate, 2-3 parts of tin antimony phosphate, 1-2 parts of lithopone, 1-2 parts of kaolin, 0.4-0.8 part of an acrylic alkali-swellable thickener, 1-2 parts of tris(2-chloropropyl) phosphate, 1-2 parts of aminoethyl aminopropyl triethoxysilane, 6-9 parts of a self-cleaning slurry and 14-20 parts of deionized water. The exterior wall coating has the characteristics of high adhesion, good adhesive force, good weather resistance and high aging resistance and chalking resistance; due to addition of the silica sol, the hardness and abrasion resistance of the coating film are enhanced; the added aluminum silver powder has a bactericidal effect, the added self-cleaning slurry has an excellent self-cleaning effect; tin antimony phosphate has self-cleaning enhancing effect and thus the staining property of the exterior wall is reduced and the cost of manual cleaning is reduced; and the added tris(2-chloropropyl) phosphate has a flame-retardant effect and reduces risk factors causing the fire disaster.

Owner:ANHUI LENCAQI BUILDING MATERIAL

High-temperature-resistant coating for high-temperature device and preparation method of high-temperature-resistant coating

InactiveCN108727981AExtended service lifeReduce energy consumptionFireproof paintsPolyurea/polyurethane coatingsFiber1-Propanol

The invention provides high-temperature-resistant coating for a high-temperature device and a preparation method of the high-temperature-resistant coating. The high-temperature-resistant coating is prepared from the following components: lithium-based bentonite, modified organic silicon resin, waterborne polyurethane emulsion, toughening fiber, high-temperature-resistant filler, high-temperature binder, mineral oil, texanol, phenoxy-1-propanol, hydroxymethyl cellulose, sodium polycarboxylate, polymethylphenylsiloxane and deionized water. The high-temperature-resistant coating can be applied tovarious high-temperature devices, can be used for a long time at a higher temperature, can save the energy consumption, can prolong the service life of the high-temperature device, and also has the advantages of simple preparation process, and suitability for industrialized mass production.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

Tile adhesive capable of solidifying fast

InactiveCN105295794AFreeze fastImprove adhesionNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

A tile adhesive capable of solidifying fast is prepared from, by weight, 6-11 parts of dichloromethane, 3-8 parts of n-butyl alcohol, 1-5 parts of zinc oxide, 6-11 parts of epoxy resin, 5-9 parts of polysulfide rubber, 4-6 parts of talcum powder, 4-10 parts of polyvinyl ester, 4-7 parts of styrene-butadiene emulsion, 3-7 parts of nano calcium carbonate, 1-5 parts of coalescing agent, 4-8 parts of dithiocarbamate accelerator, 1-3 parts of sodium polycarboxylic acid dispersing agent, 4-8 parts of sulphur, 4-9 parts of natural emulsion, 4-6 parts of curing agent and 17-26 parts of cement. The tile adhesive has the advantages that tile adhesive capable of solidifying fast can solidify fast, personnel construction is facilitated, and meanwhile waterproofness and adhesiveness are good.

Owner:宁贻伟

Exterior wall fireproofing coating free of antiseptic mildew inhibitor, and preparation method thereof

PendingCN110903712AAvoid stabilityAvoid the disadvantage of being irritating to human skinFireproof paintsAntifouling/underwater paintsCelluloseSilicic acid

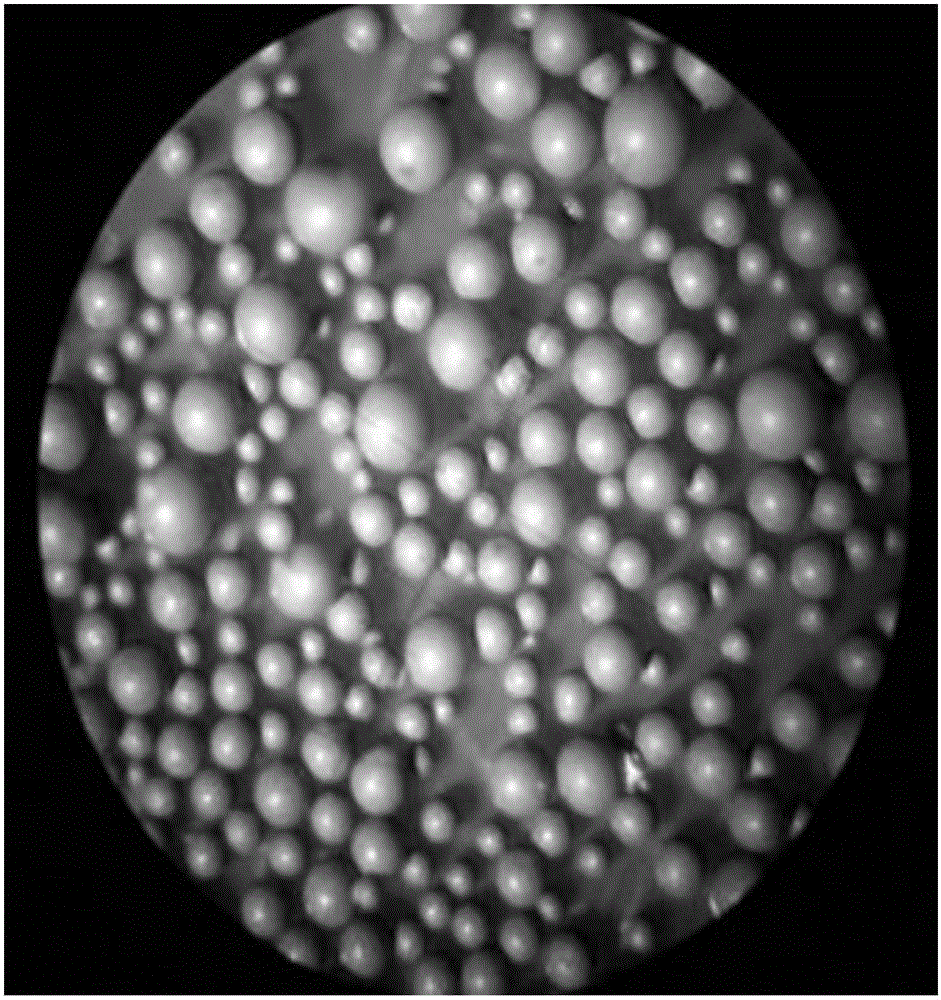

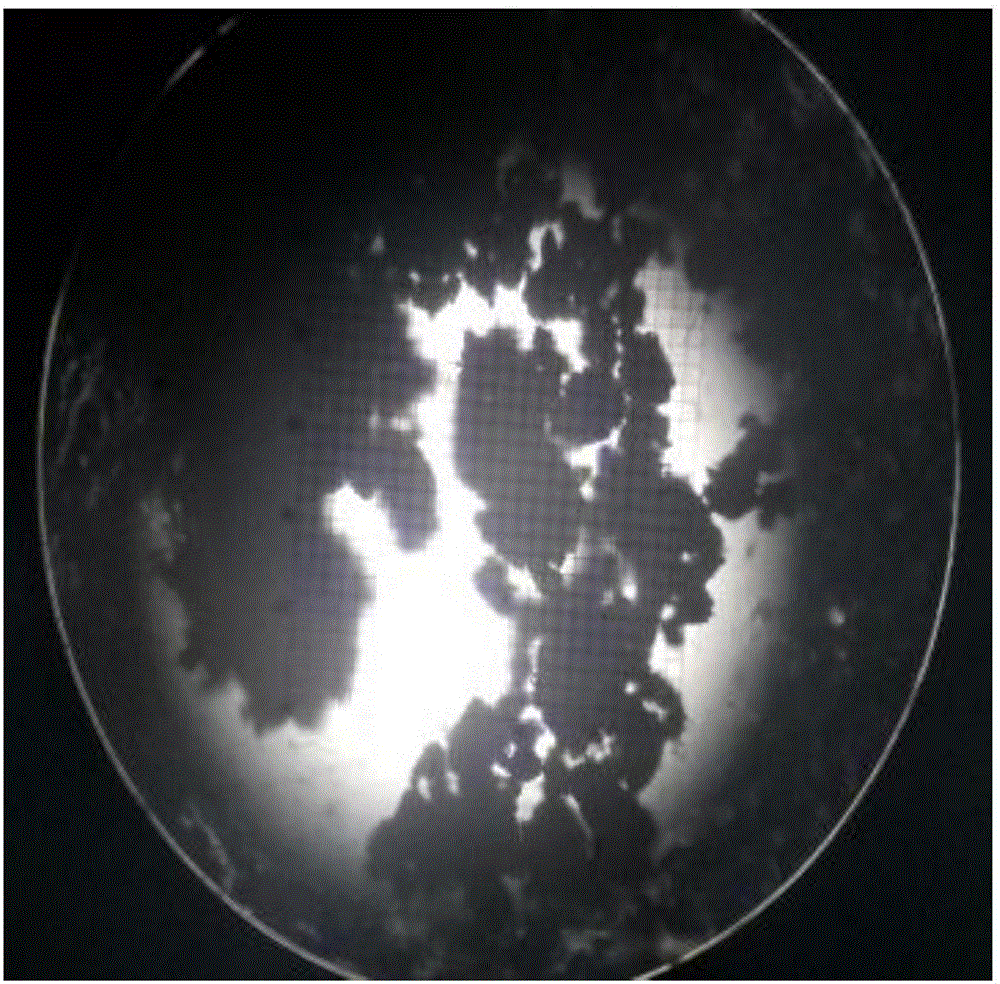

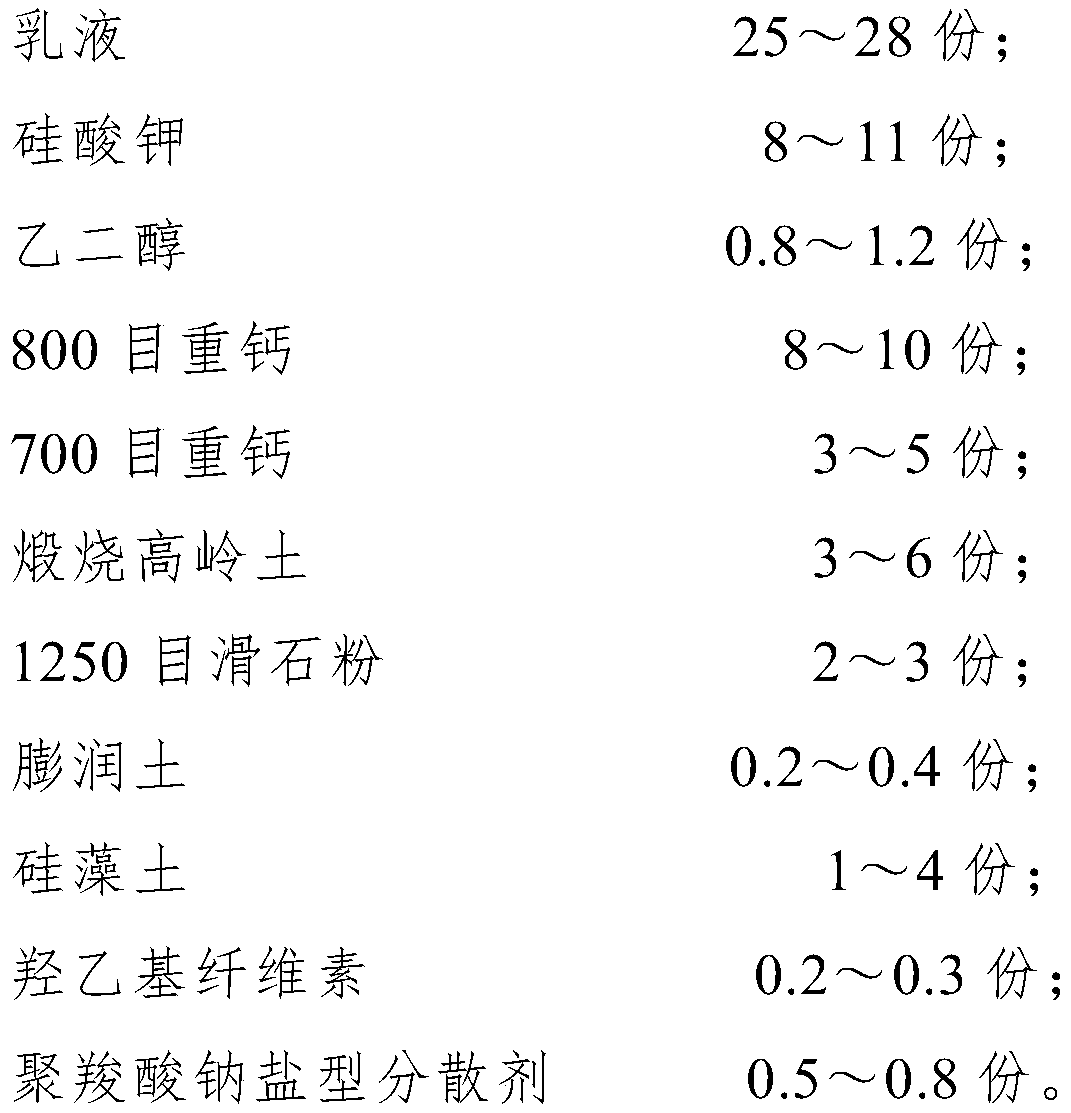

The invention relates to a coating, and concretely relates to an exterior wall fireproofing coating free of an antiseptic mildew inhibitor, and a preparation method thereof. The fireproofing coating comprises potassium silicate, ethylene glycol, 800-mesh coarse whiting, 700-mesh coarse whiting, calcined kaolin, 1250-mesh talcum powder, bentonite, diatomite, hydroxyethyl cellulose and a sodium polycarboxylate type dispersing agent. The preparation method comprises the following steps: adding the bentonite, hydroxyethyl cellulose and the sodium polycarboxylate type dispersing agent at a speed of350-550 r / min; and adding the 800-mesh coarse whiting, 700-mesh coarse whiting, diatomite, calcined kaolin and 1250-mesh talcum powder at a speed of 800-1000 r / min, and adding an emulsion, the ethylene glycol and the potassium silicate at a speed of 1000-1200 r / min. The potassium silicate is added to adjust the pH value of the coating, so that the exterior wall fireproofing coating inhibits growth and propagation of microorganisms such as bacteria and fungi without adding the antiseptic mildew inhibitor.

Owner:ANHUI SKSHU PAINT CO LTD

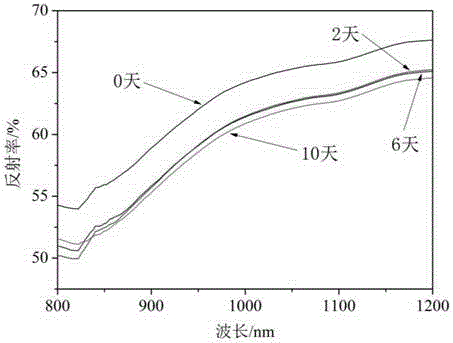

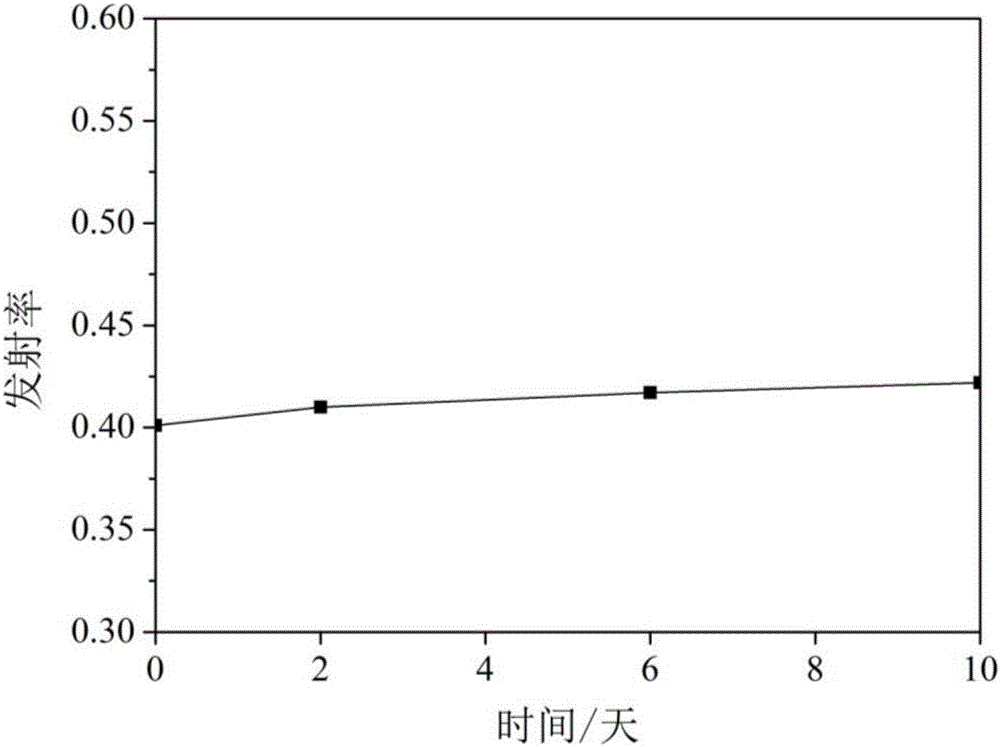

Preparation method of compatible paint and coating with high lubricating oil resisting performance, low near-infrared reflection and 8mum-14mum low emissivity

InactiveCN106634503AGood infraredImprove compatibilityPolyurea/polyurethane coatingsCamouflage paintsAl powderAdhesive

The invention relates to a preparation method of compatible paint and coating with a high lubricating oil resisting performance, low near-infrared reflection and 8mum-14mum low emissivity. The preparation method comprises the following steps: taking Al powder and Sm2O3 powder as functional pigments and taking sodium polycarboxylate as a dispersant and butyl acetate as a diluting agent; dispersing the raw materials by adopting a paint high-speed dispersion machine; adding a polyurethane (PU) adhesive, sericite, a silane coupling agent and a curing agent; after sufficiently stirring and dispersing, adjusting the viscosity to be 16s-20s by utilizing a proper amount of the diluting agent; filtering to obtain the compatible paint with the high lubricating oil resisting performance, the low near-infrared reflection and the 8mum-14mum low emissivity; then coating the surface of a pre-treated base plate with the paint by adopting a spraying method; and naturally drying for 3h-5h and drying at 50 DEG C-60 DEG C for 24h, so as to obtain the compatible coating with the high lubricating oil resisting performance, the low near-infrared reflection and the 8mum-14mum low emissivity. The compatible paint provided by the invention has relatively low infrared emissivity and 1.06mum near-infrared reflectivity and is coated on surfaces of equipment including fighter planes, guided missiles, warships, tanks, chariots and the like, and has infrared and laser and invisible effects and prominent lubricating oil resisting performance.

Owner:CHUZHOU UNIV

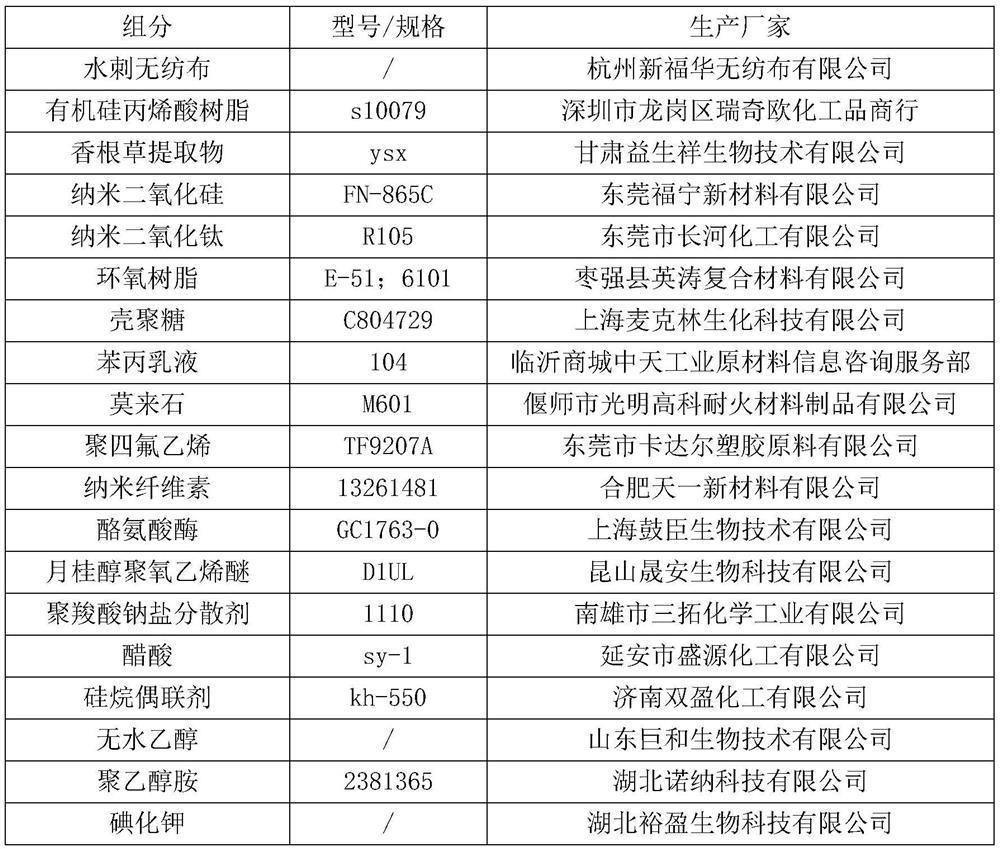

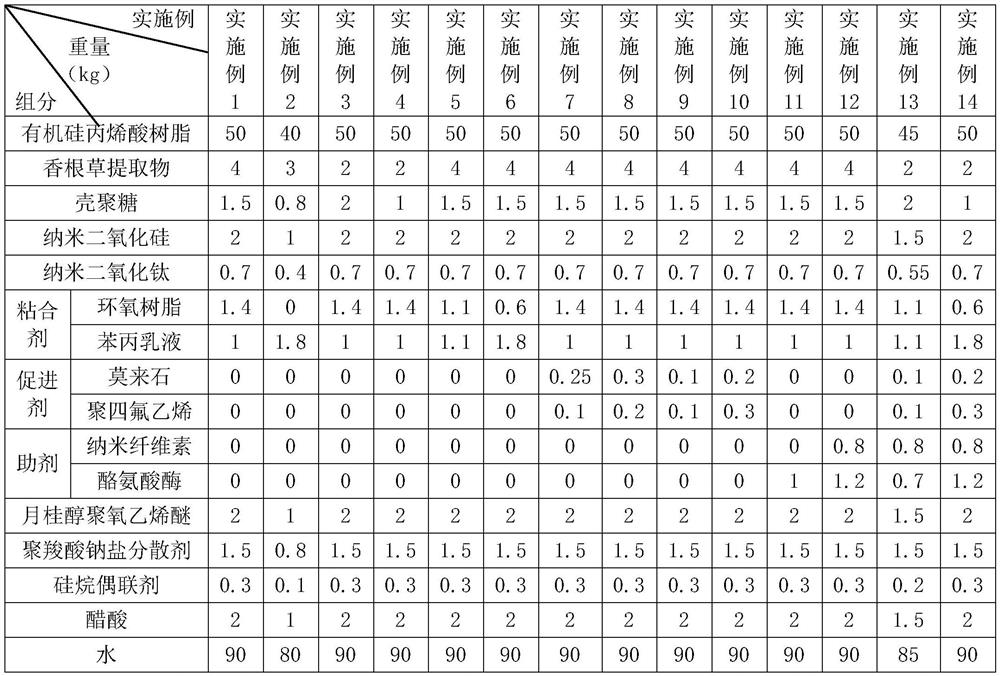

Smudginess-resistant non-woven fabric and preparation method thereof

PendingCN113026374AReduce adhesionImprove stain resistanceTextiles and paperPolymer scienceAcrylic resin

The invention relates to the technical field of non-woven fabrics, and particularly discloses a smudginess-resistant non-woven fabric and a preparation method thereof. The smudginess-resistant non-woven fabric comprises a non-woven fabric base layer, and the surface of the non-woven fabric base layer is coated with smudginess-resistant coating; and the smudginess-resistant coating is prepared from the following raw materials in parts by weight of 40 to 50 parts of organosilicone acrylic resin, 2 to 4 parts of vetiver grass extract, 0.8 to 2 parts of chitosan, 1 to 2 parts of nano silicon dioxide, 0.4 to 0.7 part of nano titanium dioxide, 1.8 to 2.4 parts of adhesive, 1 to 2 parts of polyoxyethylene lauryl ether, 0.8 to 1.5 parts of sodium polycarboxylate dispersant, 0.1 to 0.3 part of silane coupling agent, 1 to 2 parts of acetic acid and 80 to 90 parts of water. The preparation method of the smudginess-resistant non-woven fabric comprises the following steps of uniformly mixing raw materials of the smudginess-resistant coating to obtain the smudginess-resistant coating; uniformly coating the surface of the non-woven fabric base layer with the smudginess-resistant coating to obtain a coated non-woven fabric; and then carrying out drying, setting and inspecting to obtain a smudginess-resistant non-woven fabric finished product. The smudginess-resistant non-woven fabric has the advantage of smudginess resistance.

Owner:HANGZHOU XINFUHUA NONWOVENS

Novel cement grinding aid and cement thereof

The invention discloses a novel cement grinding aid and a cement thereof, and belongs to the field of cement production. The cement grinding aid is produced from, by weight, 6-12 parts of a hydramine substance, 3-8 parts of sodium polycarboxylate, 4-6 parts of sodium dodecyl sulfonate, 4-8 parts of diatomite, 4-8 parts of saturated fatty acids, 3-5 parts of hydroxyethyl cellulose, 3-5 parts of molasses and 4-8 parts of calcium formate. The invention also discloses the cement including the cement grinding aid. The cement grinding aid has the advantages of low admixture amount, good enhancement effect, improvement of the performances of cement and the output per machine hour, and reduction of the production cost of the cement, and the cement produced by using the cement grinding aid has the advantages of small clinker proportion, reduction of environment pollution, and saving of mineral product resources.

Owner:GUILIN XINYI REFRIGERATION EQUIP

Vehicle primer

InactiveCN104130674AImprove crack resistanceImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyWater based

The invention discloses a vehicle primer, and relates to the coating technical field. The vehicle primer comprises the components in parts by weight: 30 parts-45 parts of water-based epoxy acrylic resin, 8 parts-12 parts of polyether modified siloxane, 2 parts-4 parts of a talcum powder, 10 parts-15 parts of sodium polycarboxylate, 1 parts-3 parts of acrylic fibers, 30 parts-45 parts of calcium carbonate, and 30 parts-50 parts of water. The prepared primer has good anti-cracking and waterproof performance, and besides has good chemical corrosion resistance and anti-wear performance.

Owner:DRAGON FISH PAINT

Preparation method of universal type interior wall latex paint

InactiveCN102757704APaint film levelingIncreased durabilityEmulsion paintsPolymer scienceAluminum silicate

The invention discloses a preparation method of a universal type interior wall latex paint. The product belongs to the field of chemical building materials. The product is prepared by taking deionized water, a sodium polycarboxylate dispersing agent, a defoaming agent, light calcium carbonate (800 meshes), titanium dioxide, anhydrous aluminum silicate, talcum powder, lithopone, hydroxyethyl cellulose, ethanediol, a DC-216 pure acrylic emulsion for interior walls, alcohol ester-12, a thickening agent and ultramarine blue as raw materials and accessorily adopting a specific process. The product has the advantages of smooth paint film, high durability, fast drying, firm adhesion, stable color, excellent water resistance, alkali resistance, aging resistance and contamination resistance, and the like and is mainly used for protecting the surface of the interior wall of a house.

Owner:张超

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com