Smudginess-resistant non-woven fabric and preparation method thereof

A non-woven, dirt-resistant technology, applied in textiles and papermaking, etc., can solve the problems of poor dirt-resistance, non-woven fabrics prone to oil stains, dust, etc., to achieve enhanced dirt-resistance, good toughness, and good dirt resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

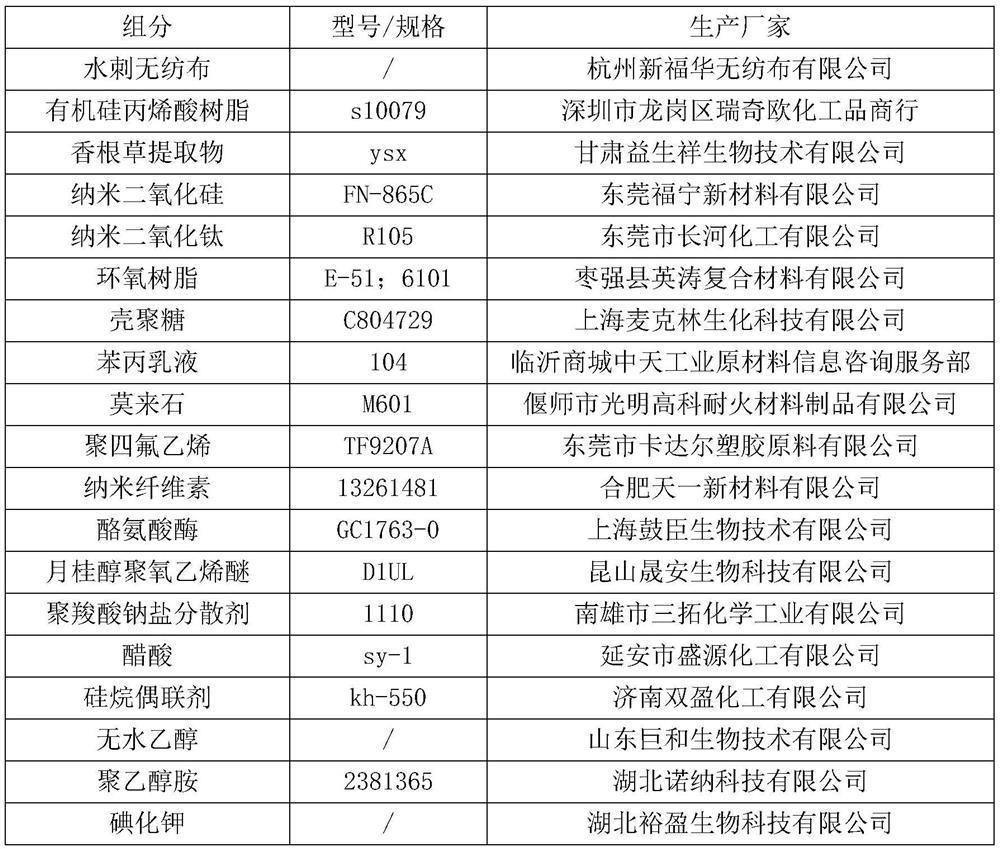

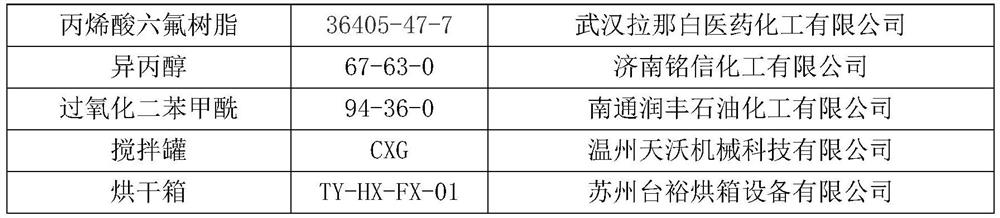

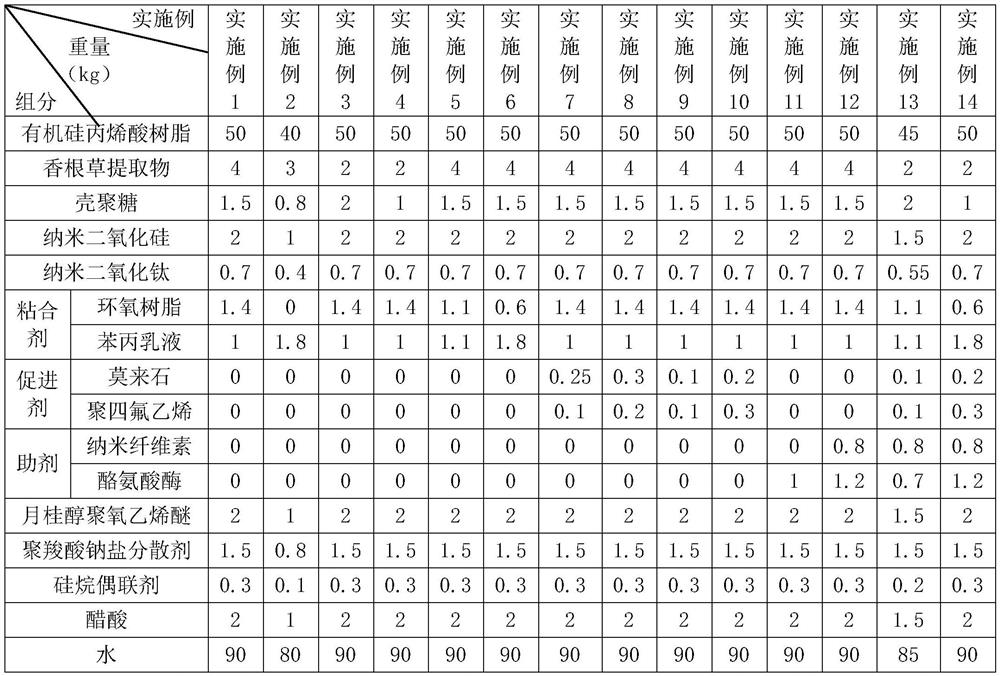

[0050] A dirt-resistant nonwoven fabric, the specific components and weights included, as shown in Table 2, by the following steps:

[0051]S1: Silicone hydroxy resin, nano-titanium dioxide, nano silica, laurin polyoxyethylene ether, silane coupling agent, sodium polycarboxylate dispersant, binder, and water are mixed with stirring, stirring speed For 800r / min, the mixture was mixed after stirring; after adding fragrant rous extract, chitosan, mixed stirring, stirring, stirred at a rate of 1000 r / min; until it was uniform to obtain a dirt-resistant coating;

[0052] S2: Even the surface of the non-woven base layer is sprayed in step S1, the coating thickness is 0.04 mm, and the coated nonwoven fabric is obtained after spraying;

[0053] S3: Put the coated nonwoven fabric in the drying box for drying, drying temperature is 35 ° C, drying time is 12h; after using a stereotype to form a nonwoven fabric, a fixed temperature 160 ° C, time 20S; after testing, the dirty non-spinning ...

Embodiment 2

[0054] Example 2: A dirt tissue nonwoven fabric, the difference from Example 1 is that the specific components and weight of the dirt-free coating are different, and the specific components and weight included are shown in Table 2.

Embodiment 3-4

[0055] Example 3-4: A dirt-free nonwoven fabric, the difference from Example 1 is that the weight ratios of the chitosan and the fragrated crust extract in the dirt-free coating are different, and the specific components and weight included. As shown in table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com