Patents

Literature

69results about How to "Control drying time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

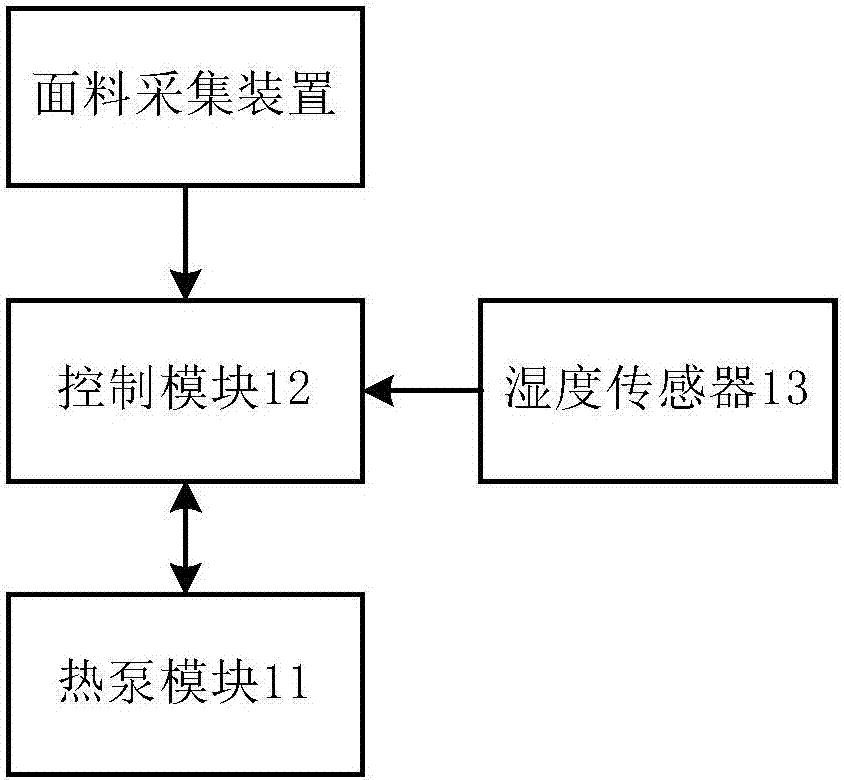

Control system of clothes dryer, clothes dryer and control method of clothes dryer

InactiveCN106930080AReduce damageIncrease working temperatureTextiles and paperLaundry driersControl systemProcess engineering

The invention discloses a control system of a clothes dryer, the clothes dryer and a control method of the clothes dryer. The system comprises a control module, a fabric collection device, a heat pump module and a humidity sensor, wherein the fabric collection device, the heat pump module and the humidity sensor are matched with the control module separately; the fabric collection device is used for collecting fabric information of to-be-dried clothes in the clothes dryer; the heat pump module is used for conveying hot air to a containing space for the to-be-dried clothes; the humidity sensor is used for collecting the air inlet humidity of an air inlet of the containing space and the air outlet humidity of an air outlet of the containing space; and the control module is used for starting the heat pump module according to the fabric information and a preset operating temperature matched with the fabric information and closing the heat pump module when the difference value between the air outlet humidity and the air inlet humidity is within a preset range. According to the control system of the clothes dryer, the clothes dryer and the control method of the clothes dryer, the defects of small application range, poor flexibility, energy waste and the like in the prior art can be overcome, and the beneficial effects of a large application range, good flexibility and energy conservation are achieved.

Owner:GREE ELECTRIC APPLIANCES INC

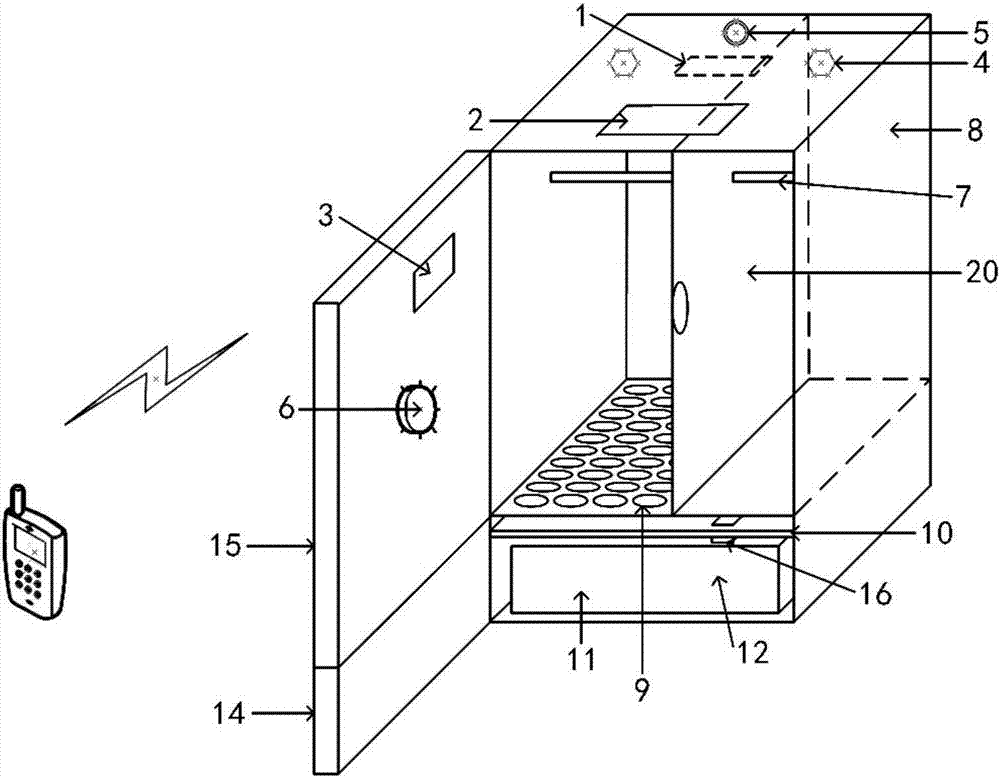

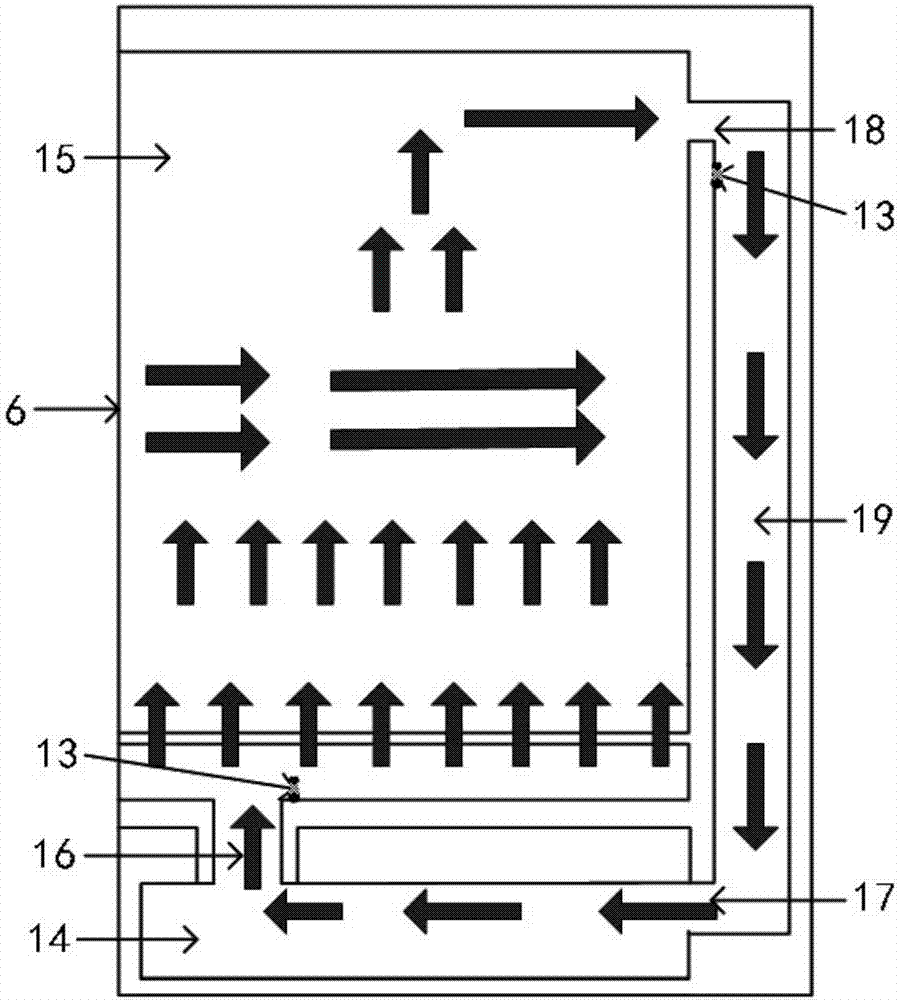

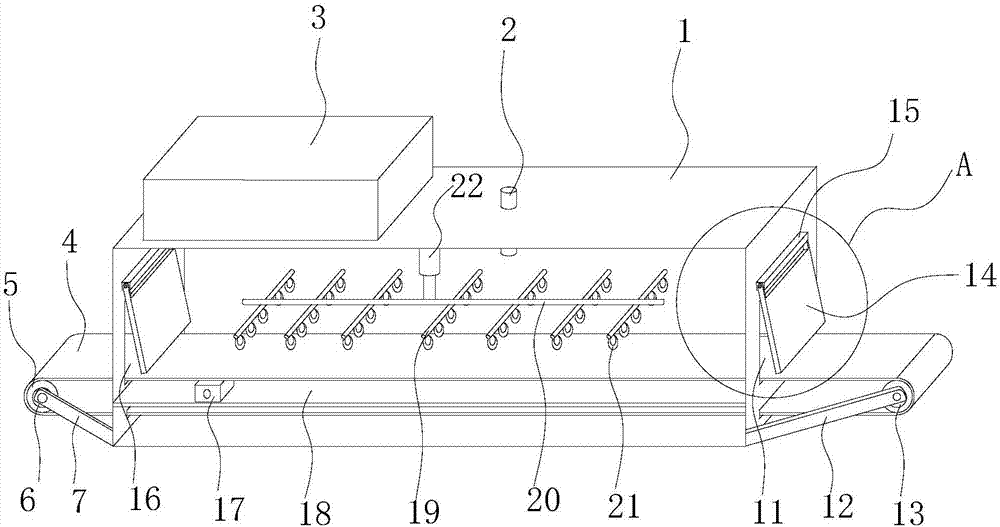

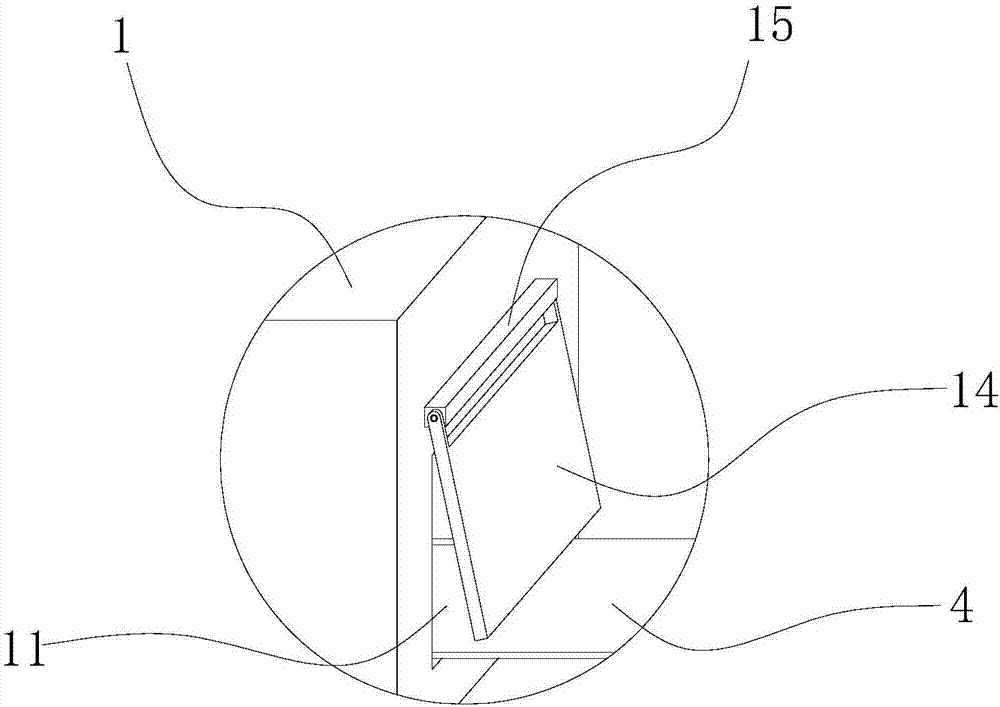

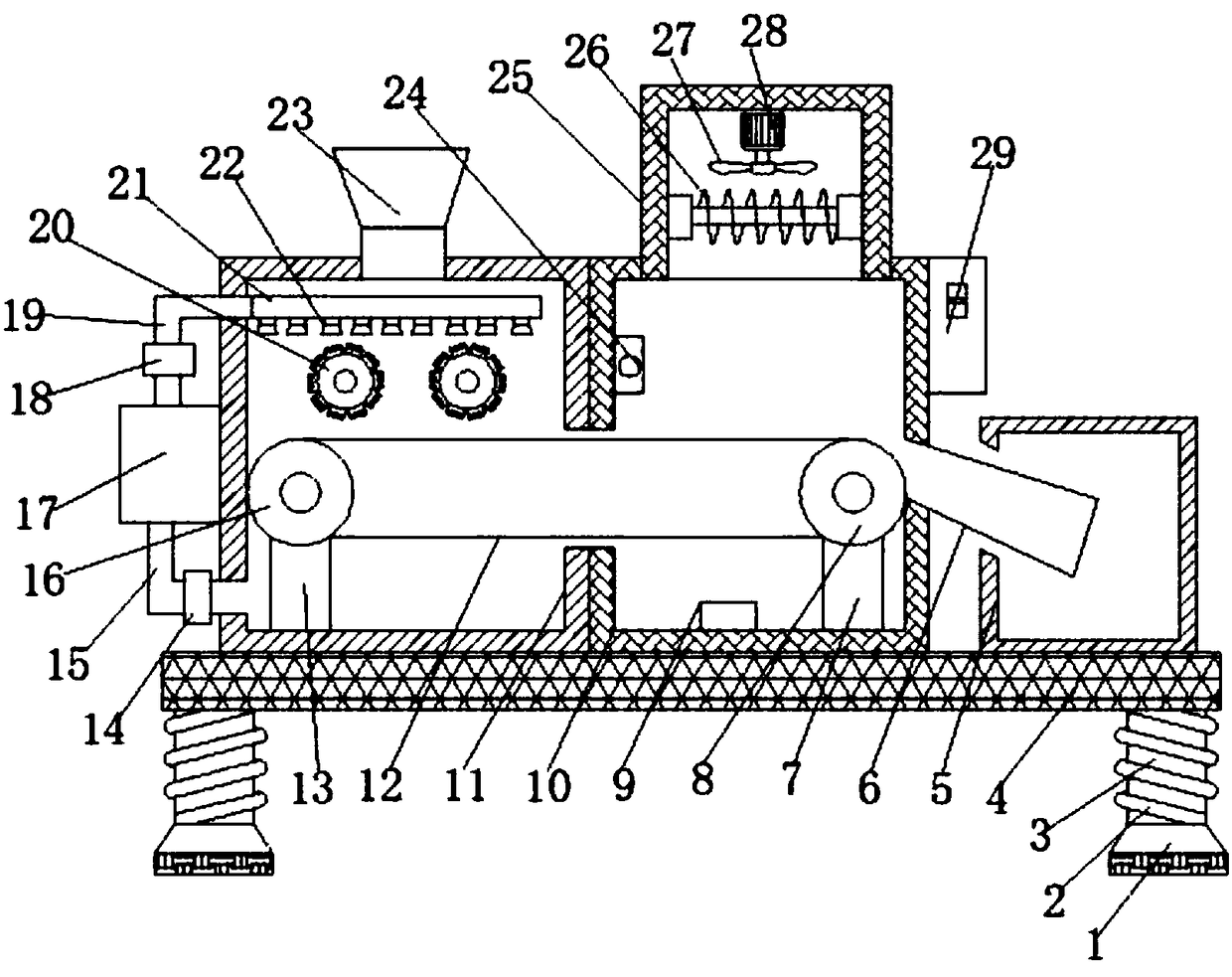

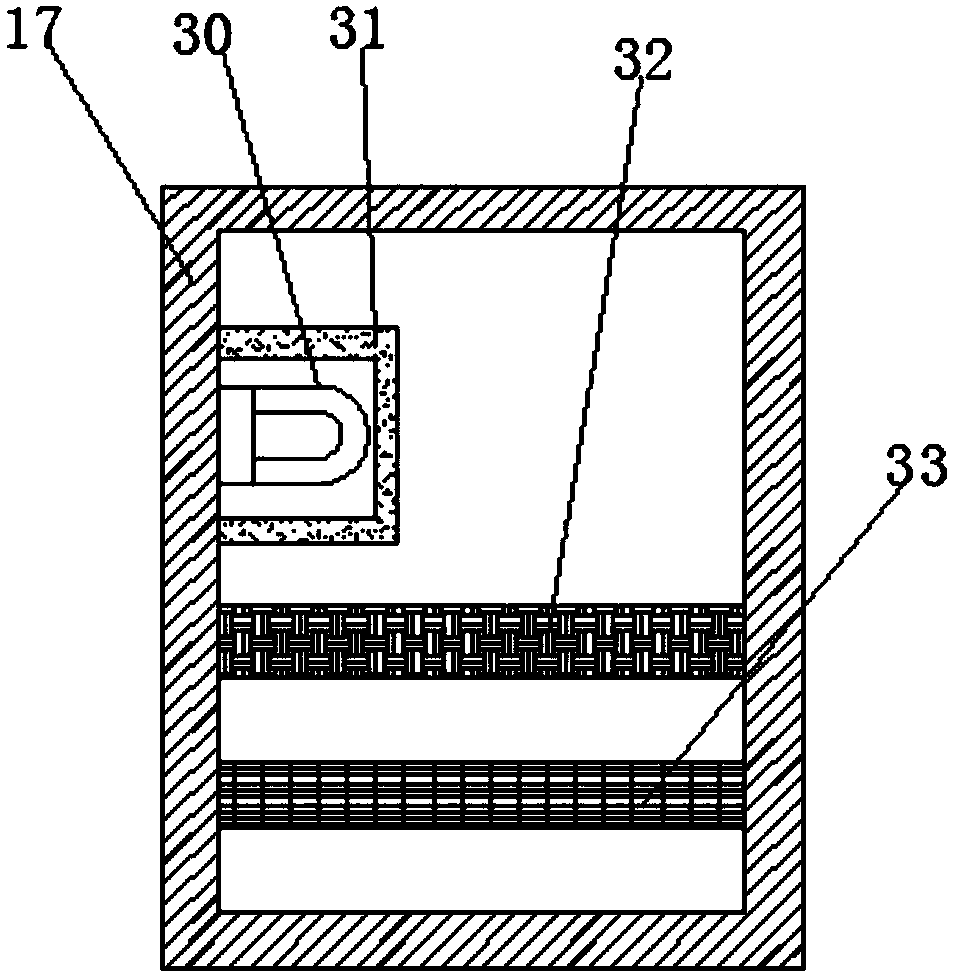

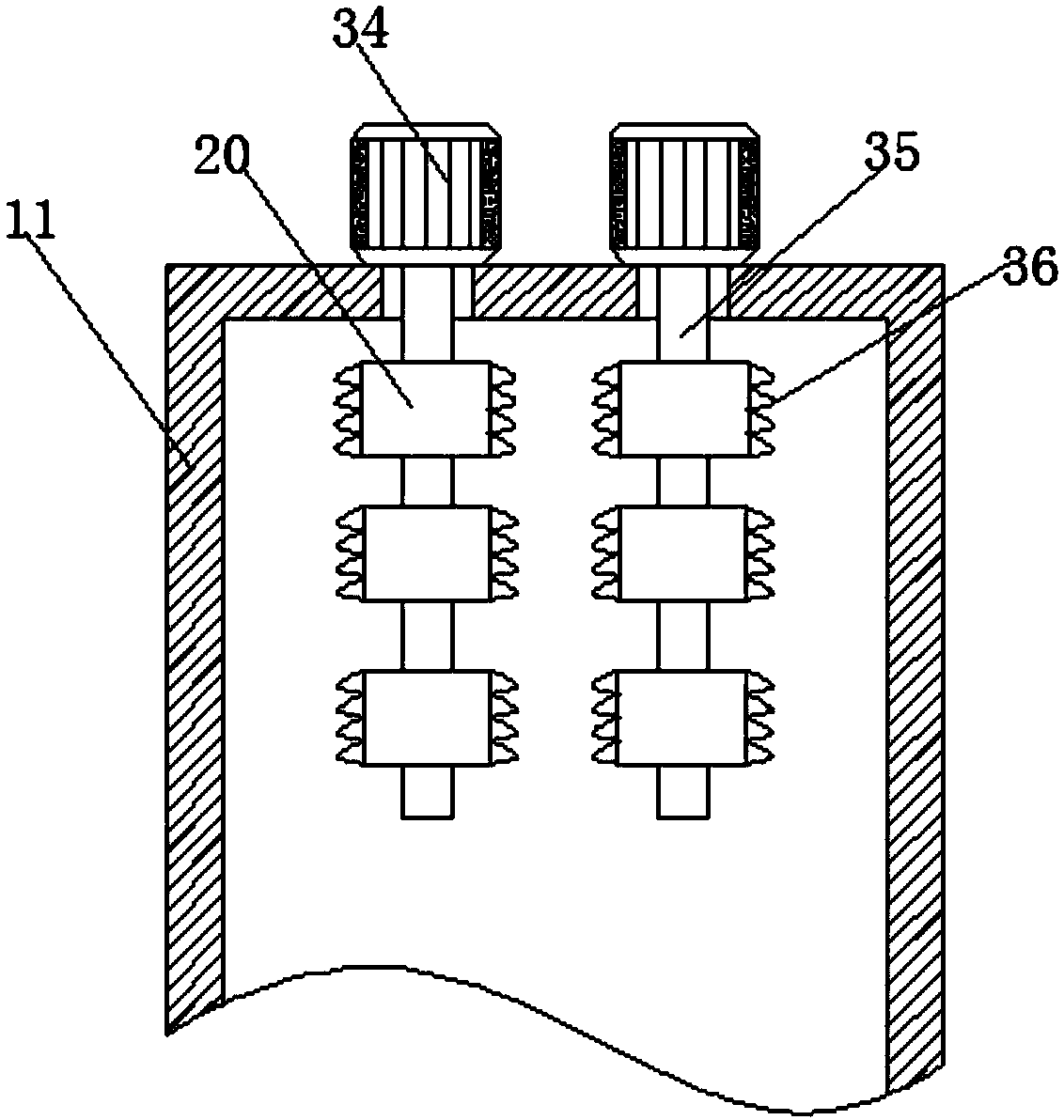

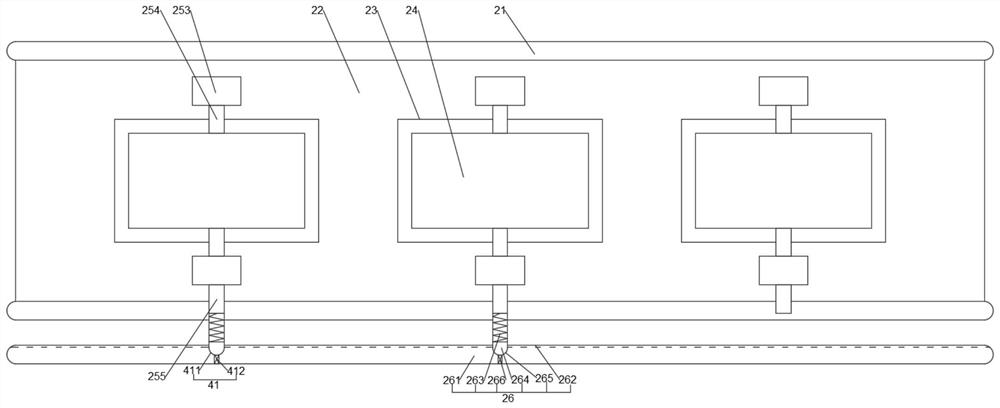

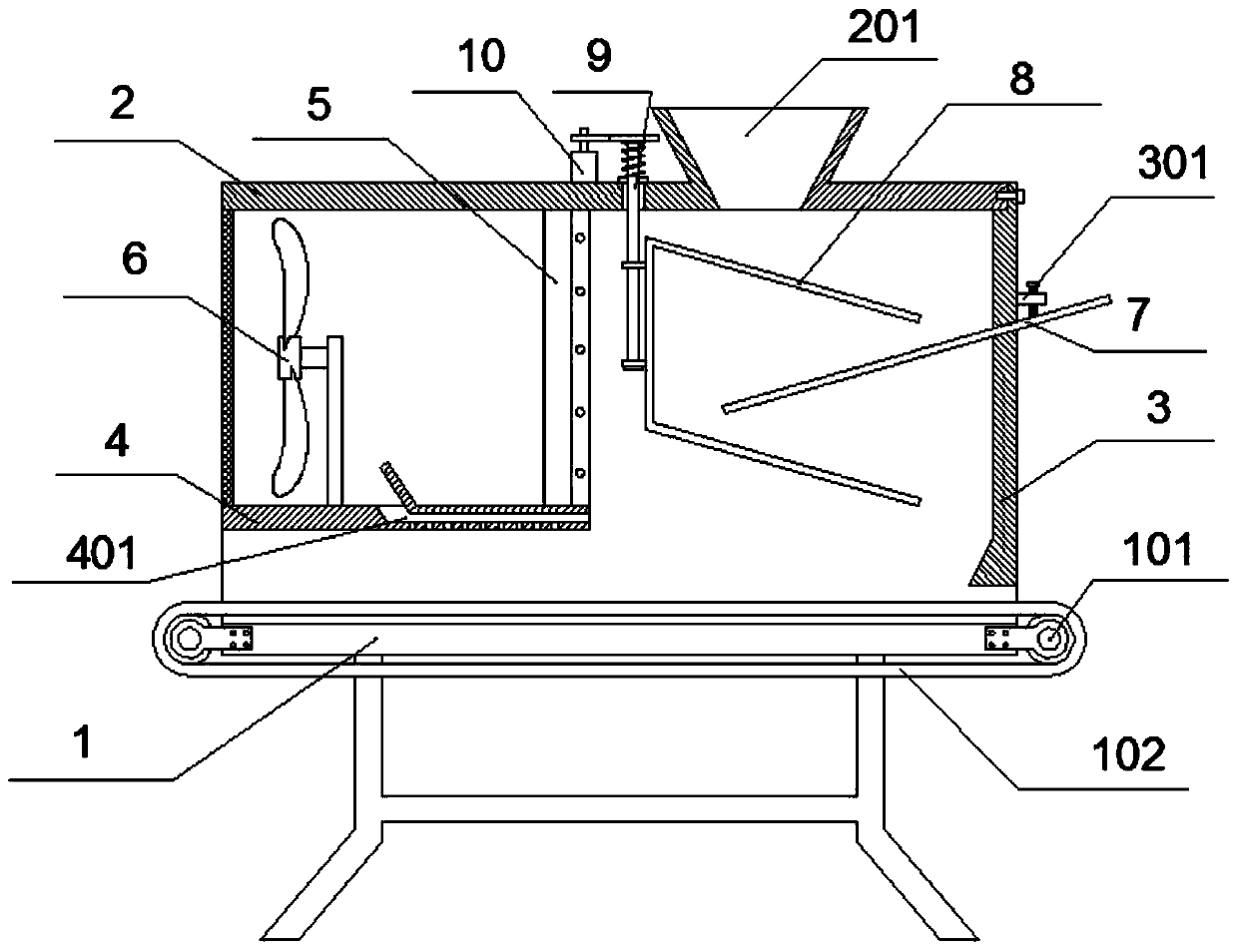

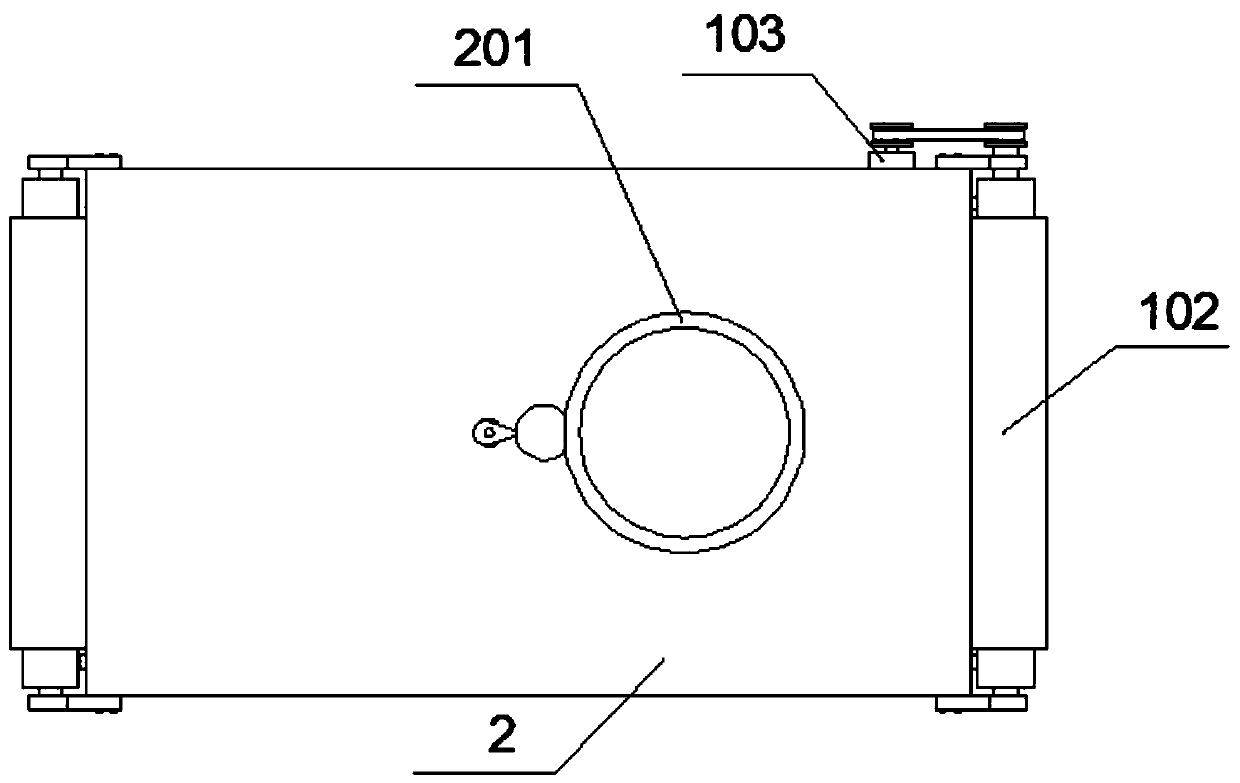

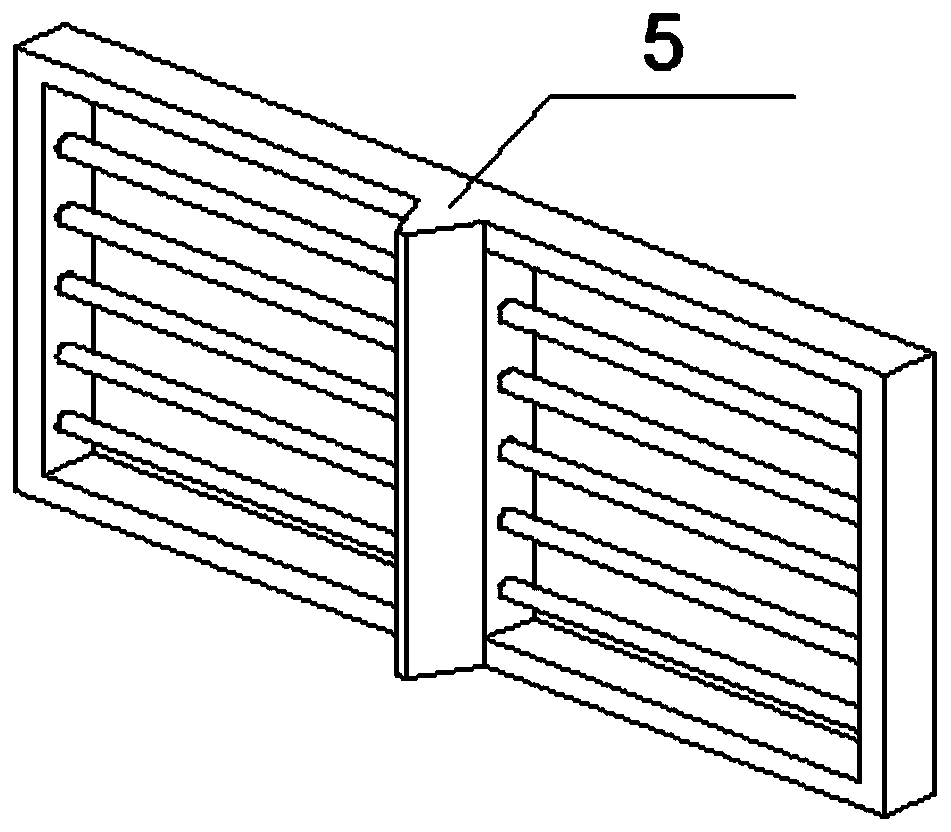

Material drying mechanical equipment

InactiveCN107504793AAvoid getting lostReduce lossDrying solid materials with heatDrying chambers/containersEngineeringMechanical equipment

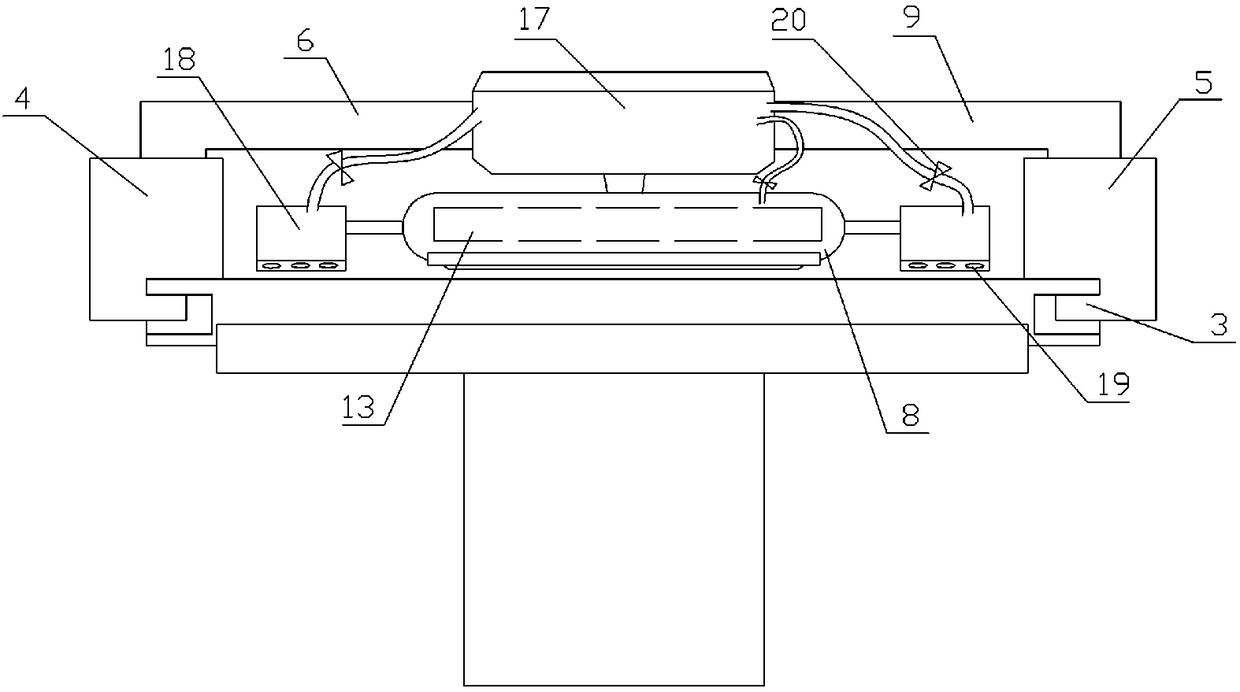

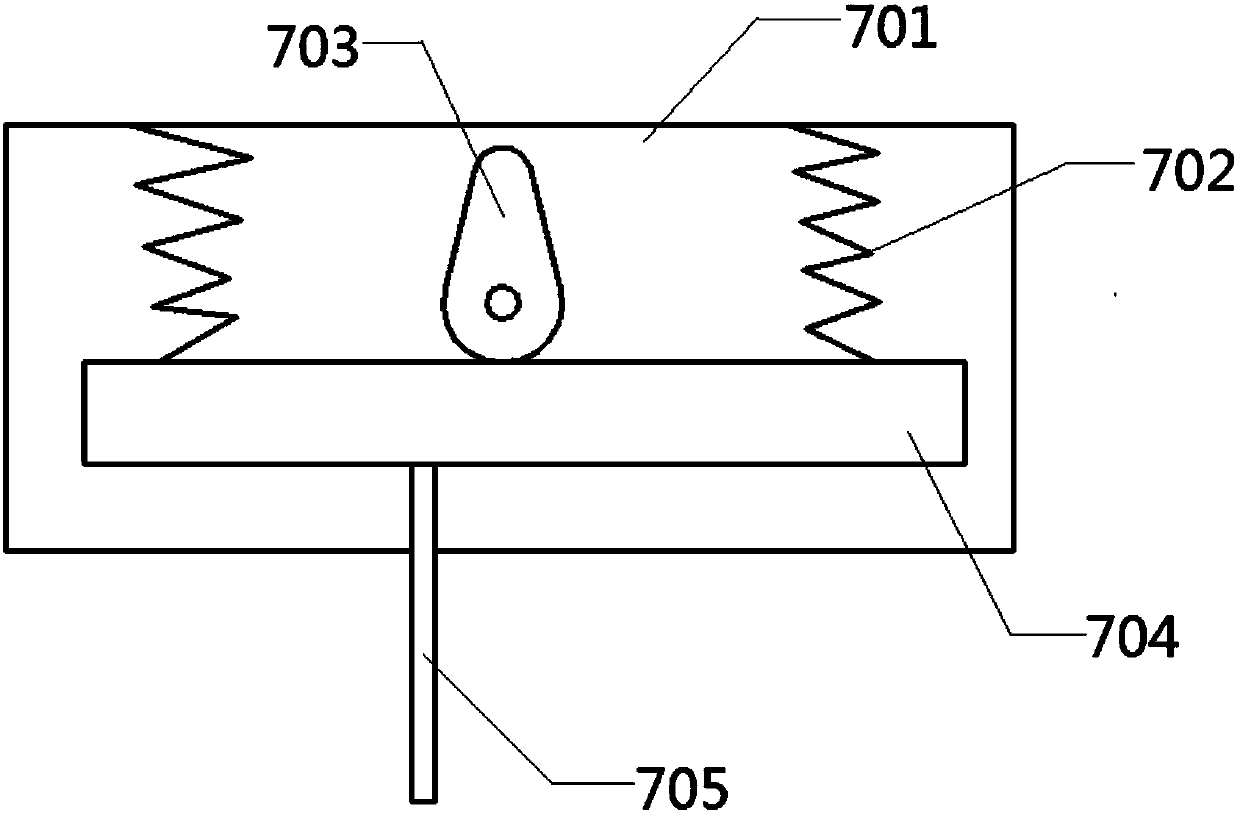

The invention discloses material drying mechanical equipment which comprises a drying box provided with a feeding inlet and a discharging outlet. Limiting fixing columns are welded to the inner wall of the feeding inlet and the outer wall of the discharging outlet, and baffles are hinged to the limiting fixing columns. The drying box is correspondingly provided with a driving carrier roller and a driven carrier roller through a first rotating shaft support and a second rotating shaft support, an electric push rod is fixed to the inner top face of the drying box, a first telescopic rod is fixed to the end of a telescopic rod of the electric push rod, a second supporting rod is fixed to the first supporting rod, and an infrared heating lamp is fixed to the second supporting rod. A temperature sensor is fixed to the upper surface of the drying box, an electrical box is arranged at one end of the upper surface of the drying box, and the electrical box is internally provided with a constant-temperature controller, a power-on and power-off controller and a PLC. According to the material drying mechanical equipment, energy is saved, the mechanization degree is high, the drying temperature can be conveniently adjusted, and a uniform drying temperature environment can be provided.

Owner:HUANGHUAI UNIV

Method for preparing black sound-absorption flame retardant paper by using gum dipping method

The invention provides a method for preparing black sound-absorption flame retardant paper by using a gum dipping method. The method comprises the following steps of: making raw paper from a mixture containing glass fiber and masson pine fiber by adopting a wet process papermaking technology, and then preparing a gum dipping solution by using a binding agent, a fire retardant and color paste according to a certain sequence and proportion; and finally uniformly putting the prepared raw paper into the gum dipping solution to be dipped, absorbing gum on the surface of the paper subjected to gum dipping and then drying the paper. According to the method provided by the invention, the glass fiber and the masson pine fiber are selected, an appropriate production process is researched on the basis of a technical theory for production of special paper, and the black sound-absorption flame retardant paper which is high in strength, strong in flame retardance and even in surface luster is obtained. The method disclosed by the invention fully takes advantages of excellent properties of the glass fiber and the masson pine fiber, is used for making the black sound-absorption flame retardant paper which is high in strength and can be used as a filling material in a building wall by using a wet process papermaking technology and a dipping and drying process in preparation of special paper, can make full use of self properties of raw materials and is in simple in preparation process and excellent in finished-product property.

Owner:SHAANXI UNIV OF SCI & TECH

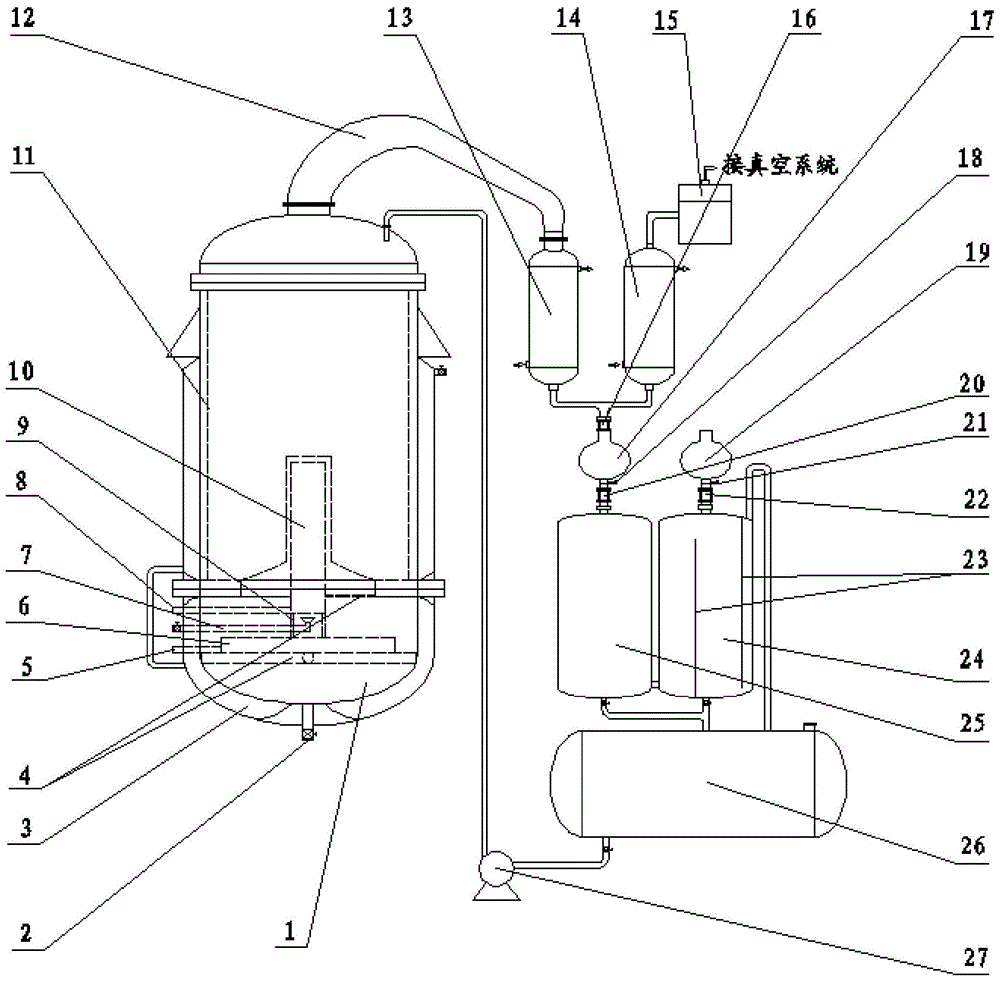

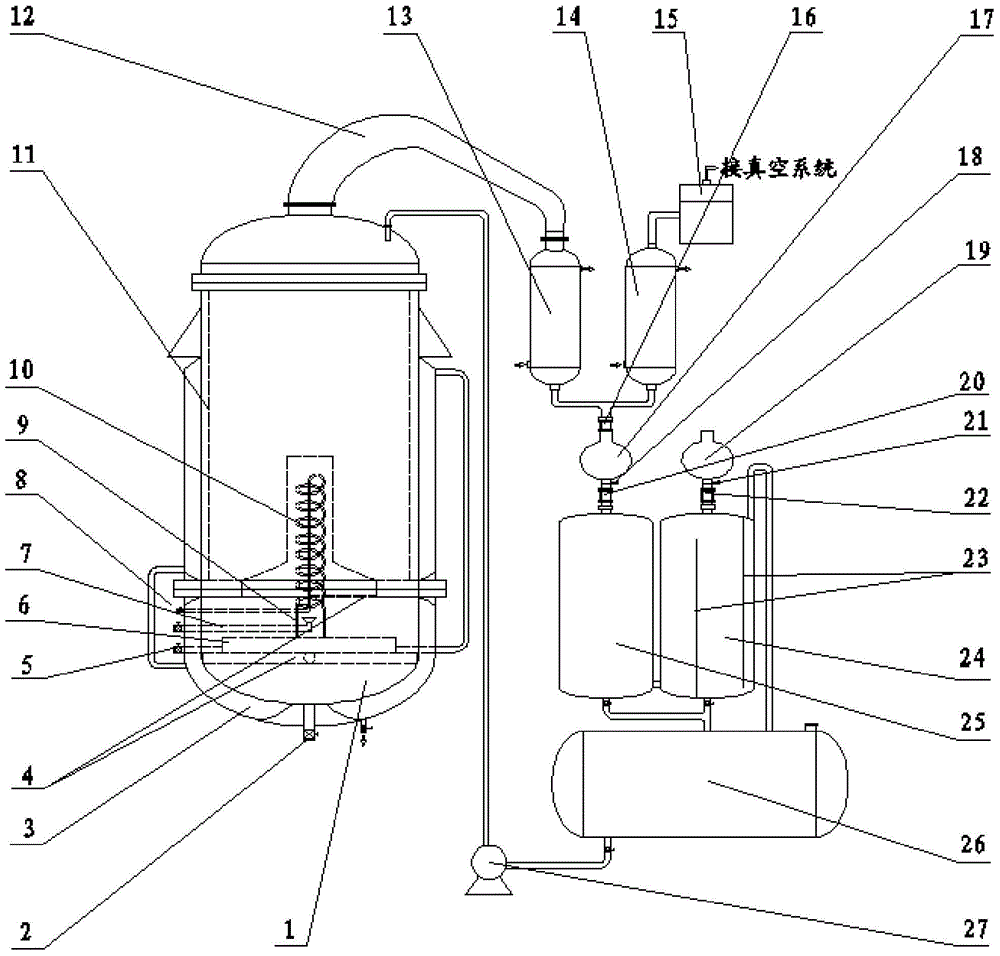

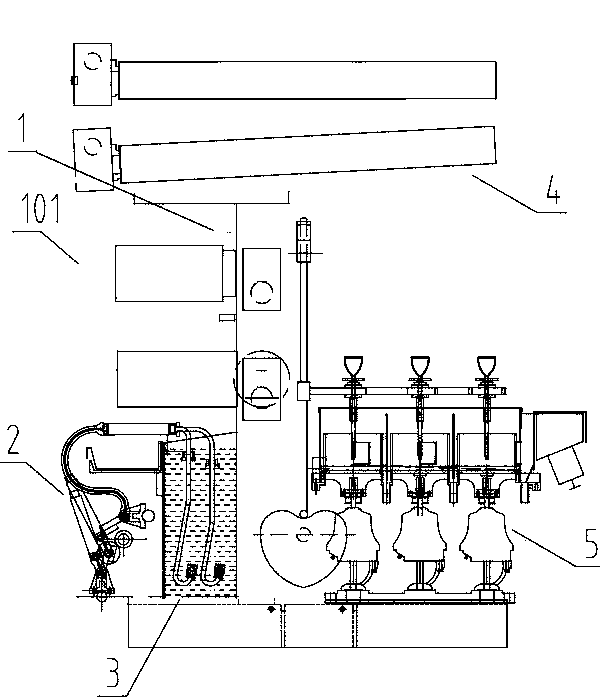

Comprehensive processing equipment for dry ginger slices and ginger oil

ActiveCN105001973AIncrease productivityReduce manufacturing costFatty-oils/fats refiningFood shapingBuffer tankPulp and paper industry

The present invention provides comprehensive processing equipment for dry ginger slices and ginger oil. The comprehensive processing equipment comprises a kettle body, a material basket, a steam outlet pipe, a condenser A, a condenser B, a buffer tank, an oil collector A, an oil collector B, an oil-water separator A, an oil-water separator B, a liquid collecting groove, and a water pump, wherein the middle-upper section of the kettle body is sleeved with the material basket, the kettle body, the steam outlet pipe, the condenser, the oil collector A, the oil-water separator A, the oil-water separator B, the liquid collecting groove and the water pump are sequentially connected, one end of the buffer tank is connected with the top portion of the condenser B, the other end is connected with a vacuum system, and the oil collector B is arranged on the top portion of the oil-water separator B. According to the present invention, with the comprehensive processing equipment, the two products such as the dry ginger slices and the ginger oil can be simultaneously obtained so as to effectively improve the production efficiency and save the production cost.

Owner:GUANGXI FORESTRY RES INST

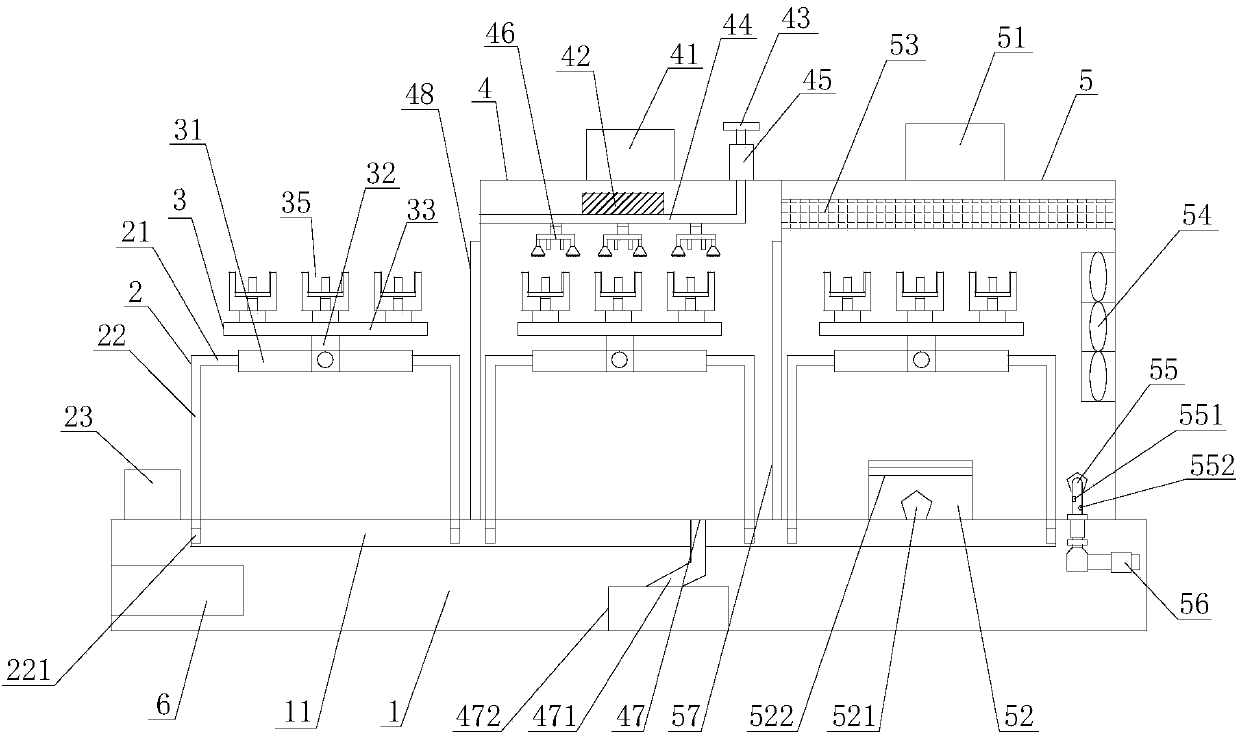

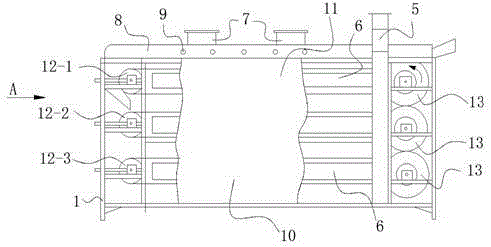

Washing device, convenient for crop collection, used for subsidiary agricultural product production

InactiveCN108421759ASpeed up dryingControl drying timeDrying gas arrangementsCleaning using toolsFiltrationWater storage tank

The invention belongs to the technical field of washing devices, particularly discloses a washing device, convenient for crop collection, used for subsidiary agricultural product production, and solves the technical problem that subsidiary agricultural products need to be aired and dehydrated for collection after being washed. Through the proposed scheme, the washing device comprises a base plate;a washing box, a drying box and a collection box are fixed on the outer wall of the top of the base plate with screws from left to right respectively; a water storage tank is fixed on the outer wallof the side, away from the drying box, of the washing box with screws; the outer wall of the top of the water storage tank is welded with a second water pumping pipe; and a second water pump is fixedon the outer wall of the second water pumping pipe with screws. According to the washing device, the washed subsidiary agricultural products can be heated and dried through a heater, the airing speedof the subsidiary agricultural products is increased, water after washing can be pumped into the water storage tank and recycled after filtration, sterilization and disinfection through the arrangement of a first water pumping pipe, a filter screen, an active carbon adsorbed layer and an ultraviolet sterilization lamp, and the water resources are saved.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

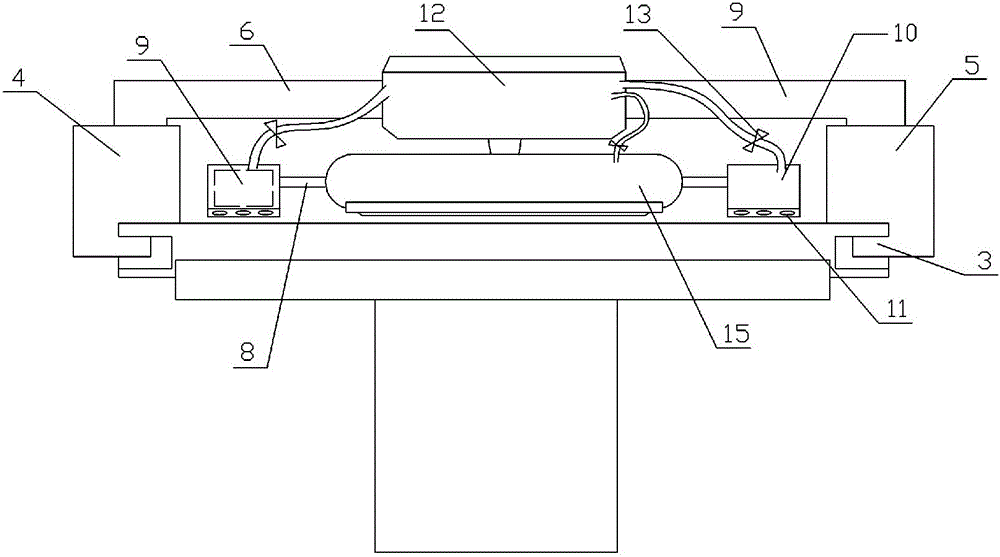

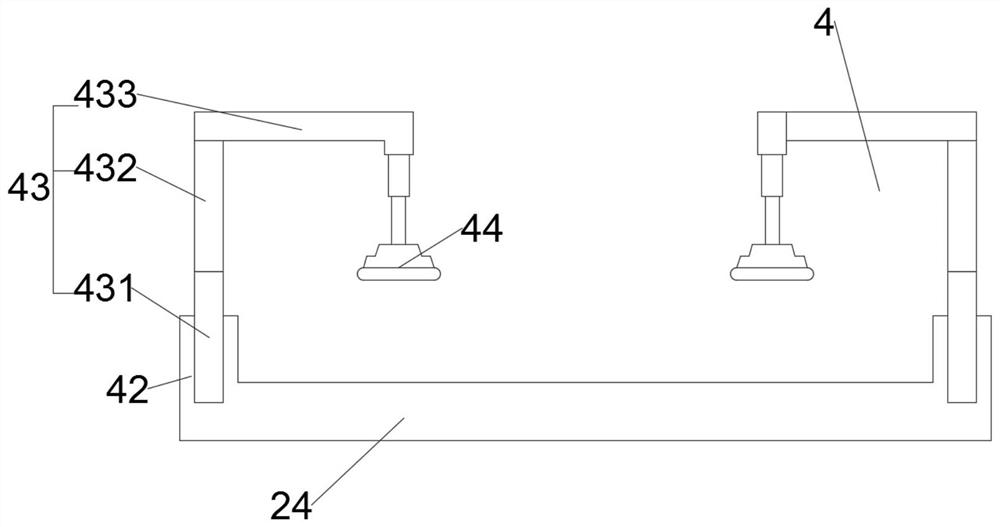

Bearing automatic cleaning and drying device

PendingCN108043816AReduce labor intensityPrevent annealing and deteriorationDrying gas arrangementsCleaning using liquidsElectrical resistance and conductanceEngineering

The invention discloses a bearing automatic cleaning and drying device which comprises a base, a movable workbench, a bearing storing frame, a cleaning mechanism, a drying mechanism and a control mechanism. The cleaning mechanism comprises a first driving motor, an ultrasonic generator, a water inlet, a water inlet pipe, a booster pump and a high-pressure spraying head. The drying mechanism comprises a second driving motor, an air bellow, a resistance wire heating plate, an air discharging opening, an air guiding pipeline and an air discharging pipe. A fan is arranged in the air bellow. According to the bearing automatic cleaning and drying device, through mutual cooperation of the ultrasonic generator, the booster pump and the high-pressure spraying head, stains of all dead corners of a bearing are removed, and the cleaning effect is good; through mutual cooperation of the air bellow, the resistance wire heating plate, the air discharging opening, the air guiding pipeline and the airdischarging pipe, the air circulating speed is increased, and the quick drying effect is achieved through ventilating and heating; and the humidity and the temperature of the drying mechanism are monitored in real time through a humidity sensor and a temperature sensor, the drying time is controlled, and the situation that due to the too high temperature, the bearing is subjected to annealing metamorphism is prevented.

Owner:XINCHANG WEIERTE BEARING

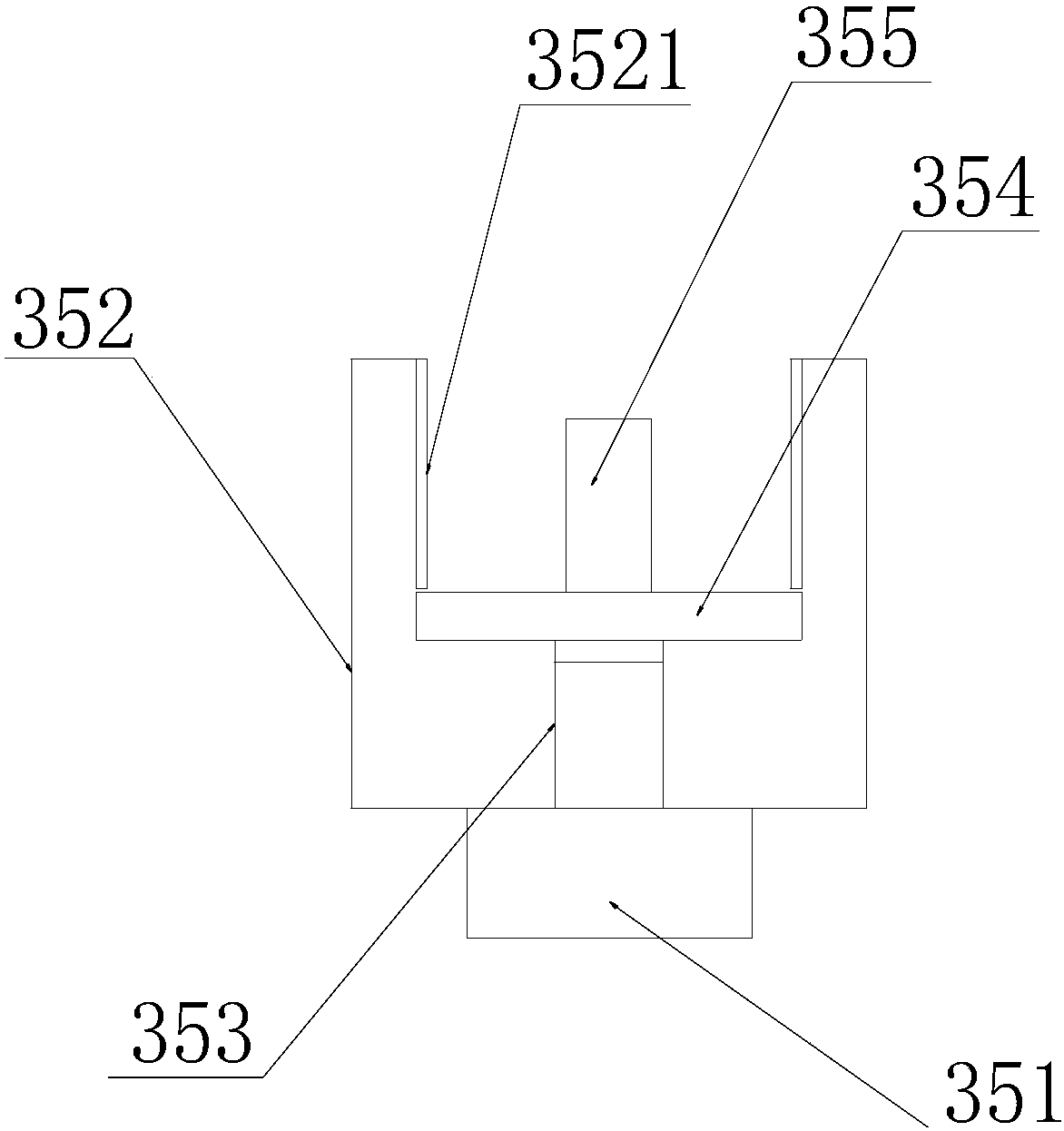

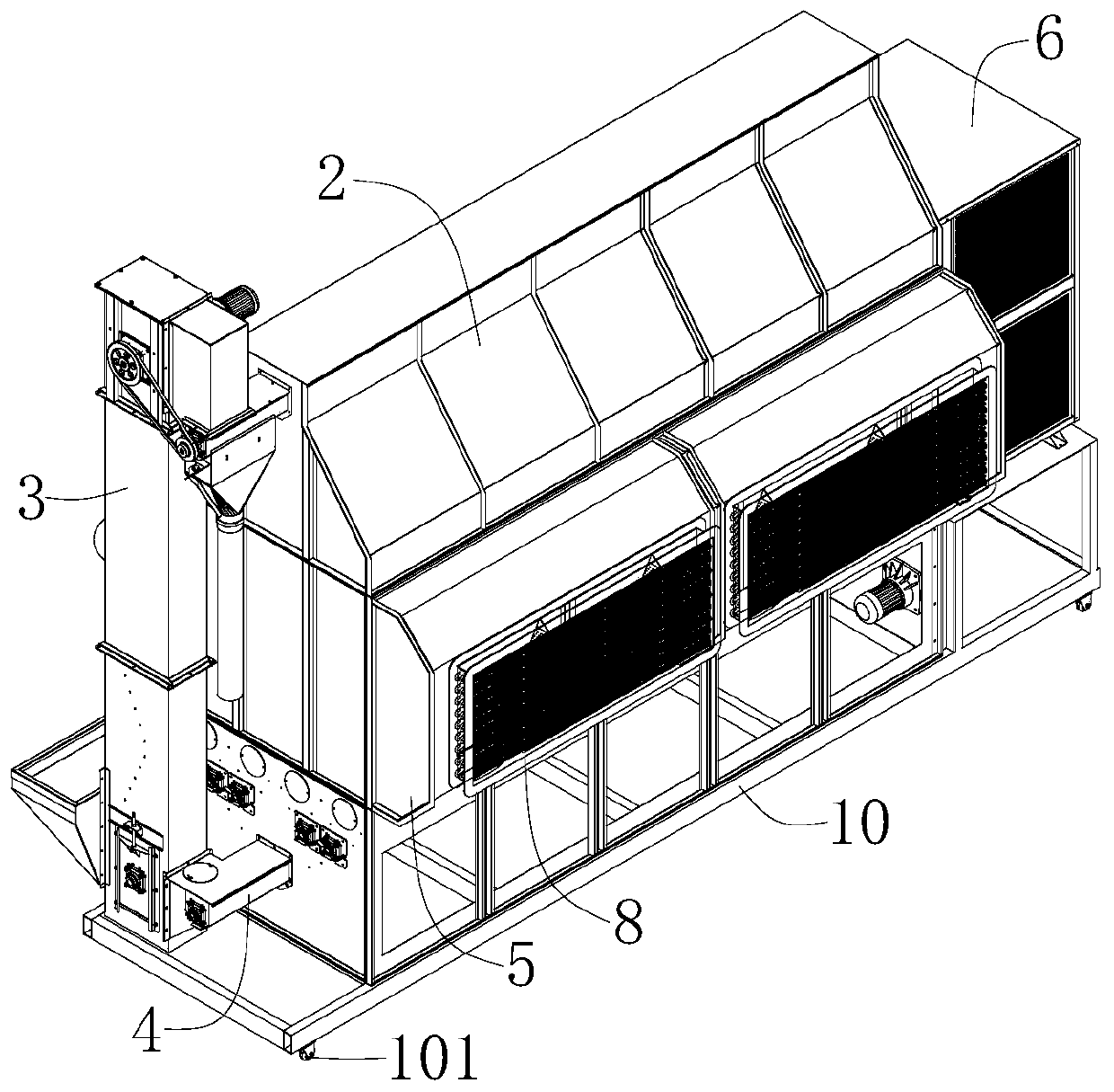

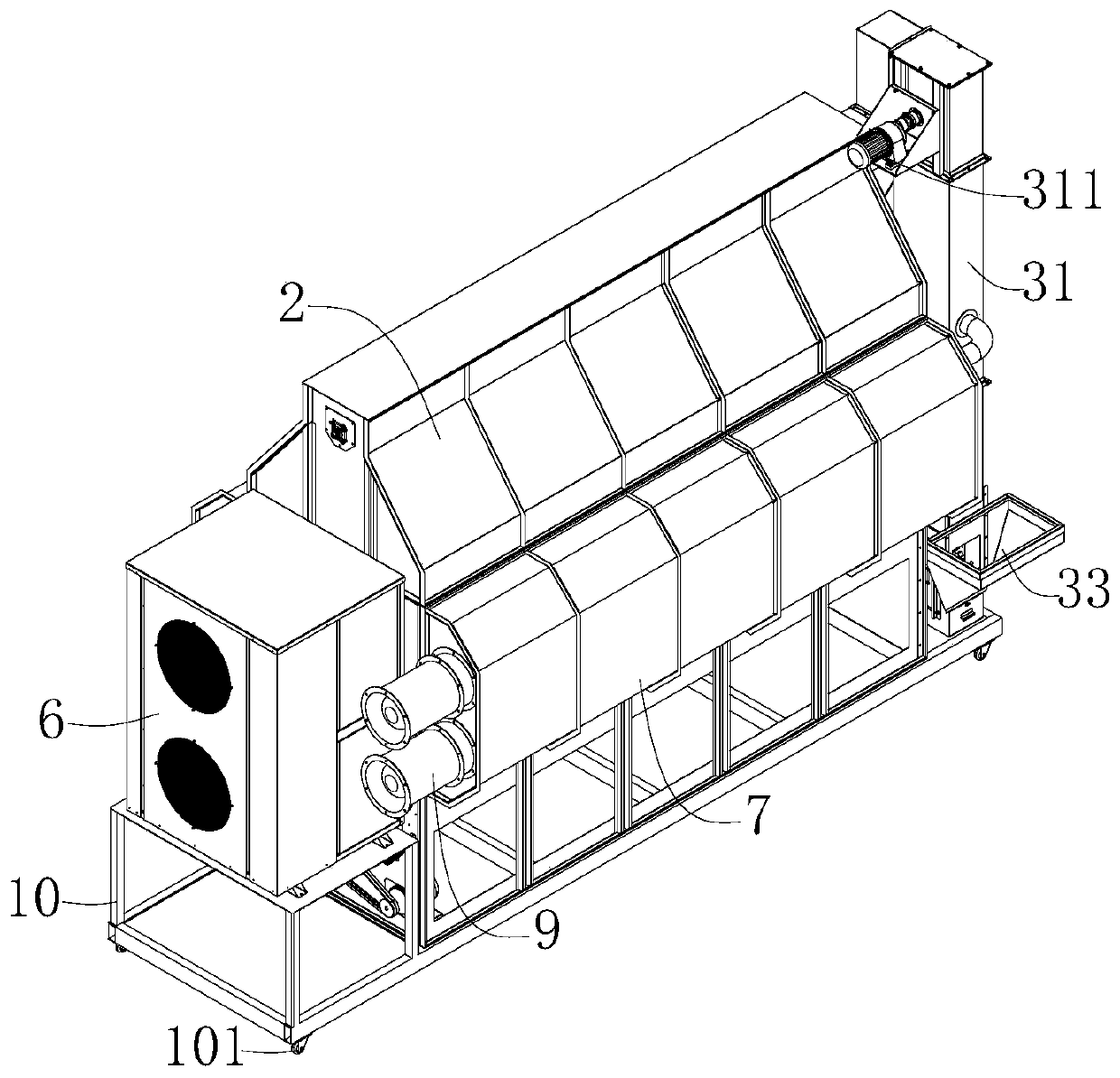

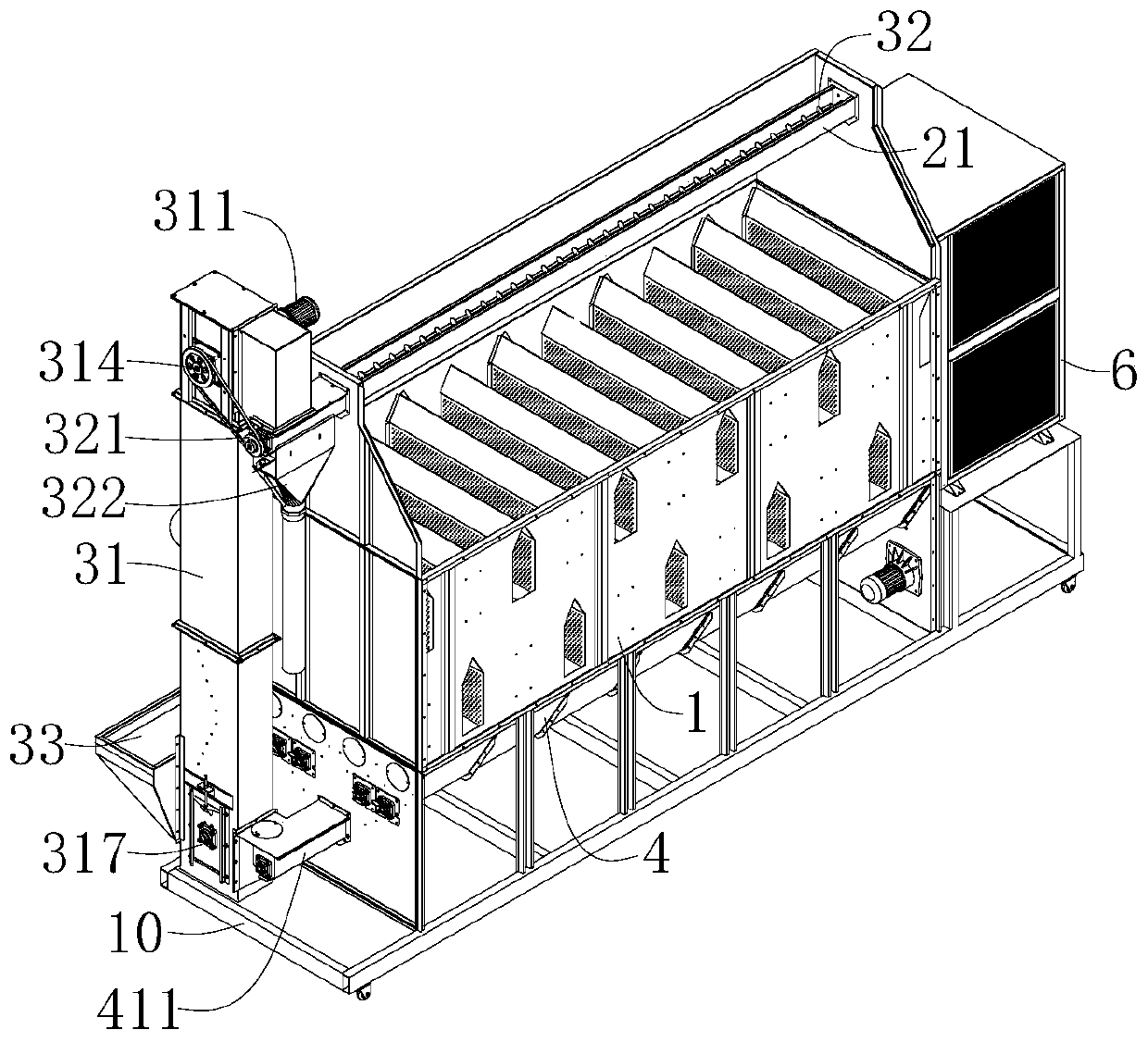

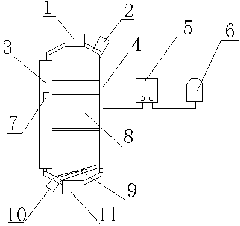

Grain drying device

PendingCN110731379AEvenly heatedControl discharge speedSeed preservation by dryingProcess engineeringMechanical engineering

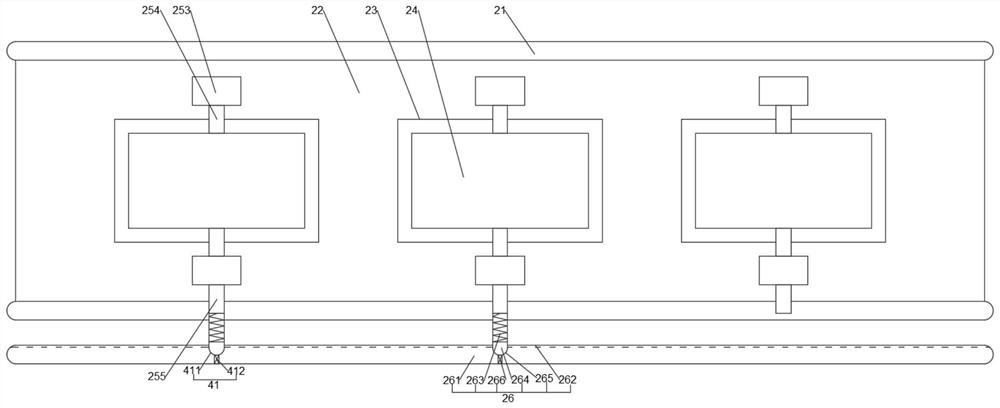

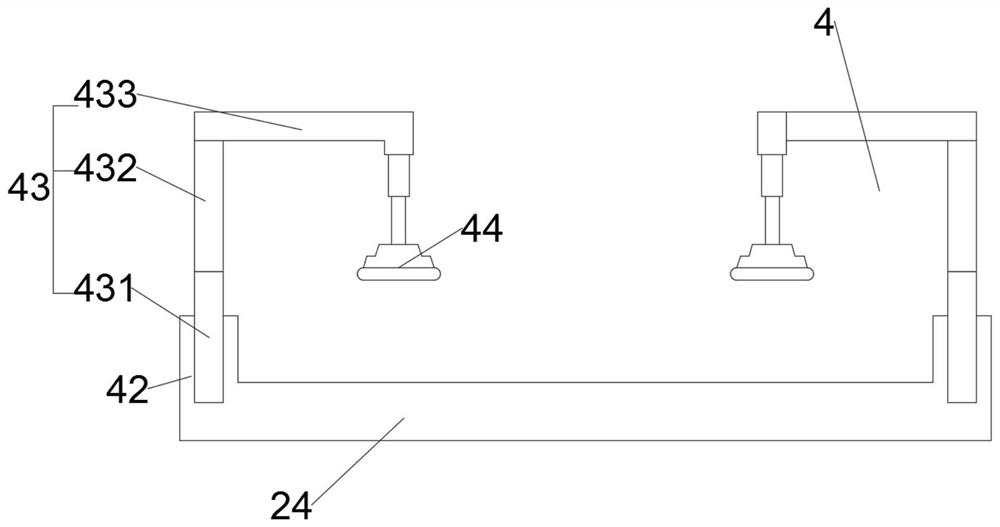

The invention relates to the field of grain drying, and discloses a grain drying device. The grain drying device comprises a drying box, a feeding mechanism, a discharging mechanism, an air inlet box,a heating device and an air outlet box. The drying box is used for carrying out hot drying on grain. Multiple drying layers are arranged inside the drying box. Each drying layer comprises a pluralityof air inlet angular boxes and a plurality of air outlet angular boxes, wherein the air inlet angular boxes and the air outlet angular boxes are arranged alternatively in the length direction of thedrying box horizontally. A cross flow type two-way ventilation structure is adopted for the drying box. Because the air inlet angular boxes and the air outlet angular boxes of each drying layer are arranged in parallel, the grain in the drying box is heated even; and the discharging mechanism is used for having control over the discharging speed of grain, then the drying time and the rate of moisture dropping of the grain in the drying box are taken under control. Compared with the prior art, the grain drying device not only can carry out continuous drying treatment on the grain with low moisture, but also can carry out circulating drying treatment on the grain with high moisture, and thereby being capable meeting various drying requirements of grains from different areas, with different contents of moisture, and of different breeds.

Owner:HUBEI KEYANG ENERGY SAVING EQUIP

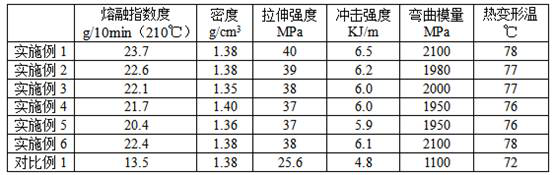

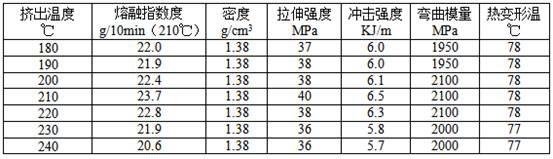

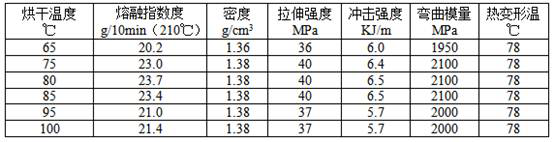

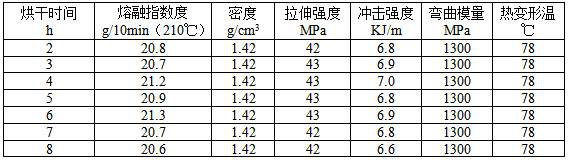

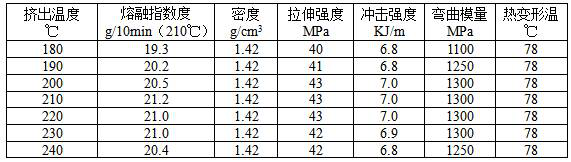

Wheat straw filled and modified PLA full-degradable plastic and preparation method thereof

PendingCN112920567AImprove mechanical propertiesEnhanced heat and water resistanceEpoxyPolymer science

The invention discloses wheat straw filled and modified PLA full-degradable plastic. The full-degradable plastic is prepared from the following ingredients in parts by weight: 20 to 30 parts of poly (butylene succinate), 15 to 25 parts of polylactic acid, 5 to 10 parts of poly (butylene adipate / terephthalate), 15 to 30 parts of talcum powder, 20 to 30 parts of wheat straw powder and 0.5 to 5 parts of auxiliary agents. The auxiliary agent comprises the following components in parts by weight: 2-5 parts of porous rare earth oxide, 1-3 parts of an epoxy compound, 1-3 parts of a lubricant and 1-3 parts of a plasticizer. The preparation method comprises the following steps: mixing the polylactic acid and the porous rare earth oxide to obtain the modified polylactic acid, mixing the modified polylactic acid with the poly (butylene succinate), the poly (butylene adipate / terephthalate) and the epoxy compound, stirring and mixing an obtained mixture with the talcum powder, the wheat straw powder, the lubricant and the plasticizer, finally performing extrusion granulation through a twin-screw extruder, and performing drying to obtain the product plastic. The invention solves the problems of poor heat resistance and water resistance in existing polylactic acid full-degradable plastic.

Owner:柳州塑友科技有限公司 +1

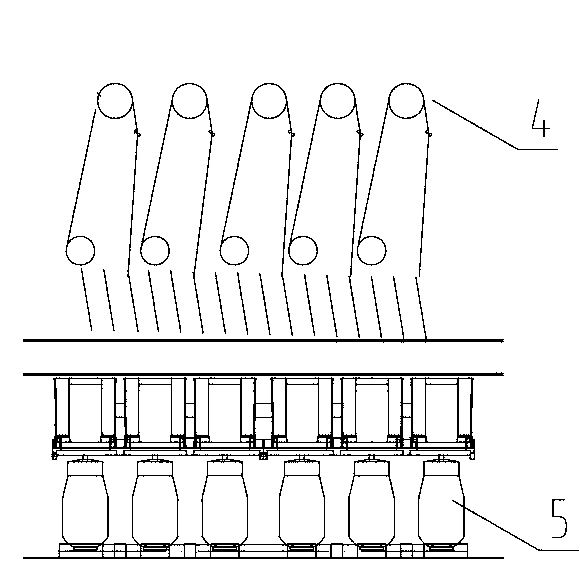

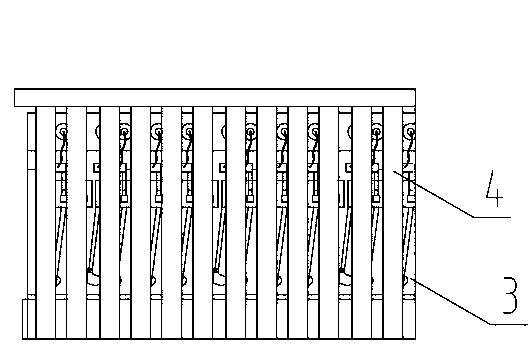

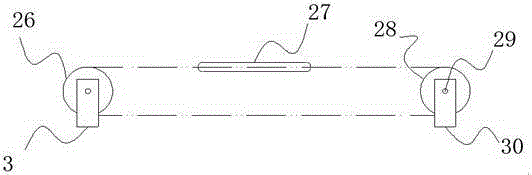

Novel high-speed spinning machine

InactiveCN103628161AAvoid unstable speedSpeed jumpNew-spun product collectionSpinning head liquid feederSpinningControl system

The invention relates to spinning equipment, in particular to a novel high-speed spinning machine. The novel high-speed spinning machine comprises a frame, adhesive supply devices, filament molding devices, spinning devices and winding devices, wherein a shaping part of each winding device is positioned on another side which is on the outer side of a region between wall plates on both sides of the frame and is opposite to a spinning surface; the adhesive supply devices and the winding devices are positioned on the outer sides of the wall plates respectively; each spinning device comprises at least one group of spinning rollers; each group of spinning rollers comprises an upper spinning roller and a lower spinning roller for drawing; the two ends of the upper spinning rollers and the lower spinning rollers are fixed; independent drying drawing rollers are arranged between the upper spinning rollers and the lower spinning rollers. According to the novel high-speed spinning machine, the winding devices are arranged externally, so that corrosion on filaments, the winding equipment and a control system of the winding equipment is low in an acid environment; the independent drying drawing rollers are arranged between the upper spinning rollers and the lower spinning rollers, so that the drying temperature and the drying time can be controlled effectively during drying of the filaments.

Owner:YIBIN GRACE GROUP CO LTD +1

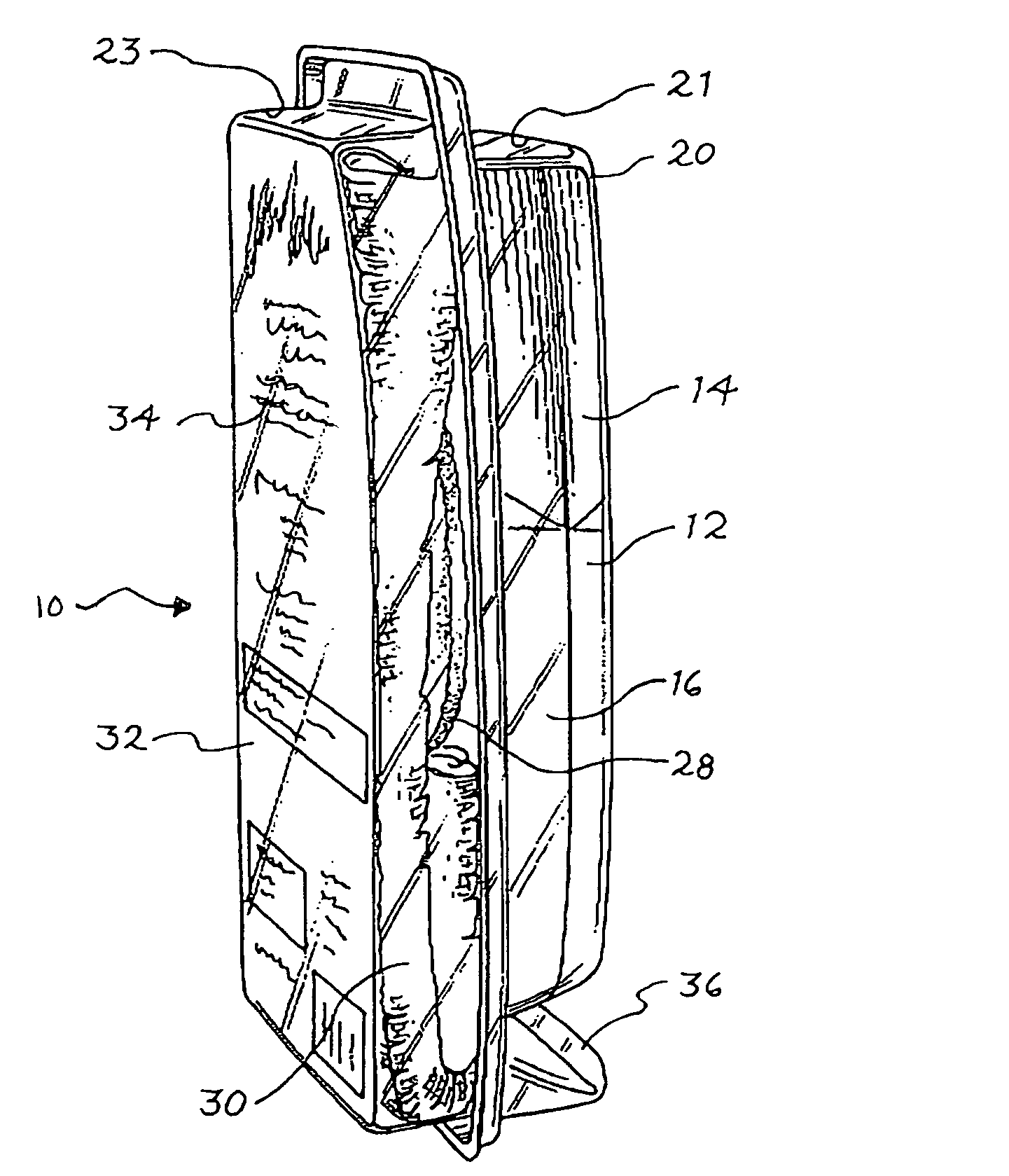

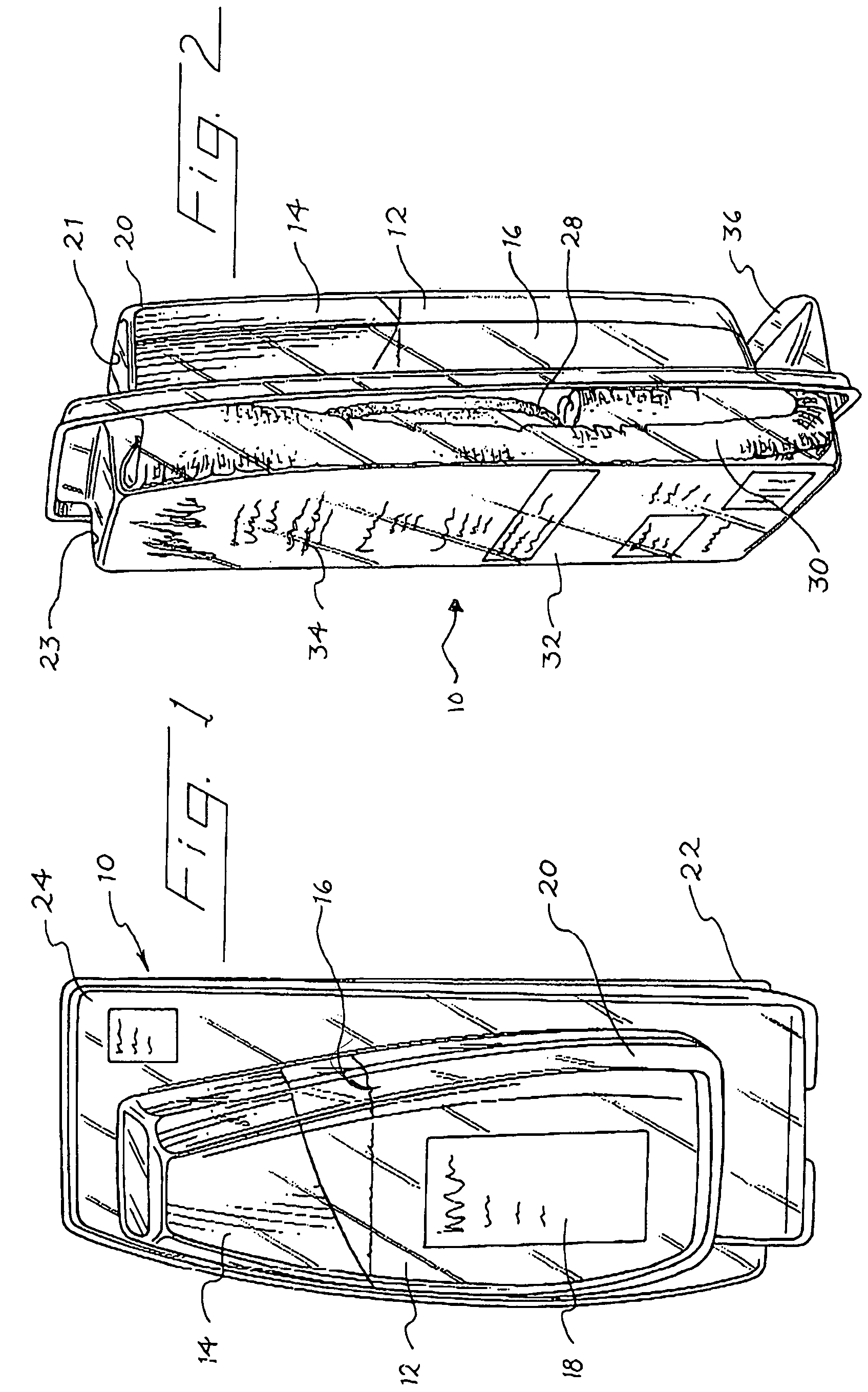

Liquid polishing composition and kit

ActiveUS7753998B2Efficient use ofDurable shine to plastic and painted metal surfacesSynthetic resin layered productsPolishing compositions with abrasivesPolymer sciencePolyolefin

A liquid polishing composition of the invention suitable for polishing an automobile and the like comprises about 0.01 to about 3 percent by weight of at least one silicone-based wax, about 0.20 to about 10 percent by weight of poly(alpha olefin) compounds including about 0.1 to about 5 percent by weight of at least one hyperbranched poly(alpha olefin), about 6 to about 60 percent by weight of at least one polydimethylsiloxane silicone fluid, about 1 to about 20 percent by weight of at least one volatile cyclic silicone, about 0.25 to about 3 percent by weight of at least one amino-functional silicone, about 0.01 to about 5 percent by weight of at least one UV absorber, and a petroleum-based carrier therefor. The liquid polishing composition can be packaged together with a microfiber polishing cloth in the form of a polishing kit. The liquid polishing composition provides a long lasting showroom finish and can be used directly on rubber, vinyl, and plastic components without leaving a white residue, commonly associated with conventional polishing compositions.

Owner:TURTLE WAX

Smudginess-resistant non-woven fabric and preparation method thereof

PendingCN113026374AReduce adhesionImprove stain resistanceTextiles and paperPolymer scienceAcrylic resin

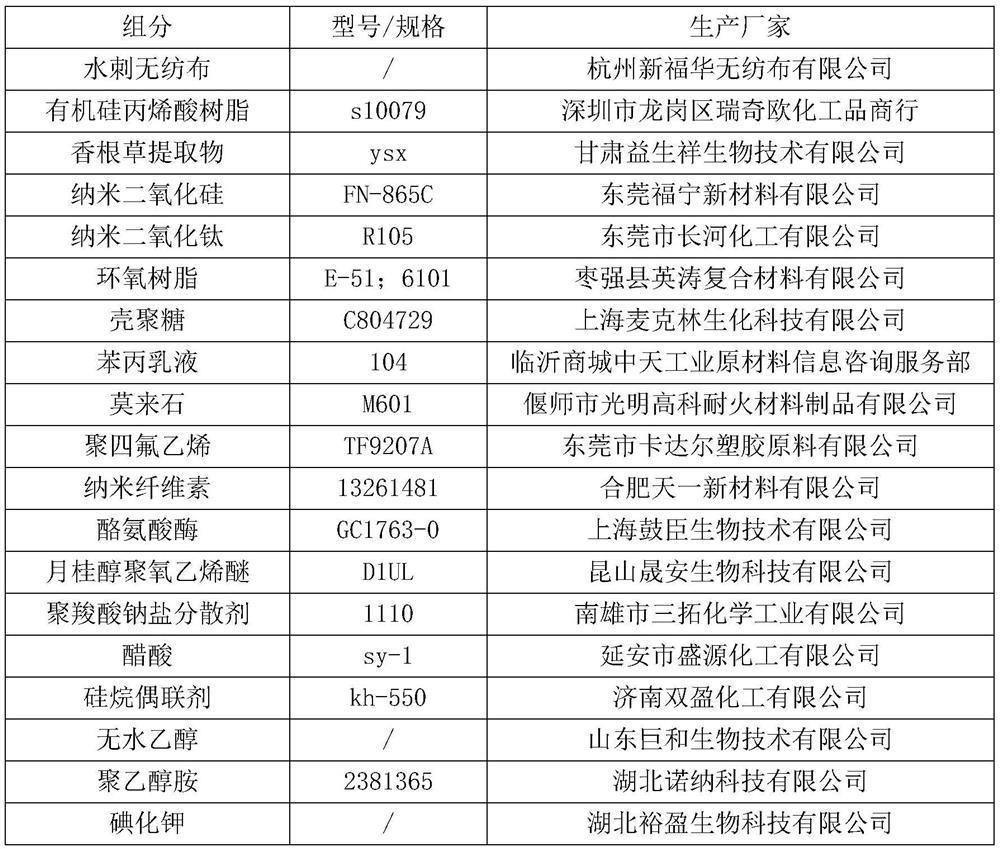

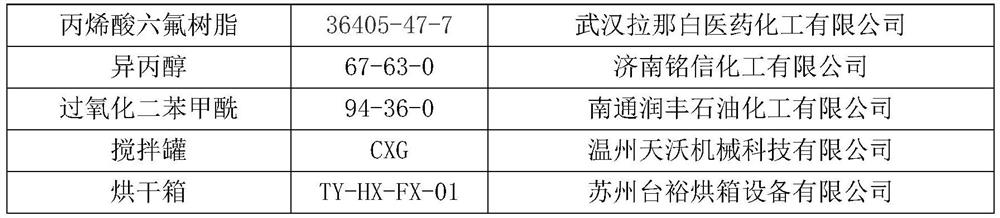

The invention relates to the technical field of non-woven fabrics, and particularly discloses a smudginess-resistant non-woven fabric and a preparation method thereof. The smudginess-resistant non-woven fabric comprises a non-woven fabric base layer, and the surface of the non-woven fabric base layer is coated with smudginess-resistant coating; and the smudginess-resistant coating is prepared from the following raw materials in parts by weight of 40 to 50 parts of organosilicone acrylic resin, 2 to 4 parts of vetiver grass extract, 0.8 to 2 parts of chitosan, 1 to 2 parts of nano silicon dioxide, 0.4 to 0.7 part of nano titanium dioxide, 1.8 to 2.4 parts of adhesive, 1 to 2 parts of polyoxyethylene lauryl ether, 0.8 to 1.5 parts of sodium polycarboxylate dispersant, 0.1 to 0.3 part of silane coupling agent, 1 to 2 parts of acetic acid and 80 to 90 parts of water. The preparation method of the smudginess-resistant non-woven fabric comprises the following steps of uniformly mixing raw materials of the smudginess-resistant coating to obtain the smudginess-resistant coating; uniformly coating the surface of the non-woven fabric base layer with the smudginess-resistant coating to obtain a coated non-woven fabric; and then carrying out drying, setting and inspecting to obtain a smudginess-resistant non-woven fabric finished product. The smudginess-resistant non-woven fabric has the advantage of smudginess resistance.

Owner:HANGZHOU XINFUHUA NONWOVENS

Preparation method of cattle and sheep feed with sugarcane leaves as raw material

The invention relates to a preparation method of a cattle and sheep feed with sugarcane leaves as a raw material. The preparation method includes the steps of: (A) cutting the sugarcane leaves into chips being 5-6 cm in length; (B) performing first-stage drying to the sugarcane leaf chips in a drying machine; (C) spraying cane molasses and performing secondary drying in a secondary hot air drier with temperature being 60-70 DEG C, time being 100-130 s and moisture being 15-18%; and (D) crushing the sugarcane leaf chips and the cane molasses and mixing the crushed components with other raw materials to perform granulation, and packaging the finish product. The preparation method fully utilizes the by-product resources of sugarcanes in our region, the cattle and sheep feed can supply required nutrients for cattle and sheep and alleviates a problem of contradiction between a straw biological granular feed and developing animal husbandry, can reduce breeding cost and can increase economical benefit.

Owner:唐秀廷

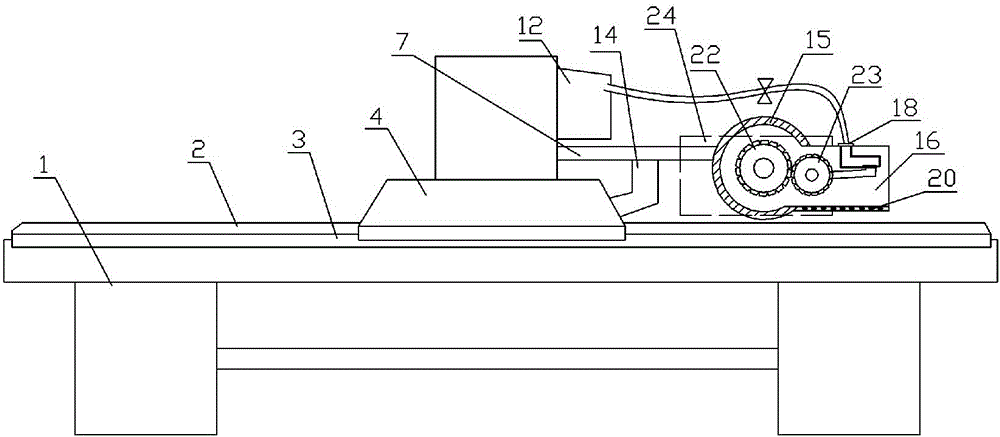

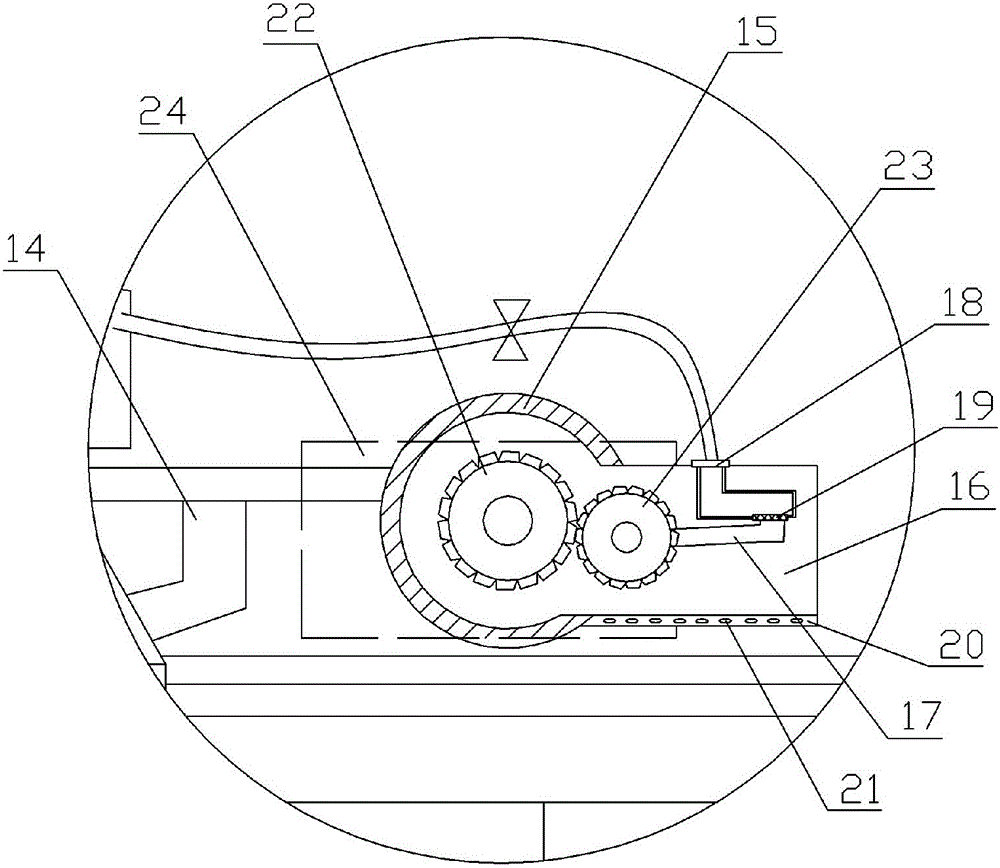

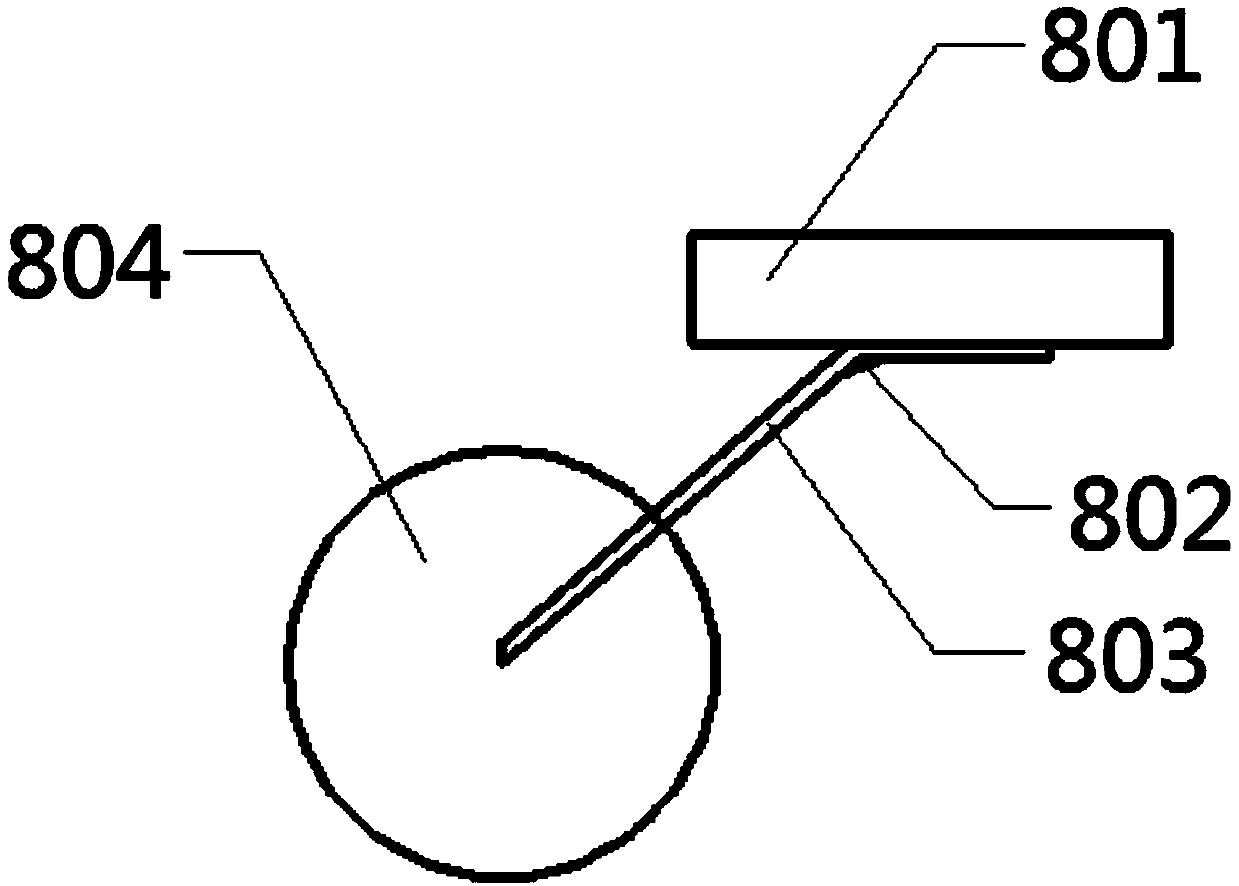

Pushing wheel type gluing system and using method

ActiveCN106076733AEvenly distributedEasy to useLiquid surface applicatorsCoatingsGear wheelEngineering

The invention discloses a pushing wheel type gluing system and a using method. The pushing wheel type gluing system comprises a machine base and a workbench arranged on the machine base, wherein guide rail slide slots are formed at the front side and the rear side in the length direction of the workbench; a first slide block and a second slide block are separately arranged in the guide rail slide slots at the front side and the rear side in a sliding fit mode; a beam is connected between the first slide block and the second slide block; a grinding roller is hinged on a supporting framework; a glue accommodating cavity is arranged at the side end of the grinding roller; a sealing plug capable of sealing a feeding hole is fixedly connected on a rotary shaft; a lower glue plate is arranged on the bottom of the glue accommodating cavity; a plurality of drip holes which are horizontally arranged are formed in the lower glue plate; the feeding hole communicates with a loading box through a glue tube; the end part of the grinding roller is fixedly connected to a first gear; and a second gear engaged with the first gear is mounted on the end part of the rotary shaft. The using method comprises three steps of discharging, motor starting and feeding hole automatic opening. The pushing wheel type gluing system aims to solve the problem that processing progress and efficiency are affected by material stacking collapse due to the fact that a current gluing section bar is flatted by a heavy object.

Owner:重庆新锐科技服务有限公司

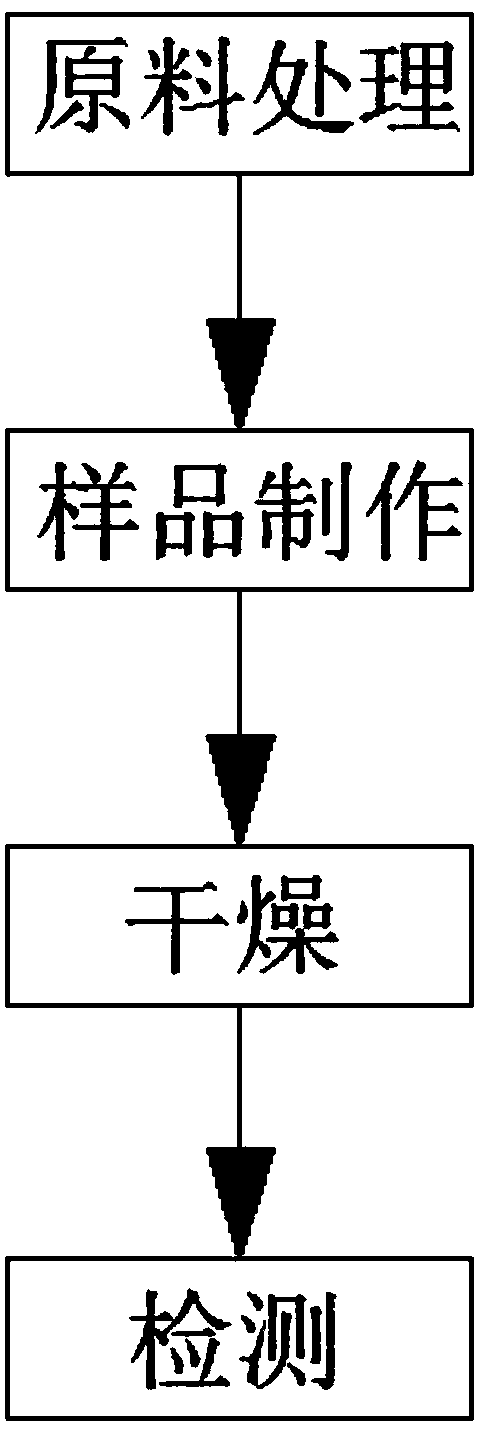

Rapid detection method of glossiness of wood paint

InactiveCN108195838AControl drying timeReduce humidityPreparing sample for investigationMaterial analysis by optical meansDrying timeMaterials science

The invention belongs to the technical field of paint film detection, in particular to a rapid detection method of the glossiness of wood paint. The method comprises the following steps: S1, materialtreatment: drying a wood paint sample to be detected in a 75 to 80 DEG C drying oven; S2, sample manufacture: grinding the surface of a wood sample, then cleaning the wood sample, and spraying dried wood paint onto the surface of the wood sample; S3, drying: drying the manufactured sample for 4 to 5 hours in a constant temperature and constant humidity environment; S4, detection: measuring the dried sample for 3 to 5 times through a digital glossmeter, and finally taking a measured average value. The rapid detection method reasonably controls the drying time and drying humidity, improves the detection accuracy, greatly shortens the detection time, improves the production efficiency, and is low in cost and convenient to operate.

Owner:中山市小榄企业服务有限公司

A gypsum board dryer

ActiveCN113154847BSmall footprintIncrease vertical spaceDrying chambers/containersDrying machines with progressive movementsStructural engineeringProcess engineering

Owner:北新建材(天津)有限公司

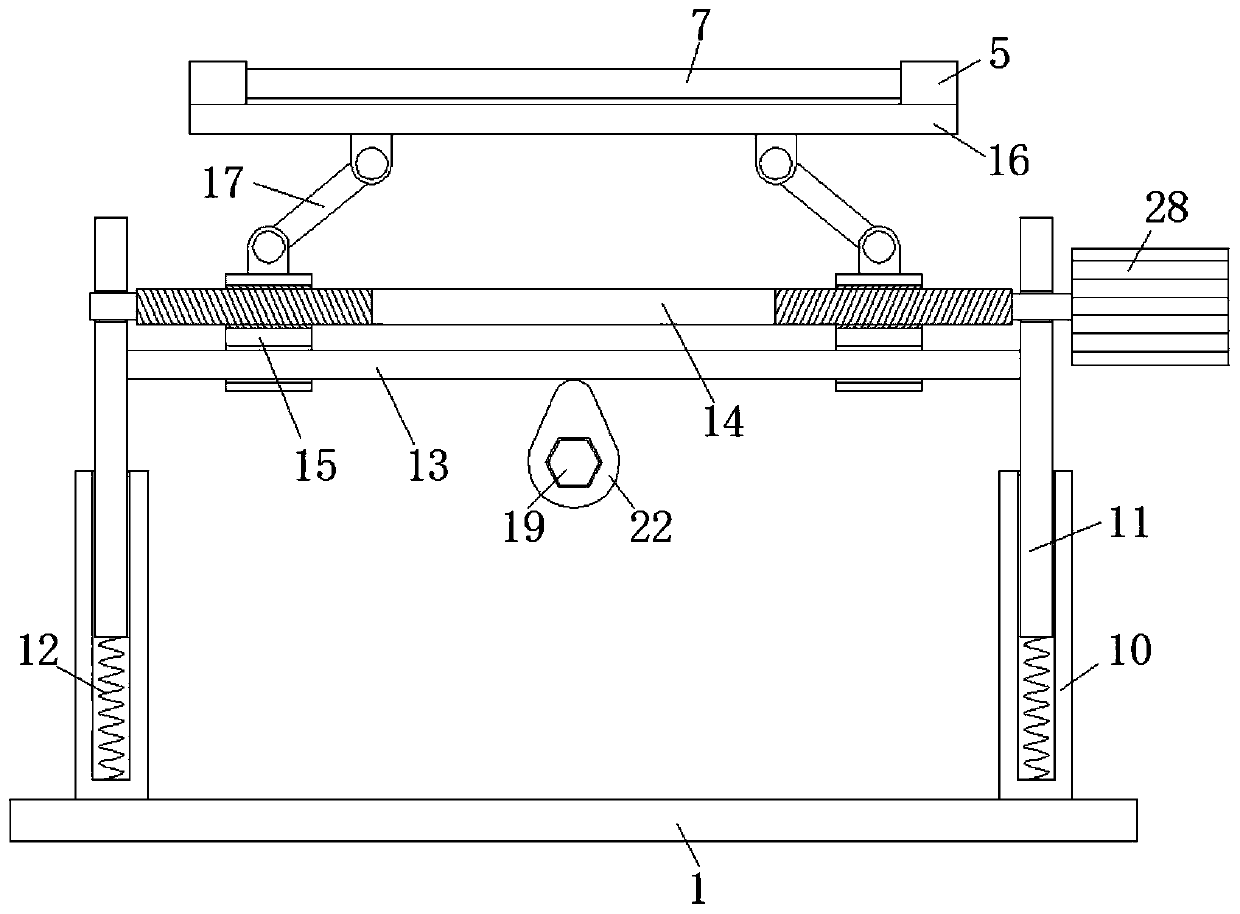

Drying device for processing trichosanthes kirilowii maxim seeds

ActiveCN110849116AControl speedControl drying timeDrying gas arrangementsDrying chambers/containersTrichosanthes kirilowiiAgricultural engineering

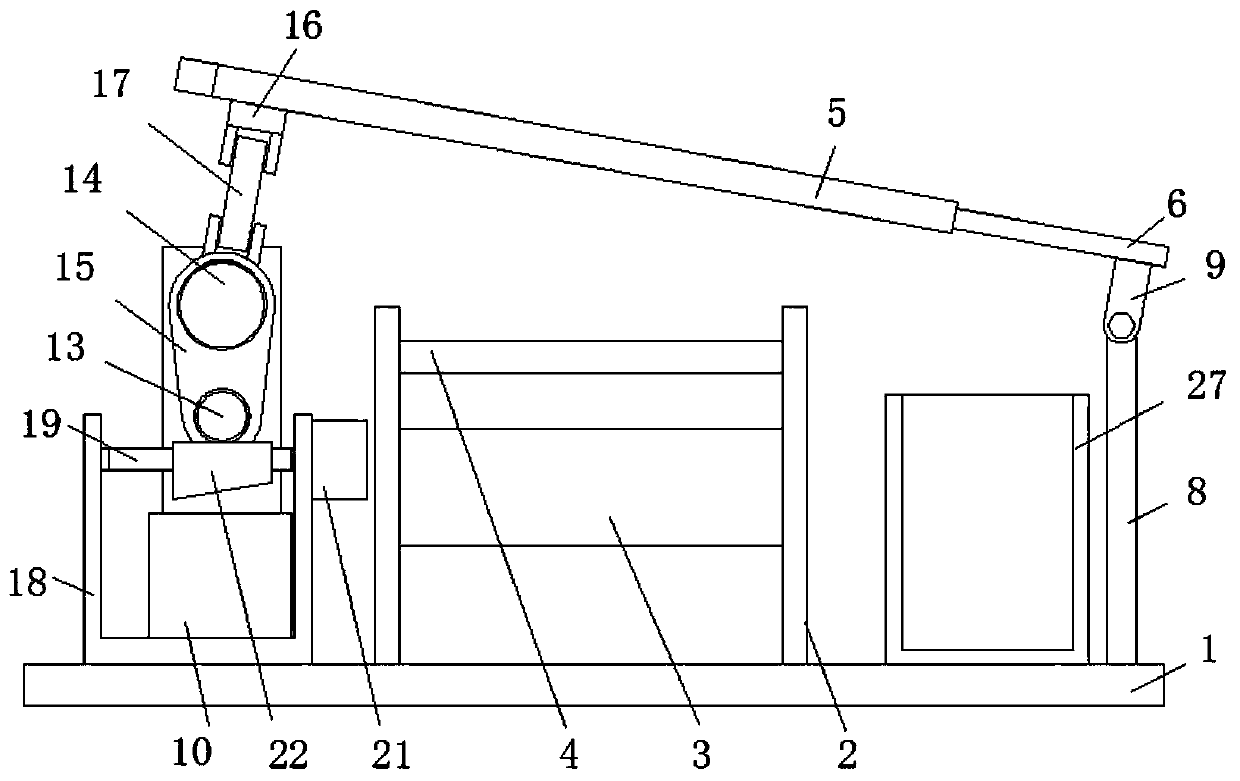

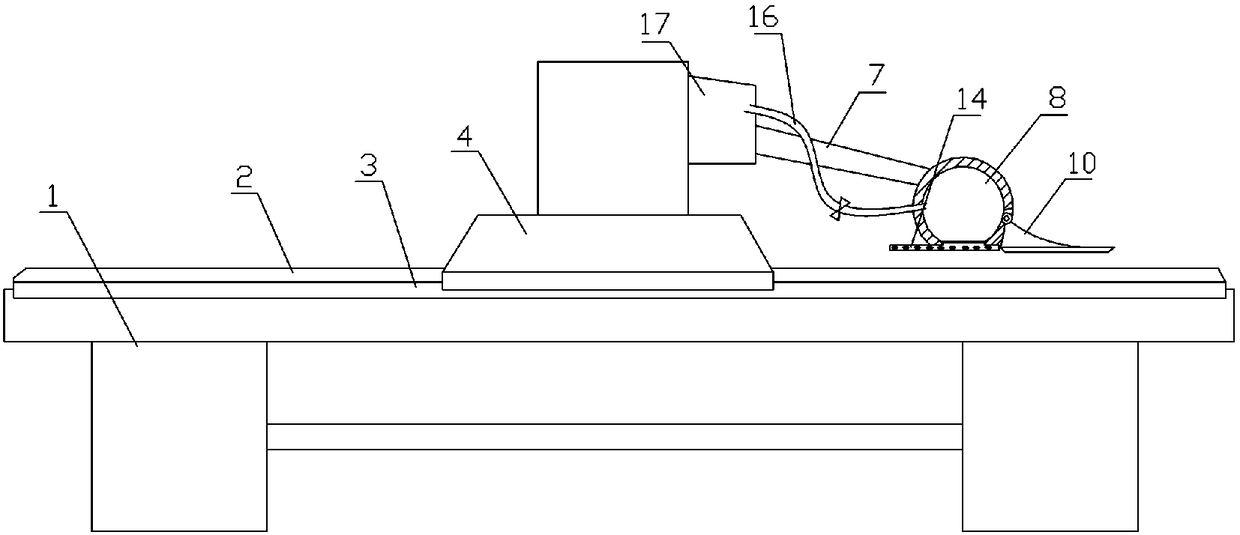

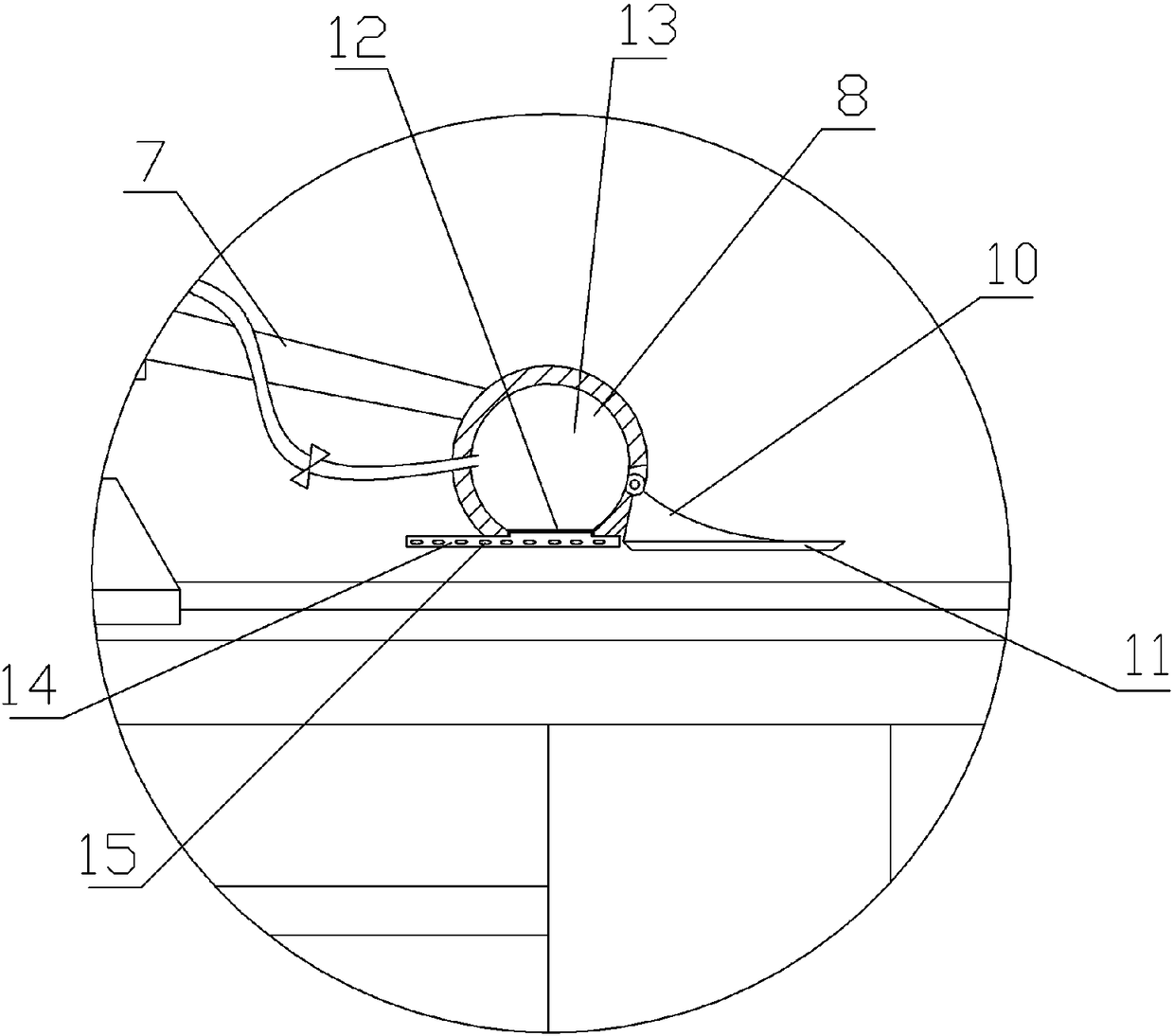

The invention discloses a drying device for processing trichosanthes kirilowii maxim seeds. The drying device comprises a bottom plate, wherein a mounting frame is fixedly connected to the top side ofthe bottom plate; an air blower and a heating net are mounted in the mounting frame; an air outlet of the air blower is vertically upward and is positioned in the bottom side of the heating net; a U-shaped main frame and a U-shaped auxiliary frame are arranged vertically above the mounting frame and are oppositely arranged; sliding chutes are respectively formed in two ends of the U-shaped main frame; two ends of the U-shaped auxiliary frame are respectively connected into the sliding chutes in a sliding manner; a ventilating net is arranged on the inner side of the U-shaped main frame; and the U-shaped main frame and the U-shaped auxiliary frame are both obliquely arranged. According to the drying device disclosed by the invention, the drying time of materials is effectively controlled,so that the production efficiency is improved while the drying effect is guaranteed; and the drying device can meet the processing requirements of different batches of trichosanthes kirilowii maxim seeds with different qualities and meet the use requirements of people in production and life.

Owner:安徽省徽岳记食品股份有限公司

Drying equipment

ActiveCN102889763BReduce energy consumptionEquilibrium moisture content decreasedDrying gas arrangementsDrying machines with progressive movementsProcess engineeringEngineering

The invention discloses drying equipment, comprising a drying box body and a heat source generating device, wherein an air inlet is formed at the front end of the drying box body; the air inlet is provided with a heat exchanger; the heat exchanger comprises a leading-in pipe, a leading-out pipe and a plurality of heat exchanging pipes; the heat source generating device is connected with an inlet of the leading-in pipe and an outlet of the leading-in pipe is communicated with inlets of the heat exchanging pipes; outlets of the heat exchanging pipes are communicated with an outlet of the leading-out pipe; and a rear end air outlet of the drying box is connected with an induced draft fan for leading an air flow out of the box body. The drying equipment utilizes steam to carry out heat exchange to dry cargoes; the energy consumption is low and the drying temperature is moderate; particularly, the drying temperature for drying wood sheets cannot be too high and the balanced water content in a drying process is relatively lower when the drying temperature is too high; and the water content slope of the cross section of a wood is more abrupt and drying defects of cracks, wrinkles and the like are easy to form, so as to influence the quality of a wood sheet.

Owner:浦北县建业胶合板有限责任公司

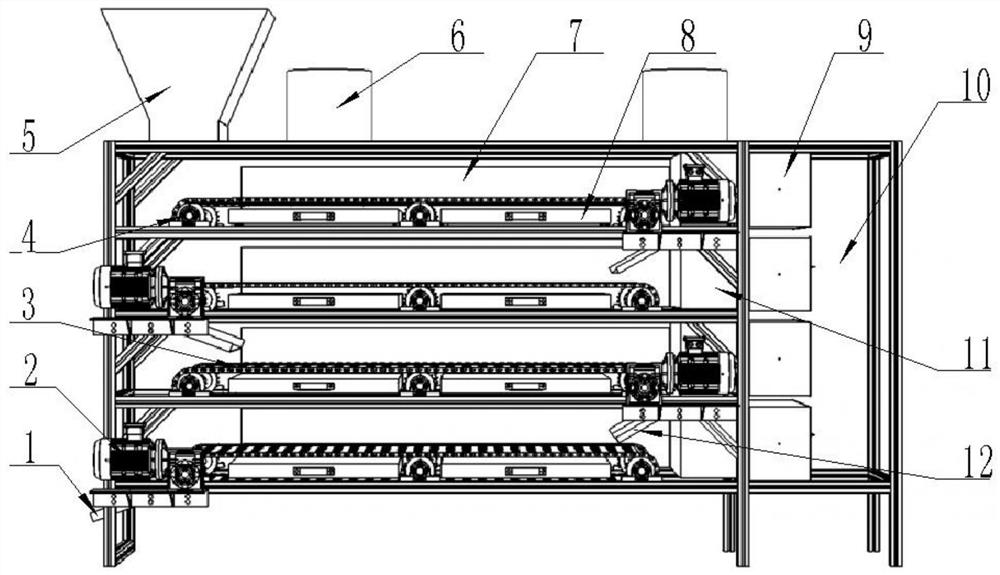

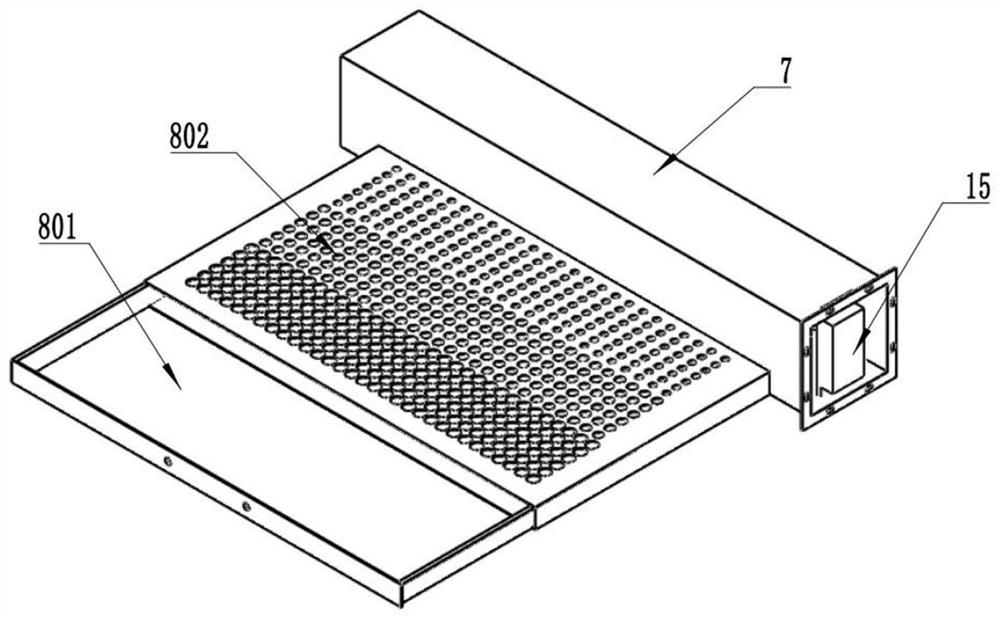

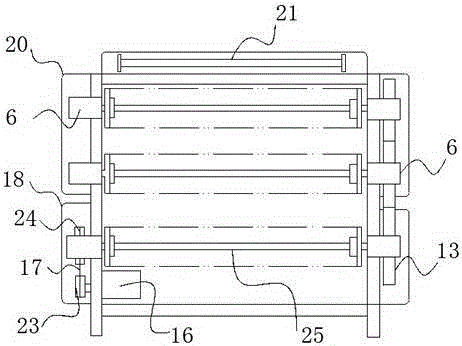

Layered temperature and time control multi-layer mesh belt type camellia seed drying device

PendingCN112577293AReduce the temperatureChange the input air volumeDrying gas arrangementsDrying solid materialsAir volumeAir velocity

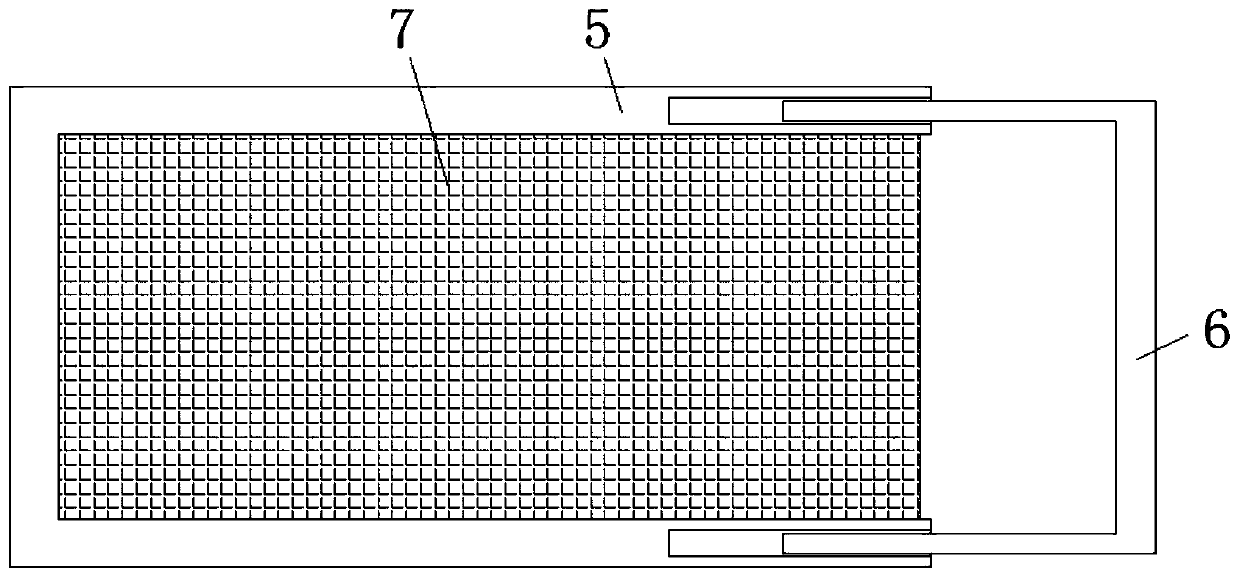

The invention discloses a layered temperature and time control multi-layer mesh belt type camellia seed drying device, and belongs to the technical field of agriculture and forestry product drying equipment. The device mainly structurally comprises a box body, a camellia seed conveying mechanism, an air volume adjusting mechanism, a temperature layered compensation mechanism, a layered air supplypipeline, a variable-aperture porous box, a transmission mechanism and the like. The layered driving, temperature compensating and air volume adjusting mechanism is provided, the operation speed, thetemperature and the air volume can be independently adjusted and controlled in a layered mode, and control can be accurately conducted according to a camellia seed drying process curve; and the variable-aperture porous box supplies air from the side surface and discharges air from the top, so that the temperature and air speed distribution uniformity is ensured, the outlet speed is reduced, air isin full contact with materials, and the drying quality of camellia seeds can be ensured.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

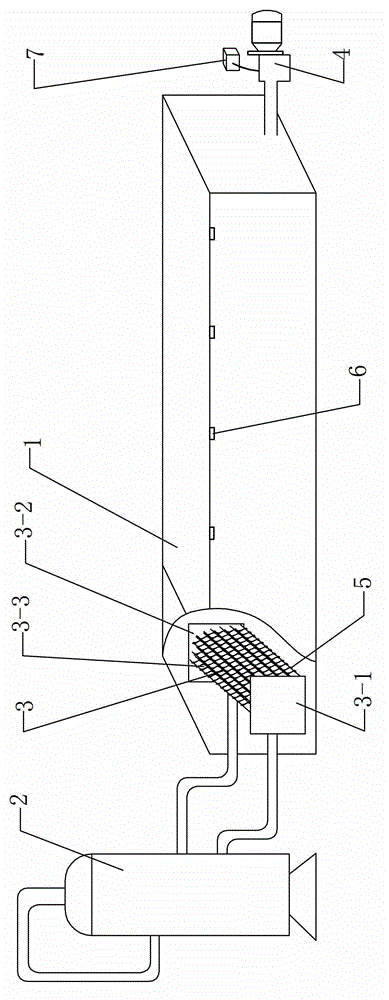

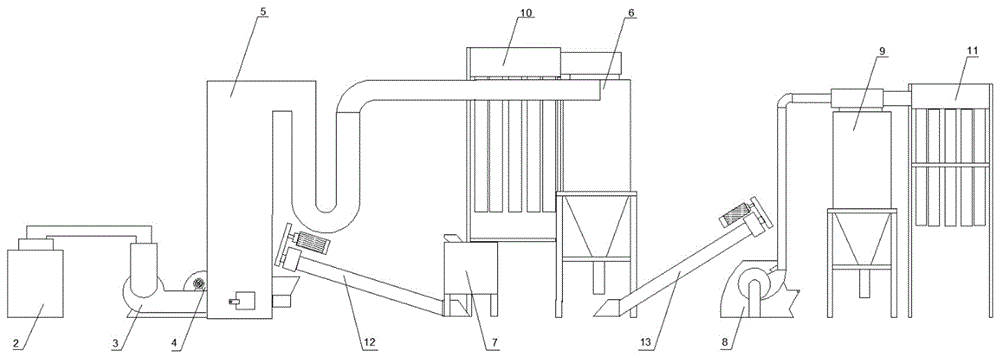

Device for rapidly preparing feed through sugarcane tail tips

ActiveCN105996087ASolve the problem of easy accumulation in the bearing and cause blockageTroubleshoot issues like downtimeFeeding-stuffCycloneTower

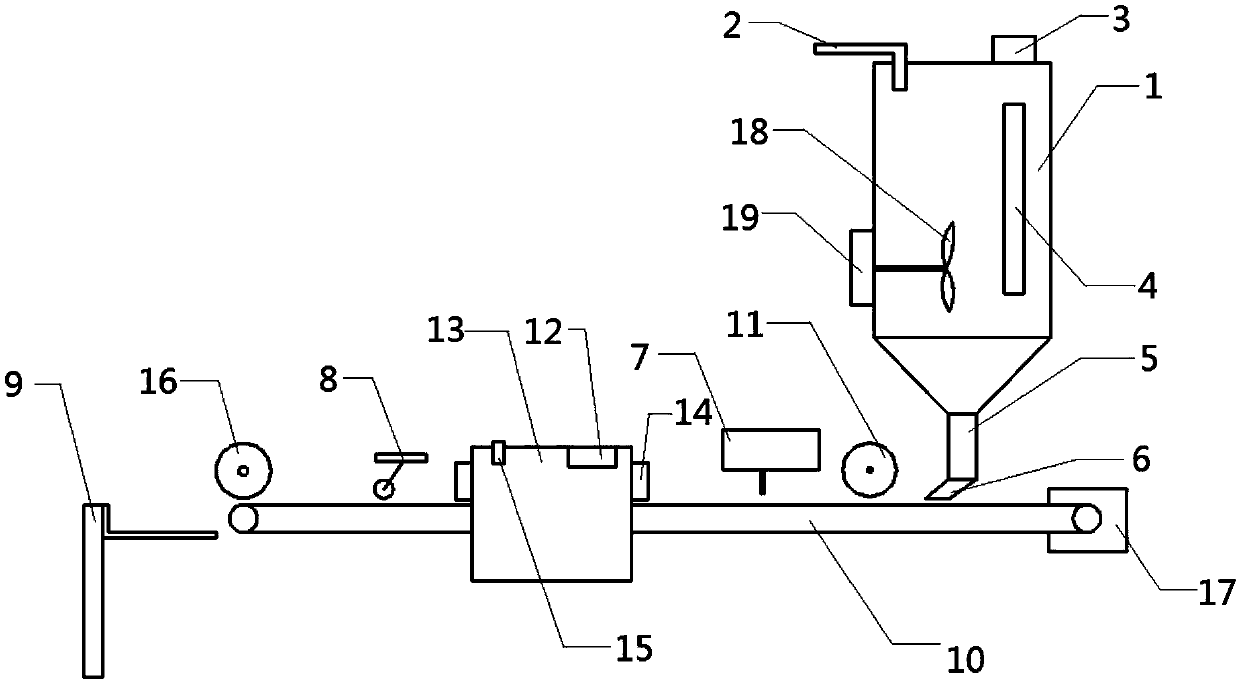

Provided is a device for rapidly preparing a feed through sugarcane tail tips. The device comprises a hot-blast stove, a main blower, a secondary blower, a drying tower, a main cyclone separator, pulverizers, a secondary cyclone separator and impurity collecting devices; the hot-blast stove is connected with the drying tower through the main blower, the secondary blower is installed on the other side of the drying tower and connected with a standby blast orifice of the drying tower, a feed inlet of a feeding auger conveyor is connected with the main pulverizer, a discharge hole of the feeding auger conveyor is connected with a feed inlet of the drying tower, the main cyclone separator is installed at the discharge end of the drying tower, an impurity outlet formed in the upper portion of the main cyclone separator is connected with the main impurity collecting device, a feed inlet of an auger conveyor is formed in the lower portion of the discharge hole of the main cyclone separator, a discharge hole of the auger conveyor is connected with the secondary pulverizer, a discharge hole of the secondary pulverizer is connected with the secondary cyclone separator, and a secondary impurity connecting device is installed at an impurity outlet formed in the upper portion of the secondary cyclone separator.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI +1

Packaging material gluing system and usage method

ActiveCN105922631BThere is no problem of stacking and collapsingEvenly distributedBox making operationsPaper-makingEngineeringSizing

This patent discloses a packaging material gluing system and a method of use, including a machine base and a workbench arranged on the machine base. The workbench is in the shape of a rectangular plate, and the workbench is equipped with Guide rail chute, the first slider and the second slider are slidably fitted in the guide rail chute on the front and rear sides respectively, and a "door"-shaped bracket is connected between the first slider and the second slider, and the "door" There is a lever connected to the shaped bracket, the bottom of the upper rubber cylinder is provided with a glue outlet, and a number of horizontally arranged drip holes are opened on the baffle. , the connecting rod is connected with a briquetting block with a cavity, the bottom of the briquetting block is provided with horizontally arranged liquid outlet holes, the cavity is connected to the feeding box through a rubber hose, and a liquid stop valve is provided on the rubber hose. The gluing profile is flattened by heavy objects, which causes the stacking and collapse of materials, which affects the processing progress and efficiency.

Owner:重庆新锐科技服务有限公司

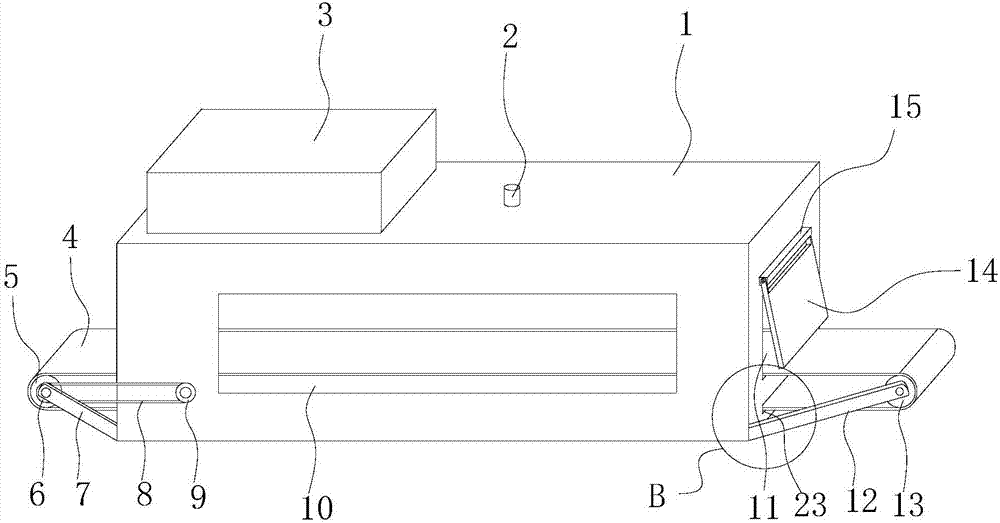

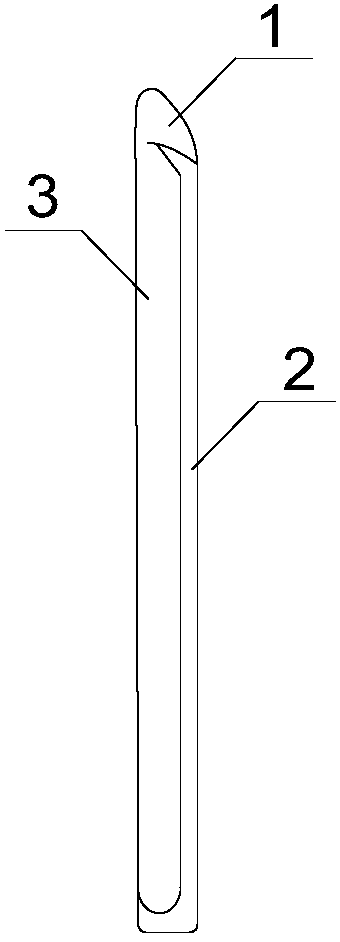

Incense strip preparation device

InactiveCN107696571ARealize automated productionControl drying timeShaping pressMotor drivePulp and paper industry

The invention discloses an incense stick preparation device, which comprises a stirring box, an extrusion head, a cutting device, a hardness detection device, a bracket, a controller, a motor, a first roller, a second roller, and a conveyor belt And the drying device, the extrusion head is installed in the center of the bottom of the mixing box through threaded connection, the conveyor belt is directly below the extrusion head, and the conveyor belt is driven by the motor to rotate, and the first roller is also installed directly above the conveyor belt , the first roller is facing the extrusion head, the conveyor belt passes through the drying device, a cutting device for cutting extruded incense sticks is installed between the first roller and the drying device, and a Hardness testing device, the hardness testing device is electrically connected to the controller, the controller is also electrically connected to the motor on the conveyor belt, a bracket is provided at the end of the conveyor belt, and a second roller is provided in the gap at the top of the bracket. The invention has simple structure and high processing efficiency, and can realize automatic production of incense sticks.

Owner:ANHUI KECHUANG PRODUCTIVITY PROMOTION CENT CO LTD

Highly esterified polyol polyesters with one pair of conjugated double bonds

InactiveUS20100041849A1Control drying timeEsterified saccharide compoundsSugar derivativesPolyesterDouble bond

A composition comprising a highly esterified polyol polyester wherein the polyester comprises a polyol residue and a plurality of fatty acids esters, and wherein from about 5% to about 80% of the fatty acid esters contains exactly one pair of conjugated double bonds.

Owner:THE PROCTER & GAMBLE COMPANY

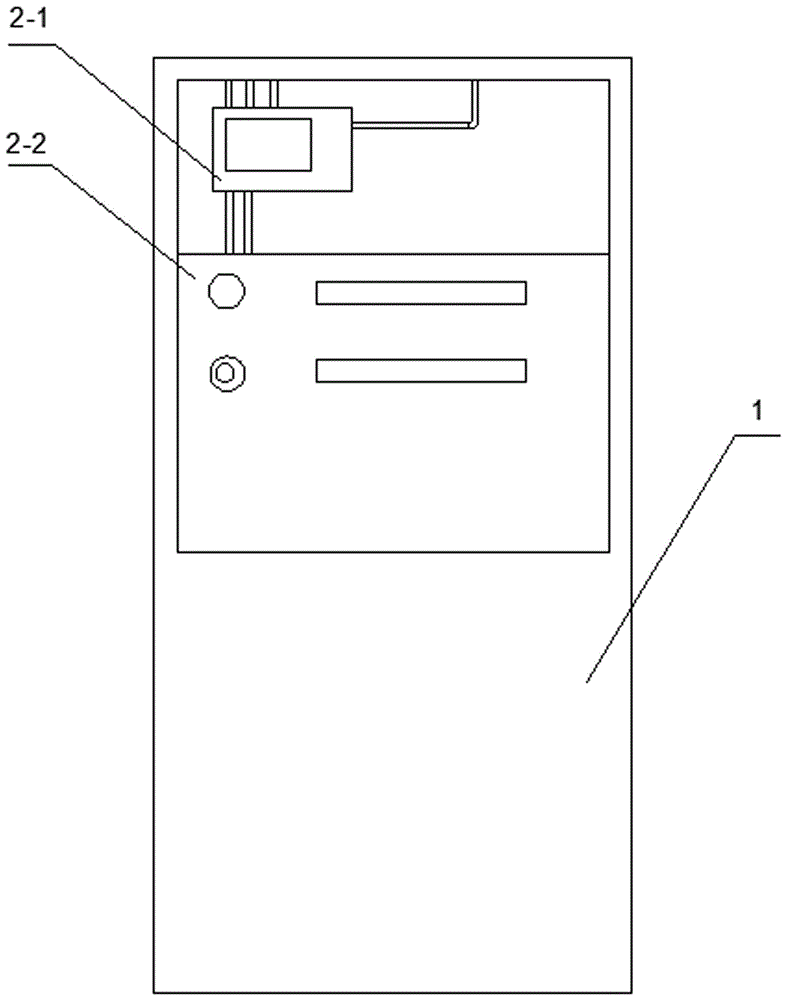

Grain drying device

InactiveCN103988897AKeep dryImprove drying efficiencySeed preservation by dryingDrying timeHuman error

The invention discloses a grain drying device, which comprises a housing (4), a drying rack (8), a vibration unit (3), a screen plate (9), a time relay (5) and an alarm device (6), the top of the housing (4) is provided with an air outlet (1), the housing (4) is provided with an air intake (11) just below the position of the air outlet (1), a feed inlet (2) is arranged near the air outlet (1), a discharge port (10) is arranged near the air intake (11), and the screen plate (9) is arranged below the drying rack (8). The beneficial effects of the grain drying device are that: grains are heated by the drying rack, the grains are dried by a vibration fluidized type drying method, grain moving direction and hot fluid movement direction are opposite, the drying effect is enhanced, the drying efficiency is improved; by setting of the time relay, the drying time can be accurately and effectively controlled, the drying quality can be guaranteed, human error can be avoided by automatic timing, and manpower consumption can be reduced.

Owner:成都市龙泉驿区齐盛机械厂

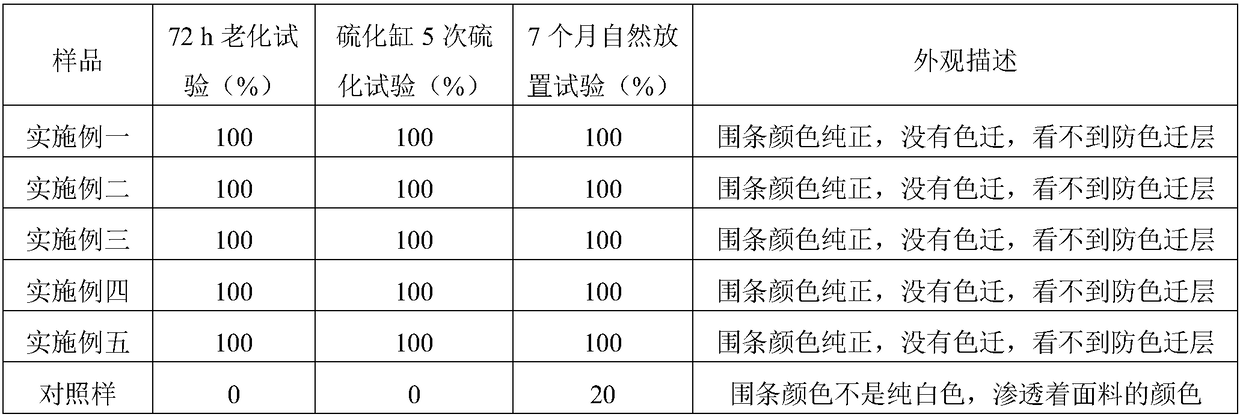

Color-transfer-resistant vulcanized shoe and production process thereof

InactiveCN109265759ASimple production processHigh degree of automationUpperBootlegsActive agentEngineering

The invention discloses a color-transfer-resistant vulcanized shoe and a production process thereof, and belongs to the technical field of vulcanized shoes. The color-transfer-resistant vulcanized shoe comprises a shoe upper, wherein the bottom portion of the shoe upper is provided with a color-transfer-resistant adhesion cloth, the outer side of the adhesion cloth is provided with an inner rubberstrip, the outer side of the inner rubber strip is provided with a treatment agent layer, the outer side of the treatment agent layer is provided with an enclosing strip, the enclosing strip comprises a water line, the bottom portion of the water line is provided with a rubber edge strip, the inner side of the rubber edge strip is provided with a color-transfer-resistant layer, the bottom portionof the rubber edge strip is wrapped with a color-transfer-resistant layer, the inner rubber strip and the color-transfer-resistant layer are respectively made of a color-transfer-resistant material,the color-transfer-resistant material comprises the following raw materials by weight: 100 parts of rubber, 50-60 parts of filler, 50-60 parts of a reddening inhibitor, 13-15 parts of a toughening agent, 7-10 parts of an active agent, and 2-3 parts of an accelerator, and the treatment agent layer comprises 10-15 parts of a curing agent and 85-90 parts of a color inhibitor. According to the presentinvention, the color transfer of the shoe upper fabric is strictly prevented, the fabric is saved, the operation process is simplified, and the mass production is achieved.

Owner:青岛千里行集团有限公司 +3

Modified PLA full-degradable plastic and preparation method thereof

PendingCN112920566AImprove mechanical propertiesEnhanced heat and water resistanceEpoxyPolymer science

The invention discloses modified PLA full-degradable plastic. The modified PLA full-degradable plastic is prepared from the following components in parts by weight: 20 to 30 parts of poly (butylene succinate), 20 to 25 parts of polylactic acid, 5 to 10 parts of poly (butylene adipate / terephthalate), 10 to 15 parts of talcum powder, 10 to 15 parts of porous ceramic, 30 to 40 parts of bamboo powder and 0.5 to 5 parts of an auxiliary agent. The auxiliary agent comprises the following components in parts by weight: 1-3 parts of an epoxy compound, 1-3 parts of a lubricant and 1-3 parts of a plasticizer. The preparation method comprises the following steps: stirring and mixing the poly (butylene succinate), the polylactic acid, the poly (butylene adipate / terephthalate) and the epoxy compound, adding the porous ceramic, performing stirring and mixing, stirring and mixing an obtained mixture with the talcum powder, a bamboo powder, the lubricant and the plasticizer, performing extruding and granulating by a double-screw extruder, and performing drying to obtain the modified PLA full-degradable plastic. The problems that existing polylactic acid full-degradable plastic is poor in rigidity, not easy to form and the like are solved.

Owner:柳州塑友科技有限公司 +1

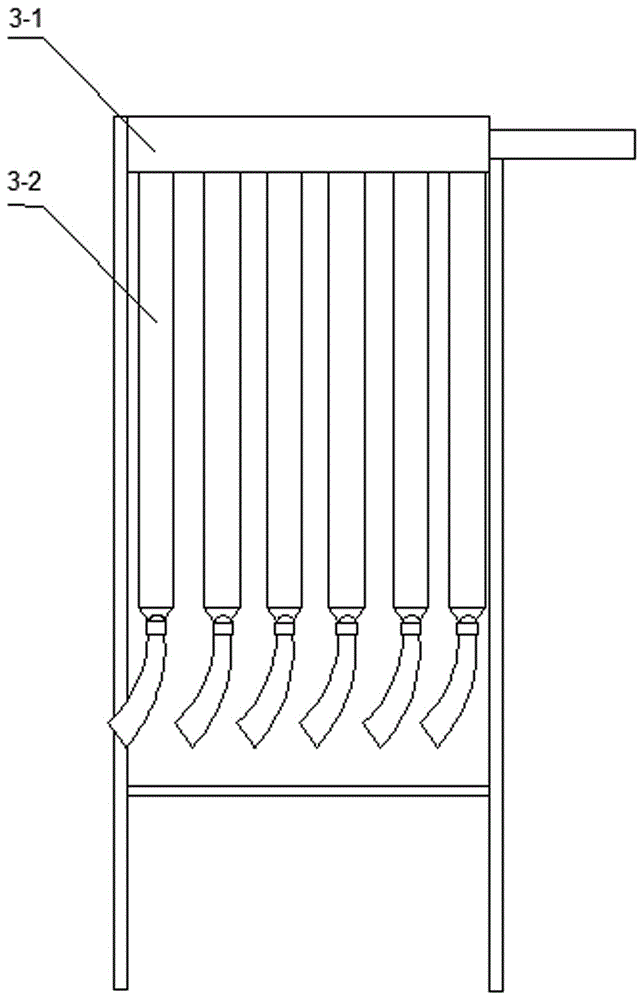

Sterilizing and drying machine for agricultural products

InactiveCN105394173AImprove temperature uniformityImprove drying qualitySeed preservation by irradiation/electric treatmentFood treatmentAgricultural engineeringMoisture

The invention discloses a sterilizing and drying machine for agricultural products, relates to the technical field of drying of agricultural products and aims at solving the problem of sterilization when the agricultural products are dried. The sterilizing and drying machine is uniform in drying and is capable of ensuring that the final moisture content of the agricultural products is consistent. The sterilizing and drying machine comprises a drying chamber, wherein at least two layers of chain plate components are arranged in the drying chamber; air separating pipes (6) of air separating devices (5 and 6) are connected between upper chain plates and lower chain plates of the chain plate components; a moisture removing hole (7) is formed in the top of the drying chamber; and a sterilizing device (9) is also arranged in the drying chamber.

Owner:熊以焯

Preparation method of high-activity mucor koji

InactiveCN106801018AIncrease vitalityLow bacteria rateFungiMicroorganism based processesMucor speciesHigh activity

The invention discloses a preparation method of high-activity mucor koji. The preparation method of the high-activity mucor koji comprises the following steps: activating strains, preparing first-level strains, preparing second-level strains, preparing third-level strains, preparing finished koji, and drying the finished koji. The invention provides the preparation method of the high-activity mucor koji. According to the preparation method of the high-activity mucor koji, with combination of solid state fermentation and pure liquid state fermentation, growth of mixed bacteria can be effectively inhibited, so that the produced mucor koji has the advantages of high activity, low mixed bacteria rate and stable performance.

Owner:湖南轻工研究院有限责任公司

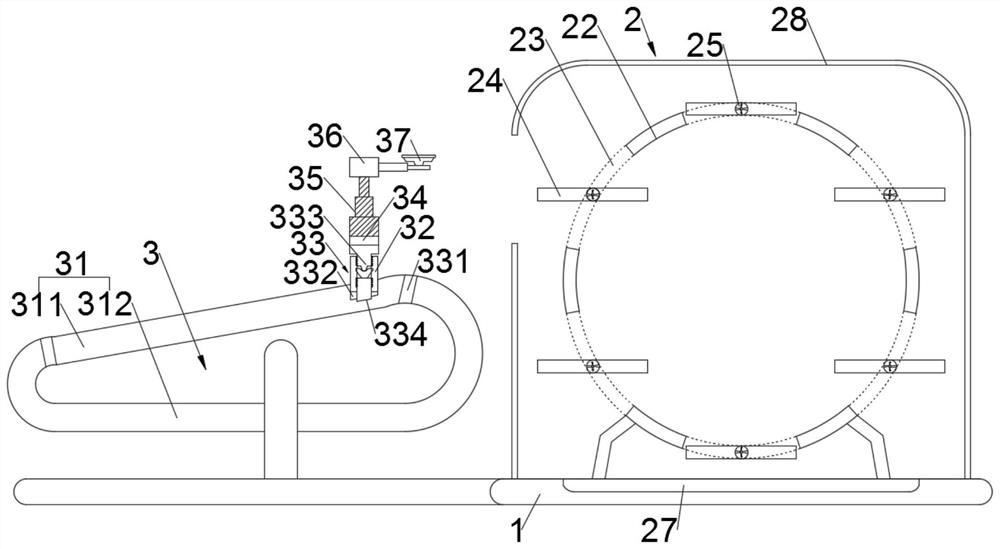

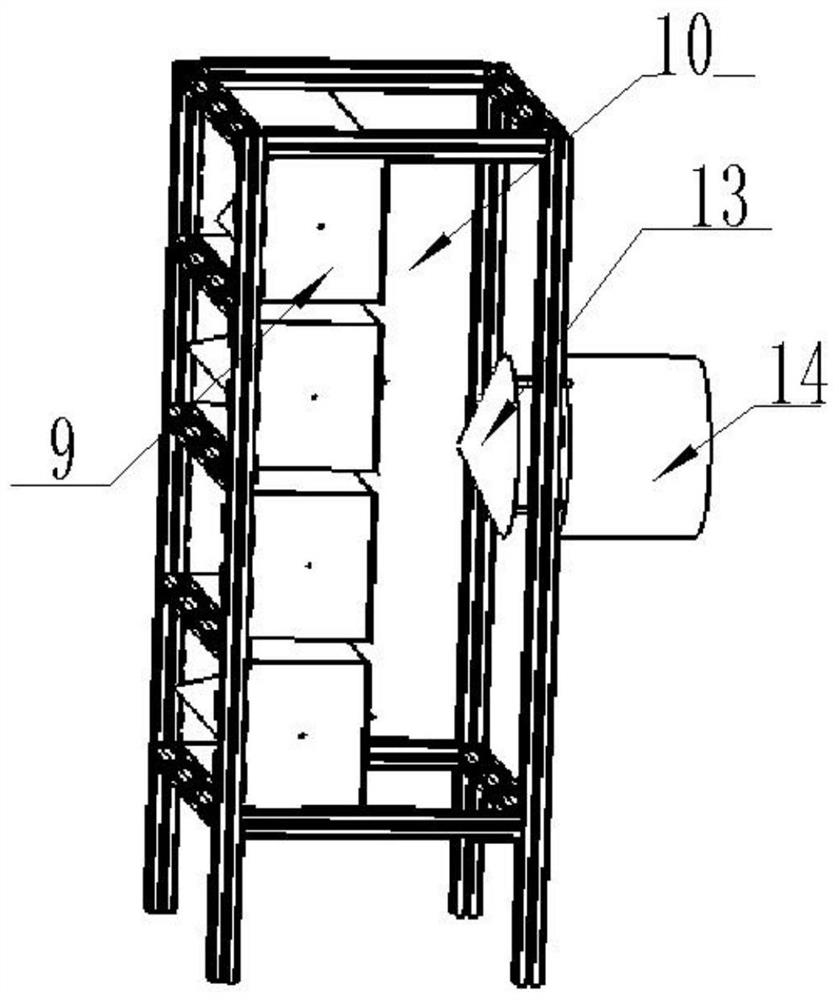

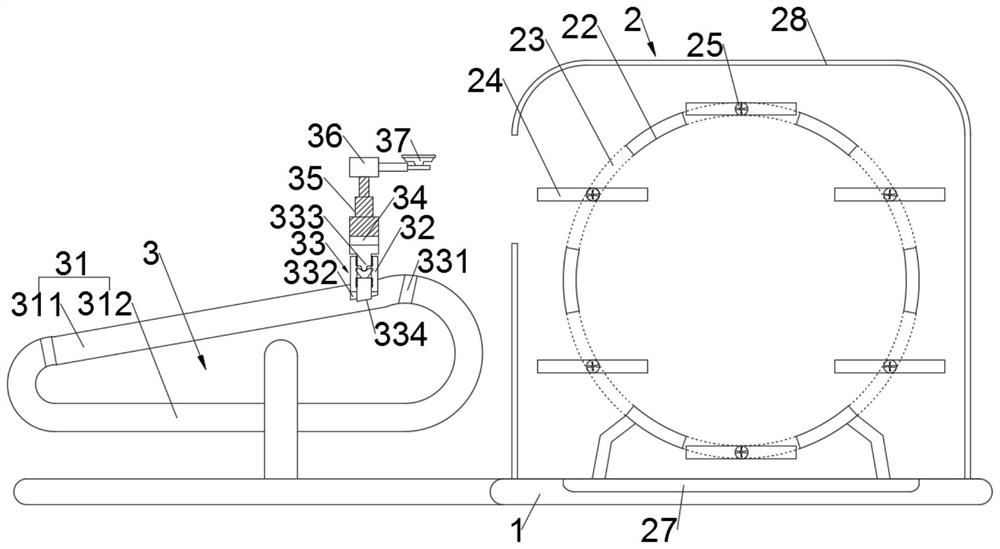

Gypsum board drying machine

ActiveCN113154847ASmall footprintIncrease vertical spaceDrying chambers/containersDrying machines with progressive movementsStructural engineeringDrying time

The invention discloses a gypsum board drying machine. The gypsum board drying machine comprises a base; a drying mechanism, a board discharging and conveying mechanism and multiple noise reduction taking and conveying mechanisms are arranged on the base; the drying mechanism is used for receiving formed gypsum boards output by a board manufacturing device and simultaneously enabling multiple gypsum board machines to rotate circumferentially so as to perform circular drying; and the board discharging and conveying mechanism is used for conveying the dried gypsum boards to the next procedure. According to the drying machine, the longitudinal space is widened, so that the gypsum boards are placed in the circumferential direction, the drying time of the gypsum boards is controlled by circularly rotating on a rigid driving ring, and the occupied space of a plant is reduced; through expansion in the longitudinal space, only short heating equipment needs to be laid at the bottom end of the rigid driving ring.

Owner:北新建材(天津)有限公司

Method for isolating caspofungin

ActiveUS20160068564A1Easy to washHigh purityOrganic chemistry methodsPeptide preparation methodsEngineeringCombinatorial chemistry

The present invention relates to a method for isolating caspofungin and to a novel crystalline form of caspofungin diacetate thus obtained.

Owner:CENTRIENT PHARMA NETHERLANDS BV

Adjustable inclined type tea drying and cooling device

InactiveCN109717258ASpeed up dryingIncrease or decrease distancePre-extraction tea treatmentElectric machinerySlide plate

The invention provides an adjustable inclined type tea drying and cooling device. The device includes a base plate, rotating wheels, a conveyor belt, a transmission motor, a vibrating rod and a smallmotor; the two sides on the top of the base plate are fixedly provided with a shell through bolts; the bottom on one side of the shell is fixedly provided with a side plate through a bolt; the top ofthe shell is provided with a feeding inlet; the middle part on one side of the shell is integrally provided with a guide plate; and the top on the inner side of the guide plate and the shell are fixedly provided with a shunting frame directly through the bolts. Through the arrangement of a twitching slide plate and an inclined mesh, the spreading distance of tea can be lengthened; through the sieving of the inclined mesh and the guiding of air flow, and part of the tea can fall down from mesh holes of the inclined mesh, and part of the tea can fall down again after falling down to the twitching slide plate to perform expansion, so that gaps can be generated, and the drying speed of the tea can be accelerated; and the draw-off of the twitching slide plate can be performed through the bolts,and the flow distance and speed of the tea can be increased or decreased by adjusting the distance of the twitching slide plate, so that the drying time can be conveniently controlled.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com