Wheat straw filled and modified PLA full-degradable plastic and preparation method thereof

A wheat straw, fully degradable technology, applied in the field of plastics, can solve the problems of poor heat resistance and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

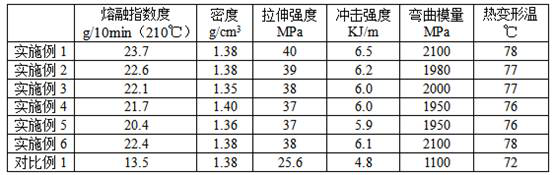

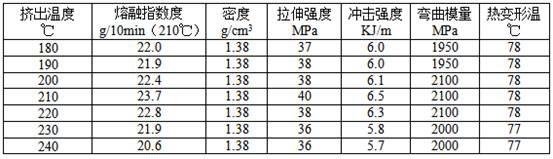

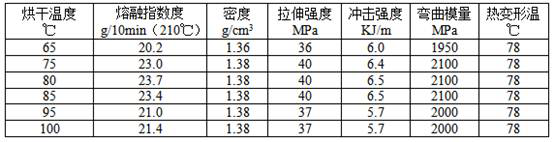

Examples

Embodiment 1

[0029] A wheat straw filled modified PLA fully degradable plastic, which includes the following components in parts by weight: 27 parts of polybutylene succinate, 20 parts of polylactic acid, polyadipate / butylene terephthalate 7.6 parts, 22.5 parts of talcum powder, 22 parts of wheat straw powder, 0.9 parts of additives;

[0030] The auxiliary agent includes the following components in parts by weight: 5 parts of porous rare earth oxide, 3 parts of epoxy compound, 2 parts of lubricant, 2 parts of plasticizer, 1 part of antioxidant, 2 parts of heat stabilizer, antistatic 1 part of agent; the epoxy compound is epoxidized soybean oil; the plasticizer is citrate plasticizer; the lubricant is paraffin; the porous rare earth oxide is porous lanthanum oxide; It is butyl hydroxyanisole; the heat stabilizer is a phosphite heat stabilizer; the antistatic agent is a cationic quaternary ammonium salt.

[0031] The preparation method of wheat straw filled modified PLA fully degradable pla...

Embodiment 2

[0037] A wheat straw filled modified PLA fully degradable plastic, which includes the following components in parts by weight: 22 parts of polybutylene succinate, 18 parts of polylactic acid, polyadipate / butylene terephthalate 6.5 parts, 18.5 parts of talcum powder, 25 parts of wheat straw powder, 2.5 parts of additives;

[0038] The auxiliary agent includes the following components in parts by weight: 3 parts of porous rare earth oxide, 1 part of epoxy compound, 1 part of lubricant, 3 parts of plasticizer, 2 parts of antioxidant, 1 part of heat stabilizer, antistatic 3 parts of agent; The epoxy compound is epoxy butyl stearate; The plasticizer is maltitol; The lubricant is oxidized polyethylene wax; The porous rare earth oxide is porous lanthanum oxide; The antioxidant is a combination of equal weights of phenylene diisodecyl phosphite and pentaerythritol bisphosphite; the heat stabilizer is a hindered phenolic heat stabilizer; the antistatic agent is a polyol ester and a fat...

Embodiment 3

[0045] A wheat straw filled modified PLA fully degradable plastic, which includes the following components in parts by weight: 25 parts of polybutylene succinate, 20 parts of polylactic acid, polyadipate / butylene terephthalate 8 parts, 20 parts of talcum powder, 28 parts of wheat straw powder, 3.5 parts of additives;

[0046] The auxiliary agent includes the following components in parts by weight: 4 parts of porous rare earth oxide, 2 parts of epoxy compound, 3 parts of lubricant, 1 part of plasticizer, 3 parts of antioxidant, 3 parts of heat stabilizer, antistatic 2 parts of agent; Described epoxy compound is the combination that epoxy soybean oil and epoxy butyl stearate equal volumes mix; Described plasticizer is the combination that glycerin, sorbitol and xylitol mix equal volumes; Described lubricating The agent is paraffin; the porous rare earth oxide is porous lanthanum oxide; the antioxidant is dibutyl hydroxytoluene; combination.

[0047] The preparation method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com