Drying equipment

A technology for drying equipment and cabinets, applied in the field of mechanical equipment, can solve problems such as easy cracking, shrinkage, affecting wood quality, and high energy consumption, so as to achieve suitable drying temperature, good drying effect, and water saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

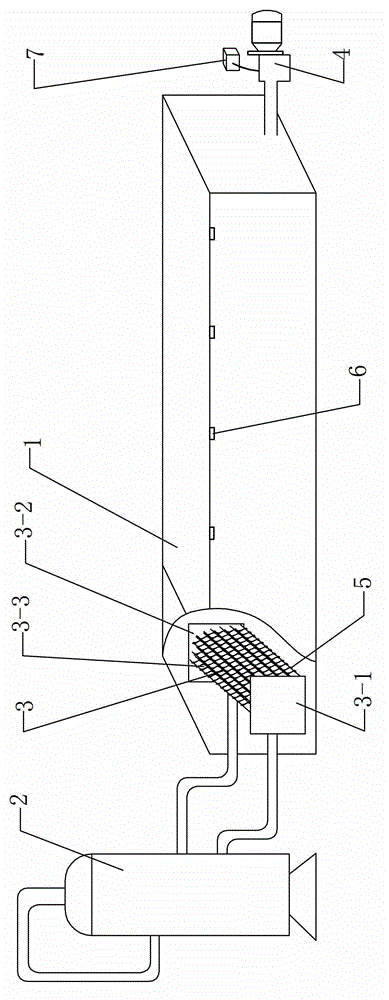

[0022] Such as figure 1 As shown, a drying device of the present invention includes a drying box 1 and a heat source generating device 2. An air inlet is provided on the upper front end of the drying box 1, and a heat exchanger 3 is arranged at the air inlet. It flows into the drying box 1 through the heat exchanger 3 . The heat exchanger 3 includes an inlet pipe 3-1, an outlet pipe 3-2 and a plurality of heat exchange pipes 3-3, the heat source generator 2 is connected to the inlet of the inlet pipe 3-1, and the outlet of the inlet pipe 3-1 is connected to the inlet of the inlet pipe 3-1. The inlets of the heat exchange pipes 3-3 are connected, and the outlets of the heat exchange pipes 3-3 are connected with the inlets of the outlet pipes 3-2; the air outlet at the rear end of the drying box is connected with an induced draft fan 4 for leading the air flow out of the box.

[0023] The heat exchange tubes 3-3 are seamless tubes, which are parallel to each other and arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com