Modified PLA full-degradable plastic and preparation method thereof

A fully degradable and modified technology, applied in the field of plastics, can solve problems such as poor rigidity and difficult molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

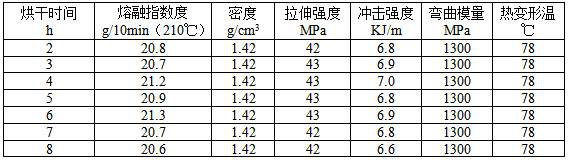

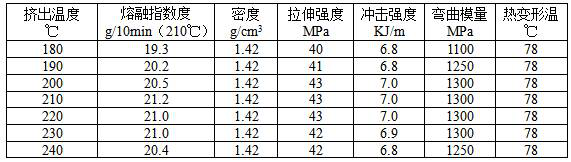

Examples

Embodiment 1

[0027] A modified PLA fully degradable plastic, which includes the following components in parts by weight: 27 parts of polybutylene succinate, 21.6 parts of polylactic acid, 6 parts of polyadipate / butylene terephthalate, 12.5 parts of talcum powder, 12 parts of porous ceramics, 32 parts of bamboo powder, and 0.9 parts of additives; the porous ceramics are mixed with silicon nitride powder and rare earth oxide according to the mass ratio of 100:4, after grinding, Obtained after drying and sintering, the rare earth oxide is lanthanum oxide;

[0028] The auxiliary agent includes the following components in parts by weight: 3 parts of epoxy compound, 2 parts of lubricant, 2 parts of plasticizer, 2 parts of antioxidant, 3 parts of heat stabilizer, 3 parts of antistatic agent; The oxygen compound is a combination of epoxy linseed oil and epoxy octyl stearate in equal volume; the plasticizer is glycerin; the lubricant is paraffin; the antioxidant is t-butyl hydroquinone and ethylene...

Embodiment 2

[0034] A modified PLA fully degradable plastic, which includes the following components in parts by weight: 25 parts of polybutylene succinate, 22.5 parts of polylactic acid, 8 parts of polyadipate / butylene terephthalate, 11.5 parts of talcum powder, 12 parts of porous ceramics, 35 parts of bamboo powder, and 1.5 parts of additives; the porous ceramics are mixed with silicon nitride powder and rare earth oxides according to the mass ratio of 100:3, after grinding, Obtained after drying and sintering, the rare earth oxide is lanthanum oxide;

[0035] The auxiliary agent includes the following components in parts by weight: 1 part of epoxy compound, 2 parts of lubricant, 1 part of plasticizer, 1 part of antioxidant, and 1 part of antistatic agent; the plasticizer is sorbitol; The lubricant is oxidized polyethylene wax; the epoxy compound is epoxy octyl stearate; the antioxidant is pentaerythritol diphosphite; and the antistatic agent is fatty acid ester.

[0036]The preparation...

Embodiment 3

[0041] A modified PLA fully degradable plastic, which includes the following components in parts by weight: 22 parts of polybutylene succinate, 20.5 parts of polylactic acid, 7 parts of polyadipate / butylene terephthalate, 13.5 parts of talcum powder, 13 parts of porous ceramics, 38 parts of bamboo powder, and 3 parts of auxiliary agents; the porous ceramics are mixed with silicon nitride powder and rare earth oxide according to the mass ratio of 100:3.5, after grinding, Obtained after drying and sintering, the rare earth oxide is lanthanum oxide;

[0042] The auxiliary agent includes the following components in parts by weight: 2 parts of epoxy compound, 1 part of lubricant, 3 parts of plasticizer, 3 parts of antioxidant, 2 parts of heat stabilizer, 2 parts of antistatic agent; The plasticizer is maltitol; the lubricant is polyethylene wax; the epoxy compound is epoxy linseed oil; the heat stabilizer is equal weight mixture of phosphite heat stabilizer and hindered phenol heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com