Drying device for processing trichosanthes kirilowii maxim seeds

A drying device and a technology for melon seeds, which are applied in the directions of drying gas arrangement, drying solid materials, drying chambers/containers, etc., can solve the problems of poor equipment versatility, poor drying effect of materials, and inability to meet the needs of use, and improve the applicability , Improve production efficiency, the effect of strong adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

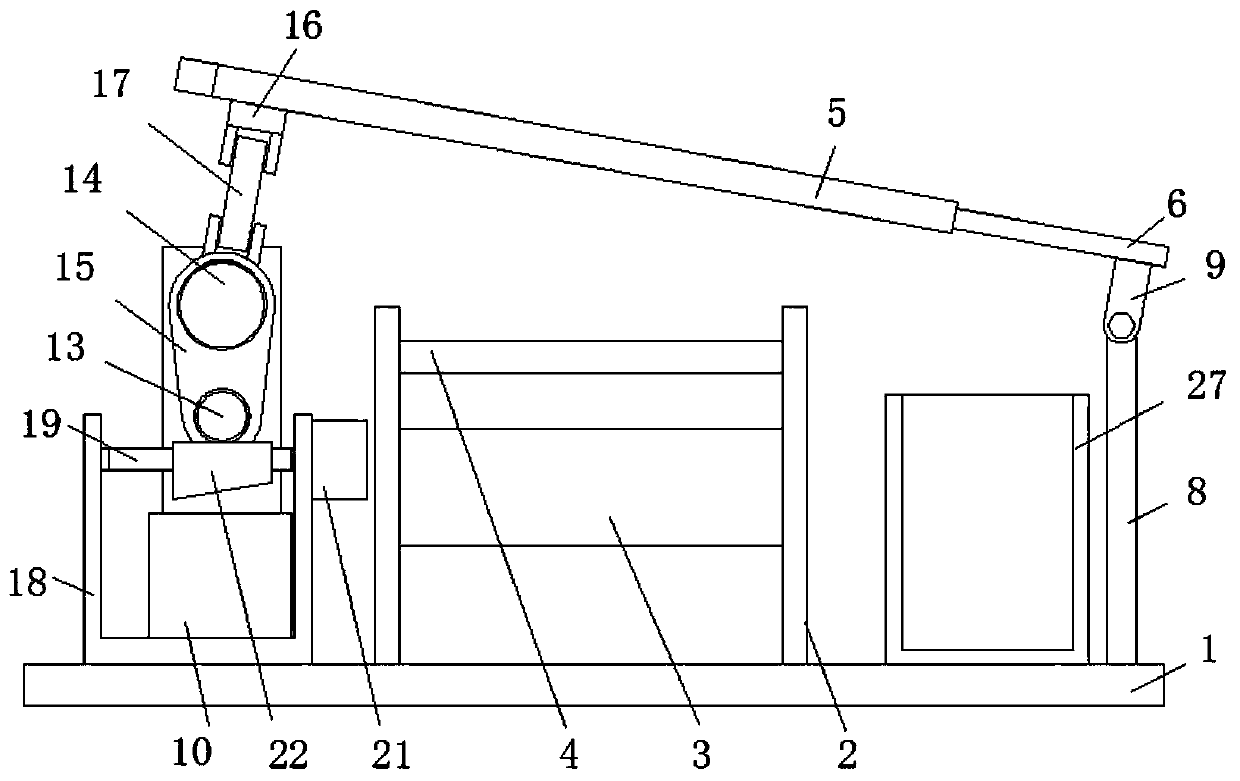

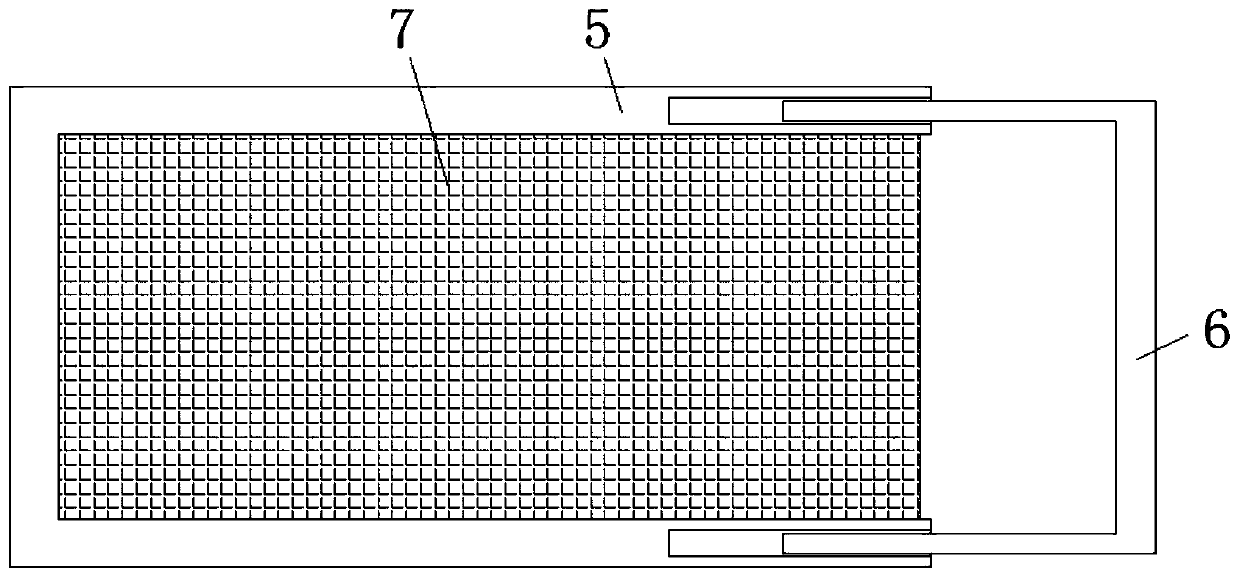

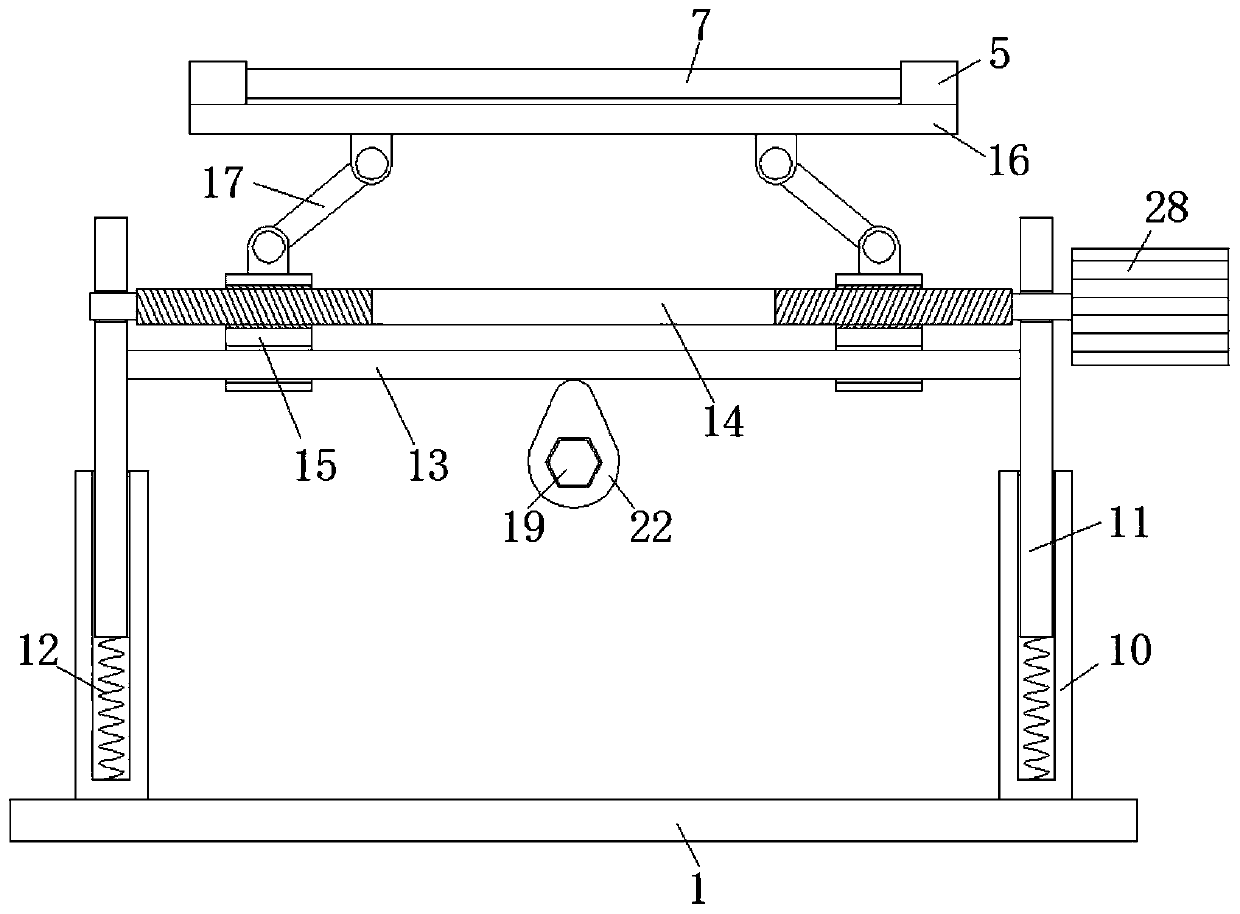

[0020] refer to Figure 1-4 , a drying device for processing Trichosanthes seeds, comprising a bottom plate 1, a mounting frame 2 is fixedly connected to the top side of the bottom plate 1, a blower 3 and a heating net 4 are installed in the mounting frame 2, and the air outlet of the blower 3 is vertically upward and located On the bottom side of the heating net 4, a U-shaped main frame 5 and a U-shaped sub-frame 6 are arranged on the vertical top of the mounting frame 2, and the U-shaped main frame 5 and the U-shaped sub-frame 6 are relatively arranged, and the two sides of the U-shaped main frame 5 The two ends of the U-shaped sub-frame 6 are provided with chute respectively, and the two ends of the U-shaped sub-frame 6 are slidably connected in the chute respectively. The inner side of the U-shaped main frame 5 is provided with a ventilation net 7, and the U-shaped main frame 5 and the U-shaped sub-frame 6 are all inclined. , and the U-shaped main frame 5 and the U-shaped ...

Embodiment 2

[0023] refer to Figure 1-4 , a drying device for processing Trichosanthes seeds, which is basically the same as Embodiment 1, and more optimally, one end of threaded rod 14 is coaxially fixedly connected with knob 2 28, and the setting of knob 2 28 is convenient for people to rotate threaded rod 1 14, thereby completing the inclination angle of the ventilation net 7, the two sliding bases 10 are respectively located on both sides of the U-shaped frame 18, so that the legs 9 and the stressed track rod 13 can be arranged perpendicular to each other, and the rod body of the polygonal transmission rod 19 and the horizontal polygon Sliding contact connection on the inner wall of the through hole. Through the polygonal structure, the cam barrel 22 can slide on the outside of the polygonal transmission rod 19, while adjusting the position, it can rotate together with the polygonal transmission rod 19. The support plate 8 and the sliding base 10 are respectively located on both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com