Color-transfer-resistant vulcanized shoe and production process thereof

A production process, technology of vulcanized shoes, applied in the field of vulcanized shoes, can solve problems such as unsightly appearance, affecting quality and economic benefits, forming defects, etc., to achieve the effect of eliminating color migration, avoiding outward migration, and saving fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

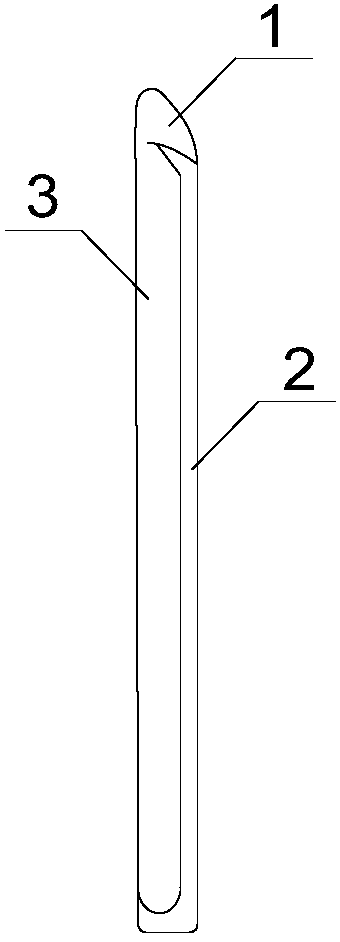

Image

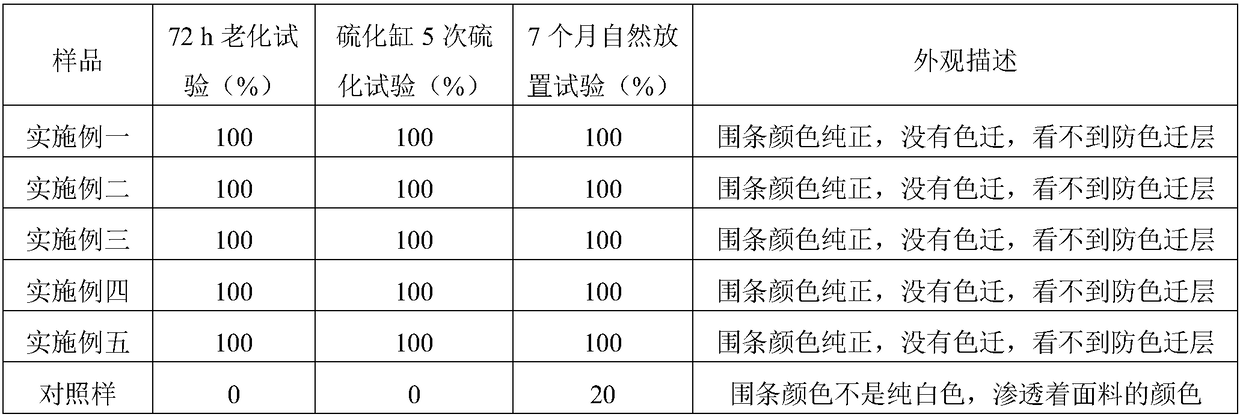

Examples

Embodiment 1

[0033] A kind of production technique of the vulcanized shoes of anti-color migration of the present invention, comprises the following steps:

[0034] 1) Use black gold velvet fabric to make the shoe upper, sew non-colored pasting cloth on the bottom of the shoe upper, the non-colored pasting cloth is Lixin cloth, apply 101 glue on the outside of the pasting cloth, and dry it;

[0035] 2) Add midsole and upper side on the inner side of the laminated cloth, paste the inner rubber strip on the outer side of the laminated cloth, and put on the outsole. The inner rubber strip is made of anti-color migration material. The anti-color migration material includes The following raw materials in parts by weight: 100 parts of rubber, 50 parts of white carbon black, 60 parts of red rheostat, 13 parts of toughening agent, 10 parts of activator, 2 parts of accelerator;

[0036] 3) apply a treatment agent on the outside of the inner rubber strip, dry, apply 101 glue, and dry. The treatment ...

Embodiment 2

[0040] A kind of production technique of the vulcanized shoes of anti-color migration of the present invention, comprises the following steps:

[0041] 1) Use gray suede fabric to make the upper, and sew a non-colored laminated fabric on the bottom of the upper. The laminated fabric is 2X2 gray fabric, and glue is applied to the outside of the laminated fabric, and dried at 100°C for 5 minutes ;

[0042] 2) Add midsole and upper side on the inner side of the laminated cloth, paste the inner rubber strip on the outer side of the laminated cloth, and put on the outsole. The inner rubber strip is made of anti-color migration material. The anti-color migration material includes Raw materials in the following parts by weight: 100 parts of rubber, 60 parts of filler, 55 parts of red varistor, 14 parts of toughening agent, 8 parts of active agent, and 3 parts of accelerator. After mixing the above raw materials, banburying, calendering, and molding , and get;

[0043] 3) Apply trea...

Embodiment 3

[0047] A kind of production technique of the vulcanized shoes of anti-color migration of the present invention, comprises the following steps:

[0048] 1) Use blue polyester fabric to make the shoe upper, and sew a non-colored laminated fabric on the bottom of the shoe upper. The laminated fabric is 2X2 gray fabric, and glue is applied to the outside of the laminated fabric, and dried at 80°C for 7 minutes ;

[0049] 2) Add midsole and upper side on the inner side of the laminated cloth, paste the inner rubber strip on the outer side of the laminated cloth, and put on the outsole. The inner rubber strip is made of anti-color migration material. The anti-color migration material includes The following raw materials in parts by weight: 100 parts of rubber, 55 parts of white carbon black, 50 parts of red varistor, 15 parts of toughening agent, 7 parts of active zinc oxide, 2.5 parts of accelerator, after mixing the above raw materials, banburying, compacting The mixing temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com