Patents

Literature

285results about How to "Poor adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

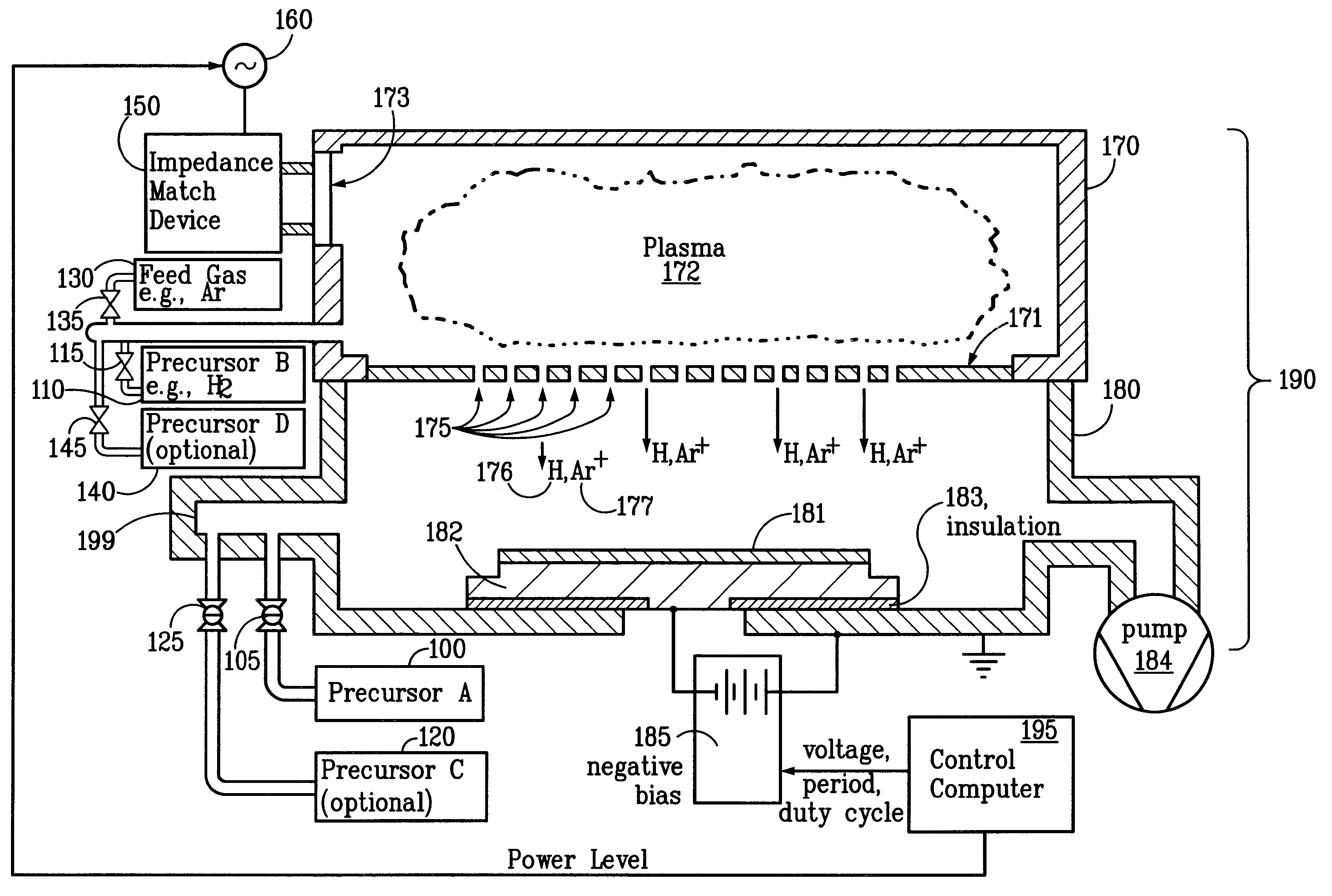

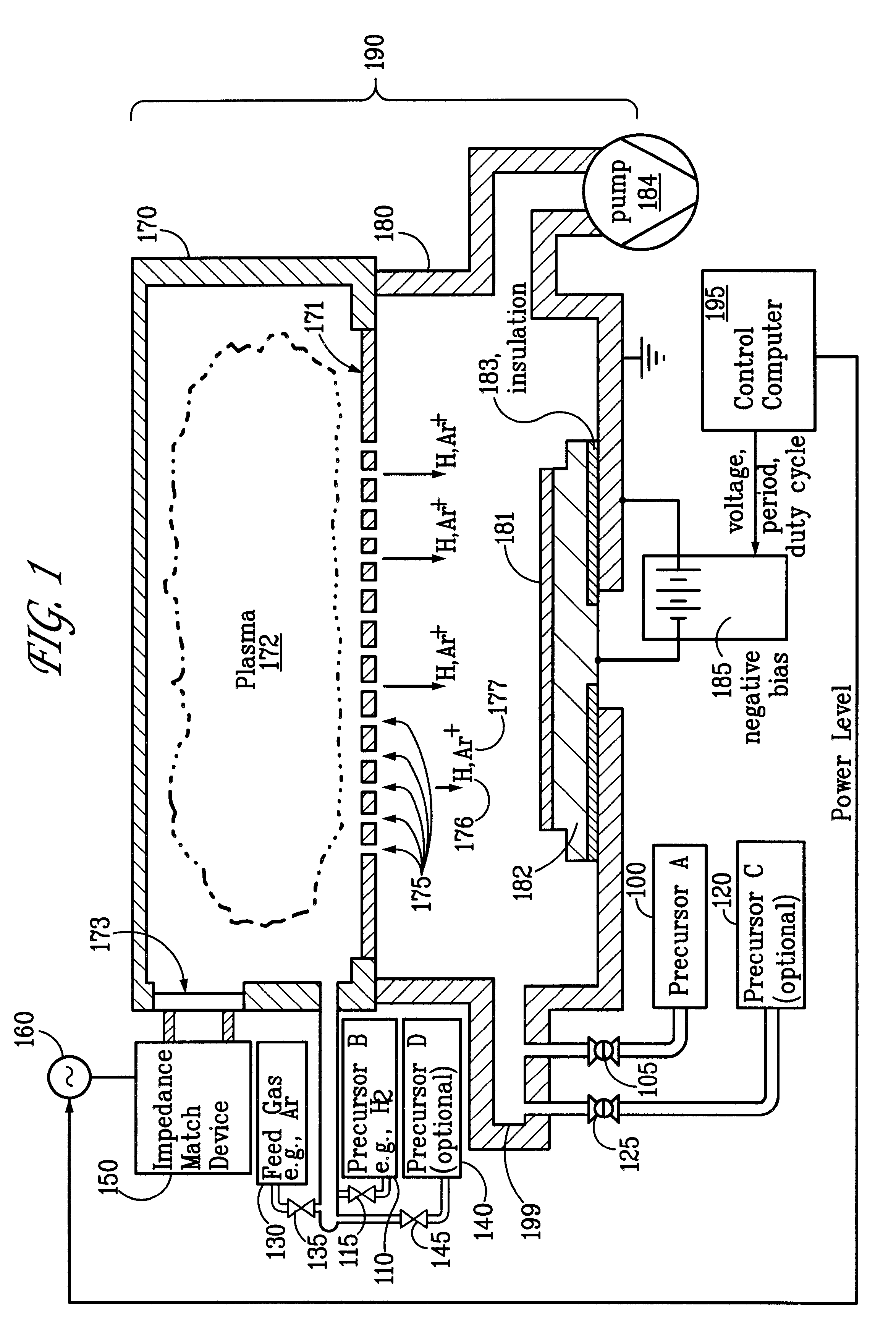

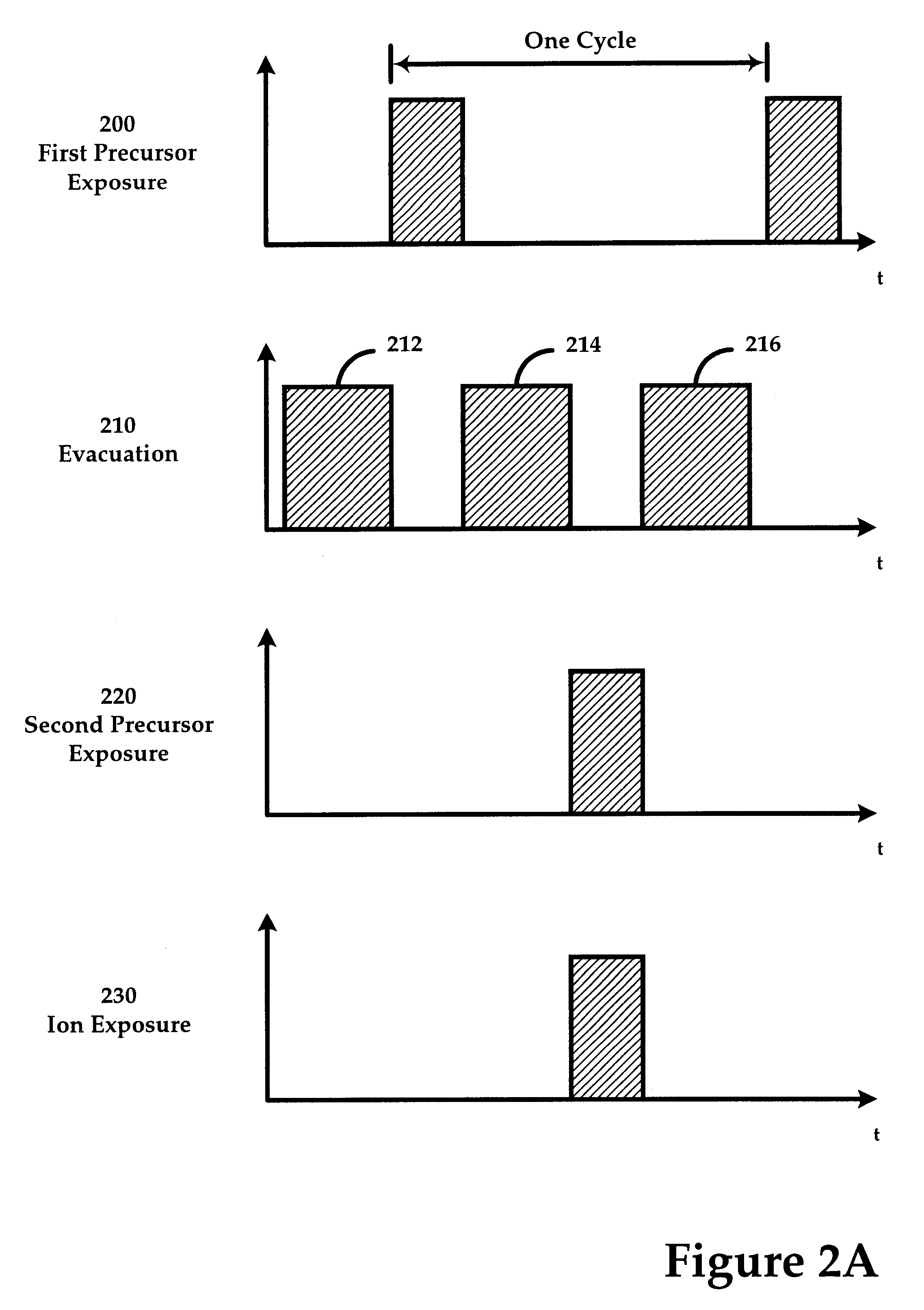

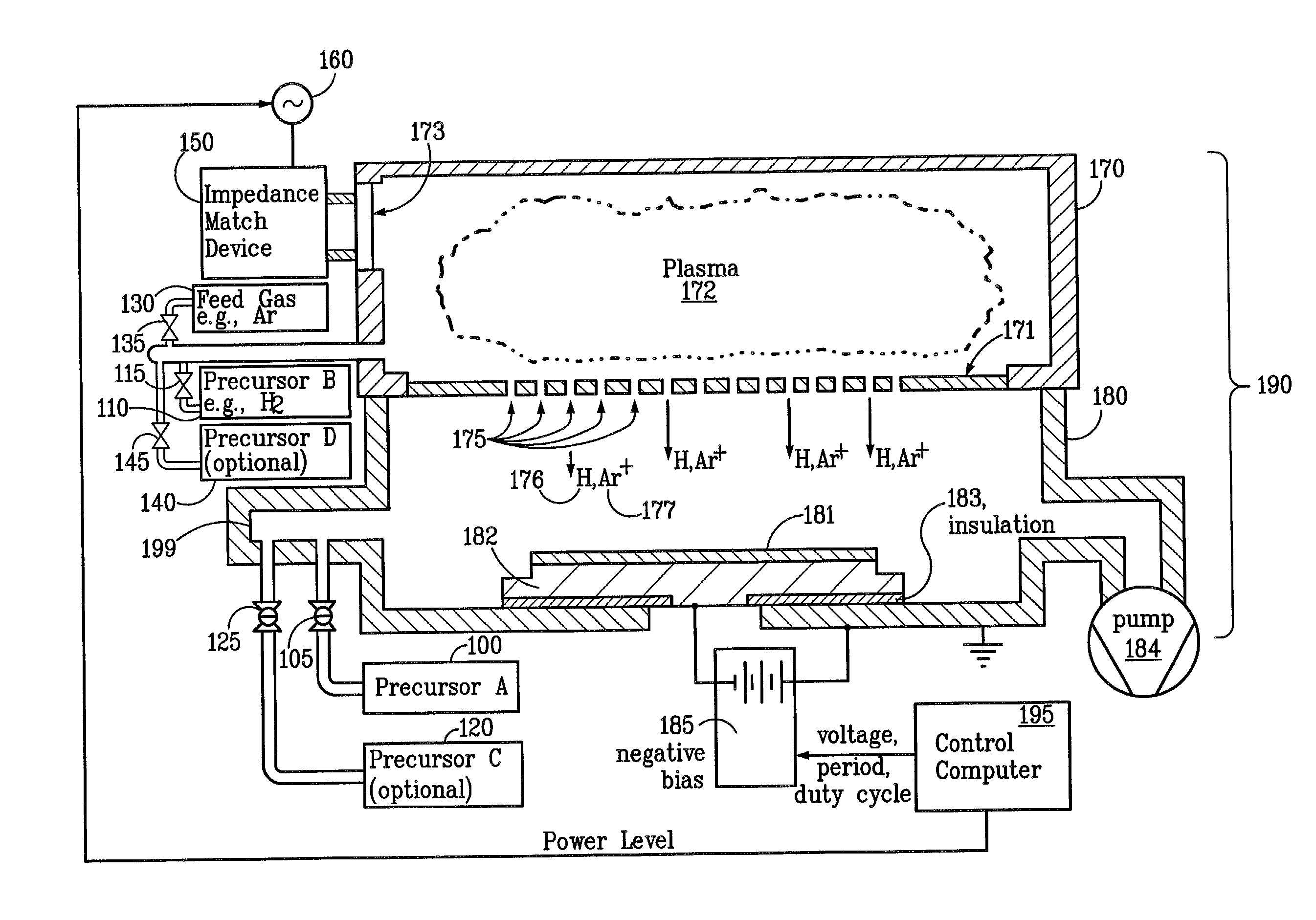

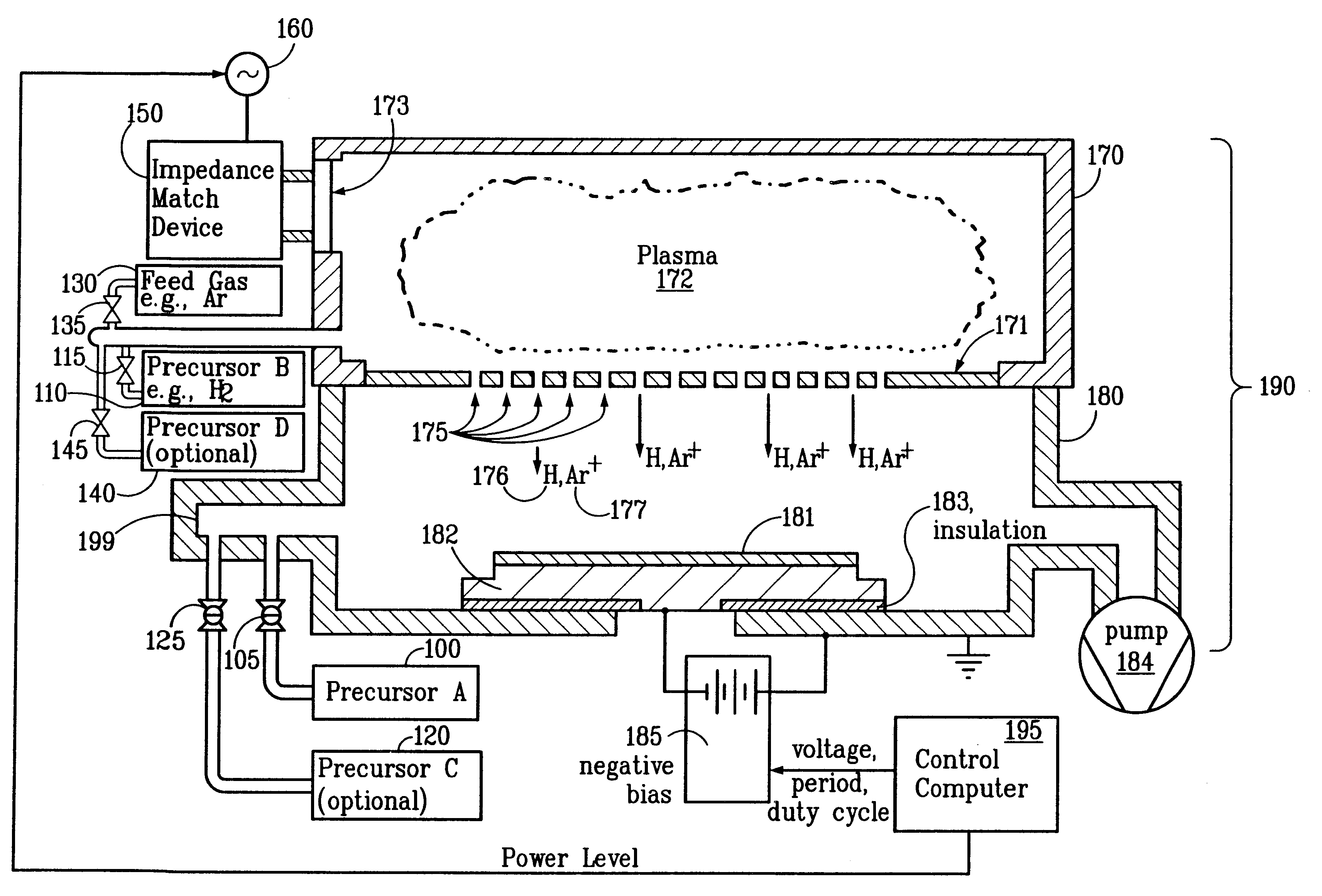

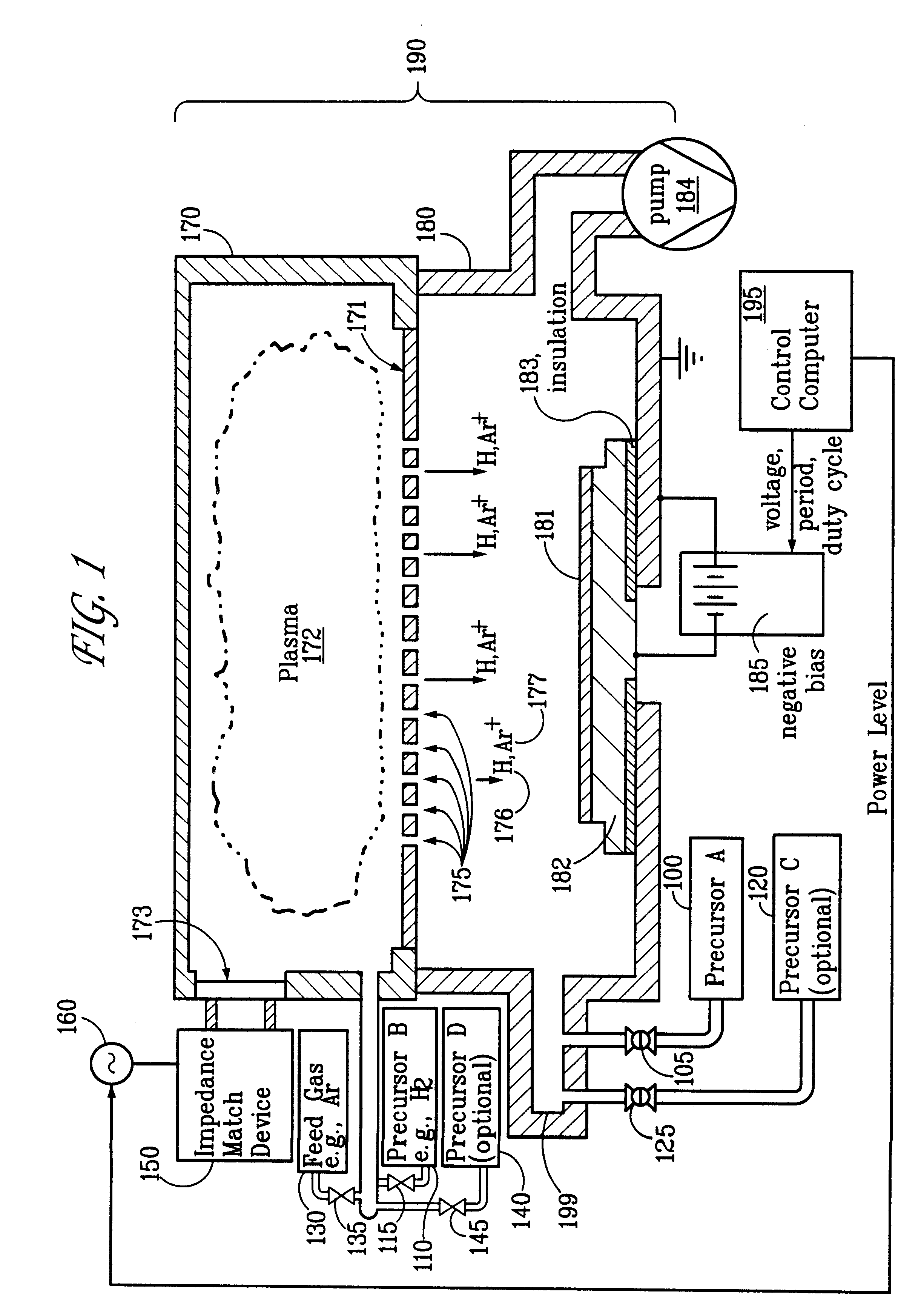

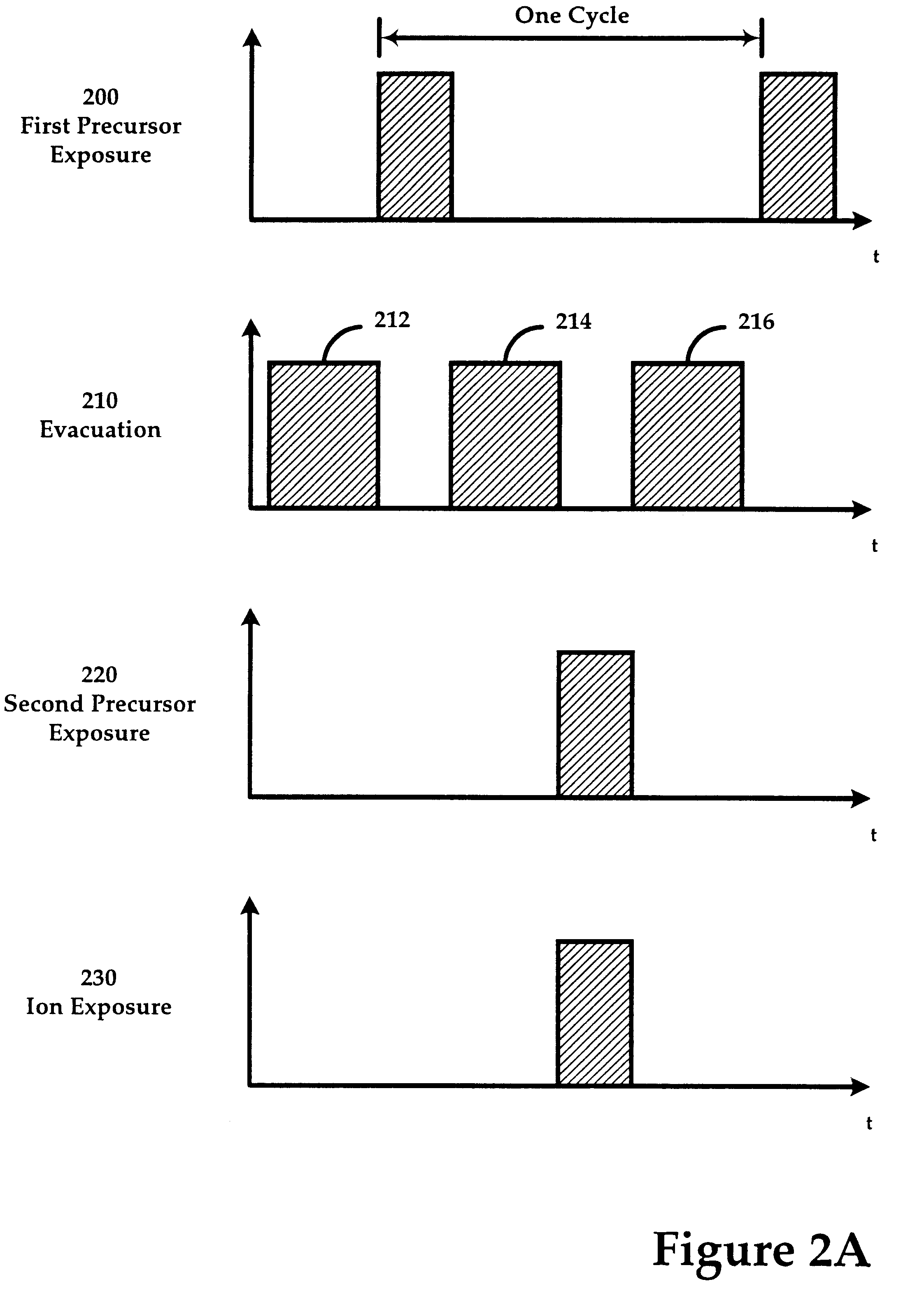

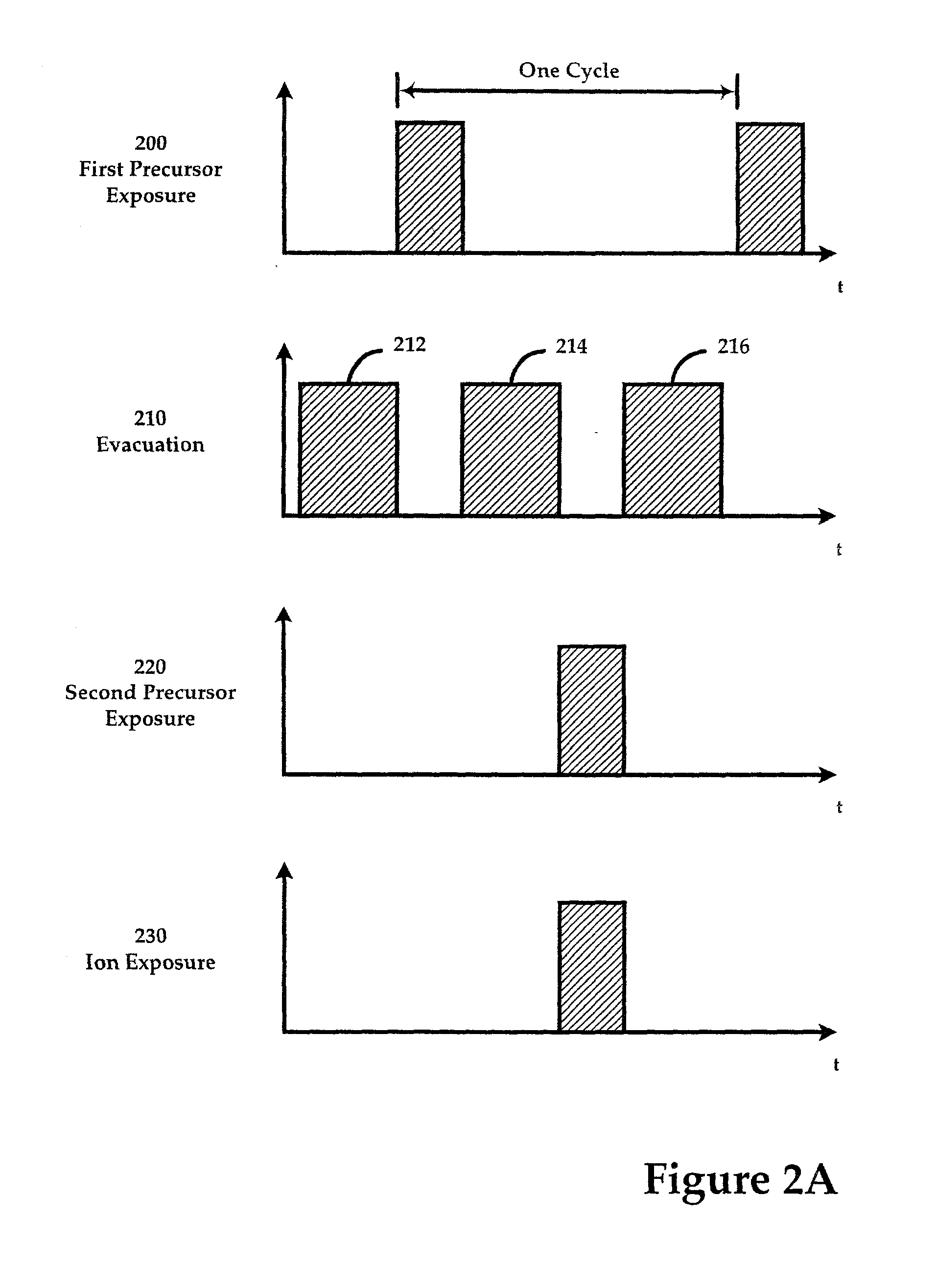

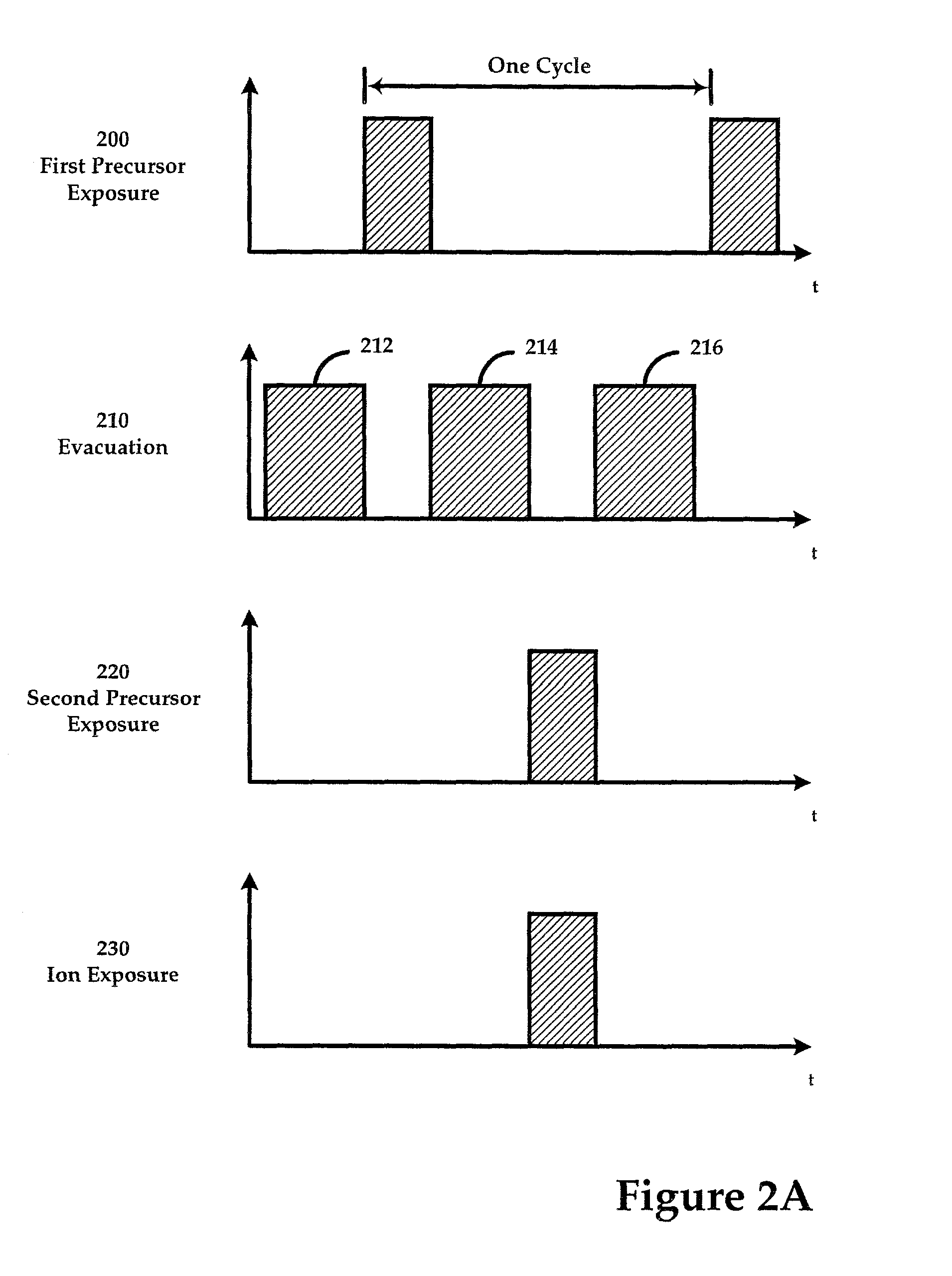

Sequential method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS6428859B1Faster efficient meanSimple methodVacuum evaporation coatingSputtering coatingSequential methodHigh density

The present invention relates to an enhanced sequential atomic layer deposition (ALD) technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; and, 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:NOVELLUS SYSTEMS

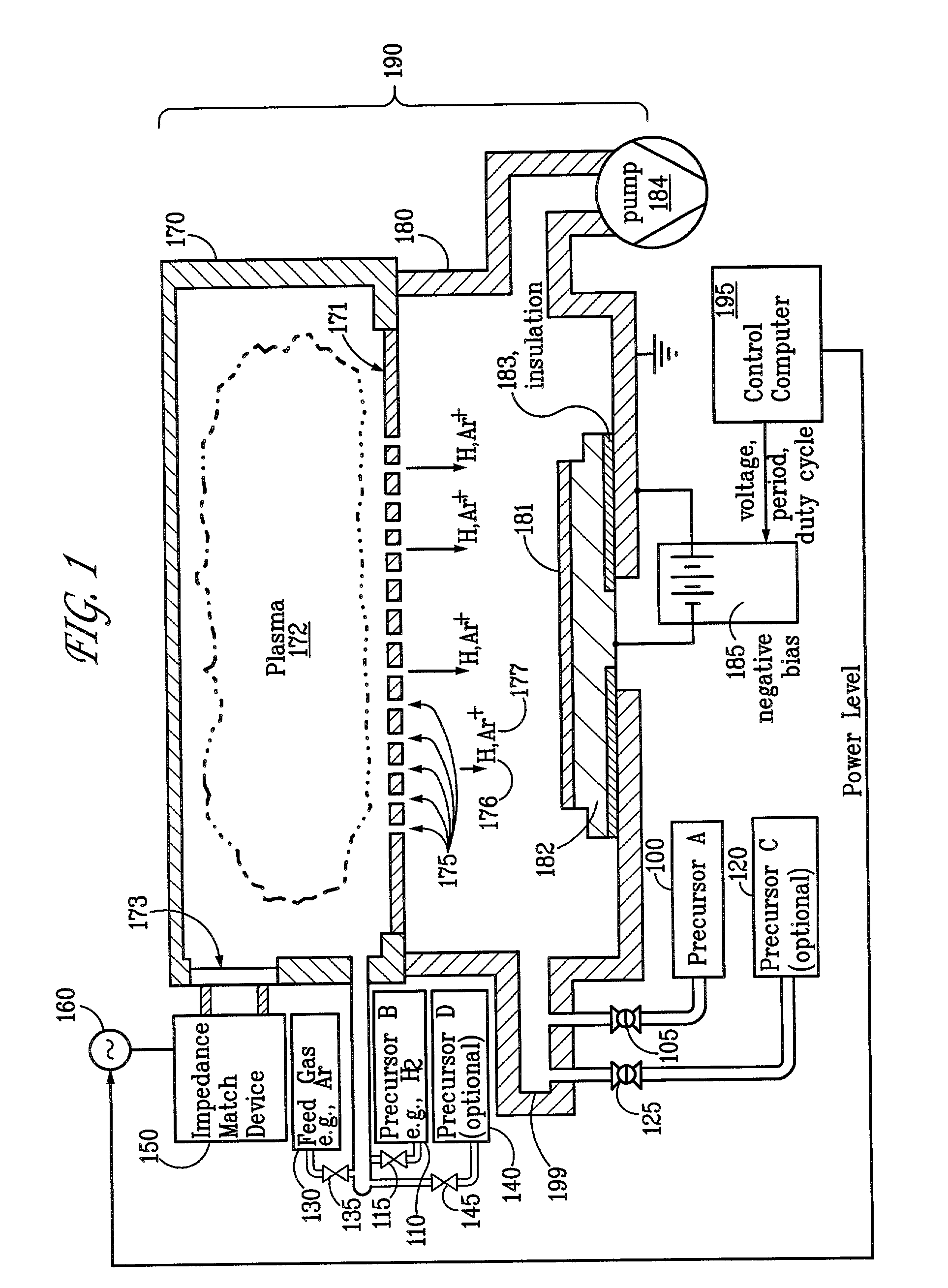

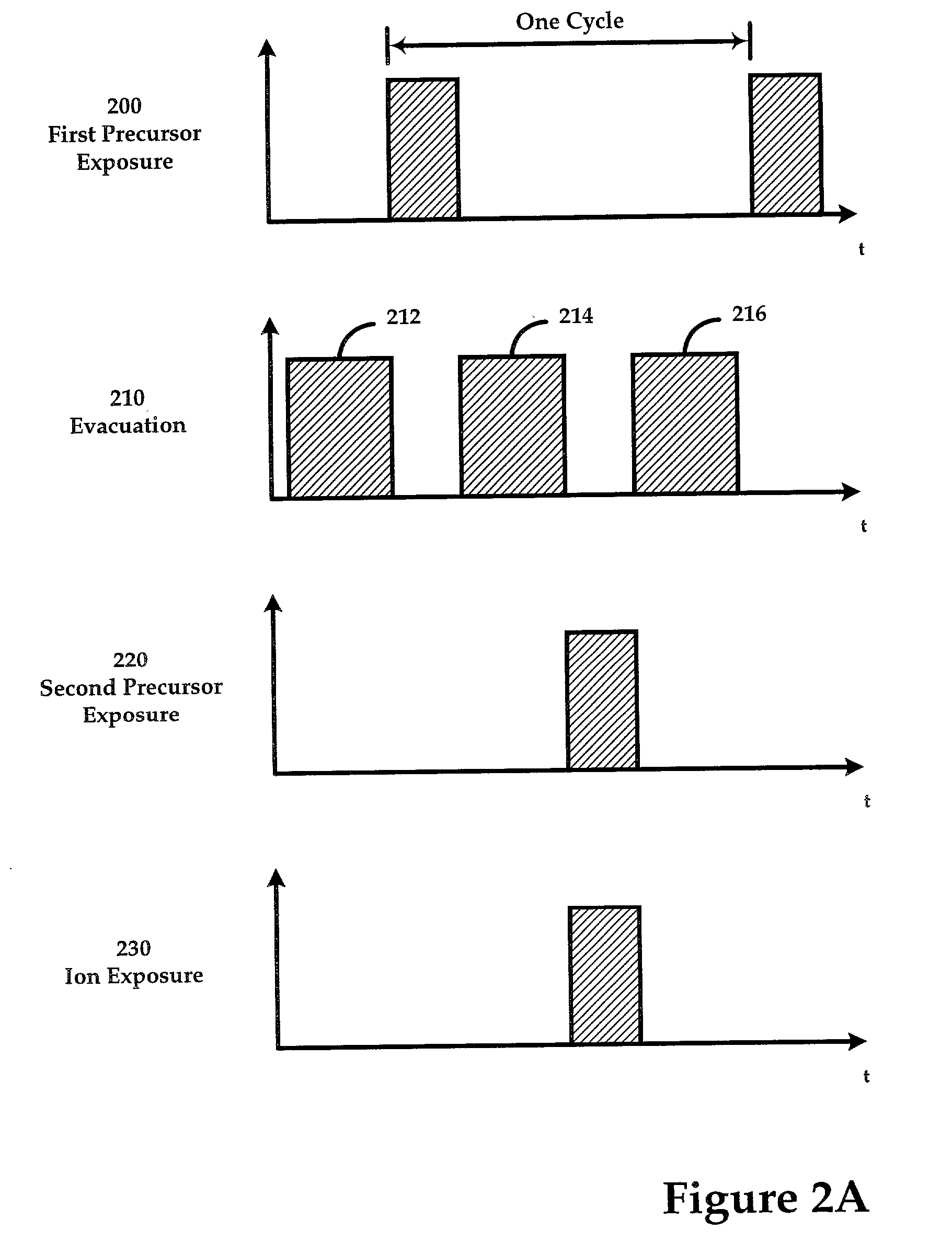

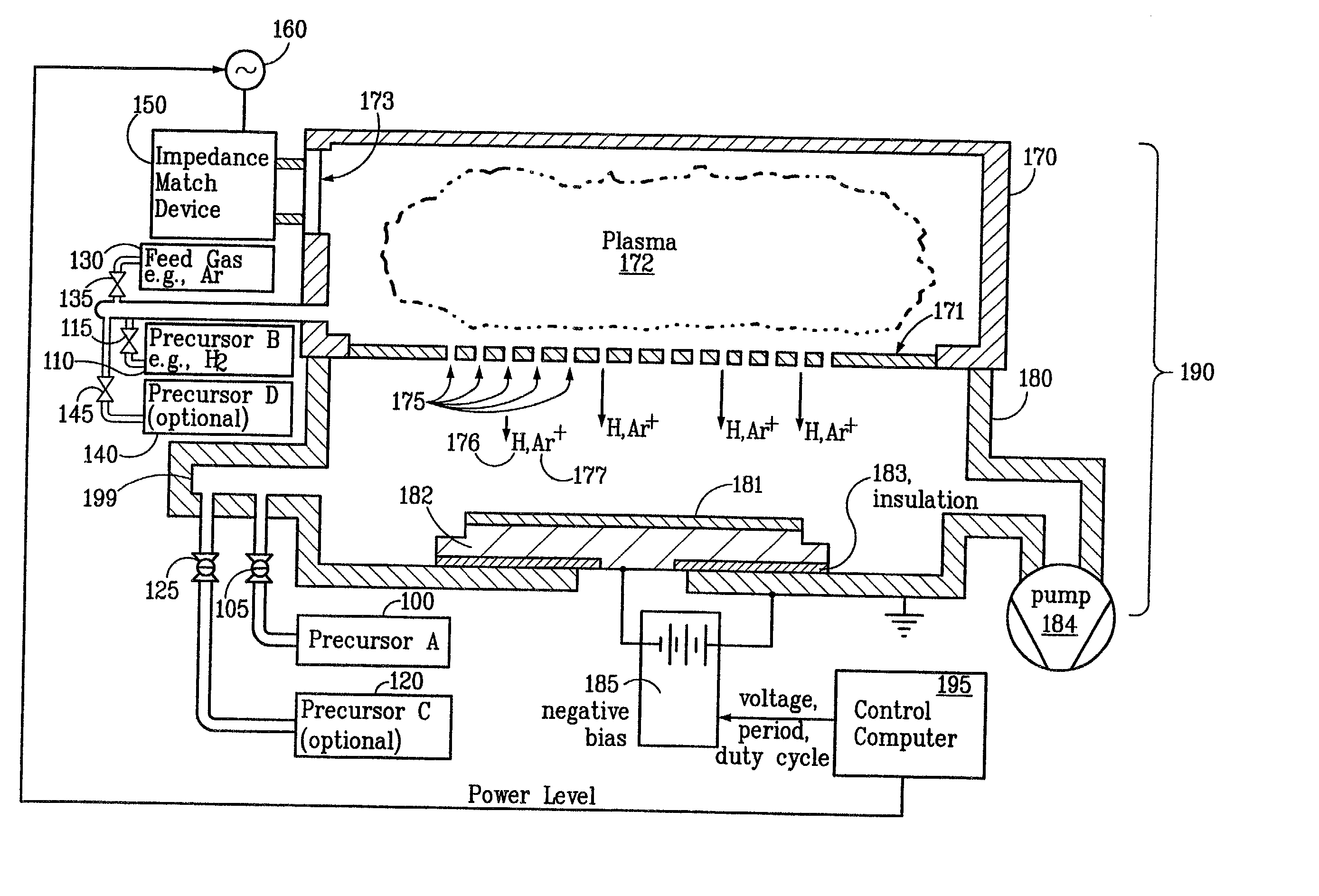

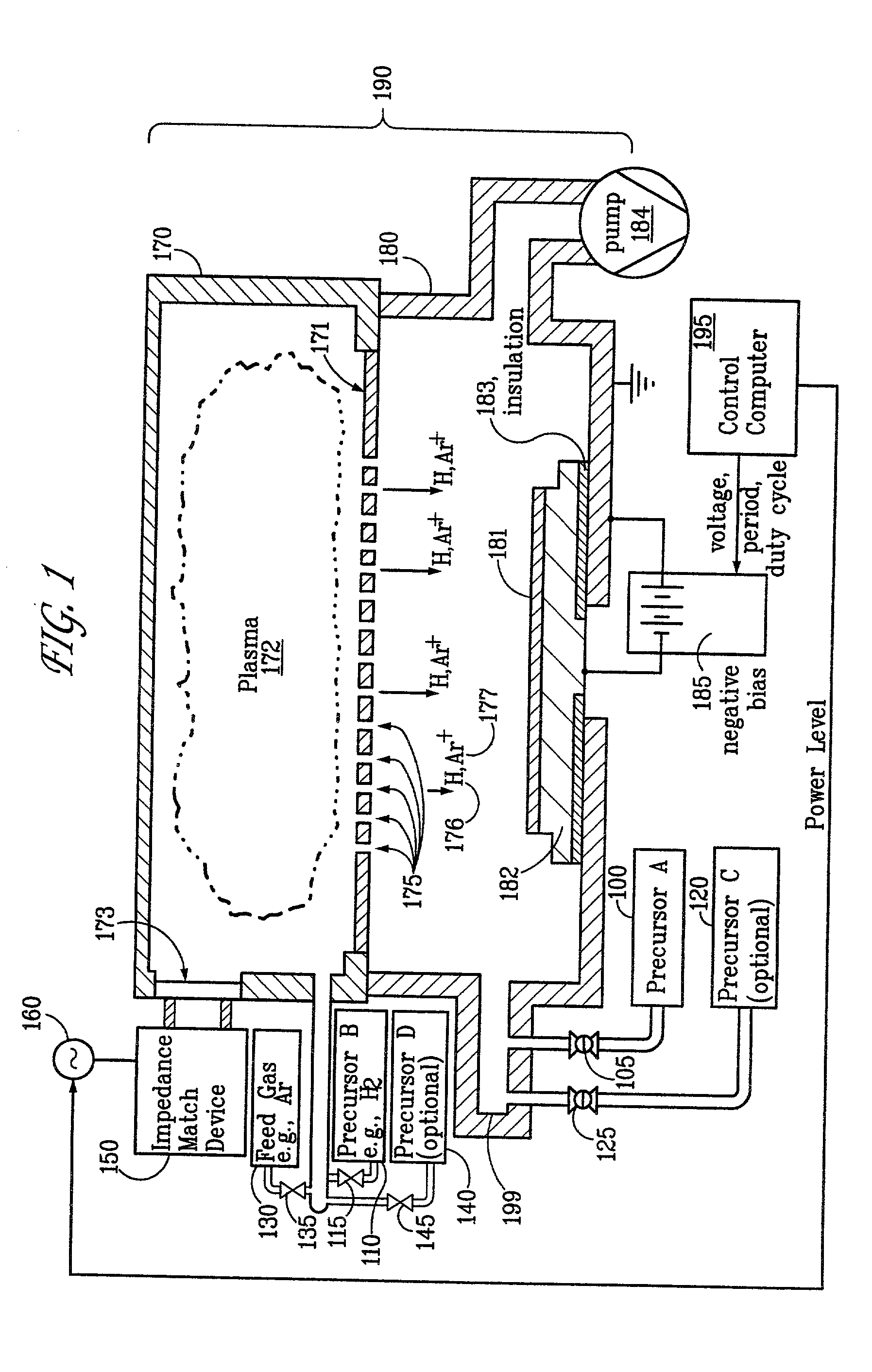

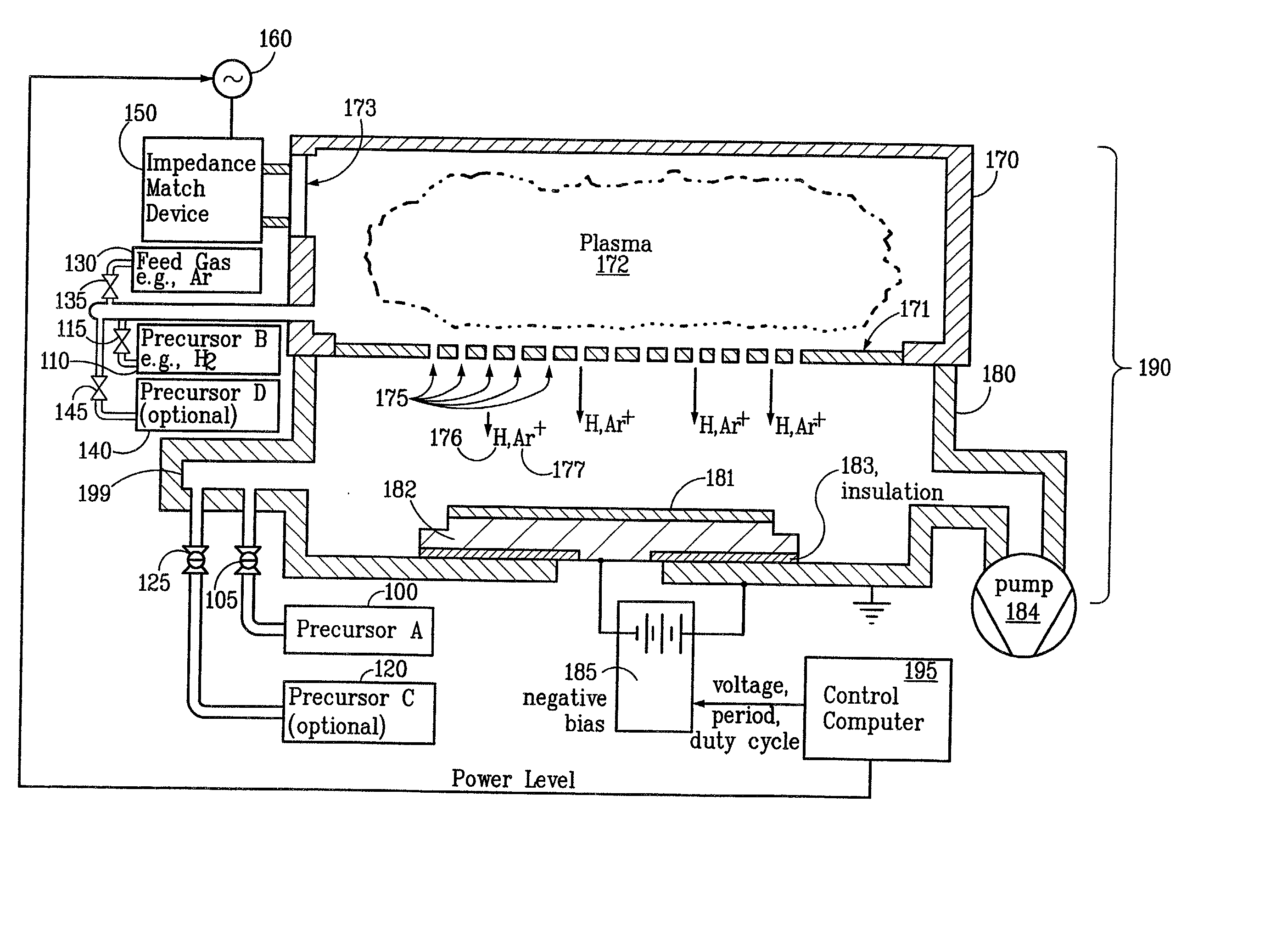

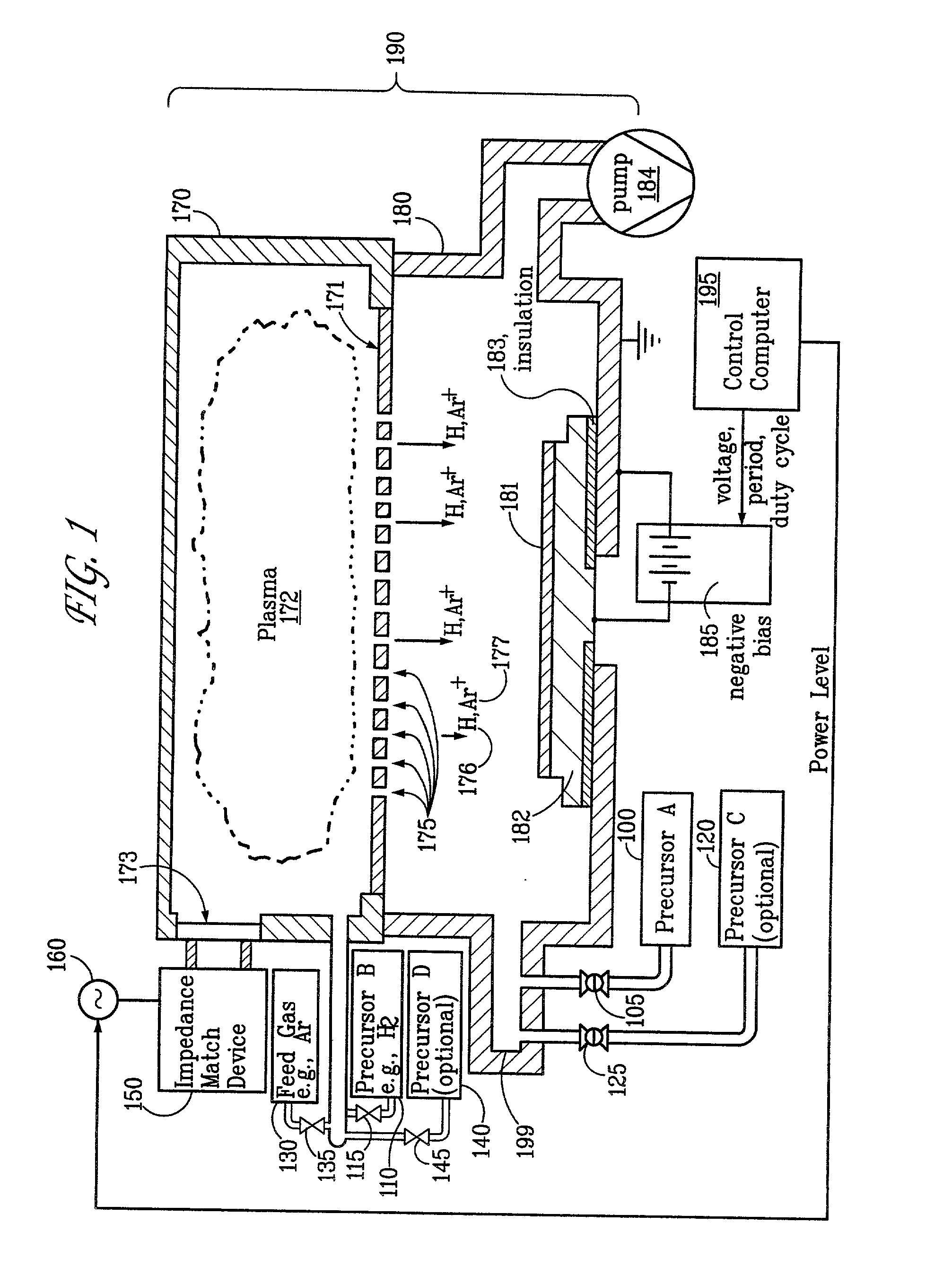

System and method for modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS20020104481A1Faster efficient meanSimple methodSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh densitySubject matter

The present invention relates to an enhanced sequential or non-sequential atomic layer deposition (ALD) apparatus and technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method; and, 4) providing a means of improved radical generation and delivery. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. [37 C.F.R. § 1.72(b)].

Owner:ANGSTRON SYST

Continuous method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS6416822B1Faster efficient meanSimple methodPretreated surfacesSemiconductor/solid-state device manufacturingHigh densityVolumetric Mass Density

The present invention relates to an enhanced non-sequential atomic layer deposition (ALD) technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; and, 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method.

Owner:NOVELLUS SYSTEMS

Continuous method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS20020164423A1Faster efficient meanSimple methodPretreated surfacesSolid state diffusion coatingHigh densityOptoelectronics

The present invention relates to an enhanced sequential atomic layer deposition (ALD) technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; and, 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method.

Owner:NOVELLUS SYSTEMS

Process for producing flexible optical waveguide

InactiveUS7120345B2Peeling can be safelyReduce adhesionCoupling light guidesOptical waveguide light guideFoaming agentWaveguide

Owner:NITTO DENKO CORP

Sequential method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS20020164421A1Faster efficient meanSimple methodVacuum evaporation coatingSemiconductor/solid-state device manufacturingSequential methodHigh density

Owner:NOVELLUS SYSTEMS

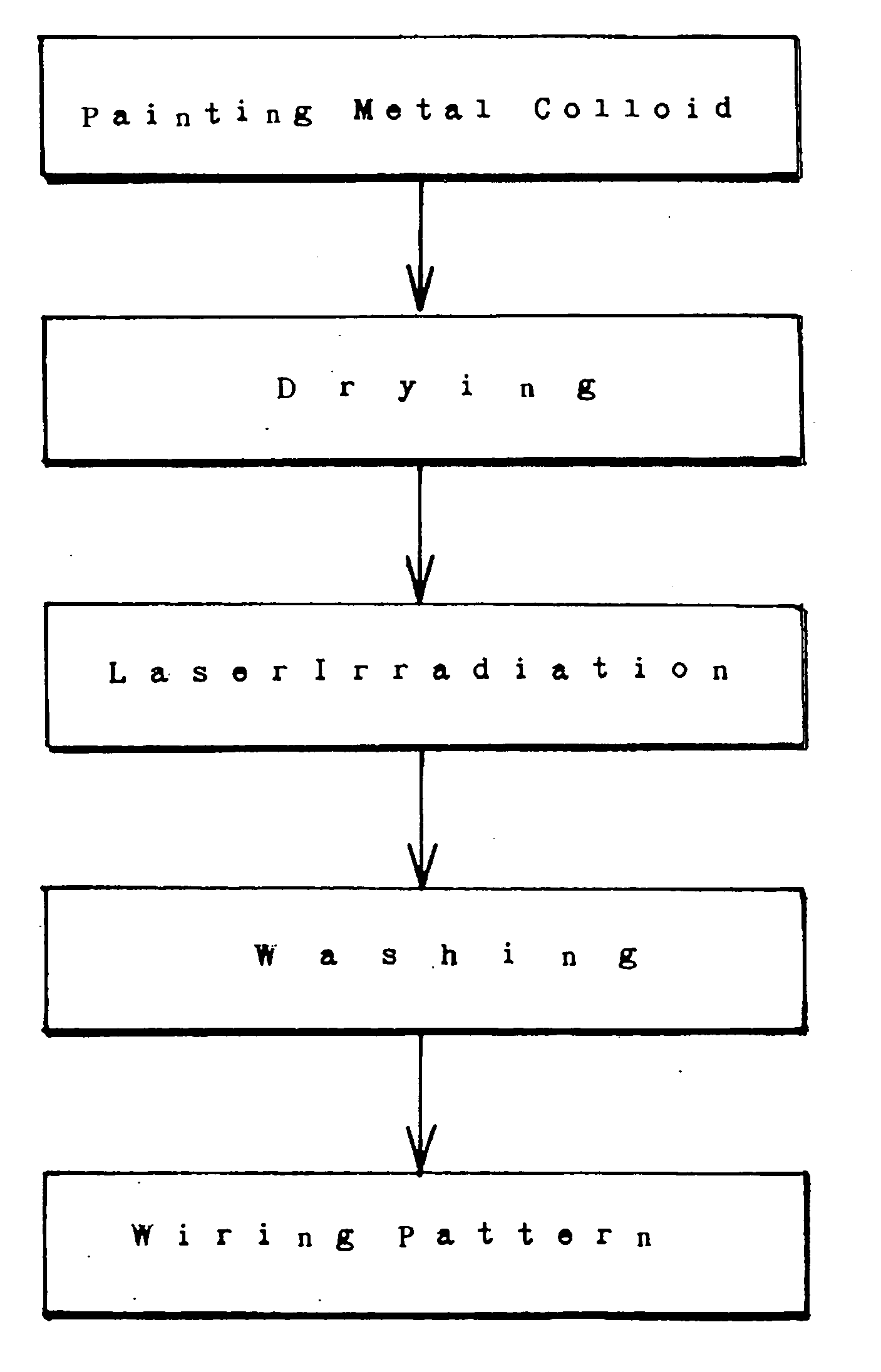

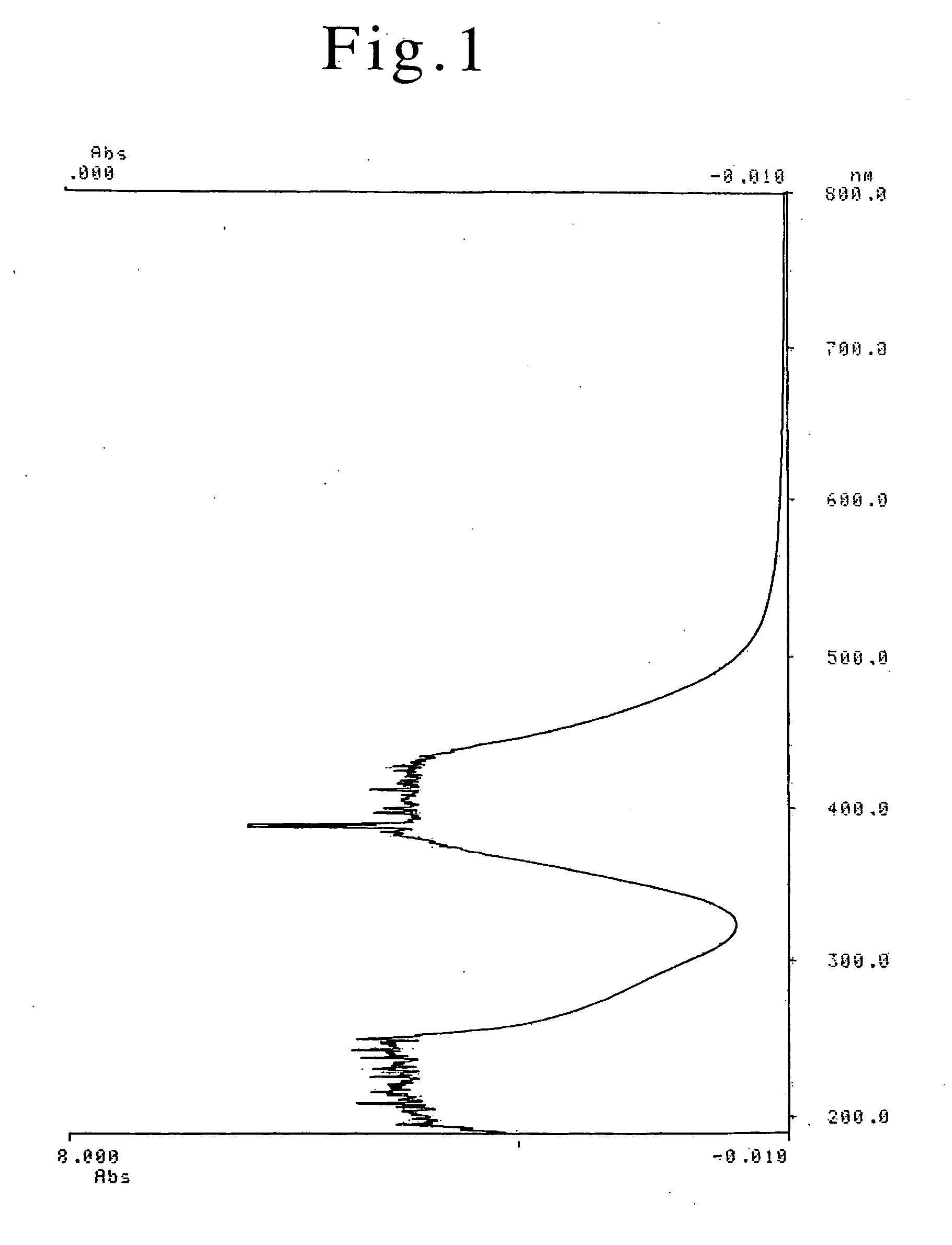

Method of forming a conductive wiring pattern by laser irradiation and a conductive wiring pattern

InactiveUS20060057502A1Poor adhesionEasily eliminateMaterial nanotechnologyPhotomechanical apparatusResistCompound (substance)

Fine wirings are made by a method having the steps of painting a board with metal dispersion colloid including metal nanoparticles of 0.5 nm-200 nm diameters, drying the metal dispersion colloid into a metal-suspension film, irradiating the metal-suspension film with a laser beam of 300 nm-550 nm wavelengths, depicting arbitrary patterns on the film with the laser beam, aggregating metal nanoparticles into larger conductive grains, washing the laser-irradiated film, eliminating unirradiated metal nanoparticles, and forming metallic wiring patterns built by the conductive grains on the board. The present invention enables an inexpensive apparatus to form fine arbitrary wiring patterns on boards without expensive photomasks, resists, exposure apparatus and etching apparatus. The method can make wirings also on plastic boards or low-melting-point glass boards which have poor resistance against heat and chemicals.

Owner:SUMITOMO ELECTRIC IND LTD

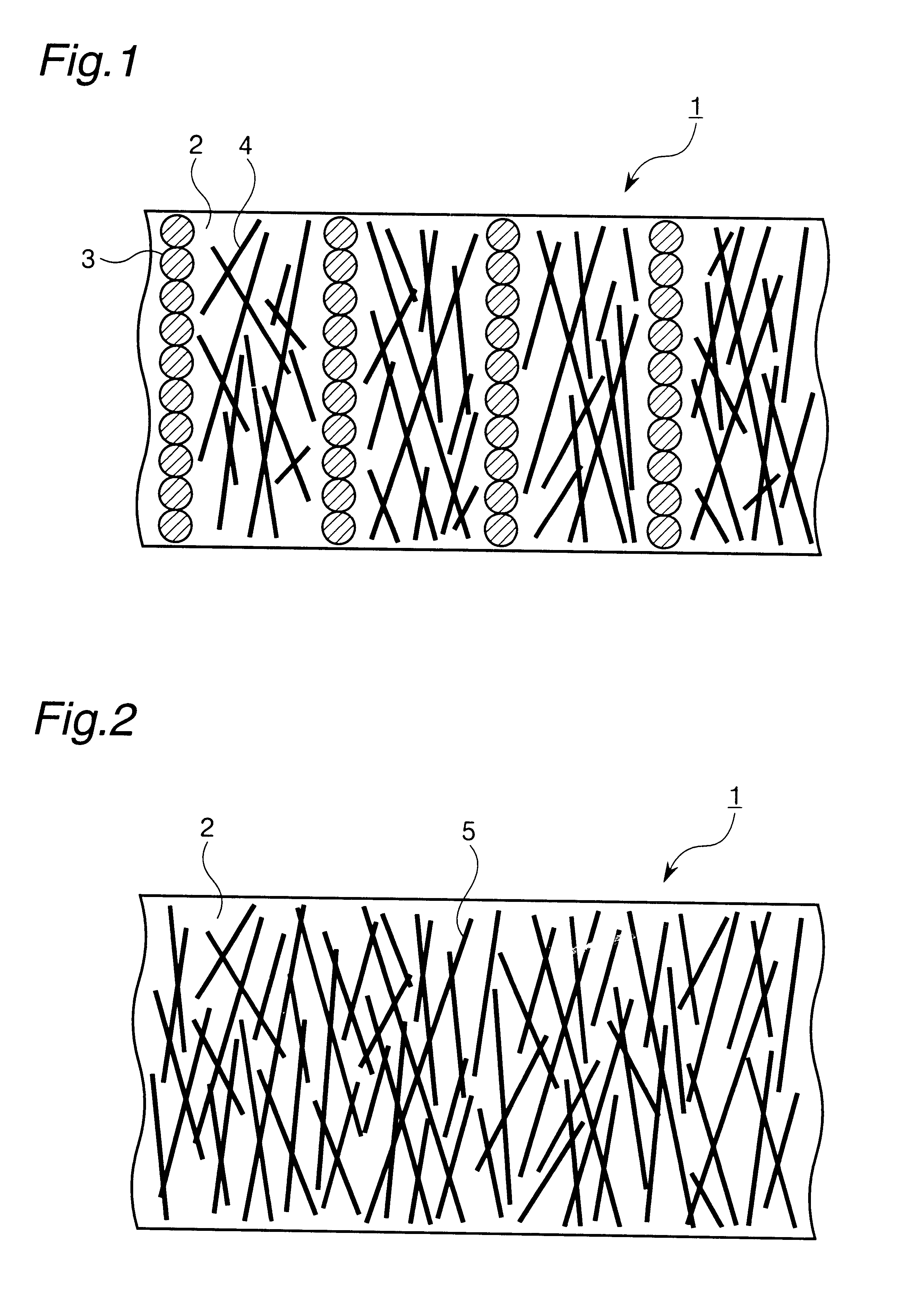

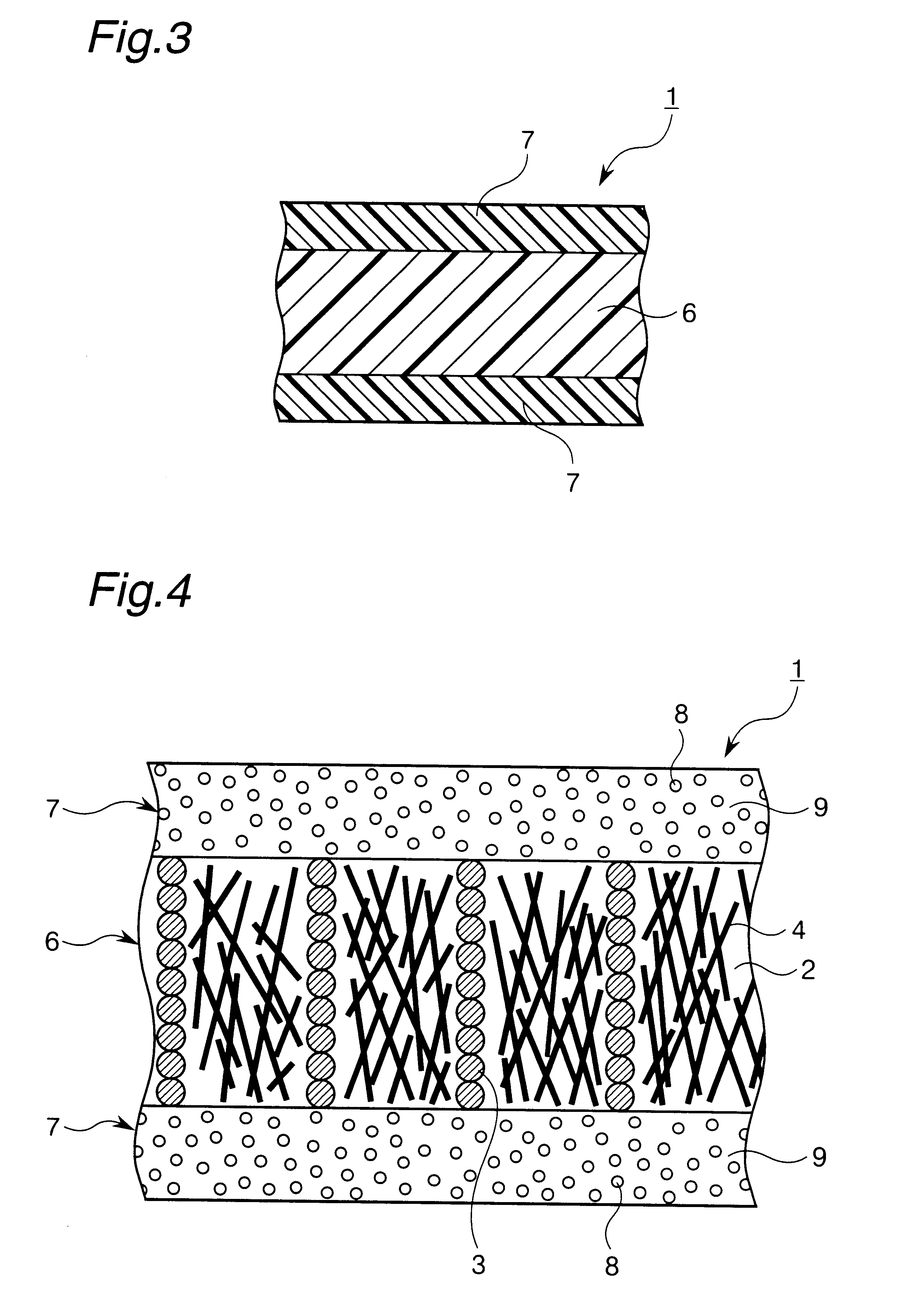

Curing composition for forming a heat-conductive sheet, heat-conductive sheet, production thereof and heat sink structure

InactiveUS6517744B1High heat conductivityImprove adhesionNon-metal conductorsConductive materialFiberCarbon fibers

A heat-conductive sheet comprising a cured or semi-cured binder wherein a carbon fiber is orientated in the direction of the thickness of the heat-conductive sheet. This heat-conductive sheet exhibits a high anisotropic heat conductivity along the direction of the thickness thereof to thereby enable efficiently releasing heat from a heating element such as a semiconductor element or semiconductor package. Moreover, the heat-conductive sheet is excellent in not only heat resistance, durability and mechanical strength but also adherence to the heating element.

Owner:JSR CORPORATIOON

Golf ball cover stocks and golf balls

Owner:BRIDGESTONE SPORTS

High strength hot dip galvanized steel sheet and high strength galvannealed steel sheet excellent in shapeability and plateability and methods of production and apparatuses for production of the same

ActiveUS20100304183A1Excellent in shapeability and plateabilityHigh strengthHot-dipping/immersion processesPretreated surfacesOxideHigh intensity

Hot dip galvanized steel sheet excellent in shapeability and plateability comprised of high strength steel sheet according to the present invention can be provided containing, by mass % about, C: 0.05 to 0.25%, Si: 0.3 to 2.5%, Mn: 1.5 to 2.8%, P: 0.03% or less, S: 0.02% or less, Al: 0.005 to 0.5%, N: 0.0060% or less and the balance of Fe and unavoidable impurities. The exemplary steel sheet can have thereon a galvanized layer containing, e.g., about Al: 0.05 to 10 mass % and Fe: 0.05 to 3 mass % and the balance of Zn and unavoidable impurities. Such exemplary hot dip galvanized steel sheet can have oxides containing Si in an average content of about 0.6 to 10 mass % at the crystal grain boundaries and in the crystal grains at the sheet steel side 5 μm or less from the interface between the high strength steel sheet and the plating layer and by the presence of Fe—Zn alloy with an average grain size of about 0.5 to 3 μm at the plating side.

Owner:NIPPON STEEL CORP

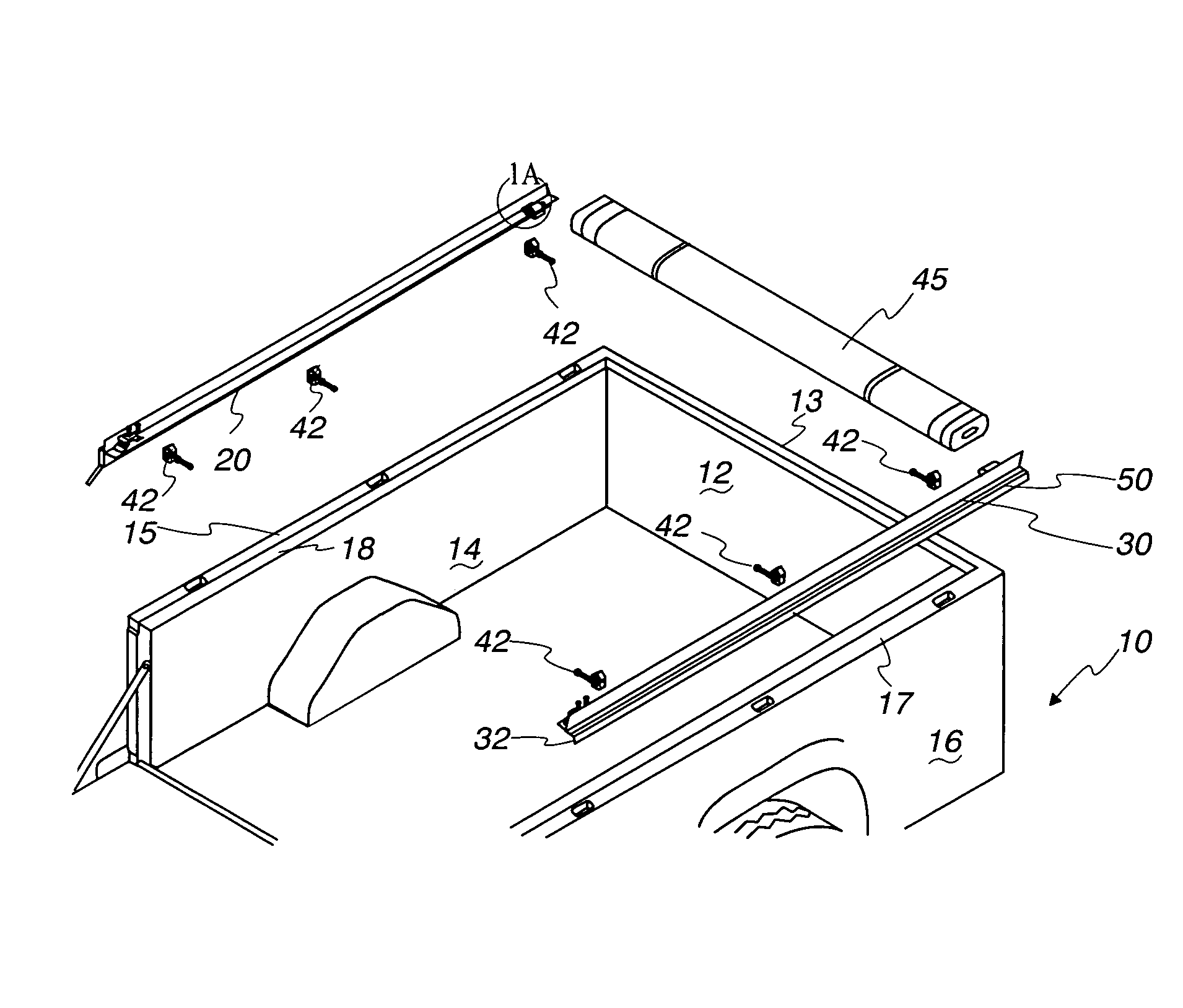

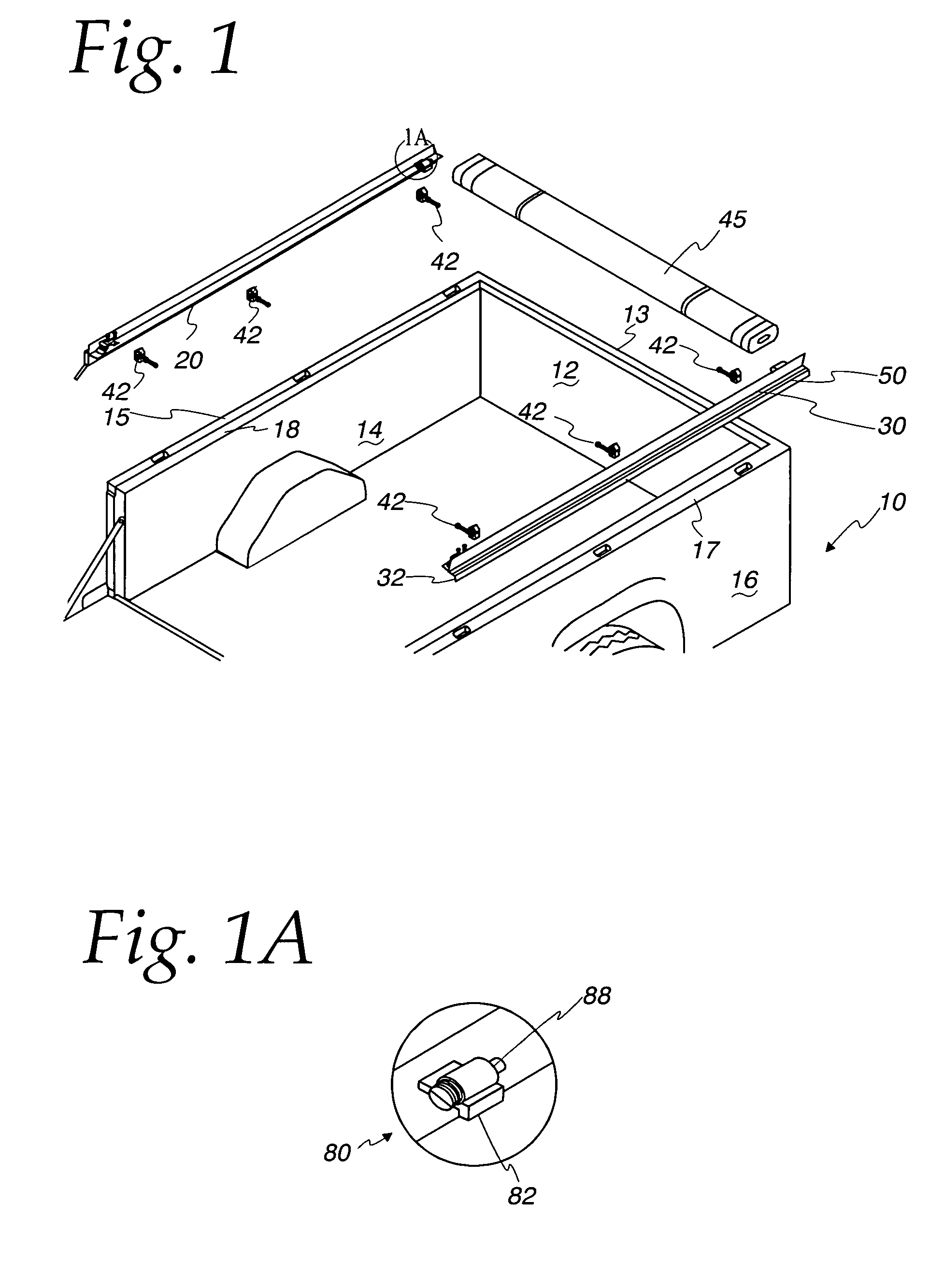

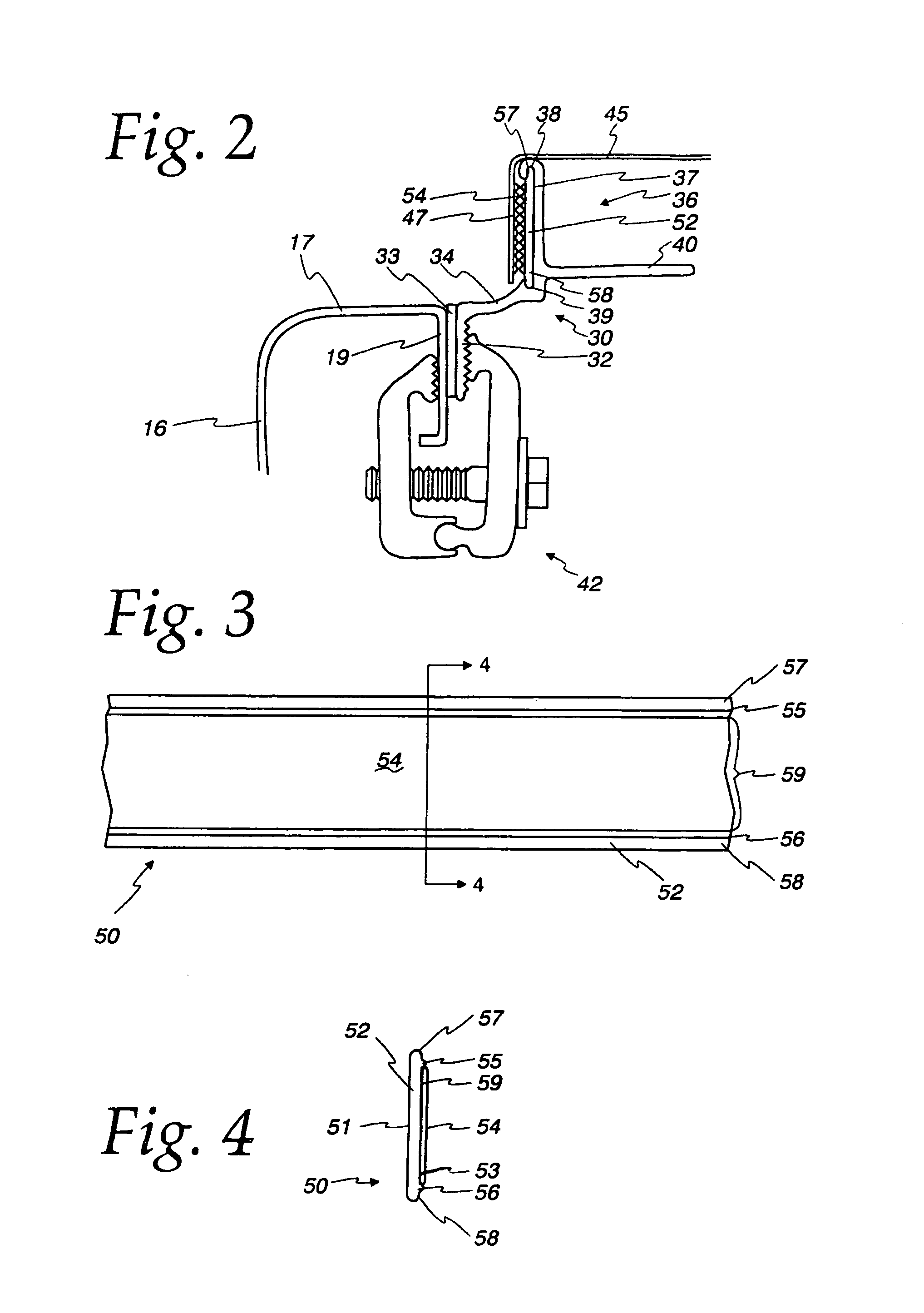

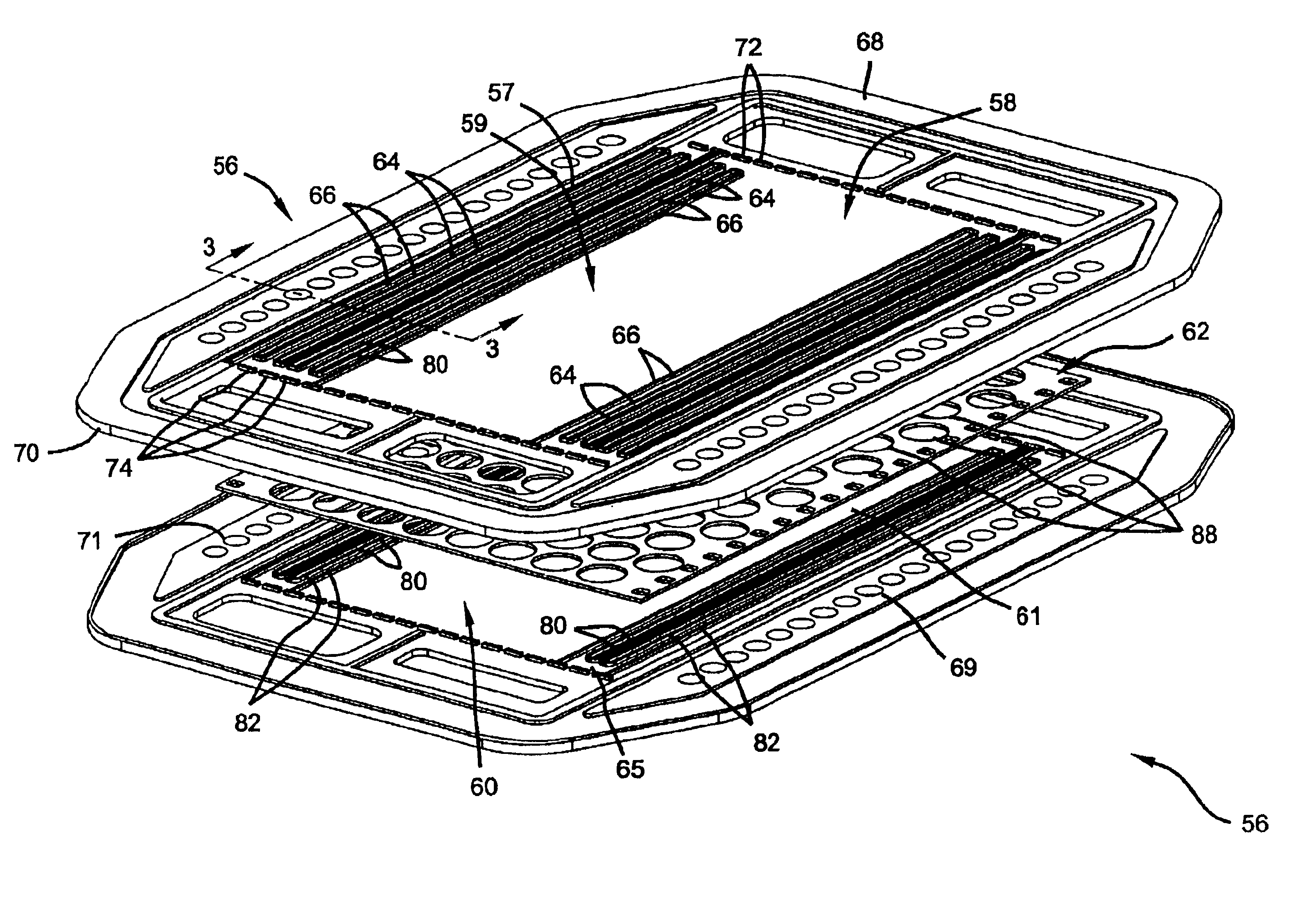

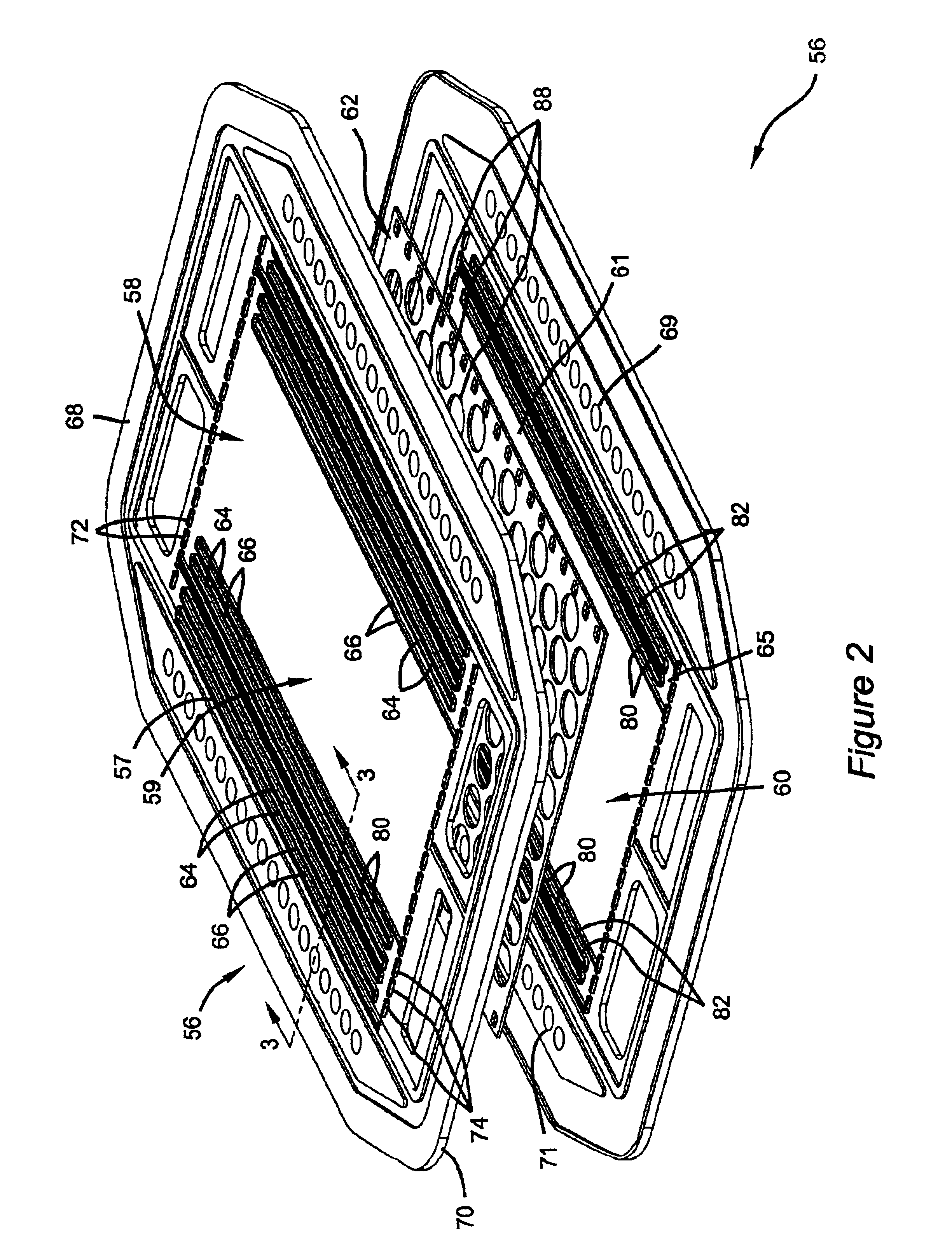

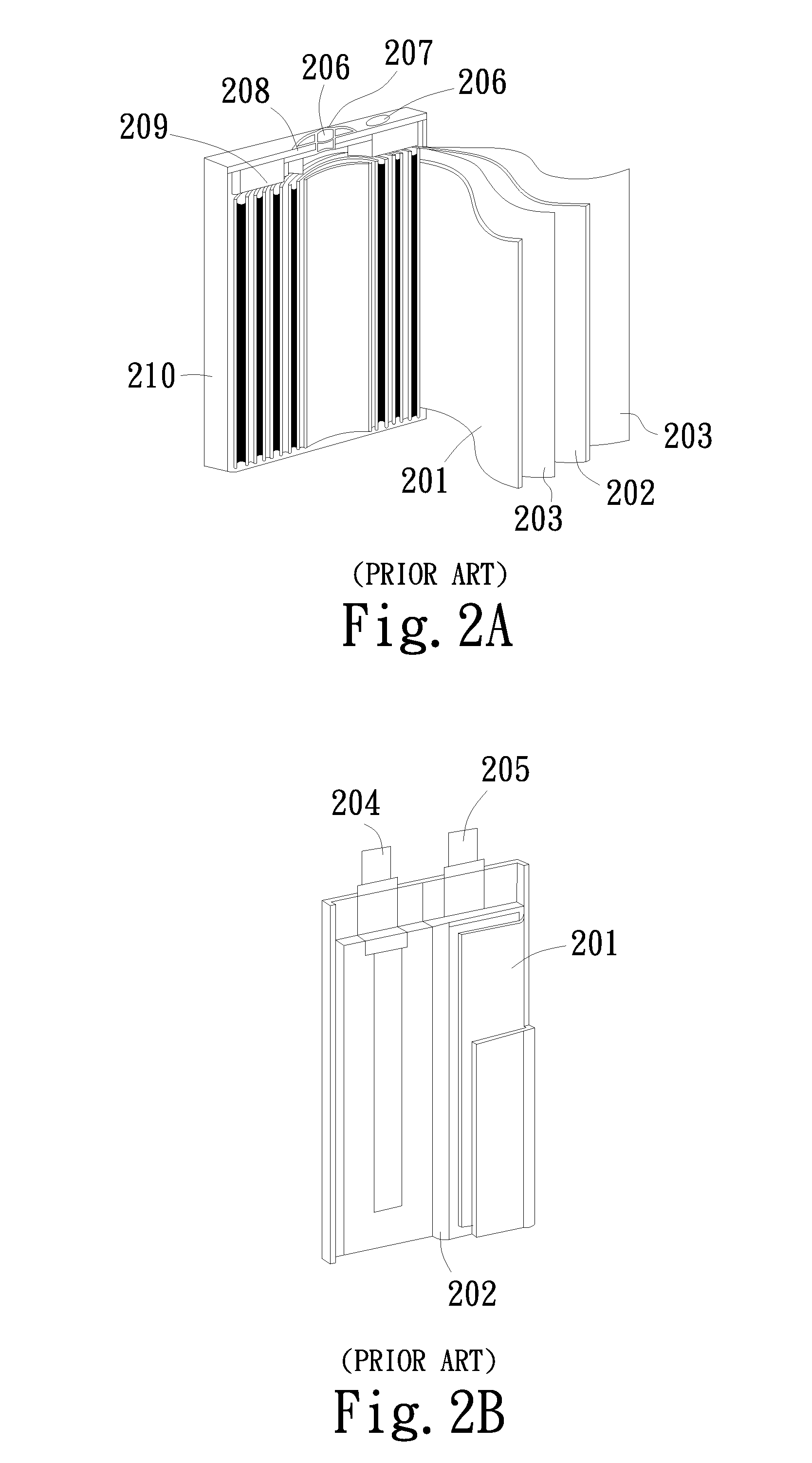

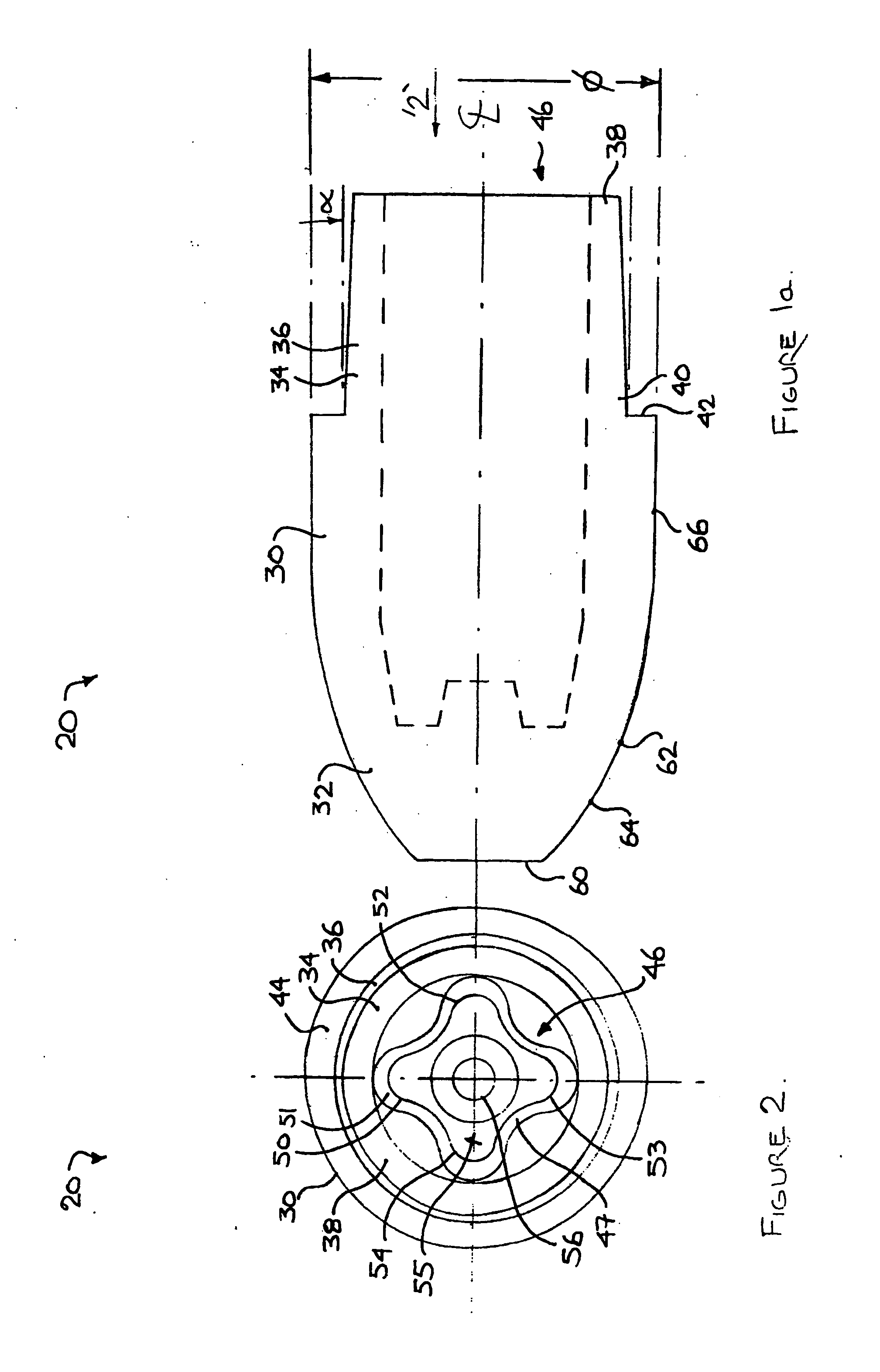

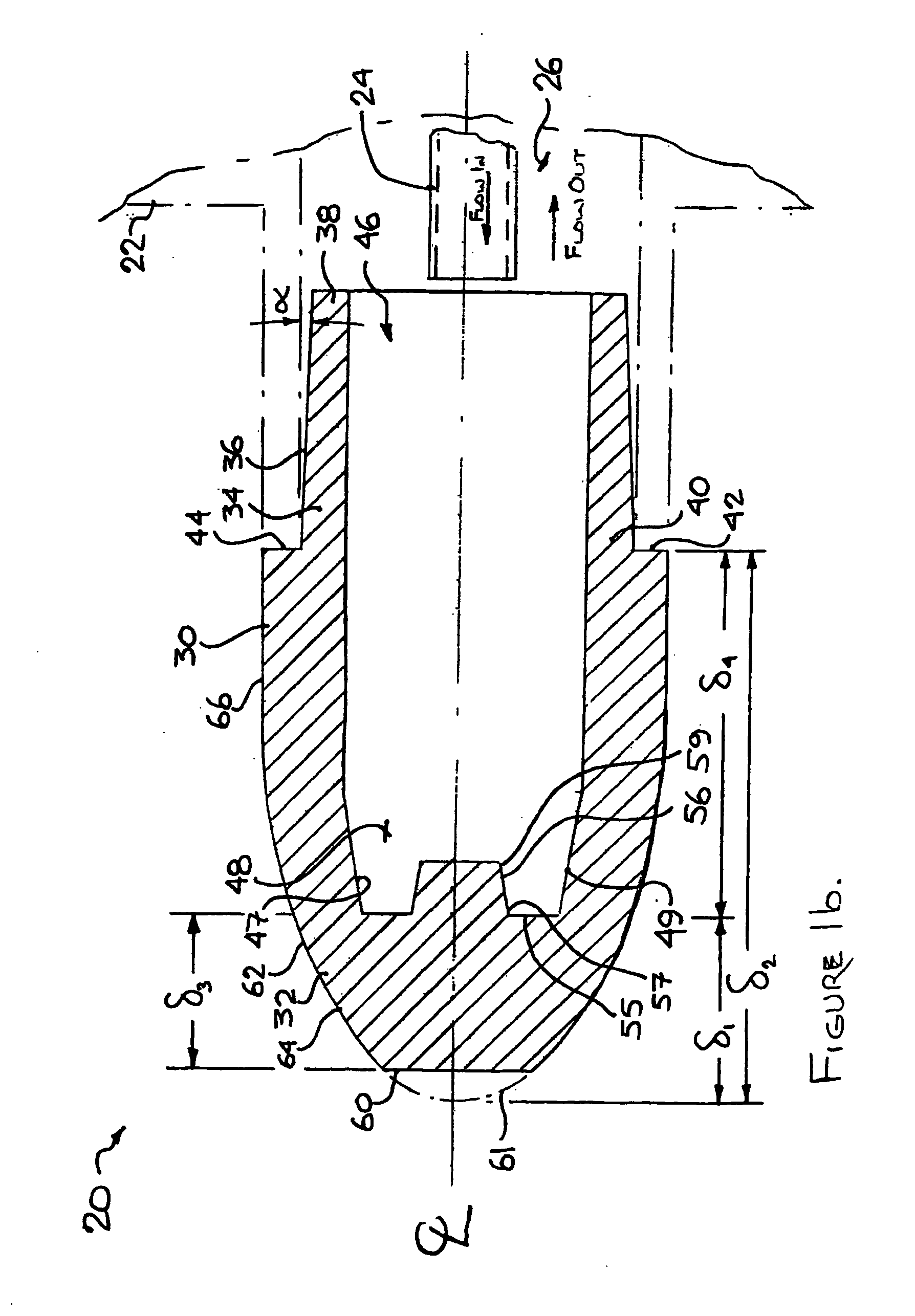

Cover system for truck box

A fastening system for a flexible cover system for a truck box includes a first fastening means on the side edges of the flexible cover and a second fastening means that releasably engages with the first fastening means. The second fastening means comprises a fastening surface disposed on an elongated slat, and is slidingly received in channel portions of side rails mounted on the side of the truck box. The first fastening means can be one member of a hook and loop type fastener and the second fastening surface can be the mating member of the hook and loop type fastener. The elongated slat may also be shorter than the channel portions of the side rail to permit the slat to slide within the channel during operation of the cover system.

Owner:TRUXEDO

Two component coating compositions and coatings produced therefrom

ActiveUS20040010091A1Reduce decreaseUnacceptable functionalityLiquid surface applicatorsLocks for portable objectsMethacrylateEpoxy

The present invention is directed to two component coating compositions that cure under ambient conditions and more particularly to those having low VOC (volatile organic content) that are suitable for use in automotive refinish and Original Equipment Manufacturing (OEM) applications. The coating composition includes crosslinkable and crosslinking components, wherein the crosslinkable component includes a low polydispersity, low molecular weight copolymer having on an average 2 to 25 functional groups, such as hydroxyl, carboxyl, acetoacetoxy, primary and secondary amine, and epoxy. The copolymer is polymerized from a monomer mixture that includes one or more non-functional acrylate monomers and one or more functional methacrylate monomers provided with the functional groups. The crosslinking component includes polyisocyanate, polyamine, ketimine, melamine, epoxy, polyacid or a combination thereof. The invention is also directed to coating produced from the coating composition.

Owner:AXALTA COATING SYST IP CO LLC

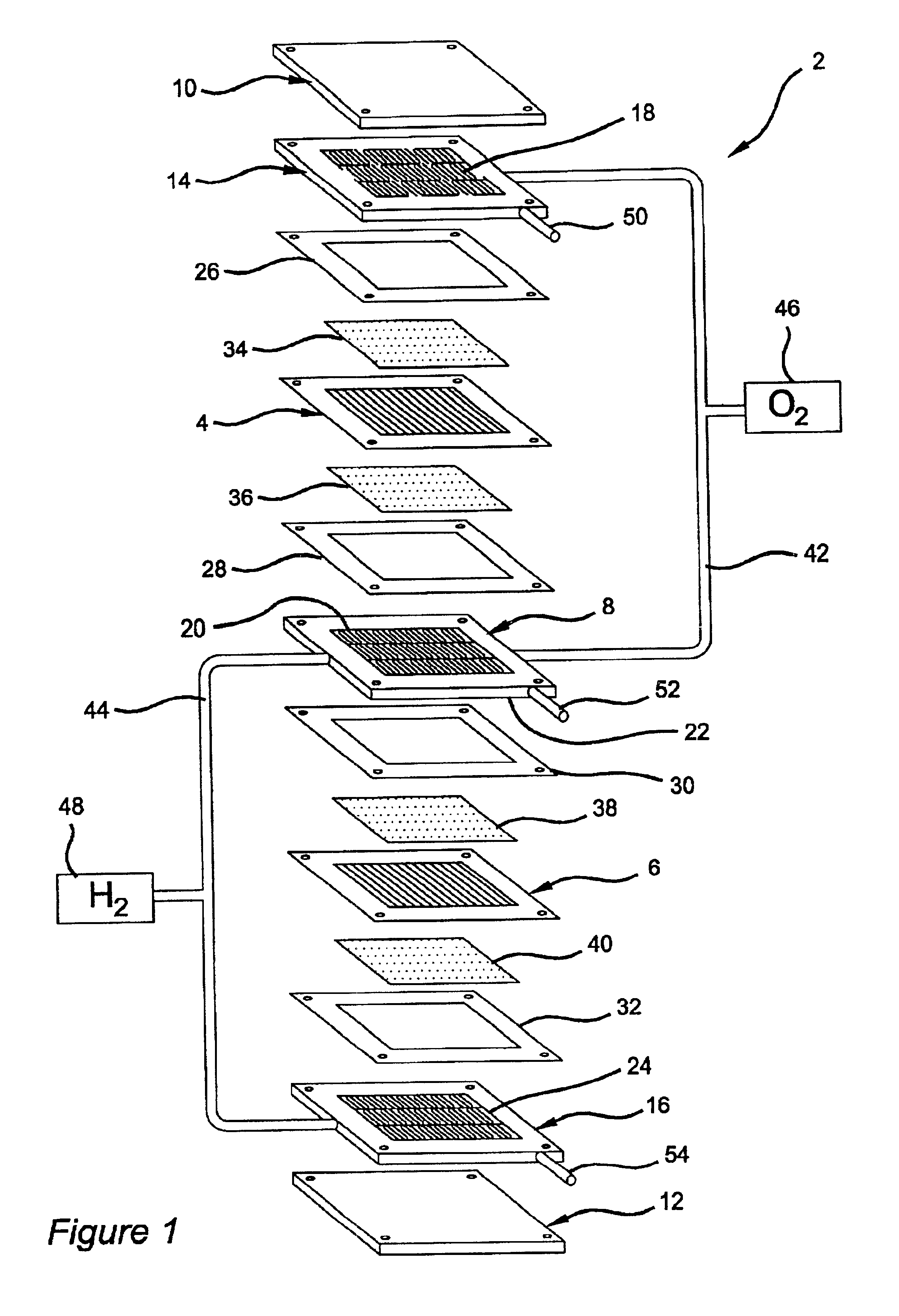

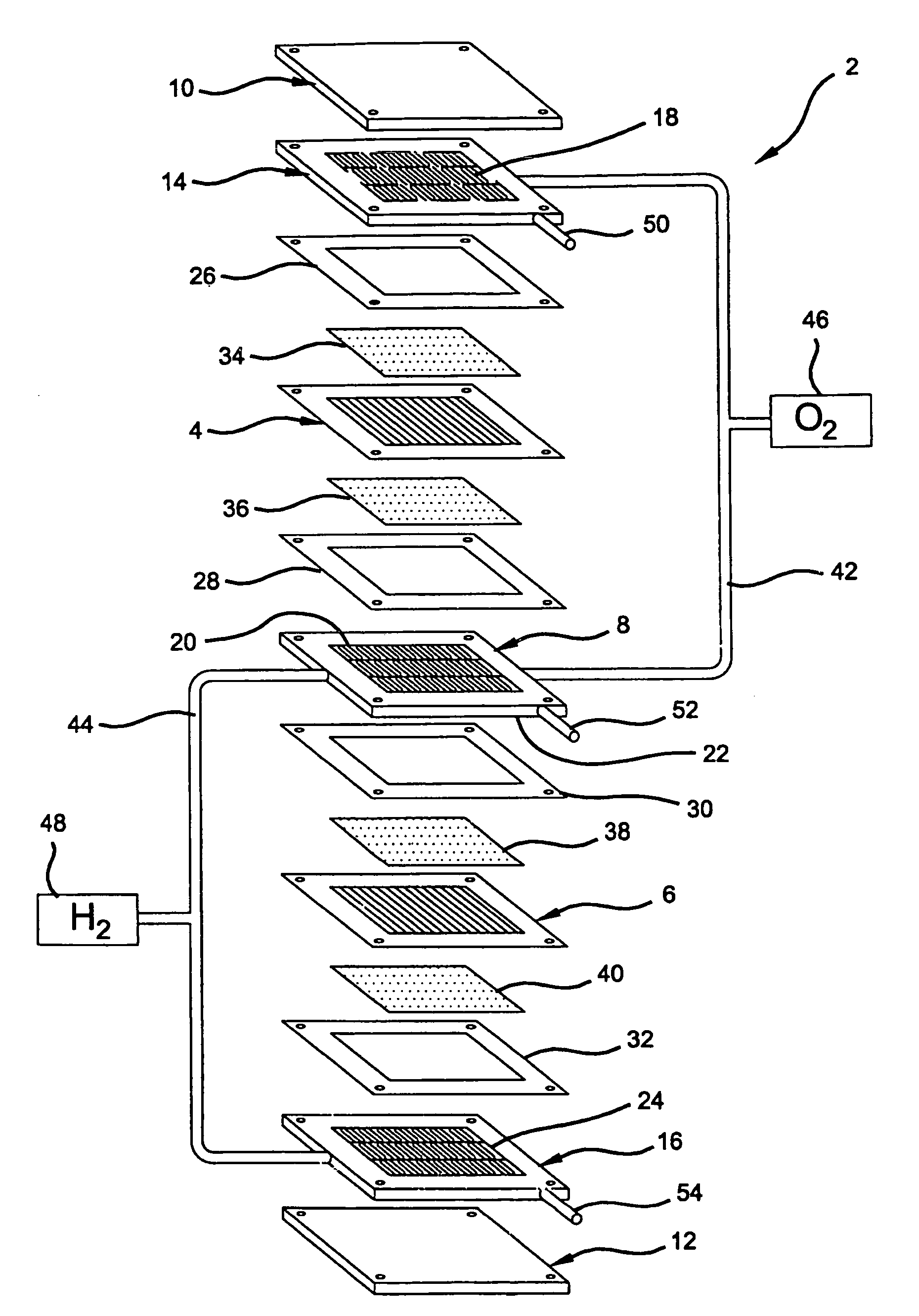

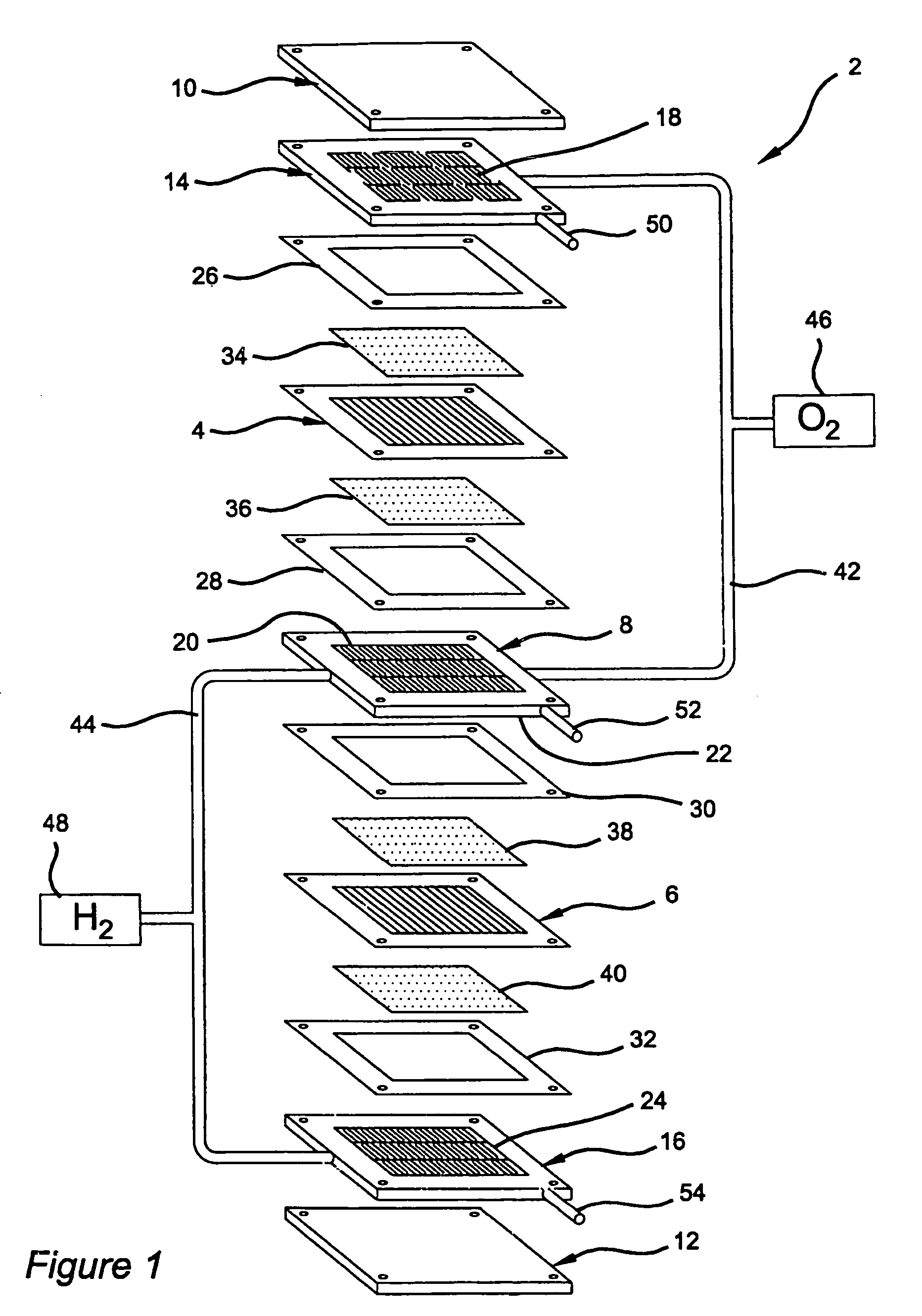

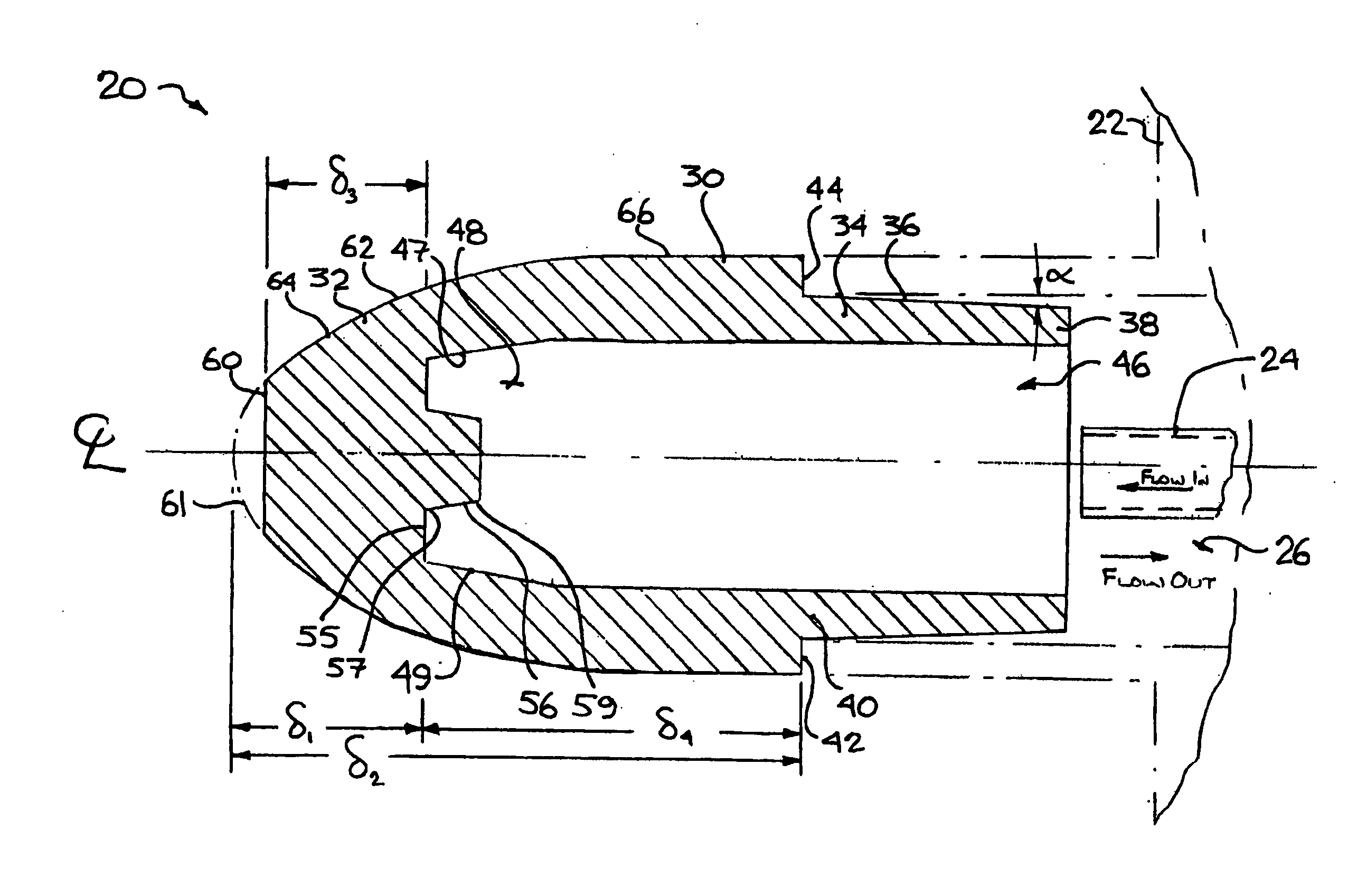

Ultra-low loadings of Au for stainless steel bipolar plates

InactiveUS6866958B2Avoid corrosionPoor adhesionElectrode carriers/collectorsVacuum evaporation coatingFuel cellsConductive coating

An electrically conductive fluid distribution element for a fuel cell which comprises an electrically conductive substrate, a flow field for distributing fluid along a surface of the substrate, and an electrically conductive coating on the surface which comprises a noble metal, desirably Ru, Rh, Pd, Ag, Ir, Pt, Os, and preferably Au.

Owner:GM GLOBAL TECH OPERATIONS LLC

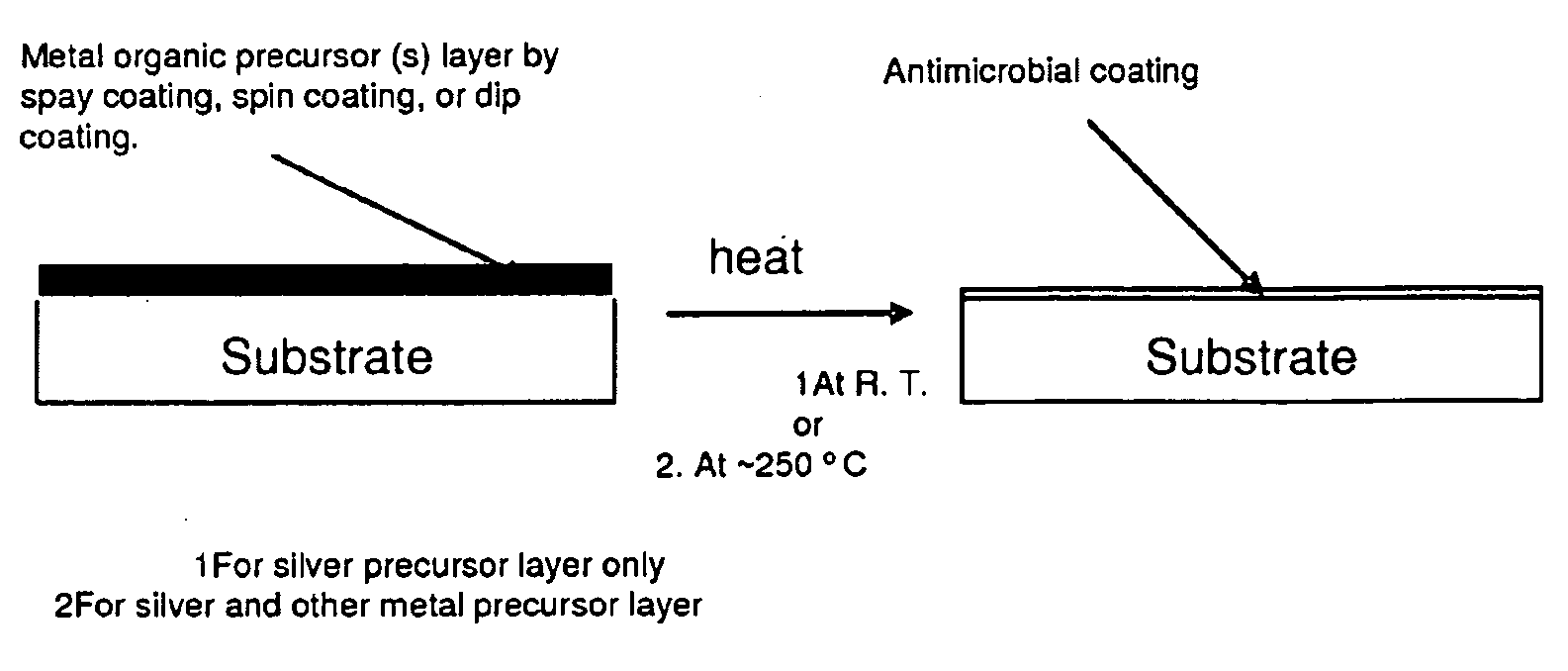

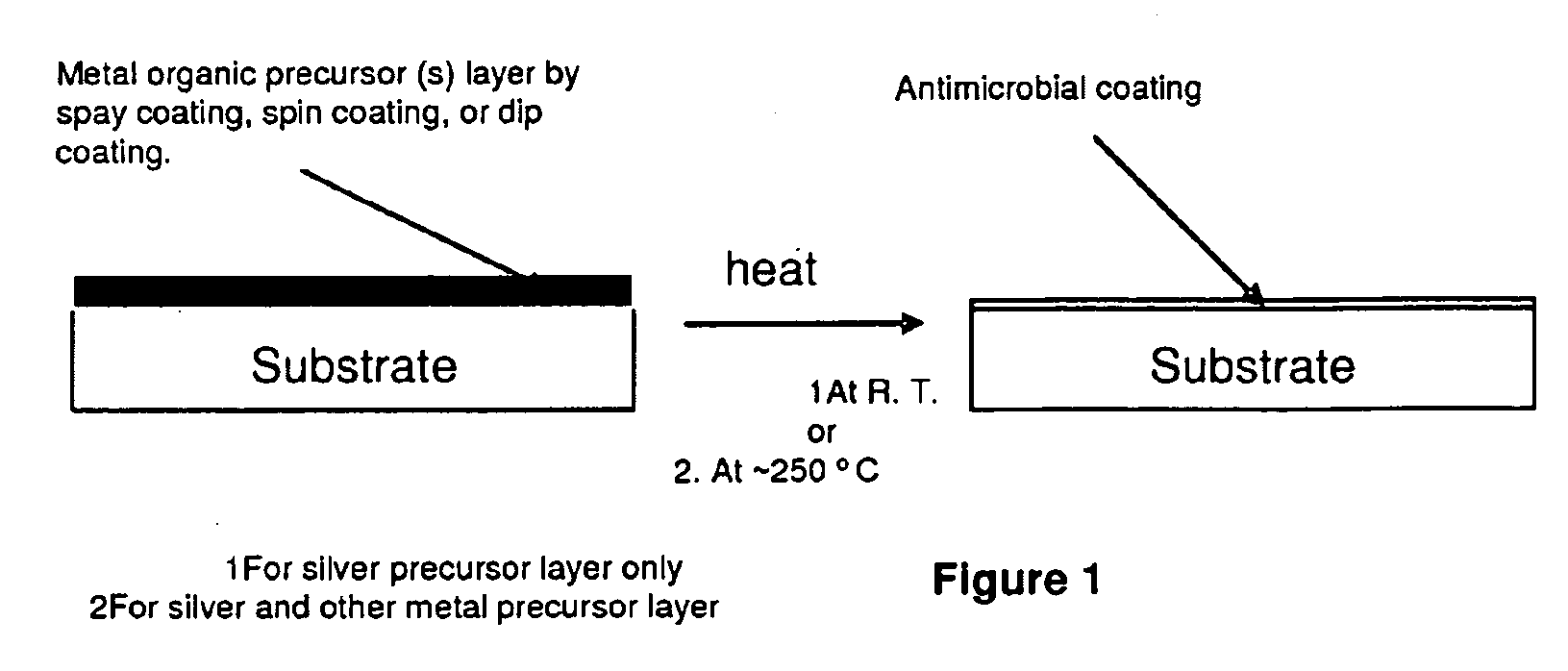

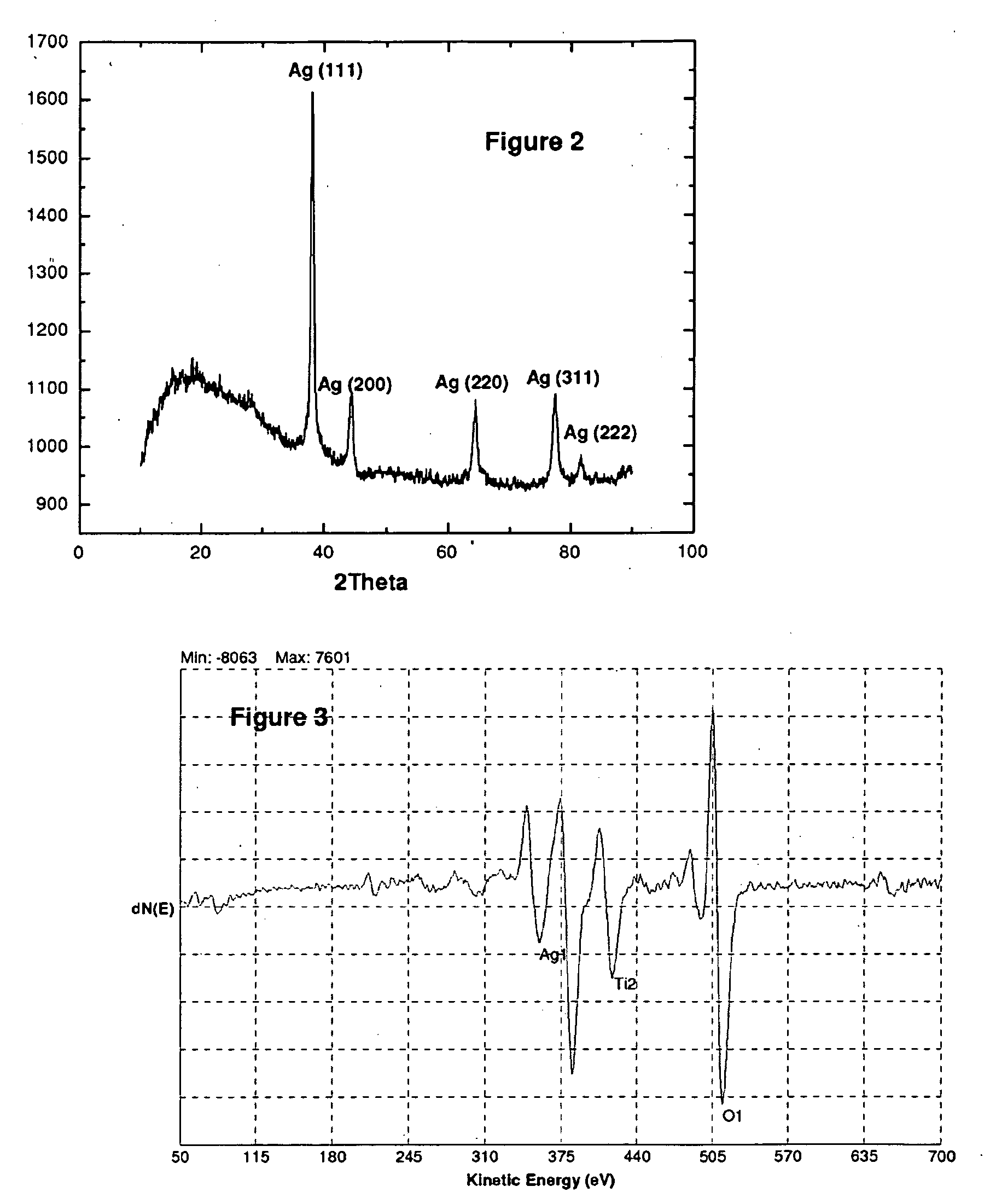

Antimicrobial material compositions enriched with different active oxygen species

InactiveUS20080085326A1Easy maintenanceLong time effectivenessHeavy metal active ingredientsBiocideLog reductionPolymer chemistry

This invention discloses novel antimicrobial materials comprising of nanocrystalline metal, metal oxide, and active oxygen species in a permeable structure. It also discloses the compositions of the inventive material enriched with different active oxygen species. The inventive material showed a strong antimicrobial ability over a wide spectrum of microbies. The average log-reduction value was eight within five minutes. The inventive materials can remain sterile in air over more than two months. The methods used to prepare this inventive material are disclosed.

Owner:RUAN HAI XIONG

Ultra-low loadings of Au for stainless steel bipolar plates

InactiveUS7625654B2Avoid corrosionPoor adhesionFuel cell auxillariesElectrode carriers/collectorsFuel cellsConductive coating

An electrically conductive fluid distribution element for a fuel cell which comprises an electrically conductive substrate, a flow field for distributing fluid along a surface of the substrate, and an electrically conductive coating on the surface which comprises a noble metal, desirably Ru, Rh, Pd, Ag, Ir, Pt, Os, and preferably Au.

Owner:GM GLOBAL TECH OPERATIONS LLC

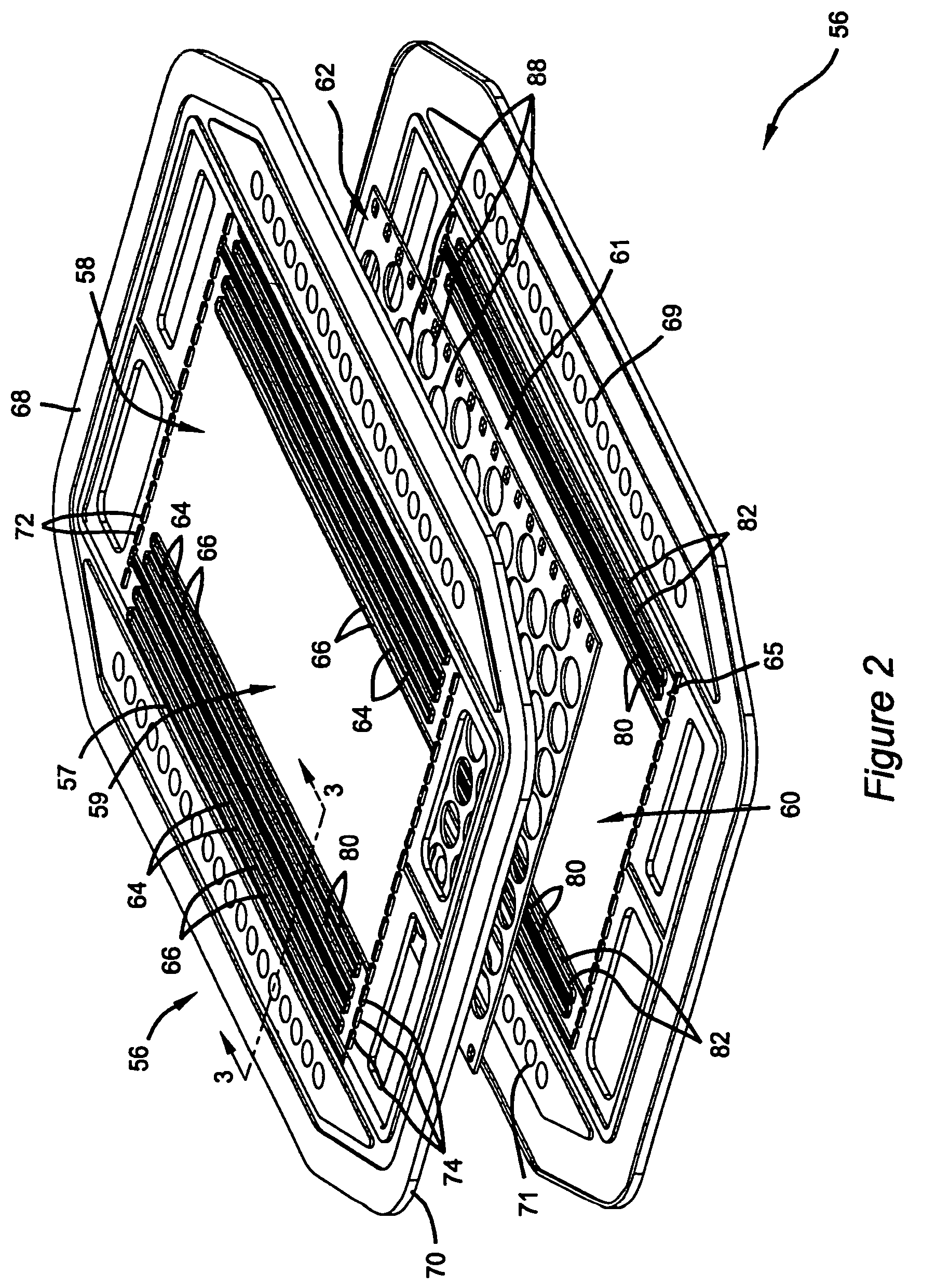

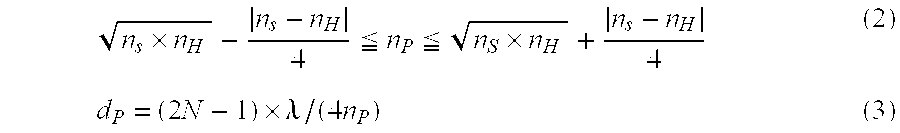

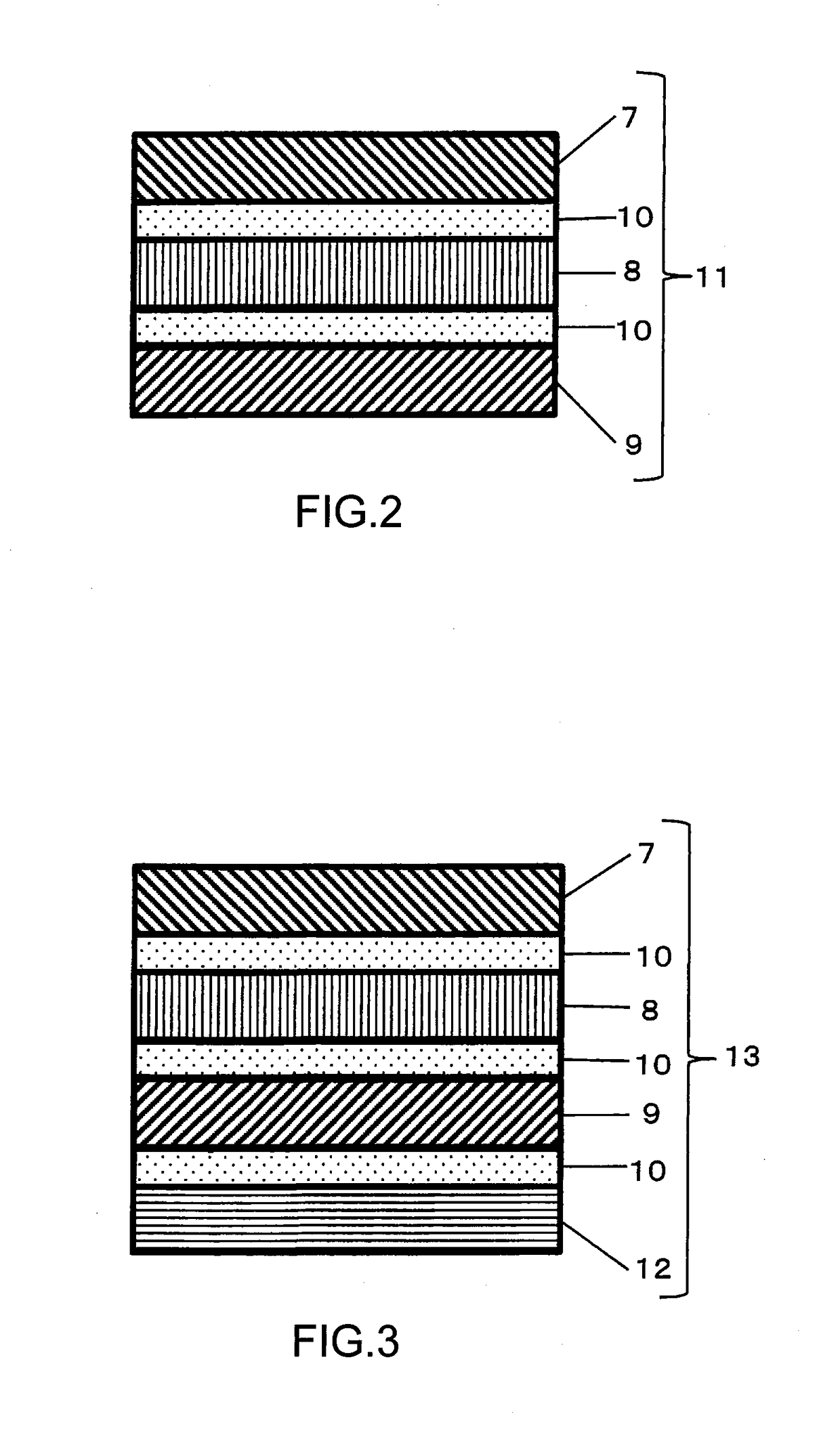

Plastic film and image display unit

ActiveUS20060056030A1Reduce distractionsAvoid it happening againSynthetic resin layered productsCoatingsRefractive indexPlastic film

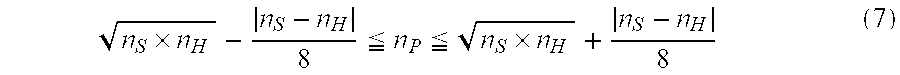

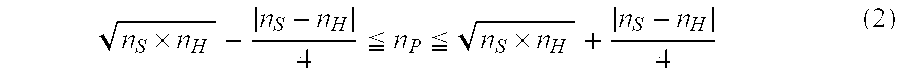

A plastic film comprising a transparent plastic substrate, a primer layer and a functional layer in this order wherein a refractive index ns of the substrate and a refractive index nH of the functional layer satisfy the following formula (1): 0.03≦|ns−nH| and an average reflectance of light of from 540 to 550 nm in wavelength incidenting perpendicular onto a face of the film at an interface among the functional layer and the substrate is 0.02% or less.

Owner:FUJIFILM CORP

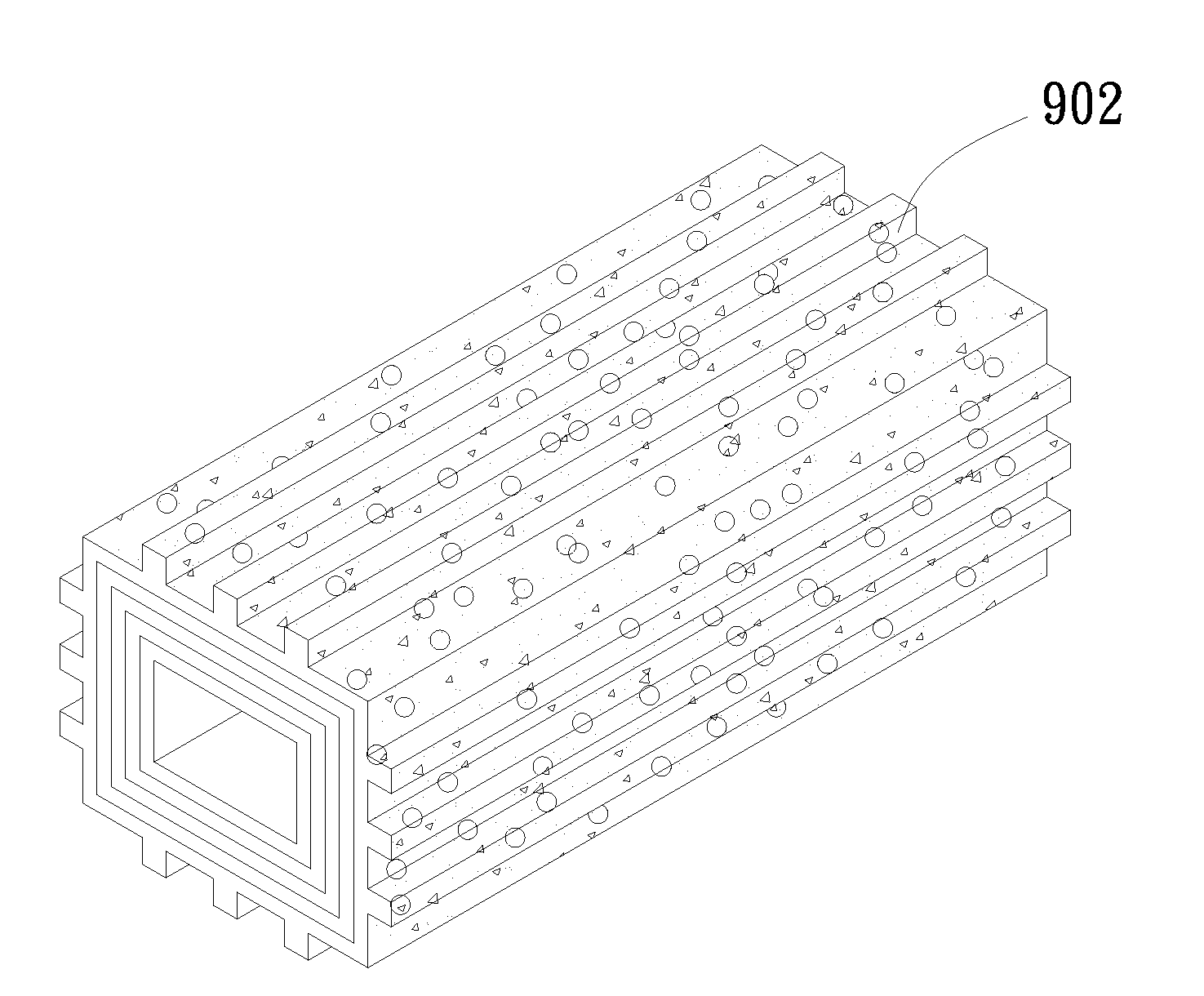

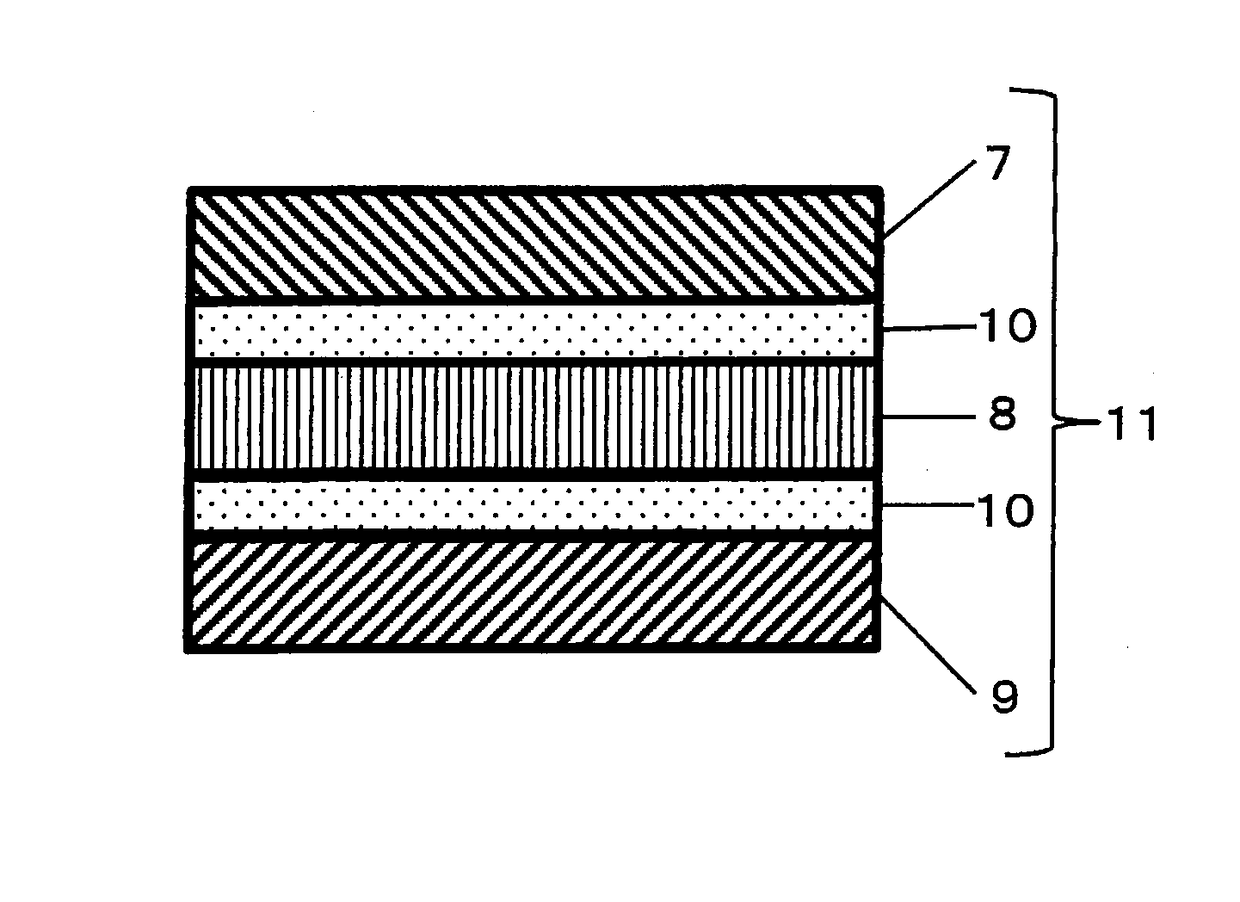

Multi-layer films, sheets, and hollow articles with thermal management function for uses as casings of secondary batteries and supercapacitors, and sleeves of secondary battery and supercapacitor packs

InactiveUS20100316821A1Improved thermal management multi-layer film/sheet/hollowImprove cooling effectSynthetic resin layered productsCeramic shaping apparatusElectrical batterySupercapacitor

The thermal management multi-layer film / sheet and hollow articles for the use with secondary battery, supercapacitor and battery pack as thermal management casings or sleeves achieve effective control of the temperature of the operating batteries / supercapacitors. The thermal management multi-layer film / sheet and hollow article structure comprises a laminate of a plurality of alternative metal, plastic, and adhesive layers. And the plastic and adhesive layers comprise of parent phase resin, heat conductive particles, and microencapsule-phase-change-material (MCPCM). The heat conductive particles enhances the thermal conductivity, the MCPCMs absorb heat while the batteries / supercapacitors are in discharging mode.

Owner:SUNNY GENERAL INT

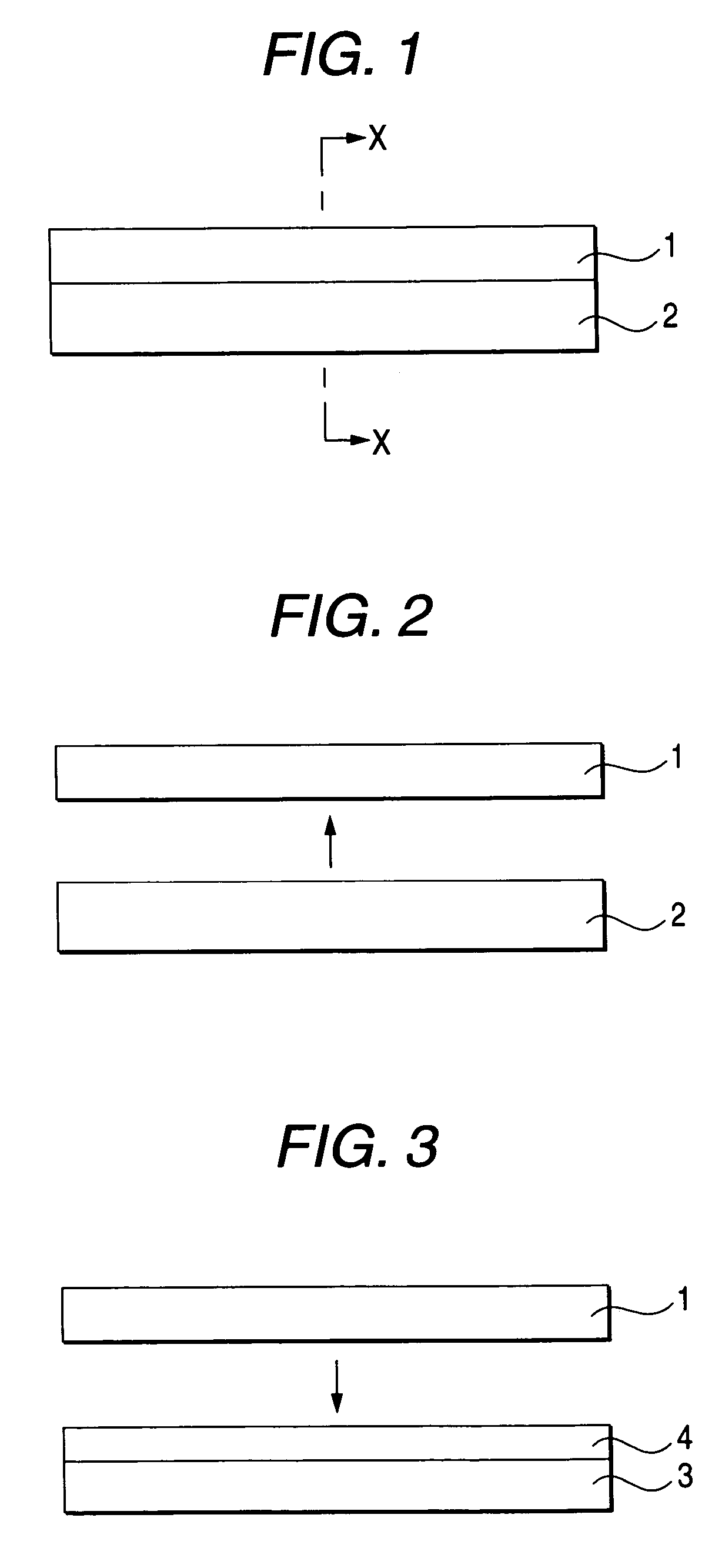

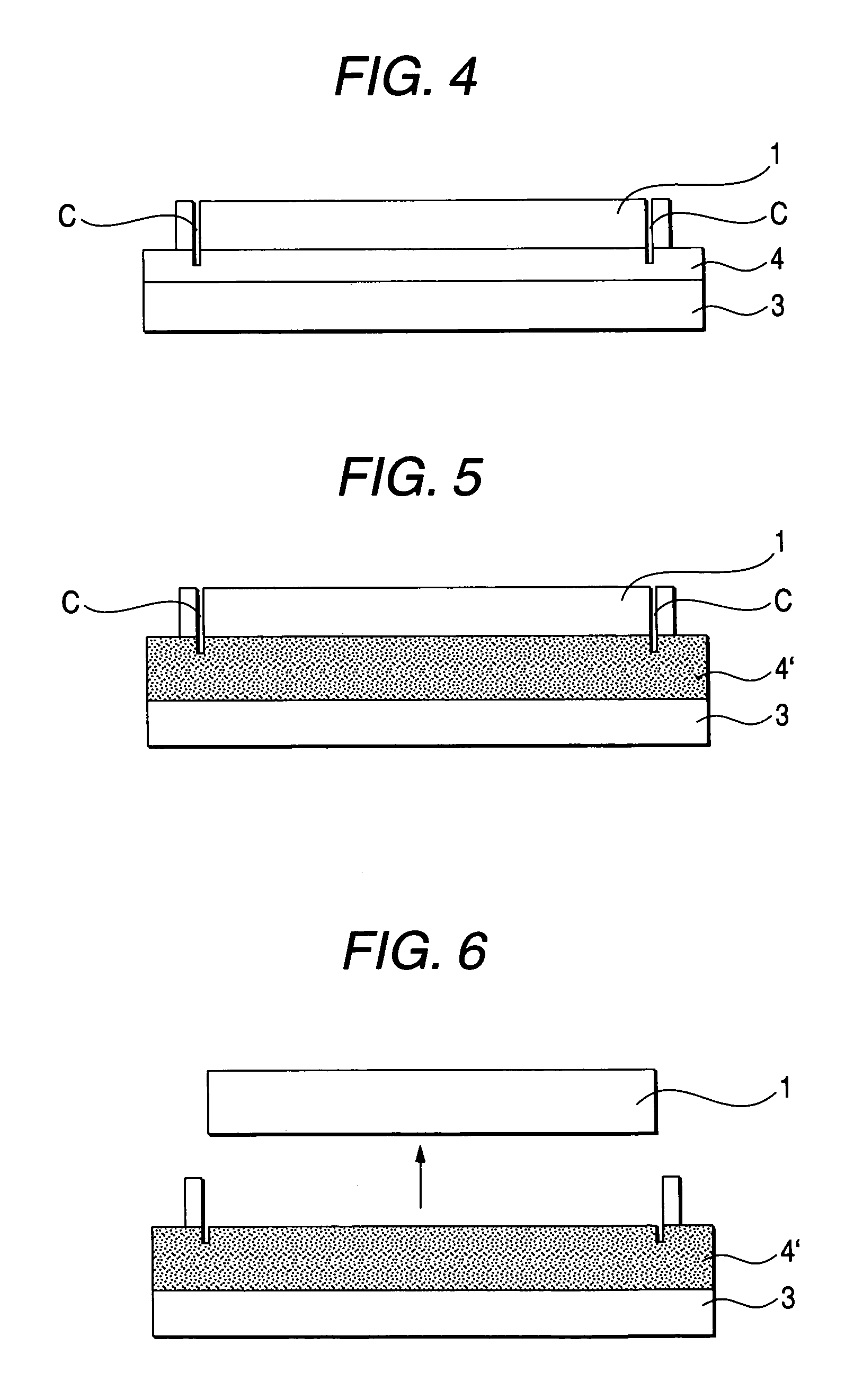

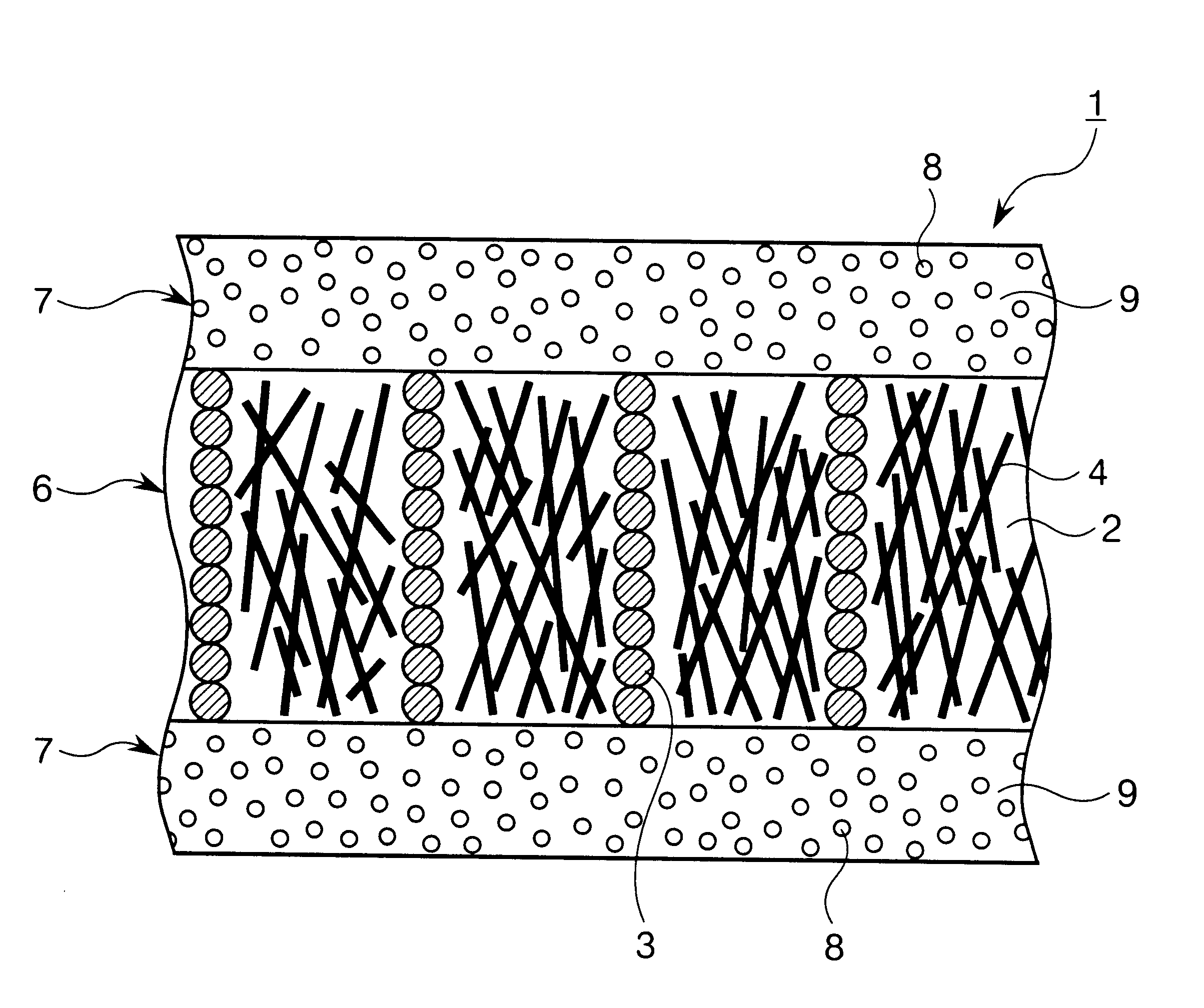

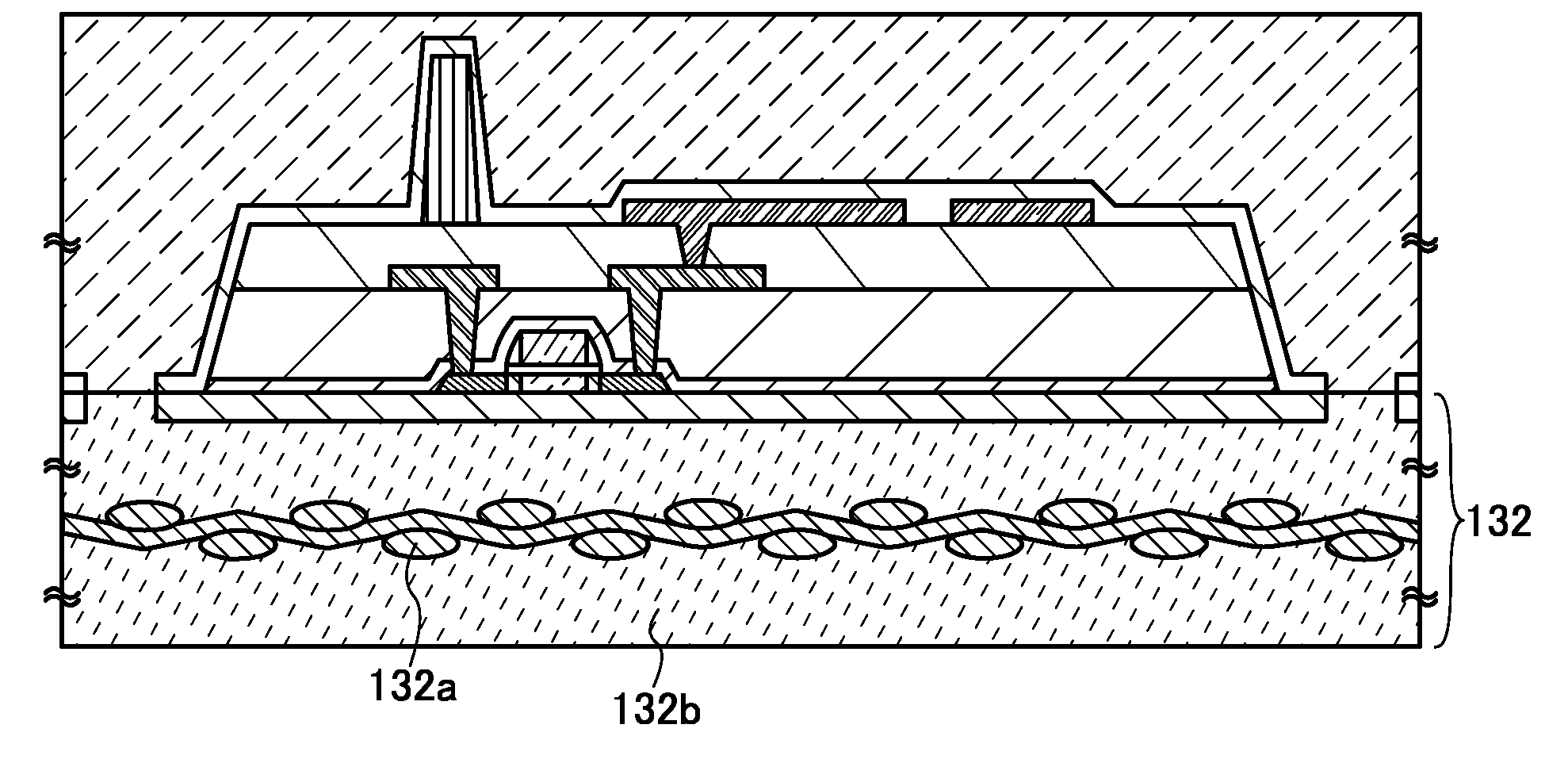

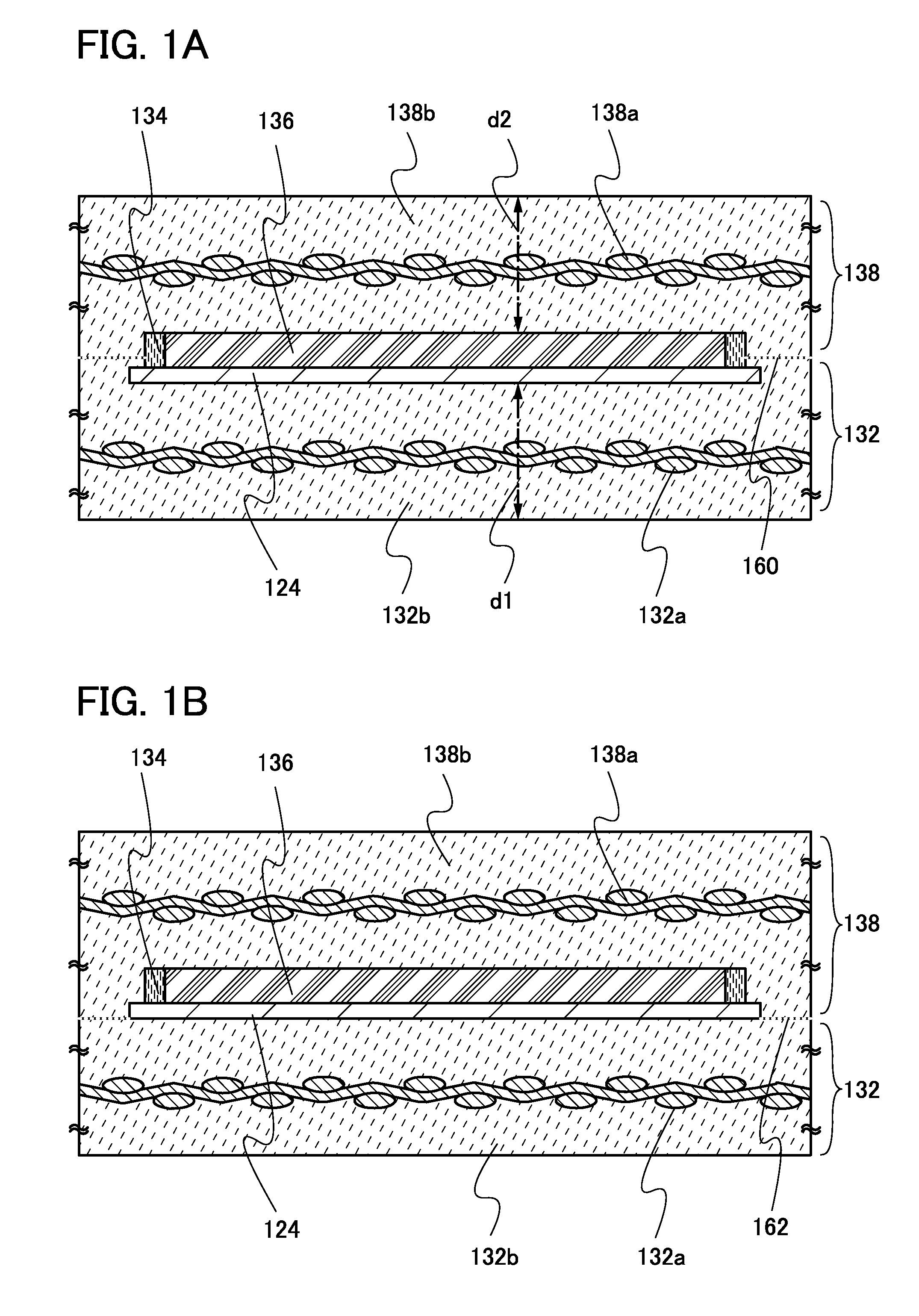

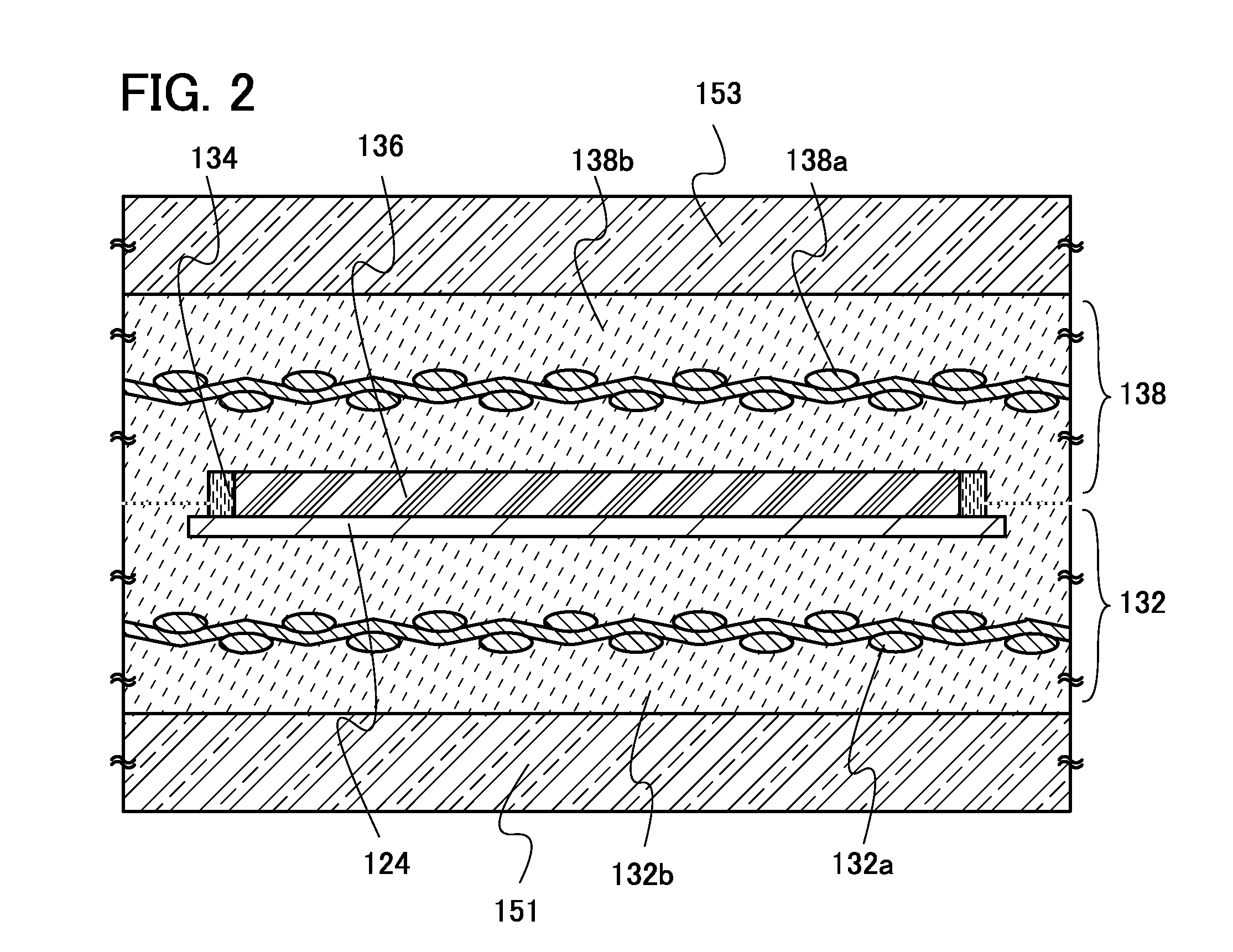

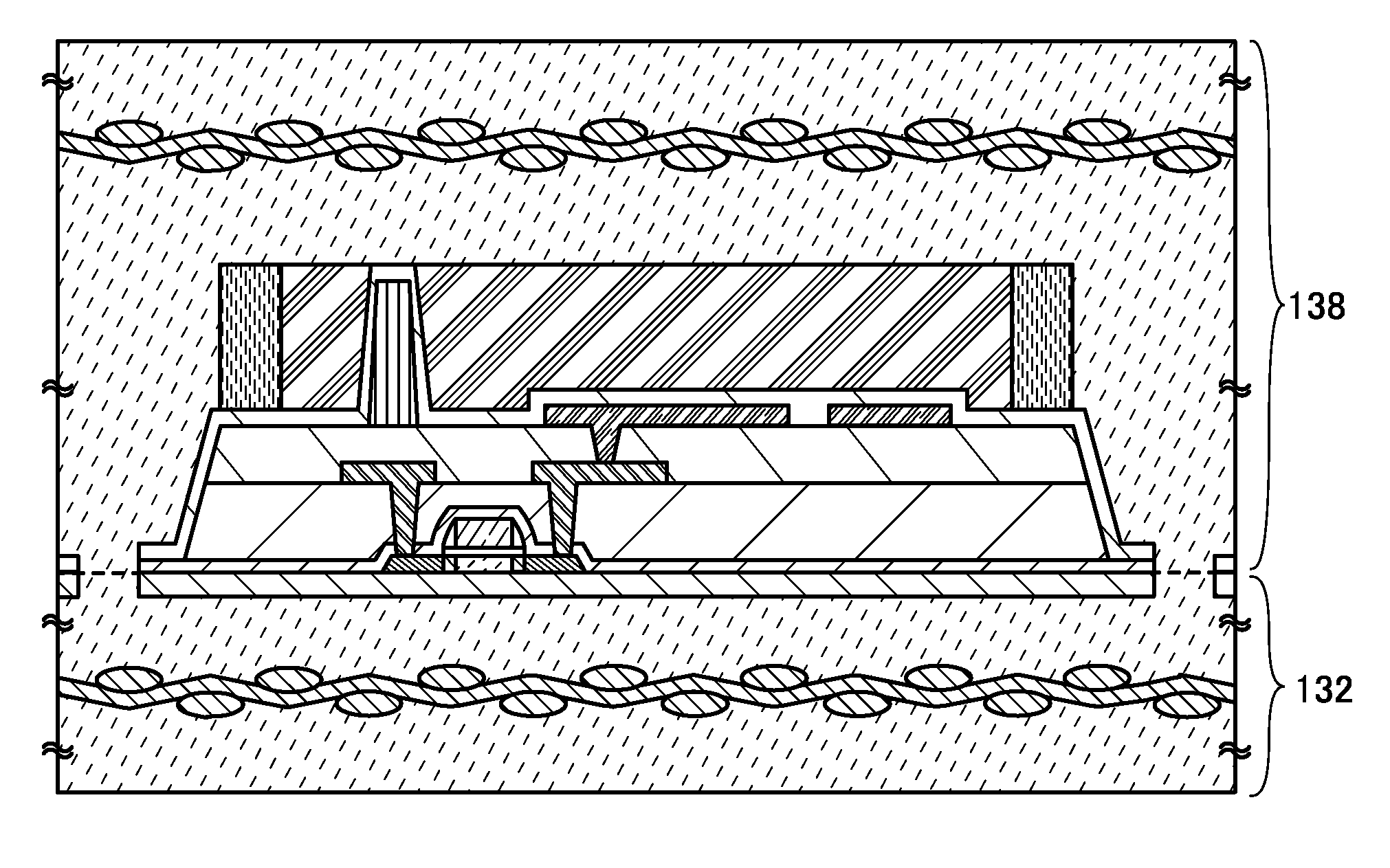

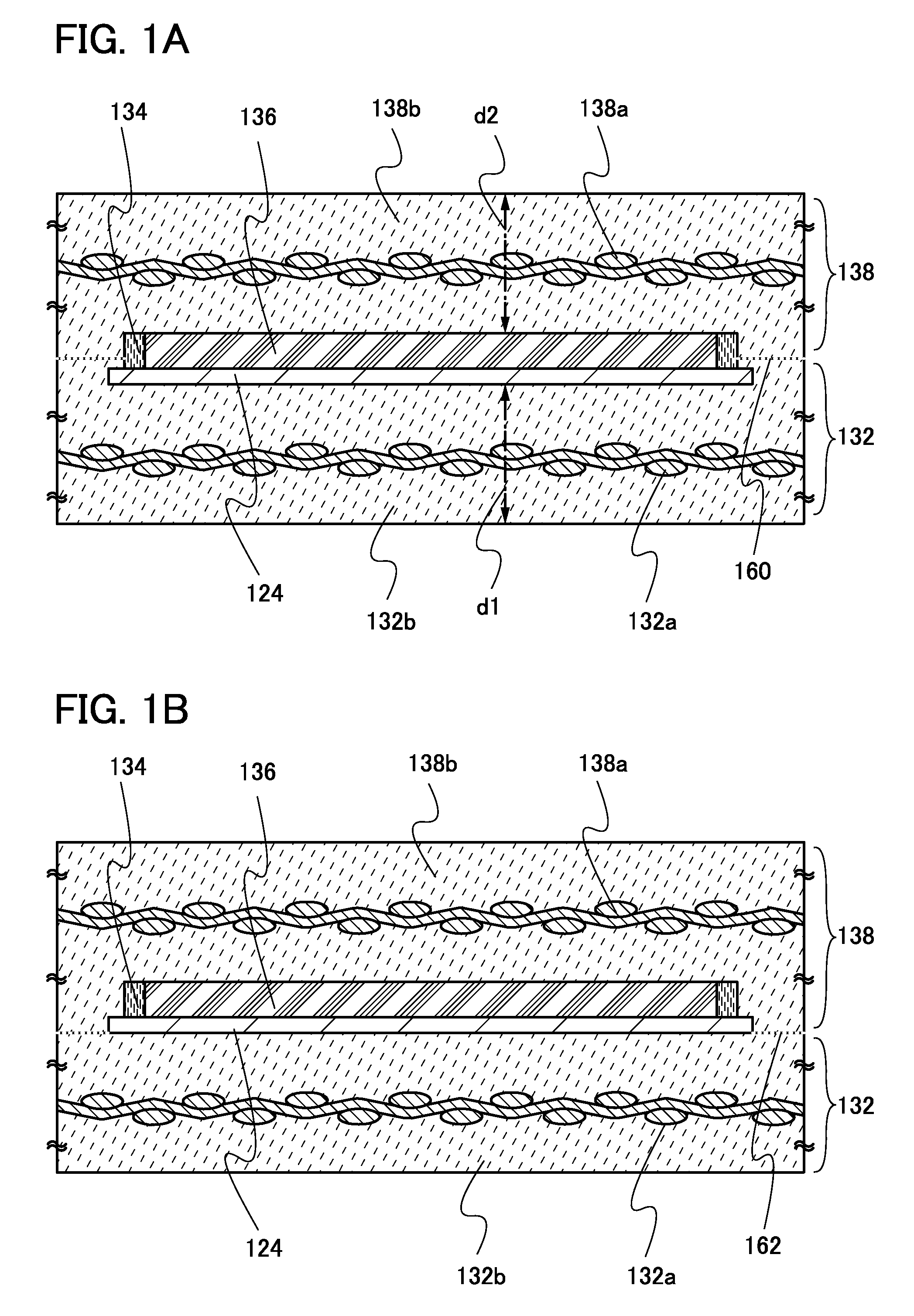

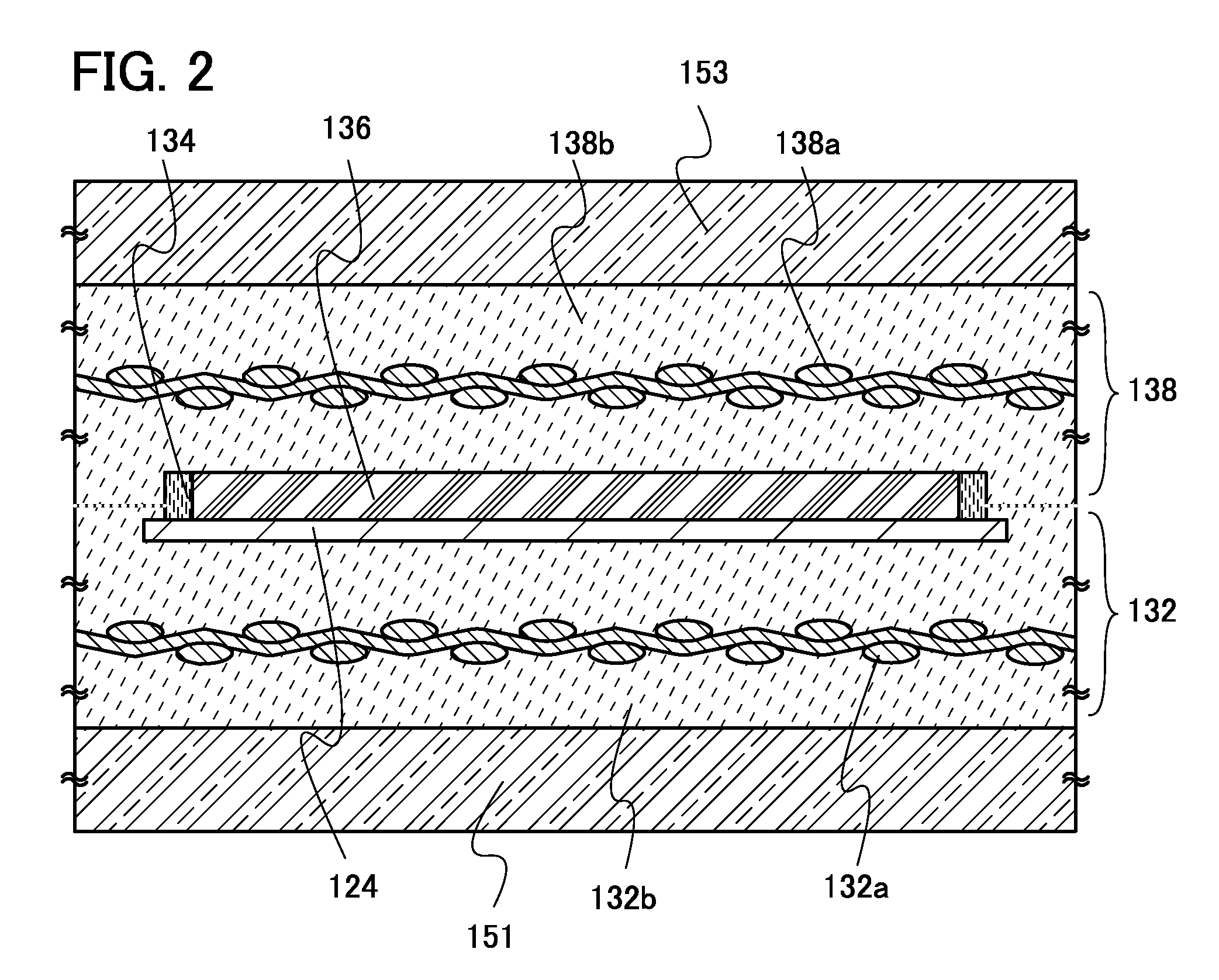

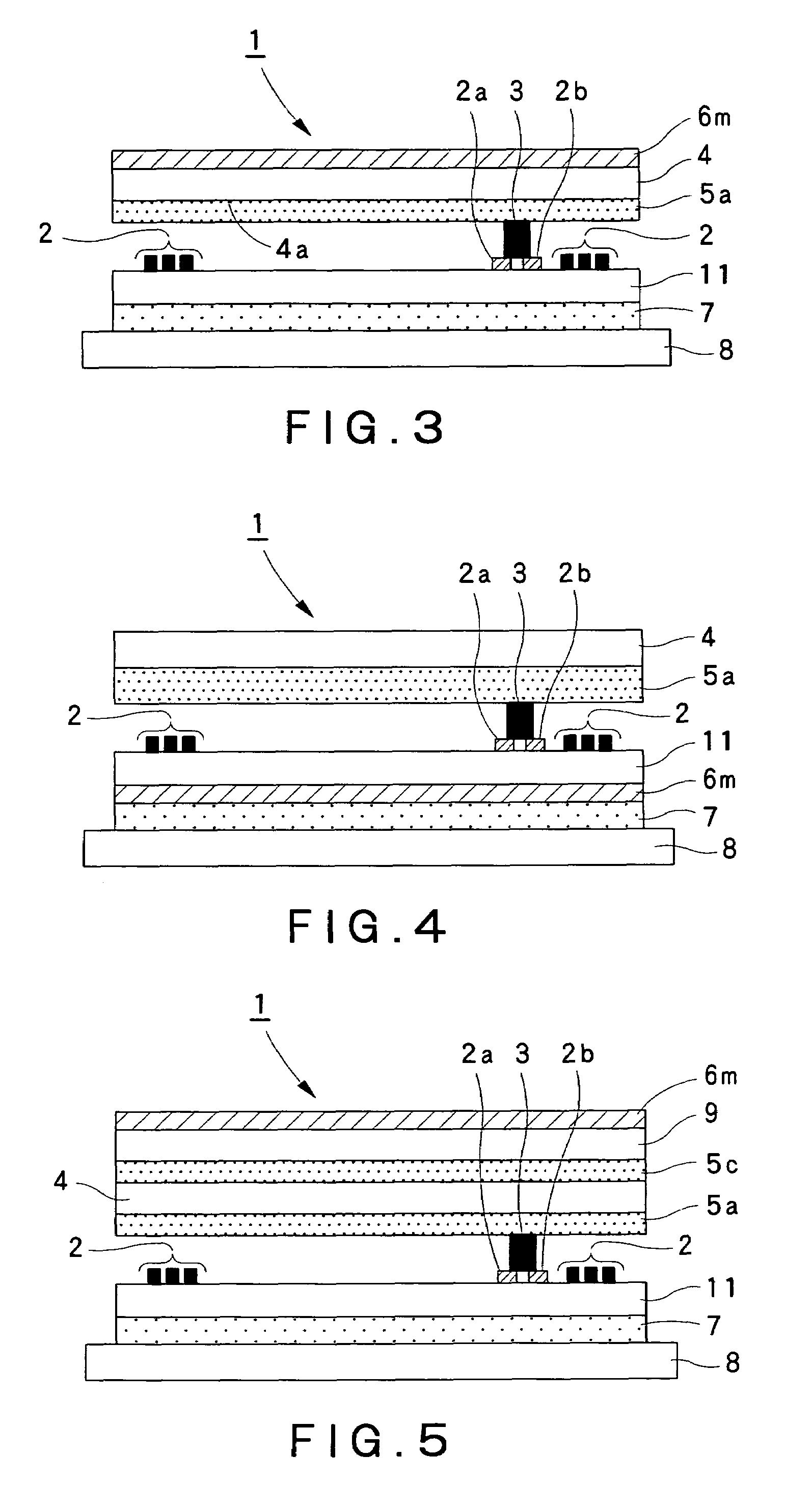

Liquid crystal display device and method for manufacturing the same

InactiveUS20100007829A1Reduce image qualityReduce harmNon-linear opticsLiquid-crystal displayEngineering

A flexible and highly reliable liquid crystal display device which is not easily damaged even if subjected to external pressure is provided. A method for manufacturing, with high yield, a flexible and highly reliable liquid crystal display device which is not easily damaged even if subjected to external pressure is also provided. A liquid crystal display device including a first structure body including a first fibrous body and a first organic resin, a second structure body including a second fibrous body and a second organic resin, a liquid crystal interposed between the first and second structure bodies, and a seal member for fixing the first and second structure bodies and for enclosing the liquid crystal. The first and second fibrous bodies are impregnated with the first and second organic resins, respectively, and the first structure body and the second structure body are in contact with each other.

Owner:SEMICON ENERGY LAB CO LTD

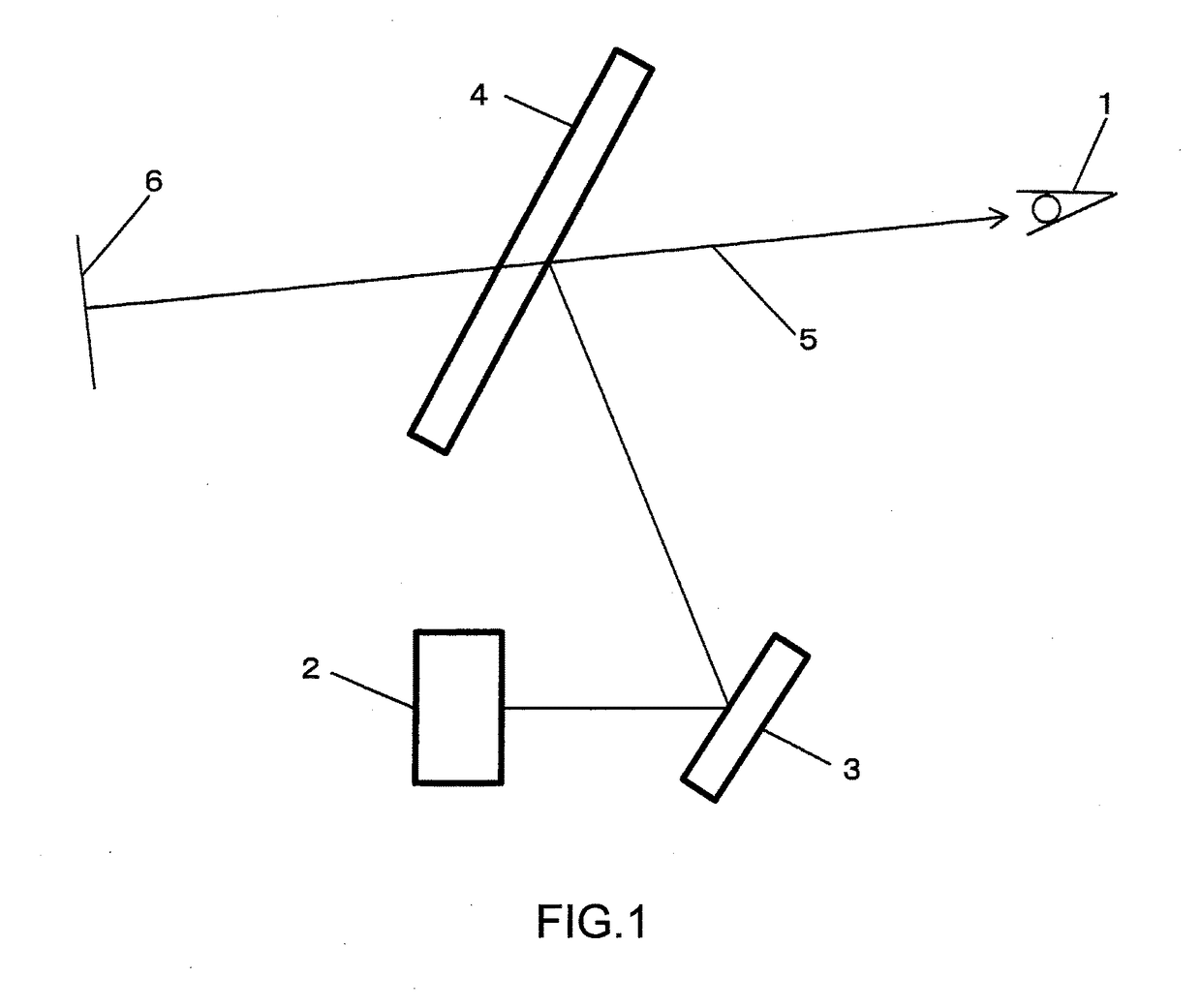

Light Reflecting Film, And Light Controlling Film, Optical Film, Functional Glass And Head-Up Display Including The Light Reflecting Film

ActiveUS20170235030A1Improve visibilityImprove reflectivityMirrorsInstrument arrangements/adaptationsHead-up displayLength wave

A light controlling film comprises a light reflecting film and a light controlling layer that are laminated. The light reflecting film comprises at least two laminated light reflecting layers including at least one of light reflecting layers PRL-1 to PRL-3 that a central reflection wavelength of 400 nm-500 nm, 500 nm-600 nm, and 600 nm-700 nm, respectively, and a reflectance to ordinary light at the central reflection wavelength of 5%-25%. The at least two light reflecting layers have central reflection wavelengths that are different from each other. All of the at least two laminated light reflecting layers have a property of reflecting polarized light having the same orientation. The light controlling layer comprises two quarter wave plates, and the light reflecting film is laminated so as to be interposed between the two quarter wave plates.

Owner:NIPPON KAYAKU CO LTD

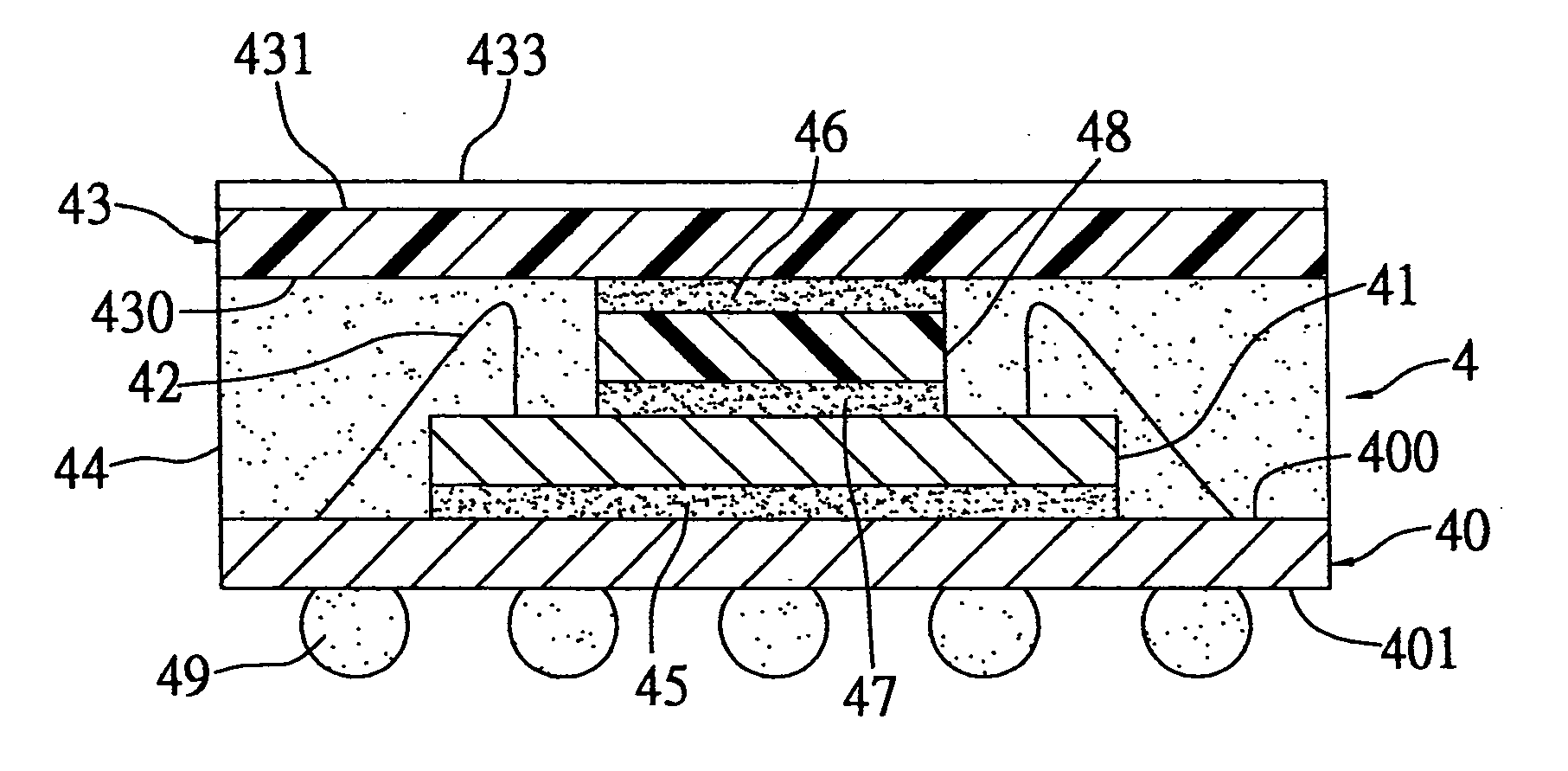

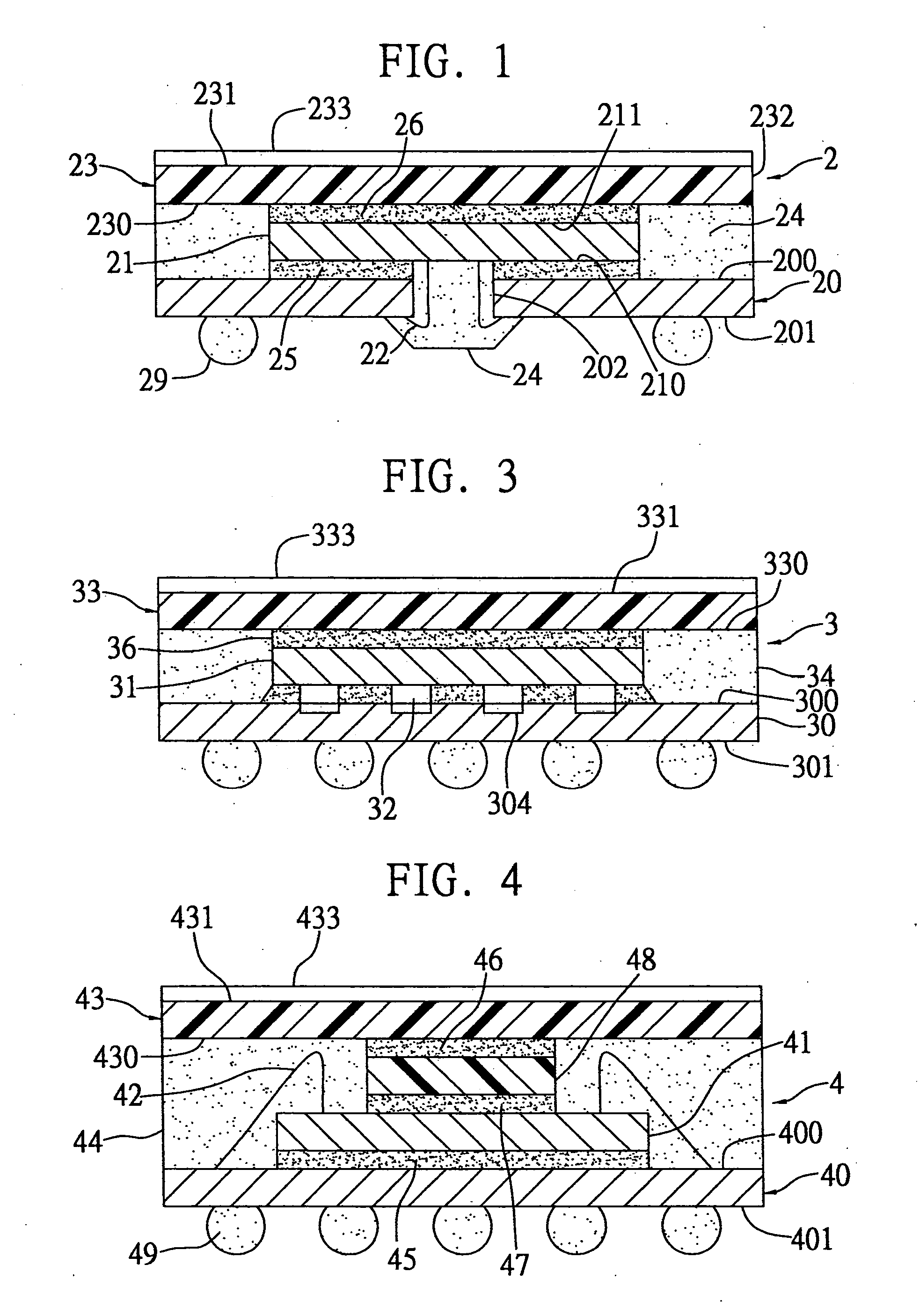

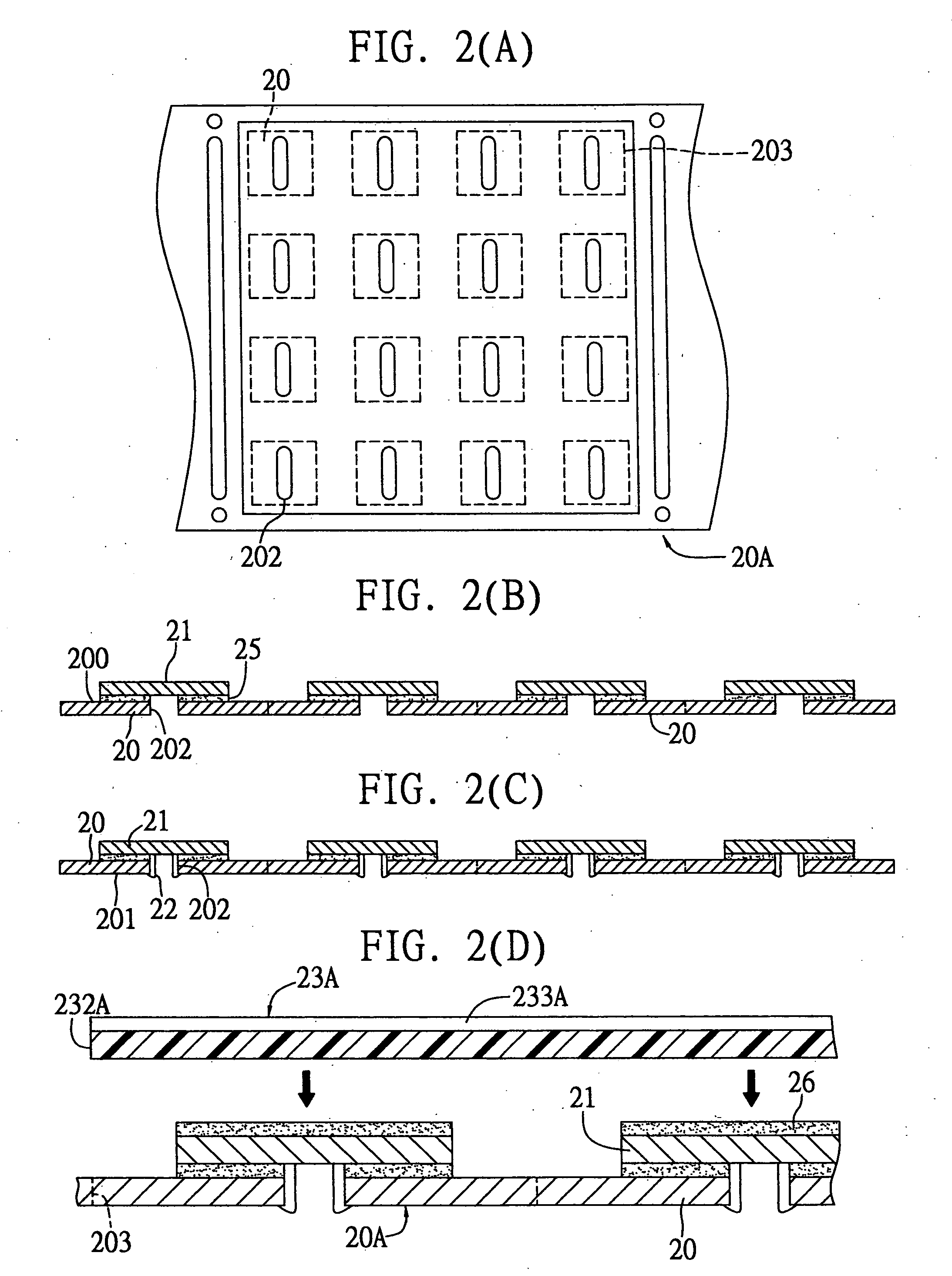

Fabrication method of semiconductor package with heat sink

InactiveUS20050095875A1Avoid crackingArea maximizationSemiconductor/solid-state device detailsSolid-state devicesAdhesiveInterface layer

A semiconductor package with a heat sink is proposed, in which a chip has its first surface attached to a chip carrier, while a second surface of the chip is attached to a heat sink through an adhesive, allowing heat generated by the chip to be transmitted to the heat sink. Moreover, in a molding process, a molding resin is used to form an encapsulant for encapsulating the chip, while a top surface and side surfaces connected to the top surface of the heat sink are exposed to outside of the encapsulant, that is, the heat sink merely has its bottom surface bonded to the encapsulant. This makes the generated heat directly dissipated to the atmosphere through the heat sink. Furthermore, the top surface of the heat sink is coated with an interface layer, while adhesion between the interface layer and the molding resin is smaller than that between the heat sink and the encapsulant. This allows the molding resin remained on the interface layer to be easily removed after completing the molding process, while delamination can be prevented from occurrence between the heat sink or the chip and the encapsulant, and also the chip can be prevented from cracking due to clamping force generated during molding.

Owner:SILICONWARE PRECISION IND CO LTD

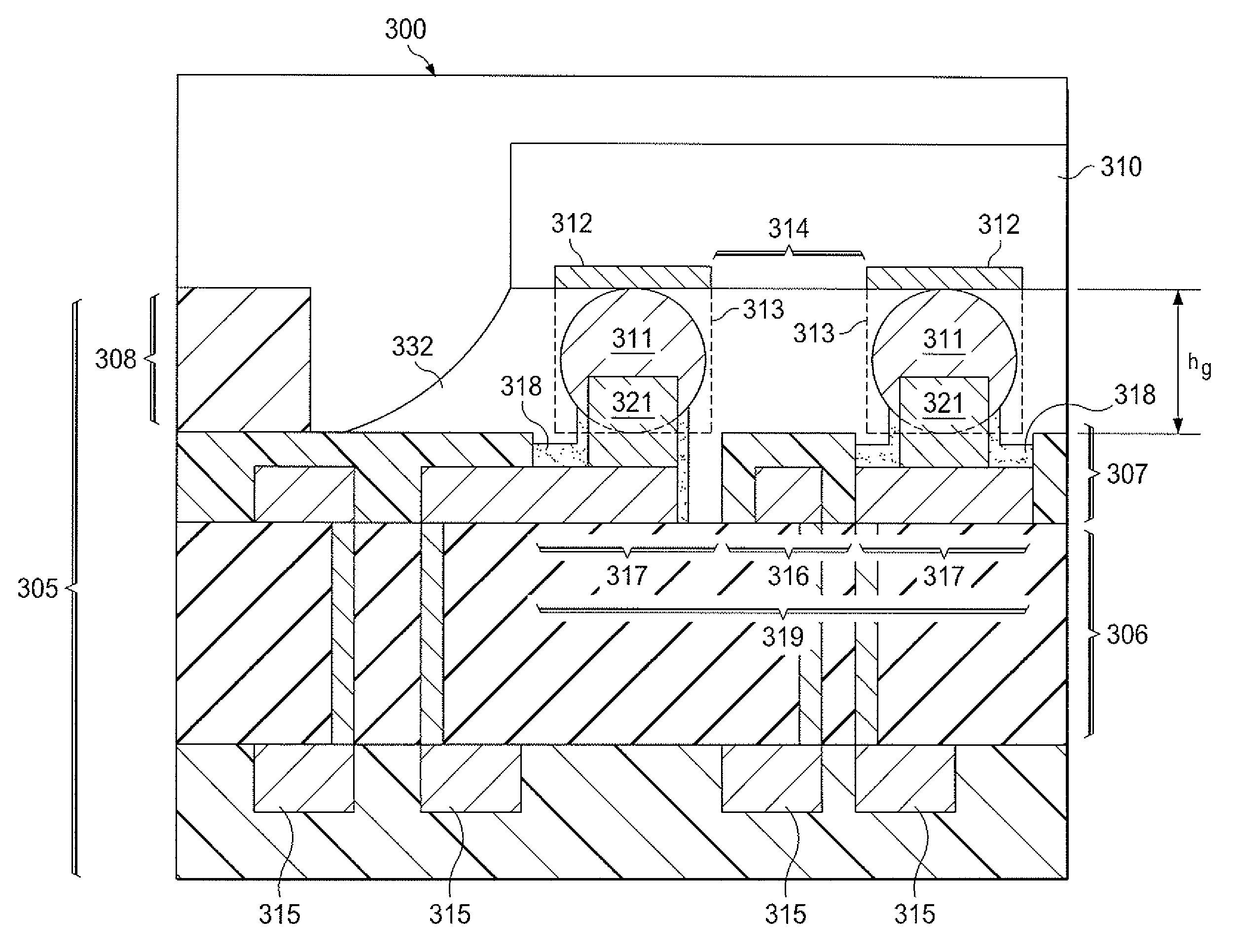

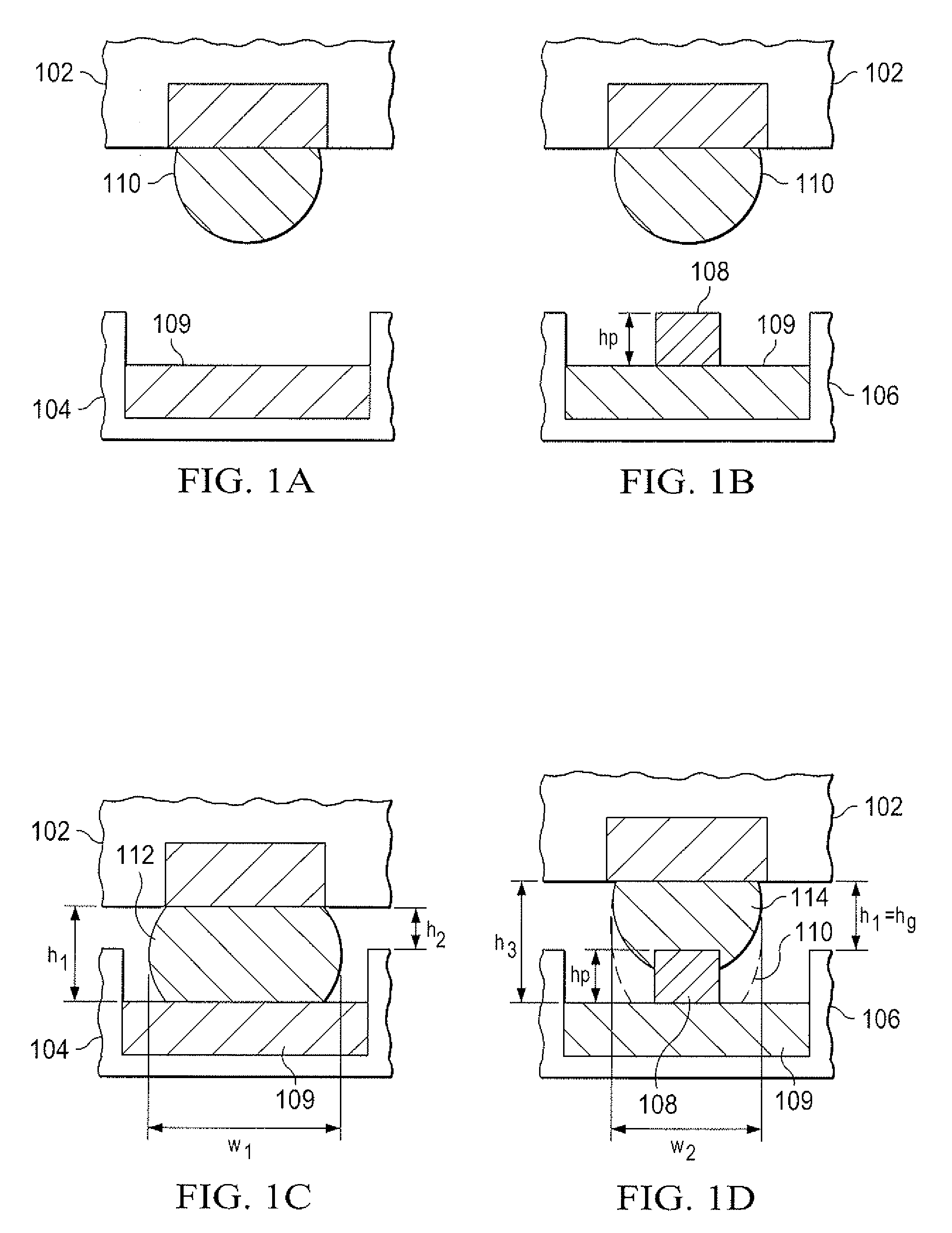

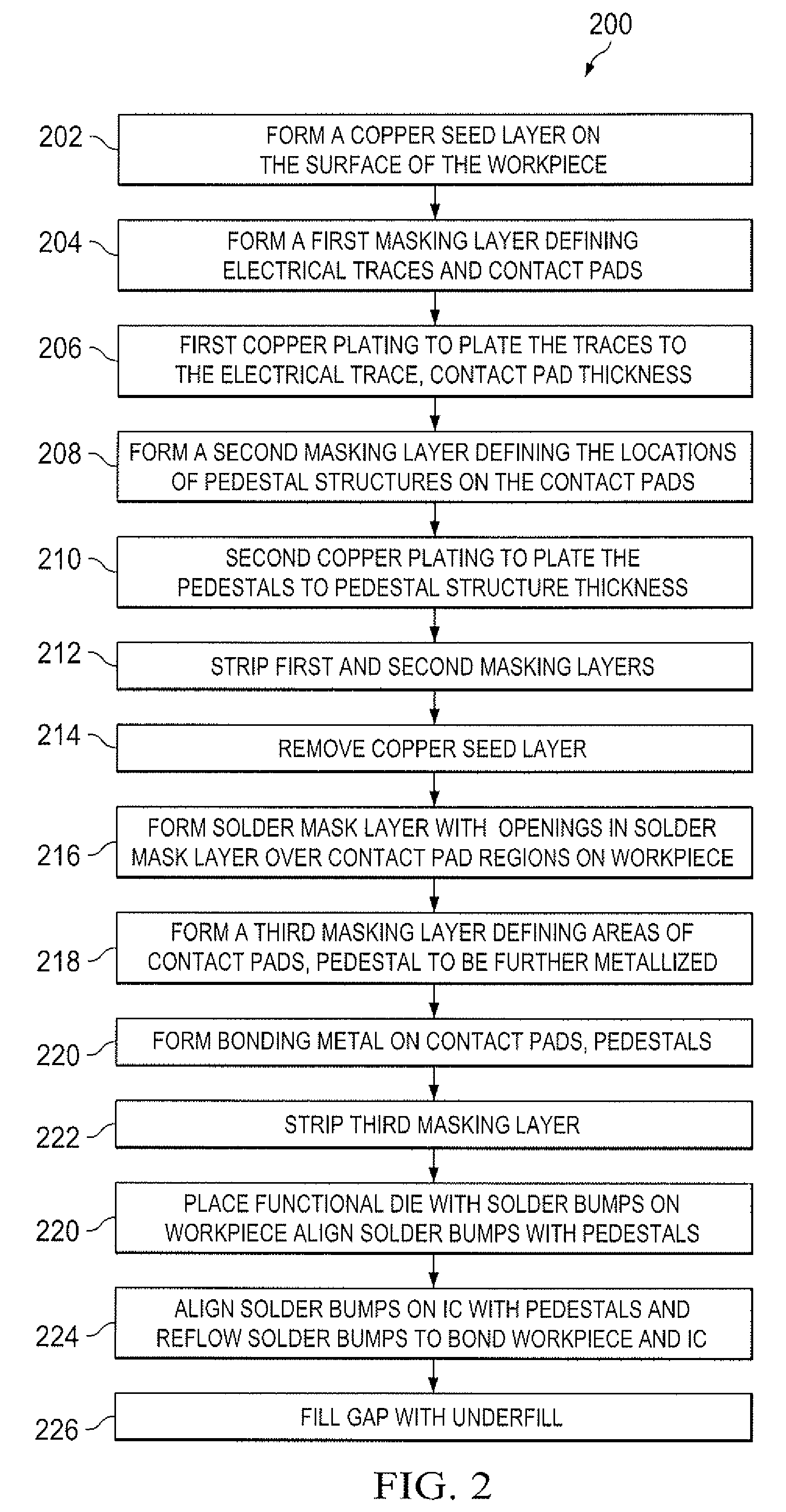

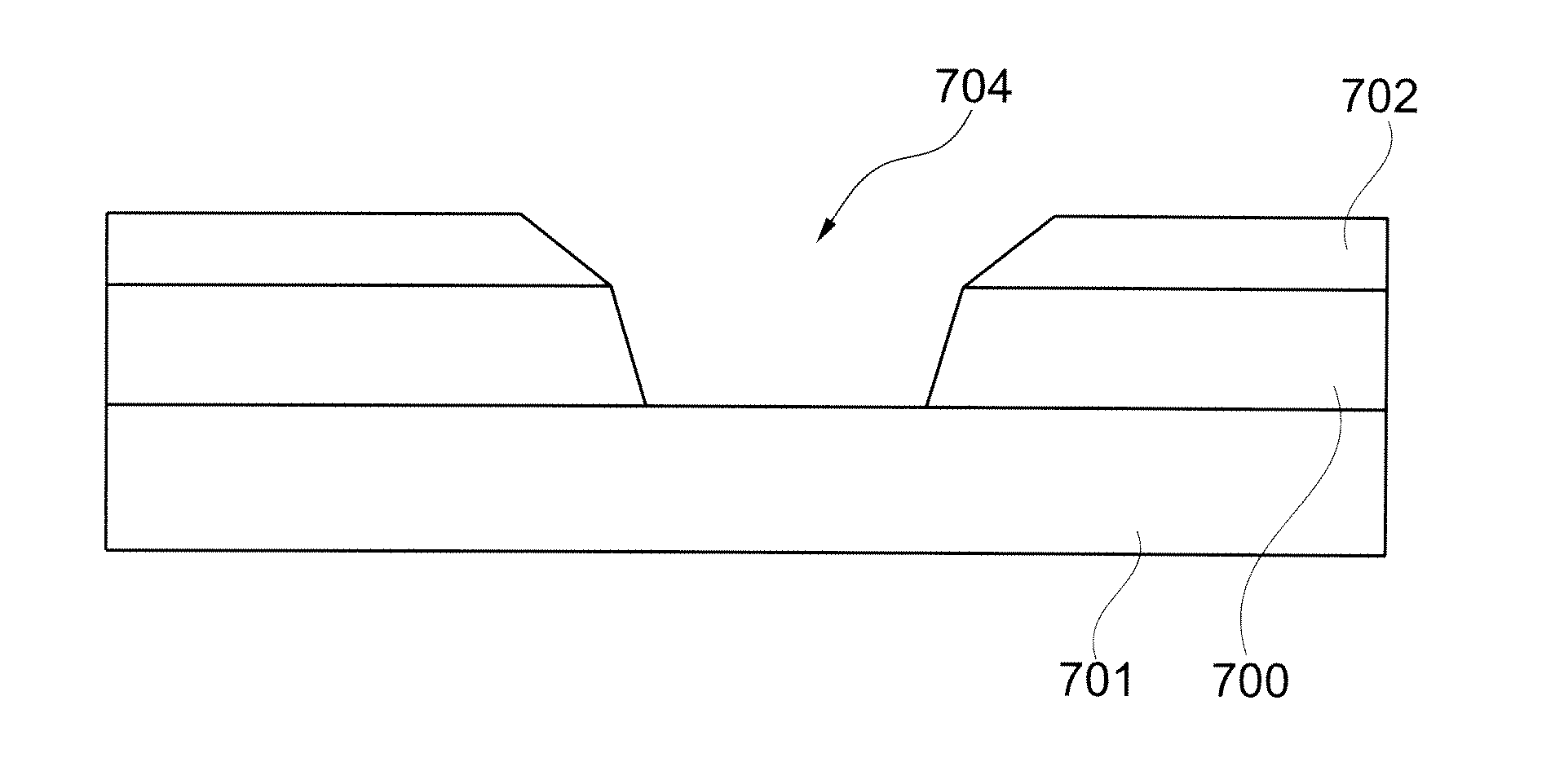

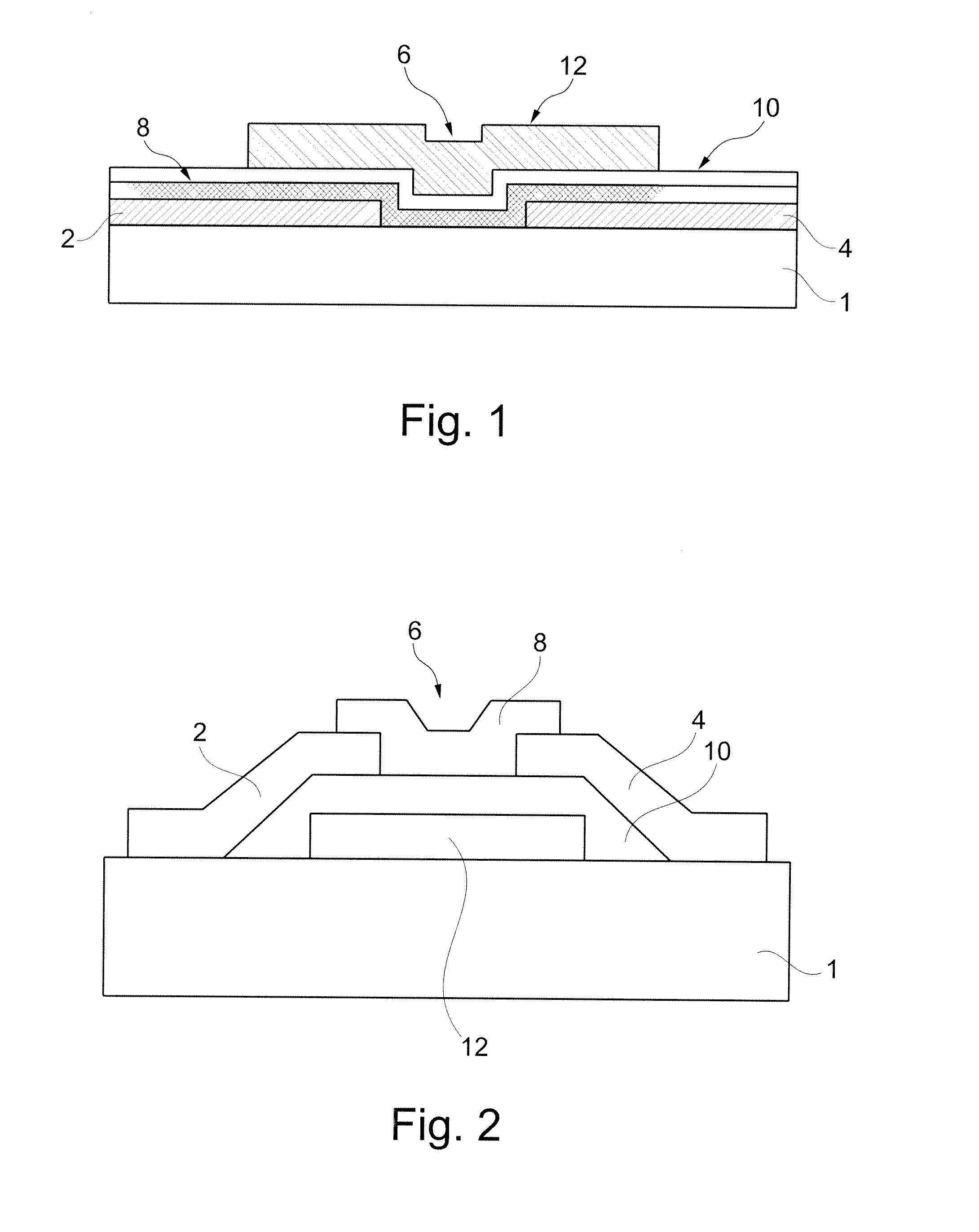

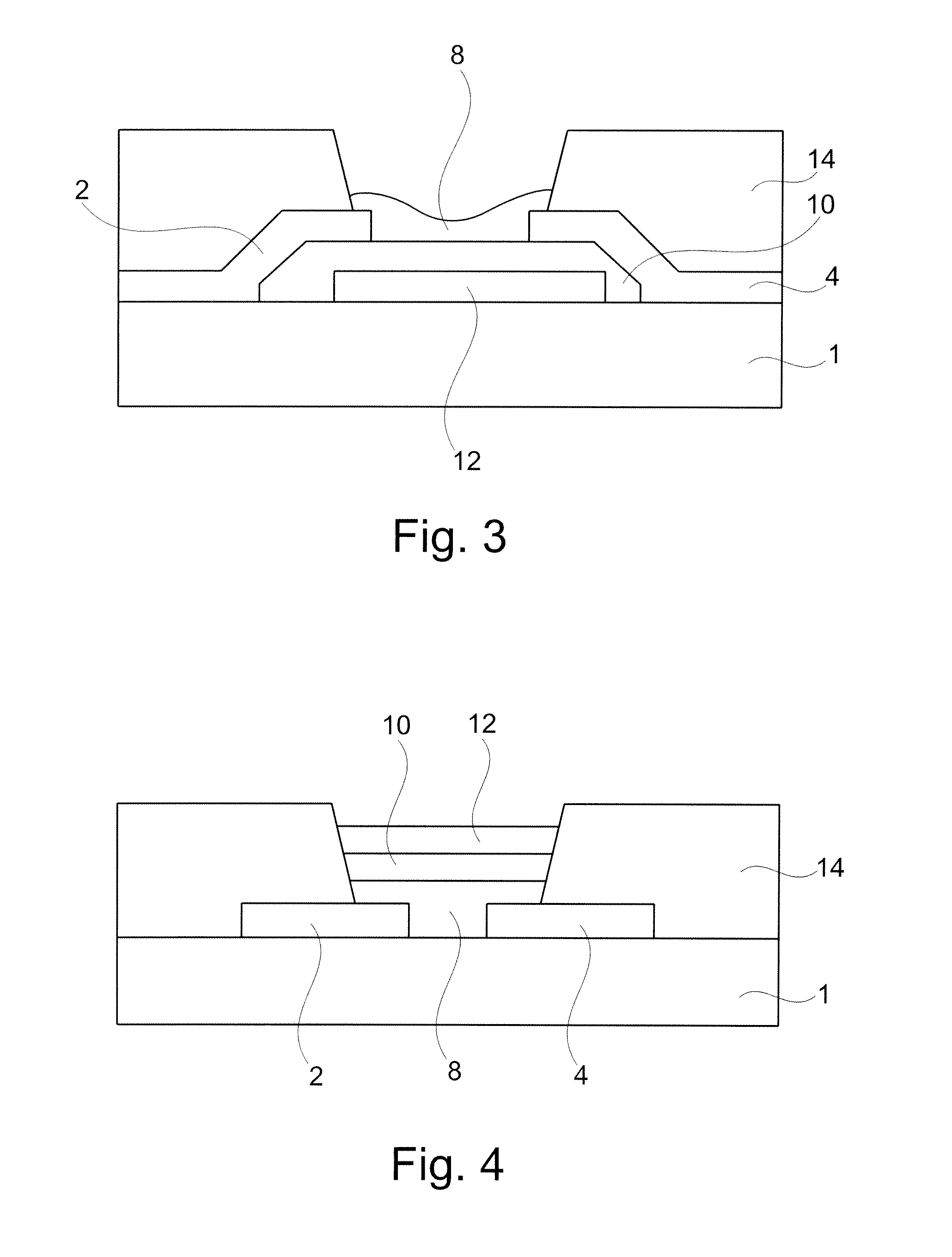

Integrated circuit device with improved underfill coverage

InactiveUS20100007015A1Reducing likelihood of interfacial failureReliable and reliableSemiconductor/solid-state device detailsSolid-state devicesContact padIntegrated circuit

An integrated circuit device (300) includes a functional integrated circuit (IC) die (310) having a top IC surface with IC non-contact regions (313) and a plurality of electrically conductive bump pads (311, 312, 313) at pad locations. In the IC (310), at least one of the bump pads (311, 312, 313) extends outward from beyond the IC non-contact regions (313). The integrated circuit device (300) can also include a workpiece (305) having a top workpiece surface comprising at least one die attach area (319) for attaching the IC die (310). The die attach area (319) can include non-contact regions (316) and a plurality of electrically conductive contact pads (317) recessed relative to the non-contact regions (316), where the contact pads (317) face the top IC surface and match the pad locations (312). In the die attach area (319), at least one of the contact pads (317) includes electrically conductive pedestal features (321) extending towards the top IC surface, where the extending bump pads (311) physically contact one of the pedestal features (321) and electrically connect the IC die (310) to the workpiece (305). In the integrated circuit device (300), the pedestal features (321) increase a gap between the IC (310) and the workpiece top surfaces to be filled with an underfill dielectric material (332).

Owner:TEXAS INSTR INC

Organic Electronic Devices and Methods of Making the Same Using Solution Processing Techniques

InactiveUS20110180907A1Low wettabilityIncreasing time and complexity and expenseElectroluminescent light sourcesSolid-state devicesSemiconductor materialsConductive materials

Owner:CAMBRIDGE DISPLAY TECH LTD

Liquid crystal display device and method for manufacturing the same

A flexible and highly reliable liquid crystal display device which is not easily damaged even if subjected to external pressure is provided. A method for manufacturing, with high yield, a flexible and highly reliable liquid crystal display device which is not easily damaged even if subjected to external pressure is also provided. A liquid crystal display device including a first structure body including a first fibrous body and a first organic resin, a second structure body including a second fibrous body and a second organic resin, a liquid crystal interposed between the first and second structure bodies, and a seal member for fixing the first and second structure bodies and for enclosing the liquid crystal. The first and second fibrous bodies are impregnated with the first and second organic resins, respectively, and the first structure body and the second structure body are in contact with each other.

Owner:SEMICON ENERGY LAB CO LTD

Waterborn polymer-modified emulsified asphalt mixture and process for producing the same

This present invention discloses a waterborne polymer modified emulsified asphalt mixture and the preparation method thereof, and particularly relates to a waterborne polyurethane emulsified asphalt concrete, a waterborne acrylic resin emulsified asphalt concrete, and a waterborne epoxy resin emulsified asphalt micro-surfacing mixture, and preparation methods thereof. A mixture containing a waterborne polymer modified emulsified asphalt forms a high-performance composite system having a spatial network structure, and has good performance and simple preparation process.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE +2

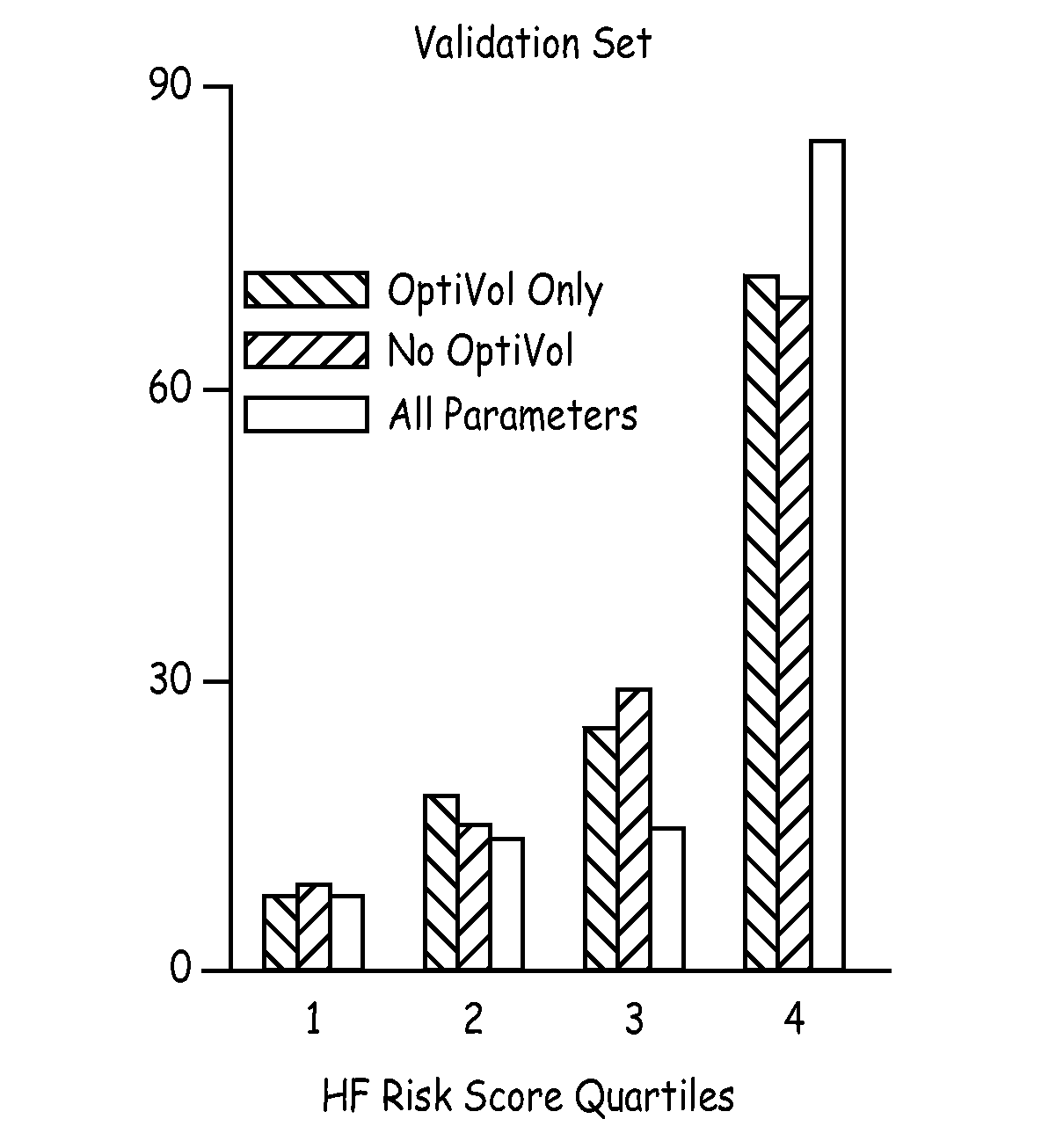

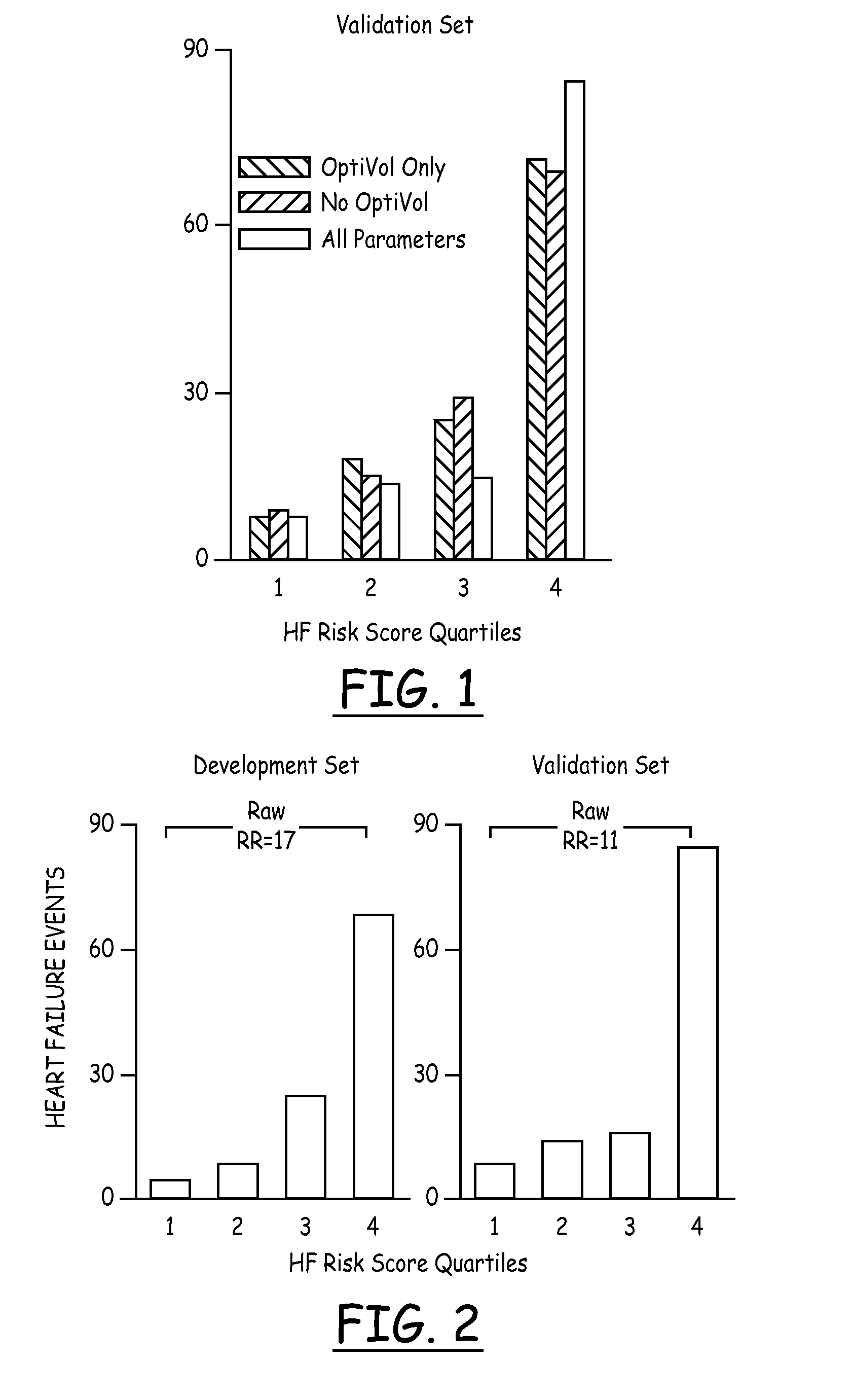

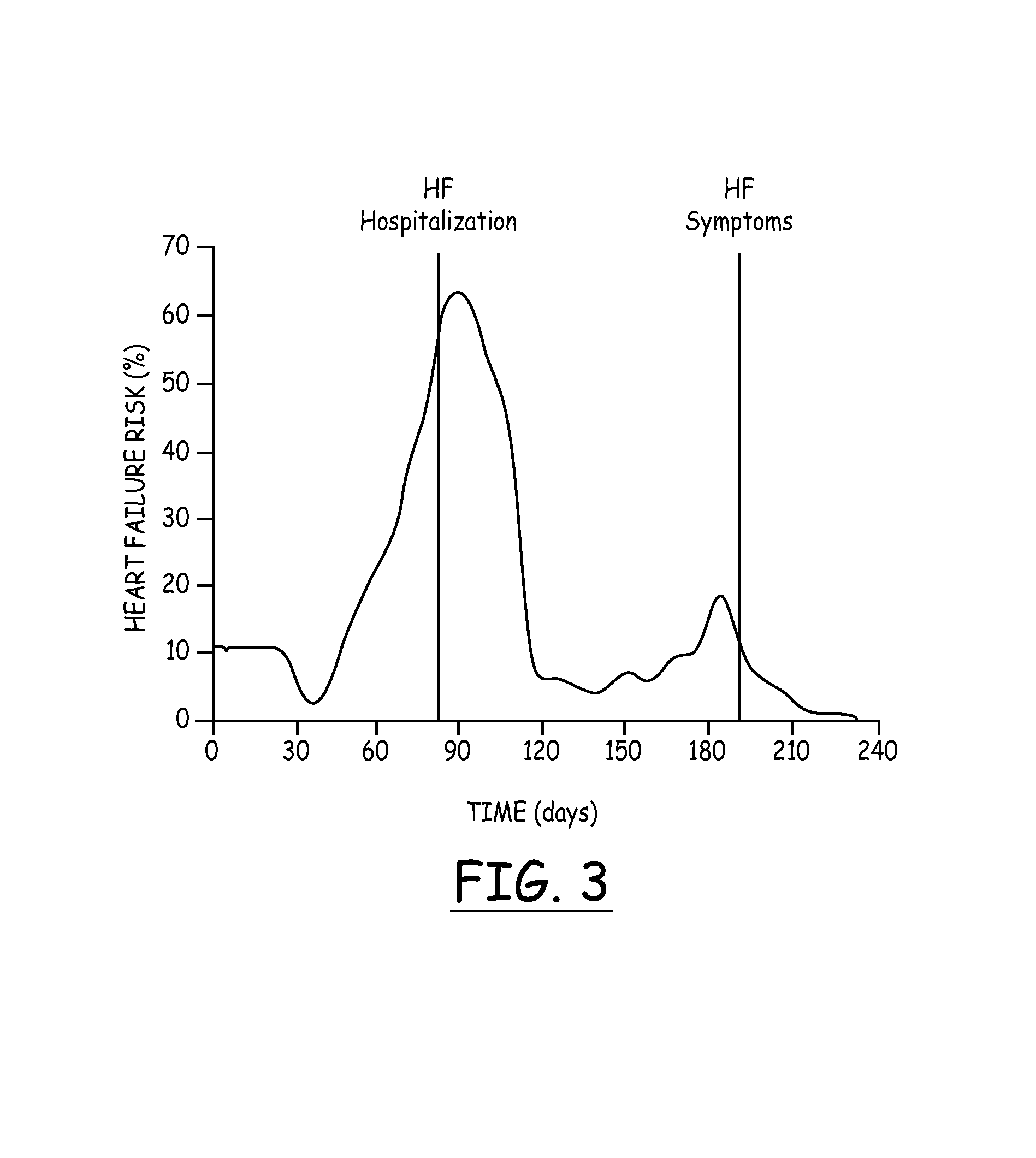

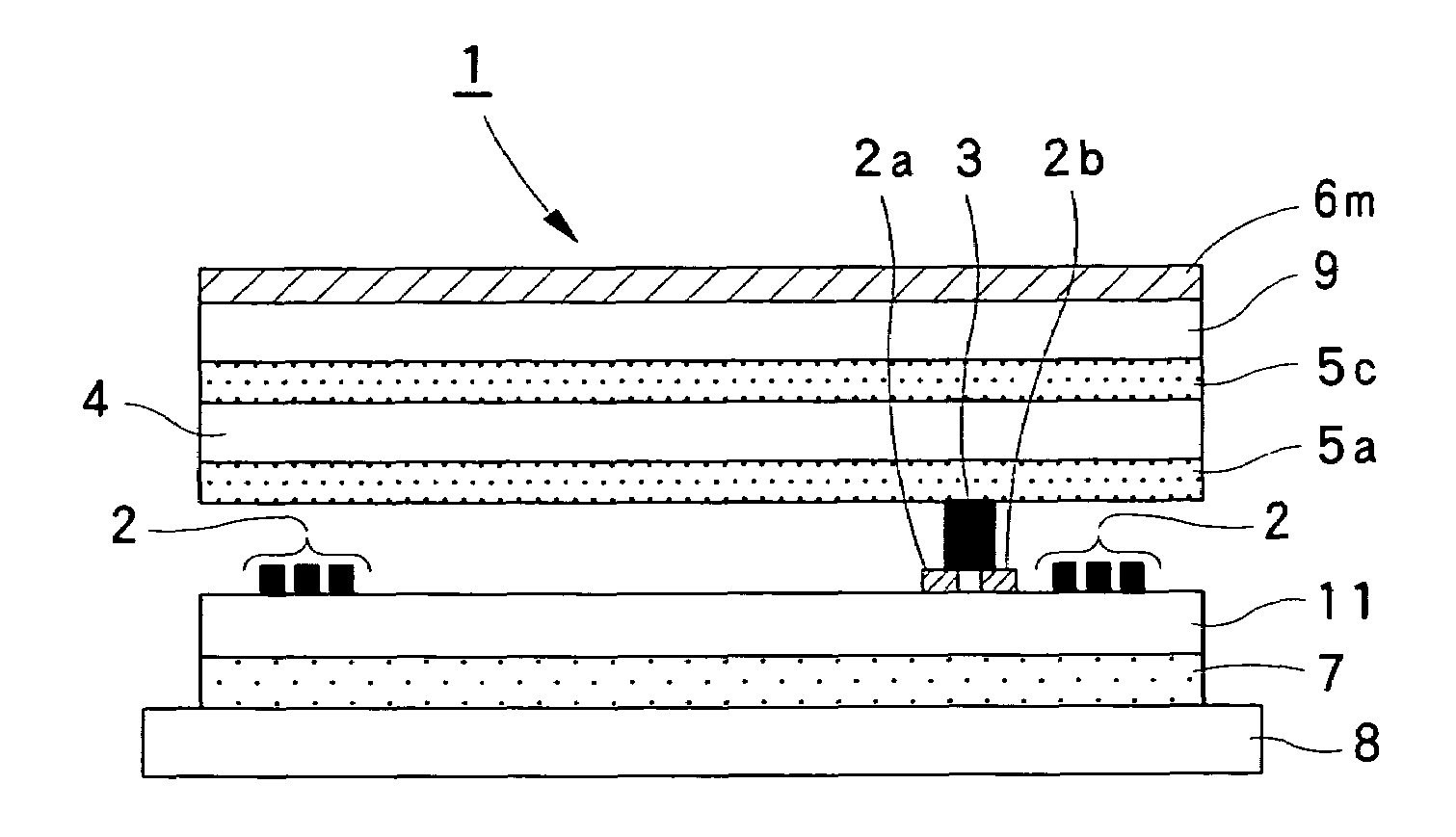

Method and apparatus for monitoring tisue fluid content for use in an implantable cardiac device

InactiveUS20160361026A1Poor adhesionHealth-index calculationMedical devicesImplanted deviceIntrathoracic impedance

Techniques for using multiple physiological parameters to provide an early warning for worsening heart failure are described. A system is provided that monitors a multiple diagnostic parameters indicative of worsening heart failure. The parameters preferably include are least one parameter acquired from an implanted device, such as intrathoracic impedance. The system device derives an index of the likelihood of worsening heart failure based upon the parameters using a Bayesian approach and displays the resultant index for review by a physician.

Owner:MEDTRONIC INC

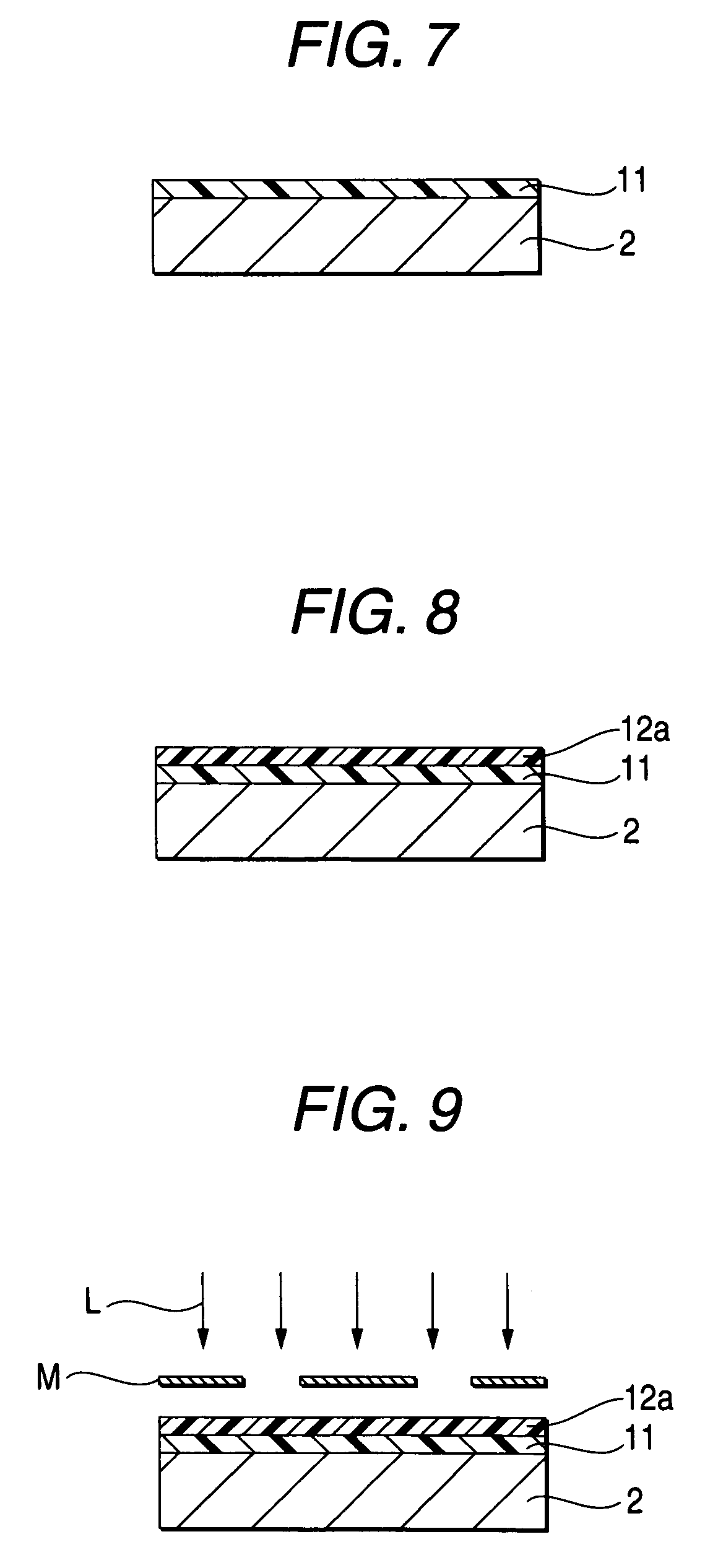

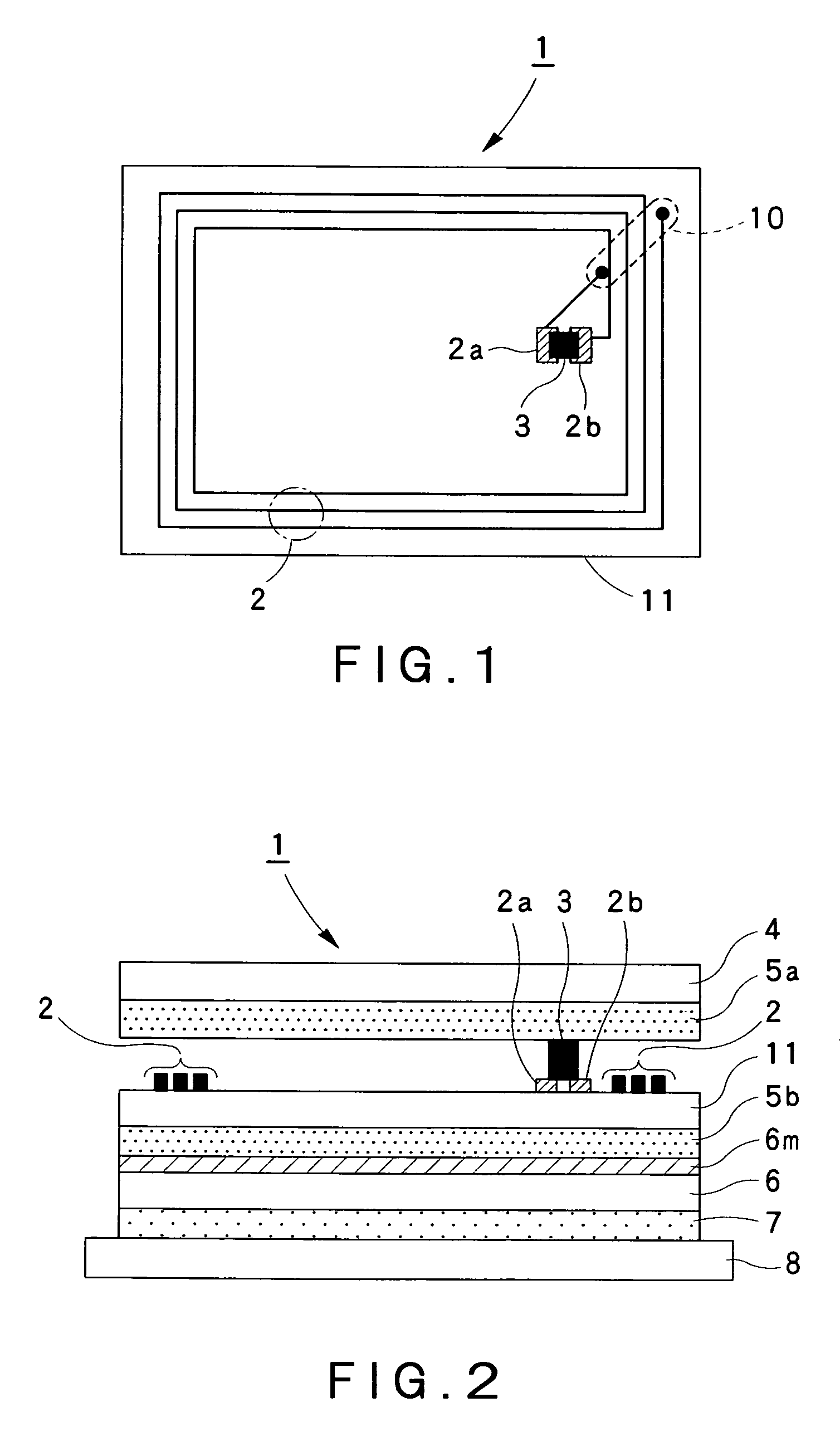

Noncontract IC tag with non-conductive metal film

InactiveUS7651033B2Less attractive in designPoor adhesionRecord carriers used with machinesThin material handlingAtomic force microscopySurface roughness

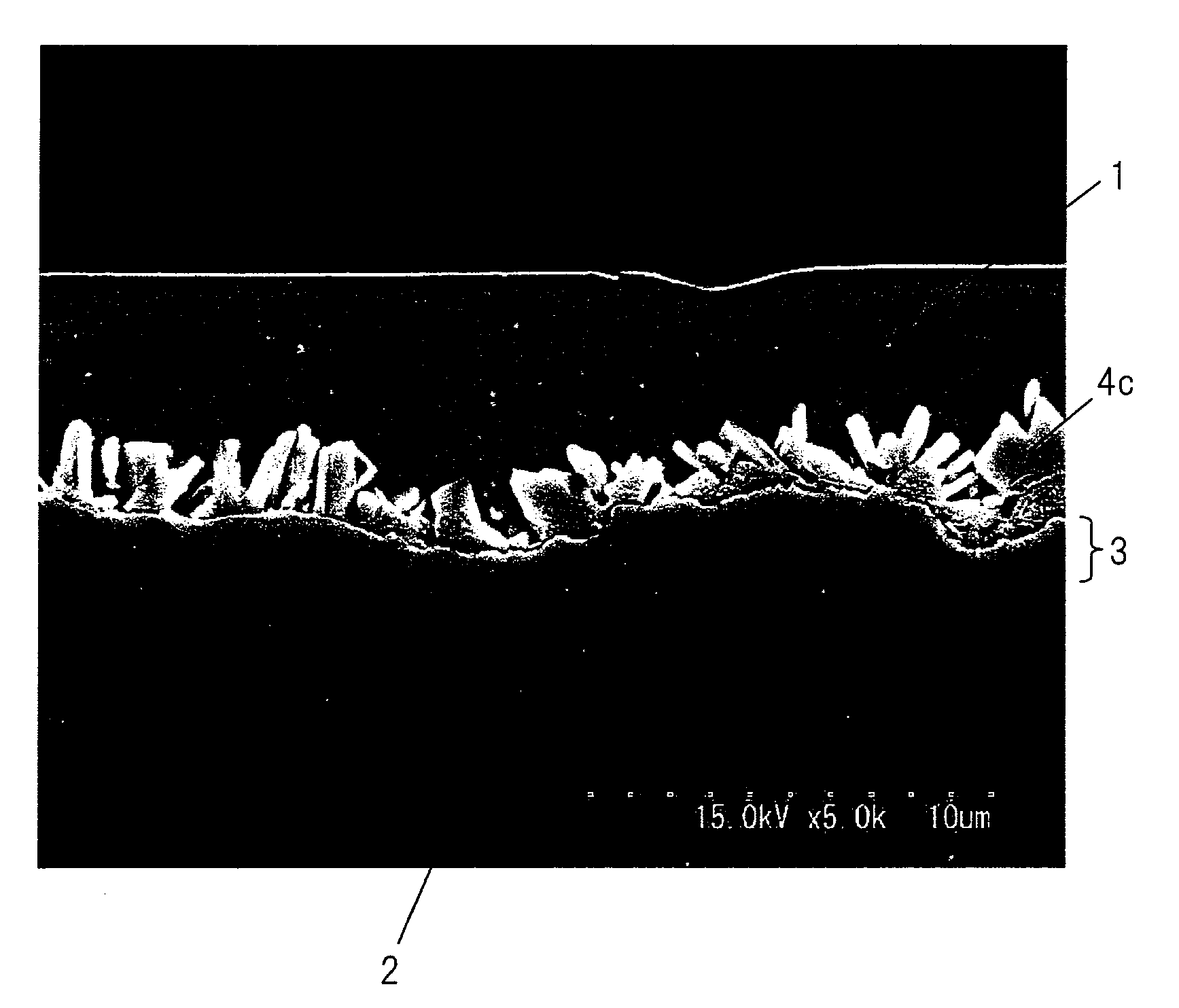

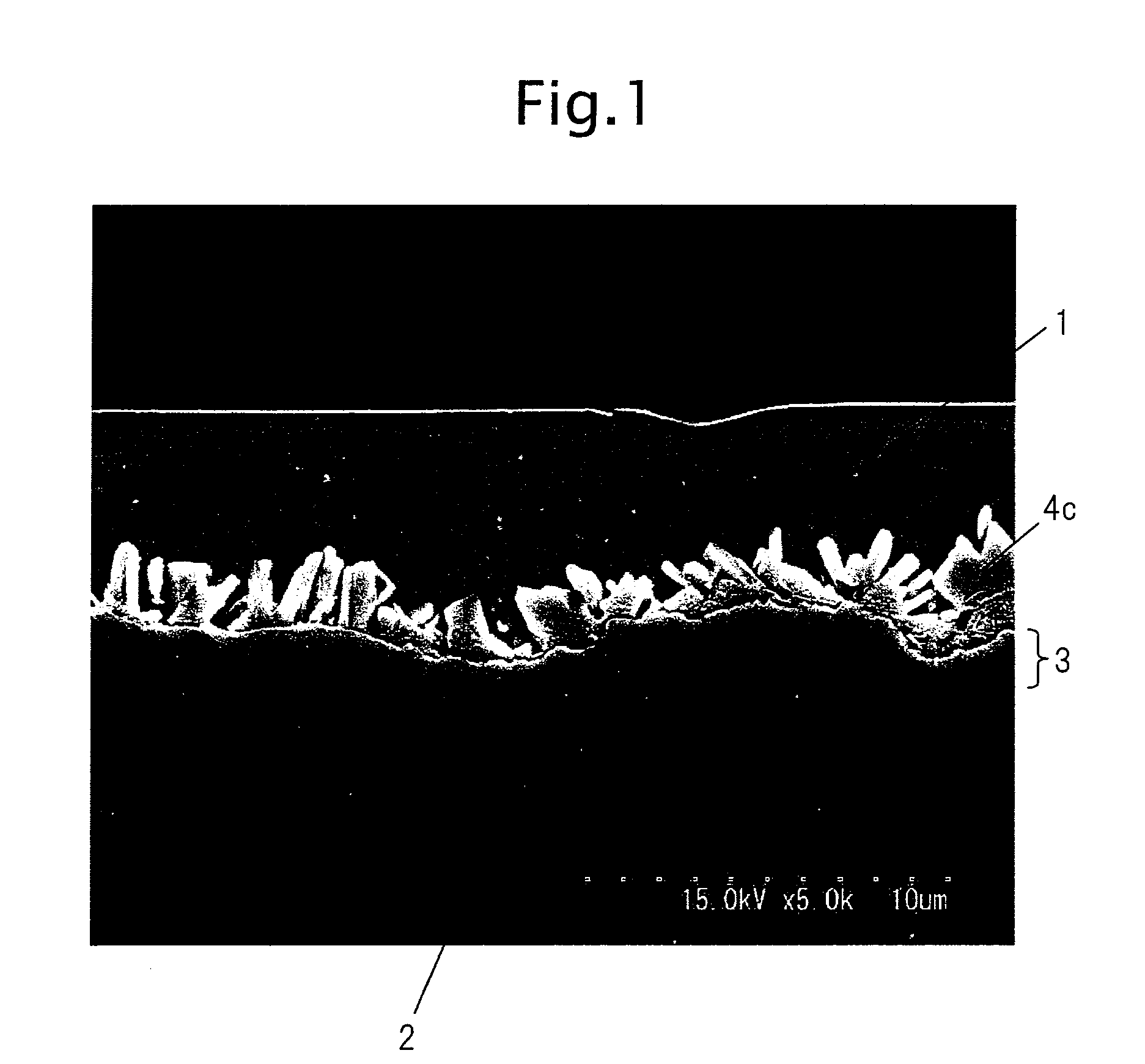

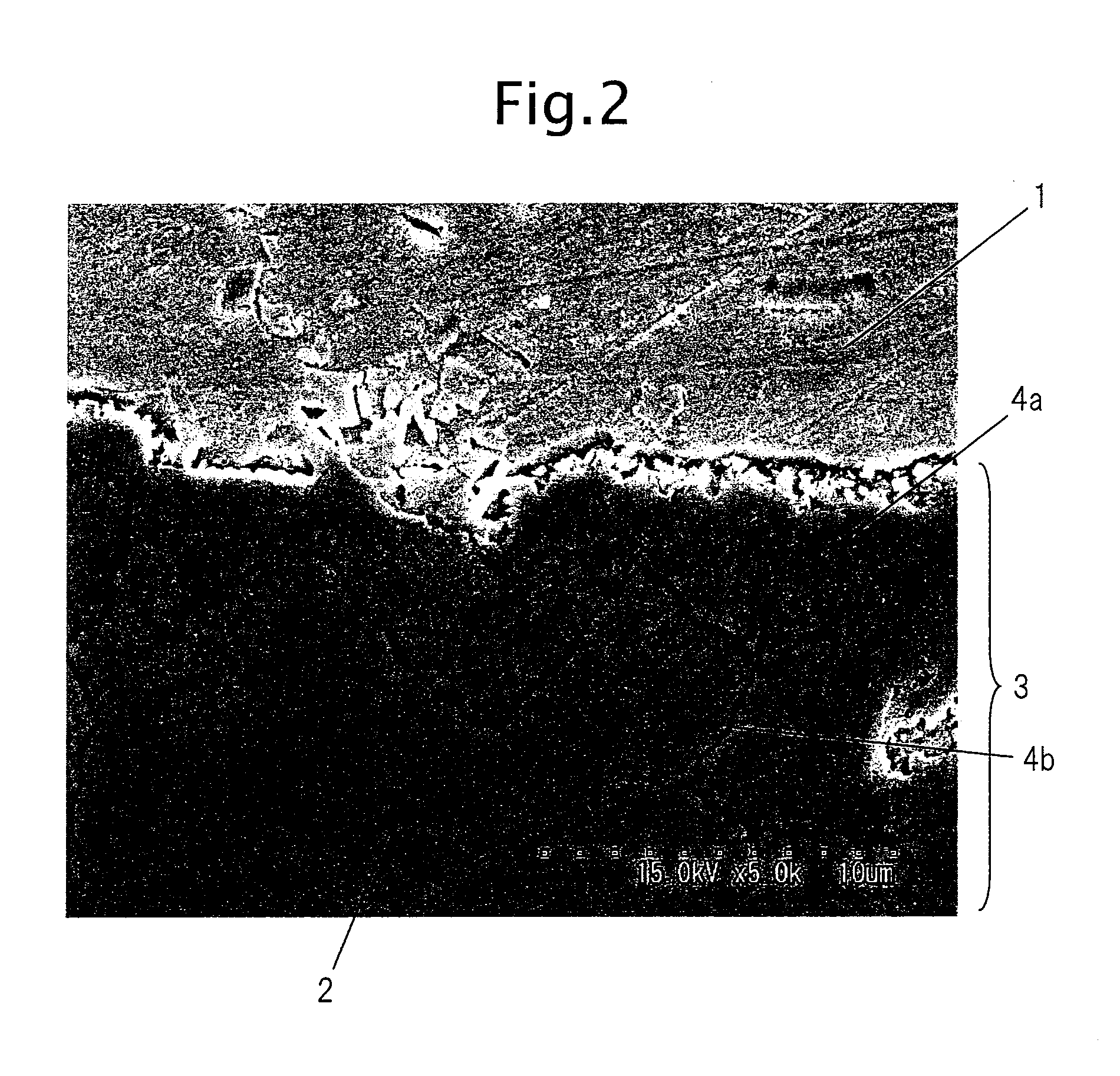

A noncontact IC tag 1 comprises a base film 11, a noncontact IC circuit 2, 3 formed on the base film 11, and a plastic film or paper serving as a surfacing sheet 4, having a non-conductive, lustrous metal film 6m formed by deposition, laminated to the base film 11 on the side of the noncontact IC tag circuit 2, 3. The surface roughness of the non-conductive, lustrous metal film 6m, determined by atomic force microscopy, is more than 10 nm and 100 nm or less as indicated by the center line average height Ra. In the case where the non-conductive, lustrous metal film 6m is formed on the outer surface of the surfacing sheet 4, a concealing layer 4a may further be formed on the inner surface of the surfacing sheet 4 in order to enhance concealing properties.

Owner:DAI NIPPON PRINTING CO LTD

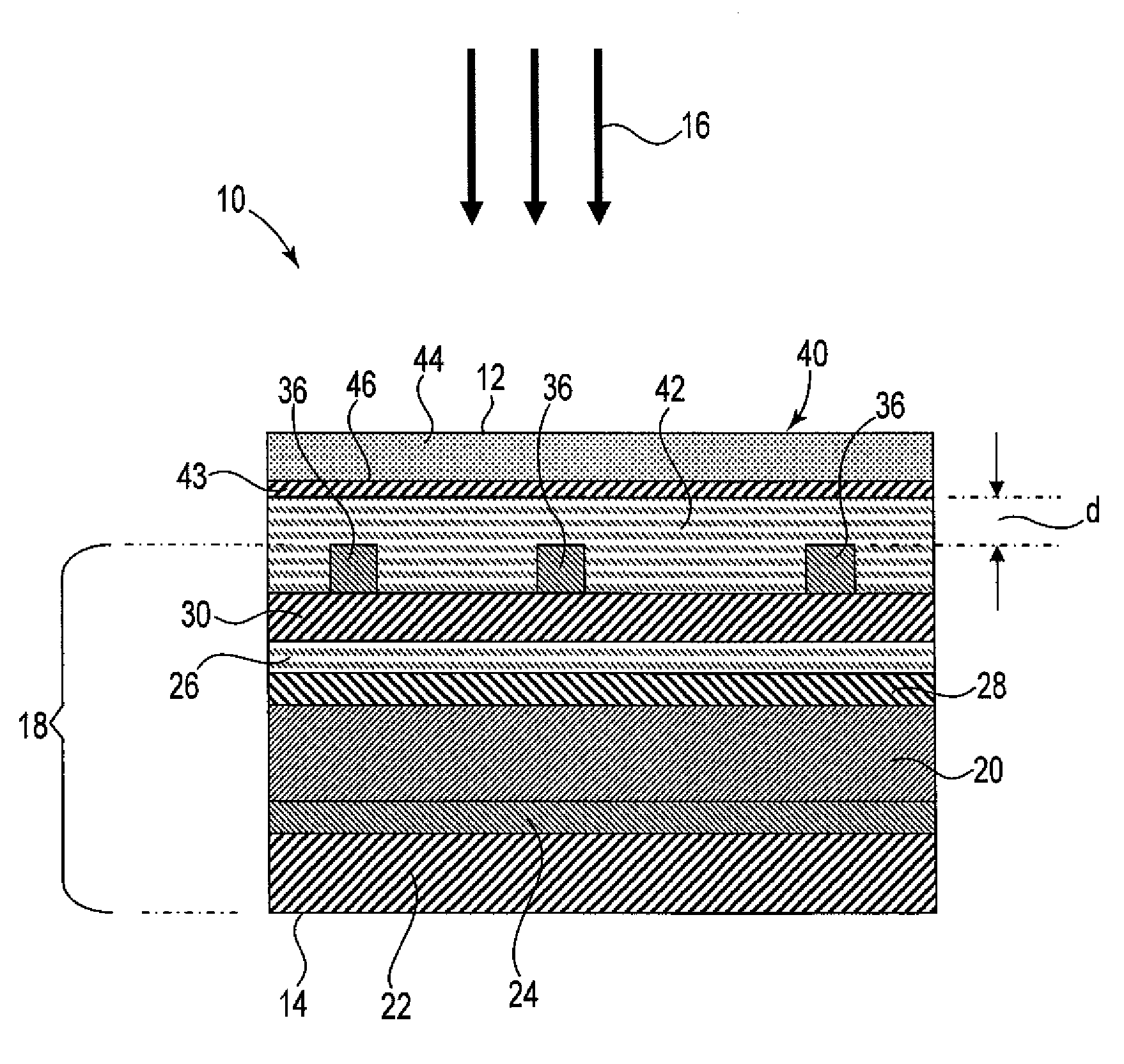

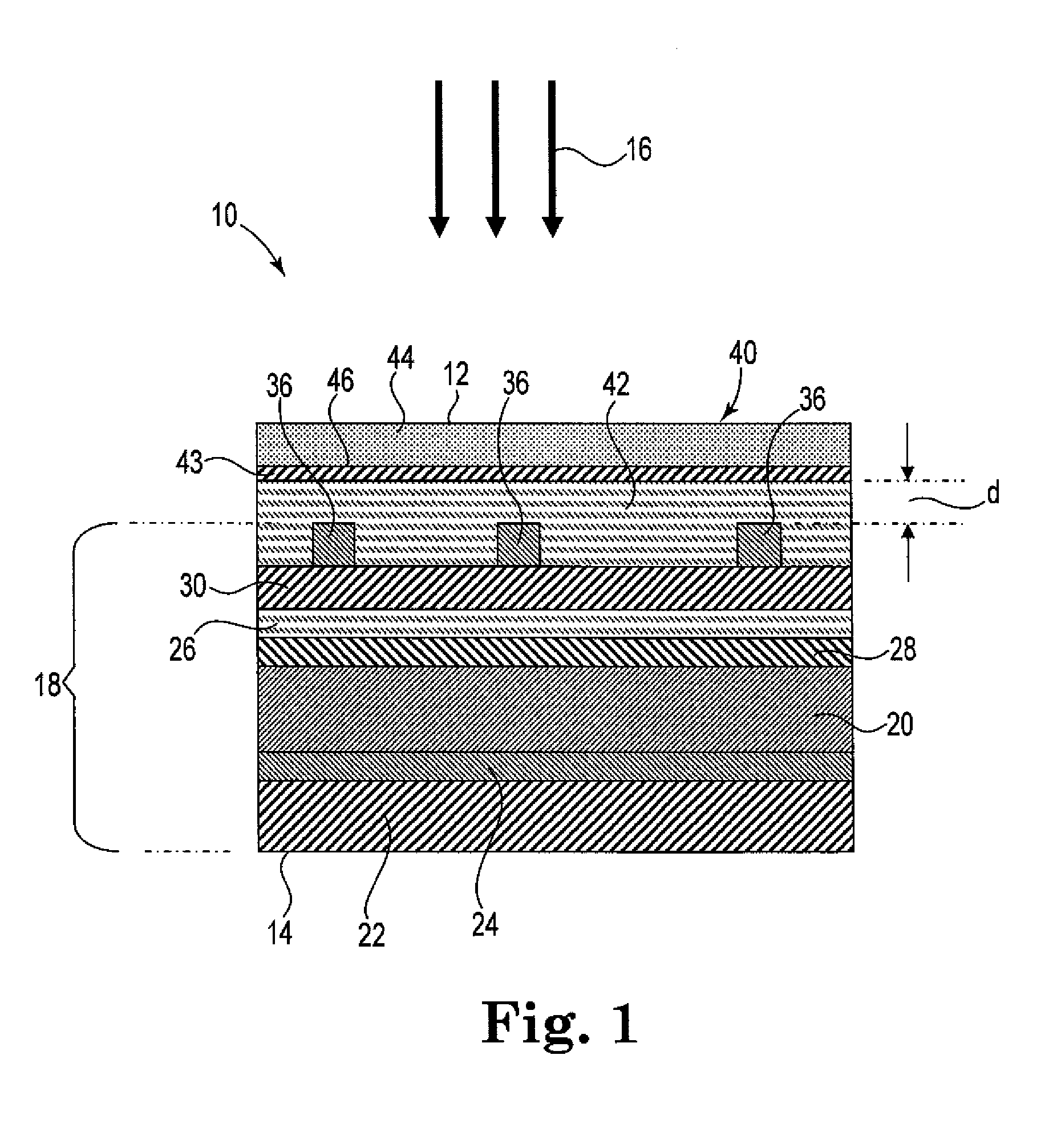

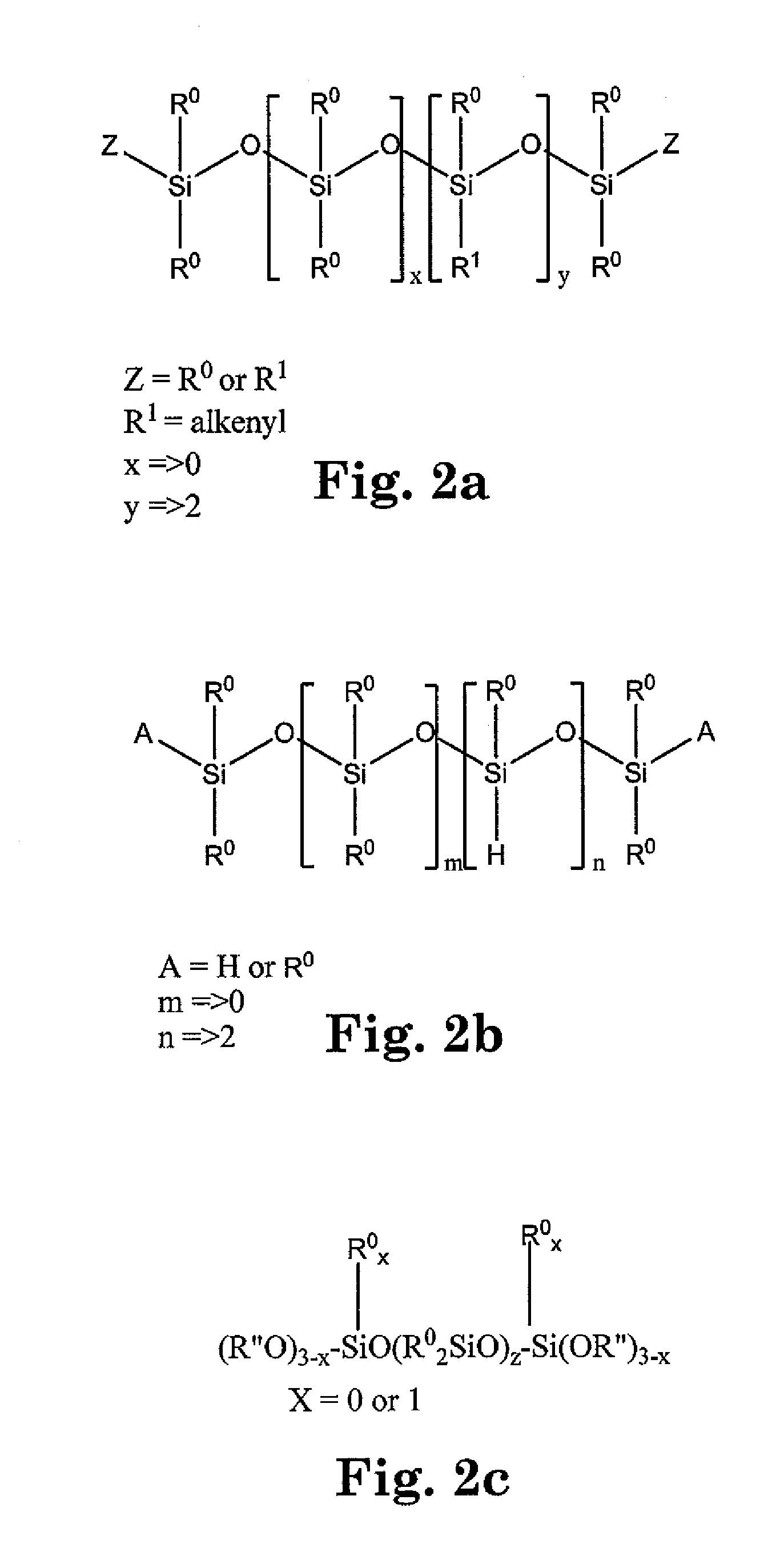

Moisture resistant photovoltaic devices with elastomeric, polysiloxane protection layer

InactiveUS20110162705A1Improves waterproof protectionImprove protectionPhotovoltaic energy generationSemiconductor devicesElastomerElectrical conductor

Improved protection systems for CIGS-based microelectronic devices of the type incorporating electric conductor(s) such as an electronic collection grid. In one aspect, the present invention relates to a photovoltaic device having a light incident surface and a backside surface. The device includes a chalcogenide-containing photovoltaic layer comprising at least one of copper, indium and / or gallium. A transparent conductive layer is interposed between the photovoltaic layer and the light incident surface, wherein the transparent conductive layer is electrically coupled to the photovoltaic layer. An electronic collection grid is electrically coupled to the transparent conductive layer and overlying at least a portion of the transparent conductive layer. An elastomeric structure having a light incident surface, said structure overlying at least portions of the electronic collection grid and the transparent conductive layer in a manner such that the light incident surface of the elastomeric structure is spaced apart from a major portion of the conductor, and wherein the elastomeric structure comprises an elastomeric siloxane polymer having a WVTR of at least 0.1 g / m2-day. An optional protective barrier overlies the elastomeric structure. The protection systems of the invention incorporate elastomers with water vapor transmission rates that are atypically high in the context of CIGS-based devices.

Owner:DOW GLOBAL TECH LLC

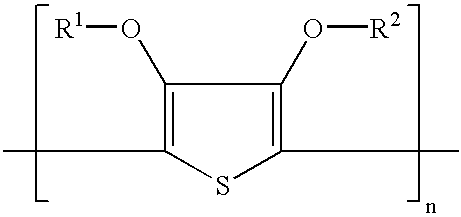

Flexographic ink containing a polymer or copolymer of a 3,4-dialkoxythiophene

InactiveUS6890584B2Improve adhesionPoor resistanceFilm/foil adhesivesConductive materialPolymer scienceAqueous medium

A non-dye containing flexographic ink containing a polymer or copolymer of a 3,4-dialkoxythiophene in which the two alkoxy groups may be the same or different or together represent an optionally substituted oxy-alkylene-oxy bridge, a polyanion and a latex binder in a solvent or aqueous medium, characterized in that the polymer or copolymer of a 3,4-dialkoxythiophene is present in a concentration of at least 0.1% by weight in the ink and that the ink is capable of producing a colorimetrically additive transparent print; a method of preparing the flexographic ink; and a flexographic printing process therewith.

Owner:AGFA GEVAERT AG

Conductive Magnetic Filler, Resin Composition Containing the Filler, Electromagnetic Interference Suppressing Sheet Using the Resin Composition and Applications Thereof, and Process for Producing the Electromagnetic Interference Suppressing Sheet

InactiveUS20090114440A1High densityExcellent electromagnetic absorptionShielding materialsInorganic material magnetismHigh densityLow frequency band

There are provided a soft magnetic material in the form of particles for suppressing occurrence of electromagnetic interference which is capable of exhibiting the suppressing effect in a broad frequency range from a low frequency band to a high frequency band, as well as an electromagnetic interference suppressing sheet using the material. When a conductive magnetic filler prepared by mixing a conductive carbon with soft magnetic particles at a volume ratio of 3 to 10:50 to 70 is highly filled in a sheet material, there can be obtained an electromagnetic interference suppressing sheet which is suitable for high-density mounting to electronic equipments, has an excellent electromagnetic absorption in a near electromagnetic field, and is fully suppressed from undergoing electromagnetic reflection thereon.

Owner:TODA IND

Welding electrode and method

ActiveUS20060261046A1High weight percentagePoor adhesionOhmic-resistance electrodesPressure electrodesBiomedical engineeringLiquid cooling system

A welding electrode has a body having a shank and a contact region for placement against a workpiece during welding. A portion of the body may be formed on a parabolic profile. A coating is formed on the contact region. The coating may have a first layer, and a second layer formed over the first layer. The first and second layers may have different compositions. The electrode may have internally formed cooling finwork for interaction with a liquid cooling system.

Owner:HUYS IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com